Page 1

IMPORTANT WARRANTY INFORMATION! PLEASE READ

Return Policy on Kits When Not Purchased Directly From Vectronics: Before continuing any

further with your VEC kit check with your Dealer about their return policy. If your Dealer

allows returns, your kit must be returned

Return Policy on Kits When Purchased Directly From Vectronics: Your VEC kit may be

returned to the factory

once you begin installing and sold ering parts, you es sentia lly take over the role of th e device's

manufacturer. From this p oint on, neith er Vect ronics nor its d ealers can reas onab ly be h eld

accountable for the quality or the outcome of your work. Because of this, Vectronics cannot

accept return of any kit-in-progress or completed work as a warranty item for any reason

whatsoever. If you are a new or inexperienced kit builder, we urge you to read the

manual carefully and determine whether or not you're ready to take on the job. If you

wish to change your mind and return your kit, you may--but you must do it

construction, and within ten (10) working days of the time it arrives.

Vectronics Warrants: You r kit c ontains each it em sp ecifi ed in th e parts list.

Missing Parts: If you determine, during your pre-construction inventory, that any part is

missing, please contact Vectronics and we'll send the missing item to you free of charge.

However,

the marking on one of the other items provided with the kit. Also, make certain an alternative

part hasn't been substituted for the i tem you're missin g. If a sp ecific part is n o longer available,

or if Engineering has d etermined that an alternative component is more suitable, Vectroni cs

reserves the right to make substitutions at any time. In most cases, these changes will be

clearly noted in an addendum to th e manual.

Defective Parts: Today's electronic part s are physically and electrica lly resilient, and def ective

components are rare. However, if you discover an it em during your pre-c onstruction in ventory

that's obviously broken or unserviceable, we'll rep lace it. Just return th e part to Vectronics at

the address below accompanied with an explanation. Upon rec eipt, we'll test it. If it's defectiv e

and appears unused, we'll ship you a new one right away at no charge.

before you

in its pre-assembled condition only.

contact Vectronics,

before you

please look ca refu lly

begin construction.

The reason for this st ipulation i s,

before you

to confirm you haven't misread

begin

Missing or Defective Parts After You Begin Assembly: Parts and materials lost or damaged

after construction begins

supplied with VEC kits are relatively inexpensive and Vectronics can replace them for a

reasonable charge. Simp ly c ontact t he factory with a complet e d esc ription. We'll p roces s you r

order quickly and get you back on track.

Factory Repair After You Begin Assembly:

specifically excluded from coverage by the Vectronics warranty.

service to customers, t echnic ian s a re a vailab le t o eva luate and r epai r malfunct ionin g kits f or a

minimum service fee of 518.00 (1/2 hour rate) plus 57.00 shipping and handling (prices subject

to change). To qualify for repair service, your kit must be fully completed, unmodified, and the

printed circuit board assembled using rosin-core solder. 1n the event your repair will require

more than an hour to fix (or 536.00, subj ect to chan ge), ou r t echnicians will c ontact you in

advance by telephone before performing the work. Defective units should be shipped prepaid

Vectronics

1007 HWY 25 South

Starkville, MS 39759

When shipping, pack your kit well and include the minimum payment plus shipping and

handling charges (525.00 tota l). No work can b e perfo rmed with out p re-p ayment. Also, p r ovide

a valid UPS return address and a day time phone number where you may be reached.

are not covered und er the t er ms of thi s war rant y. Ho wever, most pa rts

Kits-in progress and completed kits are

However, as a

Page 2

-

g

Single Side-Band Filter Kit

INTRODUCTION

Thank you for purchasing the VEC-830K Single Side-Band Filter kit. The

VEC-830K is a four stage, switch selectable filter, that will make "cleaning

up" Single Side-Band signals effortless and easy. With the VEC-830K you

bring up any hard to he ar signa l o ut o f a " band p ile up ," fo r ea sy liste ni ng, o r

get rid of unwanted , anno ying signals. The VEC-830 K a lso fe atur e s a

headphone output that will allow the use of standard mono headphones.

Although small in size, the VEC-830K is high on performance and reliability.

Powered from a 9volt transistor batten', the VEC-830K will provide you with

many hours of use.

TOOLS AND SUPPLIES

Construction Area: Kit construction requires a clean, smooth, and welllighted

area where you can easily organize and handle small parts without losing them.

An inexpensive sheet of white poster board makes an excellent construction

surface, while providing protection for the underlying table or desk. Welldiffused overhead lighting is a plus, and a supplemental high intensity desk

lamp will prove especially helpful for close-up work. Safety is an important

consideration. Be sure to use a suitable high-temperature stand for your

soldering iron, and keep the work area free of combustible clutter.

Universal Kit-buil di ng T o o ls: Altho ugh your pa rt icul ar kit ma y req uir e

additional items to complete, virtually all construction projects require a work

area outfitted with the followin

tools and supplies:

Page 3

VEC-830K Instruction Manual Single Side-Band Filter Kit

BEFORE YOU START BUILDING

Experience shows there are jour

and your kit will probably work on the first try! Here's what they are:

1. Installing the Wrong Part: It always pays to double-check each step. A 1K

and a 10K resistor may look

differently in an electronic circuit! Same for capacitors--a device marked

102 (or .001 uF) may have very different operating characteristics from one

marked 103 (or .01uF).

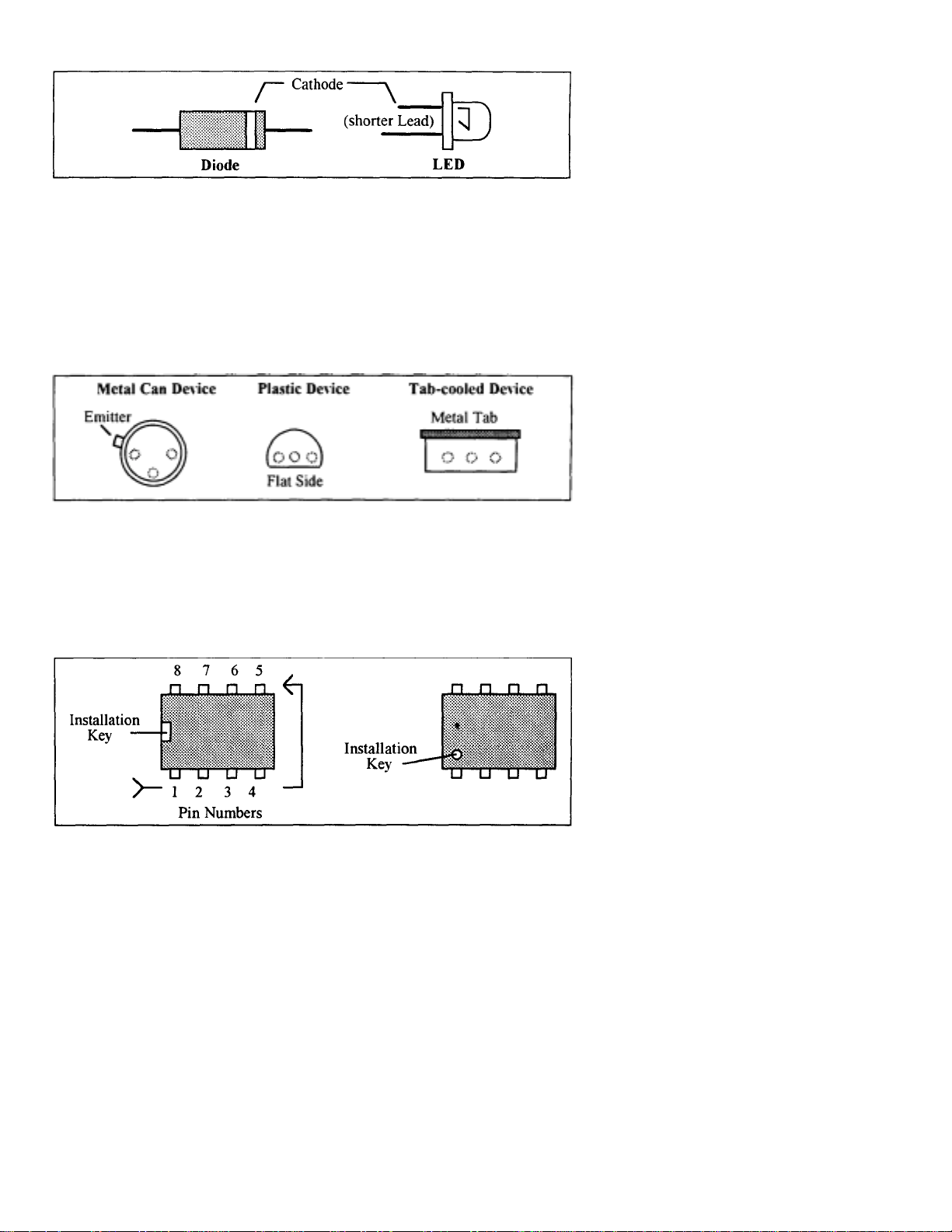

2. Installing Parts Backwards: Always check the polarity of electrolytic

capacitors to make sure the positive (+) lead goes in the (+) hole on the

circuit board. Transistors have a flat side or emitter tab to help you identify

the correct mounting position. ICs have a notch or dot at one end indicating

the correct direction of insertion. Diodes have a banded end indicating

correct polarity. Always double-check--especially before applying power to

the circuit!

3. Faulty Solder Connections: Inspect for cold-solder joints and solder

bridges. Cold solder joints happen when you don't fully heat the

connection--or when metallic corrosion and oxide contaminate a

component lead or pad. Solder bridges form when a trail of excess solder

shorts pads or tracks together (see Soldering Tips below).

common mistakes

almost

the same, but they may act very

builders make. Avoid these,

4.

Omitting or Misreading a Part: This is easier to do than you might think!

Always double-check to make sure you completed each step in an assembly

Soldering Tips:

Cleanliness

soldering. Before you install and solder each part, inspect leads or pins for

oxidation. If the metal surface is dull, sand with fine emery paper until shiny.

Also, clean the oxidation and excess solder from the soldering iron tip to

ensure maximum heat transfer. Allow the tip of your iron to contact both the

lead and pad for about one second (count "one-thousand-one") before feeding

solder to the connection. Surfaces must become hot enough for solder to flow

smoothly.

will wick around the lead toward the tip, wetting all exposed surfaces. Apply

solder sparingly, and do not touch solder directly to the hot iron tip to promote

rapid melting.

and good

Feed solder to the opposite side of the lead from your iron tip--solder

heat distribution

are the two secrets of professional

Page 4

VEC-830K Instruction Afanual Single Side-Band Filter

Desoldering Tips:

If you make a mistake and need to remove a part, follow these instructions

carefully! First, grasp the component with a pair of hemostats or needle-nose

pliers. Heat the pad beneath the lead you intend to extract, and pull gently. The

lead should come out. Repeat for the other lead. Solder may fill in behind the

lead as you extract it--especially if you are working on a double-sided board

with plate-through holes. Should this happen, try heating t he pad agai n and

inserting a common pin into the hole. Solder won't stick to the pin's chromium

plating. When the pad cools, remove the pin and insert the correct component.

For ICs or multi-pin parts, use desoldering braid to remove excess solder before

attempting to extract the part. Alternatively, a low-cost vacuum-bulb or springloaded solder sucker may be used. Parts damaged or severely overheated during

extraction should be replaced rather than reinstalled.

Work Habits:

Kit construction requires the ability to follow detailed instructions and, in many

cases, to perform new and unfamiliar tasks. To avoid making needless mistakes,

work for short periods when you're fresh and alert. Recreational construction

projects a re more informative and more fun when you take your time. Enjoy!

Sorting and Reading Resistors:

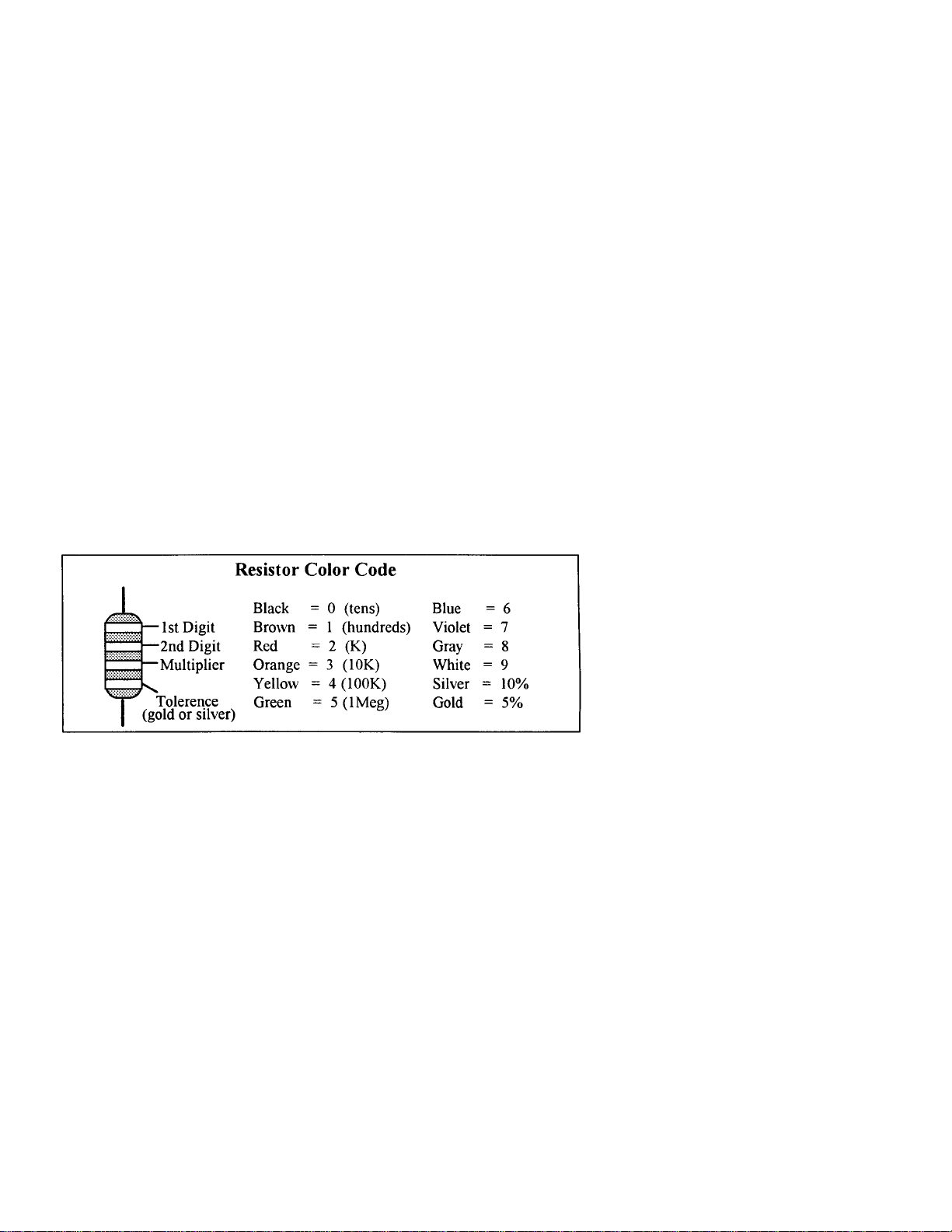

The electrical value of resistors is indicated by a color code (shown below). You

don't have to memorize this code to work with resistors, but you do need to

understand how it works:

When you look at a resistor, check its multiplier code first. Any resi stor with a

black multiplier band falls between 10 and 99 ohms in value. Bro wn designates a

value between 100 and 999 ohms. Red indicates a value from 1000 to 9999

ohms, which is also expressed as 1.0K to 9.9 K. An orange multiplier band

designates 10K to 99K, etc. To sort and inventory resistors, first separate them

into groups by multiplier band (make a pile of 10s, 100s, Ks,

Page 5

VEC-83 OK Instruction Manual Single Side-Band Filter

,

I0Ks, etc.). Next, sort each group by specific value (1K, 2.2K, 4.7K. etc.). This

procedure makes the inventory easier, and also makes locating specific parts

more convenient later on during construction. Some builders find it especially

helpful to arrange resistors in ascending order along a strip of double-sided tape.

Some VEC kits may contain molded chokes which appear, at first glance, similar

to resistors in both shape and band marking. However, a closer look will enable

you to differentiate between the two--chokes are generally larger in diameter and

fatter at the ends than resistors. When doing your inventory, separate out any

chokes and consult the parts list for specific color-code information.

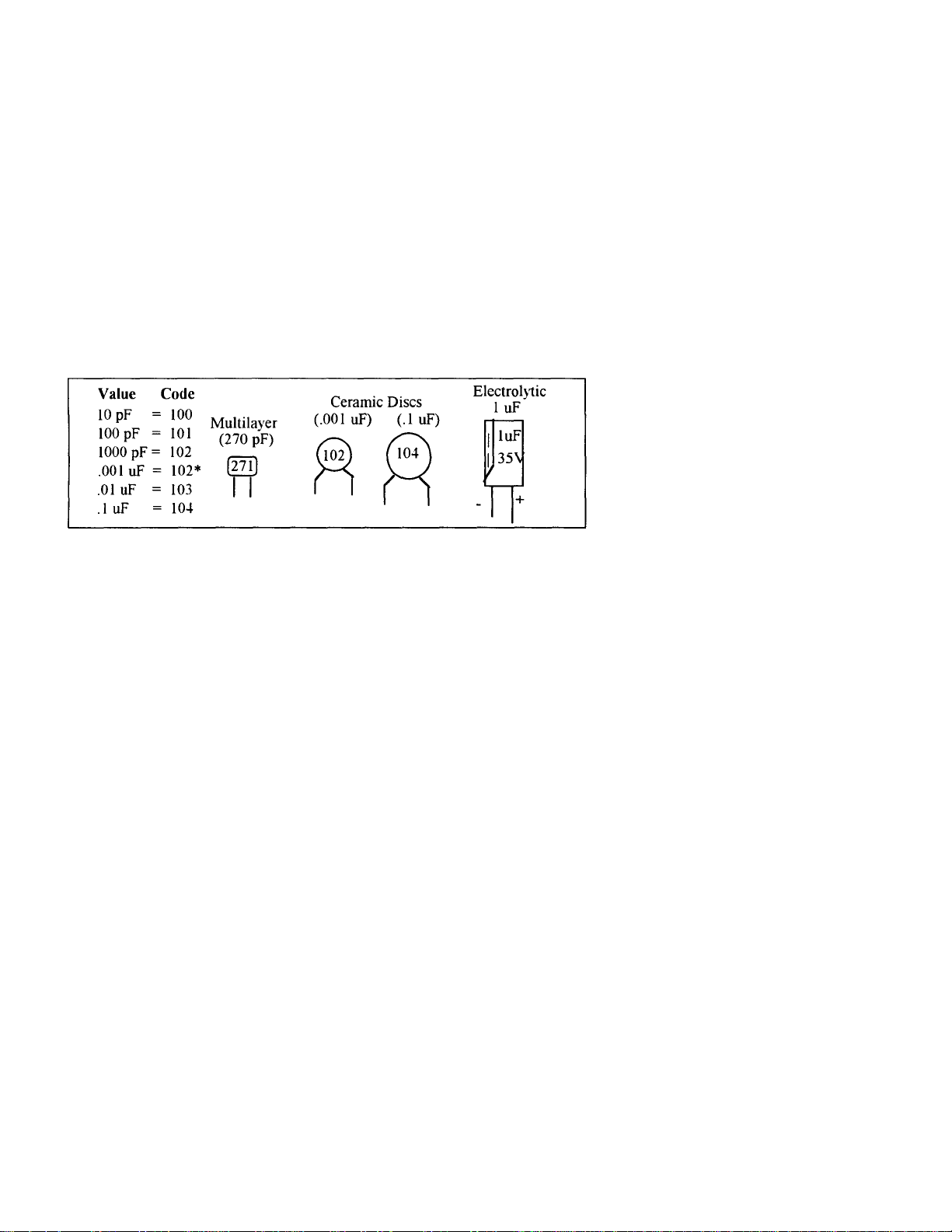

Reading Capacitors:

Unlike resistors, capacitors no longer use a color code for value

Instead

the value, or a 3-number code, is printed on the body.

As with resistors, it's helpful to sort capacitors by type, and then to arrange them

in ascending order of value. Small-value capacitors are characterized in pF (or

pico-Farads), while larger values are labeled in uF (or micro-Farads). The

transition from pF to uF occurs at 1000 pF (or .001 uF)*. Today, most

monolithic and disc-ceramic capacitors are marked with a three-number code.

The first two digits indicate a numerical value, while the last digit indicates a

multiplier (same as resistors).

Electrolytic capacitors are always marked in uF. Electrolytics are polarized

devices and must be oriented correctly during installation. If you become

confused by markings on the case, remember the uncut negative lead is slightly

shorter than the positive lead.

Diodes:

Diodes are also polarized devices that must be installed correctly. Always look

for the banded or cathode end when installing, and follow instructions carefully.

Page 6

C-830K Instruction Manual Sin

g

g

VE

Transistors:

If transistors are installed incorrectly, damage may result when power is applied.

Transistors in metal cases have a small tab near the emitter lead to identify

correct positioning. Semiconductors housed in small plastic cases (TO-92) have

an easily-identified flat side to identify mounting orientation. Many specialized

diodes and low-current voltage regulators also use this type packaging. Larger

plastic transistors and voltage regulators use a case backed with a prominent

metal tab to dissipate heat (T-220). Here orientation is indicated by the

nositionine of the colling tab.

le Side-Band Filter Kit

Inte

rated Circuits:

Proper IC positioning is indicated by a dot or square marking located on one end

of the device. A corresponding mark will be silk-screened on the PC board and

printed on the kit's parts-placement diagram. To identify specific IC pin numbers

for testing purposes, see the diagram below. Pin numbers always start at the

keyed end of the case and progress counter-clockwise around the device, as

shown:

Page 7

EC-830K Instr uction Manual Single Side-Band Filter Kit

g

PARTS LIST

Your kit should contain all of the parts listed below. Please go through the parts

bag to identify and inventory each item on the checklist before you start b uilding.

If any parts are missing or damaged, refer to the warranty section of this manual

for replacement instructions. If you can't positively identify an unfamiliar

item in the bag on the basis of the information given, set it aside u ntil all other

items are checked off. You may then be able to identify it by process of

elimination. Finally, your kit will go together more s moot hl y if parts ar e

organized by type and arranged by value ahead of time. Us e this inve nt ory as an

opportunity to sort and arrange parts so you can identify and find them quickly.

2 100K ohm resistor (brown-black-yellow-gold) R2,R3

2 150K ohm resistor (brown-green-yellow-gold) R4,R5

2 240K ohm resistor (red-yellow-yellow-gold) R6,R7

1 300K ohm resistor (orange-black-yellow-gold) R1

2 1.2M ohm resistor (brown-red-green-gold) R8,R9

5 1000 pF ploysterene capacitor (1000J)

3 470pF ploysterene capacitor (470J) C6,C7,C8

1 10 uF electrolytic capacitor (IOuf) C9

2 LM747 Op Amp IC Ul, U2

2 14-Pin Low Profile IC Socket For U1, U2

1 4P 4T Slide Switch SW1

8 6" insulated wires Circuit wiring

2 4-40 x 1/4" Phillips Machine Screws

1 9-volt battery snap; 8" GND, VCC

1Sin

1 I nstruction Manual

le Sided PC board VEC-830K

C1,C2,C3,C4,C

Page 8

VEC-830K Instruction Manual Single Side-Band Filter Kit

PARTS PLACEMENT DIAGRAM

Figure 1

Page 9

VEC-830K Instruction manual S ingle Side-Band Filter

y

g

p

y

p

g

g

-

-

Before assembling your kit, please take time to read and understand the VEC kit

warranty pr i nted on the inside cover of this manual. Also, r ead through t he

assembly instructions to make sure the kit does not exceed your skill level. Once

you begin constructio n, your kit will be non-returnable. Finally, if you haven't

already done so, please verify that all parts listed in the inventory are included.

If anything is missing or broken, refer to the warranty instructions for

replacing missing or damaged parts.

Note that part designators, such as R1, C3, etc., appear on a silk-screened legend

on the component-mounting side of the printed circuit board. This corresponds

with the parts placement page in the manual. All parts will be inserted on the

silk-screen side of the board.

If you have last-minute questions about what you need to build your kit, please

refer back to the section titled "Tools and Supplies". If you're ready to begin

now, here we go! The directions use two sets of check boxes. Check one when a

step is complete and use the other for double-checking your work before

operation.

1. Locate resistor R1. This is a 300K ohm resistor (orange-blackellow-gold).

Carefully bend the leads close to the resistor body to form right-angles (see

followin

diagram).

2. Insert R1 into its mounting holes so the resistor body rests against the board.

Solder in

3. Locate resistor R2. This is a 100K ohm resistor (brown-blackellow-gold).

Insert R2 into its mounting holes so the resistor body rests against the board.

4.

Solder in

5. Locate resistor R3. This is a 100K ohm resistor (brown-blackyellowold).

6. Locate resistor R4. This is a 150K ohm resistor (brown-greenyellowold).

lace and trim the leads.

lace and trim the leads.

Page 10

VEC-830K Instruction Manual Single Side-Band Filter

p

p

g

g

p

p

p

,

7. Insert R4 into its mounting holes so the resistor body rests against the

board. Solder in

8. Locate resistor R5. This is a 150K ohm resistor (brown-green-yellowgold).

9. Insert R5 into its mounting holes so the resistor body rests against the

board. Solder in

10. Locate resistor R6. This is a 240K ohm resistor (red-yellow-vellowold).

11. Insert R6 into its mounting holes so the resistor body rests against the

board. Solder in place and trim the leads.

12. Locate resistor R7. This is a 240K ohm resistor (red-yellow-yellowold).

13. Insert R7 into its mounting holes so the resistor body rests against the

board. Solder in place and trim the leads.

14. Locate resistor R8. This is a 1.2M ohm resistor (brown-red-greengold).

15. Insert R8 into its mounting holes so the resistor body rests against the

board. Solder in

lace and trim the leads.

lace and trim the leads.

lace and trim the leads.

16. Locate resistor R9. This is a 1.2M ohm resistor (brown-red-greengold).

17. Insert R9 into its mounting holes so the resistor body rests against the

board. Solder in

18. Locate capacitor Cl (1000pF). This is a polystyrene capacitor and will

be marked "10001" (actual value in pF). Carefully install C1, solder

in

lace, and trim the leads.

19. Locate capacitor C2 (1000pF). This is another polystyrene capacitor

and will be marked "10001" (actual value in pF). Carefully install C2

in the same manner as C1, solder in place, and trim the leads.

20. Locate capacitor C3 (1000pF). This is another polystyrene capacitor

and will be marked "10001" (actual value in pF). Carefully install C3

in the same manner as C2

lace and trim the leads.

solder in place, and trim the leads.

Page 11

VEC-830K Instruction Manual Single Side-Band Filter Kit

,

(4)

p

p

p

21.

Locate capacitor C4

and will be marked

the same manner as

22.

Locate capacitor C5

and will be marked

the same manner as

23.

Locate capacitor C6

be marked

manner as C5

24.

be marked

"470J"

solder in place, and trim the leads.

Locate capacitor

"470J"

(1000pF).

"1000J"

C3,

solder in place, and trim the leads.

(1000pF).

"1000J"

C4,

solder in place, and trim the leads.

(470pF).

(actual value in

C7 (470pF).

(actual value in

This is another polystyrene capacitor

(actual value in

pF).

This is another polystyrene capacitor

(actual value in

pF).

This is a polystyrene capacitor and will

pF).

Carefully install C6 in the same

This is a polystyrene capacitor and will

pF).

Carefully install

Carefully install

C4

Carefully install C5 in

C7

in the same

manner as C6, solder in place, and trim the leads.

25. Locate capacitor

be marked

manner as

"470J"

C7,

C8 (470pF).

(actual value in

This is a polystyrene capacitor and will

pF).

Carefully install C8 in the same

solder in place, and trim the leads.

26. Locate two (2) 6" insulated wires. Cut these wires in halt, making

four

27.

from the insulated ends of each

28.

Locate Point #1 on the circuit board. Insert one of the

3"

ieces.

Using the wire strippers, remove the about

3"

iece of insulated wire.

1/4" of

the insulation

3"

wires into

the hole at Point #1 on the circuit board. Solder in place and trim the

lead.

in

29.

Locate Point #2 on the circuit board. Insert one of the

into the hole at Point #2 on the circuit board. Solder in place and trim

the lead.

30.

Locate Point #3 on the circuit board. Insert one of the

into the hole at Point #3 on the circuit board. Solder in place and

trim the lead.

31.

Locate Point #4 on the circuit board. Insert one of the 3" wires into

the hole at Point #4 on the circuit board. Solder in place and trim the

32.

Locate one (1) 6" insulated wire. Cut this wire in half, making two

3"

(2)

pieces.

33.

Using the wire strippers, remove the about

from the insulated ends

of

each

3"

iece

1/4" of

of

insulated wire.

the insulation

3"

3"

wires

wires

Page 12

VEC-830K Instruction Manual Single Side-Band Filter Kit

,

g

g

p

g

(

34. Locate the hole on the circuit board labeled INPUT. Insert one of the

3" wires into this hole

35. Locate the hole on the circuit board labeled GND. Insert the

remainin

36. Locate the 8" battery snap. Insert the RED wire of the battery snap

into the hole on the circuit board labeled VCC. Solder in place and

trim the lead.

37. Locate the wire located at Point GND on the circuit board, and the

BLACK wire on the battery snap. Twist these two wires together,

being careful no t t o po ke yourse lf.

38. Locate a piece of insulated wire. Twist one end of this wire together

with the wires in the previous step and solder. Wrap this solder joint

with a small piece of electrical tape to keep it from shorting to other

parts of the circuit board. The other end is for audio ground.

39. Locate (1) 14 pin IC

40. Install the IC socket at the U 1 location on the circuit board.Be

careful to orient the socket correctly according to the "Parts

Placement" section Fi

41. Carefully bend over the four corner pins of the socket against the

solder

3" wire into this hole, solder in place and trim the lead.

ads on the solder side of the board. Solder all pins in place.

solder in place and trim the lead.

ure 1.

42. Locate the remainin

43. Install the IC socket at the U2 location on the circuit board. Be

careful to orient the socket correctly according to the "Parts

Placement" section Figure 1.

44. Carefully bend over the four corner pins of the socket against the

solder pads on the solder side of the board. Solder all pins in place.

45. Locate both LM747 op amp integrated circuits. Insert them into IC

sockets for U 1 and U2. Please refer to the

"Parts Placement" and Before You Start Building sections for proper

orientatio n and p la cement. Be sur e no t t o be nd any of t he p ins

underneath the IC body, and that all pins are inserted into the socket.

46. Locate the 4P4T slide switch

47. Inspect the slide switch for tarnished contacts. Remove any

tarnish with very fine sa ndpaper so t he contacts are nice and shiny.

This will provide a good soldering surface.

14 pin 1C

SW

Page 13

1 VEC-830K Instruction Manual Single Side-Band Filter

p

p

(1)

48. Connect wire located at Point #4 to Point A on SW1. Solder in

lace and trim the lead.

49. Locate capacitor C9 (IOuF). This is an electrolytic type capacitor

and will be marked "lOuF" with an arrow pointing to the negative end.

50. Trim the positive lead of C9 so about only 3/8" of the lead remains.

51. Connect the positive lead of C9 at Point B on SW1. Do not

solder this switch contact vet.

52. Locate one (1) 6" insulated wire and cut it in half, making two (2)

"

53 Cut one (1) 3" wire in half making two (2) 11/2" pieces.

54 Using the wire strippers, remove about 1/4" of the insulation from

each 1 1/2"

ieces of wire.

55. Connect one

SW1. Solder both ends in place

switch contact.

1 1/2" piece of wire between Points B and E on

and trim the excess

lead

56. Connect wire located at Point #3 to Point C on SW1.

place and trim the lead.

57. Connect wire located at Point #2 to Point D on SW1.

place and trim the lead.

58. Connect wire located at Point #1 to Point F on SW1.

place and trim the lead.

from

the

Solder

Solder

Solder

Page 14

VEC-830K Instruction Manual Single Side-Band Filter Kit

p

g

Start at one side of the board and work your way across in an organized

attern.

Inspect the solder side of the board for cold-solder joints and solder bridges

between tracks or pads. Use a magnifying glass to obtain a clear view of the

track area. If you suspect a solder bridge, hold the board in front of a

bright light for a better view. All joints should be smooth and shiny,

indicating good solder wetting and flow. Resolder any beaded or dullappearing c onnections.

If you find a construction error and need to remove a part or two, it will be

easier if you have the right tools. One very convenient item for freeing

soldered-in parts is a "solder sucker". This consists of a suction bulb or a

spring loaded vacuum pump that draws molten solder away from the pad and

lead. Alternatively, you may use a special copper braid called "solder wick"

(solder suckers and solder wick are both available at your local Radio Shack or

electronics supply house). If you suspect you've damaged a

component during removal, better to replace it than risk reusing it!

Finally, rosin flux can absorb moisture, which may cause a problem for some

electronic equipment. To remove flux, use isopropyl alcohol (or 95% grain

alcohol) and an old toothbrush. Apply a generous amount of alcohol with the

toothbrush and scrub gently. Once the flux has fully dissolved, blot the bottom

of the board dry with an untreated tissue. Give it a final alcohol wash, and allow

to dry thoroughly.

CAUTION: ALCOHOL IS HIGHLY FLAMMABLE AND MUST BE USED

WITH ADEQUATE VENTILATION! USE SAFETY GOGGLES,

AND AVOID PROLONGED SKIN CONTACT. IT'S ALSO BEST

TO DO THIS OUTDOORS.

Now that assembly and inspection is completed, you're ready to begin the

testin

and alignment phase of construction.

The best way to test the VEC-830K is with a calibrated audio signal generator

and oscilloscope. However, the VEC-830K does not require any alignment. The

filter has three switch selectable selectivity cutoff points, Hi-Pass, 2.5kHz,

2.0kHz, and 1.5kHz. The switch positions on SW1 from left to right are HiPass,

2.5kHz, 2.0kHz, and 1.5kHz. The 1.5kHz hertz cutoff is the fourth switch

position from the left and is the narrowest filter cutoff, while the 2.5kHz cuto ff

is the second position from the left and is the widest filter cuto ff.

Page 15

VEC-830K Instruction Manual Single Side-Band Filter

p

q

p

prop

y

p

Probably the best method of seeing if the VEC-830K is working, or not, is to

listen to some "on the air" side-band signals. Then using SW1, select the filter

cutoff

Carefully tune in a weak signal with the filter in the HI-PASS position. The HIPASS position is the left most switch position on SW 1. Turn the filter on and

experiment with the selectivity switch to obtain the cleanest signal. The 2.5kHz

upper cutoff could be used when signals are not too cluttered with QRM and

more fidelity is required. The 2.0kHz upper cutoff position will give you t he

best compromise between QRM reduction and fidelity. Where signals are really

bad, with a lot of QRM, try the 1.5kHz upper cutoff. The 1.5kHz upper cutoff

will slice off a large amount of the QRM at the expense of fidelity. The HIPASS position will not affect the high frequencies and removes low frequencies

below 375 hertz, including 60 and 120 hertz hum. The Hi-Pass filter is

automatically in effect when using the 2.5kHz, 2.0kHz, and 1.5kHz positions.

osition that best cleans up the signal being received.

OPERA TING IN ST RU CT ION S

You may use the VEC-830K with any communications receiver or scanner. The

VEC-830K re

There are a few items that you will need to operate the VEC-830K. We

have

rovided a list of these items below for your convenience.

uires a 9-volt battery power source.

Communications Receiver or scanner with the

9-Volt transistor radio batter

External speaker with clip leads

Receiver or Scanner O

As mentioned previously you can use the VEC-830K with a communications

receiver or scanner. The filter requires audio from the external speaker or

headphones output of the receiver or scanner. The positive side of this audio

signal is applied to the insulated wire connected to point on the circuit board

labeled INPUT. The negative side of the audio is applied to the point on the

circuit board labeled GND. Use the open end piece of insulated wire

that is emerging from the junction point with the electrical tape. Please refer to

the "Parts Placement" section, Figure I for the location of signal INPUT point.

Next, connect the POSITIVE lead of the external speaker to the NEGATIVE

end of C9. Please refer to the "Parts Placement" section Figure 3 for the

location of C9. Connect the NEGATIVE lead of the external speaker to the

wire labeled GND on the circuit board. Again please refer to the "Parts

eration

er cables.

Page 16

VEC-830K Instruction Manual Single Side-Band Filter Kit

p

p

p

p

Placement" section Figure 1 for the location of the point labeled GND on the

Neat, turn the receiver volume all the way down, then clip the 9-volt battery to

battery snap. Set SW 1 to the far left position (Hi-Pass). Now turn the receiver

up slightly so you can hear the received signals on the external speaker. The

signal you are list eni ng to is the signa l with t he hig h fr eq uenc ie s una ffec te d ,

but all low frequencies below 375 hertz are removed.. Using the tuning knob

on the radio, go find a side-band signal. A good place to find side-band signals

is in the Amateur Radio bands. Once you find a side-band signal, switch SW 1

to the different filter cutoff positions and notice the affect that the filter has on

the received signal. As you progress through the filter cutoffs from 2.5kHz to

1.5kHz you will find the switch position that gives you the best sounding and

cleanest signal.

IN CASE OF DIFFICULTY

No Signal Filtering:

A newly constructed filter that fails to work upon initial power up, generally

requires a very close and careful inspection of all work. Please go back

through all steps of assembly and inspection, referring to the "Parts Placement"

Figures 1, 2, and 3. Most of the time there will be a part that is not installed or

not installed properly, a wrong value part in place of another, or a broken part.

A close inspection at this point will reveal some accidental mistake(s).

Intermittent Filter O

A filter that operates intermittently may have poor solder connections, a

problem with broken wires, or low voltage power source. Self-oscillation, may

be caused by a defective Ul or U2. Also check for dirty or intermittent switch

operation.

Filter Sto

A working filter that fails "in-service" generally indicates a failure of one or

both U1 or U2. If you suspect a bad U1 or U2, then

your fingers. If the part is bad, it could be HOT and could cause a serious

burn. Other things that should be checked is the supply voltage of

the 9-volt battery and/or broken wires to and from the circuit board and switch.

No S

No speaker audio can be a symptom of a bad SW I, a broken wire or a bad C9.

Also check the voltage from the 9-volt battery. A broken wire at the audio

in

ut to the filter can also attribute to no speaker audio.

s Filtering:

eaker Audio:

eration:

do not touch

the part with

Page 17

VEC-830K Instruction Manua l S ingle Side-Band Filter

If technical assistance or factory repair is desired, please refer to the warranty

THEORY OF OPERATION AND SPECIFICATIONS

Operation:

The VEC-830K uses two UA747 operational amplifier integrated circuits to

form four, flat cascaded Butterworth filter stages. Unlike passive filters using

inductors, no impedance matching is necessary for optimum performance. Also,

there is no insertion loss within the passband. This results in minimum amplitude

distortion and unity passband gain for all selectivity settings.

ENCLOSURE

Vectronics has designed a matching enclosure just for your VEC-830K SSB

Audio Filter Kit. The matching enclosure is an all metal box which includes

knobs, hardware, decals, and rubber feet. The Vectronics model number for

matching enclosure is VEC-830KC.

Page 18

Loading...

Loading...