Page 1

The TP32 surge protection device is

specifically designed to protect process

transmitters and devices on Fieldbus

systems. The TP32 builds on the high

specification of the acclaimed TP48 range to

provide a level of surge protection for fieldbus

transmitters that is well in excess of the

optional transient protection available from

some transmitter manufactures.

The all important earth connection is

made via the casing of the transmitter

negating the need for a separate earth

connection or ground stake at the

transmitter. In operation, the TP32 makes

sure that the transmitter electronics are

never exposed to damaging transients

between the lines and earth. Any surge

current appearing as a series-mode or

common-mode transient is converted into a

common-mode voltage whereupon the

transmitter electronics are temporarily

raised to some higher voltage level before

‘floating’ down automatically (and without

damage) to resume normal operation.

The TP32 protection network is a hybrid

design

consisting of high-power, solid state

electronics and a gas discharge tube which

are capable of diverting surges up to 10kA.

Encased in an ANSI 16 stainless steel

enclosure, the TP32 exhibits unparalleled

mechanical durability providing years of

maintenance free operation in harsh

environments. The enclosure is available

threaded for all the common conduit entries.

Versions are available for

1

/

2

” NPT, 20mm

ISO, and G

1

/

2

” (BSP

1

/

2

inch) threaded entries.

Installation is very simple and can easily be

carried out retrospectively to existing

installations. The TP32 is screwed into any

unused conduit entry on the transmitter case

allowing flying leads to connect the device to

the terminal block (+ve, -ve) and the internal

earth stud within the transmitter housing. By

connecting in parallel to the transmitter

circuit the TP32 does not

interfere with the normal

operation of the bus –

passing ac or dc

signals without adding increased voltage

drop across the segment while consistently

diverting surge currents safely to earth and

clamping output voltages to safe levels.

For hazardous area use, approvals for both

intrinsically safe and flameproof/explosionproof

operation are available, in all gas groups and

apparatus temperature classification up to

T6. CSA and FM approval is also available.

The TP32 is designed to meet the

requirements of IEC 61158-2:2000 and

ANSI/ISA-50.02-2 1992 for 31.25kB/sec

systems as used by FOUNDATION

Fieldbus, PROFIBUS-PA and

WorldFIP.

Data & Signal

Protection

Protects transmitters and smart transmitters from induced

surges and transients on fieldbus cabling.

● Fieldbus specific - designed to meet the

requirements of IEC 61158-2:2000 &

ANSI/ISA-50.02-2 1992

● Easy and direct mounting – simply screws into

a spare conduit entry on the transmitter

● Parallel connection ensures ‘transparent’

operation - zero voltage drop across device

● FM, CSA and ATEX approved

● 10 year product warranty

TP32 Series

Page 2

Specification

All figures typical at 25°C (77°F) unless otherwise stated

Maximum surge current

10kA peak (8/20µs waveform)

Leakage current

Line-line: < 1µA at working voltage

Line-earth: < 1µA at 120V common-mode

Working voltage

±32V dc maximum

±120V peak (or DC) maximum common-mode

Maximum continuous operating voltage

35V

Limiting voltage

Line-line with 250mm cable:

< 49V (10A, 10/1000µs pulse)

Line-earth with 75mm cable:

<635V (3kA, 8/20µs waveform)

<635V (6kV, 1.2/50µs waveform)

Line resistance

No resistance introduced into the loop

Capacitance

Line-line: < 50pF

Line-earth: < 100pF

Attenuation

7·8KHz–7.5MHz monotonic & better than –1dB

typical bandwidth, 150MHz on 100Ω system

Ambient temperature limits

T6 –40°F to +140°F (–40°C to +60°C)

T5 –40°F to +185°F (–40°C to +85°C)

Humidity

5% to 95% RH (non-condensing)

Electrical connections

3 flying leads: line 1 & line 2 plus

non-polarised earth

Wire size: 32 / 0.2 (1.0mm2, 18 AWG)

Lead length: 250mm minimum supplied

≤ 75mm recommended

Casing

ANSI 316 stainless steel hexagonal barstock,

male thread

Threads

TP32-N

1

/

2

”

NPT

TP32-I 20mm ISO (M20 x 1.5)

TP32-G G

1

/

2

”

(BSP

1

/

2

inch)

Weight

175g (6.18oz)

Dimensions

See figure 1

ATEX compliance

See Approvals table for details

EMC compliance

BS EN 61643-1

Electrical Safety

EEx ia IIC T6, Ceq=0, Leq=0; the unit can be

connected without further certification into any

intrinsically safe loop with open circuit voltage

<60V and input power <1.2W.

EEx d IIC T6; the unit is apparatus-approved to

explosionproof (flameproof) standards, and can

be fitted into a similarly approved housing.

Installation

The TP32 is designed for mounting directly into an

unused conduit entry on a fieldbus transmitter

housing (see figure 2). Generally, two such entries are

provided, one of which is used for the bus wiring. On

the unused entry, the blanking plug or other closure

device is removed and an appropriately threaded

TP32 screwed into its place. The transmitter

specification should provide information indicating the

required thread type. TP32 units can be installed

using thread adaptors (such as a tee piece) if

necessary, including certified adaptors in hazardous

area applications. For applications where two conduit

entries are not provided or where both are used for

electrical connections, TP32 units can be housed in

conventional conduit hub or junction boxes, provided

access to the loop terminals is possible.

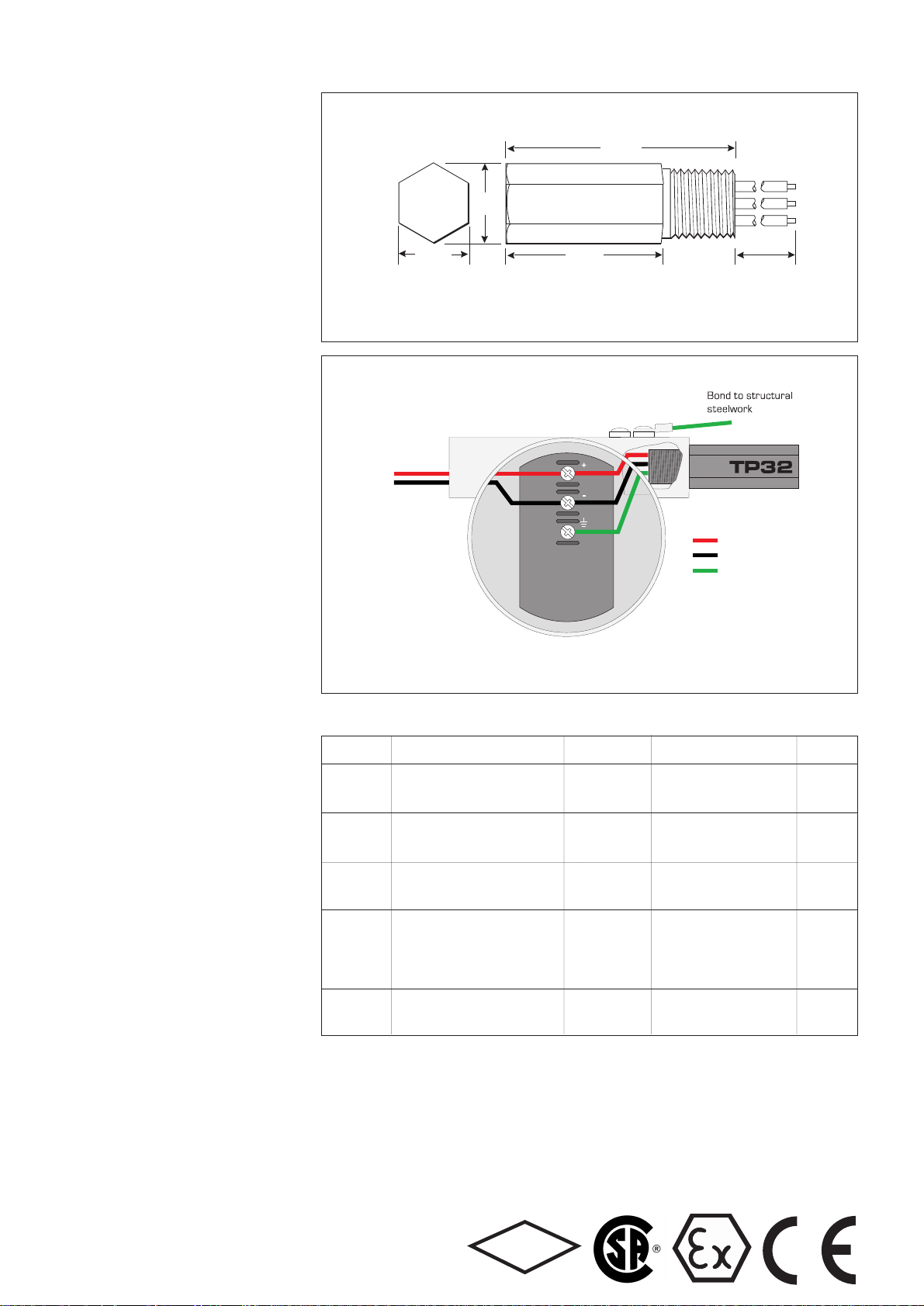

904-023 01

Figure 1 Dimensions

Figure 2 Connection detail for a typical transmitter

Approvals

To order specify -

TP32-N

1

/

2

” NPT thread

TP32-N-NDI

1

/

2

” NPT thread, with EEx ia, EEx d, FM and CSA approval

TP32-I 20mm ISO thread

TP32-I-NDI 20mm ISO thread, with EEx ia, EEx d, FM and CSA approval

TP32-G G

1

/

2

” (BSP

1

/

2

inch)

TP32-G-NDI G

1

/

2

” (BSP

1

/

2

inch), with EEx ia, EExd, FM and CSA approval

Note: In accordance with our policy of continuous improvement, we reserve the right to change the product’s specification without notice.

Telematic and Atlantic Scientific surge protection devices

are designed and manufactured by MTL Surge Technologies.

MTL Surge Technologies

Power Court, Luton, Bedfordshire, England LU1 3JJ

Tel: +44 (0)1582 723633 Fax: +44 (0)1582 422283

E-mail: enquiry@mtlsurge.com WWW: www.mtlsurge.com

A member of the MTL Instruments Group plc

Country Standard Certificate/File Approved for Product

(Authority) No.

UK (BASEEFA) EN 50014:1997 + Amendments 1 & 2 BAS00ATEX1258X EEx ia IIC T6 (T

amb

= -40 to 60°C) TP32-N-NDI

EN 50020:1994, EN 50284:1999 EEx ia IIC T5 (T

amb

= -40 to 85°C) TP32-I-NDI

TP32-G-NDI

UK (BASEEFA) EN 50014:1997 + Amendments 1 & 2 BAS00ATEX2146X EEx d IIC T6 (T

amb

= -40 to 60°C) TP32-N-NDI

EN 50018:2000 EEx d IIC T5 (T

amb

= -40 to 85°C) TP32-I-NDI

TP32-G-NDI

Atex Directive To be confirmed TML02ATEX0032X Ex n II T6 (-40°C<T

amb

<+60°C) TP32-N

94/9/EC Eex n II T5 (-40°C<T

amb

<+85°C) TP32-I

TP32-G

USA (FM) Class Nos. 3600 (1998), 3610 (1999), 311208 Intrinsically Safe: TP32-N-NDI

3611 (1999), 3615 (1989), 3810 incl. I, II, III/1/A-G, I/0/IIC TP32-I-NDI

Supp 1 (1995-07 (1989-03), Explosionproof: I/1/A-D TP32-G-NDI

ANSI/NEMA 250 (1999), Non incendive: I/2/A-D, I/2/IIC

ISA0S12.0.01 (1998) Dust ignition proof: II,III/1/EFG

Special protection: II/2/FG

Canada (CSA) C22.2 No. 30 152423 Class I, Grp A-D TP32-N-NDI

C22.2 No. 1010 (LR 36637) Class II, Grp E-G TP32-I-NDI

TP32-G-NDI

75mm

(2.95")

27mm

(1.07")

23mm

(0.91")

Dimensions across flats 23mm (0.91")

55mm

(2.17")

Lead length

250mm (9.85")

minimum supplied

+ve

-ve

Earth

M

F

APPROVED

Loading...

Loading...