Page 1

TCI-W-U Universal Controller

OVERVIEW

Features

Universal PID and/or binary control for any analog input/output

signal and range

Multiple auxiliary functions: heat-cool auto changeover, automatic

enable, setpoint compensation

Averaging, min. and max. functions

Cascading of control loops (-W22 type)

Alarm monitoring of low and high limits on all inputs

Programmable reaction in case of alarm

Feedback function for inputs and set points

Functions for dehumidifying, set point shift, cascade control

Password protected programmable user and control parameters

TCI-W22-U also includes

Power Cap protected real-time clock with 48hr power backup

7-day programmable schedules, with options including change of

setpoints and direct position of manual outputs

Blue backlight

Fan coil units

Heat exchangers

Zoning

VAV

Air handlers

Fan, Pump control

Humidifiers

Dehumidifiers

Ventilation

Radiant heating

Radiant cooling

Pressurization

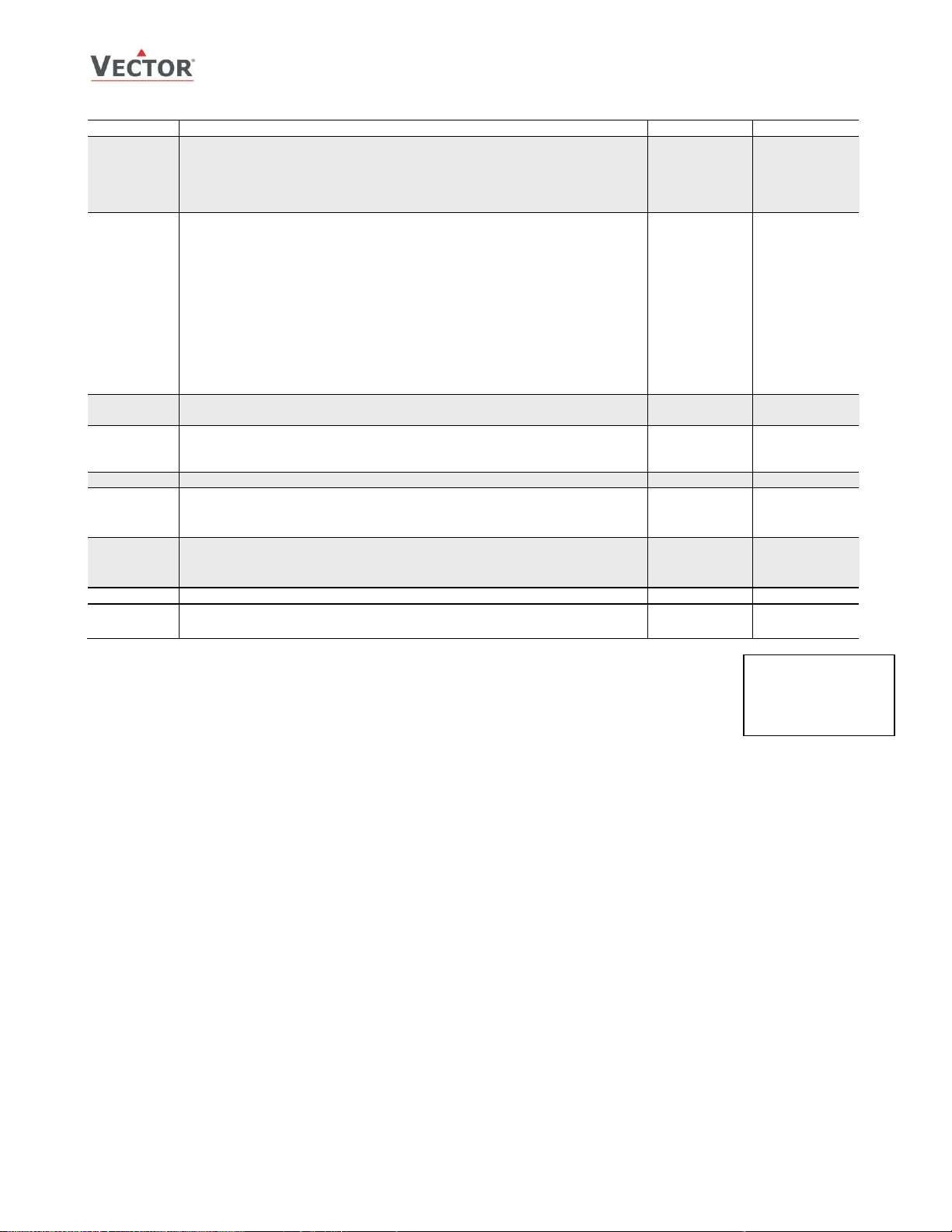

Model

Stock code

Loop

Temperature

Input

Humidity

Input

Universal

Input

Binary

Output

Analog

Output

Option

TCI-W11-U

40-10 0074 1 1 0 1 2 1

Standard

TCI-W11-U-H

40-10 0163 1 1 1 1 2 1

rH Sensor 3% acc.

TCI-W22-U

40-10 0076 2 1 0 2 2 1

Clock schedules

TCI-W22-U-H

40-10 0078 2 1 1 2 2 1

rH Sensor 3% acc.

AES3-HT-A2

40-50 0102 1

rH Sensor 2% acc.

AES3-HT-A3

40-50 0103 1

rH Sensor 3% acc.

AES3-HT-A5

40-50 0104 1

rH Sensor 5% acc.

Housing Blank = square housing

In/Outputs: See table below

Control loops: 1 = 1 control loop, 2 = 2 control loops

Mounting: W = Wall mounted

T C I

2 - W

U - 2

TCI-W-U Universal Controller

Applications

General

TCI-W11-U: 1 independent control loop, 1 internal temperature sensor, 1 universal input (analog/binary/temp), 2

binary outputs, 1 analog output

TCI-W22-U: 2 independent control loops, 1 internal temperature sensor, 2 universal inputs, 2 binary outputs, 1

analog output.

Internal temperature sensor standard. Add replaceable humidity element as required: AES3-HT-A2 (2%), AES3-

HT-A3 (3%), or AES3-HT-A5 (5%)

Flexible application configuration is made with a parameter-setting routine using the standard operation terminal.

Name

Ordering

Temperature sensors: Use Vector Controls NTC sensors to achieve maximum accuracy:SDB-Tn10-20 (duct), SRA-Tn10

(room), SDB-Tn10-20 + AMI-S10 as immersion sensor.

Actuators: Choose modulating actuators with an input signal type of 0-10 V DC or 4-20 mA (Min. and max.signal

limitations may be set with parameters.3-pointpoint actuators with constant running time are recommended.

Binary auxiliary devices (e.g. pumps, fans, on/off valves, humidifiers, etc):Do not directly connect devices that exceed

specified limits in technical specifications – observe startup current on inductive loads.

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 1

Subject to alteration

Page 2

TCI-W-U Universal Controller

OPERATION

Power Supply

Power Requirements

24 VAC ±10%, 50/60 Hz,Class 2, 2.0 A, 48 VA max.

24 VDC ±10%

Power Consumption

Max. 3 VA

Electrical Connection

Terminal Connectors

0.34…2.5 mm2 wire (AWG 24…12)

Clock backup

Min. 48 hours

Signal inputs

Universal Input

Input Signal

Resolution

Impedance

Setting for Voltage or Current

0–10 V or 0–20 mA

9.76 mV or 0.019 mA (10 bit)

Voltage: 98kΩ Current: 240Ω

Universal Input

Input configured to remote temperature (RT) or digital input (DI)

Range

NTC (Sxx-Tn10 sensor): -40…140 °C (-40…284 °F)

Accuracy

-40…0 °C (-40…32 °F): 0.5 K

0…50 °C (32…122 °F): 0.2 K

50…100 °C (122…212 °F): 0.5 K

> 100 °C (> 212 °F): 1 K

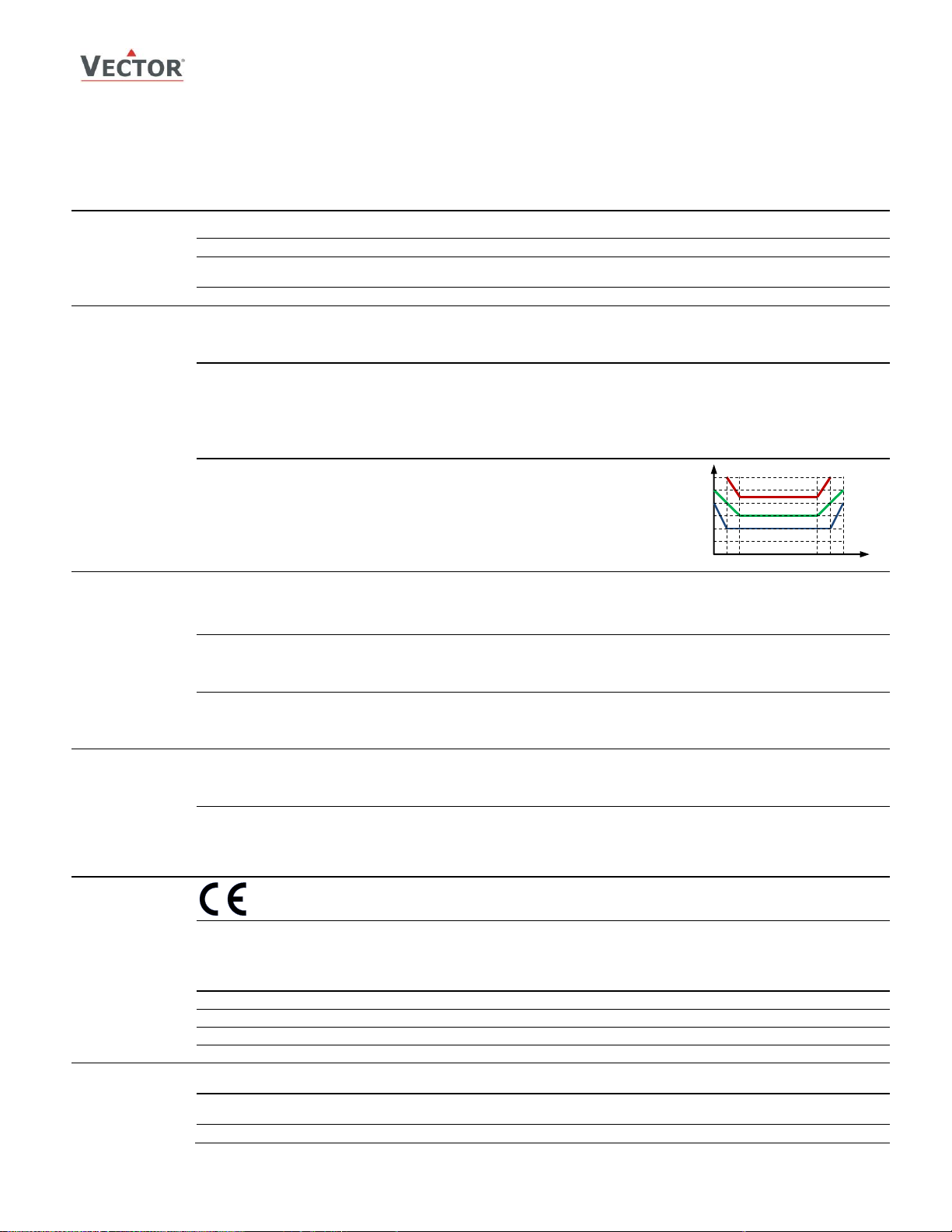

Humidity Sensor AES3-HT-Ax:

Range

Measuring Accuracy

Hysteresis

Repeatability

Stability

Capacity sensor

0…100 % rH

See Figure to the right

1%

0.1%

< 0.5% / year

Signal outputs

Analog Output

Output Signal

Resolution

Output Load

DC 0–10 V / 0–20 mA

9.76 mV / 0.019 mA

Voltage: ≥1kΩ Current: ≤250Ω

Relays Outputs

Type of disconnection

AC Voltage

DC Voltage

Micro-interruption

0…48 VAC, 2(1.2)A max. (Observe local regulation)

0…30 VDC, 2A max.

Insulation strength

between relays contacts and system

electronics:

between neighboring contacts:

2000V AC to EN 60 730-1

1250V AC to EN 60 730-1

Environment

Operation

Climatic Conditions

Temperature

Humidity

To IEC 721-3-3

class 3 K5

0…50 °C (32…122 °F)

<95 % r.H. non-condensing

Transport & Storage

Climatic Conditions

Temperature

Humidity

Mechanical Conditions

To IEC 721-3-2 and IEC 721-3-1

class 3 K3 and class 1 K3

-25…70 °C (-13…158 °F)

<95 % r.H. non-condensing

class 2M2

Standards

conforms to

EMC Standard 89/336/EEC

EMEI Standard 73/23/EEC

EN 61 000-6-1/ EN 61 000-6-3

Product standards

Automatic electrical controls for household

and similar use

Special requirement on temperature

dependent controls

EN 60 730 –1

EN 60 730 – 2 – 9

Degree of Protection

IP30 to EN 60 529

Pollution Class

II (EN 60 730-1)

Safety Class

III (IEC 60536)

Overvoltage Category

I (EN 60 730-1)

General

Material: Cover, back part

Mounting Plate

Fire proof ABS plastic (UL94 class V-0)

Galvanized Steel

Dimensions (H x W x D)

Front part: 112 x 73 x 15 mm (4.4” x 2.9” x 0.6”)

Power case: ø 58 x 32 mm (ø 2.3” x 1.3”)

Weight (including package)

TCI-W11-U = 255g (9.0 oz), TCI-W22-U = 265g (9.3 oz)

Max rH tolerance at 25°C (77°F)

%rH

%rH

10

20

30

40 1090 0 50

60

70

80

±1

±0

±2

±3

±4

AES3-HT-A2

AES3-HT-A3

AES3-HT-A5

Technical specifications

Warning! This device is intended to be used for comfort applications. Where a device failure endangers human life and/or

property, it is the responsibility of the owner, designer and installer to add additional safety devices to prevent or detect a

system failure caused by such a device failure. The manufacturer of this device cannot be held liable for any damage caused

by such a failure.

Failure to follow specifications and local regulations may endanger life, cause equipment damage and void warranty.

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 2

Subject to alteration

Page 3

TCI-W-U Universal Controller

OPERATION

1 7

G0 X1

1 8

G0X2

X

H1

X

T1

0V (COM)

24V AC/DC

2

G

TCI-W22

1

G0

0-48VAC, 0-30VDC

3

Q13

16

G0Y1

YM1

X

U1

YB1

4

Q14

YB2

5

Q24

0V AC

X

U2

X

T1

0V (COM)

24V AC/DC

2

G

TCI-W11

1

G0

0-48VAC, 0-30VDC

3

Q13

X

U1

1 7

G0X1

1 6

G0 Y1

YM1

YB1

4

Q14

YB2

5

Q24

0V AC

X

H1

Warning:

Live Electrical

Components!

During installation,

testing, servicing and

troubleshooting of

Vector Controls

products, it may be

necessary to work

with live electrical

components. Have a

qualified licensed

electrician or other

individual who has

been properly trained

in handling live

electrical components

perform these tasks.

Failure to follow all

electrical safety

precautions when

exposed to live

electrical components

could result in death

or serious injury.

112 (4.4)

73 (2.9)

32 (1.2)

15

Installation

Install the controller on an easy accessible interior

wall, approx. 1.5 m above the floor in an area of

average temperature.

Avoid direct sunlight or other heat sources, e.g. the

area above radiators and heat emitting equipment.

Avoid locations behind doors, outside walls and below

or above air discharge grills and diffusers.

Location of mounting is less critical if external

temperature sensors are used.

Ensure adequate air circulation to dissipate heat

generated during operation.

Observe local regulations.

Do not mount in a wet or condensation prone

environments.

Dimensions, mm (inch)

Connection

Terminal Description

G0 Power supply: 0V, -24VDC; common for power supply, analog in- and outputs

G Power supply: 24VAC, +24VDC

Q.. Binary outputs: Potential free relays contacts (see technical specification)

Yb1,b2 Binary output common

X

Universal input: NTC 10kΩ @ 25°C (77°F), 0…10 V or 0…20 mA(selectable by jumper)

U1, u2

Ym1 Analog output: 0…10 V or 0…20 mA

XT1 Internal temperature input

XH1 Internal humidity input if AES3-HT is inserted

Use copper, twisted pair, conductors only. The operating voltage must comply with the requirements for safety extra-low

voltage (SELV) as per EN 60 730. Use safety insulating transformers class II with double insulation as per EN 60 742; they

must be designed for 100% ON-time. When using several transformers in one system, the connection terminal 1 must be

galvanic connected. TCI is designed for operation of AC 24 V safety extra-low voltage and is short-circuit-proof. Supplying

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 3

Subject to alteration

*

Page 4

TCI-W-U Universal Controller

OPERATION

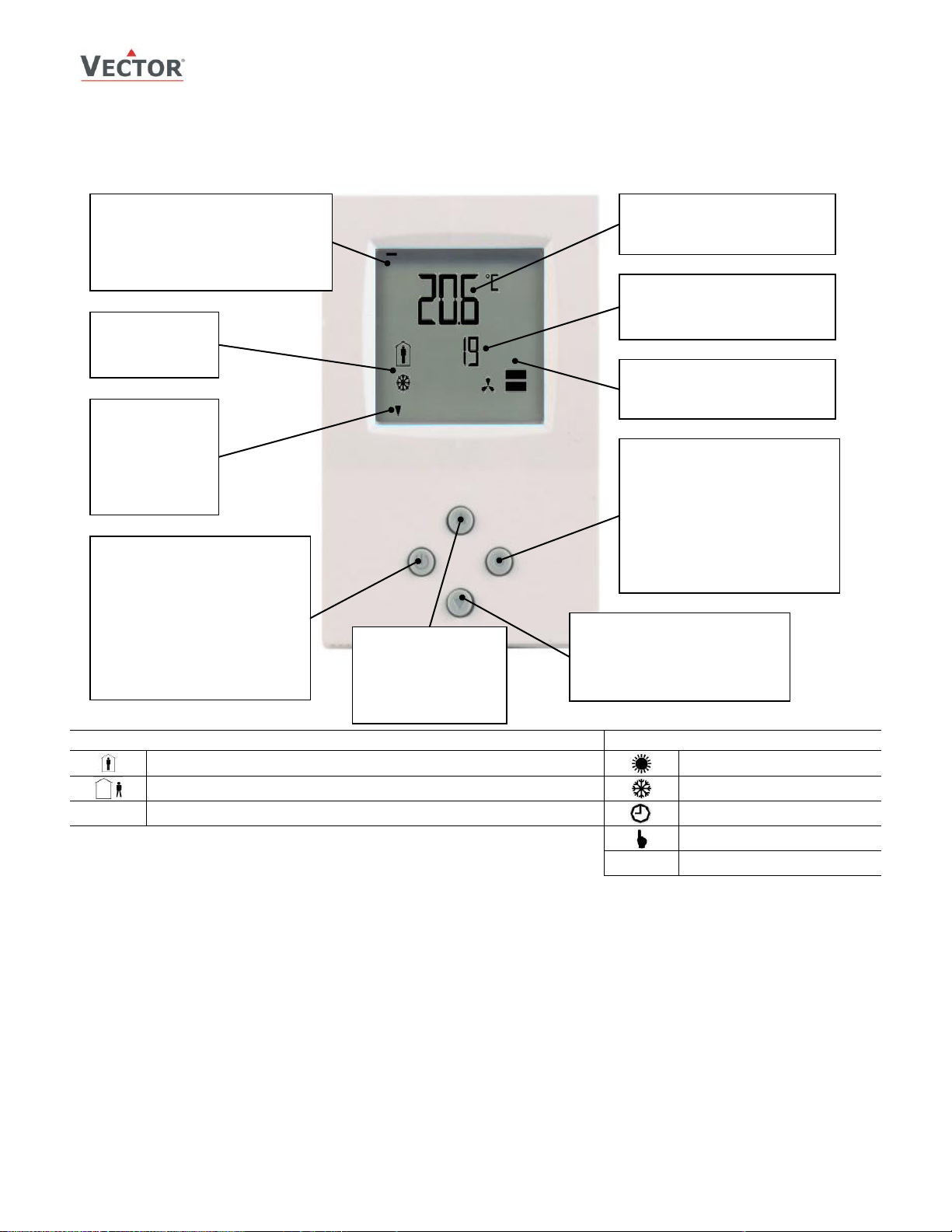

Operation mode symbols

Control symbols

Comfort (occupied): All control functions operating per set points

Heating (Reverse) Active

Economy (unoccupied): Set points shifted according to 1L07, 2L07

Cooling (Direct) Active

OFF

Energy Hold Off: Outputs are off, inputs monitored for alarms

Schedule Set

Manual Override

Fan Active

Left (POWER)

Press < 2 sec.: Toggle STANDBYCOMFORT mode or switch from OFF

to ON

Press > 2 sec.: Turn unit OFF. Text

OFF displayed with current time

(deluxe) temperature (standard)

(Parameter setting: ENTER to

select menu option, accept

parameter change)

Up

Increment SET POINT

(Parameter setting:

SCROLL menu options

and parameters)

Down

Decrement SET POINT

(Parameter setting: SCROLL menu

options and parameters)

Loop indication

Standard display (no button pressed

for 30 sec.): Not visible.

Loop display: Bar at 1 = Loop 1, Bar at

2 = Loop 2

Mode

Display of operation

mode

Large Digits

Display of input or parameter

value.

Indicators

Standard display:

Active digital

output (at 1, 2)

Loop display:

Active digital stages

(at 8,9,10)

Vertical Bar

(scrolls up/down, 10% resolution)

Small Digits

Display of setpoint, clock or

parameter number.

Right (OPTION)

Press < 2 sec.: Select Control Loop

Press > 2 sec.: Enter set-up

CLOCK, SCHEDULES, H/C

(Parameter setting: ENTER to

select menu option, accept

parameter change)

voltages above AC 24 V to low voltage connections may damage the controller or other devices. Connection to voltages

exceeding 42 V endangers personnel safety.

Display and Operation

Standard display (Parameters UP08, UP09, UP10)

Active whenno key has been pressed for 30 seconds.

Contents may be chosen with parameters.

Loop display

Active when changing set points. Large digits show input value. Small digits show set point. Vertical bars show analog

output value. Arrows in position 1, 2 and/or 3 show active binary (digital) output stages

Override of secondary set point in cascade control

If cascade control is active, withvariable air volume (VAV) for example,the user can override the primary loop and

manually select the set point of the secondary loop-the loop is now changed to constant air volume (CAV). Typically for

tuning the VAV system.This feature may be disabled with UP02.

While the secondary loop is displayed change the set point with UP/DOWN. Override Cascade symbol appears.

Press OPTIONto move back to the temperature loop and cancel cascade override.

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 4

Subject to alteration

Page 5

TCI-W-U Universal Controller

OPERATION

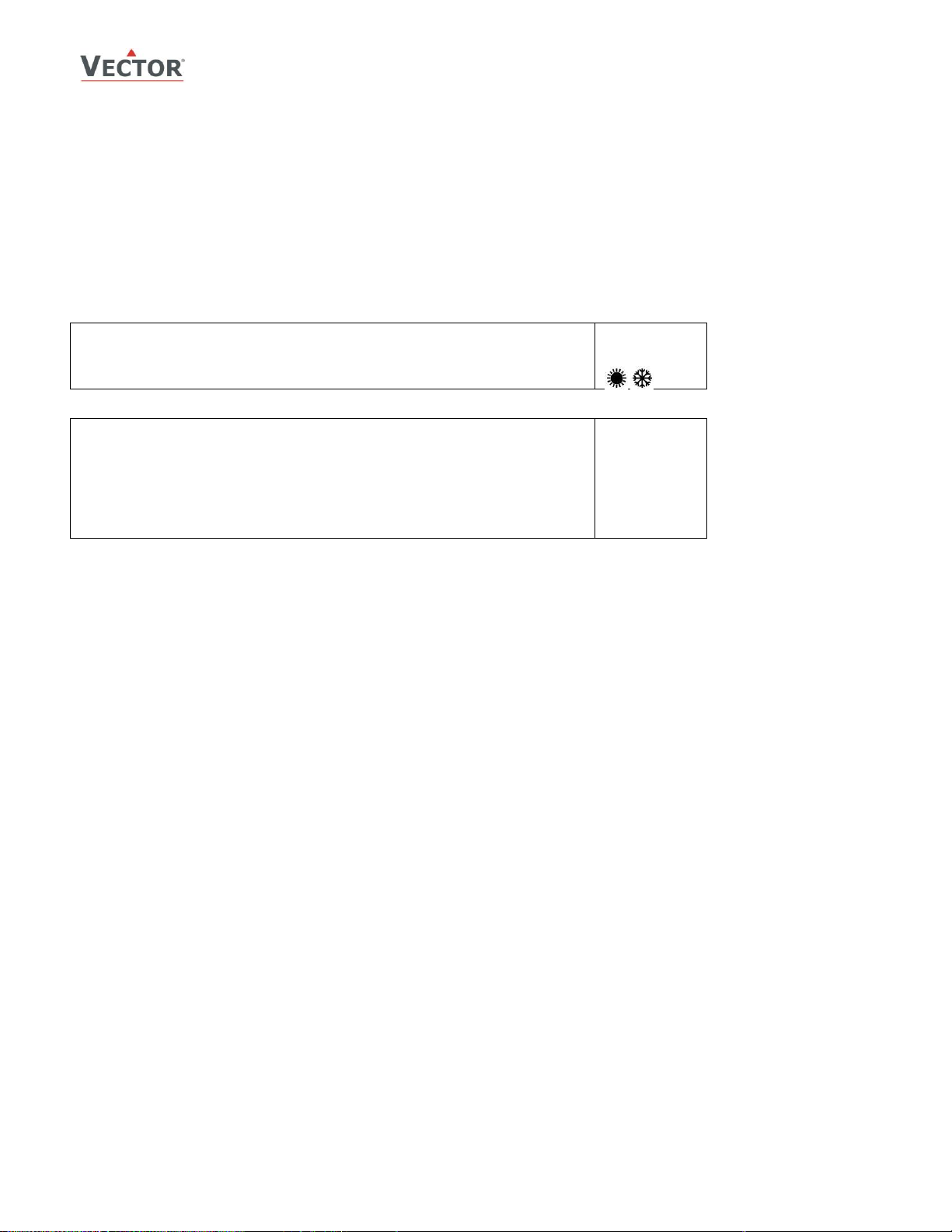

For TCI-W11-U: Press OPTION > 2 sec. SEL and H-C is displayed.

For TCI-W22-U: Press OPTION > 2 sec. SEL and current time is displayed.

Press UP key twice. SEL and H-C is displayed.

Press OPTION again to toggle H or C.

SEL

H-C

For TCI-W11-U: Press OPTION > 2 sec. SEL and H-C is displayed.

Press UP key once: UI1 and its value are displayed

For TCI-W22-U: Press OPTION > 2 sec. SEL and current time is shown.

Press UP key three times. UI1 and value are displayed.

Press UP key again to step through the next active input

Note: disabled inputs will not be shown.

75%

UI 1

Power Failure

All parameters and set points are memorized and do not need to be re-entered.

Upon return of power: SetParameter UP05to keep the unit off, switch on, or operation mode before power failure.

Clock and time schedule settings retained for 48 hours (after powered for at least 10 hours).

Error messages

Err1: An assigned input is not enabled or missing. All control loops, functions and outputs tied to this input will be disabled.

Err3: A function refers to a disabled input. Disable the function or enable the input.

Err4: Internal failure. Product must be replaced.

Verify input connections, jumper settings and parameter settings for the input involved.

Manual heat – cool change

To manually change heating or cooling mode press the OPTION key for more than 2 seconds. Access to manual heat – cool

change may be disabled with parameter UP03.

Display input values

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 5

Subject to alteration

Page 6

TCI-W-U Universal Controller

OPERATION

Press OPTION > 2 sec. SEL and current time displayed

Press OPTION< 2 sec. to change time,

Minutes blink: UP/DOWN to change, OPTION to save minutes,

Hours blink: UP/DOWN to change, OPTION to save hour,

Press OPTION to save time,

DAY1 blinks: UP/DOWN to change, OPTION to save day

SEL

00:00

DAY1 (Mon)

Press OPTION > 2 sec. SEL and current time displayed

Press UP:

SEL and PRO displayed, clock symbol blinks

Press OPTION:

Time schedule status displayed OFF or ON:

Press OPTION

OFF/ ON blinks, UP/DOWN to change, OPTION to save

SEL

PRO

Pro

OFF/ON

Press UP while PRO-ON displayed:

Large digits display Pr01, small digits display 00:00

Press OPTION:00:00 blinks

Press UP/DOWN to select Pr01switching time from 00:00–23:45

Press OPTION to save switching time (bar appears indicating step 1 complete):

DAY 1 blinks

Pr01

08:00

While Pr01 is displayed and DAY1 is blinking:

Press UP: Activate Pr01 switching time for DAY1 (triangle appears on 1),

Press DOWN:

Deactivate Pr01 switching time for DAY1(triangle disappears)

Press OPTION to save Pr01 DAY1 (2nd bar indicates step 2 complete):

Repeat for DAY2 – DAY7

Pr01

DAY1

1 2 3 4 5 6 7

After Pro1, DAY1–DAY7 is completed (Pro1 switching time activate or deactivate on desired days), press

OPTION again to come to desired action for Pro1. The following options appear in order:

No = switching time not active

OP = operation mode (select ON, OFF, COMFORT, ECONOMY)

L1 = set point of loop 1 (select set point)

L2 = set point of loop 2 (select set point)

d1 = ON/OFF status of do1 (output must be in manual mode)

d2 = ON/OFFstatus of do2 (output must be in manual mode)

A1 = set point (0-100%) of ao1 (output must be in manual mode)

After repeatedly pressing OPTION through DAY7:

First available action No appears, blinking:

Press UP/DOWN to scroll through the 8 possible actions (3nd bar indicates step 3 complete)

Pr01

no

Available actions blink as you scroll through them, Press OPTION to select one:

Characteristics of action (e.g. 0–100% for A1) appear (4th bar indicates step 4 complete)

Press UP/DOWN to select, OPTION to complete

Pr01

08:00

Clock operation

TCI-W22-Ucontains a quartz clock with battery back-up (not available in TCI-W11-U). Up to 8 mode changes based on time

and day of the week may be programmed. Also position an output or select a set point directly with a time schedule. A

blinking clock indicates that the time has not been setor thatthe unit has beenwithout power for longer than 48 hours. The

time needs to be set to allow time schedules to operate.

Clock setup

Enable/disable time schedules

Creating time schedules

Step 1: Select a switching time (Up to 8, Pr01–Pr08)

Step 2: Apply selected switching time (Pr01) to DAY1 (Mon) – DAY 7 (Sun)

Step 3: Select action for switching time (Pr01+Days)

Step 4: Complete switching event (e.g. Pro1 = 08:00, DAY 1, Comfort mode)

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 6

Subject to alteration

Page 7

TCI-W-U Universal Controller

SETUP AND CONFIGURATION

Module

Description

Notes

PW

UP

User and display parameters

Control user access and select display elements, regional settings

009

UI

Input configuration: 1T, 1H,

1U, 2U

TCI-W22-U: Internal temp. and RH, 2 universal inputs

TCI-W11-U: Internaltemp.1 universal input

241

LP

Control loops Lp1, Lp2

TCI-W22-U: 2 independent control loops

TCI-W11-U: 1 independent control loop

AO

Analog output configuration,

AO1

TCI-W11-U and TCI-W22-U : 1 analog output

DO

Binary output configuration,

do1, do2

TCI-W11-U and TCI-W22-U: 2 binary (digital) outputs - relays

FU

Special functions

Common to all TCI

Setting parametersto configurethe controller

TCI is an intelligentcontroller with the flexibility to fit a wide range of applications. The control operation is defined by

parameters set using the standard operation terminal. There are two levels:

1. User/display parameters (password 0009)

2. Control parameters (password 00241)

Recommended set-up procedure:

1. Set jumpers on the back of the controller for inputs and outputs

2. Connect power supply and inputs

3. Make sure Celsius – Fahrenheit settings are correct (UP07)

4. Program input parameters

5. Program control parameters

6. Program output parameters

7. Program auxiliary functions and user settings

8. Test function of unit

9. Switch off power

10. Connect outputs

11. Test control loop

Parameters are grouped according to modules:

How to change parameters

1. Press UP/DOWN buttons simultaneously for three seconds. The display will show firmware version and revision number.

Press the OPTION button to start login.

2. CODE is shown in small display.

3. Code to access user parameters is 009, control parameter is 241. The access numbers are fixed and cannot be changed.

4. Select this using UP/DOWN buttons.

5. Press OPTION after selecting the correct code.

6. Once logged in with 009, the user/display parameters are displayed immediately. Once logged in with 241 control

modules are displayed (Lp1, Lp2, 1u, 2u, etc.) –select with UP/DOWN and open with OPTION. As soon as the module is

open its parameters are displayed.

7. Select the parameters with the UP/DOWN buttons. Change a parameter by pressing the OPTION button. Three arrows are

displayed to indicate that the parameter may be modified. Use UP/DOWN buttons to adjust the value.

8. After you are done, press OPTION to save the new value and return to the selection level (arrows disappear when

selection is saved). Pressing left hand POWER button without pressing OPTION will discard the value and return without

saving. For control parameters press POWER again to leave parameter selection and return to control module selection.

9. Press the POWER to leave the menu. The unit will return to normal operation if no button is pressed for more than 5

minutes

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 7

Subject to alteration

Page 8

TCI-W-U Universal Controller

USER CONFIGURATION

Parameter

Description

Range

Default

UP 00

Enable access to operation modes

ON/OFF

ON

UP 01

Enable access to set points

ON/OFF

ON

UP 02

Enable manual control in cascade

ON/OFF

ON

UP 03

Enable change of heating/cooling mode for 2 pipe systems

ON/OFF

ON

UP 04

Enable access to time programs:

ON/OFF

ON

UP 05

State after power failure:

0= off, 1= on, 2= state before power failure

0, 1, 2

2

UP 06

Enable Economy (unoccupied) Mode.

Shift the setpoint to a lower temperature in winter or higher temperature in

summer in order to save energy. Economy mode may be activated through

the POWER button, or with the external input (typically for key card

switches in hotel rooms or motion detectors for meeting rooms.)

ON/OFF

ON

UP 07

Celsius or Fahrenheit: ON= Fahrenheit, OFF= Celsius

ON/OFF

OFF (Celsius)

UP 08

Show standard display while no key is pressed

ON/OFF

ON

UP 09

Select type of contentforlarge digits (00= OFF):

0–5

1

01= Input

02= Setpoint

03= Analog Output

04= Binary Output

05= Clock

UP 10

Select content sourcefor large digits (0=OFF):

0–4

1

Input:

1= 1T

2=1H

3= 1U

4= 2U

Set point:

1= Lp1

2= Lp2

Analog output:

1 – AO1

Binary output:

1 – DO1

2 – DO2

UP 11

Select type of contentforsmall digits(same options as UP09)

0–5

Standard = 2

Deluxe = 5

UP 12

Select content sourceforsmall digits (same options as UP10)

0–4

1

UP 13

Select analog output for vertical bar display (00= OFF):

0–4

3

01= AO1

02= FO1

03= Output LP1

04= Output LP2

UP 14

Display heating/cooling state in standard display mode

ON/OFF

OFF

UP 15

ON = Alarms blink after being active and need to be confirmed

OFF= Alarms are only shown when they are active

ON/OFF

ON

UP 16

(TCI-W22-

U)

Clock display type: OFF= 24-hr, ON= 12-hr(AM/PM)

ON/OFF

OFF(24hr)

UP 17

(TCI-W22-

U)

Reset timer for manual override of PRO time schedule:

0= Not active

1–255= Delay for controller to go back to the scheduled OFF, ECONOMY, or

COMFORT operation mode if the operationmode is changed manually.

0–255 Min

60(Min)

User and display parameters (password 009)

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 8

Subject to alteration

Page 9

TCI-W-U Universal Controller

INPUT CONFIGURATION

Parameter

Description

Range

Default

1T00

1H00

Enable internal sensor

OFF/ON

ON

1T01

1H01

Display minimum value

-50–205

0

1T02

1H02

Display maximum value

-50–205

100

1T03

1H03

Sensor sampling rate(control speed decrease as rate increases)

0–100

10

1T04

1H04

Sensor calibration

per input

0

1T 05

1H05

Alarm 1low limit (1T), Alarm 3low limit (1H)

OFF/ON

OFF

1T06

1H06

Alarm 1/3low limit values

-40–215°C

5

1T07

1H07

Alarm 2high limit (1T), Alarm 4high limit (1H)

OFF/ON

OFF

1T08

1H08

Alarm 2/4high limit values

-40–215°C

50

1T09

1H09

Hysteresis Alarm 1, 2, 3, 4

0–100°

5

1T10

1H10

Calculate a range of inputs (0= not active):

1=average, 2=minimum, 3=maximum, 4=differential

0–3

0

1U 00

Signal type (0= not active):

1=0-10V or 0-20mA, 2=2-10V or 4-20mA, 3= passive temperature

0–3

1

1U 01

Display minimum value

-50–205

0

1U 02

Display maximum value

-50–05

100

1U 03

Analog input display range: 0= x 0.01, 1= x 0.1, 2= x 1, 3 = x 10

0–3

1

1U 04

Analog input unit of measure: 0= no unit, 1= %, 2= °C /°F, 3= Pa

0–3

0

1U 05

Sensor sampling rate(control speed decrease as rate increases)

0–100

10

1U 06

Sensor calibration

Per input

0

1U 07

Alarm 5low limit(1U), Alarm 7low limit (2U)

OFF/ON

OFF

1U 08

Alarm 5/7low limit value

-40–215°C

5°C(40°F)

1U 09

Alarm 6high limit (1U), Alarm 8 high limit (2U)

OFF/ON

OFF

1U 10

Alarm 6/8high limit value

-40–215°C

50°C(122°F)

1U 11

Hysteresis alarm 5 and 6 (7 and 8)

0–100°

5°C(10°F)

1U 12

Calculatea range of inputs (0=not active):

1= average, 2= minimum, 3= maximum, 4= differential

0–4

0

Input

1T

1H

1U

2U

Low limit

ALA1

ALA3

ALA5

ALA7

High limit

ALA2

ALA4

ALA6

ALA8

Control configuration (Password 241)

Input configuration

Internal inputs 1T temperature and1H humidity (with added AES3-HT-A2,3 or 5 element)

Universal inputs 1U, 2U (TCI-W11-U: 1U only, TCI-W22-U: 1U and 2U)

Set jumpers on the back of the controller: 0–10VDC (default), 0–20mA, or RT/DI (passive temperature or binary)

Further define analog inputs with U00

Match sensor range to input display. With a differential pressure transmitter having 0–200 Pa measuring range set UO1

display minimum to 0 and U02 display maximum to 200. The allowable range value of -50–205 may be adjusted with

multipliers inU03. The largest displayable values are -990–9999. Limiting range increases resolution.Applies to analog as

well as passive temperature inputs.

For binary input (open/close contact) set the jumper to RT/DI and parameter U00 to an analog input. An open contact

reads as a high value (100%), a closed contact as a low value (0%).

Enable / Disable an alarm. Setting the alarm enable to OFF will prevent the alarm from being displayed on screen. It may

never the less be used to control an output by setting the appropriate output alarm flags. This way, an alarm limit may be

used as interlock.

Specify the input value that triggers an alarm. Hysteresis is the difference between alarm level input and value required

to turn the alarm off. An alarm is displayed as text if enabled (see table). Alarm text can be set to blink continuously until

acknowledged by pressing the OPTION button or only while the alarm conditions are active (see user parameter UP15).

Calculate a range of inputs for loop control or display with T10, H10, U12. The largest input of the group selected will

carry the calculated value. When average is activated on 2U12 and 1T10, the averageis carried on 2U.Inputs grouped for

calculation must be of same type and range. It is possible to use different functions on different inputs. For example,

minimum of 1T and 2U and maximum of 1U and 1H. It is not possible to use different functions on one input.

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 9

Subject to alteration

Page 10

TCI-W-U Universal Controller

CONTROL LOOP CONFIGURATION

Parameter

Description

Range

Default

1L 00

Select loop control input (0= loop disabled):

1= 1T, 2= 1H, 3= 1U, 4= 2U

0–4

1

1L 01

Minimum set point limit heating

per input

10°C(50°F)

1L 02

Maximum set point limit heating

per input

28°C(82°F)

1L 03

Minimum set point limit cooling

per input

18°C(64°F)

1L 04

Maximum set point limit cooling

per input

34°C(92°F)

1L 05

Enable set point compensation (0= disabled)

1= winter compensation, 2= summer compensation, 3= winter and summer

0–3

0

1L 06

Loop input special (0= normal):

1= combine loop 1 and loop 2

2= cascade with reverse sequence of primary loop

3= cascade with direct sequence primary loop

4= cascade with both reverse and direct sequence of primary loop

0–4

0

1L 07

Economy mode set point shift: (Function depends on 1L25)

The comfort (occupied) setpoint is shifted by the value set with parameter.

Reduces the heating set point and increases the cooling set point.

per input

5.0°C(10°F)

1L 08

Dead zone between heating and cooling set points

The Dead Zone Span lies between the heating and the cooling setpoint. The

output is off while the measured value is within the dead zone span. A negative

dead zone is not possible.

Per input

1.0°(2°F)

1L 25

Fixed setpoint in ECONOMYmode

OFF = ECONOMYset point shift applies

ON = In ECONOMYmode use minimum setpoint limit as setpoint in heating

mode or maximum setpoint limit in cooling mode

ON, OFF

OFF

1L 26

Setpoint compensation range, the maximum range the setpoint is shifted.

0 = Temperature setback: the setpoint is shifted towards setpoint limit

Acc input

0.0°C

Cascade Control Example – VAV Application

Secondary loop =airflow/pressure (2L)

Primary loop = temperature (1L)

2L01=20%, 2L02=100%, 2L06=2

Temperature output is spanned between min (20%) and max(60%) pressure

setpoint limits

When temperature output is 50%pressure set point is 40% (e.g. 4v with 0-

10v rage)

Pressure set point is determined by temperature demand. Change the pressure range to change the impact the

temperature output will have on pressure setpoint

Control loop configuration (TCI-W11-U: 1L only, TCI-W22-U: 1L and 2L)

Manipulation of the setpoint

Economy mode setpoints: There are two possibilities to change the setpoint in economy mode: Shift it by L07 or switch to

the minimum setpoint limit in heating mode and maximum setpoint limit in cooling.

Economy mode may be disabled by setting UP06 to OFF.

Control loops and sequences are activated when output parameters are defined.

In cascade control (L06) the output of the primary loop determines the set point of the secondary loop. Select the

cascade parameter on 2L to make 1L primary. Select the cascade parameter on 1L to make 2L primary. A typical

application is a variable air volume systemwhere the temperature outputdetermines the pressure set point.

Setpoint Compensation

The setpoint compensation is typically used to compensate the set point due to a change in outside temperature. The

relationship to the input used to drive the setpoint compensation is defined in auxiliary functions FU00 to FU07.

Enable summer or winter set point compensation for this control loop with L05. Define the compensation range with

L26.L26 defines the full setpoint shift once the compensation input has reached its lower limit in winter mode or upper

limit in summer mode.

Setting the range parameter to 0 will activate the setpoint setback function: The setback function shifts the set point

toward the set point minimum or the set point maximum based on an external input value.Once the compensation input

has reached its lower limit in winter mode or upper limit in summer mode, the setpoint is fixed to the setpoint minimum

or maximum value. Commonly this is used for humidity control to avoid condensation on outside walls or windows in very

cold weather.

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 10

Subject to alteration

Page 11

TCI-W-U Universal Controller

CONTROL LOOP CONFIGURATION

Legend

T, U Input signal temp/universal

X

PH

P-band heating/direct

X

PC

P-band cooling/reverse

X

DZ

Dead zone h/c set points

X

SBY

Economy mode set point shift

W

H

Set point heating/reverse

W

C

Set point cooling/direct

Y

H1, YR1

PI sequence heating/reverse

Y

C1, YD1

PI sequence cooling/direct

Parameter

Description

Range

Default

1L 09

Offset for heating PI sequence

per input

0

1L 10

Offset for cooling PI sequence

per input

0

1L 11

P-band heating

per input

2.0°C(4.0°F)

1L 12

P-band cooling

per input

2.0°(4.0°F)

1L 13

Integral gain heating (0.1 steps)

low= slow reaction, high= fast reaction

0–25.5

0.0

1L 14

Integral gain cooling(0.1 steps)

0–25.5

0.0

1L 15

Measuring interval integral (seconds)

low= fast reaction, high value= slow reaction

0–255

1 sec.

Recommended Values

heating (air)

heating (radiant)

humidifying

cooling

dehumidifying

pressure

P-band

2–3°C(4–6°F)

1–1.5°C(2–3°F)

Measuring interval (TI)

2 5 15 1 70

1

Integral gain (KI)

0.2

0.1

0.1

0.2

0.3

0.8

Heating/Reverse

Cooling/Direct

100

0

T [°C, F]

U [V, mA]

YH1, Y

R1

XPH

W

H

XPC

XDZ

Y

C1, YD1

W

C

X

SBY

X

SBY

PI control sequence

Proportional control(P-band)

The proportional control function calculates the output based on the difference between setpoint and measured value. The

proportional band (P-band) defines the difference between setpoint and measured value which will result in a 100%

output. For example, with a heating or reverse 0-10v control sequence, and a 2.0°C (4.0°F) P-band value, at 10v the

controller will be 2.0°C (4.0°F) below setpoint. This is the working range of the proportional control sequence.

Setting the proportional band to 0 disables proportional control.

Integral and Differential control

Proportional control is in most cases a very stable control mode. The flaw of proportional control alone, however, is that

the setpoint is normally not reached. As the measured value gets closer to the setpoint, the output reduces until it

reaches a point, a fraction above or below the setpoint, where the output equals the load. To reach the setpoint and

achieve a higher level in comfort the Integral/Differential function should be activated.

Integral Gain (KI)dynamically increases the output by the selected KI value every Measuring Interval TI until the

setpoint is reached. The challenge is to prevent hunting, where the output increases too fast, the temperature overshoots

the setpoint, the output goes to 0, the temperature undershoots the setpoint, and the cycle repeats itself. Hunting may

result if the integral gainis too high or measuring interval too short. Each system is different. To prevent instability the Pband should be extended when integral gain is active (L14 or L15 set above 0).

Setting the integral gain to 0 disables integral and differential control.

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 11

Subject to alteration

Page 12

TCI-W-U Universal Controller

CONTROL LOOP CONFIGURATION

Legend

T, U Input signal

O

QH

Offset heating/direct

O

QC

Offset cooling/reverse

X

DZ

Dead zone

X

SBY

Economy set point shift

W

H

Set point heating/reverse

W

C

Set point cooling/direct

QC, Q

D

Binary sequences cooling/direct

QH, Q

R

Binary sequences heating/reverse

Parameter

Description

Range

Default

1L 16

Action of stages:

0= cumulative:stage 1 stays on when 2 on comes on

1= single:stage 1 turns off when 2 on comes on

2= digital: stage 1 only, stage 2 only, then stage 1 plus 2

0–2

0

1L 17

Offset for heating/reverse binary sequences

per input

0.0°(0.0°F)

1L 18

Offset for cooling/direct binary sequences

per input

0.0°(0.0°F)

1L 19

Switching span heating

per input

1.0°(2.0°F)

1L 20

Switching span cooling

per input

1.0°(2.0°F)

1L 21

Switching hysteresis

per input

0.5°(1.0°F)

1L 22

Switching delay

0–255s

10s

1L 23

Activation of reverse/direct (heat/cool) sequence

OFF= activates based on demand

ON = follows heat/cool state of controller: Set manually or by auxiliary function

(FU20-FU23)

ON/OFF

OFF

1L 24

Delay for heat /cool changeover when L23=OFF

0–255 min

5 min

Cumulative

Single

Digital

Stage 1

Q1

Q1

Q1

Stage 2

Q1+Q2

Q2

Q2

Stage 3

Q1+Q2

ON

OFF

T [°C, F]

U [V, mA]

Q

C2, QD2

OSH

W

H

OSC

XDZ

W

C

XH

Q

C1, QD1

Q

H2, QR2

Digital control sequence

Cumulative stage action (L16=0)is typically used in electric heat applications, and single stage action (L16=1)in fan speed

applications. Digital stage action (L16=2) is especially useful in electric heat applications to generate three steps with just

two outputs. For example: Step 1=100W, step 2=200W, step 3=300W.

Switching hysteresis (L21) is the difference between switching on and switching off. A small hysteresis will increase the

number of switching cycles and thus the wear on associated equipment.

With switching delay (L22) cumulative stages will not switch on simultaneously. With a sudden demand or initial power

stage 2 will not start earlier than 10 seconds (default value) after stage 1 has been initiated.

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 12

Subject to alteration

Page 13

TCI-W-U Universal Controller

OUTPUT CONFIGURATION

W

H

W

C

100

50

0

YH1,Y

R1

XDZ

Y

C1,YD1

Heating

Cooling

1A04

1A05

1A03

1A06

T (°C/F), U(V, mA)

Output Priority

1. Alarm level low

2. Alarm level high

3. Operation mode OFF

4. Control function

Parameter

Description

Range

Default

1A 00

Select control loop or special function (0= OFF):

1= LP1, 2= LP2

3= Dehumidify (4 pipe, max LP1 cooling, LP2 direct)

4= Manual positioningor by time schedule (0–100%)

5= Transmit value ofan input

0–5

1

1A 01

When 1A00=1configure output:

0= Heating/reverse

1= Cooling/direct

2= Heating and cooling (2 pipe)

3= Transmit setpoint

When 1A00 = 4: Manual positioning or by time schedule

0 = time schedule only

1 = manual positioning and by time schedule

When 1A00=5, select input (0= function disabled):

1= 1T, 2= 1H, 3= 1U, 4= 2U

0–4

0

1A 02

Type of output signal: OFF= 0–10V, 0–20mA, ON= 2–10V, 4–20mA

ON/OFF

OFF

1A 03

Minimum limitation of output signal default and in loop heating mode

0–100%

0

1A 04

Maximum limitation of output signal default and in loop heating mode

0–100%

100%

1A 05

Minimum limitation of output signal in loop cooling mode

0–100%

0%

1A 06

Maximum limitation of output signal in loop cooling mode

0–100%

100%

1A 07

Choose alarm to set output to 100% (output 0%on conflicting alarms)

Alarm: 1 2 3 4 5 6 7 8

ALA1–ALA8

1A 08

Choose alarm to set output to 0%. (output 0% on conflicting alarms)

Alarm: 1 2 3 4 5 6 7 8

ALA1–ALA8

1A 09

Transmit value (1A00=5): minimum input value

per input

0°C

1A 10

Transmit value (1A00=5): maximum input value

per input

100°C

Output configuration

Analog output configuration (1A)

Set jumpers on the back of the controller: 0–10VDC (default), or 0–20mA.Further define analog outputs with A02.Custom

ranges can be created by setting minimum and maximum signal limits.

A control loop, special function, digital control or analog control sequence is not active until it is assigned an output.

Low and high limit alarms are defined with input parameters. With output parameters assign an

alarm to an output andselect output state. The required output for each alarmcan be

individually selected. Multiple alarms can be signed to one output. If one alarm is selected to

simultaneously activate and deactivate an output, the one to de-activate has precedence.

With manual positioning (1A00=4) position the output by time schedule or directly in 0.5%

steps. Setting 1A01 to 0 will disable manual positioning. The output will then only be controlled by time schedule.

With dehumidifying (1A00=3)the maximum value is taken of cooling and dehumidifying. When the humidity is too high,

cooling will continue to operate, even without a demand for cooling, to dehumidify the air and heating will activate to

maintain comfort.

Inputvalues of inputs and set points of control loops may be transmitted on the analog outputs.

For VAV Function individual minimum and

maximum limits may be assigned for cooling and

heating. In VAV applications maximum cooling

output matches the maximum air volume the

VAV box is set to deliver. As demand for airflow

in cooling mode decreases, airflow dwindles until

it reaches minimum cooling output (1A05). This

minimum will be based on the airflow needed at

design cooling and is typically 10% to 15% of

maximum cooling airflow. When this minimum is

reached the system is in dead-band – neither

heating nor cooling. Minimum airflow in heating

mode is set with 1A03. As the system moves into

heating mode, heating airflow increases until it

reaches the maximum heating output (1A04), typically 30 to 50% of maximum cooling airflow.

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 13

Subject to alteration

Page 14

TCI-W-U Universal Controller

OUTPUT CONFIGURATION

Output Priority

1. Alarm level low

2. Alarm level high

3. Operation mode OFF

4. Control function

Parameter

Description

Range

Default

1d00

Enable digital orfloating point output

OFF= 1dand 2D are two digital outputs

ON = 1dand 2D are one floating point output (1d open,2D close)

ON/OFF

OFF

1d01

Select control loop or special function (0= OFF)

1= LP1, 2= LP2

3= Dehumidify (4 pipe, max LP1 cooling, LP2 direct)

4= Manual positioning (open/close)

5= Controllerstate functions

0–5

0

1d02

If1d01=1 configure output:

0=Heating/reverse

1= Cooling/direct

2= Heating and cooling (2 pipe)

If 1d01 = 4 Manual positioning or time schedule controlled

0 = Time schedule controlled only

1 = Manual positioning and time schedule controlled

If 1d01=5 select state functions:

0= ON if controller operation state is ON

1= ON while demand on any output

2= ON while controller in heating mode and operation state ON

3= ON while controller in cooling mode and operation state ON

0–5

0

1d03

Running time (from open to close)

0–255s

90s

1d04

Switching difference for floating point signal

0–100s

5s

1d05

Not used

1d06

Choose alarm to set output to 100% (output 0% on conflicting alarms)

Alarm: 1 2 3 4 5 6 7 8

ALA1–ALA8

1d07

Choose alarm to set output to 0% (output 0% on conflicting alarms)

Alarm: 1 2 3 4 5 6 7 8

ALA1–ALA8

1d08

Not used

1d 09

Not used

Digital output configuration (1d, 2D)

Floating point outputs (1d00 or 2D00=ON)

Low and high limit alarms are defined with input parameters. With output parameters assign an

alarm to an output and select output state. Each alarm’s required output can be individually

selected. Multiple alarms can be signed to one output. Should one alarm be simultaneously

selected to activate and deactivate the output, the one to de-activate has precedence.

With manual positioning (1d01=4) position the output directly (open/close).

With dehumidifying (1d01=3) the maximum value is taken of cooling and dehumidifying. When the humidity is too high,

cooling will continue to operate, even without a demand for cooling, to dehumidify the air and heating will activate to

maintain comfort.

For floating point outputs the running time of the actuator used needs to be specified with 1d03. Running time is defined

as the time required for the actuator to run from fully open to fully closed and vice versa. Actuators with a fixed running

time are recommended. Once fully open or fully closed the running time for the actuator is extended for a full run-time

cycle. This will allow the actuator position to be synchronized in case it has been moved during off time or an actuator

with variable running time was used. Use switching differenceparameter 1d04, to reduce the switching frequency of the

actuator. The actuator will only move if the difference to the current actuator position is larger than this parameter.

State functions (1d01=5)activate the output based on certain conditions with or without a demand for heating or cooling,

in either comfort or standby mode. In Energy Hold OFF mode (EHO) the output will be off.

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 14

Subject to alteration

Page 15

TCI-W-U Universal Controller

OUTPUT CONFIGURATION

Output Priority

1. Alarm level low

2. Alarm level high

3. Operation mode OFF

4. Control function

Parameter

Description

Range

Default

1d01

Select control loop or special function (0= OFF)

1= LP1, 2= LP2

3= Dehumidify (4 pipe, max LP1 cooling, LP2 direct)

4= Manual positioning (on/off)

5= State functions

0–5

0

1d02

When 1d01=1, configure output:

0= Stage 1 heating/reverse

1= Stage 1 cooling/direct

2= Stage 1 heating and cooling, reverse and direct

3= Stage 2 heating/reverse

4= Stage 2 cooling/direct

5= Stage 2 heating and cooling, reverse and direct

When 1d01=5,select state functions:

0= ON if controller operation state is ON

1= ON while demand on any output

2= ON while controller in heating mode and operation state ON

3= ON while controller in cooling mode and operation state ON

0–5

0

1d03

Switch-off delay (time output active with no more demand)

Delay is in seconds or minutes depending on d09

0–255

90sec

1d04

Switch-on delay(time demand active before output on)

In state mode 1d01=5 outputs disabled during switch-on delay

Delay is in seconds or minutes depending on d09

0–255

5 sec

1d05

Activate PWM, set cycle time, seconds (>0activates,0 deactivates)

0–1650s

0s

1d06

Choose alarm to set output to ON (output OFF on conflicting alarms)

Alarm: 1 2 3 4 5 6 7 8

ALA1–ALA8

1d07

Choose alarm to set output to OFF (output OFF on conflicting alarms)

Alarm: 1 2 3 4 5 6 7 8

ALA1–ALA8

1d08

Display fan symbol while active

ON/OFF

OFF

1d 09

Binary switching delays in minutes or seconds

OFF = delays are in seconds, ON = delays are in minutes

ON, OFF

OFF

Digital outputs (1d01, 2D01=OFF)

Low and high limit alarms are defined with input parameters. With output parameters assign an

alarm to an output and select output state. Each alarm’s required output can be individually

selected. Multiple alarms can be signed to one output. Should one alarm be simultaneously

selected to activate and deactivate the output, the one to de-activate has precedence.

With manual positioning (1d01=4) position the output directly (ON/OFF).

With dehumidifying (1d01=3) the maximum value is taken of cooling and dehumidifying. When the humidity is too high,

cooling will continue to operate, even without a demand for cooling, to dehumidify the air and heating will activate to

maintain comfort.

State functions (1d01=5)activate the output based on certain conditions with or without a demand for heating or cooling,

in either comfort or standby mode. In Energy Hold OFF mode (EHO) the output will be off.

Pulse width modulation (PWM) mode is enabled with 1d05. In PWM mode the digital output will be switched on/off once

per cycle. The on and off times are calculated according to the PI settings of the respective control sequence (see control

loop Parameters L09–L15).TCI-W11-U and TCI-W22-U use relays for the digital outputs. It is not recommended to use

cycle times below 100 seconds as the lifetime of the relays will be shortened with frequent switching. For PWM

applications requiring cycle times below 100 seconds we recommend using TCI-W13 with TRIAC outputs.

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 15

Subject to alteration

Page 16

TCI-W-U Universal Controller

AUX FUNCTIONS CONFIGURATION

Parameter

Description

Range

Default

Fu 00

Select compensation input (0= function disabled):

1= 1T, 2= 1H, 3= 1U, 4= 2U

0–4

0

Fu 01

Winter compensation setpoint setback

OFF= shift toward control loop heating set point minimum

ON= shift toward control loop heating set point maximum

ON/OFF

OFF

Fu 02

Winter compensation lower limit value – end shift

per input

5°C(41°F)

Fu 03

Winter compensation upper limit value – start shift

per input

20°C(68°F)

Fu 04

Summer compensation setpoint setback

OFF= shift toward control loop cooling set point minimum

ON= shift toward control loop cooling set point maximum

ON/OFF

ON

Fu 05

Summer compensation lower limit value – start shift

per input

35°C(95°F)

Fu 06

Summer compensation upper limit value – end shift

per input

40°C(104°F)

Fu 07

Show hot/cool symbol while compensation active

ON/OFF

OFF

Fu 08

Select comfort/economy changeover input (0= disabled):

1= 1T, 2= 1H, 3= 1U, 4= 2U

0–4

0

Fu 09

Economy activation delay (seconds)

-1275s

300s

Fu 10

Input limit 1

per input

10

Fu 11

Input limit 2

Per input

90

Standby

Mode

Mode

Comfort

Input

Limit 2 > Limit 1

Comfort

Standby

Input

Limit 1 > Limit 2

Limit 1 Limit 2 Limit 2 Limit

1

1L03

FU04-OFF

Winter Compensation – FU01

Summer Compensation – FU04

1L02

T [°C,F],

U[V,mA]

FU01-ON

1L01

FU01-OFF

Set point

Min/max

FU04-ON

1L04

FU06

W

Auxiliary functions

Summer/winter compensation

Comfort/economy mode changeover

Summer/winter compensation changes the set point due to a change in an input value, typically, but not limited to, an

outdoor temperature input. Winter compensation starts when outside temperature drops below the upper limit of winter

compensation (FU03). At maximum winter compensationthe actual set point will be equal to the control loop’smaximum

heating set point (L02). Summer compensation starts when outside temperature exceeds the lower limit for summer

compensation (FU05). At maximum summer compensationthe actual set point will be equal to the control

loop’smaximumcooling set point (L04). Activatesummer/winter compensation with control loop configuration

parameter(L05).

Use comfort/economy mode changeover with key card switches, occupancy sensors, etc. Set input limit 1 and 2 with

possibilities below. Example: When Limit 2 is greater than Limit 1, switch comfort-to-economy at the lower value,

economy-to-comfort at the higher value. Activatecomfort/economy changeoverwith loop configuration parameter(L07).

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 16

Subject to alteration

Page 17

TCI-W-U Universal Controller

AUX FUNCTIONS CONFIGURATION

Parameter

Description

Range

Default

Fu 12

Select enable–disable input (0=function disabled):

1= 1T, 2= 1H, 3= 1U, 4= 2U

0–4

0

FU 13

Manual override permitted (without waiting for delay). This function allows

starting the controller, even the enable conditions are not met. The controller

will switch off again if the running conditions are not met until the disable

delay is expired.

ON/OFF

OFF

Fu 14

Enable delay (seconds)

0–1275s

0

Fu 15

Disable delay (seconds)

0–1275s

300

Fu 16

Range of limits:

OFF = When limit 2 is greater thanlimit 1, enable when input value is greater

than limit 2,disable when input value is less thanlimit 1. When limit 2 is less

thanlimit 1, enable when input value less than limit 1, disable when input

value is greater thanlimit 2.

ON = When limit 2 is greater thanlimit 1enable when input value is between

limit 1 andlimit 2. When limit 2 is less thanlimit 1, enable when input value

below limit 2 or above limit 1

ON/OFF

OFF

Fu 17

Input limit 1

per input

10

Fu 18

Input limit 2

Per input

90

Fu 19

Disable in case of alarms

Selection

Limit 2 > Limit 1

Limit 1 > Limit 2

Enable

Disable

Input

Mode

Enable

Disable

Input

Mode

FU16 = OFF

FU16 = ON

Enable

Disable

Input

Mode

Enable

Disable

Input

Mode

Limit 1 Limit 2 Limit 2 Limit 1 Limit 1 Limit

2

Limit

2

Limit

1

Enable/disable

Enable or disable the controller based on desired input values, such as high or low temperature, occupancy sensor,

window contact, etc. Can be used as and function where several conditions must be met before disable or enable. Time

schedules do not override, but manual override is permitted. Delay times may be assigned for both enable and disable

(allows for the controller to start before validation of operation values takes place). Set input limit 1 and 2 with options

below. Example: With FU16=OFF, and Limit 2 > Limit 1, switch enable-to-disable at Limit 1, disable-to-enable at Limit 2.

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 17

Subject to alteration

Page 18

TCI-W-U Universal Controller

AUX FUNCTIONS CONFIGURATION

Parameter

Description

Range

Default

Fu 20

Select heat/cool changeover input (0=function disabled):

1= 1T, 2= 1H, 3= 1U, 4= 2U, 5= h/c status loop 1, 6= h/c status loop 2

0–6

0

Fu 21

Cooling activation delay (seconds)

0–1275s

300

Fu 22

Input limit 1

per input

20

Fu 23

Input limit 2

per input

40

Cool

Mode

Mode

Heat

Input

Limit 2 > Limit 1

Heat

Cool

Input

Limit 1 > Limit 2

Limit 1 Limit 2 Limit 2 Limit

1

Heating/cooling mode changeover

Switch heating/cooling state based on a universal input value. The input may be from a supply media (air or water) or

outdoor air temperature sensor. For supply media temperature we recommend switching to cooling at 16°C/61°F and to

heating at 28°C/83°F. For outdoor temperature we recommend switching to cooling at 28°C/83°F and to heating at

16°C/61°F outdoor temperature. These recommendations are given as suggestions. The ideal settings may be different

on the actual project depending on climatic and system conditions.

The change between heating and cooling is delayed to avoid unnecessary switching (FU21). Heat/cool status of one

control loop may also be determined by the heat/cool state of the other loop (FU20= 5 or 6). The control loop used to

determine the heat /cool state must be set to demand-based heating and cooling with (L23). Set limit 1 and limit 2 to

switch between heating and cooling with options below. Example: When Limit 2 is greater than Limit 1, switch heat to

cool at Limit 1, cool to heat at Limit 2. For binary open/close contact, open is a high value (100%), closed is a low value

(0%).

Doc: 70-07-0140, V1.2, Date: 20170123 © Vector Controls GmbH, Switzerland Page 18

Subject to alteration

Loading...

Loading...