Page 1

SRC-C1

Item name

Item code

Description/option

SRC-C1

40-30 0062

CO2 transmitter

Item name

Item code

Description/option

OPA-S

40-50 0006

External display module.

For the correct display of values V1.4 and later is required

SRC-C1 Indoor CO2 Transmitter

Features

Indoor CO2 measurement

Indication with three color led

Minimum and maximum value memory

0…10 V, 0…20 mA or 2…10 V, 4…20 mA measuring signals

selectable with jumpers

Optional alternative signal ranges programmable

May be used as simple P-controller

Selectable averaging signal

Optional external display (OPA-S)

Status LED

Applications

Indoor CO2 measurement

Recording of minimum and maximum limits for critical

environments

Direct control of extraction fan

CO2 transmitter

The CO2 concentration is measured through non-dispersive infrared (NDIR) waveguide technology with ABC automatic

background calibration algorithm. The applied measuring technology guarantees excellent reliability and long term

stability. The microprocessor samples the CO2 once per second. It calculates an averaging signal over a preset number

of seconds and generates the output signal.

The output signal range and type may be customized by jumpers and if required by a programming tool. Standard

signal ranges are 0-10 VDC, 2-10 VDC, 4-20 mA and 0-20 mA. These ranges can be set by jumpers. Other ranges can

be set by using the external display and programming module. (OPA-S)

Automatic Baseline Calibration ABC

The ABC background calibration constantly supervises the measured CO2 concentrations. The calibration function

expects the CO2 values sink to 400 ppm when the room is not occupied. Over a period of several days the controller

tries to reach this value step by step through recalibration of 30ppm per day max. In order to reach the given

accuracy, it is required that the sensor is for at least 3 weeks in operation.

Note: The ABC calibration works only in those applications where the CO2 concentration sinks regularly to fresh air

levels of 400 ppm. For special applications such as green houses, animal farms, etc. the ABC calibration should be deactivated and the sensor should be manually calibrated. The automatic calibration can deactivated through the

external operation terminal. The Sensor can be calibrated by the client and does not need to be sent in for calibration.

See last page for details.

Minimum and maximum values

Using a display & programming accessory, the user has the option to read out and reset minimum and maximum

values. The minimum and maximum values may as well be used as output signals. The minimum and maximum

values are saved into the EEPROM and are available after a power interruption.

Indication of air quality indication:

A three color LED is used to indicate air quality: Green light for low CO2 concentration, orange light for medium and

red light for high concentration. The levels for low-medium-high may be programmed.

Default settings are 0 ppm< low < 800 ppm< medium < 1500 ppm < high.

Ordering

Accessories

Doc: 70-00-0220, V1.2, 20170131 © Vector Controls GmbH, Switzerland Page 1

Subject to alteration www.vectorcontrols.com

Page 2

SRC-C1

Power supply

Operating voltage

24 V AC 50/60 Hz ± 10%, 24 VDC ± 10%

SELV to HD 384, class II transformer, 48 VA max.

Power consumption

Max. 2 VA

Connection

Terminal connectors

For wire 0.34…2.5 mm2 (AWG 24…12)

CO2 measurement

Sensing method

Non-dispersive infrared (NDIR) waveguide

technology with ABC automatic

background calibration algorithm

Sampling method

Diffusion

Response time (T

1/e

)

40 sec diffusion time

Measurement range

0 - 5000 ppm

vol.

Repeatability

± 20 ppm ± 1 % of measured value

Accuracy

± 30 ppm ± 3 % of measured value

Pressure dependence

+ 1.6 % reading per kPa deviation from normal

pressure, 100 kPa

Signal outputs

Analog outputs

Output signal

Resolution

Maximum load

DC 0-10 V or 0…20 mA

10 bit, 9.7 mV, 0.019.5 mA

Voltage signal: ≥1kΩ, current signal: ≤500Ω

Environment

Operation

Climatic conditions

Temperature

Humidity

To IEC 721-3-3

class 3 K5

0…50° C (32…122° F)

<95% RH non-condensing

Transport & storage

Climatic conditions

Temperature

Humidity

Mechanical conditions

To IEC 721-3-2 and IEC 721-3-1

class 3 K3 and class 1 K3

-30…70° C (-22…158° F)

<95% RH non-condensing

class 2M2

Standards

conformity

EMC directive

2004/108/EC

EN 61 000-6-1/ EN 61 000-6-3

Degree of protection

IP30 to EN 60 529

Safety class

III (IEC 60536)

Housing materials

Cover

Mounting plate

Fire proof ABS plastic

Galvanized steel

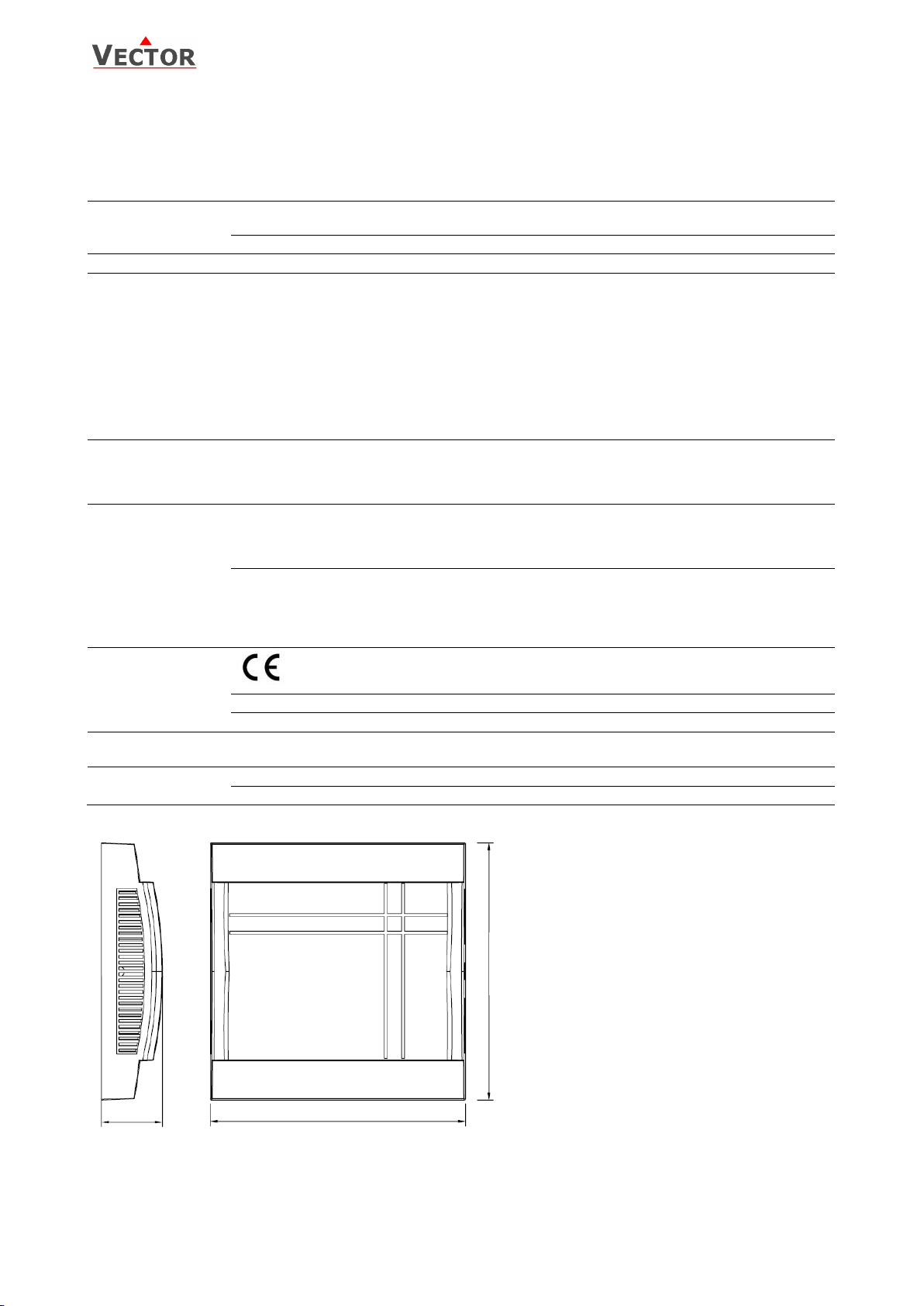

General

Dimensions (H x W x D)

21 x 88 x 88 mm (0.8” x 3.5” x 3.5”)

Weight (including package)

175 g (6.2 oz.)

88 (3.5)

88 (3.5)

21 (0.8)

Technical specification

Safety advice

This device may only be installed and configured by a skilled electrician. Where a device failure endangers human life

and/or property, it is the responsibility of the client, installer and designer to add additional safety devices to prevent

or detect a system failure caused by such a device failure.

Dimensions mm (inch)

Mounting location

Mount the transmitter on a flat interior wall of the room to be controlled. Do avoid obstructions such as shelves,

curtains and recesses. Do not place near heat sources, draft channels. Do not expose to direct sunlight.

Doc: 70-00-0220, V1.2, 20170131 © Vector Controls GmbH, Switzerland Page 2

Subject to alteration www.vectorcontrols.com

Page 3

SRC-C1

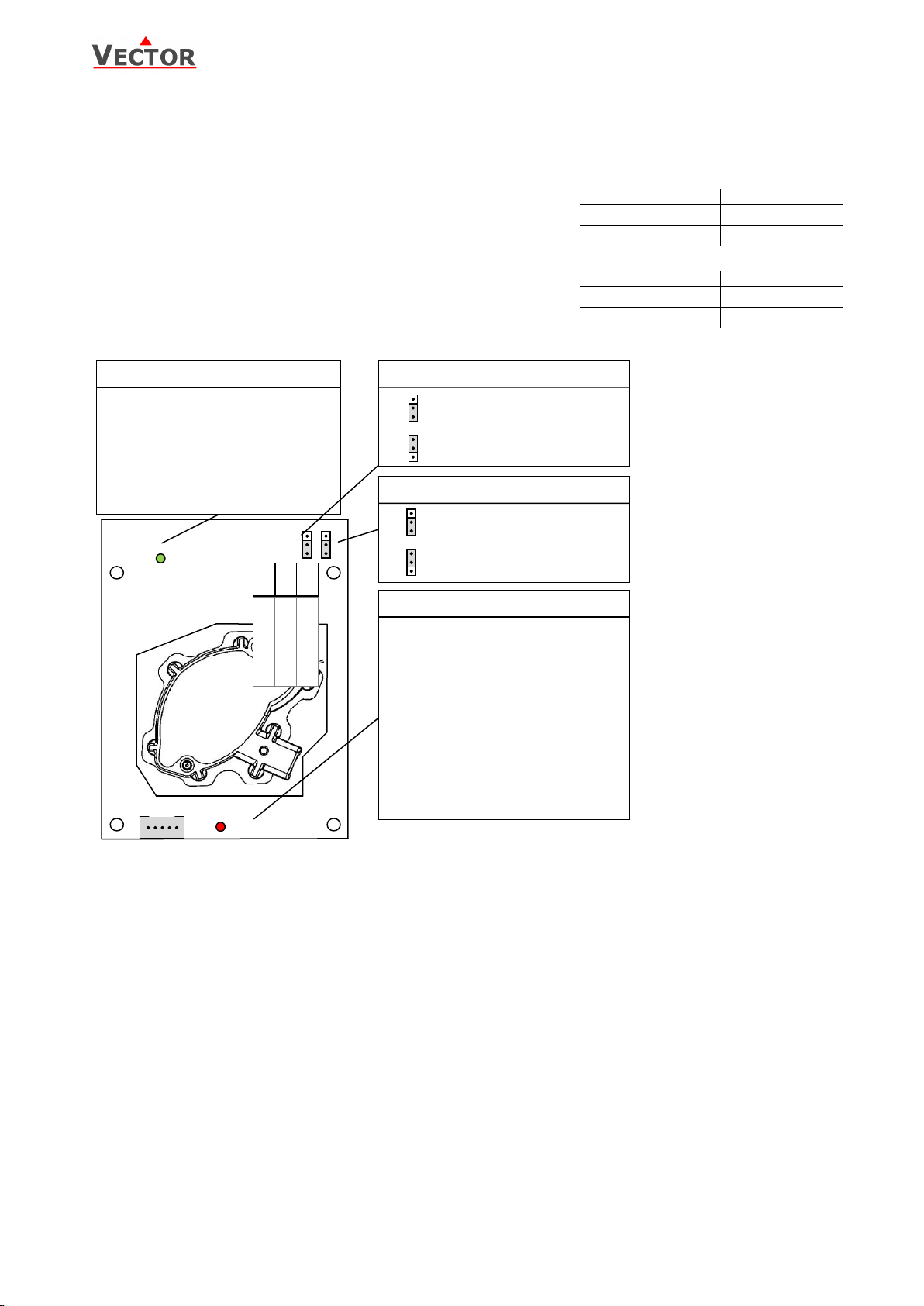

Signal type

JP1

0 – 10 V

(1-2)

0 – 20 mA

(2-3)

Signal range

JP2

0 – 10 V, 0 – 20 mA

(1-2)

2 – 10 V, 4 – 20 mA

(2-3)

JP1 Signal type

JP2 Signal range

U1: 0-10V

I1: 0-20mA

U1: 2-10V

I1: 4-20mA

3

2

1

3

2

1

U1

0-10V, 2-10V

I1

0-20mA, 4-20mA

3

2

1

3

2

1

Status LED

LED indicates status

No light: no power or unit damaged

5 sec blinking: Normal

Constant light: Error mode

Alternate in 2 sec interval with air

quality LED: Calibration is active.

Calibration end: Constant light for

10s. Success is shown on air quality

led: Green blinking: OK,

Red blinking: failed. Device enters

error mode.

OPA-S

1 2 3

JP1 JP2

STATUS

G 24V

G0 0V

U1/ I1 AO CO2

Air Quality

Air quality LED

LED indicates status

No light : no power or unit damaged

Green : Low CO2 level

Orange : Medium CO2 level

Red : High CO2 level

Red blinking: 0ppm calibration

Green blinking: 400ppm calibration

Mounting instruction

See installation sheet no. 70-000572 (www.vectorcontrols.com).

Configuration

Output signal configuration

The analog output signal type may be configured with a jumper for 0-10

VDC or 0-20 mA control signals. The jumpers are located next to the

terminal connector of each analog output. See table below for jumper

placement. The factory setting is to 0-10 VDC.

The signal range may be set with JP2 for both analog outputs. JP2 will only

operate if the output range specified with OP01 and OP02 is left at the

default position of 0…100%. With any other setting the position of JP2 has

no influence and the range defined with the output parameters applies.

Jumper settings

Doc: 70-00-0220, V1.2, 20170131 © Vector Controls GmbH, Switzerland Page 3

Subject to alteration www.vectorcontrols.com

Page 4

SRC-C1

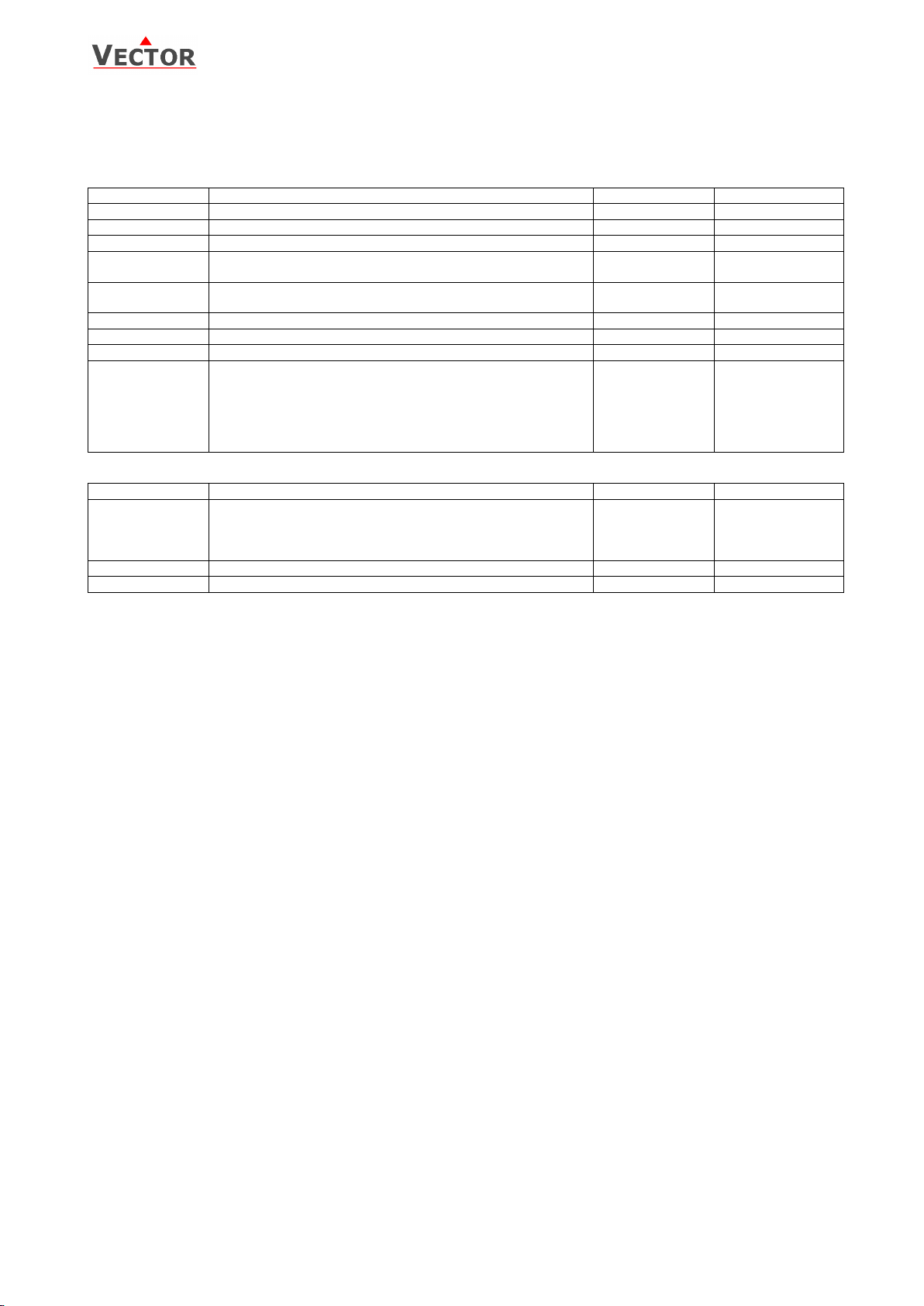

Parameter

Description

Range

Default

IP 00

Enable display of air quality LED on front.

ON, OFF

ON

IP 01

Samples taken for averaging control signal

1…255

10

IP 02

Calibration

-10…10%

0

IP 03

Minimum CO2 range ppm

(concentration when output is at its minimum)

0…5000 ppm

0 ppm

IP 04

Maximum CO2 range ppm

(concentration when output is at maximum)

0…5000 ppm

2000 ppm

IP 05

Level for medium CO2 concentration (orange light)

0…5000 ppm

800 ppm

IP 06

Level for high CO2 concentration (red light)

0…5000 ppm

1500 ppm

IP 07

Enable ABC automatic background calibration

ON, OFF

ON

IP 08

Calibrate CO2 sensor. Note: For normal operation,

calibration is not required. Only experts should calibrate

the sensor.

0 = No calibration (default)

1 = Calibrate to gas (0 ppm)

2 = Calibrate to fresh air (400 ppm)

0..2

0

Parameter

Description

Range

Default

OP 00

AO1: CO2: Configuration of output signal:

0 = Feedback CO2 input,

1 = Feedback CO2 minimum value

2 = Feedback CO2 maximum value

0 – 2

0

OP 01

AO1: CO2: Minimum limitation of output signal

0 – Max. %

0%

OP 02

AO1: CO2: Maximum limitation of output signal

Min. – 100%

100%

Parameter configuration

The transmitter can be adapted to fit perfectly into any application by adjusting the software parameters. The

parameters are set with the operation terminals OPA-S. The OPA-S may also be used as remote indicator. For correct

display version 1.4 of OPA-S is required.

Input configuration

Output configuration

Error messages shown on OPA-S

Err1: Communication error: Verify cable connections, cable type and maximum distance.

Err2: CO2 sensor error: Make sure the sensor is not miss-calibrated. If possible make a 0-ppm or 400 ppm

calibration. (See below). Make sure JP3 is removed or placed in middle position (2-3).

If error cannot be removed by calibrating the sensor, replace product.

Use as P-controller

The CO2-transmitter may be converted into a proportional fresh air controller through a simple change of two

parameter settings:

Set a minimum concentration when the fresh air fan should start to run at its minimum speed; for example 500 ppm.

Set this as the minimum value in IP03 parameter. Then define the value when the fan should run at full speed, for

example 1000 ppm and set this value in IP04. Your transmitter has now been converted into an air quality P-controller!

The fan will start to run if the CO2 concentration is higher than 500 ppm. It increases to its maximum when CO2

concentration reaches 1000 ppm.

Doc: 70-00-0220, V1.2, 20170131 © Vector Controls GmbH, Switzerland Page 4

Subject to alteration www.vectorcontrols.com

Page 5

SRC-C1

Calibration

The default sensor OEM unit is maintenance free in normal environments thanks to the built-in self-correcting ABC

algorithm (Automatic Baseline Correction). This algorithm constantly keeps track of the sensor’s lowest reading over a

7 days interval and slowly corrects for any long-term drift detected as compared to the expected fresh air value of 400

ppm CO2.

Rough handling and transportation might, however, result in a reduction of sensor reading accuracy. With time, the

ABC function will tune the readings back to the correct numbers. The default “tuning speed” is however limited to

about 30 ppm/week. For post calibration convenience, in the event that one cannot wait for the ABC algorithm to cure

any calibration offset, jumper 3 is provided for the operator to choose calibration options. There are two calibration

possibilities: 0 ppm and 400 ppm. Only one calibration needs to be performed.

Calibration to 0 ppm with CO2 free gas

1. Connect the sensor on top with a tube (soft tubing 2 x 4 mm) and

a nipple (nylon tubing 30 x 0.8 x 2.2 mm), see picture on the right

side. There are 2 alternative positions for nipple attachment.

2. Let a gas mixture which is free from CO2 (i.e. Nitrogen or Soda

Lime CO2 scrubbed air) flow into the sensor through the applied

tube. The flow shall be in the range of 0.3 – 1.0 liter/minute during

3 minutes. Keeps the gas mixtures flowing during the whole

procedure.

3. Connect OPA-S, Login and set IP08 = 1 and exit configuration

mode. The air quality LED will blink in red color alternating with

the status led in 2 second intervals.

4. The sensor will now wait for a stable concentration. Once the

calibration has been executed, the status LED will show constant

RED and the green air quality led will blink for 10s if successful. If

calibration is not successful (no stability of concentration for 5 min,

no communication with sensor) the red air quality led will blink

instead and the sensor enters error mode. Recalibrate or restart device to stop error mode.

5. Verify the zero calibration using the OPA-S or the analog outputs. They should show 0 ppm CO2.

6. If zero calibration is not executed (sensor detected unstable gas concentration) wait 10 sec and repeat steps

3 and 4 again. Do not breathe on the sensor!

Calibration to 400 ppm (Fresh air)

1. Expose the active sensor for at least 5 minutes to fresh outside air.

2. Connect OPA-S, Login and set IP08 = 2 and exit configuration mode. The air quality led will blink in green

color alternating with the status led in 2 second intervals.

3. The sensor will now wait for a stable concentration. Once the calibration has been executed, the status LED

will show constant RED and the green air quality led will blink for 10s if successful. If calibration is not

successful (no stability of concentration for 5 min, no communication with sensor) the red air quality led will

blink instead and the sensor enters error mode. Recalibrate or restart device to stop error mode.

4. Verify the calibration using the OPA-S or the analog outputs. They should show 400 ppm CO2.

5. If unsuccessful, wait at least 1 minute before repeating the procedure again. Make sure that the sensor

environment is steady and calm!

Doc: 70-00-0220, V1.2, 20170131 © Vector Controls GmbH, Switzerland Page 5

Subject to alteration www.vectorcontrols.com

Loading...

Loading...