Vector Controls B2235760 User Manual

TCI-W-U Universal Controller

OVERVIEW

TCI-W-U Universal Controller

Features

Universal PID and/or binary control for any analog input/output signal and range

Multiple auxiliary functions: heat-cool auto changeover, automatic enable, setpoint compensation

Averaging, min. and max. functions

Cascading of control loops (-W22 type)

Alarm monitoring of low and high limits on all inputs

Programmable reaction in case of alarm

Feedback function for inputs and set points

Functions for dehumidifying, set point shift, cascade control

Password protected programmable user and control parameters

TCI-W22-U also includes

Power Cap protected real-time clock with 48hr power backup

7-day programmable schedules, with options including change of setpoints and direct position of manual outputs

Blue backlight

Applications |

|

|

|

|

|

|

|

|

Fan coil units |

|

VAV |

|

Humidifiers |

|

Radiant heating |

|

Heat exchangers |

|

Air handlers |

|

Dehumidifiers |

|

Radiant cooling |

|

Zoning |

|

Fan, Pump control |

|

Ventilation |

|

Pressurization |

General

TCI-W11-U: 1 independent control loop, 1 internal temperature sensor, 1 universal input (analog/binary/temp), 2 binary outputs, 1 analog output

TCI-W22-U: 2 independent control loops, 1 internal temperature sensor, 2 universal inputs, 2 binary outputs, 1 analog output.

Internal temperature sensor standard. Add replaceable humidity element as required: AES3-HT-A2 (2%), AES3- HT-A3 (3%), or AES3-HT-A5 (5%)

Flexible application configuration is made with a parameter-setting routine using the standard operation terminal.

Name |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

|

C |

|

I |

|

- |

W |

|

2 |

|

2 |

|

- |

|

U |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Housing |

Blank = square housing |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In/Outputs: |

See table below |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Control loops: 1 = 1 control loop, 2 = 2 control loops |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mounting: |

W = Wall mounted |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Series: |

TCI |

|

|

|

|

|

Ordering |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

Stock code |

|

|

Loop |

Temperature |

Humidity |

Universal |

Binary |

Analog |

Option |

|||||||||||||||||||||

|

|

|

|

Input |

|

Input |

Input |

Output |

Output |

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

TCI-W11-U |

40-10 0074 |

|

|

1 |

|

|

1 |

|

0 |

1 |

2 |

1 |

Standard |

||||||||||||||||||

|

|

TCI-W11-U-H |

40-10 0163 |

|

|

1 |

|

|

1 |

|

1 |

1 |

2 |

1 |

rH Sensor 3% acc. |

||||||||||||||||||

|

|

TCI-W22-U |

40-10 0076 |

|

|

2 |

|

|

1 |

|

0 |

2 |

2 |

1 |

Clock schedules |

||||||||||||||||||

|

|

TCI-W22-U-H |

40-10 0078 |

|

|

2 |

|

|

1 |

|

1 |

2 |

2 |

1 |

rH Sensor 3% acc. |

||||||||||||||||||

|

|

AES3-HT-A2 |

40-50 0102 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

rH Sensor 2% acc. |

||||||||||||

|

|

AES3-HT-A3 |

40-50 0103 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

rH Sensor 3% acc. |

||||||||||||

|

|

AES3-HT-A5 |

40-50 0104 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

rH Sensor 5% acc. |

||||||||||||

Temperature sensors: Use Vector Controls NTC sensors to achieve maximum accuracy:SDB-Tn10-20 (duct), SRA-Tn10 (room), SDB-Tn10-20 + AMI-S10 as immersion sensor.

Actuators: Choose modulating actuators with an input signal type of 0-10 V DC or 4-20 mA (Min. and max.signal limitations may be set with parameters.3-pointpoint actuators with constant running time are recommended.

Binary auxiliary devices (e.g. pumps, fans, on/off valves, humidifiers, etc):Do not directly connect devices that exceed specified limits in technical specifications – observe startup current on inductive loads.

Doc: 70-07-0140, V1.2, Date: 20170123 |

© Vector Controls GmbH, Switzerland |

Page 1 |

Subject to alteration |

|

|

TCI-W-U Universal Controller

OPERATION

Technical specifications

Warning! This device is intended to be used for comfort applications. Where a device failure endangers human life and/or property, it is the responsibility of the owner, designer and installer to add additional safety devices to prevent or detect a system failure caused by such a device failure. The manufacturer of this device cannot be held liable for any damage caused by such a failure.

Failure to follow specifications and local regulations may endanger life, cause equipment damage and void warranty.

Power Supply |

Power Requirements |

24 VAC ±10%, 50/60 Hz,Class 2, 2.0 A, 48 VA max. |

|

|||||||||

|

|

|

|

24 VDC ±10% |

|

|

|

|

|

|

|

|

|

|

Power Consumption |

Max. 3 VA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Electrical Connection |

Terminal Connectors |

|

|

|

|

|

|

|

||

|

|

|

|

0.34…2.5 mm2 wire (AWG 24…12) |

|

|

|

|

|

|

|

|

|

|

Clock backup |

|

Min. 48 hours |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Signal inputs |

Universal Input |

|

Setting for Voltage or Current |

|

|

|

|

|

|

|

||

|

|

Input Signal |

|

0–10 V or 0–20 mA |

|

|

|

|

|

|

|

|

|

|

Resolution |

|

9.76 mV or 0.019 mA (10 bit) |

|

|

|

|

|

|

|

|

|

|

Impedance |

|

Voltage: 98kΩ |

Current: 240Ω |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

Universal Input |

|

Input configured to remote temperature (RT) or digital input (DI) |

|

|||||||

|

|

Range |

|

NTC (Sxx-Tn10 sensor): -40…140 °C (-40…284 °F) |

|

|||||||

|

|

Accuracy |

|

-40…0 °C (-40…32 °F): 0.5 K |

|

|

|

|

|

|

|

|

|

|

|

|

0…50 °C (32…122 °F): 0.2 K |

|

|

|

|

|

|

|

|

|

|

|

|

50…100 °C (122…212 °F): 0.5 K |

|

|

|

|

|

|

|

|

|

|

|

|

> 100 °C (> 212 °F): 1 K |

|

|

|

|

|

|

|

|

|

|

Humidity Sensor AES3-HT-Ax: |

Capacity sensor |

|

%rH |

Max rH tolerance at 25°C (77°F) |

||||||

|

|

|

|

|

|

|

|

|

||||

|

|

Range |

|

0…100 % rH |

|

|

|

|

|

|

|

|

|

|

Measuring Accuracy |

See Figure to the right |

±5 |

|

|

|

|

|

|

||

|

|

Hysteresis |

|

1% |

|

±4 |

|

|

AES3-HT-A5 |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

Repeatability |

|

0.1% |

|

±3 |

|

|

AES3-HT-A3 |

|

|

|

|

|

|

|

±2 |

|

|

|

|||||

|

|

Stability |

|

< 0.5% / year |

|

|

|

AES3-HT-A2 |

|

|||

|

|

|

|

±1 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

±0 0 |

10 20 30 40 50 60 70 80 90 10 |

%rH |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Signal outputs |

Analog Output |

|

|

|

|

|

|

|

|

|

|

|

|

|

Output Signal |

|

DC 0–10 V / 0–20 mA |

|

|

|

|

|

|

|

|

|

|

Resolution |

|

9.76 mV / 0.019 mA |

|

|

|

|

|

|

|

|

|

|

Output Load |

|

Voltage: ≥1kΩ |

Current: ≤250Ω |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Relays Outputs |

|

|

|

|

|

|

|

|

|

|

|

|

Type of disconnection |

Micro-interruption |

|

|

|

|

|

|

|

|

|

|

|

AC Voltage |

|

0…48 VAC, 2(1.2)A max. (Observe local regulation) |

|

|||||||

|

|

DC Voltage |

|

0…30 VDC, 2A max. |

|

|

|

|

|

|

|

|

|

|

Insulation strength |

|

|

|

|

|

|

|

|

|

|

|

|

between relays contacts and system |

|

|

|

|

|

|

|

|

|

|

|

|

electronics: |

|

2000V AC to EN 60 730-1 |

|

|

|

|

|

|

|

|

|

|

between neighboring contacts: |

1250V AC to EN 60 730-1 |

|

|

|

|

|

|

|

||

Environment |

Operation |

|

To IEC 721-3-3 |

|

|

|

|

|

|

|

|

|

|

|

Climatic Conditions |

class 3 K5 |

|

|

|

|

|

|

|

|

|

|

|

Temperature |

|

0…50 °C (32…122 °F) |

|

|

|

|

|

|

|

|

|

|

Humidity |

|

<95 % r.H. non-condensing |

|

|

|

|

|

|

|

|

|

|

Transport & Storage |

To IEC 721-3-2 and IEC 721-3-1 |

|

|

|

|

|

|

|

||

|

|

Climatic Conditions |

class 3 K3 and class 1 K3 |

|

|

|

|

|

|

|

||

|

|

Temperature |

|

-25…70 °C (-13…158 °F) |

|

|

|

|

|

|

|

|

|

|

Humidity |

|

<95 % r.H. non-condensing |

|

|

|

|

|

|

|

|

|

|

Mechanical Conditions |

class 2M2 |

|

|

|

|

|

|

|

|

|

Standards |

conforms to |

|

|

|

|

|

|

|

|

|

||

|

|

EMC Standard 89/336/EEC |

EN 61 000-6-1/ EN 61 000-6-3 |

|

|

|

|

|

|

|

||

|

|

EMEI Standard 73/23/EEC |

|

|

|

|

|

|

|

|

|

|

|

|

Product standards |

|

|

|

|

|

|

|

|

|

|

|

|

Automatic electrical controls for household |

EN 60 730 –1 |

|

|

|

|

|

|

|

|

|

|

|

and similar use |

|

|

|

|

|

|

|

|

|

|

|

|

Special requirement on temperature |

EN 60 730 – 2 – 9 |

|

|

|

|

|

|

|

|

|

|

|

dependent controls |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Degree of Protection |

IP30 to EN 60 529 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pollution Class |

|

II (EN 60 730-1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Safety Class |

|

III (IEC 60536) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Overvoltage Category |

I (EN 60 730-1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

General |

Material: |

Cover, back part |

Fire proof ABS plastic (UL94 class V-0) |

|

|

|

|

|

|

|

||

|

|

|

Mounting Plate |

Galvanized Steel |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

Dimensions (H x W x D) |

Front part: 112 x 73 x 15 mm (4.4” x 2.9” x 0.6”) |

|

||||||||

|

|

|

|

Power case: ø 58 x 32 mm (ø 2.3” x 1.3”) |

|

|

|

|

|

|

||

|

|

Weight (including package) |

TCI-W11-U = 255g (9.0 oz), TCI-W22-U = 265g (9.3 oz) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Doc: 70-07-0140, V1.2, Date: 20170123 |

© Vector Controls GmbH, Switzerland |

Page 2 |

Subject to alteration |

|

|

TCI-W-U Universal Controller

OPERATION

Dimensions, mm (inch)

|

|

|

|

73 (2.9) |

|

|

|

|

|

|

32 (1.2) |

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(0.6) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Installation

Install the controller on an easy accessible interior wall, approx. 1.5 m above the floor in an area of average temperature.

Avoid direct sunlight or other heat sources, e.g. the area above radiators and heat emitting equipment.

Avoid locations behind doors, outside walls and below or above air discharge grills and diffusers.

Location of mounting is less critical if external temperature sensors are used.

Ensure adequate air circulation to dissipate heat generated during operation.

Observe local regulations.

Do not mount in a wet or condensation prone environments.

0-48VAC, 0-30VDC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

24V AC/DC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

XU1 |

|

|

|

XU2 |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Live Electrical |

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Components! |

|

|

|

|

3 |

|

|

|

1 |

7 |

|

|

|

|

1 |

8 |

|

|

|

|

|

|

XT1 |

|

XH1 |

|

|

|||||||

|

|

G |

Q13 |

|

|

|

|

|

G0 |

X1 |

G0X2 |

|

|

|

|

|

|

|

During installation, |

|||||||||||||

|

|

1 |

|

4 |

|

|

5 |

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

|

testing, servicing and |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TCI-W22 |

|

troubleshooting of |

|||||||||||||

|

|

G0 |

|

Q14 |

|

|

Q24 |

|

|

|

|

|

|

|

|

|

G0Y1 |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vector Controls |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

products, it may be |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

necessary to work |

|

|

|

|

|

|

YB1 |

|

YB2 |

|

|

|

|

|

|

|

|

|

|

YM1 |

|

|

|

|

|

with live electrical |

|||||||

0V (COM) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

components. Have a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

qualified licensed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0V AC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

electrician or other |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

individual who has |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0-48VAC, 0-30VDC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

been properly trained |

|||

24V AC/DC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

XU1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

in handling live |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

electrical components |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

perform these tasks. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Failure to follow all |

|

|

2 |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

electrical safety |

||||

|

|

|

|

|

|

1 |

7 |

|

|

|

|

|

|

|

|

|

|

|

|

XT1 |

|

XH1 |

|

|

||||||||

|

|

G |

Q13 |

|

|

|

|

|

G0X1 |

|

|

|

|

|

|

|

|

|

|

|

|

precautions when |

||||||||||

|

|

1 |

|

4 |

|

|

5 |

|

|

|

|

|

|

|

|

1 |

|

6 |

|

|

|

|

|

|

|

|

exposed to live |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TCI-W11 |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

electrical components |

|||||||||||||

|

|

G0 |

|

Q14 |

|

|

Q24 |

|

|

|

|

|

|

|

|

G0 |

|

Y1 |

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

could result in death |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

or serious injury. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

YB1 |

|

YB2 |

|

|

|

|

|

|

|

|

|

|

YM1 |

|

|

|

|

|

|

|

||||||

0V (COM) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0V AC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Terminal Description |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

G0 |

Power supply: |

|

0V, -24VDC; common for power supply, analog inand outputs |

|||||||||||||||||||||||||||||

G |

Power supply: |

|

24VAC, +24VDC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

Q.. |

Binary outputs: |

|

Potential free relays contacts (see technical specification) |

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

Yb1,b2 |

Binary output common |

|

|

|

|

|

||||||||||||||||

XU1, u2 |

Universal input: |

|

NTC 10kΩ @ 25°C (77°F), 0…10 V or 0…20 mA(selectable by jumper) |

|||||||||||||||||||||||||||||

Ym1 |

Analog output: |

|

0…10 V or 0…20 mA* |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

XT1 |

Internal temperature input |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

XH1 |

Internal humidity input if AES3-HT is inserted |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

Use copper, twisted pair, conductors only. The operating voltage must comply with the requirements for safety extra-low voltage (SELV) as per EN 60 730. Use safety insulating transformers class II with double insulation as per EN 60 742; they must be designed for 100% ON-time. When using several transformers in one system, the connection terminal 1 must be galvanic connected. TCI is designed for operation of AC 24 V safety extra-low voltage and is short-circuit-proof. Supplying

Doc: 70-07-0140, V1.2, Date: 20170123 |

© Vector Controls GmbH, Switzerland |

Page 3 |

Subject to alteration |

|

|

TCI-W-U Universal Controller

OPERATION

voltages above AC 24 V to low voltage connections may damage the controller or other devices. Connection to voltages exceeding 42 V endangers personnel safety.

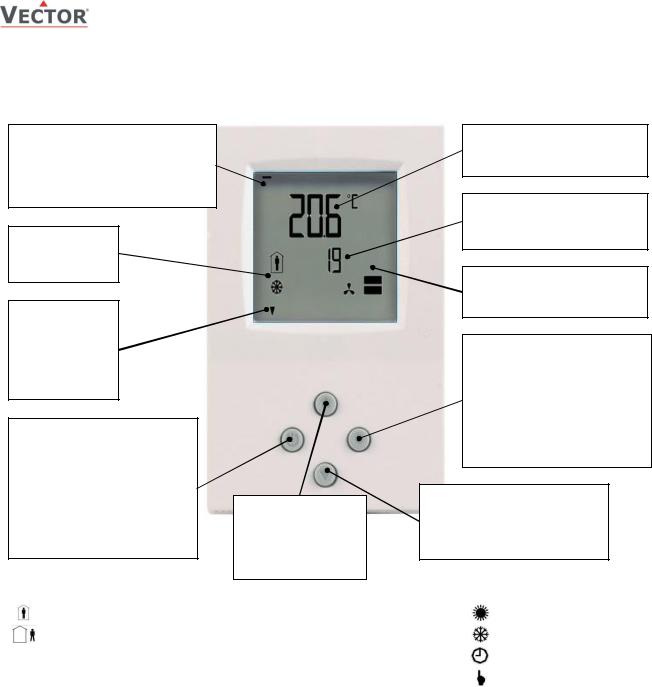

Display and Operation

Loop indication

Standard display (no button pressed for 30 sec.): Not visible.

Loop display: Bar at 1 = Loop 1, Bar at 2 = Loop 2

Mode

Display of operation mode

Indicators

Standard display: Active digital output (at 1, 2)

Loop display: Active digital stages (at 8,9,10)

Left (POWER)

Press < 2 sec.: Toggle STANDBYCOMFORT mode or switch from OFF to ON

Press > 2 sec.: Turn unit OFF. Text OFF displayed with current time (deluxe) temperature (standard)

(Parameter setting: ENTER to select menu option, accept parameter change)

Up

Increment SET POINT

(Parameter setting: SCROLL menu options and parameters)

Large Digits

Display of input or parameter value.

Small Digits

Display of setpoint, clock or parameter number.

Vertical Bar

(scrolls up/down, 10% resolution)

Right (OPTION)

Press < 2 sec.: Select Control Loop

Press > 2 sec.: Enter set-up CLOCK, SCHEDULES, H/C

(Parameter setting: ENTER to select menu option, accept parameter change)

Down

Decrement SET POINT

(Parameter setting: SCROLL menu options and parameters)

|

Operation mode symbols |

|

Control symbols |

|

|

|

|

|

Comfort (occupied): All control functions operating per set points |

|

Heating (Reverse) Active |

|

|

|

|

|

Economy (unoccupied): Set points shifted according to 1L07, 2L07 |

|

Cooling (Direct) Active |

|

|

|

|

OFF |

Energy Hold Off: Outputs are off, inputs monitored for alarms |

|

Schedule Set |

|

|

|

|

|

|

|

Manual Override |

|

|

|

|

|

|

|

Fan Active |

|

|

|

|

Standard display (Parameters UP08, UP09, UP10)

Active whenno key has been pressed for 30 seconds.

Contents may be chosen with parameters.

Loop display

Active when changing set points. Large digits show input value. Small digits show set point. Vertical bars show analog output value. Arrows in position 1, 2 and/or 3 show active binary (digital) output stages

Override of secondary set point in cascade control

If cascade control is active, withvariable air volume (VAV) for example,the user can override the primary loop and manually select the set point of the secondary loop-the loop is now changed to constant air volume (CAV). Typically for tuning the VAV system.This feature may be disabled with UP02.

While the secondary loop is displayed change the set point with UP/DOWN. Override Cascade symbol appears.

Press OPTIONto move back to the temperature loop and cancel cascade override.

Doc: 70-07-0140, V1.2, Date: 20170123 |

© Vector Controls GmbH, Switzerland |

Page 4 |

Subject to alteration |

|

|

TCI-W-U Universal Controller

OPERATION

Power Failure

All parameters and set points are memorized and do not need to be re-entered.

Upon return of power: SetParameter UP05to keep the unit off, switch on, or operation mode before power failure.

Clock and time schedule settings retained for 48 hours (after powered for at least 10 hours).

Error messages

Err1: An assigned input is not enabled or missing. All control loops, functions and outputs tied to this input will be disabled. Verify input connections, jumper settings and parameter settings for the input involved.

Err3: A function refers to a disabled input. Disable the function or enable the input. Err4: Internal failure. Product must be replaced.

Manual heat – cool change

To manually change heating or cooling mode press the OPTION key for more than 2 seconds. Access to manual heat – cool change may be disabled with parameter UP03.

For TCI-W11-U: Press OPTION > 2 sec. SEL and H-C is displayed. |

SEL |

For TCI-W22-U: Press OPTION > 2 sec. SEL and current time is displayed. |

H-C |

Press UP key twice. SEL and H-C is displayed. |

|

Press OPTION again to toggle H or C. |

|

|

|

Display input values

For TCI-W11-U: Press OPTION > 2 sec. SEL and H-C is displayed. |

75% |

Press UP key once: UI1 and its value are displayed |

UI 1 |

For TCI-W22-U: Press OPTION > 2 sec. SEL and current time is shown. |

|

Press UP key three times. UI1 and value are displayed. |

|

Press UP key again to step through the next active input |

|

Note: disabled inputs will not be shown. |

|

|

|

Doc: 70-07-0140, V1.2, Date: 20170123 |

© Vector Controls GmbH, Switzerland |

Page 5 |

Subject to alteration |

|

|

TCI-W-U Universal Controller

OPERATION

Clock operation

TCI-W22-Ucontains a quartz clock with battery back-up (not available in TCI-W11-U). Up to 8 mode changes based on time and day of the week may be programmed. Also position an output or select a set point directly with a time schedule. A blinking clock indicates that the time has not been setor thatthe unit has beenwithout power for longer than 48 hours. The time needs to be set to allow time schedules to operate.

Clock setup

Press OPTION > 2 sec. SEL and current time displayed Press OPTION< 2 sec. to change time,

Minutes blink: UP/DOWN to change, OPTION to save minutes, Hours blink: UP/DOWN to change, OPTION to save hour,

Press OPTION to save time,

DAY1 blinks: UP/DOWN to change, OPTION to save day

SEL 00:00

DAY1 (Mon)

Enable/disable time schedules

Press OPTION > 2 sec. SEL and current time displayed |

SEL |

Pro |

||

Press UP: |

PRO |

OFF/ON |

||

SEL and PRO displayed, clock symbol blinks |

||||

Press OPTION: |

|

|

|

|

Time schedule status displayed OFF or ON: |

|

|

|

|

Press OPTION |

|

|

|

|

OFF/ ON blinks, UP/DOWN to change, OPTION to save |

|

|

|

|

Creating time schedules |

|

|

|

|

Step 1: Select a switching time (Up to 8, Pr01–Pr08) |

|

|

|

|

|

|

|

|

|

Press UP while PRO-ON displayed: |

|

|

|

|

Large digits display Pr01, small digits display 00:00 |

|

Pr01 |

||

Press OPTION:00:00 blinks |

|

08:00 |

|

|

Press UP/DOWN to select Pr01switching time from 00:00–23:45 |

|

|

|

|

Press OPTION to save switching time (bar appears indicating step 1 complete): |

|

|

|

|

|

|

|

|

|

DAY 1 blinks |

|

|

|

|

Step 2: Apply selected switching time (Pr01) to DAY1 (Mon) – DAY 7 (Sun) |

|

|

|

|

|

|

|

|

|

While Pr01 is displayed and DAY1 is blinking: |

|

Pr01 |

||

Press UP: Activate Pr01 switching time for DAY1 (triangle appears on 1), |

|

DAY1 |

||

Press DOWN: |

|

|||

Deactivate Pr01 switching time for DAY1(triangle disappears) |

|

|

|

|

Press OPTION to save Pr01 DAY1 (2nd bar indicates step 2 complete): |

|

|

|

|

|

|

|

||

Repeat for DAY2 – DAY7 |

|

|

|

|

|

1 2 3 4 5 6 7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Step 3: Select action for switching time (Pr01+Days) |

|

|

|

|

|

|

|

|

|

After Pro1, DAY1–DAY7 is completed (Pro1 switching time activate or deactivate on desired days), press |

Pr01 |

|||

OPTION again to come to desired action for Pro1. The following options appear in order: |

|

no |

||

No = switching time not active |

|

|||

OP = operation mode (select ON, OFF, COMFORT, ECONOMY) |

|

|

|

|

L1 = set point of loop 1 (select set point) |

|

|

|

|

|

|

|

|

|

L2 = set point of loop 2 (select set point) |

|

|

|

|

d1 = ON/OFF status of do1 (output must be in manual mode) |

|

|

|

|

d2 = ON/OFFstatus of do2 (output must be in manual mode) |

|

|

|

|

A1 = set point (0-100%) of ao1 (output must be in manual mode) |

|

|

|

|

After repeatedly pressing OPTION through DAY7: |

|

|

|

|

First available action No appears, blinking: |

|

|

|

|

Press UP/DOWN to scroll through the 8 possible actions (3nd bar indicates step 3 complete) |

|

|

|

|

Step 4: Complete switching event (e.g. Pro1 = 08:00, DAY 1, Comfort mode) |

|

|

|

|

|

|

|

|

|

Available actions blink as you scroll through them, Press OPTION to select one: |

|

Pr01 |

||

Characteristics of action (e.g. 0–100% for A1) appear (4th bar indicates step 4 complete) |

08:00 |

|

|

|

|

|

|||

Press UP/DOWN to select, OPTION to complete |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Doc: 70-07-0140, V1.2, Date: 20170123 |

© Vector Controls GmbH, Switzerland |

Page 6 |

Subject to alteration |

|

|

Loading...

Loading...