Page 1

Operating Instruction

VEGATRENN 547 V Ex

Level and Pressure

on

VEGATRENN

547 V Ex

out

in

Page 2

Contents

Safety information ........................................................................ 2

1 Product description

1.1 Function, configuration and mounting ................................. 3

1.2 Technical data ...................................................................... 5

1.3 Dimensions ........................................................................... 7

1.4 Approvals ............................................................................. 7

1.5 Type plate ............................................................................. 7

2 Mounting ..................................................................................... 8

3 Electrical connection

3.1 Installation information ......................................................... 9

3.2 Connection instructions ..................................................... 10

3.3 Wiring plan ......................................................................... 10

3.4 Connection examples ........................................................ 11

4 Set-up ........................................................................................ 14

Contents

5 Diagnosis

5.1 Maintenance ....................................................................... 14

5.2 Repair ................................................................................. 14

5.3 Fault signal ......................................................................... 14

Safety information

The described module must only be installed

and operated as described in this operating

instruction. Please note that other action can

cause damage for which VEGA does not take

responsibility.

2 VEGATRENN 547 V Ex

Page 3

Product description

1 Product description

1.1 Function, configuration and mounting

Function

Ex-separator VEGATRENN 547 V Ex is used

for intrinsically safe, galvanically isolated

supply of up to two ultrasonic or radar

sensors. At the input side it is connected to

the two-wire-VBUS-line of the signal

conditioning instrument and provides at the

output side 2 x 2 ib-circuits. Each sensor is

supplied via two ib-circuits so that two

sensors can be connected to Ex-separator.

The Ex-separator can be used in conjunction

with the following signal conditioning

instruments or sensors:

- VEGAMET 514␣ V and 515␣ V

- EV-card of VEGALOG 571

- ultrasonic sensors VEGASON series 80

- radar sensors VEGAPULS series 64 and

series 80 for intrinscially safe supply “ib“.

The intrinsically safe ib-circuits are isolated as

well as from the not intrinsically safe circuits.

Configuration

Configuration

The Ex-separator VEGATRENN 547 V Ex is

designed in 19“-technology with 5 TE (= 25,4

mm). The connection is made via a multiple

plug acc. to DIN 41 612.

Mounting

There are the following mounting possibilities

- in housing type 506 with VEGAMET

- in carrier BGT 596 Ex with VEGAMET

- carrier BGT LOG 571 *) with VEGALOG

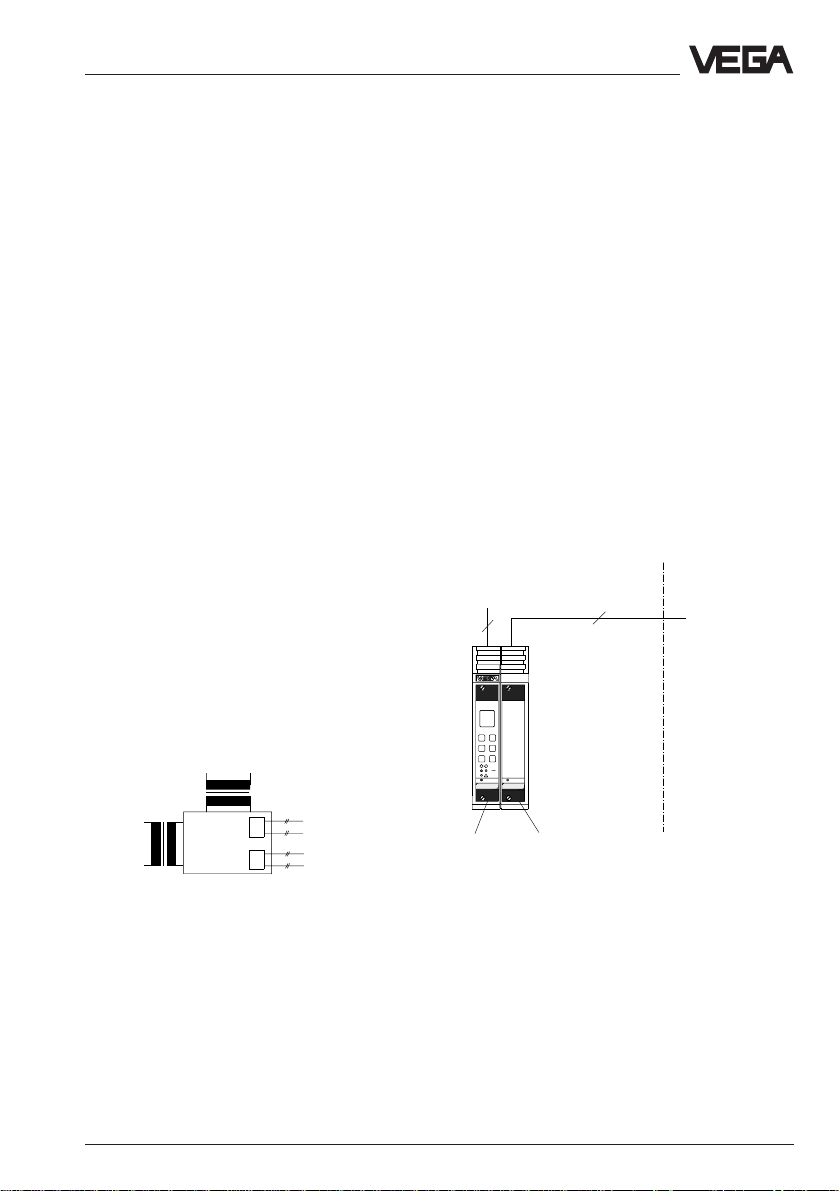

Example 1:

In housing type 506 with VEGAMET

Supply

Not-Ex-area

2

4

Ex-area

two

VBUS ib IIBcircuits per

sensor

Power supply

VEGAMET

VEGATRENN

515V

548VEx

VEGATRENN

547␣ V Ex

Signal

conditioning

instrument

(VBUS)

electronics

Intrinsically safe ibcircuits

Sensor 1

Sensor 2

VEGAMET

514␣ V

515␣ V

Fig. 1.1: Block diagram of the Ex-separator

*) If several VEGATRENN 547 V Ex are used, it is

recommended to separate them into the cheaper

BGT 596 Ex.

VEGATRENN 547 V Ex 3

Page 4

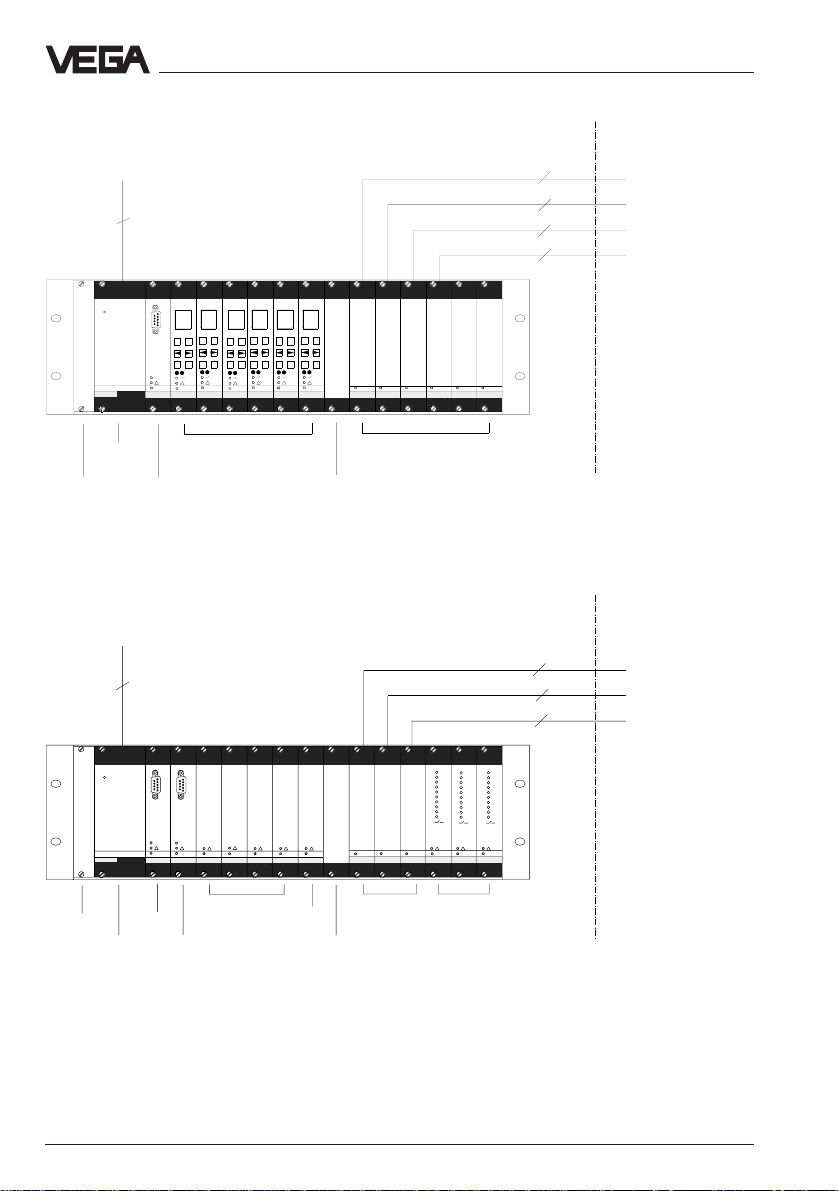

Example 2: In BGT 596 Ex M with VEGAMET 515 V

Supply

2

PC

–

–

–

+

–

+

OK

ESC

OK

ESC

BA

VEGAMET

VEGACOM

VEGASTAB

593

VEGAMET

515V

557

515V

–

+

+

–

ESC

VEGAMET

+

+

OK

ESC

OK

VEGAMET

515V

OK

ESC

OK

ESC

VEGAMET

VEGAMET

515V

515V

515V

VEGATRENNVEGATRENN

548VEx

548 V Ex

548 V Ex

Not-Ex-area

VEGATRENNVEGATRENN

VEGATRENN

548VEx

Product description

Ex-area

2 x 4

2 x 4

2 x 4

2 x 4

VEGATRENN

548 V Ex

548 V Ex

VBUS ib IIBcircuits

VEGAMET 515␣ V VEGATRENN

VEGACOM 557

Blind cover

Blind cover

Power

supply

unit

Example 3: In BGT 596 Ex M with VEGALOG

Supply

2

PC

PC

BA

BA

VEGACOM

VEGACOM

VEGALOG

VEGASTAB

Blind cover

Power

supply

unit

593

557

557

CPU

VEGACOM

557

VEGALOG

571EA

571 EA

EAcards

VEGALOG

VEGALOG

VEGALOG

EVcards

571EV

VEGATRENN

548 V Ex

VEGATRENN

547␣ V Ex

571 EA

571EA

blind cover

547␣ V Ex

VEGATRENN

548VEx

VEGATRENN

VEGALOG

548 V Ex

Not-Ex-area

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

VEGALOG

VEGALOG

571 EA

571EA

output

cards

Ex-area

2 x 4

2 x 4

2 x 4

1

2

3

4

5

6

7

8

9

10

571 EA

VBUS ib IIBcircuits

4 VEGATRENN 547 V Ex

Page 5

Product description

1.2 Technical data

Power supply

Operating voltage U

Power consumption approx. 13 W, approx. 18 VA

Fuse 1 A, slow-blow

Signal conditioning instrument circuit

For connection to signal conditioning instrument VEGAMET 514 V,

Input voltage U

The signal conditioning instrument circuit must only be connected to instruments with an

operating voltage less than 250 V.

Sensor circuit

Number 2 sensor circuits (both 2 ib-circuits)

Sensors Ultrasonic sensors

Voltage approx. 17 V DC at 85 mA

Current limitation electronically at approx. 85 mA, shortcircuit-proof

Connection line per sensor 4-wire (standard line) *

Resistance per conductor max. 7,5 Ω

Line length max. 500 m

= 24 V AC (20 … 53 V), 50/60 Hz

nom

= 24 V DC (20 … 72 V)

515 V or

EV-card of VEGALOG 571

= 25 V DC with VEGAMET

nom

= 24 V DC with EV-card VEGALOG

VEGASON 83 … 87 FV/GV Ex or Ex0,

radar sensors VEGAPULS 81 F/D Ex or Ex0

)

Sensor circuits, Ex-technical data

Classification [EEx ib] IIB

Max. values (per sensor circuit)

- voltage U

- current I

-eff

iciency P

Characteristics linear

Max. permissible outer inductance L

Max. permissible outer capacitance Ca296 nF

a

≤ 20,05 V

O

≤ 103 mA

O

≤ 2,05 W

O

0,7 mH

The intrinsically safe sensor current circuits are reliably galvanically isolated from the not

intrinsically safe circuits and supply up to a peak value of the nominal voltage of 375 V.

Indicating elements

LED in front plate green on: operating voltage on

*)screened cable is recommended for electromagnetic interferences.

VEGATRENN 547 V Ex 5

Page 6

Product description

Electrical connection

Multiple plug component acc. to DIN 41 612, series F, 33-pole,

3 rows d, b, z (partly equipped)

In conjunction with

- carrier

BGT 596 Ex, BGT LOG 571 connection to appropriate Ex-module

- housing tpye 506 connection to screw terminals (max. 2,5 mm2)

Protective measures

Protection

- not mounted IP 00

- mounted in BGT 596 Ex or

BGT LOG 571 front side (completely equipped):IP 40

upper and lower side: IP 20

wiring side:IP 00

- mounted in housing type 506 front side (completely equipped): IP 40

housing general: IP 30

terminal side: IP 20

Protection class (in housing type 506) II

Overvoltage category II

Electrical separating measures

Galvanic separation between intrinsically safe circuits, against

not intrinsically safe circuits as well as against

the power supply

- reference voltage 250 V

- isolation resistance 1,5 kV

CE-conformity

The ex-separator VEGATRENN 547 V Ex meets the protective regulations of EMVG (89/336/

EWG) and NSR (73/23/EWG). The conformity has been judged acc. to the following

standards:

EMVG Emission EN 50 081-2: 1993

Susceptibility EN 50 082-2: 1995

NSR EN 61 010

Mechanical data

Series module unit for 19“-carrier or housing type 506

Dimensions W = 25,4 mm (5 TE), H = 128,4 mm, D = 162 mm

Weight approx. 350 g

Ambient conditions

Permissible ambient temperature -20°C … +60°C

Storage and transport temperature -40°C … +80°C

6 VEGATRENN 547 V Ex

Page 7

Product description

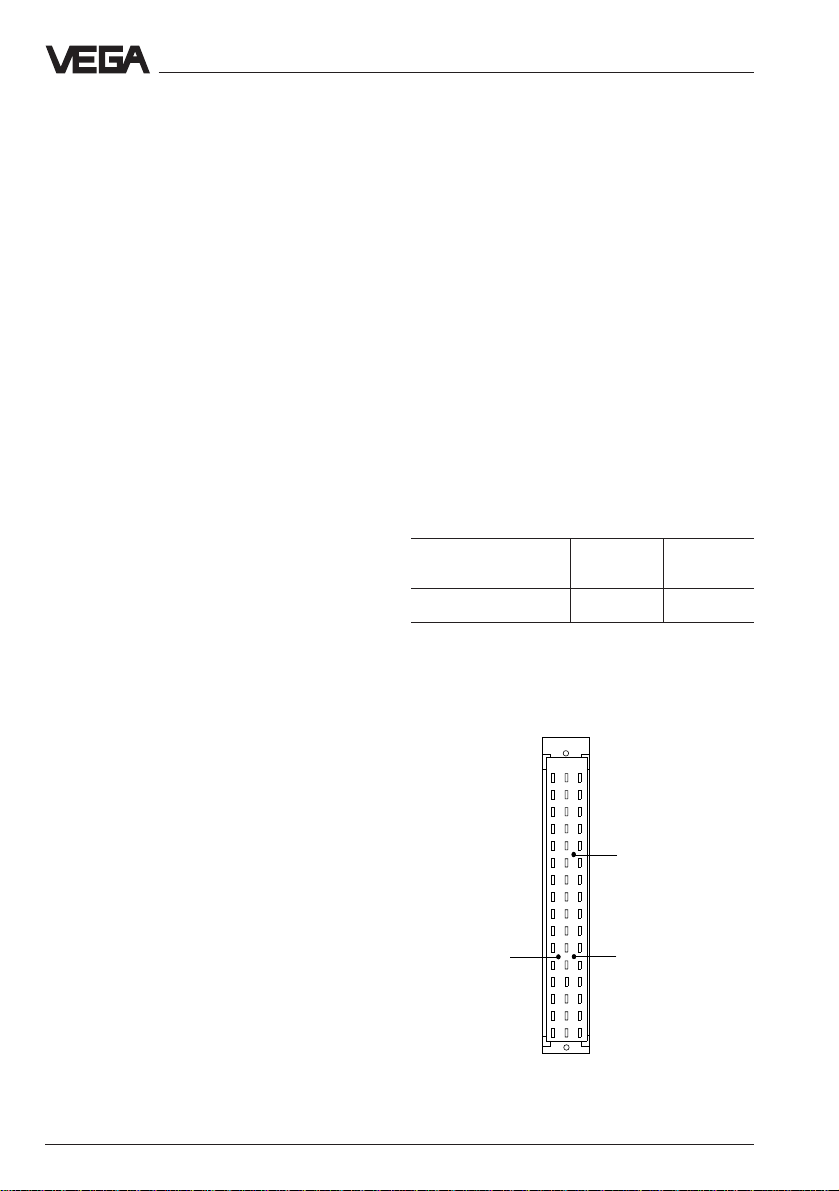

1.3 Dimensions

Circuit board

100␣ x␣ 160␣ x␣ 1,5

European size

3

5,5

9

15

162

Multiple plug

5 TE

100

128,4 (3 HE)

on

25,4

1.4 Approvals

The Ex-separator VEGTRENN 547 V Ex is approved for connection of sensors in hazardous

areas. The conformity certificate to CENELEC has PTB-no. Ex-97.D.2098 X.

1.5 Type plate

The type plate contains important data required for connection. The type plate is located

laterally on the multiple plug. The configuration and parts of the type plate are described in the

following:

PTB Nr. Ex-95.D.????X

[EEx ib] IIB

specification per circuit:

U

o

I

o

P

o

20V

103mA

2,05W

L

o

C

o

VEGA TRENN 547 V EX

0,7mH

296nF

S 2

S 1

4

1 Power supply

2 Signal conditioning instrument circuit

3 Sensor circuit

4 Data of each sensor circuit

®

a

: -20…+60°C IP40 (front)

VBUS to sensors

3 +

2 –

1 +

d 22

z 20

z 18

d 30

z 32

z 30

4 –

d 24

d 32

to evaluation

z10

3

VBUS

(MET/LOG)

+

–

d10

power supply

20…53AC/72VDC

L+

d2

2

18VA

N –

13W

z2

Insp.

1

VEGATRENN 547 V Ex 7

Page 8

2 Mounting

The Ex-separator VEGATRENN 547 V Ex can

be mounted as follows:

- in carrier BGT 596 Ex or

BGT LOG 571

- in housing type 506

Mounting in carrier

First of all mount the Ex-module into your

carrier. The Ex-module consists of a multipoint

connector acc. to DIN 41 612, individual

coded pins (see coding), a separating

chamber as well as guide rails and mounting

material.

Montage

Coding

The multipoint connector of the carrier or the

housing must be provided with coded keys to

avoid interchanging of the various signal

conditioning instruments. The multiple plug of

VEGATRENN is provided with the appropriate

holes (mechanical coding).

The instrument coding ensures that the

various signal conditioning instruments are not

interchanged. The appropriate coded pins are

attached to each module or housing. Provide

the multipoint connector with these coded

pins acc. to the following table and figure.

Wire the connections of the multipoint

connector acc. to the wiring plan on the

following pages.

The multipoint connector is available as

follows:

- Wire-Wrap standard connection

1,0␣ x␣ 1,0␣ mm

- Plug connection 2,8␣ x␣ 0,8 mm

- Termi-Point standard connection

1,6␣ x␣ 0,8␣ mm

- Soldering connection

- Screw terminal 2␣ x␣ 0,5␣ mm

2

Further information concerning mounting is

stated in the operating instructions of the

carrier.

Mounting in single housing

The housing socket can be either screwed

directly to a mounting plate or plugged on a

carrier rail (TS 35 x 7,5 acc. to EN 50 022 or

TS 32 acc. to EN 50 035). Further information

concerning mounting are stated in the

operating instructions of the housing. Connect

the wires acc. to the wiring plan.

The Ex-coding with fixed coded pins ensures

that not-Ex and Ex-instruments are not

interchanged.

Instrument- Excoding coding

VEGATRENN 547 V Ex a23 / c11 c23

Fig. 2.1 Coding table

Instrument coding Function coding

z b d

a c

o 1 o

o 3 o

o 5 o

o 7 o

o 9 o

VEGATRENN

547 V Ex

a23

o11o

o13o

o15o

o17o

o19o

o21o

o23o

o25o

o27o

o29o

o31o

c11

c23

safety barrier

Ex-coding

Fig. 2.2 Module codingVEGATRENN

8 VEGATRENN 547 V Ex

Page 9

Electrical connection

3 Electrical connection

3.1 Installation information

Generally the following instructions must be

noted for installation:

Installation place

VEGATRENN 547 V Ex as well as the

appropriate signal conditioning instrument

must be generally installed outside the

hazardous area.

Protection

In Ex-applications protection IP 20 must be

maintained. Cover the gaps or free modules

from the front with appropriate blind covers.

Ex-separating chamber

An Ex-separating chamber must be mounted

to the connections of VEGATRENN to ensure

sufficient “air and creep distances“. Loop the

cable through the Ex-separating chamber and

connect the cables. Fasten the Ex-separating

chamber with the lower screw. Note the

operating instructions of the carrier BGT 596

Ex.M.

Mounting in carrier

When you mount VEGATRENN in a carrier,

you have to use a VEGA-Ex-module. Keep a

distance of at least 10 mm ( 2TE) to module

cards of other manufacturers. If you want to

mount VEGATRENN in the complete left

position in the carrier, a blind cover of at least

20 mm (4 TE) must be mounted in front of the

module of the instrument.

2

on

VEGATOR

Blind cover

not intrinsically safe circuits so that the min.

distance of 50 mm must be kept.

When using a separating chamber (supplied

with the module) this condition is met.

General conditions

In addition the valid “installation and operating

instructions“ as well as the special conditions

and instructions in the conformity certificates

must be noted.

Separation from not intrinscially safe

circuits

A separating wall must be provided between

the connection parts of intrinsically safe and

VEGATRENN 547 V Ex 9

Page 10

2

6

12

20

28

24

22

10

16

18

30

32

d b z

1 +

2 –

3 +

4 –

1 +

2 –

L (+)

N (–)

26

–

14

+

8

4

3 +

4 –

Electrical connection

3.2 Connection instructions

Not intrinsically safe input

The not intrinsically safe input of the Exseparator is connected via a standard twowire line with a signal conditioning instrument.

If electromagnetic interferences have to be

expected, screened cable should be used.

The screen must only be earthed at one end

of the signal conditioning instrument.

Intrinsically safe output

The wiring of the intrinsically safe outputs of

the Ex-separator with the sensors must meet

with the valid installation regulations. E.g. the

DIN-regulations prescribe that the connection

lines between Ex-separator and sensors must

be marked on the entire length. For coverings

light blue must be used as colour.

If electromagnetic interferences must be

expected, screened cable must be used. The

screen must only be earthed at one sensor.

3.3 Wiring plan

Power

supply

VBUSconnection

of signal

conditioning

instrument

VBUSsensor 2

VBUSsensor 2

VBUSsensor 1

VBUSsensor 1

10 VEGATRENN 547 V Ex

Page 11

Electrical connection

3.4 Connection examples

In conjunction with VEGALOG 571

Power

supply

+

–

d b z

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

EV-cards

L (+)

N (–)

Rack 1

Rack 2

VBUSSensor 2

VBUSSensor 2

3 +

4 –

1 +

2 –

d b z

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

VEGATRENN

547 V Ex

No. 1

VBUS-line

3 +

VBUSSensor 1

4 –

1 +

VBUSSensor 1

2 –

VBUSSensor 2

VBUSSensor 2

+

–

3 +

4 –

1 +

2 –

d b z

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

VEGATRENN

547 V Ex

No. 2 …

3 +

VBUSSensor 1

4 –

1 +

VBUSSensor 1

2 –

VBUSSensor

2

VBUSSensor 2

+

–

3 +

4 –

1 +

2 –

d b z

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

VEGATRENN

547 V Ex

… No. 8

3 +

4 –

1 +

2 –

VBUSSensor

1

VBUSSensor 1

conne tion of sensors 1 … 15

VEGATRENN 547 V Ex 11

Page 12

In conjunction with VEGAMET 515 V (carrier)

Electrical connection

Power

supply

L (+)

N (–)

d b z

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

VEGAMET

515␣ V

+

–

VBUS

VBUS-line

VBUSSensor 1

VBUSSensor 1

d b z

2

4

6

+

–

3 +

4 –

1 +

2 –

8

10

12

14

16

18

20

22

24

26

28

30

32

VEGATRENN

547 V Ex

3 +

4 –

1 +

2 –

VBUSSensor 2

VBUSSensor 2

12 VEGATRENN 547 V Ex

Page 13

Electrical connection

In conjunction with housing type 506

power supply

multipoint

connector

für VEGAMET

514 V / 515 V

L (+)

N (–)

z6b6d6N–L+z16z18z

z10b10d

b22b24z

10

z12b12d

d22d24z

12

GEH506

socket

1 2 3 4 5 6 7 8

3

1

2

1

2

4

1

2

22

24

5

b16b18b

d16d18d

3

20

20

20

multipoint connector for

VEGATRENN 547 V Ex

6

7

8

3

4

4

sensor number

VBUSSensor 1

VBUSSensor 2 *

)

*) only with VEGAMET 515 V

VEGATRENN 547 V Ex 13

Page 14

Set-up, diagnosis

4 Set-up

For set-up note additionally the operating

instructions and the legal documents of the

sensors and signal conditioning instruments

used.

5 Diagnosis

5.1 Maintenance

The instrument is maintenance free.

5.2 Repair

Due to safety and guarantee reasons repair

work must only be done by VEGA-staff.

In case of defect please return the respective

instrument with a short description of the error

to our repair department.

5.3 Fault signal

VEGATRENN 547 V Ex has no own monitoring.

The sensor lines are monitored by the signal

conditioning instrument on shortcircuit and

line break.

14 VEGATRENN 547 V Ex

Page 15

Notes

VEGATRENN 547 V Ex 15

Page 16

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (0 78 36) 50 - 0

Fax (0 78 36) 50 - 201

e-mail vega@vega-g.de

ISO 9001

Technical data subject to alterations 2.20 965 / Jan. ’98

Loading...

Loading...