Page 1

Operating Instructions

VEGATOR 620, 621, 622

12 43

5

Level and Pressure

max.

0

5

min.

010

on

VEGATOR 622

56 78

9 1011121314

10

!

out

in

Page 2

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 3

1.2 Approvals ............................................................................. 3

1.3 Types and versions ............................................................. 4

1.4 Technical data and dimensions .......................................... 5

2 Mounting and installation instructions ................................ 9

3 Electrical connection

3.1 Connection instructions ..................................................... 10

3.2 Connection instructions for Ex approved

applications ........................................................................ 10

3.3 Connection diagrams ........................................................ 11

4Setup

4.1 Indicating and adjustment elements ................................ 13

4.2 Setup sequence ................................................................. 14

4.3 Switching point adjustment ............................................... 15

Contents

5 Diagnostics

5.1 Maintenance ....................................................................... 17

5.2 Repair .................................................................................. 17

5.3 Failure rectification ............................................................. 18

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

2 VEGATOR 620 … 622

Note Ex area

Please note the attached safety instructions

containing important information on installation

and operation in Ex areas.

These safety instructions are part of the

operating instructions and come with the Ex

approved instruments.

Page 3

Product description

1 Product description

1.1 Function and configuration

VEGATOR 620 … 622 signal conditioning

instruments are module units with plug-in

socket, suitable for carrier rail mounting (DIN

46 277). In conjunction with sensors they are

used for level detection and switching command output, which is triggered by relay and

transistor switches.

Typical applications are double point controls, e.g. pump controls (on/off) and monitoring functions such as overfill or dry run

protection.

The instruments are equipped with adjustable integration time. The integrated fault

monitoring (not with VEGATOR 620) detects

short circuit or interruption of the measuring

circuit. In case of failure, a failure LED lights

up. The level relay and the transistor output

deenergise.

To construct a measuring system you need a

VEGATOR … level switch and a sensor with

analogue measured data transmission, i.e.

- capacitive meas. probes,

- hydrostatic pressure transmitters or

- process pressure transmitters.

1.2 Approvals

If measuring systems are installed according

to the following approvals, the appropriate

official documents have to be noted and the

regulations observed. The documents are

supplied with the respective measuring system.

WHG approval

VEGATOR 621 and 622 signal conditioning

instruments with capacitive meas. probes or

pressure transmitters as part of an overfill

protection according to WHG.

General type approval

no. Z.-65.13-105

Ex approval

When using measuring systems in Ex and

StEx areas, the instruments must be suitable

and approved for these applications and

explosion zones. The suitability is checked

by approval authorities and certified in approval documents. VEGATOR 621 Ex and

622 Ex are provided with Ex approval according to CENELEC (PTB no.

Ex-96.D.2068).

12 43

max.

0

min.

010

on

VEGATOR 622

56 78

91011121314

5

10

5

!

p

p

CE conformity

VEGATOR 620, 621 and 622 signal conditioning instruments see „1.4 Technical data“.

VEGATOR …

VEGATOR 620 … 622 3

Page 4

Product description

off

on

off

on

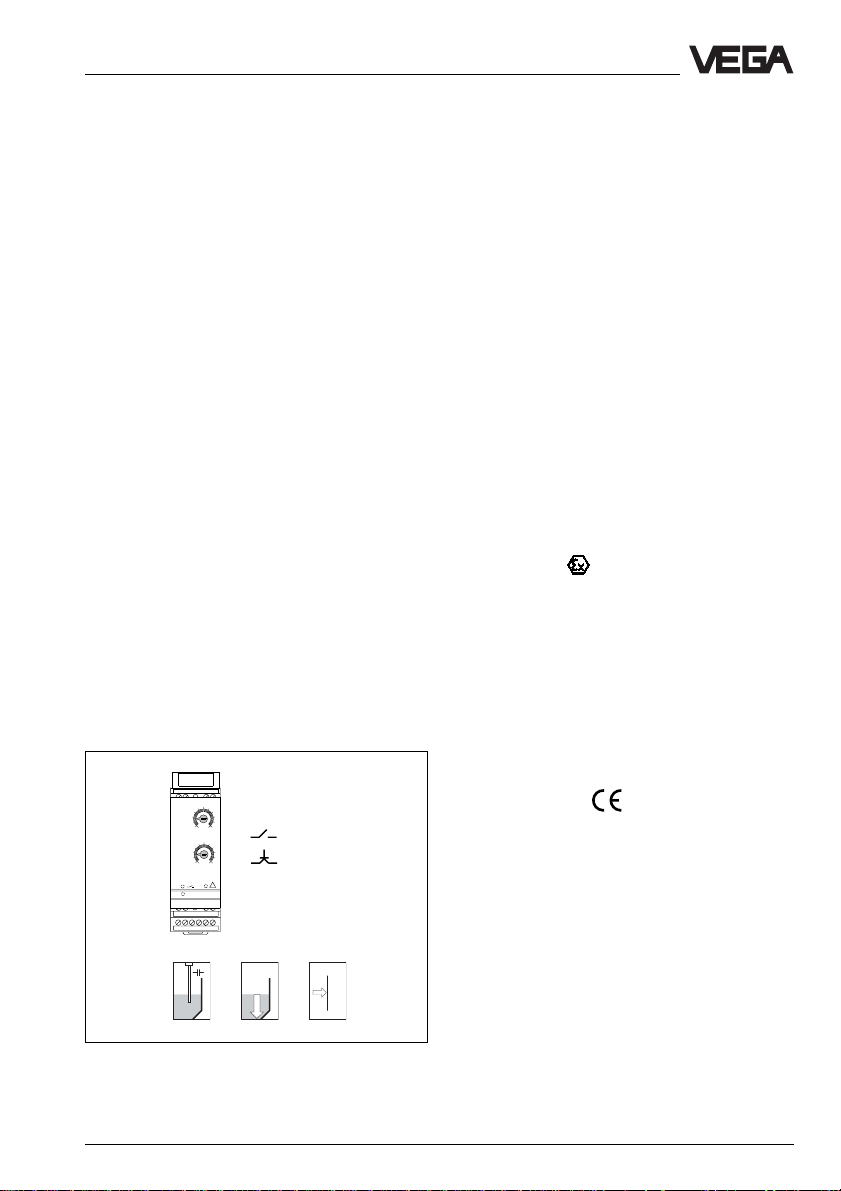

1.3 Types and versions

VEGATOR 620

Single point level switch (fixed switching hysteresis)

with selectable mode A/B (A = overfill protection, B = dry run

protection) and adjustable integration time

Inputs:

- active 1 capacitive probe,

1 hydrostatic pressure transmitter or

1 process pressure transmitter

- passive for connection to an active circuit

Output: 1 relay (spdt)

Application: level detection, overfill protection, dry run

protection

When using two VEGATOR 620 connected to one sensor, it

is possible to provide a dual single point control.

It is possible to connect up to 10 VEGATOR 620 to one

sensor, see „3.3 Connection diagrams“.

Level

Time t

VEGATOR 620 single point level

switch

Level

on 1

1

2

off 1

on 2

off 2

off 1

on 2

Time t

Double single point control with two

VEGATOR 620

VEGATOR 621

Level

Single point level switch (fixed switching hysteresis)

with fault monitoring, selectable mode A/B (A = overfill protection, B = dry run protection) and adjustable integration

time

Input: 1 capacitive probe or

1 hydrostatic pressure transmitter or

Outputs: 1 relay (spdt)

1 process pressure transmitter

1 transistor

Approval: [EEx ia] IIC,

as part of an overfill protection acc. to WHG

Ex area

Non-Ex area

VEGATOR 621 single point level

switch

Time t

Application: level detection, overfill protection, dry run

protection

4 VEGATOR 620 … 622

Page 5

Product description

VEGATOR 622

Double point level switch

with fault monitoring, adjustable switching hysteresis, selectable mode A/B (A = overfill protection, B = dry run protection) and with adjustable integration time

Input: 1 capacitive electrode

1 hydrostatic pressure transmitter

1 process pressure transmitter

Outputs: 1 relay (spdt)

1 transistor

Approvals: [EEx ia] IIC,

as part of an overfill protection acc. to WHG

Application: Min./max. control, overfill protection, dry run

protection

1.4 Technical data and dimensions

General data

Power supply

Operating voltage 20 … 72 V DC

20 … 250 V AC, 50/60 Hz (sine)

in case of emergency power supply with curve

form extremely deviating from sine: max.

125 V AC (rectangle)

Power consumption max. 3 W (3 … 18 VA)

Fuse

- supply range T 1 A, 250 V

Level

Max.

Min.

Ex area Non-Ex area

VEGATOR 622 double point level

switch

off

on

off

Time t

Measurement data input, general

Number 1 current input

Input type active two-wire input analogue

Range 4 … 20 mA

Sensor capacitive probes

hydrostatic pressure transmitters

process pressure transmitters

Sensor supply voltage

- VEGATOR 620 24 V DC

- VEGATOR 621, 622 15 … 18 V DC

Switching threshold 4 … 20 mA adjustable

Min. hysteresis

- VEGATOR 620, 621 80 µA

- VEGATOR 622 80 … 16000 µA

Current limitation at 24 mA, permanently shortcircuit proof

Temperature error 0.05 %/10 K of range

Connection cable 2-wire (standard cable)

Resistance per wire

- VEGATOR 620 max. 250 Ohm

- VEGATOR 621, 622 max. 35 Ohm

VEGATOR 620 … 622 5

Page 6

Product description

Additional measurement data input on VEGATOR 620

Number 1 additional current input

Input type passive two-wire input analogue

Range 4 … 20 mA

Inner resistance 22 Ohm

Application switching in series with active inputs of e.g.

VEGATOR 620, VEGAMET 601

Hysteresis 80 µA

Temperature error 0.05 %/10 K of range

Relay output

Number 1 output

Contact 1 spdt

(12 - 13 open, 12 - 14 close)

Contact material AgCdO and Au plated

Switching voltage min. 10 mV DC

max. 250 V AC, 250 V DC

Switching current min. 10 µA DC

max. 3 A AC, 1 A DC

Breaking capacity max. 750 VA, 54 W

Transistor output (not on VEGATOR 620)

Number 1 output

(synchronously switching with the relay outputs)

Switching voltage U

Switching current I

CE

C

max. 36 V DC

max. 60 mA DC (short circuit proof, transistor

limits the current in case of short circuit to a

stand-by current of approx. 5 mA)

Voltage loss U

Blocking current I

CE

O

- 1.5 V at IB = 60 mA

< 10 µA

Electrical connection

Screw terminal max. 1.5 mm

2

Electrical protective measures

Protection

- instrument IP 30

- socket IP 20

Protection class II

Overvoltage category II

Mechanical data

Mounting carrier rail mounting acc. to DIN 46 277, p. 3

Dimensions W = 36 mm, H = 118.5 mm, D = 134 mm

Weight approx. 170 g

6 VEGATOR 620 … 622

Page 7

Product description

Ambient conditions

Permissible ambient temperature -20°C … +60°C

VEGATOR 620: With an operating voltage of

60 V DC … 72 V DC the permissible ambient

temperature declines linearly from 60°C to

40°C.

Storage and transport temperature -40°C … +70°C

Option specially protected (tropicalised) electronics

Indicating elements

LED in front plate green on: operating voltage on

yellow: switching point control

red: fault signal

Functions

Mode (selectable) overfill protection (A)

dry run protection (B)

Integration time (adjustable) 0.2 … 20 sec.

Adjustment elements

Front plate one or two potentiometers with scale 0 … 10

for switching point adjustment

On top cover, to the side DIL for adjustment of:

- mode A/B

(A = overfill protection, B = dry run protection)

- integration time

- switch on/off delay

Electrical separation measures

Reliable separation acc. to

VDE 0106, part 1; between power supply, measurement data input,

level relay and transistor output

- reference voltage 250 V

- insulation resistance 2.3 kV

- test voltage 2.3 kV

CE conformity

VEGATOR 620 … 622 signal conditioning instruments meet the protective regulations of

EMC (89/336/EWG) and NSR (73/23/EWG). The conformity has been judged acc. to the

following standards:

EMC Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

VEGATOR 620 … 622 7

Page 8

Product description

Ex technical data

Measurement data input (intrinsically safe signal circuit)

Classification [EEx ia] IIC

Max. values

- voltage UO - 20 V

- current IO - 125 mA

- wattage PO - 624 mW

Characteristics linear

Effective internal inductance L

Effective internal capacitance C

i

i

Max. permissible external inductance LO0.5 mH 1 mH 1.5 mH 2 mH

Max. permissible external capacitance CO97 nF 78 nF 68 nF 200 nF

The intrinsically safe circuits are reliably separated from the non intrinsically safe circuits up

to a peak value of 375 V.

In case of failure, the max. voltage on the non intrinsically safe circuits must not exceed

250 V.

Carrier rail mounting 35 x 7.5

or 35 x 15 acc. to EN 50 022

Transparent cover

negligible

negligible

[EEx ia] IIC [EEx ib] IIC

12 34

118,5

on

54,5

134

56 78

9 1011121314

36

8 VEGATOR 620 … 622

Page 9

12 4

56 78

9 1011121314

3

A o

B o

C o

1 o

2 o

3 o

o

o

o

7 o

8 o

9 o

o

o

o

N

L1

VEGA

0...10V

Mounting and installation instructions

2 Mounting and installation instructions

Mounting

Each series 600 signal conditioning instrument consists of a terminal socket for carrier

rail mounting DIN 46 277 and a module unit.

The supply voltage can be connected to the

terminals 9 and 10 of the terminal socket.

If there are adjoining series 600 instruments,

it is possible to continue the connection L1

and N via the supplied jumpers.

Note!

The jumpers must never be used on single

instruments or at the respective end of a row

of instruments, as there is the danger of

coming into contact with the supply voltage,

or of causing a short circuit.

The signal conditioning instrument must always be mounted outside hazardous areas

or special Ex protective measures must be

taken.

Transparent cover

To protect the instrument against unauthorised or inadvertent use, the front plate of

VEGATOR can be provided after setup with a

lockable transparent cover. To remove

transparent cover, see drawing below.

Coding

To avoid inadvertent swapping of the different signal conditioning instruments, the terminal socket is provided with pins and the

signal conditioning instrument with appropriate gaps (mechanical coding). An instrument

coding with coded pins in different positions

ensures that the various signal conditioning

instruments cannot get mixed up.

Ex instruments

An Ex coding with fixed coded pin

ensures that non Ex and Ex instruments cannot get mixed up.

The coding is part of the explosion protection: On VEGATOR… Ex the supplied coded

pins (instrument coded pin and Ex coded

pin) must be inserted by the user according

to the table below.

Instrument Ex

coding coding

VEGATOR 620 2 ––

VEGATOR 621 2 ––

VEGATOR 622 2 ––

VEGATOR 621 Ex 2 A

VEGATOR 622 Ex 2 A

Separating wall

(must be always plugged

on Ex instruments)

Ex coding

VEGATOR 620 … 622 9

Instrument coding

VEGATOR 620 … 622

Plug

Page 10

3 Electrical connection

Electrical connection

3.1 Connection instructions

The following connection plans are valid for

standard as well as for Ex versions of the

signal conditioning instruments. Please observe the following instructions:

- the relay contacts are shown in their condition in the absence of current

- if strong electromagnetic interferences are

expected, we recommend the use of

shielded cable for the signal cables

- the shielding must be grounded only on

one sensor or signal conditioning instrument side

- if there is the danger of overvoltage, the

use of VEGA overvoltage arresters is

recommended

- the connection should be made according

to country-specific installation standards

(e.g. in Germany acc. to the VDE

regulations).

3.2 Connection instructions for Ex approved applications

For the following applications, certified instruments are required:

- in hazardous areas (if necessary, observe

the special national regulations)

- as part of an overfill protection system

acc. to WHG

- in the shipbuilding industry

- for pressurized vessels.

For these applications, the respective official

documents (test reports, test certificates,

general type approval and conformity certificates) as well as the applicable mounting

and operating instructions should be observed. The official documents are supplied

with the respective instrument.

In Ex applications, the voltage supply of the

sensor must be delivered only through an

intrinsically safe circuit. This can be done by

means of:

- VEGATOR series 600 signal conditioning

instrument in Ex version

- not certified VEGATOR series 600 signal

conditioning instrument with VEGA safety

barrier type 145

Please also note the official documents of

these additional instruments.

10 VEGATOR 620 … 622

Page 11

Electrical connection

3.3 Connection diagrams

Sensor

Current input

passive

Sensor Sensor

-+

+

12 4

VEGATOR 620

910111213

+

Ð

NL1

L1

-

3

+

12

-

VEGATOR 621

-

+

56

14

910

+

11

12 13

14

Ð

N

Transistor outputs in conjunction with a PLC

I

C

+

U

CE

-

U

-

B

E 1.0

+

-

+

12

VEGATOR 622

-

+

56

11

910

+

Ð

L1 N

Transistor output

Relay output

12

14

13

Supply voltage

I

C

+

U

CE

E 1.1

+

PLC

VEGATOR 621

VEGATOR 622

-

VEGATOR 620 … 622 11

Page 12

Extension example for VEGATOR 620

Instrument 1 = VEGATOR 620 … 622 switched to active mode

Instrument 2 through (max.) 10: VEGATOR 620 switched to passive mode

Sensor

Electrical connection

(active)

-

+

-

+

12

VEGATOR 620

-

+

43

-

+

12

VEGATOR 620

-

+

43

(passive) (passive)

-

+

12 43

VEGATOR 620 … 622

Instrument 1 Instrument 2 ..................... through ....... (max.) instrumen t 10

As the above extension example shows, it is possible to control several signal conditioning

instruments with one sensor in order to detect different levels.

This wiring layout can be extended to include 10 instruments (loop current).

12 VEGATOR 620 … 622

Page 13

Setup

;

;

;

;

;

;

;

4 Setup

4.1 Indicating and adjustment elements

12 43

5

1

010

2

3

on

VEGATOR 620

56 78

9 1011121314

View, laterally on top

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

4

5

1

12 43

5

min.

010

4

5

12 43

max.

min.

8

2

3

6 6 6

7

VEGATOR 621

56 78

9 1011121314

11

12

13

!

on

1 Potentiometer for switching point adjustment

2 Status indication of the outputs

3 LED, supply voltage

4 Separating wall

5 Terminals, inputs

6 Terminals, transistor output

7 Terminals, supply voltage

and relay output

8 LED, fault signal

9 Potentiometer for max. switching point

10 Potentiometer for min. switching point

11 Bar code, serial number

12 DIL switch block

13 Screws

14 Ventilation opening

15 Transparent cover

2

3

7

on

VEGATOR 622

56 78

91011121314

14

5

10

0

5

010

!

4

5

9

10

8

7

VEGATOR 620 … 622 13

15

Page 14

Potentiometer

The potentiometers (1, 9 and 10), allow

continuous adjustment of the switching

points.

Signal lamps

Green (3)

- supply voltage available

- ready for operation

Yellow (2)

- status indication of the relay and transistor

outputs

LED lights (relay energised, transistor

conductive), LED extinguished (relay

deenergised, transistor blocked)

Red (8)

- failure indication

DIL switch block (12)

When VEGATOR is installed, the terminal

socket covers the DIL switch block. Adjustments are only possible when the instrument

is dismounted.

VEGATOR 620 VEGATOR 621, 622

12

t sec

6

off

2

ze

za

B

A

t sec

12

6

off

2

ze

za

A

B

The individual switches are assigned as

follows:

- switch A/B: mode switch

A - max. detection (overfill protection)

B - min. detection (dry run protection)

- switch ze and za

ze - switch on delay

za - switch off delay

- switch 2, 6, 12

With these you can adjust the delay time.

The time intervals of the activated time

switches sum up. When the on delay/off

delay switches are switched on together,

the set time is valid for both delay modes

(see the following table).

Setup

Switch on/off Switch

delay za ze 2 6 12

0,2 s off off off off off

0,3 s on on off off off

2 s on on on off off

6 s on on off on off

8 s ononononoff

12 s on on off of on

14 s on on on off on

18 s on on of f on on

20 s ononononon

4.2 Setup sequence

The following list explains briefly the essential

setup steps

- mount the terminal socket

- wire the terminal socket according to your

control requirements

- cover the input terminals with the separating wall (4)

- set the requested mode (A/B) on the DIL

switch block (12)

- deactivate the on delay/off delay modes

(switches ze, za, 2, 6, 12 to position „off“)

on the DIL switch block (12)

- mount the instrument module onto the terminal socket

- switch on the power supply, the green LED

(3) lights

- adjust the switching points acc. to „4.3

Switching point adjustment“

- if an integration time (on delay/ off delay)

should be necessary, the instrument must

be removed again to set the time on the

DIL switch block (12).

14 VEGATOR 620 … 622

Page 15

Setup

4.3 Switching point adjustment

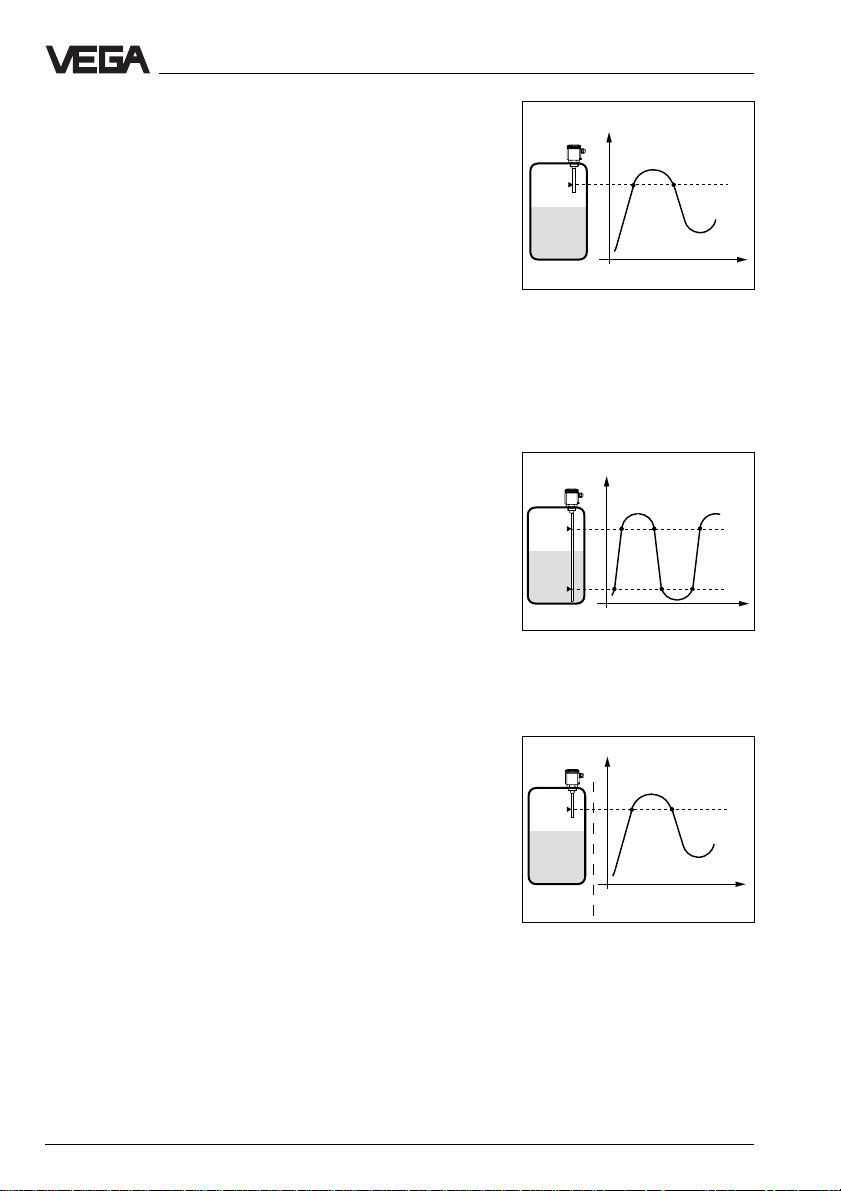

Adjustment example 1, mode A (overfill

protection)

- VEGATOR 620, 621

- single point control

- sensors: vertically mounted measuring

probes, hydrostatic pressure transmitters

or process pressure transmitters

Capacitive

meas. probes

Hydrostatic pressure

transmitters

Level/Pressure

Switching

point

Mode A

Mode B

Procedure

• Set the potentiometer (1) to 10.

• Fill the vessel up to the requested level or

pressure.

• Turn the potentiometer (1) very slowly

anticlockwise until the status indication (2)

changes, i.e. the status indication extinguishes.

• The signal conditioning instrument is now

ready for operation.

Please close with the transparent cover

(15).

Process pressure

transmitters

Rel.

t

12 13 14

12 13 14

Transistor

conductive

blocked

conductive

blocked

Adjustment example 2, mode B (dry

run protection)

- VEGATOR 620, 621

- single point control

- sensors: horizontally mounted capacitive

meas. probes or capacitive meas. probes

for adhesive products

Capacitive

meas. probes

Procedure

• Set the potentiometer (1) to 0.

• Fill the vessel up to 100 mm below the

electrode.

100 mm

• Turn the potentiometer (1) very slowly

clockwise until the status indication (2)

changes, i.e. lights in mode A, extinguishes

in mode B. Note the dial position of the

potentiometers (1).

• Continue filling the vessel until the measuring probe is completely covered. With

measuring probes for adhesive products,

the sensitive tip must be covered completely (standard 100 mm above the electrode). The status indication (2) changes

due to the additional filling.

100 mm

VEGATOR 620 … 622 15

Page 16

Setup

• Turn the potentiometer (1) very slowly

clockwise until the status indication (2)

changes, i.e. lights in mode A, extinguishes

in mode B. Note the position of the potentiometer.

• Determine the average value and adjust it

on the potentiometer (1).

• The signal conditioning instrument is now

ready for operation.

Please close with the transparent cover

(15).

The relay and transistor output as well as the

status indication behave in mode A and B as

previously shown in „Adjustment example 1“,

see top left.

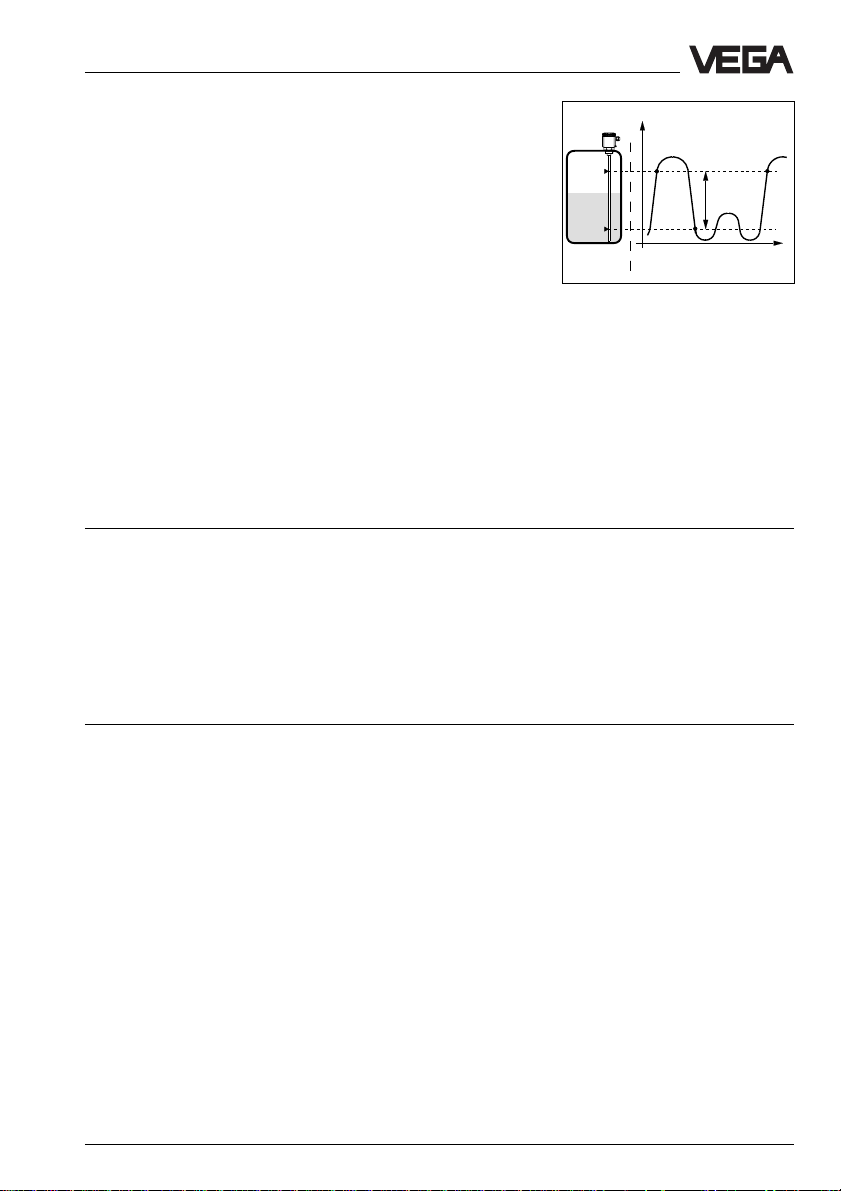

Adjustment example 3

- two VEGATOR 620

- as dual single point control (see „3.3

Connection plans, extension example“)

- vertically mounted capacitive measuring

probes

Level 2

2nd VEGATOR…

Level 1

1st VEGATOR…

Procedure

• Set the potentiometers (1) of the two signal

conditioning instruments to 10.

• Fill the vessel up to level 1.

• Turn the potentiometer (1) of the first VEGATOR … very slowly anticlockwise until

the status indication (2) changes, i.e. lights

in mode B, extinguishes in mode A.

• Now fill the vessel up to level 2.

• Now turn the potentiometer (1) of the second VEGATOR … very slowly anticlockwise

until the status indication (2) changes, i.e.

lights in mode B, extinguishes in mode A.

• The two signal conditioning instruments are

now ready for operation.

Please close each with the transparent

cover (15).

Adjustment example 4

- VEGATOR 622

- double point control

- sensors: vertically mounted capacitive

meas. probes or hydrostatic pressure

transmitters

Max. level

Min. level

Level/Pressure

Switching

points

2nd VEGATOR

Mode A

Mode B

1st VEGATOR

Mode A

Mode B

Level 2

Level 1

t

Rel.

12 13 14

12 13 14

12 13 14

12 13 14

Transistor

conductive

blocked

conductive

blocked

conductive

blocked

conductive

blocked

Level/Pressure

Switching

points

Mode A

Mode B

Max. level

Min. level

Rel.

t

12 13 14

12 13 14

Transistor

conductive

blocked

conductive

blocked

16 VEGATOR 620 … 622

Page 17

Setup / Diagnostics

Procedure

• Set both potentiometers (9 and 10) to 0.

• Fill the vessel to min. level.

• Turn the min. potentiometer (10) very

slowly clockwise until the status indication

(2) changes, i.e. lights in mode A, extinguishes in mode B.

• Now turn the potentiometer (9) to 10.

• Continue filling the vessel to max. level, the

status indication (2) remains unchanged.

• Turn the max. potentiometer (9) very slowly

anticlockwise until the status indication (2)

changes, i.e. extinguishes in mode A, lights

in mode B.

• The signal conditioning instrument is now

ready for operation.

Please close with the transparent cover

(15).

Note:

VEGATOR 622 can also be used for single

point control. The max. potentiometer must

be set to 0, the min. potentiometer then acts

as single point adjustment.

5 Diagnostics

5.1 Maintenance

The instrument is maintenance free.

5.2 Repair

Repairs require accessing internal parts of

the instrument to correct an instrument defect. For safety and warranty reasons, repair

must only be carried out by qualified VEGA

personnel.

In case of a defect, please return respective

instrument with a short description of the flaw

to our repair department.

Failures are short-term malfunctions caused

by wrong adjustment or defects in the sensor

or in the connection cables.

Failures, their possible causes and their

rectification are listed under „5.3 Failure rectification“.

VEGATOR 620 … 622 17

Page 18

Diagnostics

5.3 Failure rectification

Failu re Rectification / Measure

Instrument is dead/

Green operating

lamp extinguishes Check the voltage supply and the mains connections as described

VEGATOR 620 Check the sensor inputs for the following failures:

functions incorrectly - short-circuit on the input

or not at all - sensor not connected correctly or polarity-reversed

Red failure LED

of VEGATOR 621 Check if the sensor is connected correctly.

or 622 lights - failures in the sensor, effecting a current change to below 2 mA or

under „Connection instructions“. If the instrument still does not function,

please call our service department.

- sensor line interrupted

- supply voltage too low

above 23 mA, generate a fault signal on VEGATOR.

15 … 18 V

(24 V with VEGATOR 620)

V

VEGATOR

12 43

Measure the current in

the connection cable

to the sensor.

4 … 20 mA

+

-

mA

For Ex systems, make sure that the Ex protection is not degraded

by the measuring instruments.

a. Current value < 2 mA

- Check the supply voltage on the connection cable to the sensor. The

voltage should be at least 17 V.

Should a value below 17 V be measured, it indicates a defect in the

signal conditioning instrument. In this case, return the instrument for

repair to VEGA.

- If at least 17 V are available, separate the signal conditioning instrument from the connection cable and connect to the sensor input of

the signal conditioning instrument a resistor of 2.2 kOhm.

If the failure lamp continues to light, the signal conditioning instrument

is defective. In such a case, return the instrument for repair to VEGA.

- Should the failure lamp extinguish, reconnect the signal conditioning

instrument. Separate the sensor from the connection cable and connect a resistor of 2.2 kOhm in its place.

- Should the failure lamp continue to light, there is probably an interruption of the connection line. Check the connection cable to the

sensor.

- If the failure lamp extinguishes, the sensor is defective. Check the

connected sensor.

18 VEGATOR 620 … 622

Page 19

Diagnostics

Failu re Rectification / Measure

VEGATOR 620

functions incorrectly

or not at all

Red failure LED

of VEGATOR 621

or 622 lights b.Current value > 22 mA

- Check all connections and the connection cable to the sensor.

- Should the red failure lamp continue to light, separate the sensor

from the connection cable and connect a resistor of 2.2 kOhm in its

place.

If the failure lamp extinguishes, the sensor is defective. Check the

connected sensor.

- Should the failure lamp continue to light, reconnect the sensor. Separate the signal conditioning instrument from the connection cable and

connect a resistor of 2.2 kOhm to its sensor input.

- Should the failure lamp continue to light, the signal conditioning instrument is defective. In such a case, return the instrument for repair to

VEGA.

- If the failure lamp extinguishes, there is probably a short circuit in the

connection line. Check the connection cable to the sensor.

Note:

A flawlessly operating VEGATOR… has the following switching point values:

Potentiometer position Sensor current

0 approx. 4 mA

5 approx. 12.5 mA

10 approx. 21 mA

VEGATOR 620 … 622 19

Page 20

VEGA Grieshaber KG

Am Hohenstein 113

77761 Schiltach/Germany

Phone +49 (0) 7836 50-0

Fax +49 (0) 7836 50-201

E-Mail info@de.vega.com

www.vega.com

ISO 9001

The statements on types, application, use and operating conditions of the sensors and processing systems correspond to

the latest information at the time of printing.

Technical data subject to alterations

2.19 950 / July 2001

Loading...

Loading...