Page 1

Operating Instructions

VEGATOR 632

Signal conditioning instrument

Document ID:

35243

conditioning instruments

and communication

Signal

Page 2

Contents

Contents

1 About this document

1.1 Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Symbolism used . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 For your safety

2.1 Authorised personnel . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Warning about misuse . . . . . . . . . . . . . . . . . . . . . . .

2.4 General safety instructions . . . . . . . . . . . . . . . . . . . .

2.5 CE conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Safety instructions for Ex areas . . . . . . . . . . . . . . . . .

2.7 Environmental instructions. . . . . . . . . . . . . . . . . . . . .

3 Product description

3.1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Packaging, transport and storage . . . . . . . . . . . . . . .

4 Mounting

4.1 General instructions . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Instructions for installation . . . . . . . . . . . . . . . . . . . . .

5 Connecting to power supply

5.1 Preparing the connection . . . . . . . . . . . . . . . . . . . . .

5.2 Connection procedure. . . . . . . . . . . . . . . . . . . . . . . .

5.3 Wiring plan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

4

4

5

5

5

5

6

6

6

7

7

8

8

10

10

12

13

13

6 Adjustment elements

6.1 Adjustment elements - Overview . . . . . . . . . . . . . . . .

7 Set up - Single channel control (level detection)

7.1 Adjust relay function . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Sensitivity adjustment . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Adjust switching delay . . . . . . . . . . . . . . . . . . . . . . .

7.4 Activate line break monitoring . . . . . . . . . . . . . . . . . .

7.5 Master/Slave function . . . . . . . . . . . . . . . . . . . . . . . .

8 Set up - Two-point control Δs (pump control)

8.1 Adjust relay function . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Adjust switching delay . . . . . . . . . . . . . . . . . . . . . . .

8.4 Activate line break monitoring . . . . . . . . . . . . . . . . . .

8.5 Master/Slave function . . . . . . . . . . . . . . . . . . . . . . . .

9 Set up - Two-channel control

9.1 Adjust relay function . . . . . . . . . . . . . . . . . . . . . . . . .

2 VEGATOR 632 • Signal conditioning instrument

19

23

25

27

27

28

29

31

33

34

34

35

35243-EN-120228

Page 3

Contents

9.2 Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Adjust switching delay . . . . . . . . . . . . . . . . . . . . . . .

9.4 Activate line break monitoring . . . . . . . . . . . . . . . . . .

9.5 Master/Slave function . . . . . . . . . . . . . . . . . . . . . . . .

10 Set up - Four-channel control

10.1 General information . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Adjust relay function . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Adjust switching delay . . . . . . . . . . . . . . . . . . . . . . .

10.5 Activate line break monitoring . . . . . . . . . . . . . . . . . .

10.6 Master/Slave function . . . . . . . . . . . . . . . . . . . . . . . .

11 Switching examples

11.1 Single channel operation. . . . . . . . . . . . . . . . . . . . . .

11.2 Two-channel operation . . . . . . . . . . . . . . . . . . . . . . .

11.3 Two-point control . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 Four-channel operation . . . . . . . . . . . . . . . . . . . . . . .

11.5 Two-point control and two-channel operation . . . . . . .

12 Maintenance and fault rectification

12.1 Maintaining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 Remove interferences . . . . . . . . . . . . . . . . . . . . . . . .

12.3 Function test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4 Instrument repair . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 Dismounting

13.1 Dismounting steps . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37

39

39

40

41

41

41

41

41

42

43

45

46

48

49

50

50

51

52

53

53

14 Supplement

14.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplementary documentation

Information:

Supplementary documents appropriate to the ordered version come

with the delivery. You can find them listed in chapter "Product

description".

Editing status: 2012-02-20

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 3

54

Page 4

1 About this document

1 About this document

1.1 Function

This operating instructions manual provides all the information you

need for mounting, connection and setup as well as important

instructions for maintenance and fault rectification. Please read this

information before putting t he instrument into operation and keep this

manual accessible in the immediate vicinity of the device.

1.2 Target group

This operating instructions manual is directed to trained qualified

personnel. The contents of this manual should be made available to

these personnel and put into practice by them.

1.3 Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or malfunctions can

result.

Warning: If this warning is ignored, injury to persons and/or serious

damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or

destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

l List

The dot set in front indicates a list with no implied sequence.

à Action

This arrow indicates a single action.

1 Sequence

Numbers set in front indicate successive steps in a procedure.

4 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 5

2 For your safety

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual must be

carried out only by trained specialist personnel authorised by the plant

operator.

During work on and with the device the required personal protective

equipment must always be worn.

2.2 Appropriate use

VEGATOR 632 is a universal signal conditioning instrument for

connection of a level switch.

You can find detailed information on the application range in chapter

"Product description".

Operational reliability is ensured only if the instrument is properly used

according to the specifications in the operating instructions manual as

well as possible supplementary instructions.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbitrary

conversions or modifications are explicitly forbidden.

2.3 Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to

application-specific hazards, e.g. vessel overfill or damage to system

components through incorrect mounting or adjustment.

2.4 General safety instructions

This is a high-tech instrument requiring the strict observance of

standard regulations and guidelines. The user must take note of the

safety instructions in this operating instructions manual, the countryspecific installation standards as well as all prevailing safety

regulations and accident prevention rules.

The instrument must only be operated in a technically flawless and

reliable condition. The operator is responsible for trouble-free

operation of the instrument.

During the entire duration of use, the user is obliged to determine the

compliance of the necessary occupational safety measures with the

current valid rules and regulations and also take note of new

regulations.

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 5

Page 6

2 For your safety

2.5 CE conformity

This device fulfills the legal requirements of the applicable EC

guidelines. By attaching the CE mark, VEGA provides a confirmation

of successful testing. You can find the CE conformity declaration in the

download area of

www.vega.com.

2.6 Safety instructions for Ex areas

Please note the Ex-specific safety information for installation and

operation in Ex areas. These safety instructions are part of the

operating instructions manual and come with the Ex-approved

instruments.

2.7 Environmental instructions

Protection of the environment is one of our most important duties. That

is why we have introduced an environment management system with

the goal of continuously improving company environmental protection.

The environment management system is certified according to DIN

EN ISO 14001.

Please help us fulfil this obligation by observing the environmental

instructions in this manual:

l Chapter "Packaging, transport and storage"

l Chapter "Disposal"

6 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 7

3 Product description

1

1

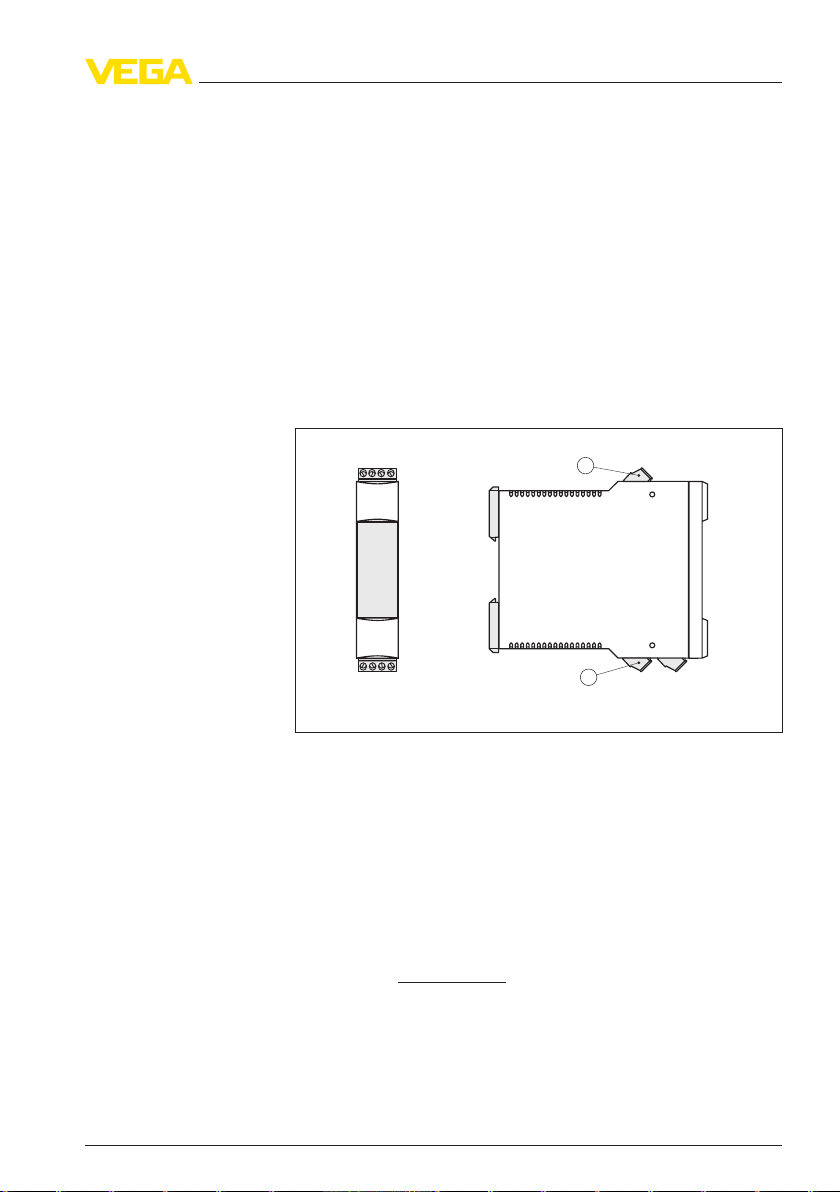

3.1 Structure

3 Product description

Scope of delivery

Constituent parts

Type label

The scope of delivery encompasses:

l VEGATOR 632 signal conditioning instrument

l Documentation

- this operating instructions manual

- Ex-specific "Safety instructions" (with Ex-versions)

- if necessary, further certificates

VEGATOR 632 consists of:

l VEGATOR 632 signal conditioning instrument

Fig. 1: VEGATOR 632

1 Pluggable terminal blocks

The type label contains the most important data for identification and

use of the instrument:

l Article number

l Serial number

l Technical data

l Article numbers, documentation

l Information about connection and adjustment of the instrument

The serial number allows you to access the delivery data of the

instrument via www.vega.com, "VEGA Tools" and "serial number

search".

3.2 Principle of operation

Application area

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 7

VEGATOR 632 is a single signal conditioning instrument with two

channels (relay) for processing the signals of conductive probes.

Page 8

3 Product description

Functional principle

The following switching functions are possible:

l Single channel control (simple level detection)

l Two-point control (pump control)

l Two-channel control (two separate switching points)

l Four-channel control or combination of two-point and two-channel

control (with two VEGATOR 632)

The VEGATOR 632 signal conditioning instrument powers connected

sensors and simultaneously processes their measuring signals.

It delivers a small alternating current to the measuring cell via the

signal cable. Electrolytic decomposition of the electrode rods and the

medium is avoided by using alternating current.

The cable is connected to the measurement loop or the metallic vessel

and the probe.

When the medium reaches the switching point of the sensor, the

voltage on the sensor drops. The output relays then switch according

to the set mode.

Voltage supply

Packaging

Transport

Transport inspection

Detailed information about the power supp ly can be found in chapter

"Technical data".

3.3 Operation

The damping and the mode can be adjusted on the signal conditioning

instrument via the slide switch. The instrument function can be

preadjusted with a DIL switch block.

The switching point can be adjusted with a potentiometer.

3.4 Packaging, transport and storage

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

according to DIN EN 24180.

The packaging of standard instruments consists of environmentfriendly, recyclable cardboard. For special versions, PE foam or PE foil

is also us ed. Dispose of the packaging material via specialised

recycling companies.

Transport must be carried out under consideration of the notes on the

transport packaging. Nonobservance of these instructions can cause

damage to the device.

The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or

concealed defects must be appropriately dealt with.

35243-EN-120228

8 VEGATOR 632 • Signal conditioning instrument

Page 9

3 Product description

Storage

Storage and transport

temperature

Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

l Not in the open

l Dry and dust free

l Not exposed to corrosive media

l Protected against solar radiation

l Avoiding mechanical shock and vibration

l Storage and transport temperature see chapter "Supplement -

Technical data - Ambient conditions"

l Relative humidity 20 … 85 %

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 9

Page 10

a

a

a

? ? ? ? ?

E

X

E

X

E

X

4 Mounting

4 Mounting

4.1 General instructions

Installation location

Front plate

Protected mounting lo-

cation

Installation

Min. distances

VEGATOR 632 signal conditioning instrument for mounting on carrier

rail according to EN 60715 TH 35 x 7.5 or EN 60715 TH 35 x 15.

The adjustment elements of VEGATOR 632 are protected under a

hinged front plate against unauthorised or inadvertent adjustment.

VEGATOR 632 must be mounted outside the hazardous area in a

switching cabinet (at least protection rating IP 55).

For moisture-protected mounting outside the switching cabinet, we

offer an insulated protective housing with transparent cover (IP 65) for

surface mounting.

4.2 Instructions for installation

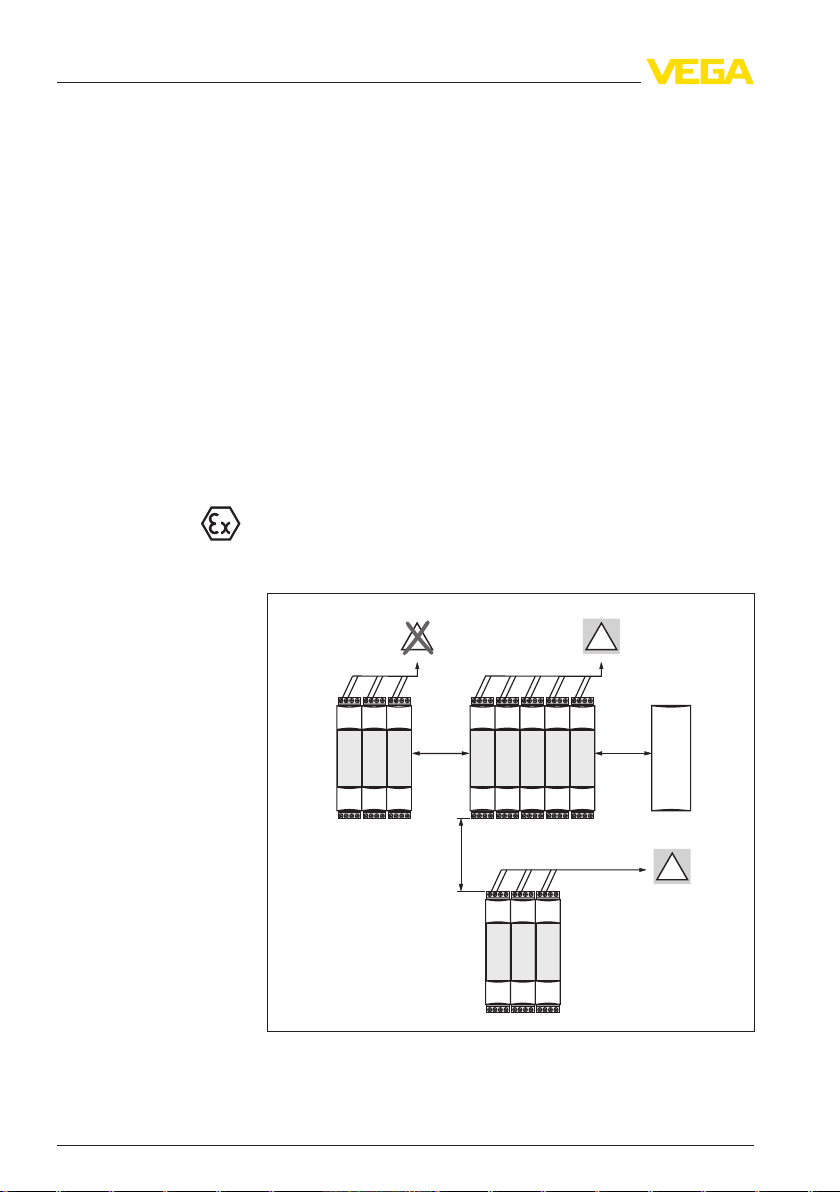

A VEGATOR 632 in Ex version is an auxiliary, intrinsically safe

instrument and may not be installed in explosion-endangered areas.

Please keep the following min. distances when mounting.

Fig. 2: Min. distances to other instruments

a Distance ≥ 50 mm (1.97 in)

10 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 11

1

1

2

b

b

a

a

4 Mounting

Carrier rail mounting

Dismounting

Snap in the instrument vertically on a suitable carrier rail (EN 60715

TH 35 x 7.5 or EN 60715 TH 35 x 15).

Fig. 3: Mounting of the signal conditioning instrument

1 Carrier rail EN 60715 TH 35

Dismount the instrument in the following sequence.

1 Switch off power supply

Fig. 4: Dismounting of the signal conditioning instrument

2 Remove the terminal blocks with a screwdriver ①

3 Open the slide with a screwdriver ②

4 Flip up the signal conditioning instrument and remove it from the

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 11

carrier rail

Page 12

5 Connecting to power supply

5 Connecting to power supply

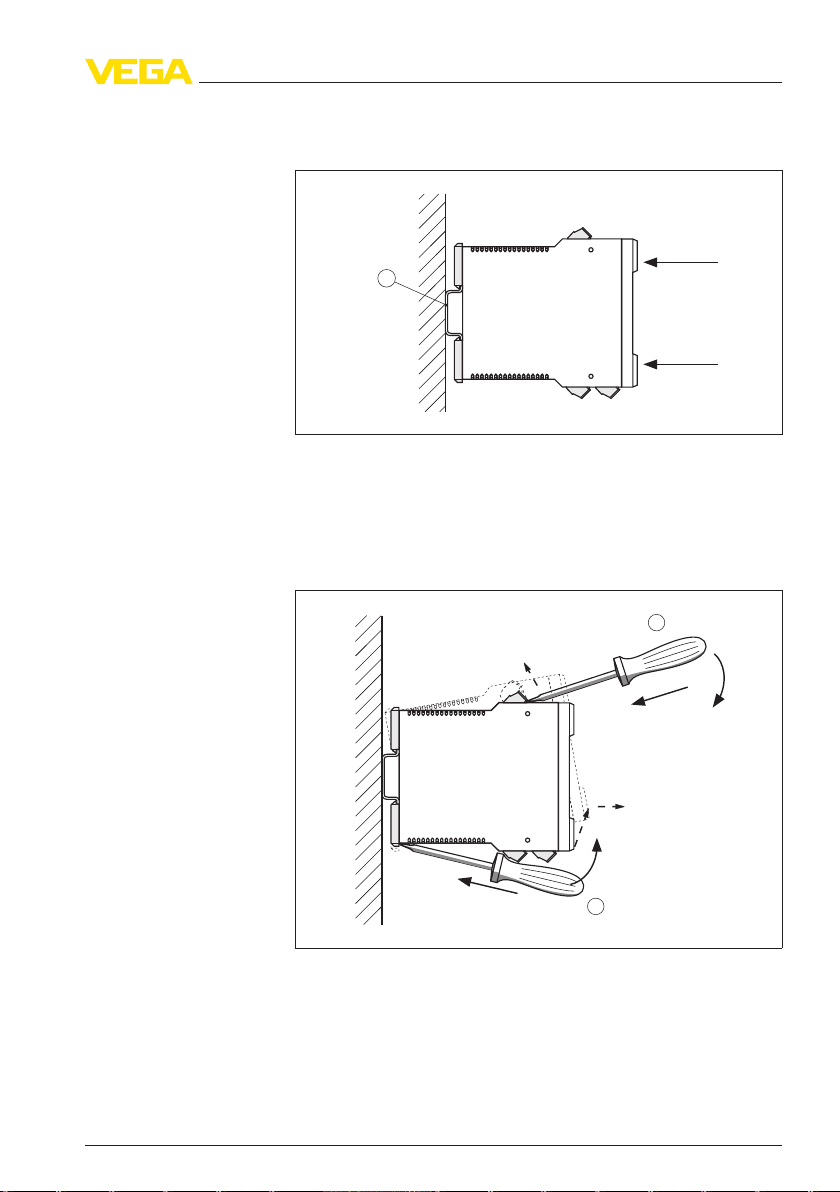

5.1 Preparing the connection

Note safety instructions

Take note of sa-

fety instructions

for Ex applications

Select power supply

Selecting connection

cable

Cable screening and

grounding

Always keep in mind the following safety instructions:

l Connect only in the complete absence of line voltage

l If overvoltage surges are expected, overvoltage arresters should

be installed

Tip:

We recommend VEGA overvoltage arresters B61-300 (power supply

VEGATOR 632) and B62-36G (sensor supply).

In hazardous areas you must take note of the respective regulations,

conformity and type approval certificates of the sensors and power

supply units.

The power supply can be 85 … 253 V AC, 50/60 Hz or 20 … 60 V DC.

The operating voltage of VEGATOR 632 is connected with standard

cable according to the national installation standards. The line

resistance must be max. 25 Ω per wire. If electromagnetic interference

is expected which is above the test values of EN 61326 for industrial

areas, screened cable should be used.

If screened cable is necessary, connect the cable screen on both ends

to ground potential. In the sensor, the screen must be connected

directly to the internal ground terminal. The ground terminal on the

outside of the housing must be connected to the potential equalisation

(low impedance).

If potential equalisation currents are expected, the connection on the

processing side must be made via a ceramic capacitor (e. g. 1 nF,

1500 V). The low frequency potential equalisation currents are thus

suppressed, but the protective effect against high frequency interference si gnals remains.

Select connection cable for Ex

applications

12 VEGATOR 632 • Signal conditioning instrument

Take note of the corresponding installation regulations for Ex

applications.

35243-EN-120228

Page 13

L1L+N

L–

7 8 9 10

4 5 6 17

1 2

15 16

CH2

CH1

Master/

Slave

1 2 3 4

5

6 7

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

5 Connecting to power supply

5.2 Connection procedure

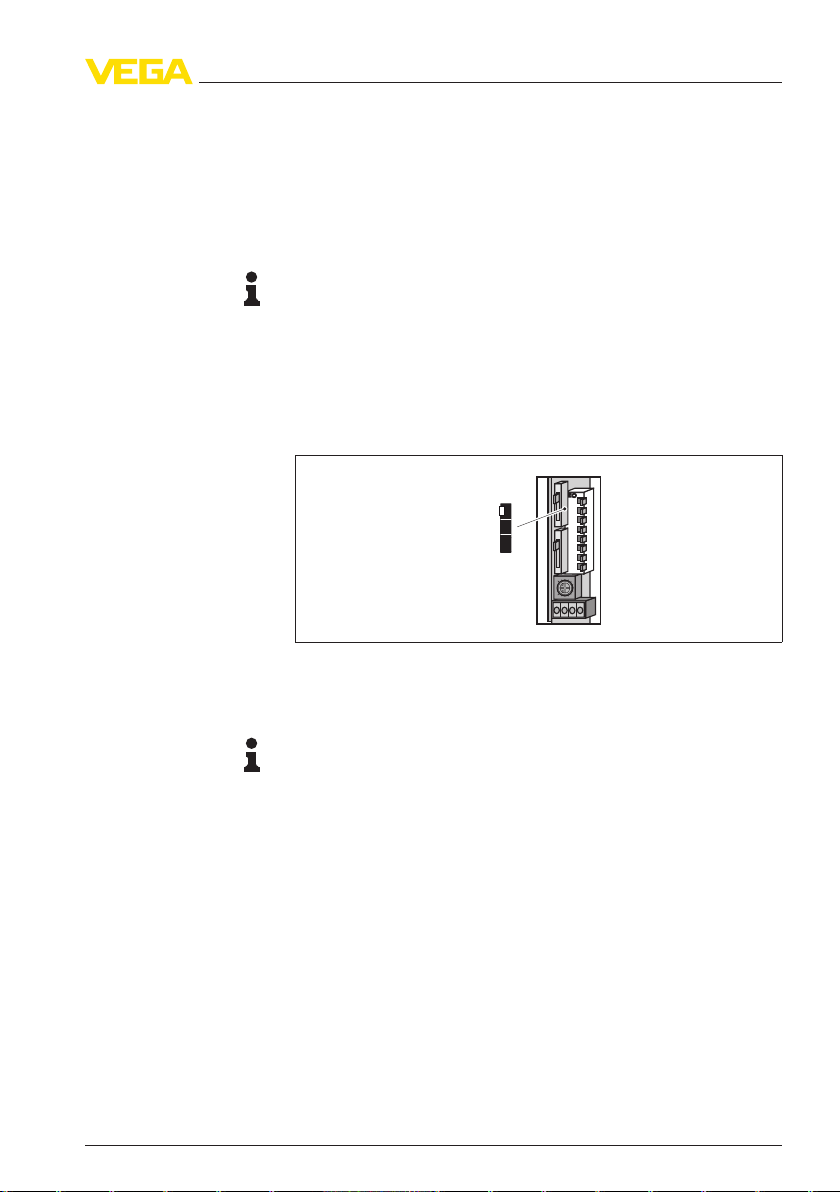

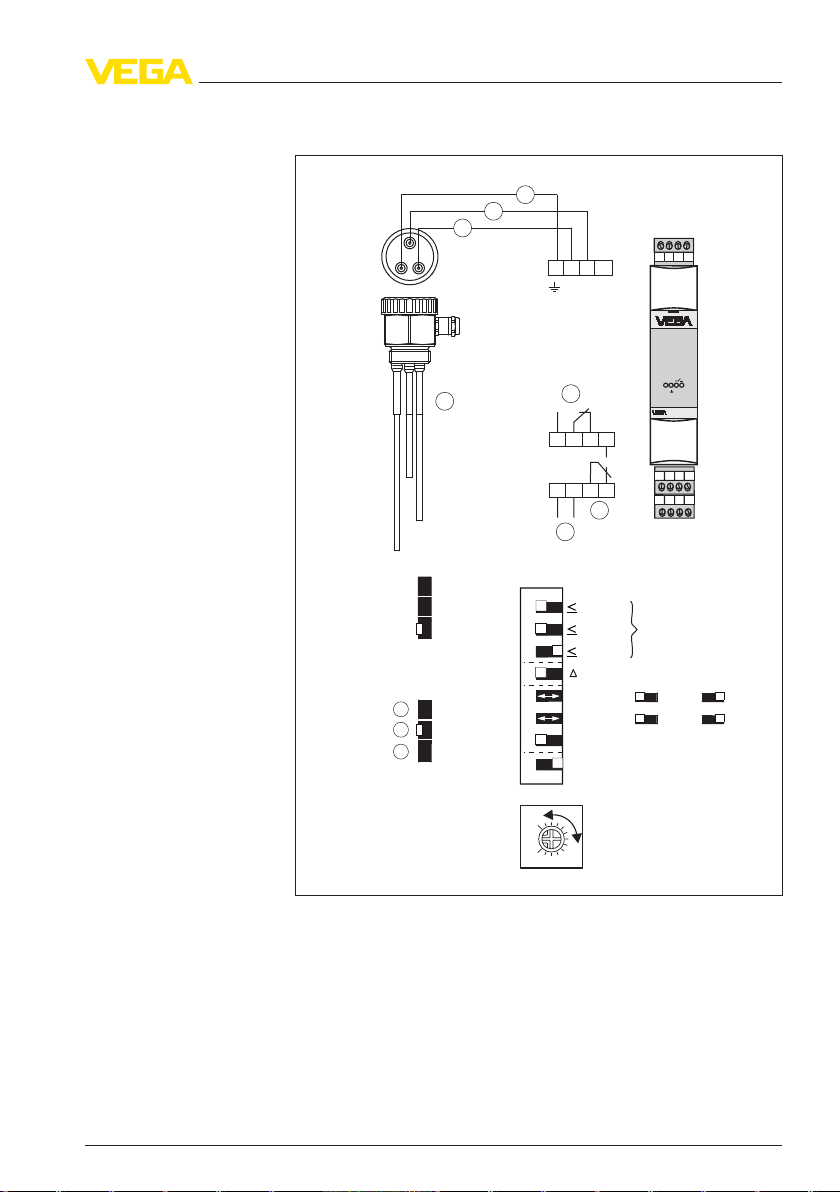

Fig. 5: Terminal assignment

1 Ground

2 Sensor input - Channel 1 (CH 1)

3 Sensor input - Channel 2 (CH 2)

4 Master/Slave

5 Level relay 1

6 Voltage supply

7 Level relay 2 or operating relay

Move on to electrical connection and proceed as follows:

1 Snap VEGATOR 632 onto the carrier rail

2 Connect the sensor cable to terminals 7 to 10 (see the following

wiring plans)

3 Connect relay outputs (4 to 6 and 15 to 17)

4 Connect power supply (switched off) to terminal 1 and 2

The electrical connection is finished.

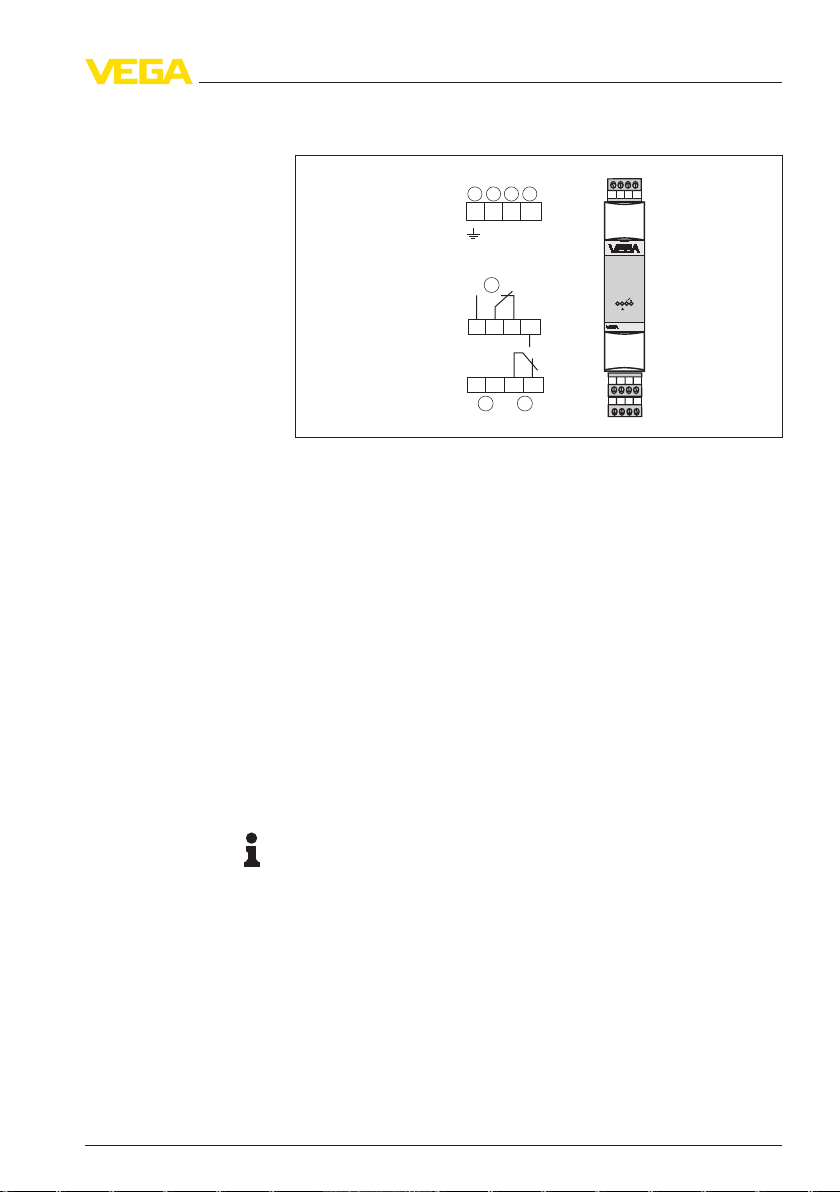

5.3 Wiring plan

Note:

In conductive vessels, the ground cable has contact to the grounded

vessel via the process fitting.

In non-conductive vessels, the probe requires a ground rod which is

connected to the ground terminal of VEGATOR 632.

Line monitoring

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 13

The line break monitoring or alarm function defines the function of the

signal conditioning instrument in case of failure.

The line monitoring is required for probes with approval according to

WHG (WRA) or Ex.

To realize a line monitoring, an additional electronics must be

integrated in the connection housing of the probe.

Page 14

1

2

5 Connecting to power supply

Fig. 6: Additional electronics for line break monitoring in conjunction with a

conductive probe

1 Connect the eyelet according to the following illustration.

Make sure that the eyelets have no contact to other metal parts.

2 Open one of the other terminals and attach the additional

electronics.

3 Tighten the terminal.

Fig. 7: Mounting of the additional electronics for line break monitoring

1 Connection to terminal 1 (ground rod = longest rod)

2 Connection to terminal 2 (max. rod = shortest rod)

3 Additional electronics for line break monitoring

If you are using a probe without additional electronics for line break

monitoring, a fault signal will be triggered.

Keep in mind that in case of a fault signal also the switching output will

be activated.

Only failures of channel 1 are monitored.

14 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 15

1 2

2

1

6

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

L1L+N

L–

7 8 9 10

4 5 6 17

1 2

15 16

CH2

CH1

Master/

Slave

3

5

4

Level detection in conductive vessels

5 Connecting to power supply

Take note of the operating instructions of the conductive probe.

Fig. 8: Level detection in metallic (conductive) vessels

1 Ground

2 max. - channel 1 (CH 1)

3 Level relay 1

4 Level relay 2 or fail safe relay

5 Voltage supply

6 Probe, e.g. EL1

You can find detailed information under "Set up - Single point control"

as well as under "Switching examples".

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 15

Page 16

1

2

2

1

6

1

2

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

L1L+N

L–

7 8 9 10

4 5 6 17

1 2

15 16

CH2

CH1

Master/

Slave

3

5

4

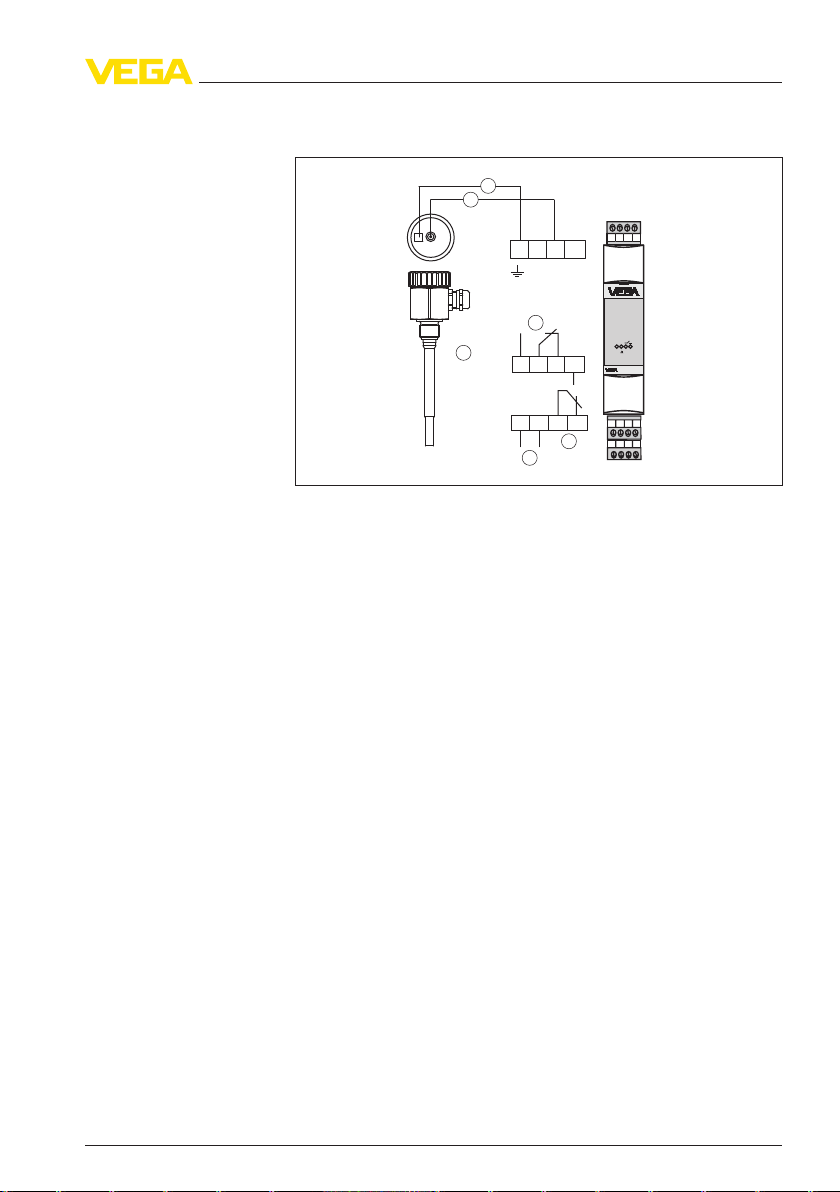

5 Connecting to power supply

Level detection in nonconductive vessels

Fig. 9: Level detection in non-conductive vessels

1 Ground

2 max. - channel 1 (CH 1)

3 Level relay 1

4 Level relay 2 or fail safe relay

5 Voltage supply

6 Probe, e.g. EL3

You can find detailed information under "Set up - Single point control"

as well as under "Switching examples".

16 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 17

1 3

2

2

3

1

7

1

2

3

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

L1L+N

L–

7 8 9 10

4 5 6 17

1 2

15 16

CH2

CH1

Master/

Slave

4

6

5

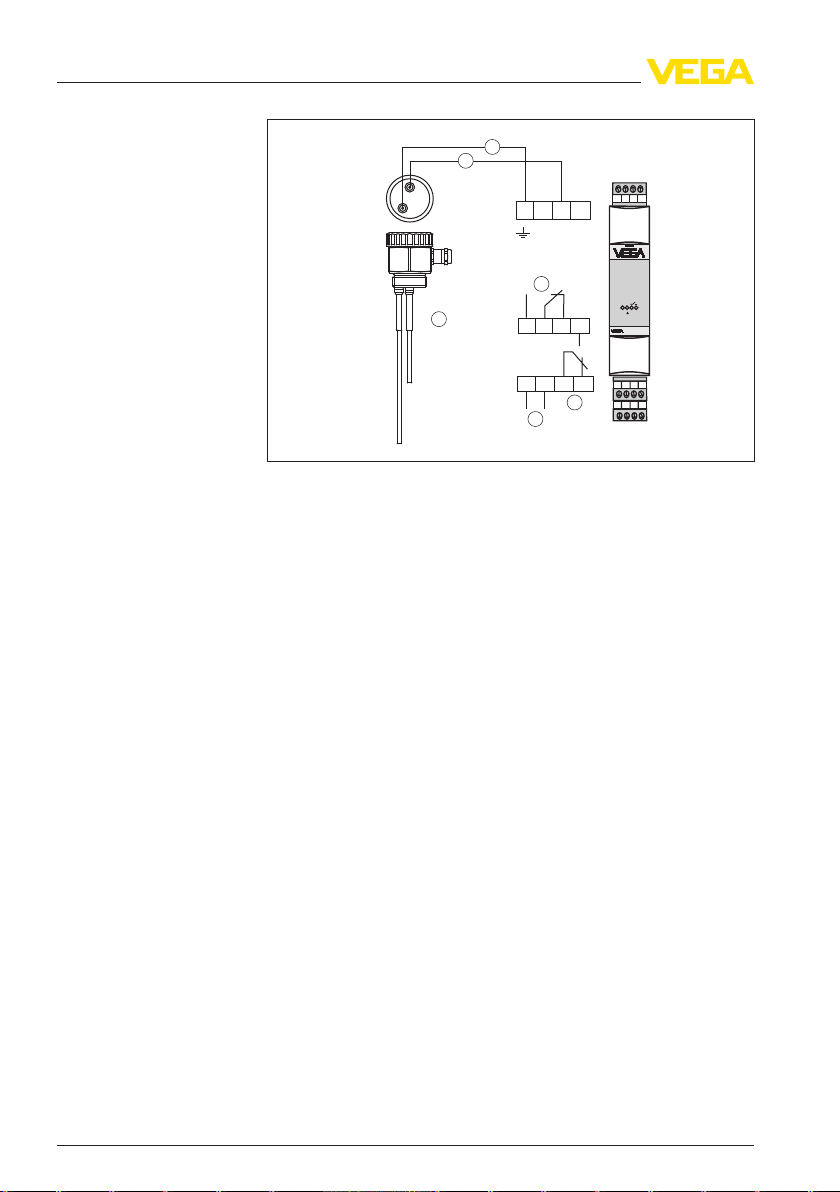

Two-point control (min./

max. control)

5 Connecting to power supply

Fig. 10: Two-point control

1 Ground

2 max. - channel 1 (CH 1)

3 min. - channel 2 (CH 2)

4 Level relay 1

5 Level relay 2 or fail safe relay

6 Voltage supply

7 Probe, e.g. EL3

You can find detailed information under "Set up - Two-point control" as

well as under "Switching examples".

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 17

Page 18

1

2 3

4

5

1

4

2

5

3

3

4

5

1

9

A B

2

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

L1L+N

L–

7 8 9 10

4 5 6 17

1 2

15 16

CH2

CH1

Master/

Slave

6

8

7

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

L1L+N

L–

7 8 9 10

4 5 6 17

1 2

15 16

CH2

CH1

Master/

Slave

6

8

7

5 Connecting to power supply

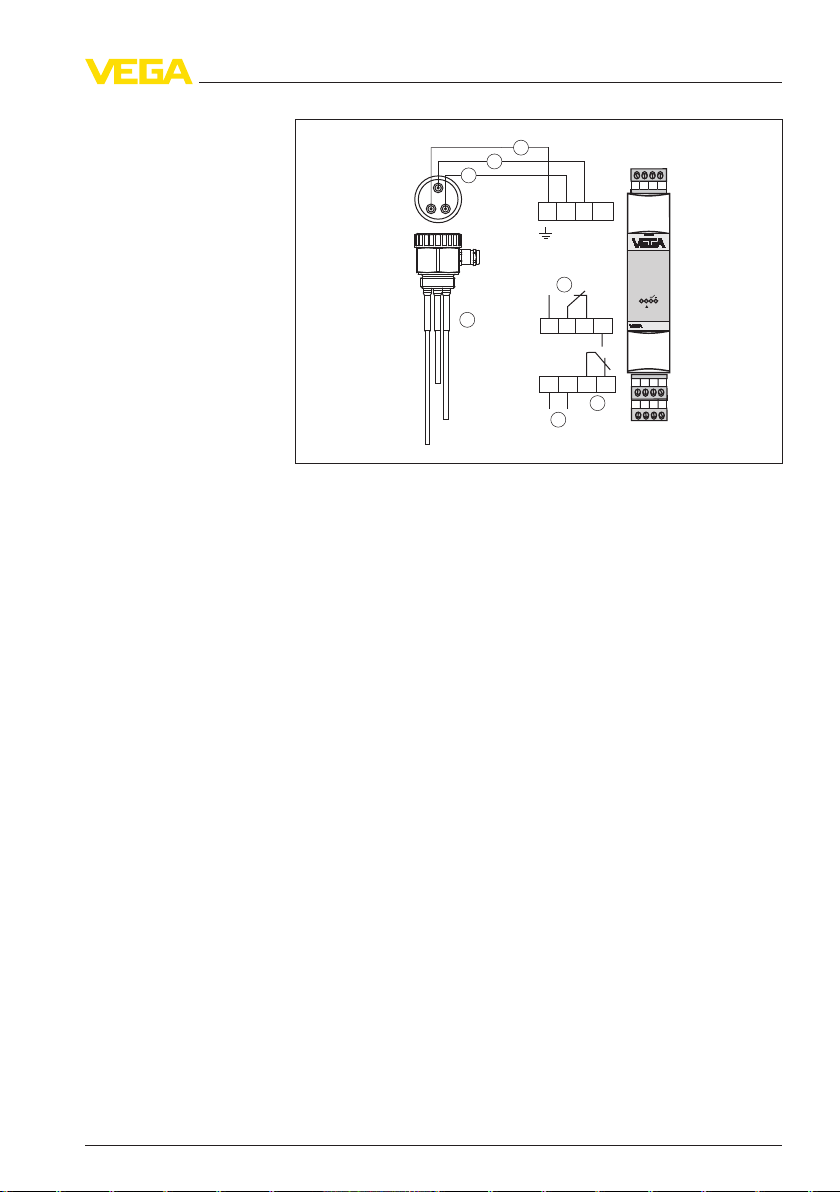

Four-channel control

with two signal conditioning instruments

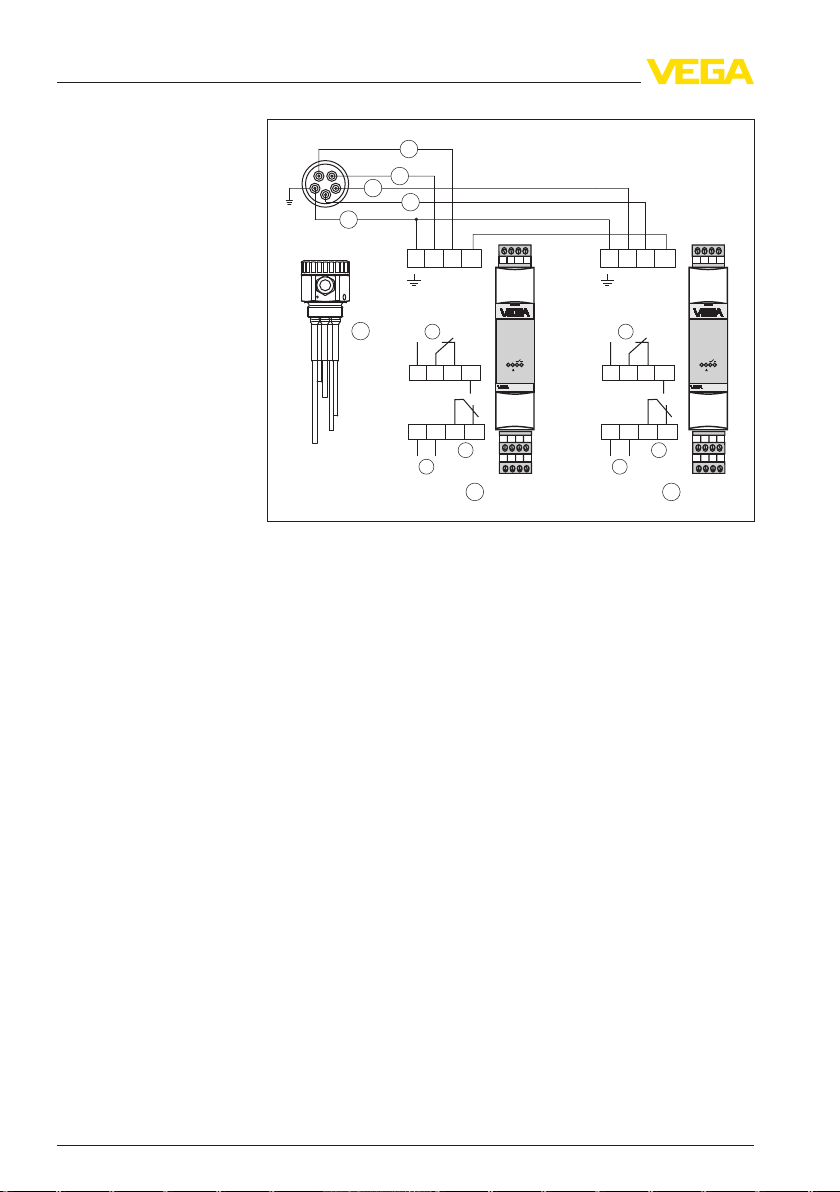

Fig. 11: Four-channel control with two signal conditioning instruments VEGATOR

632

1 Ground

2 max. - channel 1 (CH 1)

3 min. - channel 2 (CH 2)

4 min. - channel 2 (CH 2)

5 max. - channel 1 (CH 1)

6 Level relay 1

7 Level relay 2 or fail safe relay

8 Voltage supply

9 Probe, e.g. EL3

A Min./max. control (signal conditioning instrument 1 - Master)

B Min./max. control (signal conditioning instrument 2 - Slave)

You can find detailed information under "Set up - Four-channel control"

as well as under "Switching examples".

18 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 19

1 2 3 4 5 6 7 8

O

N

7

8

4

5

6

15

16

L1

N

L+ L-

1

2

9

10

CH 2

CH

1

master

/

slave

output

mode

delay

s

alarm

master/

slave

range

1 2 3 4 5 6 7 8

calibration

CH1

CH2

17

min/

max

3

1

3362

C

B

A

D

E

6 Adjustment elements

6 Adjustment elements

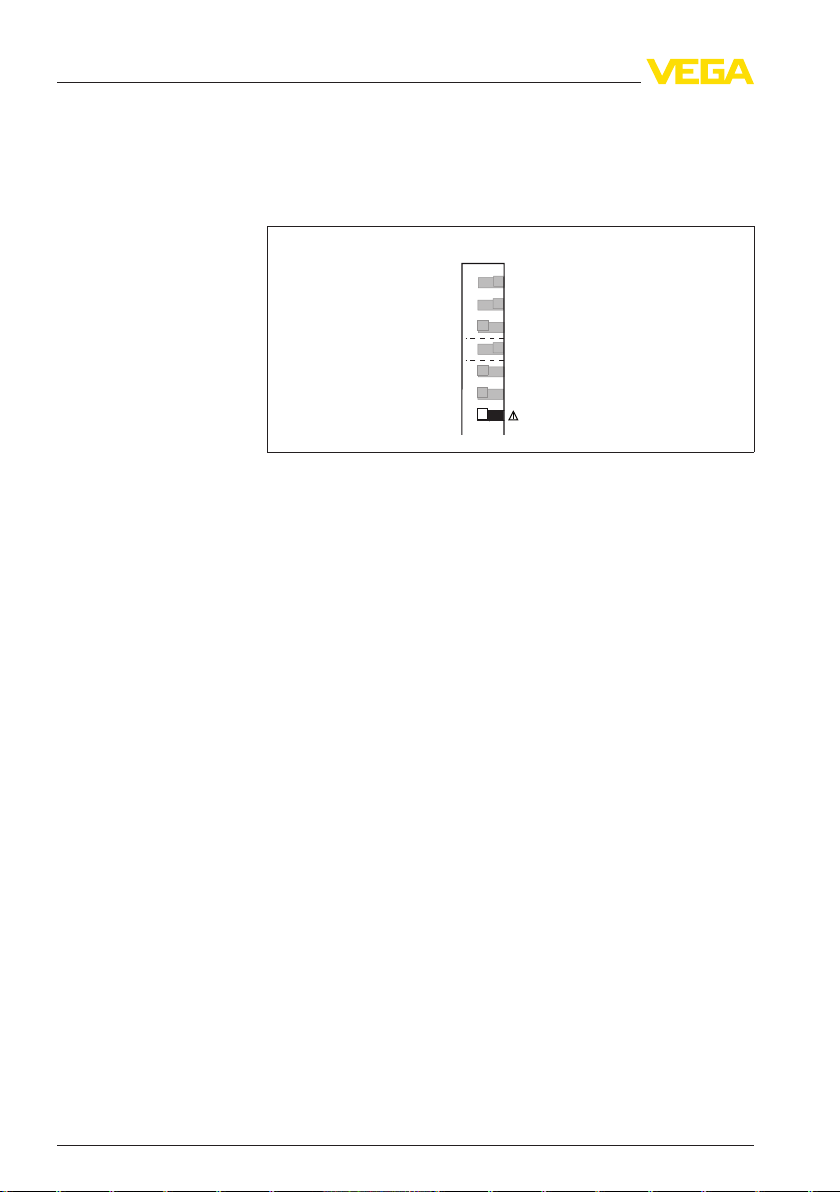

6.1 Adjustment elements - Overview

The following adjustment elements are located below the cover.

DIL switch block (A)

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 19

Fig. 12: VEGATOR 632 - Adjustment elements

A DIL switch block

B Potentiometer for switching point adjustment

C Control lamps

D Slid switch for mode adjustment

E Slide switch for setting the switching delay

SIL switch block with 8 switches. The individual switches are assigned

as follows:

Page 20

1 KΩ

10 KΩ

200 KΩ

s

CH1

CH2

Alarm

Slave/Master

min.

min.

max.

max.

off on

1

2

3

4

5

6

7

8

Calibration

3

1

6 Adjustment elements

(numbering from top to bottom)

Fig. 13: DIL switch block (A)

1 Sensitivity adjustment - range up to 1 kΩ

2 Sensitivity adjustment - range up to 10 kΩ

3 Sensitivity adjustment - range up to 200 kΩ

4 Two-point control

5 Mode - channel 1 (CH 1)

6 Mode - channel 2 (CH 2)

7 Line monitoring (alarm)

8 Master/Slave adjustment

l A1 - Sensitivity adjustment - range up to 1 kΩ

l A2 - Sensitivity adjustment - range up to 10 kΩ

l A3 - Sensitivity adjustment - range up to 200 kΩ

l A4 - Two-point control

l A5 - Mode - Channel 1 (CH 1)

- off: Max. detection or overflow protection

- on: Min. detection or dry run detection

l A6 - Mode - Channel 2 (CH 2)

- off: Max. detection or overflow protection

- on: Min. detection or dry run detection

l A7 - Line monitoring (alarm)

l A8 - Master/Slave adjustment (on = Master)

Potentiometer for switching point adjustment

(B)

20 VEGATOR 632 • Signal conditioning instrument

A potentiometer for switching point adaptation is located below the

cover of the signal conditioning instrument. With this potentiometer you

can adapt the measuring system to the conductivity of the product.

Fig. 14: Potentiometer for switching point adjustment (B)

35243-EN-120228

Page 21

TOR

149A

ON

3

4

1

2

6 Adjustment elements

Note:

When carrying out switching point adjustments keep in mind that there

is a switching delay of 0.5 sec between the moment when the

switching point is reached and the moment when the switching

function is triggered. The potentiometer must therefore be turned

slowly.

A possible additional switching delay should only be switched on after

the adjustment.

Signal lamps (C)

Control lamps (LED) in the front plate indicate operation, switching

status and fault signal.

Fig. 15: Control lamps in the instrument front (C)

1 Control lamp - Operating voltage - green (gn)

2 Control lamp - Fault signal - red (rd)

3 Control lamp - Switching status channel 2 - yellow (ye)

4 Control lamp - Switching status channel 1 - yellow (ye)

l Green (gn)

- Operating control lamp

- Mains voltage on, instrument is operating

l Red (rd)

- Failure lamp

- Fault on the sensor circuit due to sensor failure or line break

- If the fail safe relay is deenergized, the red failure lamp will

light

l Yellow (ye)

- Relay control lamps

- The yellow relay control lamps react depending on the set

mode (min./max.)

- The relay control lamp generally indicates the activated

(energized) condition of the relay

- A dark relay control lamp means that the relay is deenergised

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 21

Page 22

1 2 3 4 5 6 7

8

O

N

3

1

3362

CH1 output parallel

CH2 output separate

CH1 with alarm

O

N

3

1

3362

6 s

3 s

0,5 s

1 2 3 4 5 6 7

8

6 Adjustment elements

Slide switch for adjustment of the relay outputs (D)

Slide switch for setting

the switching delay (E)

3-step switch for mode adjustment of the second output relay. The

individual switch positions are assigned as follows:

Fig. 16: Slide switch for adjustment of the relay outputs (D)

l CH 1 output parallel - Both relay outputs switch in parallel. The

second relay (15 - 17) switches analogue to relay 1 (4 - 6)

l CH 2 output separate - Two-point control or two independent relay

outputs. The second relay (15 - 17) switches independently of

relay 1 (4 - 6)

l CH 1 with alarm - Fault signal with relay output 2. The second relay

(4 - 6) triggers a fault signal.

3-step switch for adjustment of the switching delay. The adjusted

switching delay applies to the switch on and switch off delay.

Fig. 17: Slide switch for setting the switching delay (E)

l 6 s

l 3 s

l 0.5 s

22 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 23

1 2 3 4 5 6 7

8

O

N

3

1

3362

CH1 output parallel

CH2 output separate

CH1 with alarm

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

7 Set up - Single channel control (level detection)

7 Set up - Single channel control (level

detection)

7.1 Adjust relay function

Adjustment of the relay

outputs (slide switch D)

CH 1 output parallel

3-step switch. The individual switch positions are assigned as follows:

Fig. 18: Slide switch for adjustment of the relay outputs (D)

l CH 1 output parallel - Both relay outputs switch in parallel

l CH 2 output separate - Relay outputs switch separately

l CH 1 with alarm - Fault signal with relay output 2

The following charts provide an overview of the relay switching

conditions and the control lamps depending on the adjusted mode and

level.

Level detection with one switching point

l Min. (dry run protection) or mac. (overfill protection)

l Channel 1 (relay 1) and channel 2 (relay 2) switch in parallel (CH 1

output parallel)

Mode Level Channel 1 Channel 2 Control lamps

max.

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 23

max.

min.

Page 24

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

7 Set up - Single channel control (level detection)

Mode Level Channel 1 Channel 2 Control lamps

min.

CH 2 output separate

CH 1 with alarm

In this switch position, channel 2 (relay 2) has no switching function

and remains deengerised.

Switching reaction of channel 1 see "CH 1 output parallel".

Level detection with one switching point - Fault signal with relay

output 2

l Min. (dry run protection) or mac. (overfill protection)

l Channel 1 (switching relay) and channel 2 (fail safe relay) - (CH 1

with alarm)

Mode Level Channel 1 Channel 2 Control lamps

max.

max.

min.

min.

Malfuncti-onany

Voltage in-

any

terruption

24 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 25

1 KΩ

10 KΩ

200 KΩ

200 KΩ

CH1

CH2

max.

max.

off on

1

2

3

4

5

6

7

7 Set up - Single channel control (level detection)

7.2 Sensitivity adjustment

Medium: Non-conducti-

ve liquids

Standard adjustment for conductive liquids.

Specifications:

The probe is covered with medium by at least 1 cm.

1 Set DIL switch 1 to 3 on the DIL switch block (A) according to the

following illustration

Fig. 53: Medium: Conductive liquids up to 200 kΩ

2 Turn potentiometer (B) to complete left position

3 Turn potentiometer (B) slowly clockwise until the relay output

switches and the yellow control lamp changes condition

4 Turn the potentiometer approximately 15° in the same direction

5 If the relay output does not change, you have to switch to the next

range (10 kΩ).

If the relay output has switched, empty the vessel until the electrode is

uncovered.

The relay output must now switch again.

Medium: Liquids in the

resistance range up to

10 kΩ

Adjustment in liquids with resistance range up to 10 kΩ

Specifications:

The probe is covered with medium.

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 25

Page 26

1 KΩ

10 KΩ

200 KΩ

10 KΩ

CH1

CH2

max.

max.

off on

1

2

3

4

5

6

7

1 KΩ

10 KΩ

200 KΩ

1 KΩ

CH1

CH2

max.

max.

off on

1

2

3

4

5

6

7

7 Set up - Single channel control (level detection)

1 Set DIL switch 1 to 3 on the DIL switch block (A) according to the

following illustration

Fig. 54: Medium: Liquids in the resistance range up to 10 kΩ

2 Turn potentiometer (B) to complete left position

3 Turn potentiometer (B) slowly clockwise until the relay output

switches and the yellow control lamp changes condition

4 Turn the potentiometer approximately 15° in the same direction

5 If the relay output does not change, you have to switch to the next

range (1 kΩ).

If the relay output has switched, empty the vessel until the electrode is

uncovered.

The relay output must now switch again.

Medium: Liquids in the

resistance range up to

1 kΩ

Adjustment in liquids with resistance range up to 1 kΩ

Specifications:

The probe is covered with medium.

1 Set DIL switch 1 to 3 on the DIL switch block (A) according to the

following illustration

26 VEGATOR 632 • Signal conditioning instrument

Fig. 55: Medium: Liquids in the resistance range up to 1 kΩ

2 Turn potentiometer (B) to complete left position

35243-EN-120228

Page 27

O

N

3

1

3362

6 s

3 s

0,5 s

1 2 3 4 5 6 7

8

7 Set up - Single channel control (level detection)

3 Turn potentiometer (B) slowly clockwise until the relay output

switches and the yellow control lamp changes condition

4 Turn the potentiometer approximately 15° in the same direction

If the relay output has switched, empty the vessel until the electrode is

uncovered.

The relay output must now switch again.

Note:

A failure exists, if the relay output does not switch over even in the last

range. You will find instructions for fault rectification in chapter

"Maintenance and fault rectification".

7.3 Adjust switching delay

Adjustment of the swit-

ching delay (slide switch

E)

Adjust the switching delay for the instrument with the slide switch (E).

Fig. 56: Slide switch (E) for setting the switching delay

The adjusted switching delay refers to the switching function of the

relay and applies only to the switch on delay.

Note:

When carrying out switching point adjustments keep in mind that there

is a switching delay of 0.5 sec between the moment when the

switching point is reached and the moment when the switching

function is triggered. The potentiometer must therefore be turned

slowly.

A possible additional switching delay should only be switched on after

the adjustment.

The following switching delays can be selected with the 3-step switch.

l 6 s

l 3 s

l 0.5 s

7.4 Activate line break monitoring

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 27

The line break monitoring or alarm function defines the function of the

instrument in case of failure.

Page 28

Alarm

off on

1

2

3

4

5

6

7

7 Set up - Single channel control (level detection)

If you are using a probe without line break monitoring, a fault signal will

be triggered. In this case, set the switch (7) to off.

Only failures of channel 1 are monitored.

A failure is signalled via the red control lamp on the front plate.

Fig. 57: Switch block (A) with switch (7) for activation of the line break monitoring

(alarm)

You find detailed information on how to trigger a fault signal via the

second relay output in the previous chapter "Adjust relay function".

7.5 Master/Slave function

Definition of the instru-

ment as Master or Slave

Adjust the instrument as Master with switch 8 of the DIL switch block

(A).

(DIL switch block A)

28 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 29

1 2 3 4 5 6 7

8

O

N

3

1

3362

CH1 output parallel

CH2 output separate

CH1 with alarm

64 5

1617 15

ye yegn rd

8 Set up - Two-point control Δs (pump control)

8 Set up - Two-point control Δs (pump

control)

8.1 Adjust relay function

Adjustment of the relay

outputs (slide switch D)

CH 1 output parallel

CH 2 output separate

3-step switch. The individual switch positions are assigned as follows:

Fig. 58: Slide switch for adjustment of the relay outputs (D)

l CH 1 output parallel - Both relay outputs switch in parallel

l CH 2 output separate - Relay outputs switch separately

l CH 1 with alarm - Fault signal with relay output 2

The following charts provide an overview of the relay switching

conditions and the control lamps depending on the adjusted mode and

level.

Output relay 2 operates like output relay 1. The function of the two

output relays is the same.

Switching condition of the two channels see "CH 2 output separate".

Two-point control (pump control) Δs - Overfill protection (max.)

Specifications:

l Overfill protection (max.) - DIL switch block (A) switch 5 and 6 to

off

l Channel 1 (relay 1) and channel 2 (relay 2) switch separately (the

respective mode is selectable for each relay)

l Two-point control (pump control) - DIL switch block (A) switch 4 to

on (Δs)

Mode Level Channel 1 Channel 2 Control lamps

Two-point

control max.

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 29

Page 30

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

8 Set up - Two-point control Δs (pump control)

Mode Level Channel 1 Channel 2 Control lamps

Two-point

control max.

Two-point

control max.

Two-point

control max.

Two-point

control max.

Two-point control (pump control) Δs - Dry run protection (min.)

Specifications:

l Dry run protection (min.) - DIL switch block (A) switch 5 and 6 to on

l Channel 1 (relay 1) and channel 2 (relay 2) switch separately (CH

2 output separate)

l Two-point control (pump control) - DIL switch block (A) switch 4 to

on (Δs)

Mode Level Channel 1 Channel 2 Control lamps

Two-point

control min.

Two-point

control min.

Two-point

control min.

Two-point

control min.

30 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 31

64 5

1617 15

ye yegn rd

1 KΩ

10 KΩ

200 KΩ

200 KΩ

CH1

CH2

max.

max.

off on

1

2

3

4

5

6

7

8 Set up - Two-point control Δs (pump control)

Mode Level Channel 1 Channel 2 Control lamps

Two-point

control min.

CH 1 with alarm

Adjustment with con-

ductive liquids

Level detection with one switching point - Fault signal with relay

output 2

Switching reaction of channel 1 see "CH 2 output separate".

l Dry run protection (min.) or overfill protection (max.)

l Channel 1 (switching relay) and channel 2 (fail safe relay) - (CH 1

with alarm)

8.2 Adjustment

Standard adjustment for conductive liquids.

Specifications:

The probe is covered with medium.

1 Set DIL switch 1 to 3 on the DIL switch block (A) according to the

following illustration

Fig. 95: Conductive liquids up to 200 kΩ

2 Turn potentiometer (B) to complete left position

3 Turn potentiometer (B) slowly clockwise until the relay output

switches and the yellow control lamp changes condition

4 Turn the potentiometer approximately 15° in the same direction

5 If the relay output does not change, you have to switch to the next

range.

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 31

If the relay output has switched, empty the vessel until the electrode is

uncovered.

The relay output must now switch again.

Page 32

1 KΩ

10 KΩ

200 KΩ

10 KΩ

CH1

CH2

max.

max.

off on

1

2

3

4

5

6

7

8 Set up - Two-point control Δs (pump control)

Resistance range up to

10 kΩ

Adjustment in liquids with resistance range up to 10 kΩ.

Specifications:

The probe is covered with medium.

1 Set DIL switch 1 to 3 on the DIL switch block (A) according to the

following illustration

Fig. 96: Resistance range up to 10 kΩ

2 Turn potentiometer (B) to complete left position

3 Turn potentiometer (B) slowly clockwise until the relay output

switches and the yellow control lamp changes condition

4 Turn the potentiometer approximately 15° in the same direction

5 If the relay output does not change, you have to switch to the next

range.

If the relay output has switched, empty the vessel until the electrode is

uncovered.

The relay output must now switch again.

Resistance range up to

1 kΩ

Adjustment in liquids with resistance range up to 1 kΩ.

Specifications:

The probe is covered with medium.

32 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 33

1 KΩ

10 KΩ

200 KΩ

1 KΩ

CH1

CH2

max.

max.

off on

1

2

3

4

5

6

7

O

N

3

1

3362

6 s

3 s

0,5 s

1 2 3 4 5 6 7

8

8 Set up - Two-point control Δs (pump control)

1 Set DIL switch 1 to 3 on the DIL switch block (A) according to the

following illustration

Fig. 97: Resistance range up to 1 kΩ

2 Turn potentiometer (B) to complete left position

3 Turn potentiometer (B) slowly clockwise until the relay output

switches and the yellow control lamp changes condition

4 Turn the potentiometer approximately 15° in the same direction

If the relay output has switched, empty the vessel until the electrode is

uncovered.

The relay output must now switch again.

Note:

A failure exists, if the relay output does not switch over even in the last

range. You will find instructions for fault rectification in chapter

"Maintenance and fault rectification".

8.3 Adjust switching delay

Adjustment of the swit-

ching delay (slide switch

E)

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 33

Adjust the switching delay for the instrument with the slide switch (E).

Fig. 98: Slide switch (E) for setting the switching delay

The adjusted switching delay refers to the switching function of the

relay and applies only to the switch on delay.

Page 34

Alarm

off on

1

2

3

4

5

6

7

8 Set up - Two-point control Δs (pump control)

Note:

When carrying out switching point adjustments keep in mind that there

is a switching delay of 0.5 sec between the moment when the

switching point is reached and the moment when the switching

function is triggered. The potentiometer must therefore be turned

slowly.

A possible additional switching delay should only be switched on after

the adjustment.

The following switching delays can be selected with the 3-step switch.

l 6 s

l 3 s

l 0.5 s

8.4 Activate line break monitoring

The line break monitoring or alarm function defines the function of the

instrument in case of failure.

If you are using a probe without line break monitoring, a fault signal will

be triggered. In this case, set the switch (7) to off.

Only failures of channel 1 are monitored.

A failure is signalled via the red control lamp on the front plate.

Fig. 99: Switch block (A) with switch (7) for activation of the line break monitoring

(alarm)

You find detailed information on how to trigger a fault signal via the

second relay output in the previous chapter "Adjust relay function".

8.5 Master/Slave function

Definition of the instru-

ment as Master or Slave

(DIL switch block A)

34 VEGATOR 632 • Signal conditioning instrument

Adjust the instrument as Master with switch 8 of the DIL switch block

(A).

35243-EN-120228

Page 35

1 2 3 4 5 6 7

8

O

N

3

1

3362

CH1 output parallel

CH2 output separate

CH1 with alarm

9 Set up - Two-channel control

9 Set up - Two-channel control

9.1 Adjust relay function

Adjustment of the relay

outputs (slide switch D)

CH 1 output parallel

CH 2 output separate

3-step switch. The individual switch positions are assigned as follows:

Fig. 100: Slide switch for adjustment of the relay outputs (D)

l CH 1 output parallel - Both relay outputs switch in parallel

l CH 2 output separate - Relay outputs switch separately

l CH 1 with alarm - Fault signal with relay output 2

The following charts provide an overview of the relay switching

conditions and the control lamps depending on the adjusted mode and

level.

Output relay 2 operates like output relay 1. The function of the two

output relays is the same.

Switching reaction of the two channels see "CH 2 output separate".

Not useful for two-channel control.

Two-channel control - max./min.

Specifications:

l Channel 1: Overfill protection (max.) DIL switch block (A) switch 5

to off

l Channel 2: Dry run protection (min.) DIL switch block (A) switch 6

to on

l Channel 1 (relay 1) and channel 2 (relay 2) switch separately (CH

2 output separate)

l Two-channel control (two separate switching points) - DIL switch

block (A) switch 4 to off

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 35

Page 36

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

64 5

1617 15

ye yegn rd

9 Set up - Two-channel control

Two-channel control - min./max.

Specifications:

l Channel 1: Dry run protection (min.) - DIL switch block (A) switch 5

l Channel 2: Overfill protection (max.) - DIL switch block (A) switch

l Channel 1 (relay 1) and channel 2 (relay 2) switch separately (CH

l Two-channel control (two separate switching points) - DI L switch

Mode Level Channel 1 Channel 2 Control lamps

max. min.

max. min.

max. min.

to on

6 to off

2 output separate)

block (A) switch 4 to off

Mode Level Channel 1 Channel 2 Control lamps

min. max.

min. max.

min. max.

CH 1 with alarm

Level detection with one switching point - Fault signal with relay

output 2

Switching reaction of channel 1 see "CH 2 output separate".

Not useful for two-channel control.

36 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 37

1 KΩ

10 KΩ

200 KΩ

200 KΩ

CH1

CH2

max.

max.

off on

1

2

3

4

5

6

7

Adjustment with conductive liquids

9 Set up - Two-channel control

9.2 Adjustment

Standard adjustment for conductive liquids.

Specifications:

The probe is covered with medium.

1 Set DIL switch 1 to 3 on the DIL switch block (A) according to the

following illustration

Fig. 125: Conductive liquids up to 200 kΩ

2 Turn potentiometer (B) to complete left position

3 Turn potentiometer (B) slowly clockwise until the relay output

switches and the yellow control lamp changes condition

4 Turn the potentiometer approximately 15° in the same direction

5 If the relay output does not change, you have to switch to the next

range.

If the relay output has switched, empty the vessel until the electrode is

uncovered.

The relay output must now switch again.

Adjustment in liquids with resistance range up to 10 kΩ.

Resistance range up to

10 kΩ

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 37

Specifications:

The probe is covered with medium.

Page 38

1 KΩ

10 KΩ

200 KΩ

10 KΩ

CH1

CH2

max.

max.

off on

1

2

3

4

5

6

7

1 KΩ

10 KΩ

200 KΩ

1 KΩ

CH1

CH2

max.

max.

off on

1

2

3

4

5

6

7

9 Set up - Two-channel control

1 Set DIL switch 1 to 3 on the DIL switch block (A) according to the

Fig. 126: Resistance range up to 10 kΩ

2 Turn potentiometer (B) to complete left position

3 Turn potentiometer (B) slowly clockwise until the relay output

4 Turn the potentiometer approximately 15° in the same direction

5 If the relay output does not change, you have to switch to the next

If the relay output has switched, empty the vessel until the electrode is

uncovered.

The relay output must now switch again.

following illustration

switches and the yellow control lamp changes condition

range.

Resistance range up to

1 kΩ

Adjustment in liquids with resistance range up to 1 kΩ.

Specifications:

The probe is covered with medium.

1 Set DIL switch 1 to 3 on the DIL switch block (A) according to the

following illustration

38 VEGATOR 632 • Signal conditioning instrument

Fig. 127: Resistance range up to 1 kΩ

2 Turn potentiometer (B) to complete left position

35243-EN-120228

Page 39

O

N

3

1

3362

6 s

3 s

0,5 s

1 2 3 4 5 6 7

8

9 Set up - Two-channel control

3 Turn potentiometer (B) slowly clockwise until the relay output

switches and the yellow control lamp changes condition

4 Turn the potentiometer approximately 15° in the same direction

If the relay output has switched, empty the vessel until the electrode is

uncovered.

The relay output must now switch again.

Note:

A failure exists, if the relay output does not switch over even in the last

range. You will find instructions for fault rectification in chapter

"Maintenance and fault rectification".

9.3 Adjust switching delay

Adjustment of the swit-

ching delay (slide switch

E)

Adjust the switching delay for the instrument with the slide switch (E).

Fig. 128: Slide switch (E) for setting the switching delay

The adjusted switching delay refers to the switching function of the

relay and applies only to the switch on delay.

Note:

When carrying out switching point adjustments keep in mind that there

is a switching delay of 0.5 sec between the moment when the

switching point is reached and the moment when the switching

function is triggered. The potentiometer must therefore be turned

slowly.

A possible additional switching delay should only be switched on after

the adjustment.

The following switching delays can be selected with the 3-step switch.

l 6 s

l 3 s

l 0.5 s

9.4 Activate line break monitoring

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 39

The line break monitoring or alarm function defines the function of the

instrument in case of failure.

Page 40

Alarm

off on

1

2

3

4

5

6

7

9 Set up - Two-channel control

If you are using a probe without line break monitoring, a fault signal will

be triggered. In this case, set the switch (7) to off.

Only failures of channel 1 are monitored.

A failure is signalled via the red control lamp on the front plate.

Fig. 129: Switch block (A) with switch (7) for activation of the line break

monitoring (alarm)

You find detailed information on how to trigger a fault signal via the

second relay output in the previous chapter "Adjust relay function".

9.5 Master/Slave function

Definition of the instru-

ment as Master or Slave

Adjust the instrument as Master with switch 8 of the DIL switch block

(A).

(DIL switch block A)

40 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 41

Alarm

off on

1

2

3

4

5

6

7

10 Set up - Four-channel control

10 Set up - Four-channel control

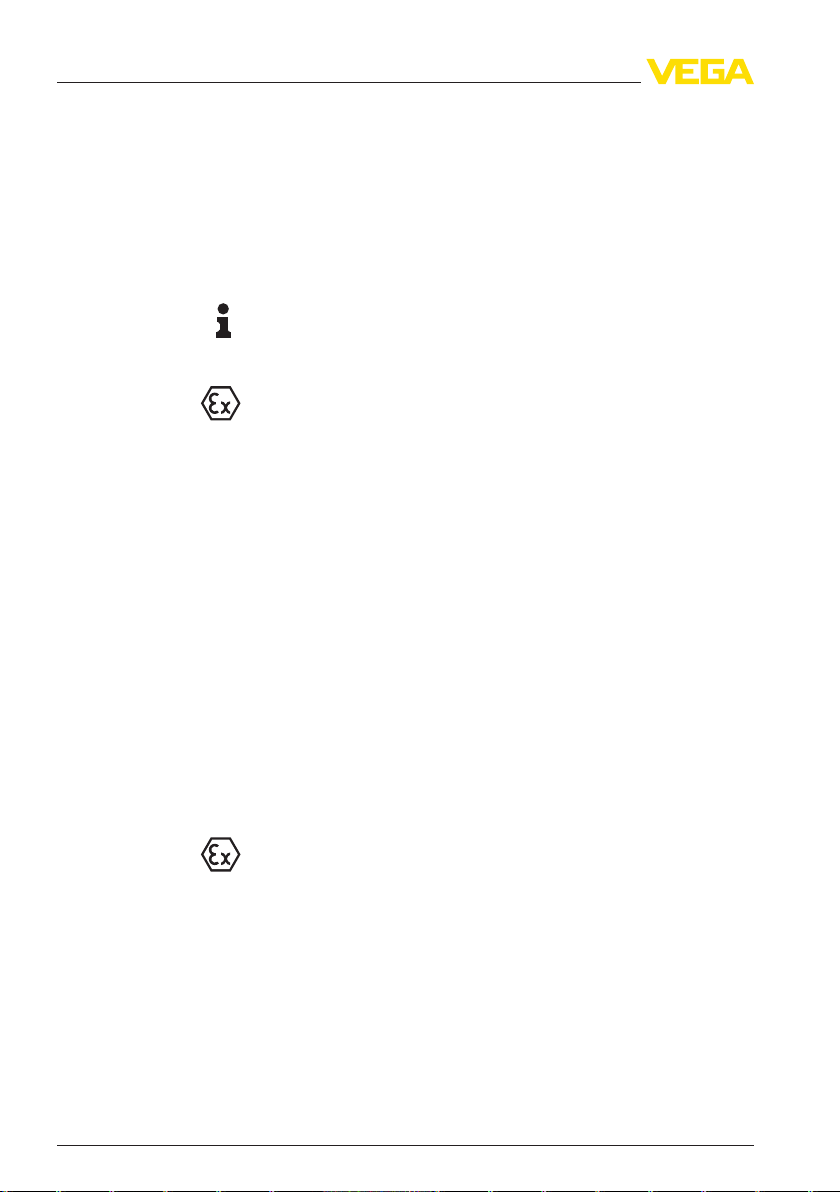

10.1 General information

You require two VEGATOR 632 signal conditioning instruments for a

four-channel control.

10.2 Adjust relay function

Depending on the switching function of the signal conditioning

instrument.

See single channel, two-point or two-channel control.

10.3 Adjustment

Depending on the switching function of the signal conditioning

instrument.

See single channel, two-point or two-channel control.

10.4 Adjust switching delay

See single channel, two-point or two-channel control.

10.5 Activate line break monitoring

The line break monitoring or alarm function defines the function of the

instrument in case of failure.

If you are using a probe without line break monitoring, a fault signal will

be triggered. In this case, set the switch (7) to off.

Only failures of channel 1 are monitored.

A failure is signalled via the red control lamp on the front plate.

Fig. 130: Switch block (A) with switch (7) for activation of the line break

monitoring (alarm)

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 41

Page 42

Master Slave

VEGA

TOR

632

3

2

Master / Slave

1

541

7 8 9 10

3

2

5

4

1

7 8 9 10

2

VEGA

TOR

632

1

8 8

1

2 max

3 min

4 max

5 min

10 Set up - Four-channel control

You find detailed information on how to trigger a fault signal via the

second relay output in the previous chapter "Adjust relay function".

10.6 Master/Slave function

Definition of the instru-

ment as Master or Slave

(DIL switch block A)

When connecting two VEGATOR 632 signal conditioning instruments,

one instrument must be configured as reference power supply unit

(Master) and one as Slave.

Adjust the respective instrument as Master or Slave with switch 8 of

the DIL switch block (A).

To ensure that the two VEGATOR 632 can synchronize their phases, a

connection cable is required between the two signal conditioning

instruments.

Connect this connection cable according to the following illustration

between terminals 10 of the signal conditioning instruments.

Fig. 131: Connection cable between terminals 10

42 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 43

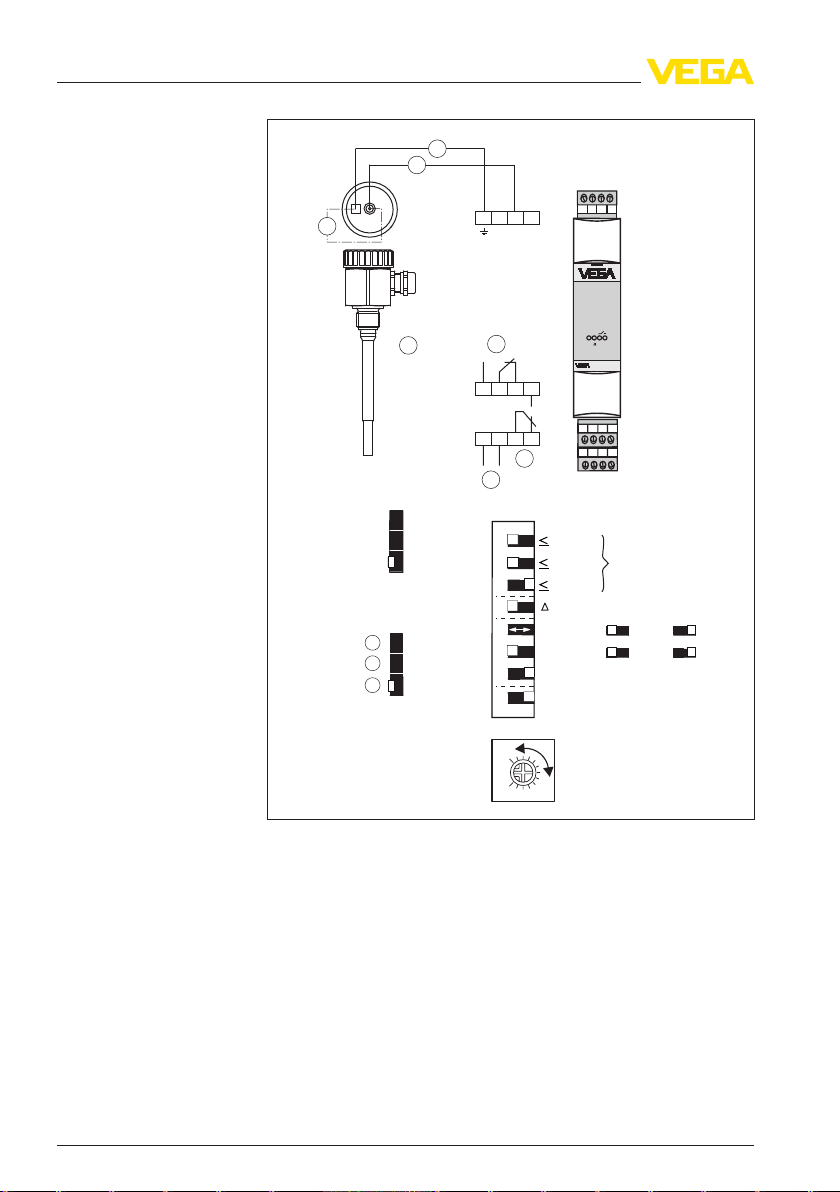

Calibration

3

1

1 KΩ

10 KΩ

200 KΩ

Range

s

CH1

CH2

Alarm

Slave/Master

min.

min.

max.

max.

6 s

off on

3 s

0,5 s

Output Mode

Delay Time

1

2

3

4

5

6

7

8

1

2

3

1

2

2

1

6

1

2

3

4

5

L1L+N

L–

4 5 6 17

1 2 15 16

7 8 9 10

CH2

CH1

Master/

Slave

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

Single channel operation without alarm monitoring

11 Switching examples

11 Switching examples

11.1 Single channel operation

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 43

Fig. 132: Level detection - Single channel operation without alarm monitoring

with ground electrode

1 Ground

2 max. - channel 1 (CH 1)

3 Level relay

4 Level relay or fail safe relay

5 Voltage supply

6 Probe, e.g. EL1

Page 44

Calibration

3

1

1 KΩ

10 KΩ

200 KΩ

Range

s

CH1

CH2

Alarm

Slave/Master

min.

min.

max.

max.

6 s

off on

3 s

0,5 s

Output Mode

Delay Time

1

2

3

4

5

6

7

8

1

2

3

1 2

2

3

4

5

1

7

L1L+N

L–

4 5 6 17

7 8 9 10

1 2 15 16

CH2

CH1

Master/

Slave

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

6

11 Switching examples

Single channel operation with alarm monitoring

44 VEGATOR 632 • Signal conditioning instrument

Fig. 133: Level detection - Single channel operation with alarm monitoring

1 Ground

2 max. - channel 1 (CH 1)

3 Level relay

4 Level relay or fail safe relay

5 Voltage supply

6 Line break monitoring

7 Probe, e.g. EL3

35243-EN-120228

Page 45

Calibration

3

1

1 KΩ

10 KΩ

200 KΩ

Range

s

CH1

CH2

Alarm

Slave/Master

min.

min.

max.

max.

6 s

off on

3 s

0,5 s

Output Mode

Delay Time

1

2

3

4

5

6

7

8

1

2

3

1 3

2

2

3

1

7

1

2

3

4

5

6

L1L+N

L–

4 5 6 17

1 2 15 16

7 8 9 10

CH2

CH1

Master/

Slave

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

Level detection - Twochannel operation (outputs separate)

11.2 Two-channel operation

11 Switching examples

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 45

Fig. 134: Level detection - Two-channel operation, outputs separate

1 Ground

2 max. - channel 2 (CH 2)

3 min. - channel 1 (CH 1)

4 Level relay 1

5 Level relay 2 or fail safe relay

6 Voltage supply

7 Probe, e.g. EL3

Page 46

Calibration

3

1

1 KΩ

10 KΩ

200 KΩ

Range

s

CH1

CH2

Alarm

Slave/Master

min.

min.

max.

max.

6 s

off on

3 s

0,5 s

Output Mode

Delay Time

1

2

3

4

5

6

7

8

1

2

3

1 3

2

2

3

1

8

1

2

3

4

5

6

L1L+N

L–

4 5 6 17

1 2 15 16

7 8 9 10

CH2

CH1

Master/

Slave

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

7

11 Switching examples

Two-point control (Δs)

with alarm monitoring

11.3 Two-point control

Fig. 135: Two-point control (Δs) with alarm monitoring

46 VEGATOR 632 • Signal conditioning instrument

1 Ground

2 max. - channel 2 (CH 2)

3 min. - channel 1 (CH 1)

4 Level relay 1

5 Level relay 2 or fail safe relay

6 Voltage supply

7 Line break monitoring

8 Probe, e.g. EL3

35243-EN-120228

Page 47

Calibration

3

1

3362

1 KΩ

10 KΩ

200 KΩ

Range

s

CH1

CH2

Alarm

Slave/Master

min.

min.

max.

max.

6 s

off on

3 s

0,5 s

Output Mode

Delay Time

1

2

3

4

5

6

7

8

1

2

3

1 3

2

2

3

1

7

1

2

3

4

5

6

1

2

15

16

4

5

6

17

7

8

9

10

L1L+N

L–

4 5 6 17

1 2 15 16

7 8 9 10

CH2

CH1

Master/

Slave

4

5

6

17

TOR

149A

ON

Two-point control (Δs)

without alarm monitoring

11 Switching examples

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 47

Fig. 136: Two-point control (Δs) without alarm monitoring, outputs parallel

1 Ground

2 max. - channel 2 (CH 2)

3 min. - channel 1 (CH 1)

4 Level relay 1

5 Level relay 2 or fail safe relay

6 Voltage supply

7 Probe, e.g. EL3

Page 48

Calibration

3

1

1 KΩ

10 KΩ

200 KΩ

Range

s

CH1

CH2

Alarm

Slave/Master

min.

min.

max.

max.

6 s

off on

3 s

0,5 s

Output Mode

Delay Time

1

2

3

4

5

6

7

8

1

2

3

Calibration

3

1

1 KΩ

10 KΩ

200 KΩ

Range

s

CH1

CH2

Alarm

Slave/Master

min.

min.

max.

max.

6 s

off on

3 s

0,5 s

Output Mode

Delay Time

1

2

3

4

5

6

7

8

1

2

3

1

2 3

4

5

1

4

2

5

3

3

4

5

1

9

A

B

2

A B

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

L1L+N

L–

7 8 9 10

4 5 6 17

1 2

15 16

CH2

CH1

Master/

Slave

6

8

7

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

L1L+N

L–

7 8 9 10

4 5 6 17

1 2

15 16

CH2

CH1

Master/

Slave

6

8

7

11 Switching examples

Four-channel operation min./max.

11.4 Four-channel operation

Fig. 137: Four-channel operation - min./max. individual combination

1 Ground

2 max. - channel 1 (CH 1)

3 min. - channel 1 (CH 1)

4 min. - channel 2 (CH 2)

5 max. - channel 2 (CH 2)

6 Level relay 1

7 Level relay 2 or fail safe relay

8 Voltage supply

9 Probe, e.g. EL3

48 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 49

Calibration

3

1

1 KΩ

10 KΩ

200 KΩ

Range

s

CH1

CH2

Alarm

Slave/Master

min.

min.

max.

max.

6 s

off on

3 s

0,5 s

Output Mode

Delay Time

1

2

3

4

5

6

7

8

1

2

3

1

2 3

4

5

1

4

2

5

3

3

4

5

1

9

A B

2

Calibration

3

1

1 KΩ

10 KΩ

200 KΩ

Range

s

CH1

CH2

Alarm

Slave/Master

min.

min.

max.

max.

6 s

off on

3 s

0,5 s

Output Mode

Delay Time

1

2

3

4

5

6

7

8

1

2

3

A B

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

L1L+N

L–

7 8 9 10

4 5 6 17

1 2

15 16

CH2

CH1

Master/

Slave

6

8

7

1

2

15

16

4

5

6

17

7

8

9

10

4

5

6

17

TOR

149A

ON

L1L+N

L–

7 8 9 10

4 5 6 17

1 2

15 16

CH2

CH1

Master/

Slave

6

8

7

Two-point control without alarm monitoring

and two-channel operation, outputs separate

11 Switching examples

11.5 Two-point control and two-channel operation

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 49

Fig. 138: Two-point control without alarm monitoring and two-channel operation,

outputs separate

1 Ground

2 max. - channel 1 (CH 1)

3 min. - channel 1 (CH 1)

4 min. - channel 2 (CH 2)

5 max. - channel 2 (CH 2)

6 Level relay 1

7 Level relay 2 or fail safe relay

8 Voltage supply

9 Probe, e.g. EL3

Page 50

12 Maintenance and fault rectification

12 Maintenance and fault rectification

12.1 Maintaining

If the instrument is used properly, no special maintenance is required

in normal operation.

12.2 Remove interferences

Failure reasons

Fault rectification

24 hour service hotline

Malfunction

A maximum of reliability is ensured. Nevertheless, faults can occur

during operation. These may be caused by the following, e.g.:

l Measured value from sensor not correct

l Voltage supply

l Interference on the cables

The first measure to be taken is to check the input and output signals.

The procedure is described as follows. In many cases the causes can

be determined this way and faults can be easily rectified.

Should these measures not be successful, please call in urgent cases

the VEGA service hotline under the phone no. +49 1805 858550.

The hotline is available to you 7 days a week round-the-clock. Since

we offer this service world-wide, the support is only available in the

English language. The service is free of charge, only the standard

telephone costs will be charged.

? The red failure control lamp (LED) of the signal conditioning

instrument lights

l Sensor not connected correctly

à Check the electrical connection by means of the wiring plans

l Line break

à Check the electrical connection cables from the probe to the

signal conditioning instrument

l Probe without line break monitoring

à Check if in the sensor housing between terminals 1 and 2 the

electronics for line break monitoring is mounted. If the probe

has no line break monitoring, set the switch for line break

monitoring (alarm) on the signal conditioning instrument to off.

In Ex systems, make sure that the Ex protection is not compromised by

the possible use of measuring instruments.

? The signal conditioning instrument does not switch when the

respective probe is covered or uncovered

l Operating voltage missing (green control lamp is off)

à Check the electrical connection cables

50 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 51

b

a

12 Maintenance and fault rectification

l Signal conditioning instrument defective

à Exchange VEGATOR 632

l Probe mechanically damaged

à Exchange probe

l Conductivity of the product too low

à Check if the conductivity value of your product is at least

7.5 µS/cm

l Welded contacts - for example after a shortcircuit

à Exchange VEGATOR 632. If necessary, integrate a fuse into

the contact circuit

? Wrong switching function of the signal conditioning instrument.

l Wrong setting of the change over switch for the level signal

à Set the change over switch for the level signal correctly. See

chapter "Adjustment".

12.3 Function test

Simulation of a fault sig-

nal

For simulation of a fault signal you can remove the upper plug

connection from VEGATOR 632.

Fig. 139: Function test

The instruments signals a failure and the switching relays take on

deenergized (safe) condition.

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 51

Page 52

ye yegn rd

12 Maintenance and fault rectification

Caution:

Take note that when switching over the relay output also the

connected instruments can be energized.

Fig. 140: Status of the control lamps in case of fault signal

After the function test is finished, plug the plug connection again into

the signal conditioning instrument.

Simulation of a level

signal

For simulation of a level signal, the covering of the probe must be

changed. The relay outputs and the corresponding control lamps than

change their status.

Caution:

Take note that when switching over the relay output also the

connected instruments can be energized.

After the function test is finished, plug the plug connection again into

the signal conditioning instrument.

12.4 Instrument repair

If a repair is necessary, please proceed as follows:

You can download a return form (23 KB) from our homepage at

vega.com under: "Downloads - Forms and certificates - Repair form".

By doing this you help us carry out the repair quickly and without

having to call back for needed information.

l Print and fill out one form per instrument

l Clean the instrument and pack it damage-proof

l Attach the completed form and, if need be, also a safety data

sheet outside on the packaging

l Please ask the agency serving you for the address of your return

shipment. You can find the respective agency on our website

www.vega.com under: "Company - VEGA worldwide"

www.

52 VEGATOR 632 • Signal conditioning instrument

35243-EN-120228

Page 53

13 Dismounting

13 Dismounting

13.1 Dismounting steps

Take note of chapters "Mounting" and "Connecting to power supply"

and carry out the listed steps in reverse order.

13.2 Disposal

The instrument consists of materials which can be recycled by

specialised recycling companies. We use recyclable materials and

have designed the electronics to be easily separable.

WEEE directive 2002/96/EG

This instrument is not subject to the WEEE directive 2002/96/EG and

the respective national laws. Pass the instrument directly on to a

specialised recycling company and do not use the municipal collecting

points. These may be used only for privately used products according

to the WEEE directive.

Correct disposal avoids negative effects on humans and the environment and ensures recycling of useful raw materials.

Materials: see chapter "Technical data"

If you have no way to dispose of the old instrument properly, please

contact us concerning return and disposal.

35243-EN-120228

VEGATOR 632 • Signal conditioning instrument 53

Page 54

14 Supplement

14 Supplement

14.1 Technical data

General data

Series Module unit with plug-in socket for mounting on

Weight 170 g (6 oz)

Housing material Housing: Polycarbonate, front cover: Polypropylene

Fixing slide for rail fastening Polyamide PA6

Power supply - Alternating voltage version AC

Operating voltage 85 … 253 V AC, 50/60 Hz

Max. power consumption 4.5 W

Power supply - Direct voltage version DC

Operating voltage 20 … 30 V AC, 50/60 Hz, 20 … 60 V DC

Max. power consumption 1.2 W (at 20 V)

Sensor input

Quantity 2 x level detection or 1 x pump control (min./max.)

Response resistor 1 … 200 kΩ adjustable

Measuring circuit max. 5 V eff., max. 1 mA

Permissible line capacitance 1 x 100 nF or 2 x 70 nF with min./max. control

Switching hysteresis 15 %

carrier rail 35 x 7.5 or 35 x 5 according to EN 60715

PPN

Relating to the conductivity of the medium

Adjustment elements

DIL switch block For preadjustment of the damping and the mode

Potentiometer for switching point adjustment

Control lamps in the front plate

- Status indication operating voltage Signal lamp green (LED)

- Status indication fault signal Signal lamp red (LED)

- Status indication switching point control 2 signal lamps yellow (LED)

Relay output

Number - Relay outputs

- Level relay (spdt) 1

- Fail safe relay (spdt) 1 (adjustable as second level relay)

Mode (adjustable) Max. detection or overfill protection or min. detec-