User Manual

bidirectional

Multifunctional-Counter

Part-No. 2 772 058 englisch; 05/2011

Table of Contents

1 General Information 6

1.1 Information about the Operating Instructions 6

1.2 Explanation of symbols 7

1.3 Limitation of Liability 8

1.4 Copyright protection 9

1.5 Guarantee conditions 9

1.6 Customer Service 11

2 Safety 10

2.1 Intended Use (Proper Use) 10

2.2 Assembly, connecting, programming 11

2.3 Responsibilities of the machine/plant manufacturer

and operator 13

2.4 Staff-related requirements 14

2.5 Special hazards 15

2.6 Safety devices 16

3 Setup and Operation 17

3.1 Dimension Sheet / Multifunction Counter Installation 18

3.2 Connecting the Multifunction Counter 18

3.3 Display 20

3.4 Keyboard functions 21

3.5 Overview of Operating Elements 23

3.6 Programming the Standard Function 24

3.7 Programming the Function Codes 25

3.8 Programming the Preset Modes 26

3.9 Prescaler Programming 28

3.10 Programming the (User) Times 29

3.11 Output of ID Data 30

3.12 Adjusting the intensity of the backlight 31

III

Table of Contents

4 General Description of Multifunctional Counter 32

5 Pulse Counter 37

5.1 Description of Pulse Counter 37

5.2 Signal diagrams – counter input signals 38

5.3 Signal diagrams – counter output signals 40

5.4 Programming the counter function codes 42

6 Tachometer 54

6.1 Tachometer description 54

6.2 Signal diagrams - tachometer 55

6.3 Programming the tachometer function codes 56

7 Timer 65

7.1 Timer description 65

7.2 Signal diagram – timer input signals 67

7.3 Signal diagrams – timer output signals 68

7.4 Programming the timer function codes 69

8 Shift Counter 82

8.1 Shift counter description 82

8.2 Scroll between Total Sum and Partial Sums 83

8.3 Signal diagrams – shift counter input signals 83

8.4 Signal diagrams – shift counter output signals 84

8.5 Programming the shift-counter function codes 85

9 Batch Counter 96

9.1 Batch counter description 96

9.2 Signal diagrams – batch counter 97

9.3 Programming the batch counter function codes 97

IV

Table of Contents

10 Technical Data 110

11 Transport, Packaging, Storage 117

12 Maintenance and cleaning 117

13 Malfunctions 118

14 Spare Parts 120

15 Dismantling and Disposal 120

16 Ordering Information 121

17 Accessories and spare parts 122

18 Supplementary information

relating to the users‘ manual 124

V

General Information

1 General Information

1.1 Information about the Operating Instructions

These operating instructions provide important information about the handling of the multifunctional counter. To ensure safe operation it is vital that the

safety information and instructions be strictly observed.

For Counters with interfaces VersaCount 773 and VersaCount 774 please see

attached the amendment „Supplementary information relating to the users‘

manual“ (page 123)

The multifunctional counter has been designed for industrial use and for installation in machinery or industrial plants.

The manufacturer of the machine/plant in which the multifunctional counter

is used has to ensure that the function of the counter is properly described in

the Operating Instructions of the machine or plant, and that the description is

in accordance with manufacturer’s programming functions.

The manufacturer’s safety rules shall be applicable.

In addition, the local regulations concerning the prevention of accidents and

general safety information applicable to the machinery/plant shall be adhered

to.

Before starting any work on the machine/plant, the operating instructions and

in particular, the Safety chapter and the respective safety information must be

fully read.

These operating instructions are an integral part of the product and must be

maintained in the direct vicinity of the machine/plant and in a place that is

readily accessible for the operating staff.

These operating instructions contain important information concerning the installation, connection and programming of the multifunctional counter.

6

General Information

Description of the programming sequence:

- Programming of the basic functions

- Programming of the function codes

- Programming of the user times

- Programming of the prescaler

- Programming of the presettings

Before starting to run the machine/plant, all functions that are not allowed to

be changed by the operator have to be blocked.

The executed programming functions have

to be documented.

1.2 Explanation of symbols

The warnings in these operating instructions are designated by symbols. Signal

words at the beginning of the warnings indicate the severity of a safety hazard.

These notes have to be observed by all means, and all actions have to be taken

with utmost care so as to prevent any accidents or damage or personal injury.

Danger!

This warning indicates a direct safety hazard,

which may lead to serious injuries or even death

if preventative action is not taken.

Warning!

This warning indicates a possible safety hazard,

which may lead to serious injuries or even death

if preventative action is not taken.

7

General Information

Caution!

This warning indicates a possible safety hazard,

which may lead to minor damage or injuries if

preventative action is not taken.

Note!

This symbol indicates a potentially hazardous

situation, which may lead to damage to property

or to the environment if preventative action is not

taken.

Tips and recommendations

This symbol is used to point out to useful tips and

recommendations and information ensuring efficient and trouble-free operation.

1.3 Limitation of Liability

The information and notes contained in these operating instructions were

gathered in accordance with the applicable standards and regulations, the

state-of-the-art, as well our long-standing experience and know-how.

The manufacturer shall not assume any liability for damage caused by:

- Non-adherence to the operating instructions

- Improper use

- Employment of unskilled or untrained personnel

- Makeshift changes or manipulation

- Opening of the multifunctional counter

As a result of special design versions, special ordering options or the latest

technical developments, the actual scope of delivery may deviate from the

scope described and illustrated here.

8

General Information

1.4 Copyright protection

The operating instructions must be treated confidentially and used exclusively

by the personnel responsible for the setup, maintenance, repair and operation

of the machine/plant. Disclosure of these operating instructions to any third

parties shall not be permissible without the prior written consent of the manufacturer.

The data and information stated here, including

text, drawings, images and other illustrations, are

protected by copyrights and subject to industrial

property rights. Any misuse of such information

shall be subject to prosecution.

1.5 Guarantee conditions

Our standard warranty is available on our website at

www.veeder-rootcounters.com.

1.6 Customer Service

Our customer service is available to provide technical information and assistance for our customers. Detailed information on your responsible contact

partner is given on our homepage (www.veeder-rootcounters.com).

9

Safety

2 Safety

This section provides an overview of all the important safety-relevant aspects

to ensure best possible protection of the operating personnel as well as safe

and trouble-free operation. Non-adherence to the instructions given in this

manual may result in considerable safety hazards.

2.1 Intended Use (Proper Use)

The multifunctional counter is exclusively designed and constructed for the

intended use and purposes described here.

The multifunctional counter serves together with a corresponding sensor

for the counting of piece numbers, lengths, flow rates, velocities and

times, as well as for the controlling and monitoring of machinery and

equipment by sending control signals.

Warning!

Safety hazards due to improper use / misuse!

Using the multifunctional counter for any purposes

other than the ones described within the scope of

intended use may cause hazardous situations. Claims

for damages resulting from any kind of misuse

shall be expressly excluded.

10

Safety

2.2 Assembly, connection, programming

These multifunctional counters are built and tested in accordance with IEC/EN

61010-1, Protection Class II – Safety Measures for Electronic Measuring

Equipment. They have left the factory in a condition that is in compliance with

all safety-relevant requirements. In order to maintain this condition and ensure operational safety, the User is requested to observe the safety notes and

warnings given in these operating instructions!

Danger!

Risk of safety hazards due to incorrect/faulty assembly and connection.

• Themax.operatingvoltagesmustnotbeexceeded!

• 12–24VDCand24VACmultifunctionalcountershavetobeoperatedat

safety extra-low voltages (SELV) and under potential-compensated conditions in order to prevent hazardous shock currents.

• Anexternalfusehastobeprovidedtoprotectthemultifunctionalcounter

(see Chapter 10, Technical Data).

• Installationandassemblyshallbecarriedoutbyskilledandtrainedelectricians only.

• Donotconnectthemultifunctionalcounterwithoutmakingsurethatitno

longer carries any live voltages. Always separate it from the mains supply

before connecting.

• Makesurethatliveterminalsareproperlyprotectedagainstinadvertent

contact.

• Toensureproperprotectionofterminalsagainsthandcontact,makesure

that the live conductors are properly connected to the terminals.

• It‘snotallowedtousethemultifunctionalcounteroutsideofthespecified

temperature range. If neccessary appropriate precoutions have to be applied

11

Safety

(e.g.airventilation).•Therulesandregulationssetforthbythelocalelectricity providers have to be observed.

• Donotestablishanyconnectionswithnon-allocated(NC)terminals.

• Multifunctioncountersmayonlybeoperatedinaproperlyinstalledcondi-

tion.

• Ifsafeoperationseemstobeimpaired,makethemultifunctionalcounter

inoperable and secure it against inadvertent operation.

• Scopeofapplications:industrialprocessesandcontrols.Overvoltageacross

the terminals must be limited to the values of overvoltage category II.

• Theinstallationandwiringenvironmenthasconsiderableimpactonthe

electromagnetic compatibility of the multifunctional counter. Therefore,

electromagnetic compatibility of the entire plant has to be ensured during

the installation.

• InareaspresentingtheriskofESD(electrostaticdischarge),makesureto

use ESD-protected plugs and switches during the installation.

• Ifthefunctions“prescalerinput”,“presetinput”and“keyreset”arenotallowed to be used by the machine/plant operator, access to these functions

must be blocked for machine operators. Depending on the machine/plant

design or concept, non-permissible input may impair the operational safety

and function of the machine or plant.

Danger!

The manufacturer of the machines / plants has to

ensure, that no risks result from this.

• Themachine/plantmanufacturershallberesponsibleforthepreparationof

operating instructions / plant description including the following:

12

Safety

•Descriptionoffunctionsaccordingtotheprogrammingofthemultifunction counter;

•Descriptionofthesettingstobeadjustedbythemachine/plantoperator;

•Informationconcerningtheoccupationalsafetyrequirementsandpossi-

ble hazards arising from the operation of the machine/plant.

2.3 Responsibilities of the machine/plant manufacturer

and operator

Multifunctional counters are designed for installation in machines/plants.

Therefore, the manufacturer and

operator of the machine/plant are subject to the legal obligations concerning occupational safety and health.

Besides the safety notes given in these operating instructions, the relevant

rules and regulations concerning safety and the prevention of accidents,

and the applicable environmental requirements have to be met. In particular:

• Themachine/plantmanufacturershallbeobligatedtoensurethatallthe

requirements mentioned in section 2.2 be fulfilled during the assembly,

connection and programming.

• Theoperatorshallobtainalltherequiredinformationabouttheapplicable

occupational safety rules. In addition, the operator shall be obligated to

prepare a risk assessment of possible hazards that may arise due to the special working conditions at the place of installation of the machine/plant.

This risk assessment shall be documented in the form of operating instructions for the machine/plant.

• Throughouttheentireoperatingtimeofthemachine/planttheoperator

shall be obligated to check if the operating instructions prepared are in accordance with the latest status of requirements and, if required, make the

appropriate adjustments.

13

Safety

• Theoperatorshallensurethatallstaffmemberswhoareinvolvedinthe

machine/plant operation have read and fully understood these instructions.

Moreover, the operator shall be obligated to train the operating personnel

at regular intervals and inform them about any potential hazards.

• Theoperatorshallensurethattheoperationandcleaningofthemachine/

plant is exclusively carried out by skilled and trained personnel.

• Theoperatorshallensurethatallmaintenanceandrepairworkshallonly

be carried out by skilled and trained personnel.

2.4 Staff-related requirements

Warning:

Danger of personal injuries if handled by insufficiently qualified staff! Improper handling may cause

severe personal injuries and damage to property.

• Actionsrequiringspecialskillshavetobecarriedoutonlybythepersonnel

designated in the appropriate sections of these instructions.

• Keepunqualifiedpersonnelawayfromhazardareas.

The following staff qualification requirements have been

defined for the various scopes of activities:

• Instructed personnel

These persons have been instructed by the operator with regard to the tasks

assigned and the potential hazards caused by improper handling.

• Skilled personnel

Due to their educational and professional skills, know-how and experience,

as well as due to their knowledge of the relevant regulations, these persons

are capable of executing their assigned tasks and recognize potential hazards independently.

14

Safety

• Skilled and trained electricians

Due to their educational and professional skills, know-how and experience,

and due to their knowledge of the relevant regulations in the field of electrical engineering, these persons are capable of executing electrical work

and recognizing potential hazards independently.

2.5 Special hazards

This section indicates certain residual risks, which may arise as a result of the

risk assessment.

The safety information and warnings given here and in the following chapters

of these instructions have to be observed in order to reduce any health hazards and avoid hazardous situations.

Electric current

Danger!

Lethal hazard of electric shock!

Any contact with hazardous live components presents a direct lethal hazard.

Damages of the insulation or individual components present a potential lethal hazard.

• Intheeventofanydamagetotheinsulation,immediately disconnect the voltage supply and initiate the

appropriate repair work.

• Anyworkontheelectricalplanthastobecarriedout

by skilled and trained electricians only.

• Beforecommencingyourworkontheelectricalsystem,

disconnect it from the main supply and check that it

no longer carries any live voltages.

15

Safety

• Priortoconductinganymaintenance,cleaningorrepair

work, disconnect the mains supply and secure it against

inadvertent switching on.

• Donotshort-circuitormakefusesinoperable.

2.6 Safety devices

Warning! Lethal hazard by non-functional safety

devices! Safety devices are provided to ensure a

maximum of operational safety.

The multifunctional counter itself does not include any installed safety devices.

These safety devices have to be attached externally.

Protect the electrical supply of the multifunctional counter by means of external fuses (see Chapter 10, Technical Data).

Whether or not additional safety devices (e.g. emergency-off buttons) have to

be provided depends on the general design and construction of the machine or

plant.

The machine/plant manufacturer shall be responsible for providing such additional safety devices in according with his own risk assessment.

16

Safety

3 Setup and Operation

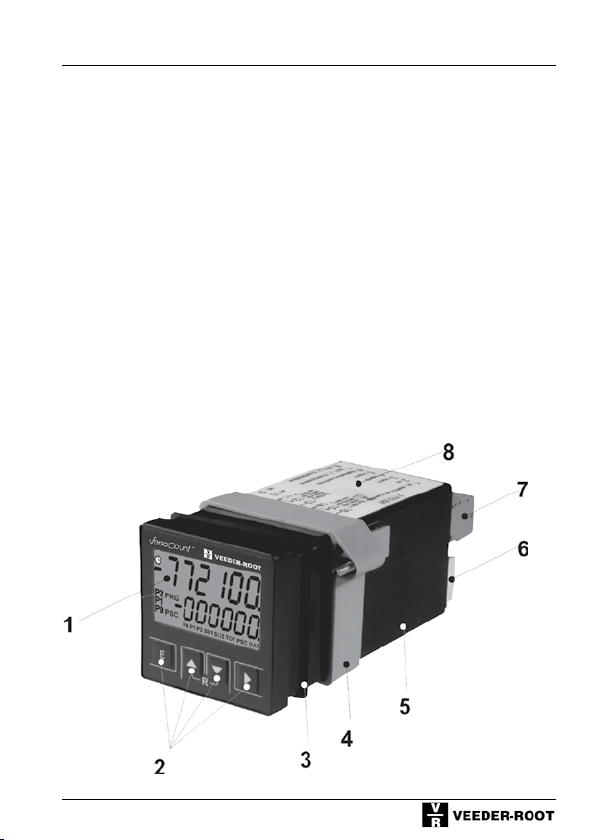

1 Display

2 Operating keys

3 Flat gasket

4 Bracket

5 Enclosure

6 Plug for DC or sensor supply;

Electronic inputs and outputs

7 Connection terminal AC supply and relay contacts

8 Circuit diagram

17

Safety

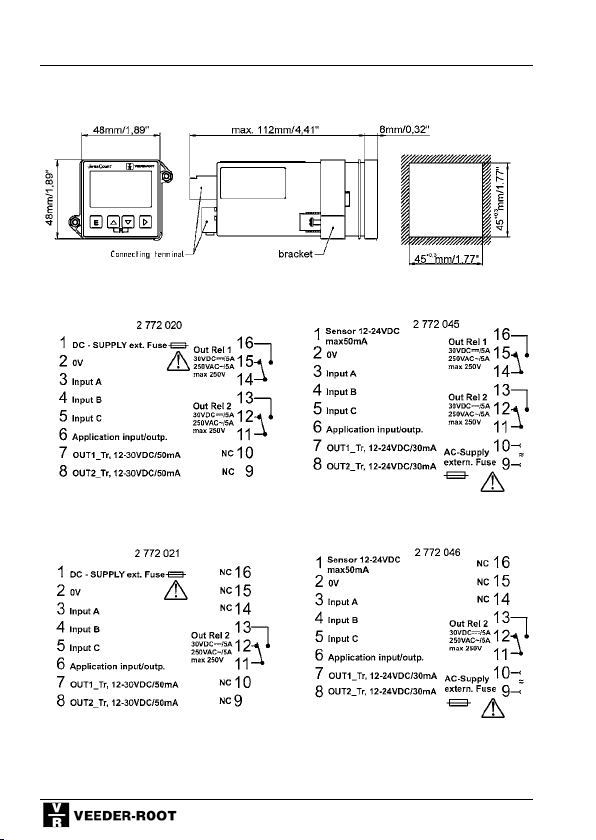

3.1 Dimension Sheet /

Installation of Multifunction Counter

3.2 Connecting the Multifunctional Counter

VDC 2 relays / 2 transistors VAC Trafo 2 relays / 2 transistors

VDC 1 relay / 2 transistors VAC transformer 1 relay / 2 transistors

18

Setup and Operation

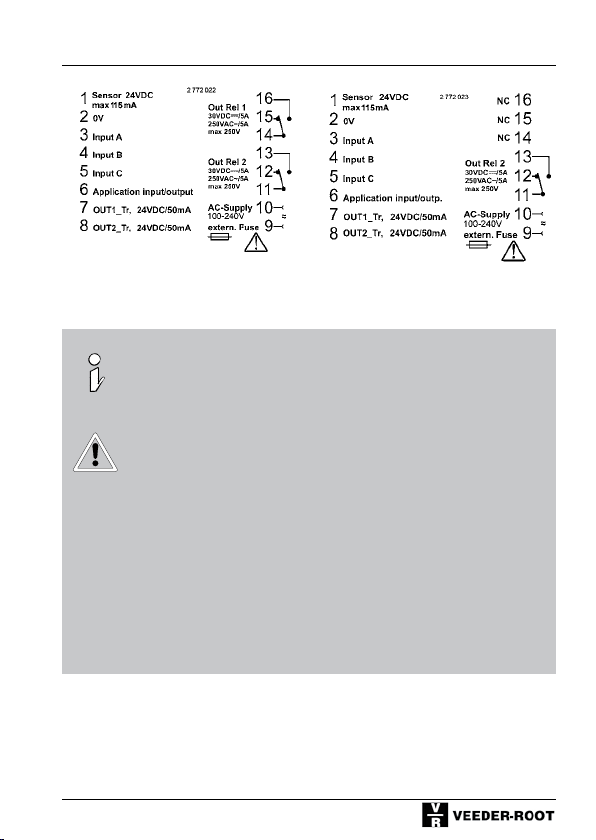

VAC switching power supply VAC switching power supply

2 relays / 2 transistors 1 relay / 2 transistors

The plug has to be disconnected from the counter

before the cables are fastened by means of screws

or screw-type terminals.

It is not allowed to contact the encoder to a direct

current line voltage without protective circuit for

EMC. For cable lengths > 30 m a protective circuit

is always necessary!

When programming the input level to TTL an additional protective circuit is necessary.

We recommend the installation in an metallic

environment.

19

Setup and Operation

Only valid for DC-Versions:

When switching on the device in PNP-Mode, a short signal is applied to inputs

A,B,C and the application input.

To suppress the pulse in TTL-Mode each input has to be connected to a resistor of 10 kOhm/0,125W against 0V.

When switching on the device a short signal is applied to the application output.

This pulse, if needed, is possible to suppress by connecting a resistor of 10

kOhm / 0,225 W against 0 V to the application-output.

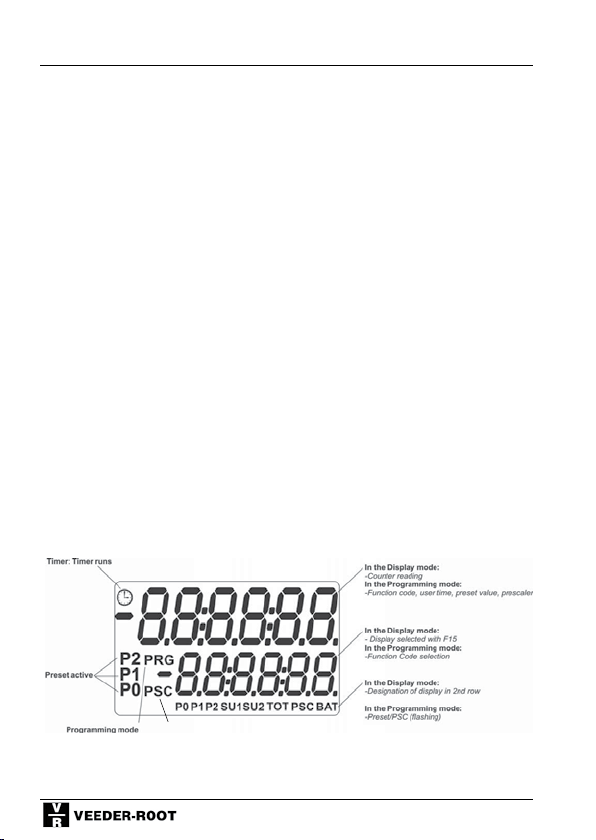

3.3 Display

After switching on, all segments and characters are illuminated for approx. 2

seconds; then the display changes over to the Display or Programming Mode.

The display is available in five different versions:

Reflectiv: black figures on bright reflecting background

Transflective positive: black figures on back lighted ground

Transmissive white: white figures on black ground

Transmissive red: red figures on black ground

Transmissive green: green figures on black ground

Prescaler

20

Setup and Operation

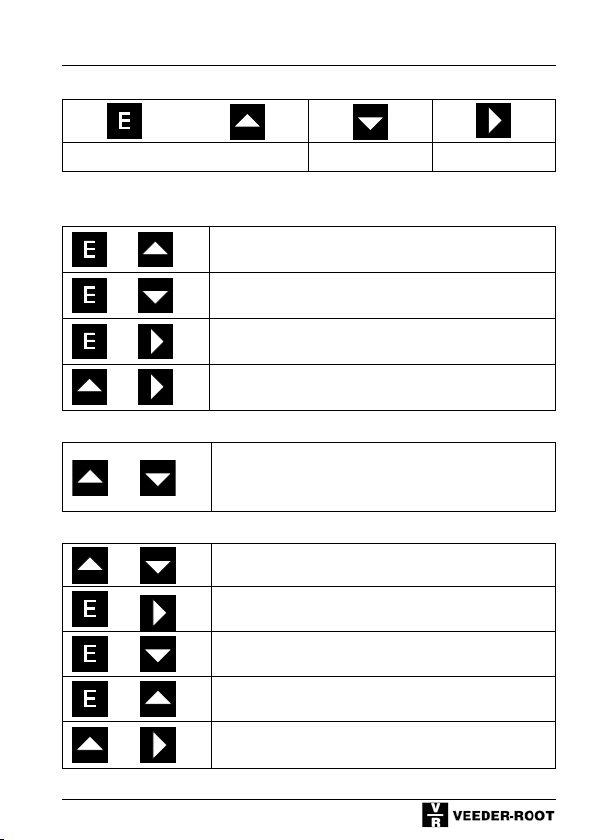

During the Programming of Function Codes

Enter - Key UP - Key Down - Key SHIFT - Key

Programming

If pressed together with POWER ON (keep keys pressed and switch on the device)

+

+

+

+

Selects standard functions

Sets function codes

Selects ID data

(Article code (ID No.), manufacturing date, serial number,...)

Sets User Times

During the Programming of Function Codes

Display of function code

+

Switches between function code text and function code

number

During Operation

+

+

+

+

+

Reset

Sets preset 0

Sets preset 1

Sets preset 2

Sets prescaler

21

Setup and Operation

Additional function for shift and batch counters

Switches between total sum and partial sums and/or

count value and totalizer or batch counter

Additional function for timers

Timer start

(If enabled with function code F15)

Timer stop

(If enabled with function code F15)

Additional function backlight versions

Go to the adjustment menu

(pressing > 5 s)

+

Adjustment of the intensity

(brighter or darker)

Save and going back to display mode

(Pressing within 15 s)

22

Setup and Operation

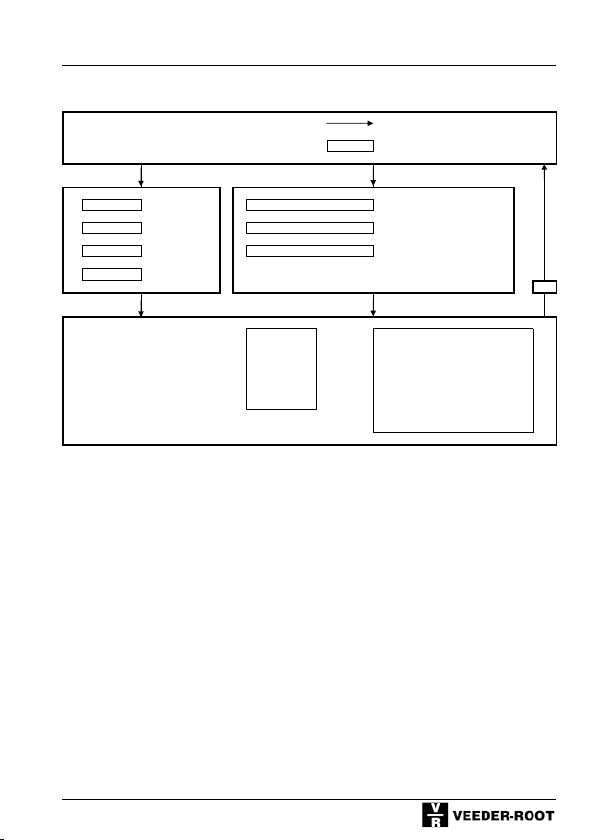

3.5 Overview of Operating Elements

Display Mode Reset

up + shift = Prescaler

123456 up + dn 0

E + up at power on

E + dn at power on

up + shift at power on

semit langiS = 0 teserP = tfihs + E

Programming Mode Standard Funct. Function parameters:

Pulse counter Operat. Mode Count frequency

Tachometer Decimal point Reset Behavior

Shift counter Display-Mode Keylock

Batch counter Output signals npn/pnp selection

Applic. Input/Output

+ many other function parameters

noitcnuf dradnatS = 2 teserP = pu + E

retemaraP noitcnuF = 1 teserP = nd + E

E

yromeM tuptuOedoM-teseR/teSremiT

23

Setup and Operation

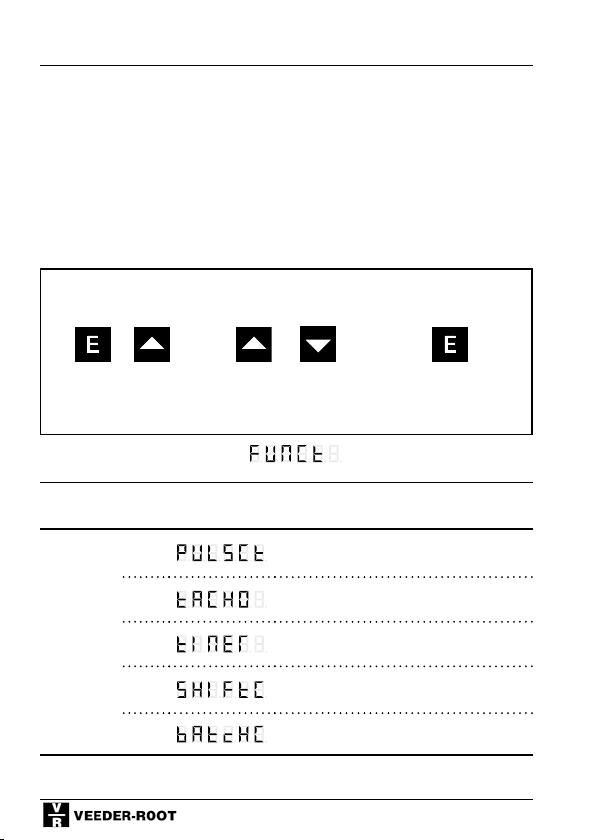

3.6 Programming the Standard Function

The device described here is a multifunctional counter, which can be programmed for a variety of functions, i.e. pulse counter, tachometer, timer, shift

counter or batch counter functions. The first step is to set the standard func-

tion(thefactorysettingofthedeviceisthe“pulsecounter”setting).

Now continue with the programming of the function codes (Chapters 5-9) or

User Times (Chapter 3.10)

Programming mode Change function

+ or

Keep pressed and

switch voltage on

simultaneously

Function code Fn, Display Row 1

Function No.

Setting of

Standard

Function

0*

1

2

3

4

Display

Row 2

setting:

operation

press press

Pulse counter

Tachometer

Timer

Shift Counter

Batch Counter

24

Save, return to counter

Setup and Operation

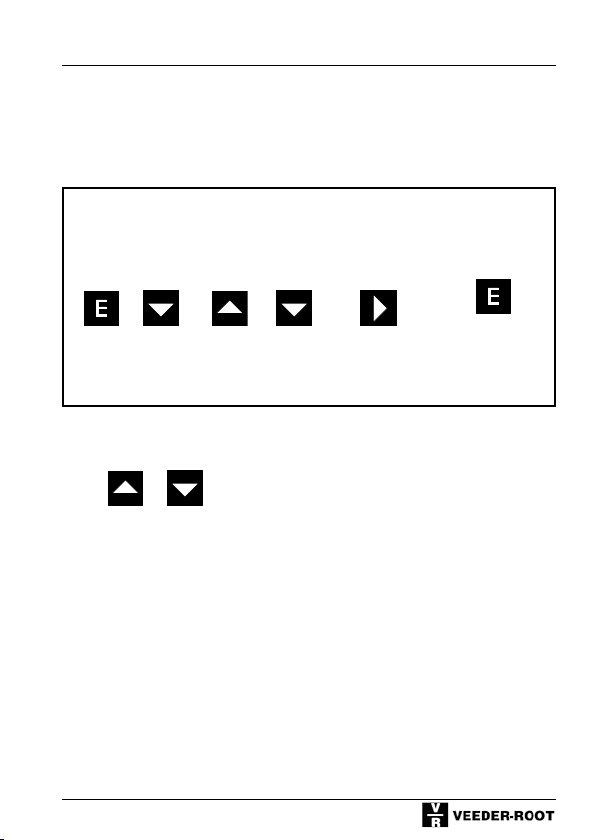

3.7 Programming the Function Codes

The function codes (system parameters) are used to program the function and

behavior of the inputs and outputs, as well as the behavior of the device in its

adjusted basic mode. The detailed selection options are described in Chapters

5 to 9.

Programming

mode

Change function

setting

Save and

change to

next function

code

Save and change

to counter

operation

+ or

Keep pressed and

switch voltage on

simultaneously

press press press

Change between Text Display and Numerical Display

In the function code Programming Mode, the first row shows the name of the

function code in the form of text (7-segment display). The second row shows

the selectable option in a text form, too. By simultaneously pressing the Up

and Down buttons, the display in the first row changes to a numerical display;

after pressing these buttons once again, the display in the second row also

changes to a numerical display. Pressing these buttons for a third time reverts

both rows to the text display again.

+

25

Setup and Operation

Attention: With each change among text and

numeric display, the currently activated function

code will return to the factory setting and may

have to be readjusted.

The factory setting is designated with an asterix *.

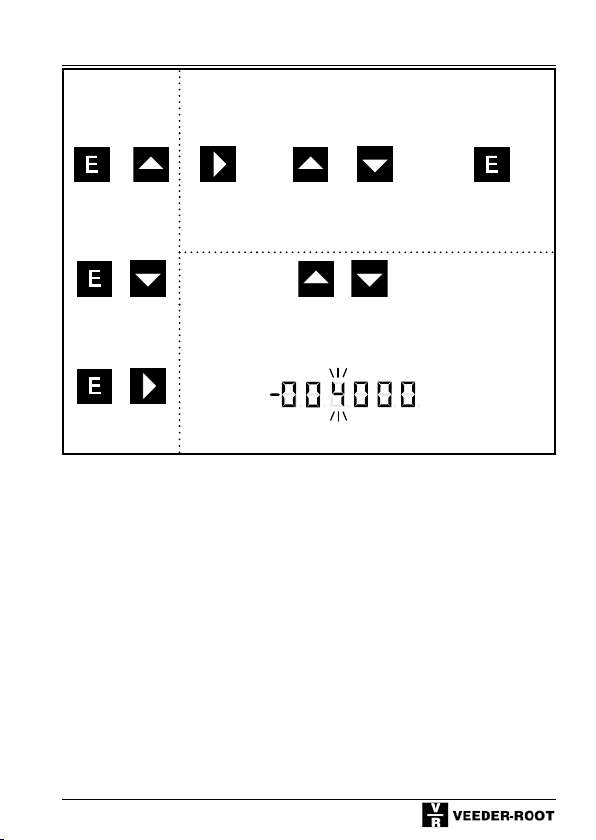

3.8 Programming the Preset Values

By simultaneously pressing the E + Up, E + Down or E + Shift key you can

change to the Preset programming mode:

Use the shift key in the programming mode to change a setting position. The

selected position will start to flash. Use the shift key again to move by one position to the right. Then use the UP or Down key to increment or decrement

the position by 1.

Rule for the 6th position: The change from 9 to 0 or 0 to 9 is indicated by a

changing prefix.

Use the E key to leave the programming mode and return to the display mode.

Your entries will be saved.

On leaving the programming mode, the presets are tested for attainability and

recalculated, if necessary, because not all the values may be attained at a

prescaler value of >1. The presetting is then rounded to the next attainable

value.

If no key is pressed for more than 16 seconds in the programming mode, the

counter will automatically return to the display mode. In this case, however,

no entries will be saved except the last value saved with the E-key.

Set the preset value to 0 by pressing Up and Down keys simultaneously.

26

Setup and Operation

Programming

mode

+ or

Preset 2 press press press

+ +

Preset 1

+

Preset 0

Position

flashes:

Set position: Save and return

display mode

to

Zero in

Set Preset

27

Setup and Operation

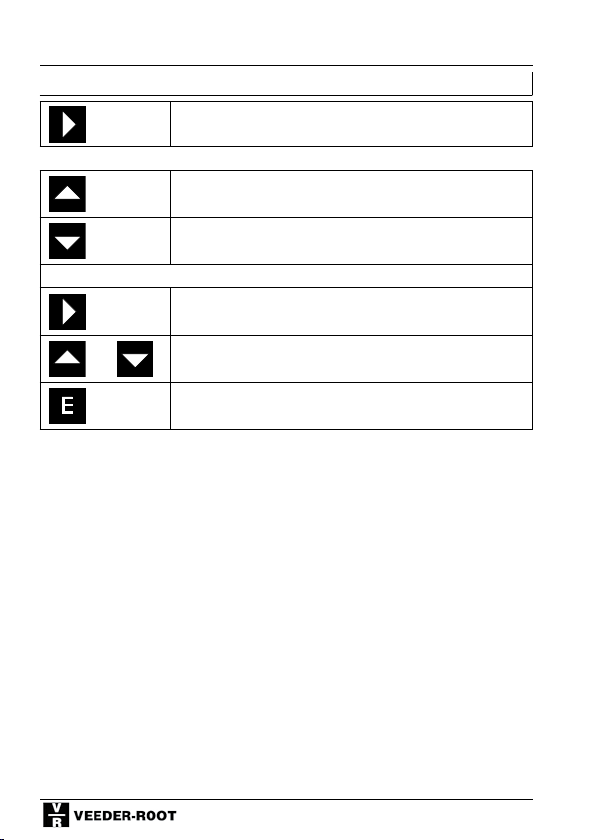

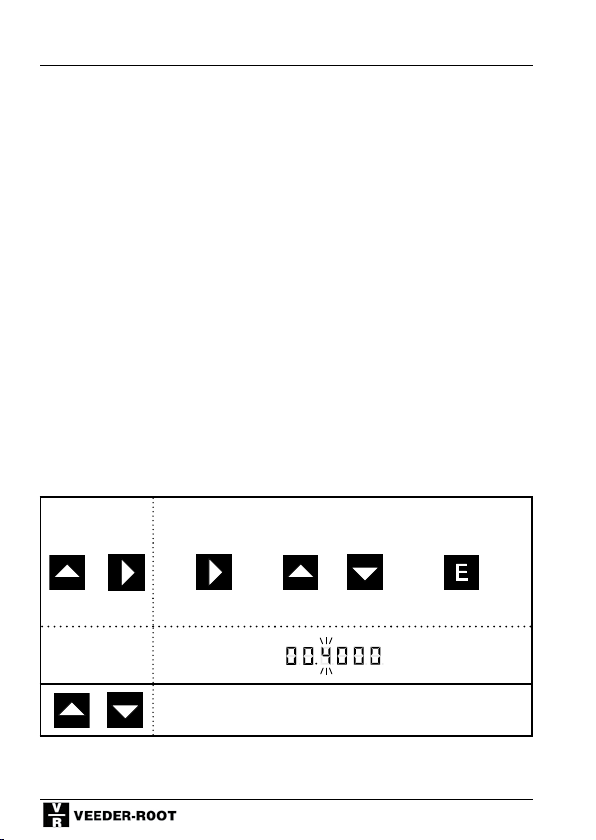

3.9 Prescaler programming

By pressing the Up + Shift keys simultaneously you can change to the Prescaler Programming Mode.

In the Programming mode, the position to be changed is selected by means of

the shift key. The selected position will start flashing. Use the shift key again

to move by one position to the right. Then use the UP or Down key to increment or decrement the position by 1. It is not possible to save a value of

00,0000. In this case the system will save 01,0000.

Use the E key to leave the programming mode and return to the display mode.

Your entries will be saved.

On leaving the programming mode, all the presets are recalculated because

not all the values may be attained with a prescaler value of >1. Therefore, the

presets have to be checked and corrected as necessary after saving the prescaler.

If no key is pressed for more than 16 seconds in the programming mode, the

counter will automatically return to the display mode. In this case, however,

no entries will be saved except the last value saved with the E-key.

Press the Up and Down keys simultaneously to set the prescaler to 01,0000.

Programming

mode

select a position:

(starts flashing)

Set position Save and return to

+ or

press press press press

set to 01,0000

+

28

display mode

Set prescaler

Setup and Operation

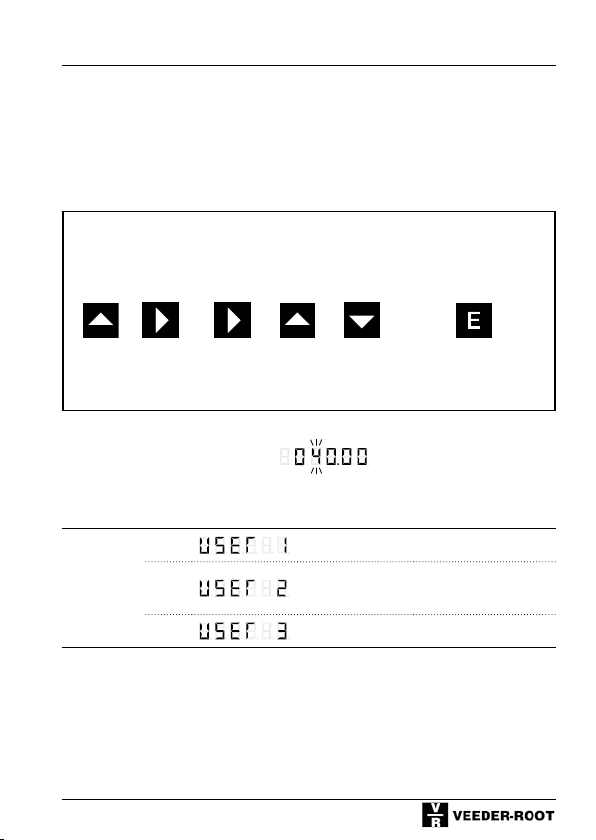

3.10 Programming the user times

For programming the signal time for monostable output signals, 9 fixed signal

times between 0.02 s and 10 s are available. In addition, three different signal

times between 0,01s and 599,99s can be set by the user. The outputs are

deactivated if the setting is 0.00 s.

Programming

mode

Select a

position

+ or

Keep pressed and

switch voltage on

simultaneously

Function code Fn, Display-Row 1

Function No.

Sets the

Signal

Times

0*

1

2

press press press

Display

Row 2

Set position Save and go to the

next user setting; after

user 3, return to dis-

play mode

Signal time 1

Signal time 2

Signal time 3

29

Setup and Operation

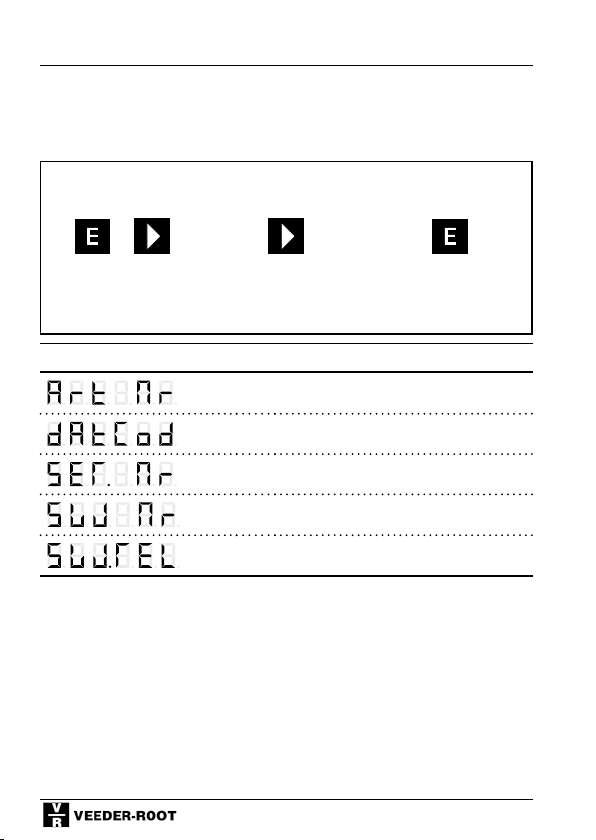

3.11 Output of ID data

This function is used to retrieve ID data, e.g. article numbers and various manufacturing data.

Output mode Change to the next

output

+

Keep pressed and

switch voltage on

simultaneously

Display row 1 Display row 2

press press

Article number

Manufacturing date

Serial number

Software number

Software release

Return to counter ope-

ration

30

Loading...

Loading...