Page 1

Operating Instructions

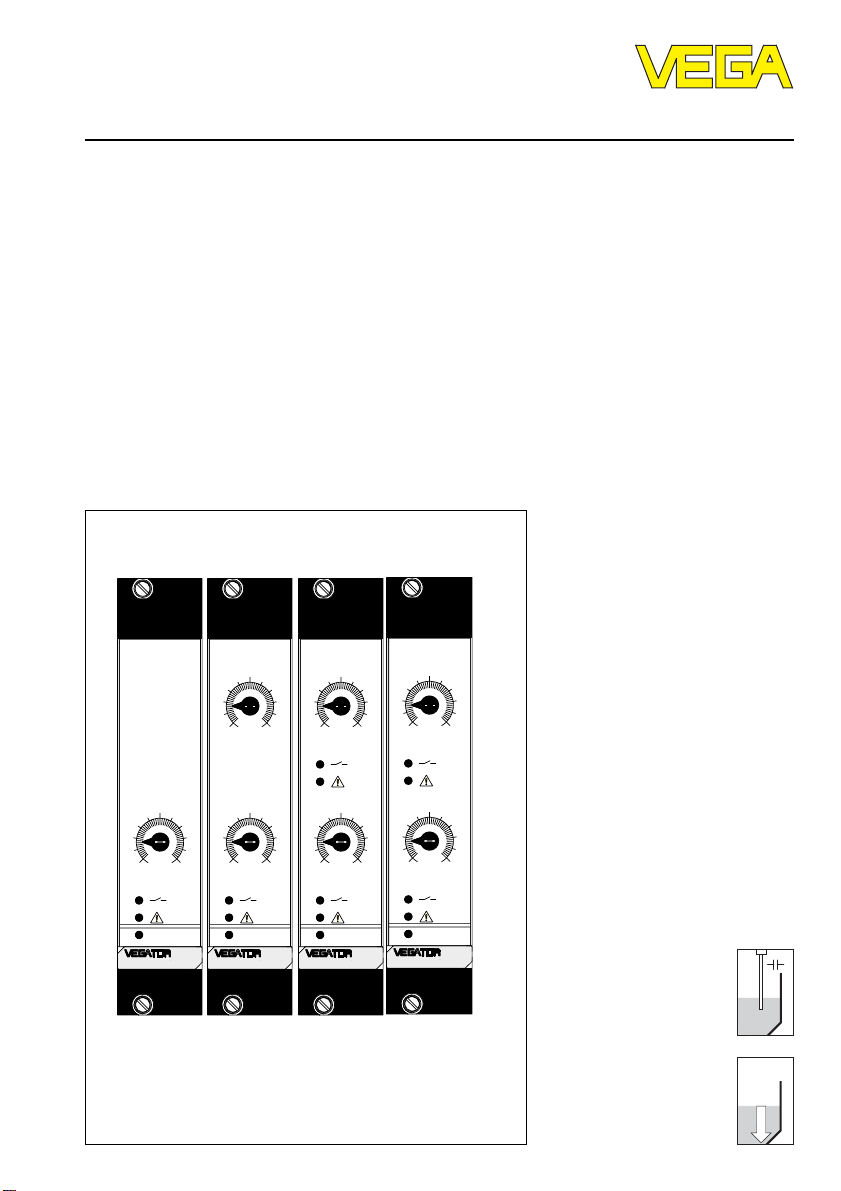

VEGATOR 521, 522, 523, 527

Level and Pressure

5

010

on

521

5

010

max

5

010

min

on

522

5

010

1

5

010

2

on

523

5

010

1

5

010

2

on

527

p

Page 2

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 3

1.2 Types and versions ............................................................. 3

1.3 Approvals ............................................................................. 3

1.5 Dimensions ........................................................................... 6

2 Mounting

2.1 Mounting instructions ........................................................... 7

3 Electrical connection

3.1 Connection instructions ....................................................... 9

3.2 Connection schematic ......................................................... 9

4Setup

4.1 Indicating and adjustment elements ................................ 11

4.2 Principle of operation ......................................................... 13

4.3 Switching point adjustment ............................................... 14

Contents

5 Diagnostics

5.1 Maintenance ....................................................................... 21

5.2 Repair.................................................................................. 21

5.3 Failure rectification ............................................................. 22

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident

prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved

in normal installation and electrical connection,

must be carried out only by qualified VEGA

personnel.

2 VEGATOR

Note Ex area

Please note the approval documents (yellow

binder), and especially the included safety

data sheet.

Page 3

Product description

1 Product description

1.1 Function and configuration

VEGATOR 521, 522, 523 and 527 level

switches are signal conditioning instruments

in European size (DIN 41 494) for level

detection. Typical applications are overfill

protection in vessels and dry run protection

or double point control of pumps. Depending

on the instrument type, up to 2 sensors with

analogue transmission of measured data can

be connected to the input. 2 relays (spdt)

and 2 floating transistors are available as

outputs. All instruments are equipped with a

fail-safe relay and transistor. The instruments

are provided with fault monitoring and

adjustable integration time.

All VEGATORs are available with Ex

approvals or as overfill protection systems

acc. to WHG and VbF.

Function

VEGATOR signal conditioning instruments

enable detection of min./max. levels. The

measured data of the sensor are converted

into a switching command, and connected

instruments can be switched on or switched

off. The integrated fault monitoring detects

short-circuit or break of the measuring cable

as well as selected failures from the

transmitter. The failure lamp lights and the

output relays and output transistors are

deenergised in case of failure.

1.2 T ypes and versions

VEGATOR 521 (Ex)

Signal conditioning instrument as level switch

for single point control. 1 sensor input for

capacitive electrodes or pressure

transmitters. 1 relay output (spdt) and 1

transistor output with fixed switching

hysteresis.

VEGATOR 522 (Ex)

Signal conditioning instrument as level switch

for one sensor for double point control. 1

sensor input for capacitive electrodes or

pressure transmitters. 1 relay output (spdt)

and 1 transistor output with adjustable

switching hysteresis.

VEGATOR 523 (Ex)

Signal conditioning instrument as level switch

for one sensor for dual single point control.

1 sensor input for capacitive electrodes or

pressure transmitters. 2 relay outputs (spdt)

and 2 transistor outputs with fixed switching

hysteresis.

VEGATOR 527 (Ex)

Signal conditioning instrument as level switch

for two sensors for single point control. 2

sensor inputs for capacitive electrodes or

pressure transmitters. 2 relay outputs (spdt)

and 2 transistor outputs with fixed switching

hysteresis.

In case of mains failure, the relays

deenergise.

Configuration

For configuration of a measuring system, a

VEGATOR and one or two sensors with

analogue measured data transmission, e.g. a

capacitive electrode or a pressure

transmitter are required.

VEGATOR 3

1.3 Approvals

VEGATOR is available with the following

approvals:

- explosion protection: respective instrument

with intrinsically safe circuit(s) [EEx ia] IIC

- overfill protection acc. to WHG applied for

For these applications, please note the relevant offical documents (test report, test

certificates, type approvals and conformity

certificates). These are supplied with the

respective instrument.

Page 4

Product description

1.4 Technical data

General

Version European size DIN 41 612

Dimensions W = 25.4 mm (5 TE); H = 128.4 mm; D = 162 mm

Weight approx. 180 g

Ambient temperature -20°C … +60°C

Storage and transport temperature -40°C … +70°C

Power supply

Operating voltage 20 … 53 V AC, 50/60 Hz or 20 … 72 V DC

Power consumption max. 4 VA

Electrical protective measures

Protection class II

Overvoltage class II

Protection

- mounted in carrier

BGT 596 with module IP 00

- front side completely equipped IP 30

- upper and lower side IP 20 (only Ex carrier)

- wiring side (rear) IP 00

- single housing IP 20

Inputs

Transmission analogue

Switching threshold adjustable 4 … 20 mA

Hysteresis (fixed / min.) 80 µA

Current limitation 24 mA (permanently short-circuit proof)

Connection cable to the sensor 2-wire

Sensor supply voltage approx. 15 … 18 V DC

Resistance per wire max. 35 Ω

Temperature error 0.05 %/10 K (relating to range)

Integration time 0.2 … 20 s

Relay output

Number of

- VEGATOR 521, 522 1 level relay

- VEGATOR 523, 527 2 level relay

Modes A/B-switch

Contact floating spdt

Contact material AgNi and Au plated

Turn-on voltage min. 10 mV

Switching current min. 10 µA

Breaking capacitance max. 500 VA AC, 54 W DC

4 VEGATOR

1 fail-safe relay

1 fail-safe relay

A - max. detection or overfill protection

B - min. detection or dry run protection

max. 250 V AC/DC

max. 3 A AC, 1 A DC

Page 5

Product description

Transistor ouput

Number of

- VEGATOR 521, 522 2 (synchronous switching with relays)

- VEGATOR 523, 527 3 (synchronous switching with relays)

Galvanic separation floating

Operating voltage max. 36 V DC

Operating current max. 60 mA

Transistor voltage loss U

- 1.5 V

CE

Approvals

VEGATOR 521 Ex, 522 Ex, 523 Ex, 527 Ex

with input in classification

Intrinsic safety EEx ia IIC, EEx ia IIB

EEx ib IIC, EEx ib IIB

Max. values U

= 20 V

O

IK = 126 mA

P = 626 mW

Characteristics linear

EEx ia IIC EEx ia IIB EEx ib IIC EEx ib IIB

Max. permissible external inductance (mH) 0.5 1 1.5 2 2 9

Max. permissible external capacitance (nF) 97 78 68 486 200 1000

The intrinsically safe circuits are reliably (galvanically) separated from the non-intrinsically

safe circuits up to a peak value of the nominal voltage of 375 V.

On instruments with 2 channels (VEGATOR 527 Ex) the intrinsically safe circuits are reliably

separated.

CE conformity

VEGATOR 521 Ex, 522 Ex, 523 Ex and 527 Ex signal conditioning instruments meet the

protective regulations of EMC (89/336/EW) and NSR (73/23/EWG). Conformity has been

judged acc. to the following standards:

EMC Emission EN 50 081 - 1: 1993

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

VEGATOR 5

Page 6

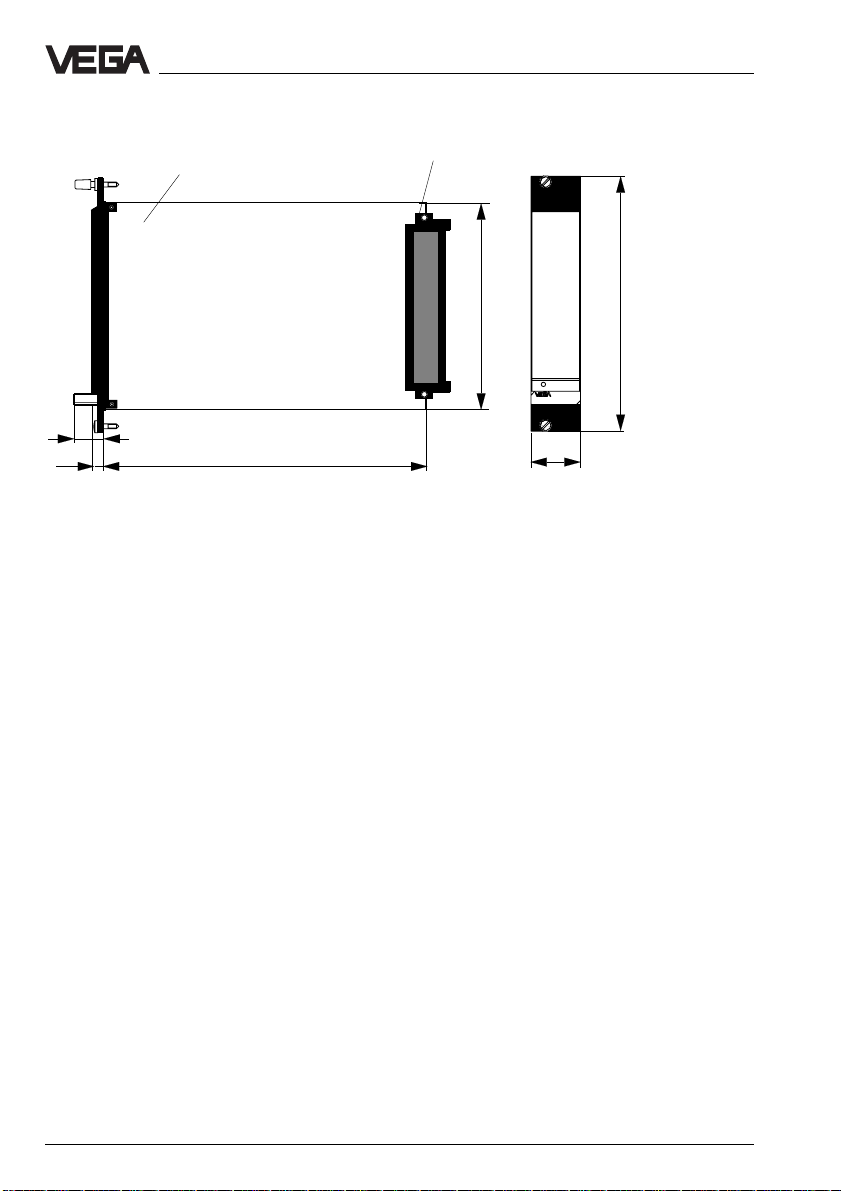

1.5 Dimensions

Circuit board 100 x 160 x 1.5

European size

Multiple plug

Product description

5 TE

9

5,5

162

100

128,4

on

25,4

6 VEGATOR

Page 7

Mounting

2 Mounting

2.1 Mounting instructions

VEGATOR can be mounted either in a card

slot in a carrier BGT 596 or in a single

housing type 505.

Card slot

Multipoint connector DIN 41 612, series F, 33pole (d, b, z) with coded pin and mounting

material for mounting in carrier BGT 596.

Card slot Ex

Multipoint connector DIN 41 612, series F, 33pole (d, b, z) with coded pins, Ex separating

chamber and mounting material for mounting

in carrier BGT 596 Ex.M.

Single housing

Plastic housing type 505 for individual

mounting of signal conditioning instruments

with instrument width 5 TE (25.4 mm).

Mounting carrier

Mount the respective module (standard or Ex

version) on your carrier BGT 596. Wire the

connections of the multipoint connector

according to the connection schematic on the

following page.

The multipoint connector is available as

follows:

- Wire-Wrap standard connection

1.0 x 1.0 mm

- Plug connection 2.8 x 0.8 mm

- Termi-Point standard connection

1.6 x 0.8 mm

- Soldering connection

- Screw terminals 2 x 0.5 mm

For further information on mounting, use the

operating instructions of the carrier.

2

Mounting single housing

The socket can be either screwed directly to

the mounting plate or plugged to a carrier rail

(TS 35 x 7.5 acc. to EN 50 022 or TS 32 acc.

to EN 50 035). Connect the terminals of the

basic plate according to the connection

schematic on the following page. For further

information on mounting, use the operating

instructions of the housing.

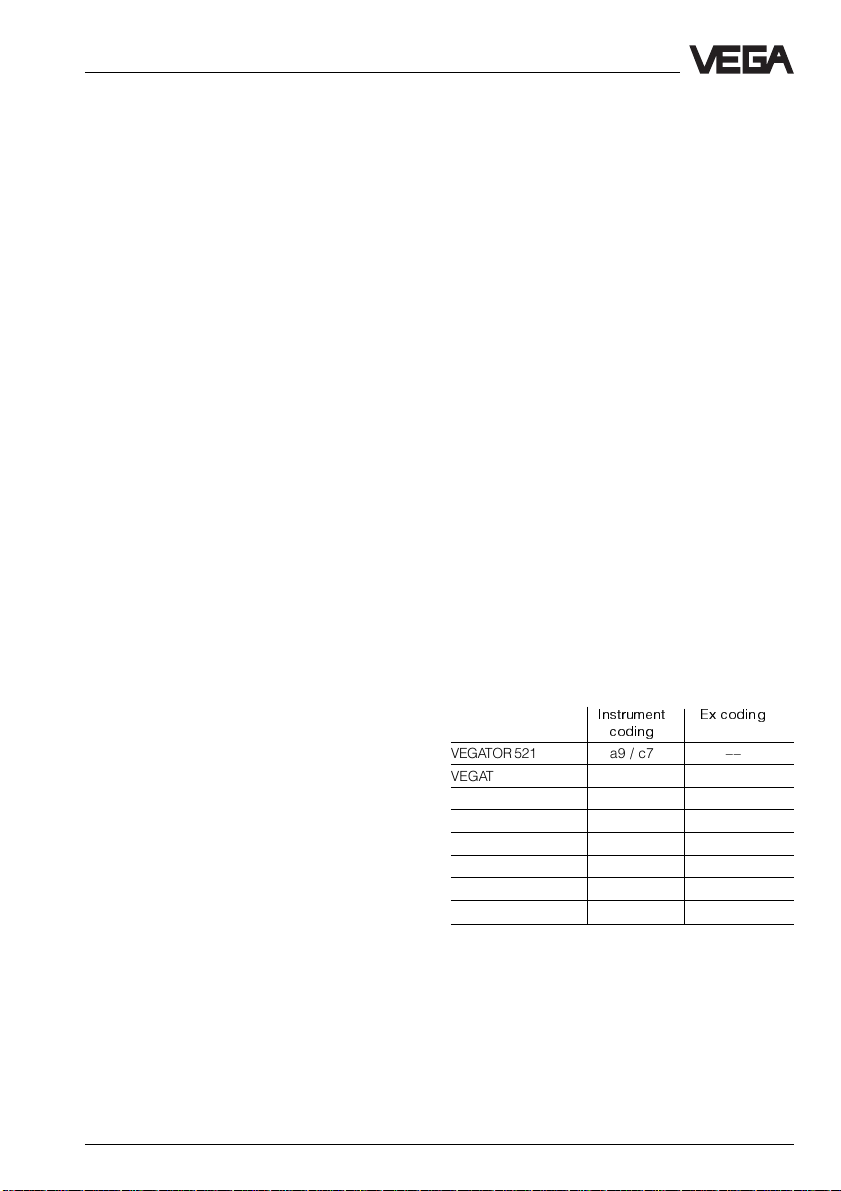

Coding

To prevent inadvertent swapping of the

various instruments, the multiple plug of the

instrument is provided with one or several

coding holes.

By means of a fixed coded pin on the Ex

module, it is ensured that only Ex instruments

can be inserted.

To prevent inadvertent swapping of the

various instruments, two additional coded

pins are included with the instrument. Insert

these coded pins into the predetermined

holes on the multipoint connector. The coded

pins must be inserted into the following

positions:

Instrument Ex coding

coding

VEGATOR 521 a9 / c7 ––

VEGATOR 521 Ex a9 / c7 c23

VEGATOR 522 a11 / c7 ––

VEGATOR 522 Ex a11 / c7 c23

VEGATOR 523 a13 / c7 ––

VEGATOR 523 Ex a13 / c7 c23

VEGATOR 527 a15 / c7 ––

VEGATOR 527 Ex a15 / c7 c23

VEGATOR 7

Page 8

Mounting

z b d

a c

o 1 o

o 3 o

o 5 o

VEGATOR 521 a9

VEGATOR 522 a11

VEGATOR 523 a13

VEGATOR 527 a15

o 7 o

o 9 o

o11o

o13o

o15o

o17o

o19o

o21o

o23o

o25o

o27o

o29o

o31o

c7

VEGATOR

c23

Ex-Codierung

Transparent cover

To protect the instrument against unauthorized or inadvertent use, the front plate of

VEGATOR can be provided with a lockable

transparent cover.

Ex version

Ex separating chamber

To ensure sufficient "air and creeping

distance", an Ex separating chamber must

be mounted to the connections of VEGATOR.

Lead the cables through the Ex separating

chamber and connect the cables. Fasten the

Ex separating chamber with the lower

holding screw. Note the operating

instructions of the carrier BGT 596 Ex.M.

Mounting in carriers

When mounting VEGATOR with Ex approval

in a carrier, a VEGA-Ex card slot must be

used. Keep a distance of at least 10 mm

(2 TE) to modules of other manufacturers.

When mounting VEGATOR to the complete

left position in the carrier, a blind cover of at

least 20 mm (4 TE) must be mounted in front

of the card slot of the instrument.

2

on

VEGATOR

Blind cover

Protection for Ex applications

For Ex applications, a protection of IP 20

must be maintained. Cover the gaps or free

card slots with blind covers from the front.

8 VEGATOR

Page 9

Electrical connection

3 Electrical connection

3.1 Connection instructions

The electrical connection should be carried

out according to the following connection

schematics. If only one channel is used on

the VEGATOR 527 signal conditioning

instruments, connect a resistor of 1 kΩ

(0.5 W) to the free connection pin of the second channel. The resistor prevents the

triggering of a fault signal caused by a missing sensor.

For each relay output, an additional paralleloperating transistor output is available.

Reset of alarm functions

For deactivation of a signalling device (horn,

diode etc.) in case of alarm (e.g. reaching the

max. permissible level), an additional key can

be connected to VEGATOR 521 or 522. This

key can deactivate a level alarm. In case of

failure (e.g. cable breakage), the alarm

cannot be deactivated.

If the key is connected, the fail-safe relay has

the same function as the level relay. However,

it is possible to reset the fail-safe relay by

pressing the key for reset of alarm functions.

If, for example, the max. level is reached and

an acoustic warning system is activated, this

system can be deactivated by pressing the

key for reset of alarm functions. The second

output (level relay) still signals the process

control that the max. level has been reached.

Note

If very strong electromagnetic interferences

are expected, screened cable is

recommended. The screening of the cable

should only be grounded on one sensor side

(e.g. capacitive electrode).

The following illustrations show the

currentless condition.

3.2 Connection schematic

VEGATOR 521 (Ex), 522 (Ex)

d b z

+-

Power

supply

Fail safe transistor

Level transistor

+

-

Sensor 1

L1 (+)

N (-)

2

6

10

12

+

16

-

18

+

20

-

22

24

28

30

32

Fail safe relay

Level relay

Key for reset of

alarm functions

(opener

function)

+

-

VEGATOR 9

Page 10

Electrical connection

VEGATOR 523 (Ex)

Power supply

Fail safe transistor

Level transistor 1

+

-

Sensor 1

L1 (+)

N (-)

2

6

10

12

16

18

20

22

24

28

30

32

VEGATOR 527 (Ex)

Power

supply

Fail safe transistor

Level transistor 1

L1 (+)

N (-)

2

6

10

12

16

18

20

22

24

d b z

+-

+

+

+

-

-

+

-

d b z

+-

+

+

+

-

-

Fail safe relay

Level relay 1

Level relay 2

Level transistor 2

Fail safe relay

Level relay 1

Level relay 2

Level transistor 2

Ex version

Please note the instructions in the attached

approval documents as well as the valid

installation regulations for connection of Ex

certified instruments.

Keep in mind that the Ex separating chamber

must be mounted on the multipoint connector.

Always lead the cables through the Ex

separating chamber. Check also the

operating instructions of the carrier BGT 596

Ex.M and the Ex instructions on page 8.

Wiring of the transistor outputs

(example VEGATOR 527 Ex)

VEGATOR 527 Ex PLC

+

I

B

U

CE

±

R

S

+

±

R

S

+

±

The resistor RS is used as short-circuit

protection

±

+

0.1

+

0.2

+

0.3

Example:

UB = 24 V, UCE - 1.5 V, IB = max. 60 mA

UB – U

R

= ––––––––– = ––––––––––––– = 375 Ω

S

I

B

CE

24 V – 1.5 V

60 mA

Sensor 1

28

+

+

+

-

30

-

-

32

+

-

Sensor 2

10 VEGATOR

Page 11

Setup

4 Setup

4.1 Indicating and adjustment elements

VEGATOR 521 VEGATOR 522 VEGATOR 523 VEGATOR 527

5

010

on

521

VEGATOR 527

B--

123456

zaze26

A

B--

123456

zaze26

A

5

010

5

010

on

sec

0

00

12

sec

sec

0

00

12

sec

5

max

min

522

010

1

5

010

2

on

523

5

010

1

5

010

2

on

527

12

3

5

4

010

5

6

on

off

on

off

7

8

9

1

5

010

2

on

527

16 13 1012

1 Connection plan

2 Lockable screw

3 Potentiometer as switching point

adjuster for max. (on VEGATOR 527

switching point adjuster for channel 1)

4 LED relay output 1

5 LED fault signal channel 1

6 Potentiometer as switching point

adjuster for min. (on VEGATOR 527

switching point adjuster for channel 2)

7 LED relay output 2

8 LED fault signal channel 2

9 LED power supply

10 Fixing screw

11 Multiple plug

111415

12 Min./Max. switch (VEGATOR 527)

13 Mode switch for variable fail-safe

adjustment (VEGATOR 522)

14 DIL switch block for channel 1

15 DIL switch block for channel 2

16 Transparent cover

VEGATOR 11

Page 12

Setup

Potentiometer

The switching point of VEGATOR or the

hysteresis (VEGATOR 522) can be changed

via potentiometer (3 and 6). For

potentiometer setting, use a small

screwdriver.

Signal lamps

LEDs in the front plate indicate, operation,

switching conditions and failures.

Green

- operation control lamp (9)

- mains voltage on, instrument in operation.

Red

- failure lamp (5 und 8)

- failure on the respective sensor current

circuit by sensor failure or cable breakage.

- if the fail-safe relay is deenergised, the red

signal lamp lights.

Yellow

- relay control lamp (4 and 7)

- the yellow control lamp reacts according to

the adjusted mode (A/B).

- in general, the relay control lamp signals

the activated (energised) condition of the

relay.

- a dark signal lamp means that the relay is

deenergised.

Min./Max. switch

(only on VEGATOR 527)

The min./max. switch (12) is used for

connection of both sensor inputs to one

common min./max. signal.

DIL switch block

One DIL switch block (14 and 15) per output

with 6 switches each is located on the circuit

board of VEGATOR. The individual switches

are assigned as follows:

1 A/B mode

A - max. detection (overfill protection)

B - min. detection (dry run protection)

2 Switch off delay (za)

3 Switch on delay (ze)

4 Integration time 2 s

5 Integration time 6 s

6 Integration time 12 s

You can set the mode (A - overfill protection,

B - dry run protection) with switch 1. When

used as part of a certified overfill protection

system, switch 1 must be set to A.

With switches 2 and 3, the switch on and/or

off delay can be adjusted independently. The

switch on or off delay relates to the switching

conditions of the relay and transistor outputs.

As example in the following illustration, mode

A (max. detection or overfill protection) is

selected (switch 1). The switch on delay is

activated (switch 3) and the integration time

is set to 8 seconds (switch 4, 5 and 6).

sec

0

00

zaze26

sec

12

1A/B mode

2 Switch off delay

3 Switch on delay

4 Integration time +2 s

5 Integration time +6 s

6 Integration time +12 s

B- -

123456

A

12 VEGATOR

Page 13

Setup

With the switches 4, 5 and 6 the integration

time can be adjusted respectively. The times

of the activated time switches sum up, see

illustration 10. When the switch on and off

delay are switched on together, the set time

is valid for both delay modes.

Switch

Time

0.2 sA/B00000

0.5 s A/B 0 0 0

2 s A/B 12 0 0

6 s A/B 060

8 s A/B 260

12 s A/B 0 0 12

14 s A/B 2 0 12

18 s A/B 0 6 12

20 s A/B 2 6 12

123456

adjusted delay mode.

The times are valid for the

3 to "-".

Either set switch 2 or switch

Changeover switch for variable failsafe adjustment

(only on VEGATOR 522, VEGATOR 522 Ex)

The switch for the variable fail-safe

adjustment (13) is located on the circuit

board of VEGATOR 522. For detection of a

measured value reduction due to failure, e.g.

break of the probe or damage of the

electrode, this function can be activated.

With separate sensor housing, a full signal or

failure information is triggered, if the

connection cable is broken.

As soon as the actual value falls below a

previously adjusted measured value, a fault

signal is triggered. By this means, a single

point control with safety monitoring can be

achieved (see "4.3 Switch point adjustment

VEGATOR 522").

4.2 Principle of operation

The following illustrations show mode A (max.

detection, overfill protection).

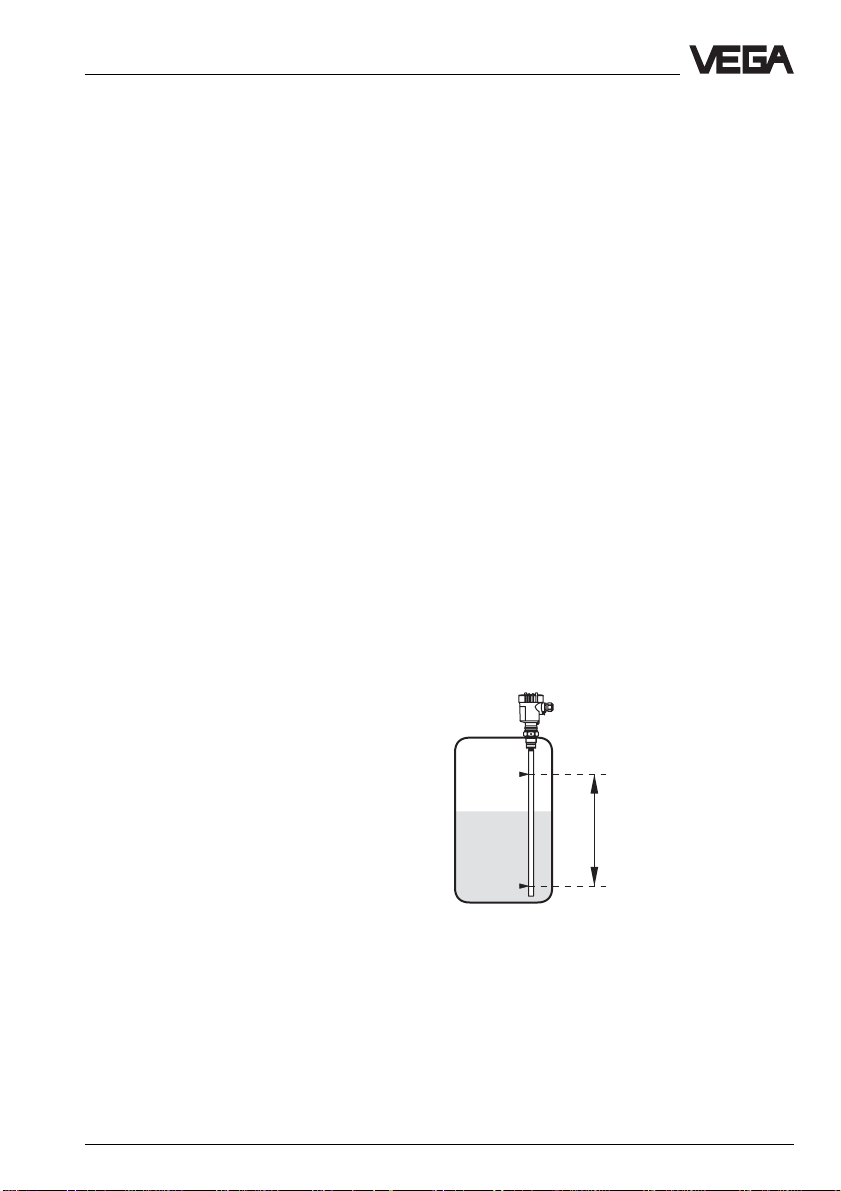

VEGATOR 521

Signal conditioning instrument as level switch

for a sensor with single point control. A horn

can be activated, if e.g. a certain level is

exceeded. If the level falls below the set

value, the horn is switched off. A typical

application for this level switch is an overfill

protection or dry run protection with one

sensor. The point that can be adjusted has a

fixed hysteresis.

off on

VEGATOR 522

Signal conditioning instrument as level switch

for one sensor with double point control

(adjustable hysteresis). The instrument has

two potentiometers. Both points, the switch

on and off point can be adjusted

independently. This ensures that, e.g. a filling

or emptying pump or a valve control can be

achieved.

off off

on

VEGATOR 13

Page 14

Setup

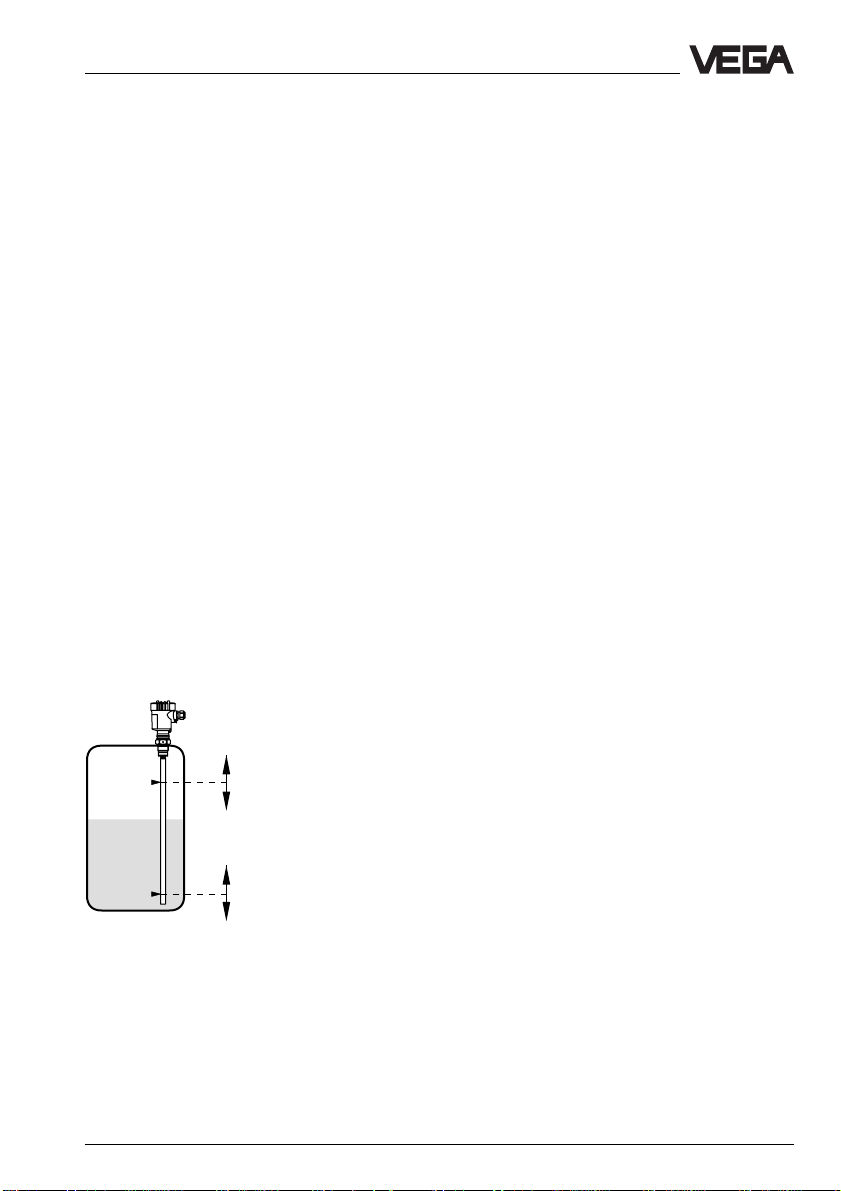

VEGATOR 523

Signal conditioning instrument as level switch

for a sensor with dual single point control.

The instrument has two potentiometers.

Therefore it is possible to achieve with one

sensor, e.g. an overfill protection and a dry

run protection or an overfill protection with

pre- or main alarm. The two points that can

be adjusted have a fixed hysteresis.

off1

1

2

on1

off2on2 on2

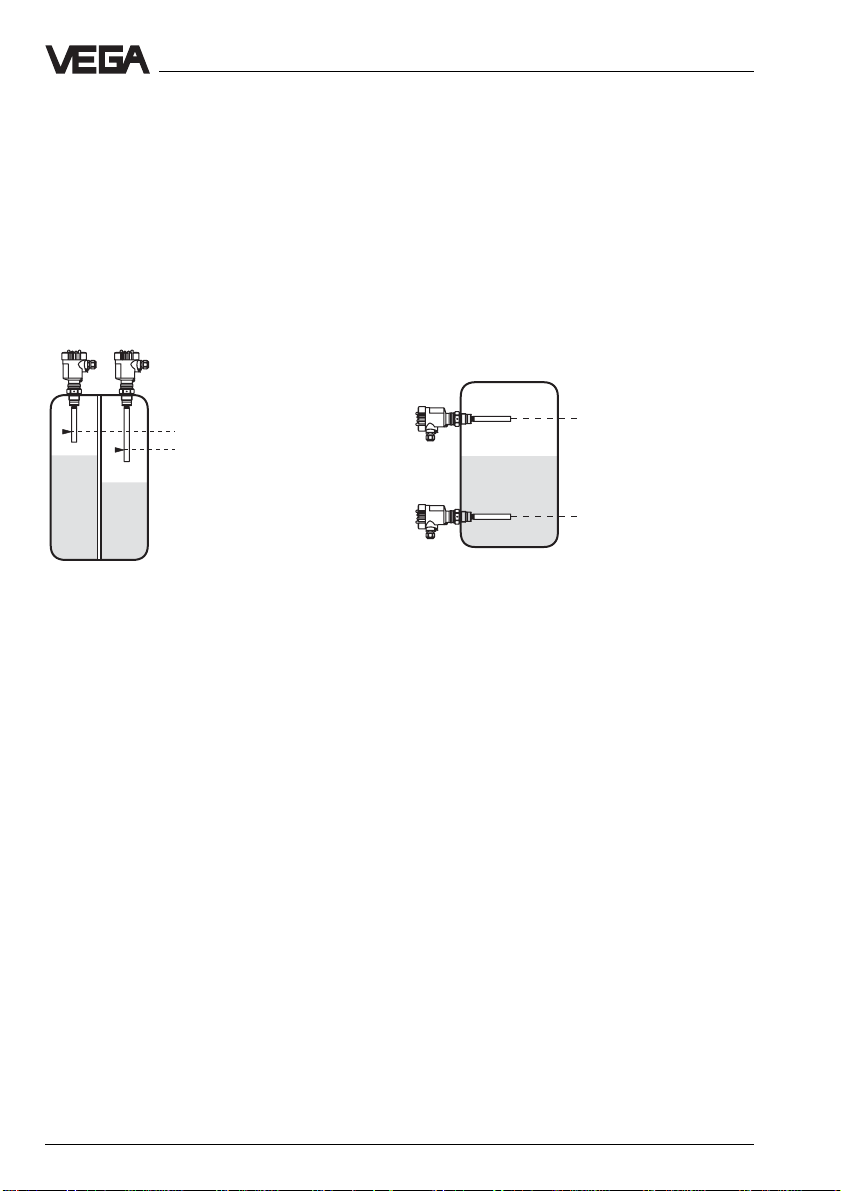

VEGATOR 527

Signal conditioning instrument as level switch

for single point control with two sensors or

double point control with two sensors (see

illustration 18). With VEGATOR 527, two

sensors can be monitored at the same time

with one signal conditioning instrument. The

two points that can be adjusted have a fixed

hysteresis.

4.3 Switching point adjustment

The following control modes are possible with

the individual instruments:

- level detection [521, 522, 523, 527]

- double point control with one sensor and

adjustable hysteresis (min./max. control)

[522]

- single point control with one sensor and 2

level switches [523]

- two single point controls with 2 sensors

[527]

- double point control with 2 sensors [527]

Note

In general, the relay control lamp shows the

activated (energised) condition of the relay. A

dark control lamp means that the relay is

deenergised. This means also that in case of

power failure the relay always returns to

deenergised condition.

VEGATOR 521

Single point control

Please note for single point control also "4.1

Indicating and adjustment elements" (the

numbers in brackets refer to the illustration).

off1

1

2

12

14 VEGATOR

on1

on2 off2

Page 15

Setup

Vertically installed measuring probes and

pressure transmitters

Fill the vessel to the requested level.

On the DIL switch block (14) you select the

mode (A - overfill protection, B - dry run

protection).

Make sure that the integration time is

switched off. The switches 2 - 6 on the DIL

switch block (14) must be in Off position. Set

the potentiometer (6) to 0.

Turn the potentiometer (6) very slowly

clockwise until the relay control lamp (7)

lights (mode A) or extinguishes (mode B).

If necessary, choose the following

adjustments on the DIL switch block (14):

- switch off delay, switch on delay

- integration time (0.2 … 20 s)

VEGATOR is now ready for operation.

Horizontally mounted meas. probes and

meas. probes for very adhesive products

On the DIL switch block (14) you select the

mode (A - overfill protection, B - dry run

protection).

Make sure that the integration time is

switched off. The switches 2 - 6 on the DIL

switch block (14) must be in Off position. Set

the potentiometer (6) to 0.

Fill the vessel until the measuring probe is

covered completely. In case of measuring

probes for very adhesive products, the sensitive tip (standard 100 mm) must be totally

covered.

Turn the potentiometer (6) very slowly

clockwise until the relay control lamp (7)

lights (mode A) or extinguishes (mode B).

Now note the adjusted value.

Set the potentiometer (6) to the average

value of the two noted values.

If necessary, choose the following

adjustments on the DIL switch block (14):

- switch off delay, switch on delay

- integration time (0.2 … 20 s)

VEGATOR is now ready for operation.

VEGATOR 522

Double point control with one sensor

and adjustable hysteresis

For switch point adjustment, please also note

"4.1 Indicating and adjustment elements" (the

numbers in brackets refer to the illustration).

1

Lower the level at least down to 100 mm

below the measuring probe.

Turn the potentiometer (6) very slowly

clockwise until the relay control lamp (7)

2

lights (mode A) or extinguishes (mode B).

Now note the adjusted value.

VEGATOR 15

Page 16

Setup

Vertically mounted measuring probes or

pressure transmitters

Fill the vessel to the required max. level.

Make sure that the integration time is

switched off. The switches 2 - 6 on the DIL

switch block (14) and the changeover switch

(13) must be in Off position.

On the DIL switch block (14) you select the

mode (A - overfill protection, B - dry run

protection).

Set the min. potentiometer (6) to 0 and the

max. potentiometer (3) to 10.

If you have chosen mode A, the relay control

lamp (7) must light. If the control lamp does

not light, turn the min. potentiometer (6)

shortly to 10, to activitate the relay control

lamp. Then turn the min. potentiometer again

to 0.

If you have chosen mode B, the relay control

lamp (7) should not light. If the control lamp

lights, turn the min. potentiometer (6) shortly

to 10, to deactivate the relay control lamp.

Then turn the min. potentiometer again to 0.

Turn the max. potentiometer (3) very slowly

anticlockwise until the relay control lamp

lights or extinguishes.

VEGATOR 522

Single point control with safety

monitoring

Note for the switch point adjustment "4.1

Indicating and adjustment elements" (the

numbers in brackets refer to the illustration).

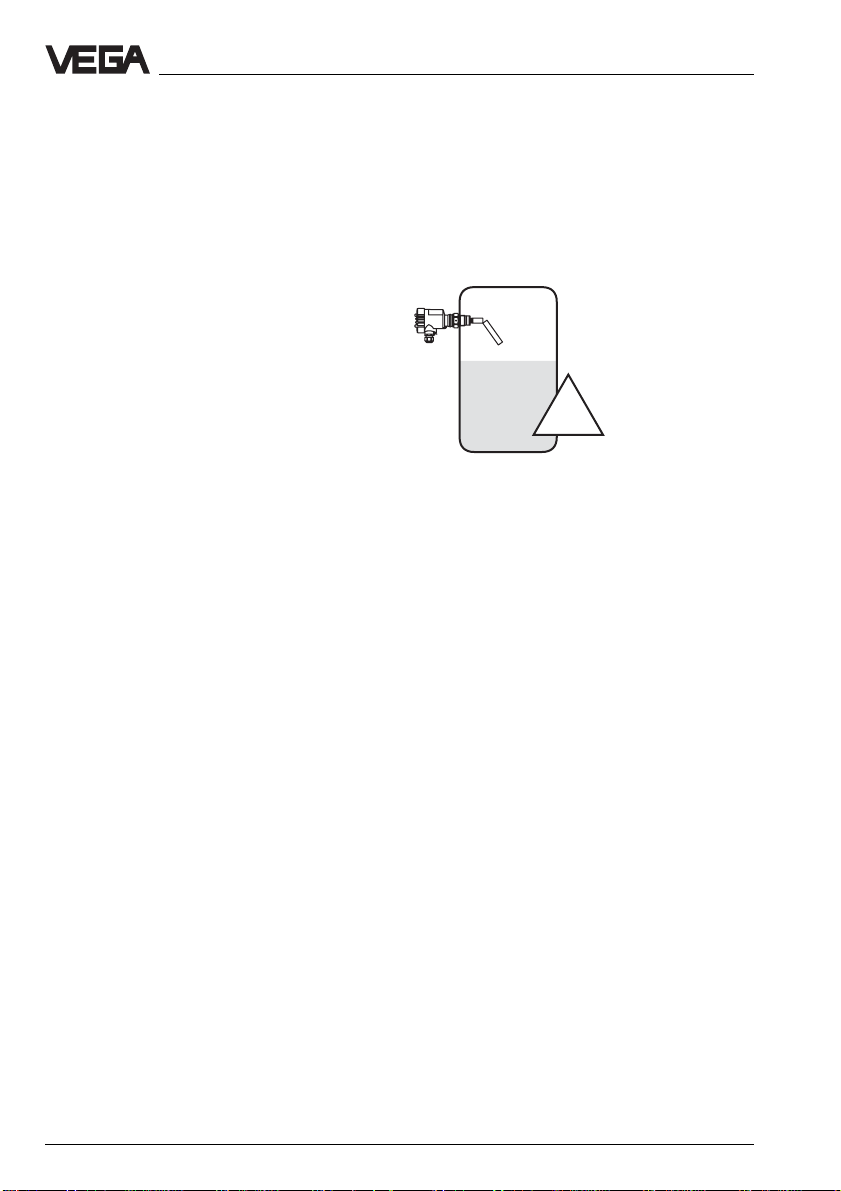

!

Only possible with horizontally mounted

meas. probes or meas. probes for very

adhesive products

Make sure that the integration time is

switched off. The switches 2 - 6 on the DIL

switch block (14) must be in Off position.

Lower the medium until the probe is

uncovered. The level should be at least

=100 mm below the probe.

Lower the medium to the required min. level.

Turn the min. potentiometer (6) very slowly

clockwise until the relay control lamp lights or

extinguishes.

If necessary, choose the following

adjustments on the DIL switch block (14):

- switch off delay, switch on delay

- integration time (0.2 … 20 s)

VEGATOR is now ready for operation.

16 VEGATOR

Set the changeover switch for the variable

fail-safe adjustment (13) to "on". Set the two

potentiometers (3 and 6) to 0. The red failure

lamp (8) extinguishes.

Turn the max. potentiometer (3) to 10. The

red failure lamp (8) lights. Turn the max.

potentiometer very slowly clockwise until the

relay control lamp (7) extinguishes. Turn the

max. potentiometer (3) another step

anticlockwise.

Turn the min. potentiometer (6) very slowly

clockwise until the relay control lamp (7)

lights or extinguishes. Note this value.

Page 17

Setup

Fill the vessel until the measuring probe is

covered completely or is submerged into the

medium by approx. 100 mm. The relay

control lamp (7) changes switching condition.

Turn the min. potentiometer (6) very slowly

clockwise until the relay control lamp (7)

lights or extinguishes.

Note the value of the potentiometer. Set the

potentiometer (6) to the average value of the

two noted values.

If necessary, choose the following

adjustments on the DIL switch block (14):

- switch off delay, switch on delay

- integration time (0.2 … 20 s)

VEGATOR is now ready for operation.

VEGATOR 523

Single point control with one sensor

and two level switches

Note for switch point adjustment "4.1

Indicating and adjustment elements" (the

numbers in brackets refer to the illustration).

For min. and max. information, max. and

max. alarm or min. and min. alarm

information

Make sure that the integration time is

switched off. The switches 2 - 6 of the DIL

switch blocks (14 and 15) must be in Off

position.

Choose on the DIL switch blocks (14 and 15)

the mode (A - overfill protection, B - dry run

protection).

Set the two potentiometers (3 and 6) to 0.

Lower the medium to the required min. level.

Turn the min. potentiometer (6) very slowly

clockwise until the relay control lamp (7)

lights or extinguishes.

Fill the vessel to the required max. level.

Turn the max. potentiometer (3) very slowly

clockwise until the relay control lamp (4)

lights or extinguishes.

If necessary, choose the following

adjustments on the DIL switch blocks (14

and 15):

- switch off delay, switch on delay

- integration time (0.2 … 20 s)

VEGATOR is now ready for operation. (see

1

2

VEGATOR 17

also illustration 7 c).

Page 18

Setup

VEGATOR 527

Single point control with 2 sensors

For switch point adjustment also note "4.1

Indicating and adjustment elements" (the

numbers in brackets refer to the illustration).

Vertically mounted measuring probes and

pressure transmitters

1

2

12

Choose on the DIL switch blocks (14 and 15)

the mode (A - overfill protection, B - dry run

protection). Make sure that the integration

time is switched off. The switches 2 - 6 of the

DIL switch blocks (14 and 15) and the min./

max. changeover switch (12) must be in Off

position. Set the two potentiometers (3 and 6)

to 0.

Channel 1

Fill the vessel to the required level. Turn the

potentiometer (3) very slowly clockwise until

the relay control lamp (4) lights (mode A) or

extinguishes (mode B).

Channel 2

Carry out the adjustment for channel 1. Then

repeat the adjustment with the adjustment

elements for channel 2.

If necessary, choose the following

adjustments on the DIL switch blocks (14

and 15):

- switch off delay, switch on delay

- integration time (0.2 … 20 s)

VEGATOR is now ready for operation.

Horizontally mounted meas. probes and

meas. probes for very adhesive products

1

2

Choose on the DIL switch blocks (14 and 15)

the mode (A - overfill protection, B - dry run

protection). Make sure that the integration

time is switched off. The switches 2 - 6 of the

DIL switch blcoks (14 and 15) and the min./

max. changeover switch (12) must be on in

Off position. Set the two potentiometers (3

and 6) to 0.

Channel 1

Lower the level at least 100 mm below

electrode 1.

Turn the potentiometer (3) very slowly

clockwise until the relay control lamp (4)

lights (mode A) or extinguishes (mode B).

Note the value adjusted now.

Fill the vessel until electrode 1 is covered

completely. With electrodes for very adhesive

products, the sensitive tip (standard

100 mm) must be covered completely.

18 VEGATOR

Page 19

Setup

Turn the potentiometer (3) very slowly

clockwise until the relay control lamp (4)

lights (mode A) or extinguishes (mode B).

Note the value adjusted now.

Set the potentiometer (3) to the average

value of the two noted values.

Channel 2

Carry out the adjustment like for channel 1.

Then repeat the adjustment with the

adjustment elements for channel 2.

If necessary, choose the following

adjustments on the DIL switch blocks (14

and 15):

- switch off delay, switch on delay

- integration time (0.2 … 20 s)

VEGATOR is now ready for operation.

VEGATOR 527

Double point control with 2 sensors

For switch point adjustment also note "4.1

Indicating and adjustment elements" (the

numbers in brackets refer to the illustration).

Choose on the DIL switch blocks (14 and 15)

the mode (A - overfill protection, B - dry run

protection). Make sure that switch 1 of the

two DIL switch blocks (14 and 15) is

adjusted to the same mode (both the mode A

or both the mode B)

Set the min./max. changeover switch (12) to

off.

After having selected mode A, make sure

that the meas. probe of channel 1 is always

mounted in a higher position than the meas.

probe for channel 2.

In mode B, the meas. probe of channel 1

must be mounted lower than the meas. probe

of channel 2.

Make sure that the integration time is

switched off. The switches 2 - 6 of the DIL

switch blocks (14 and 15) must be in Off

position. Set the potentiometer (3) to 0.

Channel 1

Lower the level at least 100 mm below the

measuring probe 1.

Turn the potentiometer (3) very slowly

clockwise until the relay control lamp (4)

lights (mode A) or extinguishes (mode B).

Note the adjusted value now.

1

Fill the vessel until the measuring probe is

covered completely. With measuring probes

for very adhesive products, the sensitive tip

(standard 100 mm) must be covered

completely.

2

Turn the potentiometer (3) very slowly

clockwise until the relay control lamp (4)

lights (mode A) or extinguishes (mode B).

Note the adjusted value now.

Horizontally mounted meas. probes or

Set the potentiometer (3) to the average

meas. probes for very adhesive products

Here, signals of two measuring probes, e.g.

mounted to min. or max. levels, can be linked

to one common pump control signal.

VEGATOR 19

Page 20

value of the two noted values.

Channel 2

Carry out the adjustment like for channel 1.

Then repeat the adjustment with the

adjustment elements for channel 2.

Set the min./max. changeover switch (12) to

"on".

The relay of channel 1 now has the function of

a min./max. relay (hysteresis signal). The

relay of channel 2 still signals the covering of

electrode 2.

If necessary, choose the following

adjustments on the DIL switch blocks (14

and 15):

- switch off delay, switch on delay

- integration time (0.2 … 20 s)

VEGATOR is now ready for operation.

Setup

20 VEGATOR

Page 21

Diagnostics

5 Diagnostics

5.1 Maintenance

The instrument is maintenance free.

5.2 Repair

Repairs require accessing internal parts of

the instrument to correct an instrument defect. For safety and warranty reasons, repair

must only be carried out by VEGA personnel.

In case of a defect, please return the respective instrument with a short description of the

flaw to our repair department.

Failures, their possible causes and their

rectification are listed under “5.3 Failure

rectification“.

VEGATOR 21

Page 22

Diagnostics

5.3 Failure rectification

Fai lur e Rectification / Measure

Instrument is dead /

Green operating

control lamp

extinguishes Check the voltage supply and the mains connections as described

Red failure LED

lights Check the sensor inputs for the following failures:

under “Connection instructions“ on page 8. If the instrument still

does not function, please call our service department.

- short circuit on the input

- sensor not connected correctly or polarity-reversed

- sensor line interrupted

- supply voltage too low

Check if the sensor is connected correctly

- failures in the sensor, effecting a current change to below 2 mA or

above 23 mA, generate a fault signal on VEGATOR.

Measure the current in

the connection cable to

the sensor.

4 … 20 mA 12 … 20 V

mA

+

±

Sensor

V

28

+

+

30

-

-

32

VEGATOR

For Ex systems, make sure that the Ex protection is not degraded by the measuring instruments.

22 VEGATOR

Page 23

Diagnostics

a. Current value < 2 mA

- Check the supply voltage on the connection cable to the sensor.

The voltage should be at least 18 V.

Should a value below 18 V should be measured, it indicates a

defect in the signal conditioning instrument. In this case, return

the instrument for repair to VEGA.

- Should the red failure lamp continue to light, separate the

connection cable from the signal conditioning instrument and

connect to the sensor inputs of the signal conditioning instrument

a resistor of 1 kOhm.

If the failure lamp continues to light, the signal conditioning

instrument is defective. In such a case, return the instrument for

repair to VEGA.

- Should the failure lamp extinguish, reconnect the signal

conditioning instrument. Separate the sensor from the connection

cable and connect a resistor of 1 kOhm in its place.

- Should the failure lamp continue to light, there is probably a short

circuit in the connection line. Check the connection cable to the

sensor.

- If the failure lamp extinguishes, the sensor is defective. Check the

connected sensor.

b. Current value > 22 mA

- Check all connections and the connection cable to the sensor.

- Should the red failure lamp continue to light, separate the sensor

from the connection cable and connect a resistor of 1 kOhm in its

place.

If the failure lamp extinguishes, the sensor is defective. Check the

connected sensor.

- Should the failure lamp continue to light, reconnect the sensor.

Separate the signal conditioning instrument from the connection

cable and connect a resistor of 1 kOhm to its sensor input.

- Should the failure lamp continue to light, the signal conditioning

instrument is defective. In such a case, return the instrument for

repair to VEGA.

- If the failure lamp extinguishes, there is probably a short circuit in

the connection line. Check the connection cable to the sensor.

VEGATOR 23

Page 24

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (0 78 36) 50 - 0

Fax (0 78 36) 50 - 201

e-mail info@vega-g.de

ISO 9001

The statements on types, application, use and operating conditions of

the sensors and processing systems correspond to the latest information at the time of printing.

Technical data subject to alterations

19312-EN-041110

Loading...

Loading...