Page 1

SDC-H1

Item name

Item code

Description/Option

SDC-H1-08-A3-1

40-30 0146

Transmitter for duct mounting: probe length 8cm (3”), incl. cable gland AMC-1

and humidity sensor element AES3-HT-A3

SDC-H1-16-A3-1

40-30 0147

Transmitter for duct mounting: probe length 16cm (6.2”), incl. cable gland

AMC-1 and humidity sensor element AES3-HT-A3

Item Name

Item Code

Humidity

Accuracy

[%RH]

Temperature

Accuracy [K]

@25°C (77°F)

Description/Option

AES3-HT-A2

40-50 0102

± 2%

±0.5°

Humidity - temperature sensor element

AES3-HT-A3

40-50 0103

± 3%

±0.4°

AES3-HT-A5

40-50 0104

± 5%

±0.3°

Item name

Item code

Description/Option

OPC-S

40-50 0029

Add-on display & programming module

OPA-S

40-50 0006

External display module

AMS-1

20-10 0116

Weather shield to protect the sensor element

AMC-2

40-50 0074

Conduit connector NPT 1/2

SDC-H1

Duct humidity transmitter

Features

Replaceable sensor element

Humidity measurement for air ducts

Minimum and maximum value memory

0…10 V, 0…20mA or 2…10V, 4…20mA measuring

signals selectable with jumpers

Optional alternative signal ranges programmable

Selectable averaging signal

Optional LCD display (OPC-S) or external display

(OPA-S)

Status LED

Applications

Humidity measurement for supply and return air ducts in heating, ventilation and air conditioning applications.

Recording of minimum and maximum values for critical environments

Supervision of critical humidity

Humidity transmitter

A unique capacitive sensor element is used for measuring relative humidity. The applied measuring technology

guarantees excellent reliability and long term stability. The microprocessor samples the humidity once per second. It

calculates an averaging signal over a preset number of seconds and generates the output signal.

Standard output signal range and types may be selected by jumpers. Standard signal ranges are: 0…10VDC, 0…10VDC,

4…20mA and 0…20mA. Other ranges can be defined by using a programming tool (OPA-S or OPC-S). A version with

display is possible by ordering the integrated display accessory OPC-S.

Minimum and maximum values:

Using a display and programming accessory, the user has the option to read out and reset minimum and maximum

values. The minimum and maximum values may as well be used as output signals. The minimum and maximum

values are saved into the EEPROM and are available after a power interruption.

Ordering

Per default a sensor element with 3% RH accuracy and a PG9 cable gland (item AMC-1)for cables 4 – 8 mm (AWG 6

– 1) is included. Contact your local sales contact to order sensing elements with different accuracies or if you prefer a

sensor with conduit connector or a built in display module.

Transmitter (default)

Sensor element (for replacement only)

Accessories

Doc:70-00-0162, V1.1, 20170509 © Vector Controls GmbH, Switzerland Page 1

Subject to alteration www.vectorcontrols.com

Page 2

SDC-H1

Power supply

Operating voltage

Transformer

24VAC 50/60 Hz 10%, 24VDC 10%

SELV to HD 384, Class II, 48VA max

Power consumption

Max 2 VA

Terminal connectors

For wire 0.34…2.5 mm2 (AWG 22…13)

Sensing probe

Humidity sensor

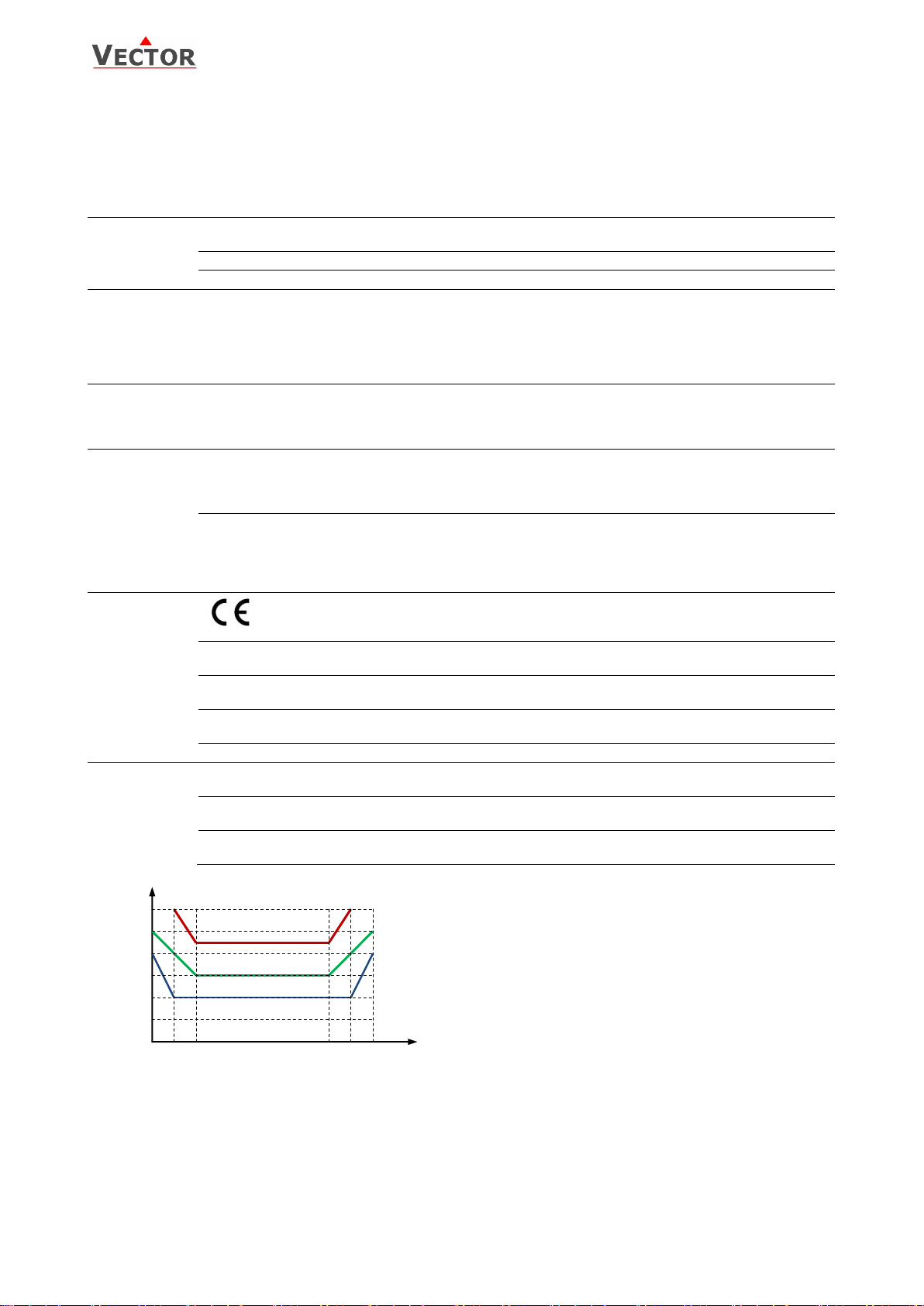

Range

Measuring accuracy

Hysteresis

Repeatability

Stability

Capacity sensor element

0…100%RH

See figure 1

1%

0.1%

< 0.5% / year

Signal outputs

Analog outputs

Output signal

Resolution

Maximum load

0…10VDCor 0…20mA

10 Bit, 9.7 mV, 0.019.5 mA

Voltage: ≥ 5 kΩ Current: ≤ 250Ω

Environment

Operation

Climatic conditions

Temperature

Humidity

To IEC 721-3-3

class 3K5

-40…70°C (-40…158°F)

<95% RH non-condensing

Transport &storage

Climatic conditions

Temperature

Humidity

Mechanical conditions

To IEC 721-3-2 and IEC 721-3-1

class 3K3 and class 1K3

-40…80°C (-40…176°F)

<95% RHnon-condensing

class 2M2

Standards

conformity

EMC directive

Low voltage directive

2004/108/EC

2006/95/EC

Product standards automatic electrical controls for

household and similar use

EN 60730–1

Electromagnetic compatibility for

domestic and industrial sector

Emissions: EN 60730-1

Immunity: EN 60730-1

Degree of protection to EN 60529

Mounted probe down with AMS-1

IP60

IP63

Safety class

III (IEC 60536)

General

Housing Materials Cover, back part

Filter material

PC+ABS (UL94 class V-0)

PTFE coated 1μm pores

Dimensions (H x W x D) Transmitter case

Probe

68 x 91 x 47mm (2.7” x 3.7” x 1.9”)

14 x 77/157 mm ( 0.55 x 3/6.2”)

Weight (incl. package) SDC-H1-08-A3-1

SDC-H1-16-A3-1

229g (8.1oz)

264g (9.3oz)

Figure 1: Max RH-tolerance at 25°C (77°F)

per sensor type

Relative humidity absolute accuracy

%RH

%RH

10

20

30

40

100

90 0 50

60

70

80

±1

±0

±2

±3

±4

±5

AES-HT-A2

AES-HT-A3

AES-HT-A5

Technical Specification

Warning!Safety advice!This device is intended to be used for comfort applications. Where a device failure endangers

human life and/or property, it is the responsibility of the owner, designer and installer to add additional safety devices

to prevent or detect a system failure caused by such a device failure. The manufacturer of this device cannot be held

liable for any damage caused by such a failure. Failure to follow specifications and local regulations may endanger life,

cause equipment damage and void warranty.

Doc:70-00-0162, V1.1, 20170509 © Vector Controls GmbH, Switzerland Page 2

Subject to alteration www.vectorcontrols.com

Page 3

SDC-H1

Parameter

Description

Range

Default

IP 00

H1: Show percent

ON, OFF

ON

IP 01

H1: Samples taken for averaging control signal

1…255

10

IP 02

H1: Calibration

-10…10%

0

Parameter

Description

Range

Default

OP 00

AO1: Humidity: Configuration of output signal:

0 = Feedback humidity input,

1 = Feedback humidity minimum value

2 = Feedback humidity maximum value

0…2

0

OP 01

AO1: Humidity: Minimum limitation of output signal

0…max%

0%

OP 02

AO1: Humidity: Maximum limitation of output signal

min…100%

100%

14 x 77 /157

(0.55 x 3 / 6.2)

47 (1.9)

91 (3.6)

68(2.7)

Dimensions mm(inch)

Installation and storage

Mounting location

The transmitter should be installed on the duct in an area where the air stream is well mixed:

Locate a supply air sensor two or three meters downstream from the nearest fan and coil.

Mount the return air sensor close to the air inlet but downstream from a return fan if one is present.

Mounting instruction / replacing the sensor element

See installation sheet no. 70-000525 (www.vectorcontrols.com).

Warning about storage, packaging and usage environment

The sensing part is a polymer, which measures the humidity in the ambient air. For proper sensor operation some

mandatory precautions need to be taken during storage, packaging and usage.

The transmitter and its sensing element should not be packaged, stored or used in out-gassing plastic materials, which

could cause sensor contamination. In particular, it is recommended not to use any glue or adhesive tapes (Sellotape,

Scotch-Tape, Tesa-Film, etc.) within the package or close proximity of the sensor. Foamed materials often cause

contamination problems and should not be used to package the transmitter. Best packaging material is a simple

cardboard box or a deep-drawn plastic case in a cardboard box.

Configuration

The transmitter can be adapted to fit perfectly into any application by adjusting the software parameters. The

parameters are set with the operation terminals OPA-S or OPC-S. The OPA-S may also be used as remote indicator.

Input configuration

Output configuration

Doc:70-00-0162, V1.1, 20170509 © Vector Controls GmbH, Switzerland Page 3

Subject to alteration www.vectorcontrols.com

Page 4

SDC-H1

LEFT

key:

Exit from parameter menu

UP

key:

Display maximum values,

Press for more than 2 seconds resets

maximum value

DOWN

key:

Display minimum values,

Press for more than 2 seconds resets

minimum value

RIGHT

key:

Select transmitter, for transmitters

with more than one input.

Legend:

1: 4-digit display of current value,

minimum, maximum or control

parameter

2: Unit of displayed value, °C, °F, % or

none

3: Vertical display of output or input signal

with a resolution of 10%

4: 4-digit display of current value or control

parameter

Operation of the –OP type sensors

Standard display:

Single input transmitters: The current, minimum or maximum value is shown in the large digits. The small digits

indicate the active input (IN 1). The vertical bar on the right side indicates the actual output voltage or current in 10%

steps.

Indication and reset of minimum and maximum values

Activate the desired transmitter for dual transmitter by pressing the RIGHT key. Press UP to display maximum values,

press DOWN key to display minimum values.

Resetting minimum or maximum values: Pressing either UP or DOWN keys for longer than 3 seconds while the

minimum or maximum values are displayed.

Display and keys

Operation keys:

Configuration parameters

The SDC and SOC intelligent sensors can be adapted to fit perfect into your application. The preparation of the sensing

signal is defined by parameters.

The parameters are password protected. The parameters can be changed as follows:

1. Press UP and DOWN key simultaneously for three seconds. The display will indicate CODE.

2. Select a password using UP or DOWN keys. Dial 09 in order to get access to the configuration parameters. Press

the RIGHT key after selecting the correct password.

3. Once logged in, choose IP for input configuration or OP for output configuration using UP or DOWN. Press the

RIGHT key after selection.

4. The parameters are now displayed. The small digits show the parameter number, the large one its value.

5. Select the parameters with the UP/DOWN keys. Change a parameter by pressing the RIGHT key. The MIN and

MAX symbols show up and indicate that the parameter may be modified now. Use UP and DOWN key to adjust

the value.

6. After you are done, press RIGHT or LEFT key in order to return to the parameter selection level.

7. Press the LEFT key again so as to leave the menu. The unit will return to normal operation if no key is pressed for

more than 5 minutes.

8. The parameters and its values depend on the transmitter. Please use the respective datasheet for the list of

parameters.

Doc:70-00-0162, V1.1, 20170509 © Vector Controls GmbH, Switzerland Page 4

Subject to alteration www.vectorcontrols.com

Page 5

SDC-H1

Signal type

JP1

0…10 V

(1-2)

0…20 mA

(2-3)

Signal range

JP3

0…10 V, 0…20 mA

(1-2)

2…10 V, 4…20 mA

(2-3)

JP3 Signal range

U1: 0-10V

I1: 0…20mA

U1: 2-10 V

I1: 4…20mA

3

2

1

3

2

1

JP1 Signal type

U1

0-10V, 2-10V

I1

0…20mA, 4…20mA

3

2

1

3

2

1

OPA-S

JP1

JP3

1 2 3

G 24 V

G0 0 V

U1/ I1 AO H

STATUS

LED

OPC-S

Status LED

LED indicates status

No light: either no power or sensing element is

reversed.

5 sec blinking: Normal

2 sec blinking: OPA or OPC connected

1 sec blinking: Sensor element error

Output signal configuration

The analog output signal type may be configured with a jumper for

0…10VDC or 0…20 mA control signals. The jumpers are located next to the

terminal connector of each analog output. See table below for jumper

placement. The factory setting is to 0…10VDC.

The signal range may be set with JP3 for both analog outputs. JP3 will only

operate if the output range specified with OP01 and OP02 is left at the

default position of 0…100%. With any other setting the position of JP3 has

no influence and the range defined with the output parameters applies.

Jumper settings

Doc:70-00-0162, V1.1, 20170509 © Vector Controls GmbH, Switzerland Page 5

Subject to alteration www.vectorcontrols.com

Loading...

Loading...