Manual No: 577013-934 ● Revision: E

Site Prep Certification Manual

TLS-450/TLS-450PLUS Consoles

Notice

Veeder-Root makes no warranty of any kind with regard to this publication, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Veeder-Root shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing,

performance, or use of this publication.

Veeder-Root reserves the right to change system options or features, or the information contained in this publication.

This publication contains proprietary information which is protected by copyright. All rights reserved. No part of this publication may be

photocopied, reproduced, or translated to another language without the prior written consent of Veeder-Root.

Contact TLS Systems Technical Support for additional troubleshooting information at 800-323-1799.

DAMAGE CLAIMS / LOST EQUIPMENT

Thoroughly examine all components and units as soon as they are received. If any cartons are damaged or missing, write a complete

and detailed description of the damage or shortage on the face of the freight bill. The carrier's agent must verify the inspection and sign

the description. Refuse only the damaged product, not the entire shipment.

Veeder-Root must be notified of any damages and/or shortages within 30 days of receipt of the shipment, as stated in our Terms and

Conditions.

VEEDER-ROOT’S PREFERRED CARRIER

1. Contact Veeder-Root Customer Service at 800-873-3313 with the specific part numbers and quantities that were missing or

received damaged.

2. Fax signed Bill of Lading (BOL) to Veeder-Root Customer Service at 800-234-5350.

3. Veeder-Root will file the claim with the carrier and replace the damaged/missing product at no charge to the customer. Customer

Service will work with production facility to have the replacement product shipped as soon as possible.

CUSTOMER’S PREFERRED CARRIER

1. It is the customer’s responsibility to file a claim with their carrier.

2. Customer may submit a replacement purchase order. Customer is responsible for all charges and freight associated with

replacement order. Customer Service will work with production facility to have the replacement product shipped as soon as

possible.

3. If “lost” equipment is delivered at a later date and is not needed, Veeder-Root will allow a Return to Stock without a restocking fee.

4. Veeder-Root will NOT be responsible for any compensation when a customer chooses their own carrier.

RETURN SHIPPING

For the parts return procedure, please follow the appropriate instructions in the "General Returned Goods Policy” pages in the

"Policies and Literature" section of the Veeder-Root North American Environmental Products price list. Veeder-Root will not accept

any return product without a Return Goods Authorization (RGA) number clearly printed on the outside of the package.

©Veeder-Root 2014. All rights reserved

.

ii

Table of Contents

Introduction

Related Documents ..........................................................................................................1

Documents Required to Install Equipment ...............................................................1

Safety Precautions ............................................................................................................1

National Electrical Code Compliance ................................................................................2

Probe- and Sensor-to-Console Wiring......................................................................2

Power Wiring ............................................................................................................2

Console Installation

Locating the Console ........................................................................................................3

Mounting the Console .......................................................................................................3

Wiring the Console ...........................................................................................................5

Special Mag Probe Installation Kits

AST Installation Kit ...........................................................................................................6

Vapor Extraction Riser Kit W/ Coupling Adapter ...............................................................7

Vapor Extraction Riser Kit W/O Coupling Adapter ............................................................8

Riser Cap Kit for Mag Probe Installations .........................................................................9

Cap and Cord Grip Kit ..............................................................................................9

Metal Cap and Ring Kit.............................................................................................9

Mag Probe Installation

UST/AST Tank - Dedicated Riser ...................................................................................11

UST Riser Cap Attachment ....................................................................................11

AST Riser Cap Attachment ....................................................................................13

UST Installation - Vapor Extractor Riser W/ Coupling Adapter .......................................13

UST Installation - Vapor Extractor Riser W/O Coupling Adapter ....................................15

Probe and Sensor Conduit Installation

Wiring Run Methods .......................................................................................................17

Buried Rigid Conduit...............................................................................................17

Direct Burial Cable..................................................................................................18

Wiring Module Bay Devices

I/O Module Wiring ...........................................................................................................19

MDIM Module Wiring ......................................................................................................20

LVDIM Module Wiring .....................................................................................................21

iii

Figures

Table of Contents

Figure 1. TLS-450/TLS-450PLUS Consoles Dimensions and

Designated Conduit Knockouts ..............................................................4

Figure 2. Wiring AC Power to the TLS-450/TLS-450PLUS Consoles ...................5

Figure 3. Mag Probe AST Installation Kit ...............................................................6

Figure 4. Mag Probe vapor extractor w/coupling adapter installation kit ...............7

Figure 5. Mag Probe vapor extractor w/o coupling adapter installation kit ............8

Figure 6. Cap and Cord Grip Kit ............................................................................9

Figure 7. Metal Cap and Ring Kit .........................................................................10

Figure 8. Modifying an existing metal riser cap ....................................................10

Figure 9. UST probe installation - dedicated riser ................................................11

Figure 10. AST probe installation - dedicated riser ................................................12

Figure 11. Installing a riser adapter beneath the metal cap and adapter ring ...........12

Figure 12. Vapor extractor cabling entry ................................................................13

Figure 13. Mag probe vapor extractor riser installation - w/ coupling adapter...........15

Figure 14. Mag probe vapor extractor riser installation - w/o coupling adapter.........16

Figure 15. Example Probe Wiring Run in Buried Rigid Conduit .............................17

Figure 16. Example Probe Wiring Run via Direct Burial Cable ..............................18

Figure 17. I/O Relay Module Connections .............................................................19

Figure 18. MDIM Module Pulser Connections .......................................................20

Figure 19. LVDIM Module POS/Pulser Connections .............................................21

Tables

Table 1. Mag Probe AST Installation Kit - Part No. 312020-984 .............................6

Table 2. Vapor Extraction Riser Kit (w/ coupling adapter)

- Part No. 846500-001 ...............................................................................7

Table 3. Vapor Extraction Riser Kit (W/O Coupling Adapter)

- Part No. 846500-002 ...............................................................................8

Table 4.- Cap and cord grip kit - Part No. 330020-282 .............................................9

Table 5.- Metal cap and ring kit - Part No. 312020-952 ............................................9

iv

Introduction

OFF

This manual assumes that you are installing the console in a new site (before pavement is put down and with no

wiring runs in place). Among the topics covered are:

• Site layout considerations.

• Installing the console and connecting wiring from the AC power panel.

• Probe installation procedures.

• Sensor installation procedures.

• Installing wiring conduit between the console and the probes and sensors.

• Probe and sensor field junction box wiring diagrams.

• Attaching sensor wiring to the console.

Related Documents

DOCUMENTS REQUIRED TO INSTALL EQUIPMENT

This equipment must be installed according to the applicable installation document:

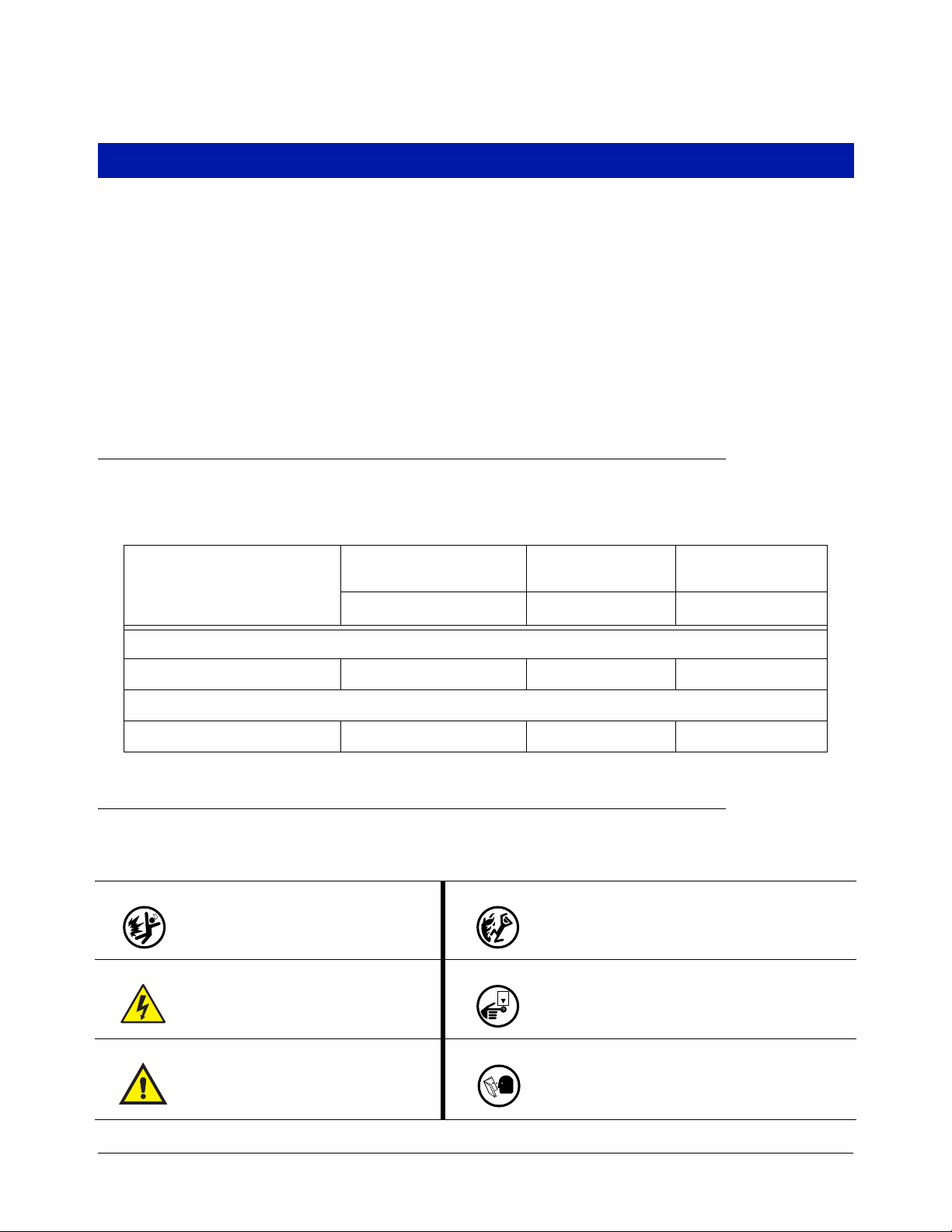

Equipment

ATEX

Descriptive System

Document No. Document No. Document No.

IECEx

Descriptive System

UL/cUL

Control Drawing

Associated Apparatus

TLS-450/TLS-450PLUS 331940-006 331940-106 331940-008

Intrinsically Safe Apparatus for Wireless Applications

Tank Gauge Accessories 331940-005 331940-105 331940-012

Safety Precautions

The following safety symbols may be used throughout this manual to alert you to important safety hazards and

precautions.

EXPLOSIVE

Fuels and their vapors are extremely

explosive if ignited.

ELECTRICITY

High voltage exists in, and is supplied to,

the device. A potential shock hazard

exists.

FLAMMABLE

Fuels and their vapors are extremely flammable.

TURN ELECTICAL POWER OFF

Live power to a device creates a potential shock

hazard. Turn Off electrical power to the device and

associated accessories when servicing the unit.

WAR N ING

Heed the adjacent instructions to avoid

damage to equipment, property, environment or personal injury.

1

READ ALL RELATED MANUALS

Knowledge of all related procedures before you

begin work is important. Read and understand all

manuals thoroughly. If you do not understand a procedure, ask someone who does.

Introduction National Electrical Code Compliance

National Electrical Code Compliance

The following information is for general reference and is not intended to replace recommended National Electric

Code (NEC) procedures. It is important for the installer to understand that electrical equipment and wiring located

in Class I, Division 1 and 2 installations shall comply with the latest appropriate Articles found in the National

Electric Code (NFPA 70), the Automotive and Marine Service Station Code (NFPA 30A), CEC codes and all

applicable local codes.

PROBE- AND SENSOR-TO-CONSOLE WIRING

Wire Type

To ensure the best operating systems available, Veeder-Root REQUIRES the use of shielded cable for all probes

and sensors regardless of conduit material or application. In these installations, shielded cable must be rated less

than 100 picofarad per foot and be manufactured with a material suitable for the environment, such as Carol™

C2534 or Belden™ 88760, 8760, 8770 or similar.

Note: Throughout this manual, when mentioning any cable or wire being used for probe and sensor to console

wiring, it will be referring to shielded cable.

Wire Length

Improper system operation could result in undetected potential environmental and health hazards if the probe- or

sensor-to-console wire runs exceed 1000 feet. Wire runs must be less than 1000 feet to meet intrinsic safety

requirements.

Wire Gauges - Color coded

Shielded cable must be used in all installations. Sensor-to-console wires should be #14-#18 AWG stranded

copper wire and installed as Class 2 circuits. As an alternate method when approved by the local authority having

jurisdiction, #22 AWG wire such as Belden 88761 may be suitable in installations with the following provisions:

• Wire run is less than 750 feet

• Capacitance does not exceed 100 pF/foot

• Inductance does not exceed 0.2 H/foot

POWER WIRING

Wires carrying 120 or 240 Vac from the power panel to the console should be #14 AWG (or larger) copper wire

for line, neutral and chassis ground (3); and #12 AWG copper wire for barrier ground.

2

Console Installation

Locating the Console

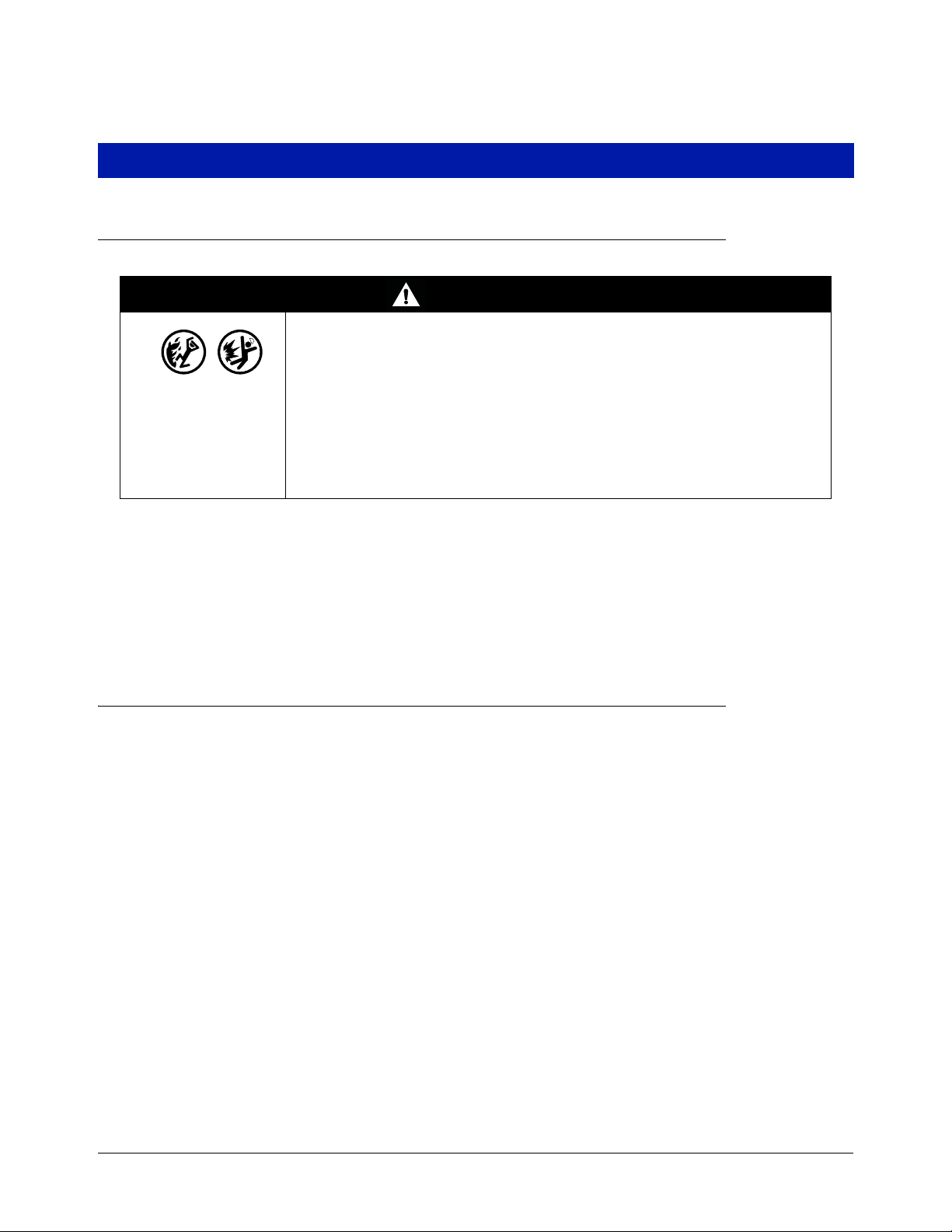

WARNI NG

FAILURE TO COMPLY WITH THE FOLLOWING WARNINGS AND SAFETY

PRECAUTIONS COULD CAUSE DAMAGE TO PROPERTY, ENVIRONMENT,

RESULTING IN SERIOUS INJURY OR DEATH.

Explosive vapors or flammable liquids could be present near locations where

fuels are stored or being dispensed.

This console is not explosion proof. Do not install this console in a volatile,

combustible, or explosive atmosphere.

An explosion or fire resulting in serious injury or death, property loss and

equipment damage could occur if the console is installed in a volatile,

combustible or explosive atmosphere (Class I, Division 1 or 2).

Select a mounting location on the inside of any building. The console must be protected from severe vibration,

extremes in temperature and humidity, rain, and other conditions that could harm computerized electronic

equipment. The console’s operating temperature range is 32 to 104°F (0 to 40°C), and its storage temperature

range is -40 to +162°F (-40 to +74°C).

The mounting surface should be strong enough to support the console’s weight which could be approximately 35

pounds with a full complement of modules. You should also consider wall space for routing the power wiring

conduits and probe and sensor wiring conduits that must be connected to the console.

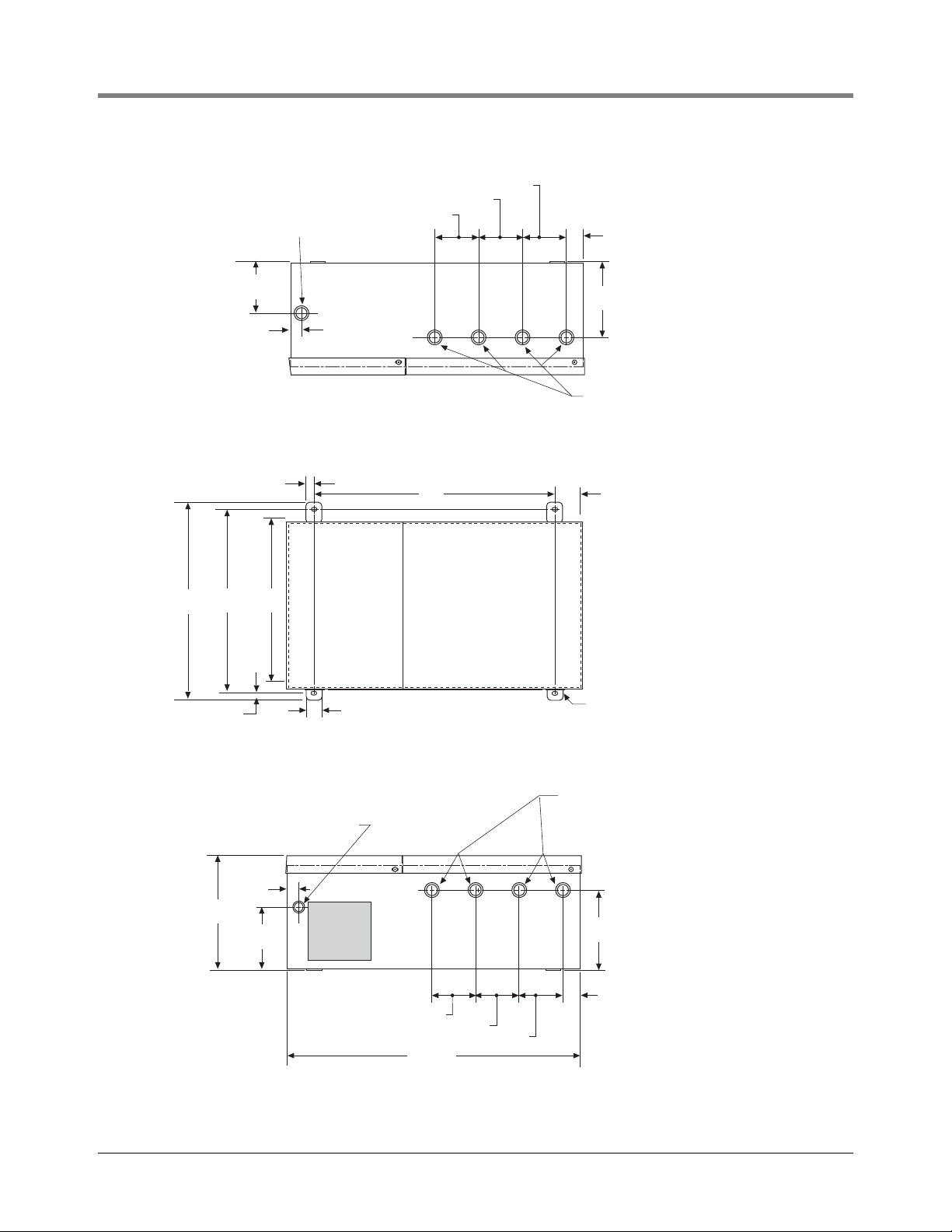

Mounting the Console

Install the console fastening devices to the mounting surface using the hole pattern shown in Figure 1. Up to 1/4”

diameter screws may be used.

Mount the console to the mounting surface using the four mounting flanges on the back of the unit. Install metal

conduit between the console and the power panel. Figure 1 shows the two designated knockouts through which

power wiring can safely enter the console.

3

Console Installation Mounting the Console

Conduit entry for

console power

3/4, 1 I.P.S. knockouts

4-5/8''

0.65''

1/2'' TYP.

11''13''

12''

3-1/8''

3-1/8''

3-1/8''

1"

5.925''

Conduit entries to Module bay

TOP VIEW

3/4, 1 I.P.S. knockouts

(typ. 4 places)

16'' 1-1/8" Typ.

1/2'' TYP.

1'' TYP.

Mounting flanges w/ 1/4'' x 3/8''

slotted hole - typ 4 places

FRONT VIEW

Conduit entry for console power

0.540", 1/2 I.P.S. knockouts

Conduit entries to Module bay

3/4, 1 I.P.S. knockouts

(typ. 4 places)

0.65''

8-7/8''

4-5/8''

3-1/8''

3-1/8''

3-1/8''

5.925''

1-7/16''

18.35''

BOTTOM VIEW

Figure 1. TLS-450/TLS-450PLUS Consoles Dimensions and Designated Conduit Knockouts

tlsng\dim.eps

4

Loading...

Loading...