Page 1

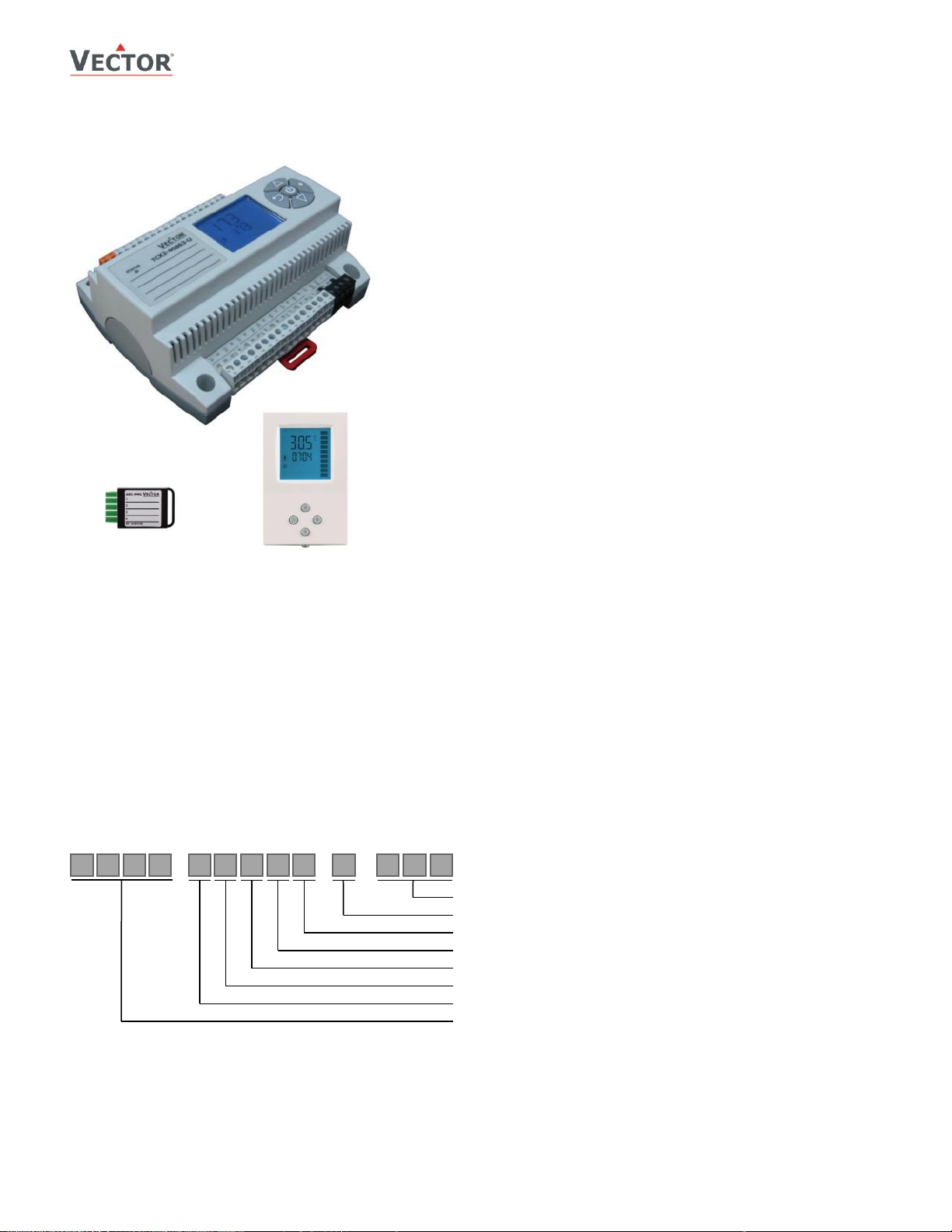

TCX2 Universal Controller

TECHNICAL DATA

Features

RS485 bus communication with remote operation terminal

OPU2-VC.

Universal PI and/or binary control for any analog input/output

signal and range.

Multiple auxiliary functions: heat-cool auto changeover,

automatic enable, set point compensation.

Free heating or cooling with economizer function based on

enthalpy or temperature.

Differential, averaging, min and max functions

Cascading of control loops.

8 free assignable alarm conditions,

Selectable state of outputs on alarm condition.

Transmitter function for inputs and set points.

Functions for dehumidifying, set point shift, and cascade

control.

Password protected programmable user and control

parameters.

Power Cap protected real-time clock with 48hr power backup.

7-day programmable schedules, with options including change

of setpoints and direct position of manual outputs.

Blue backlight.

Clone parameter sets with plug-in memory AEC-PM1 – easily

transport application parameters to multiple controllers.

Heat exchangers

Fan coil units

Boilers

VAV with reheat/recool

Air handlers

Fan, Pump control

Humidifiers

Dehumidifiers

Ventilation

Radiant heating/cooling

Pressurization

Package units

OPU2-VC

AEC-PM1

Com: Communication standard

Option: OP = with operation terminal

# AO: 3 Analog outputs

# DO: 6 Binary outputs

# UI: 8 Universal inputs

# DI: 0 Binary inputs

# LP: 4 control loops

Series: TCX2

T C X

4 - 2 0 8 6 3

- M (

) -

D

O

TCX2-40863-OP

TCX2-Series Communicating Cabinet Mounted Universal Controller

Applications

General

The TCX2 is a programmable electronic universal controller with communication capabilities. Each control loop may use 2 PI

sequences and 6 binary stages. The TCX2 comes with a built in RS485 communication interface that allows peer to peer

communication with an operation terminal e.g. OPU2-(2TH)-VC or a PC.

Communication plug-ins allow for integration of the controller into a network. These modules are described in their own

manual. Currently available are plug ins for BACnet and MODBUS.

Flexible application configuration is made with a parameter-setting routine using the standard operation terminal.

Complete parameter sets may be copied by use of an accessory called AEC-PM1 or exchanged with a PC using an RS485-USB

converter and the EasySet program.

Name

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 1

Page 2

TCX2 Universal Controller

TECHNICAL DATA

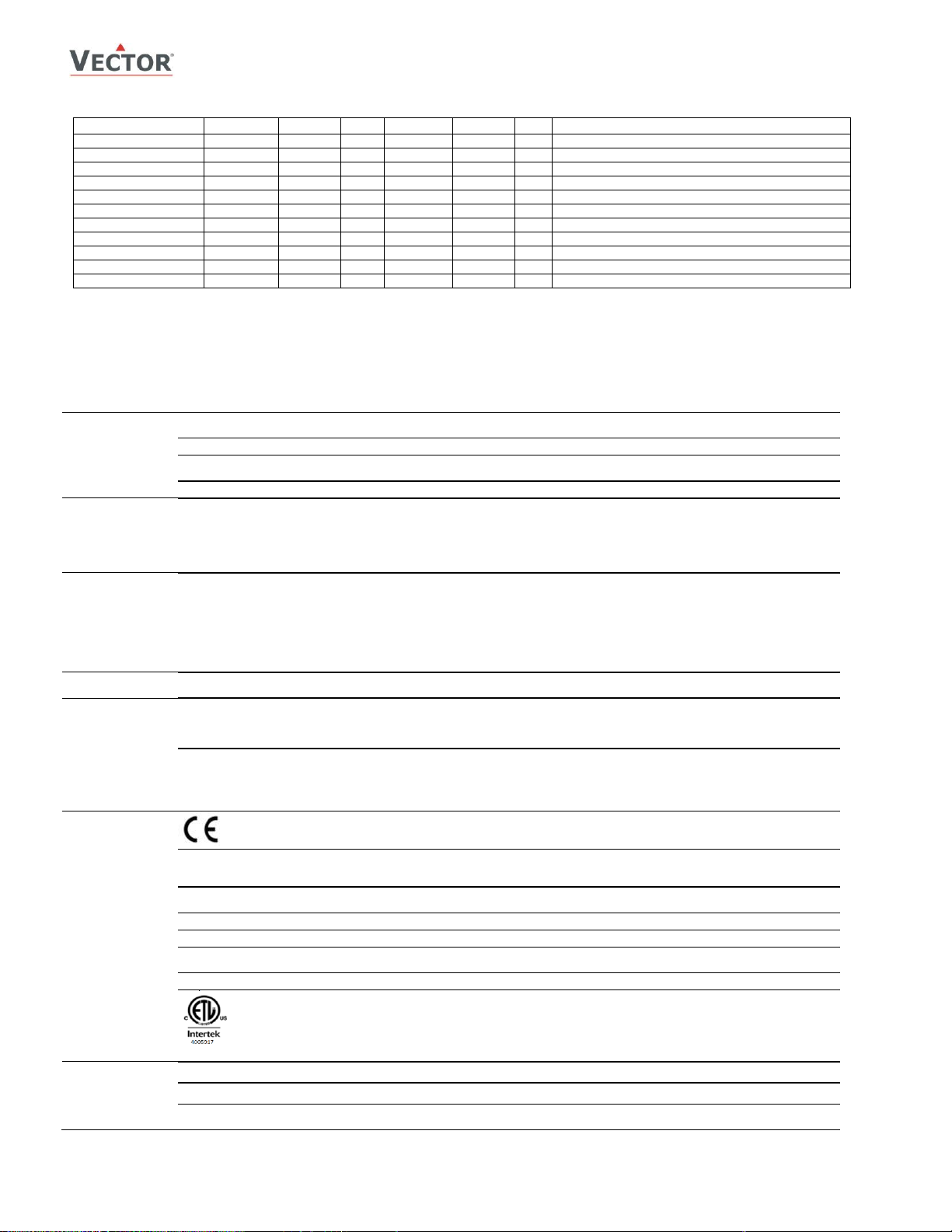

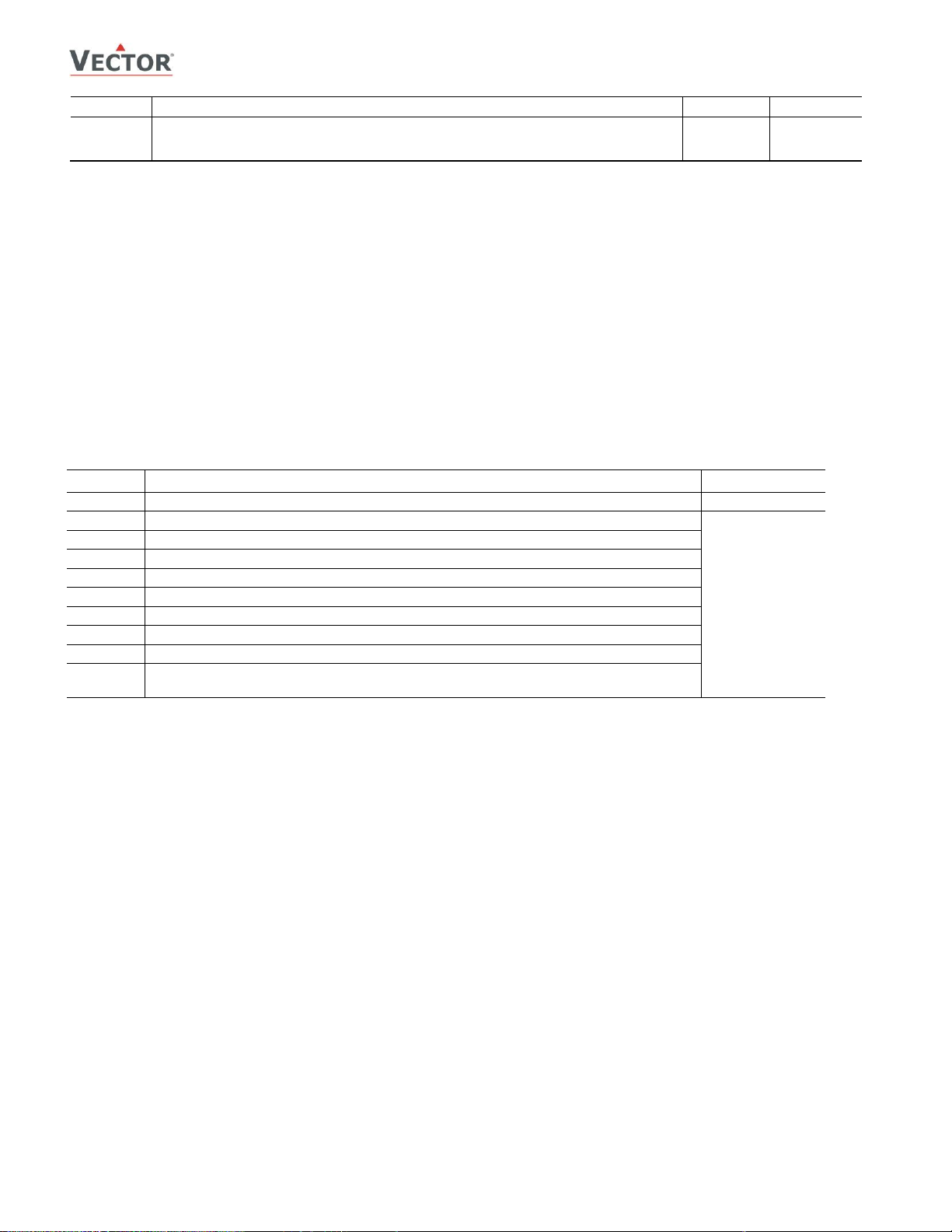

Model

Item#

Display

Loop

UI

DO

AO

Description

TCX2-40863

40-11 0032

no 4 8

6 Relays

3

Universal controller stand alone

TCX2-40863-OP

40-11 0036

Yes 4 8

6 Relays

3

Controller with display stand alone

OPU2-VC

40-50 0021

Yes - 1T - -

Remote terminal

OPU2-2TH-VC

40-50 0025

Yes

-

1T+1RH+2

Remote terminal with RHT + 2 passive inputs

OPU2-2T-VC

40-50 0024

Yes - 1T+2

Remote terminal with RT + 2 passive inputs

OPU2-2TH-VC

40-50 0025

Yes

-

1T+1RH+2

Remote terminal with RHT + 2 passive inputs

AEC-PM1

40-50 0016

- - - - -

Plug-In memory module

AEX-MOD

40-50 0013

- - - - -

Modbus communication module

AEX-BAC

40-50 0044

- - - - -

BACnet MS/TP communication module

AMM-1

40-51 0022

- - - - -

Accessory for cabinet door mounting

AEC-USB-01

40-50 0046

-

- - -

-

Accessory to exchange parameter set with PC

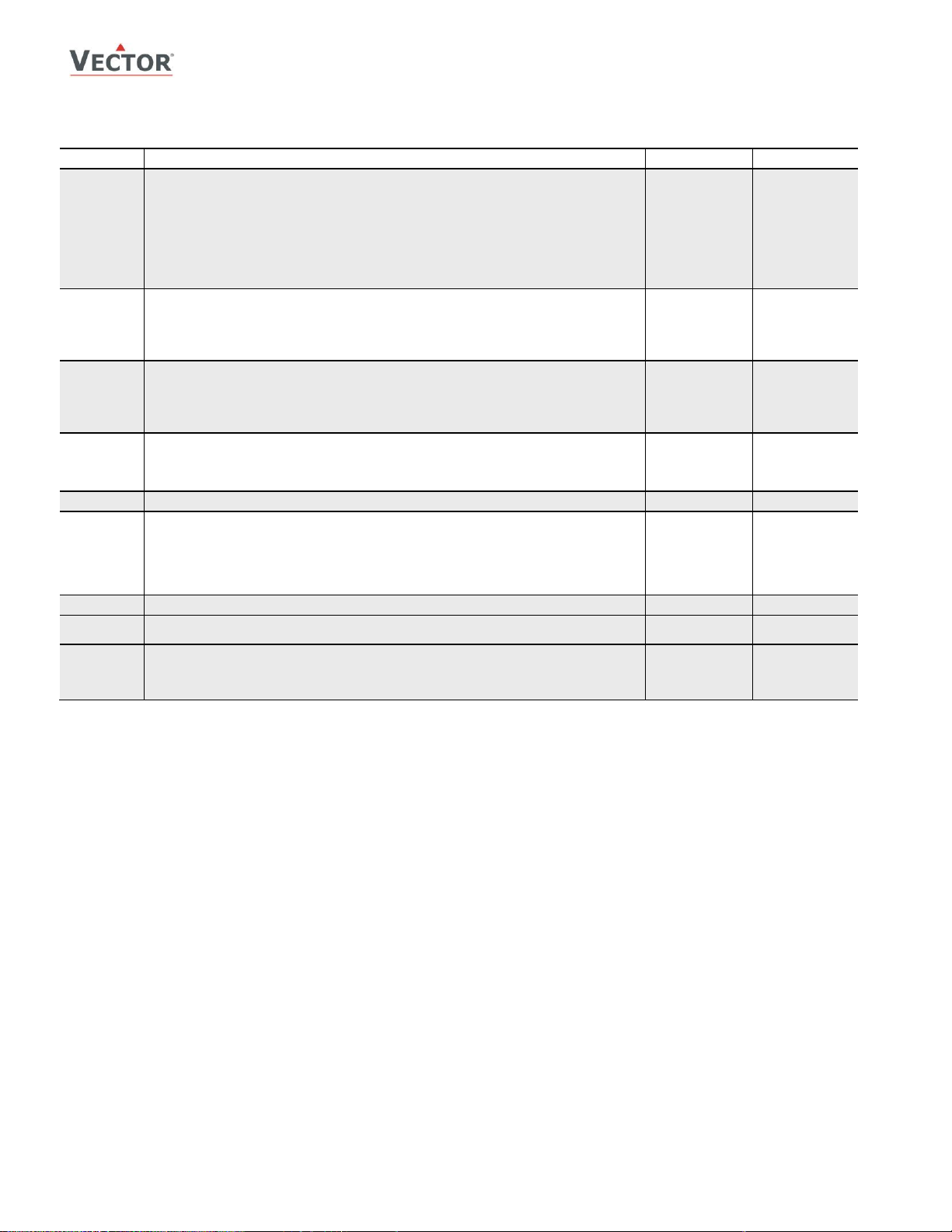

Power supply

Power requirements

24 VAC ±10%, 50/60 Hz, 24VDC ±10%

SELV to HD 384, Class II, 48VA max

Power consumption

Max. 10 VA

Electrical connection

Removable terminal connectors,

wire 0.34…2.5 mm2 (AWG 24…12)

Clock backup

Min. 48 hours

Signal inputs

Universal input

Input signal

Resolution

Impedance

Input jumper set for voltage or current

0...10 V or 0...20 mA

9.76 mV or 0.019 mA (10 bit)

Voltage: 98kΩ Current: 250Ω

Passive input

Type & range:

Input jumper set to temperature (RT) or digital input (DI)

NTC (Sxx-Tn10): -40…140 °C (-40…284 °F)

Signal outputs

Analog outputs: Output signal

Resolution

Maximum load

DC 0...10 V or 0...20 mA

9.76 mV or 0.019 mA (10 bit)

Voltage: ≥1kΩ Current: ≤250Ω

Relays outputs: AC Voltage

DC Voltage

0…250 VAC, full-load current 3A, locked-rotor 18A.

0…30 VDC, full-load current 3A, locked-rotor 18A.

Insulation strength

between relays contacts and system electronics:

between neighboring contacts:

4000V AC to EN 60 730-1

1250V AC to EN 60 730-1

Connection to

remote terminal

Hardware interface

Cabling

RS485 in accordance with EIA/TIA 485

Twisted pair cable

Environment

Operation

Climatic conditions

Temperature

Humidity

To IEC 721-3-3

class 3K5

0…50 °C (32…122 °F)

<85 % RH non-condensing

Transport & storage

Climatic conditions

Temperature

Humidity

Mechanical conditions

To IEC 721-3-2 and IEC 721-3-1

class 3K3 and class 1K3

-25…70 °C (-13…158 °F)

<95 % RH non-condensing

class 2M2

Standards

conformity

EMC directive

Low voltage directive

2004/108/EC

2006/95/EC

Product standards

Automatic electrical controls for household and similar use

Special requirement on temperature dependent controls

EN 60 730 –1

EN 60 730 – 2 – 9

Electromagnetic compatibility for

industrial and domestic sector

Emissions: EN 60 730-1

Immunity: EN 60 730-1

Degree of protection

IP00 to EN 60 529

Pollution class

II (EN 60 730-1)

Safety class: Local regulations must be observed!

III (IEC 60536) if SELV is connected to DO

II (IEC 60536) if line voltage is connected to DO.

Overvoltage category

III (EN 60 730-1)

Product standards:

Temperature- indicating and -regulating equipment

Mark: c(ETL)us

UL 873

CSA C22.2 No. 24

Certified by Intertek: 4005917

General

Material

Fire proof ABS plastic (UL94 class V-0)

Dimensions (H x W x D)

57 x 147 x 115 mm (2.3 x 5.8 x 4.5 in)

Weight (including package)

TCX2-40863: 430g (15.2 oz)

TCX2-40863-OP: 490g (17.3 oz)

Ordering

Technical specifications

Important notice and safety advice

This device is for use as operating controls. It is not a safety device! Where a device failure endangers human life and/or property, it is the

responsibility of the client, installer and system designer to add additional safety devices to prevent a system failure caused by such a device failure.

Ignoring specifications and local regulations may cause equipment damage and endangers life and property. Tampering with the device and

misapplication will void warranty.

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 2

Page 3

TCX2 Universal Controller

TECHNICAL DATA

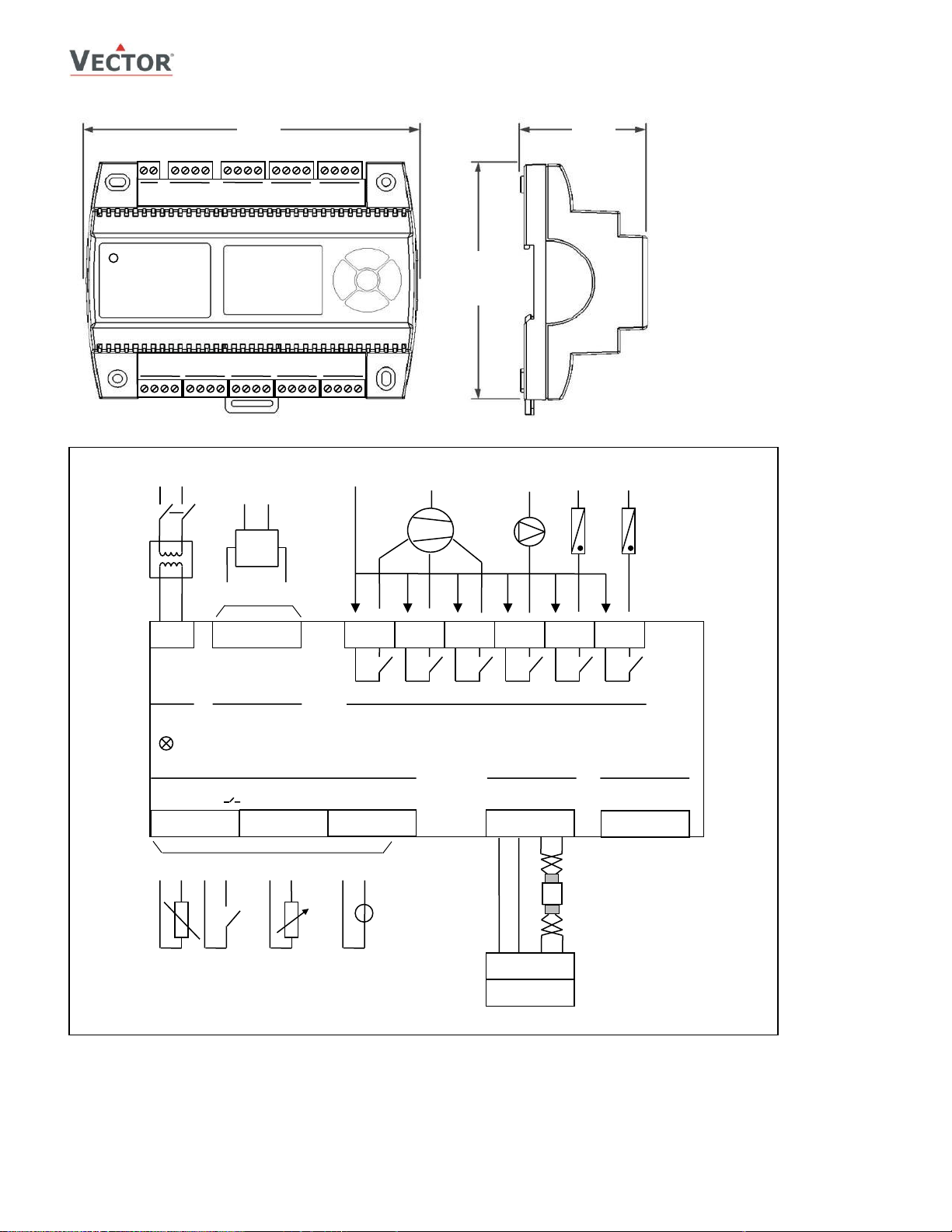

147 (5.8)

57 (2.3)

115 (4.5)

M

X1

X2

X3 M X4

X5

X6 M X7

X8

M

OP1

OP2

OP3

OP4

TX1

TX2

TX3

TX4

Status

G0 G

N L

M Y1 Y2 Y3

M

Y

AO 0...10VDC

Select by JP

Actua-

tor

Q13 Q14

Analog Output (3x)

Power

24VAC

10VA

Q23 Q24

Q33 Q34

Q43 Q44

Digital Output (6x)

Relays 3A

N

L

N

Outputs are

Status LED

M X1 X2 X3

NTC10kΩ, DI ( ), 0...10VDC, 4...20mA select by JP

M X4 X5 X6

Universal Input (8x)

OP1

OP2

OP3

OP4

RS485

Operation Terminal

RS485

AEX Plug-In

M X M

X

NTC

10kΩ

M

X

Pot.

M

X

0...10VDC

4...20mA

Temperature

Pressure

Humidity

CO2

etc.

Door contact

Dew point

Occupancy

Alarm

Enable

1 2 3 4

OPU2-(2TH)-VC

+V

CAT5

CAT6

Q53 Q54

N

Q63 Q64

N

M X7 X8

TX1

TX2

TX3

TX4

Dimensions, mm (inch)

Connection diagram

4...20mA

assignable

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 3

Page 4

TCX2 Universal Controller

TECHNICAL DATA

AO: Selection of analog output type

Left position: voltage output (0…10 V)

factory default

Right position: current output (0…20 mA)

AO1

UI: Selection of universal input type

Left position: voltage input (0…10 V)

factory default

Middle position: current input (0…20 mA)

Right position: RT or dry-contact

UI1

0…10V

0…20mA

0…10V

0…20mA

RT / DI

█ █

Jumpers

Jumpers are located on the backside of the controller

Installation

See installation sheet no. 70-000599 (www.vectorcontrols.com).

Selection of actuators and sensors

Temperature sensors: Use Vector Controls NTC sensors to achieve maximum accuracy: SDB-Tn10-20 (duct), SRA-Tn10 (room),

SDB-Tn10-20 + AMI-S10 as immersion sensor.

Actuators: Choose modulating actuators with an input signal type of 0-10 V DC or 4-20 mA (Min. and max. signal limitations

may be set with parameters. 3-point point actuators with constant running time are recommended.

Binary auxiliary devices (e.g. pumps, fans, on/off valves, humidifiers, etc.): Do not directly connect devices that exceed

specified limits in technical specifications – observe startup current on inductive loads.

Electrical connections

Use only twisted pair copper conductors for input connections. The operating voltage must comply with the requirements for

safety extra-low voltage (SELV) as per EN 60 730.

Use safety insulating transformers with double insulation. They must be designed for 100% ON-time. When using several

transformers in one system the connection terminal 1 must be galvanically connected. The TCX2 is designed for operation by AC

24 V, max. 10 Amp, safety extra-low voltage that is short-circuit-proof. Supplying voltages above AC 24 V may damage or

destroy the controller or any other connected devices.

Additionally, connections to voltages exceeding 42 V endanger personnel safety. Observe limits mentioned in the technical

specifications. Local regulations must be observed at all times.

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 4

Page 5

TCX2 Universal Controller

OPERATION

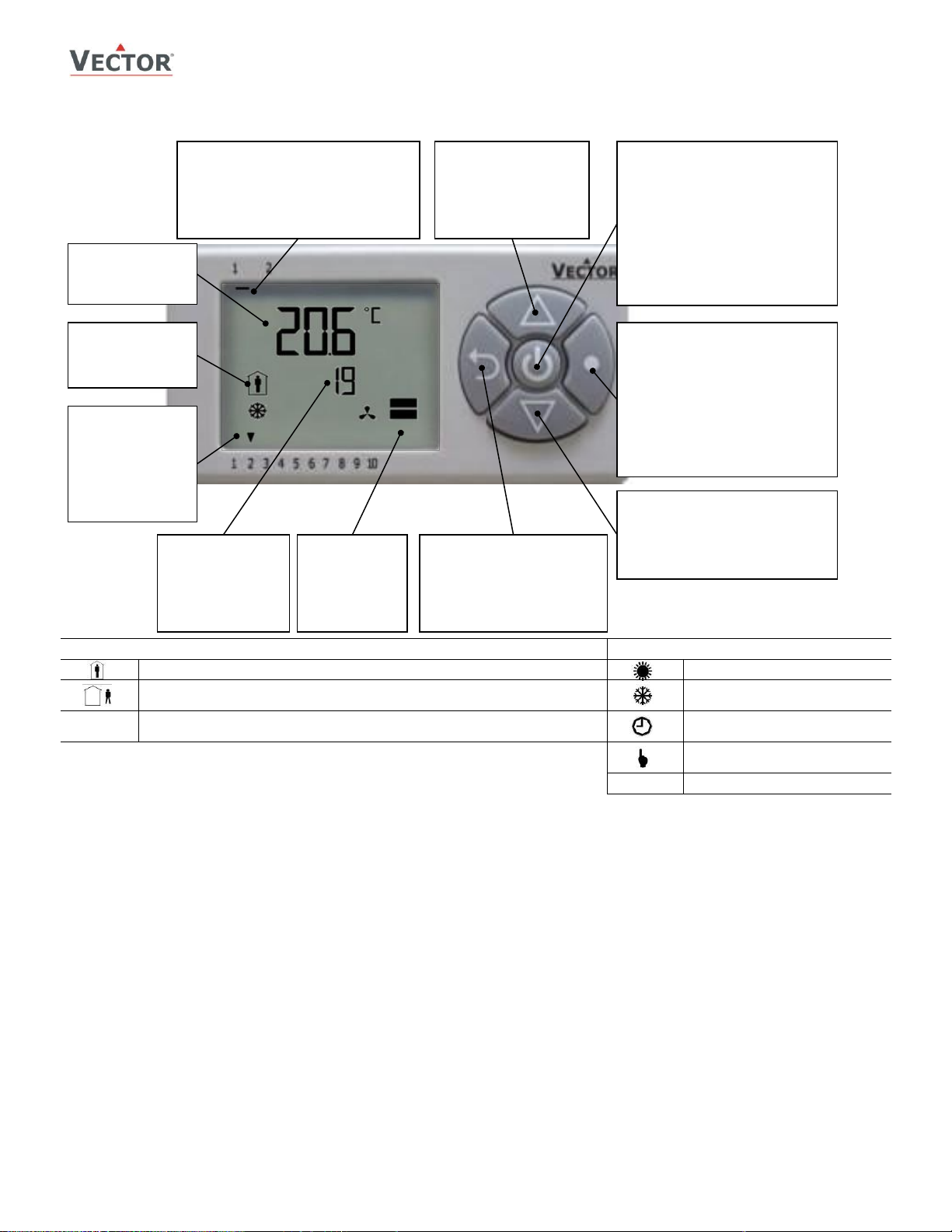

Operation modes

Control symbols

Occupied: (Comfort) All control functions operating per set points.

Heating (reverse) active

Unoccupied: (Standby, Economy) If enabled, alternative setpoints are

used with the intention to reduce energy consumption.

Cooling (direct) active

OFF

OFF: (Energy Hold Off, EHO) Normal control functions are inactive,

inputs are monitored for alarms.

Schedule set

Manual override,

delay on enable function

Fan active

Left (ESC)

parameter setting)

Center (POWER)

UP

and parameters)

DOWN

Loop indication

Mode

Display of operation

mode

Large Digits

Display of input or

parameter value.

Indicators

Idle display: Active

digital output (at 1

to 6)

Parameter setting:

8,9,10 indicate

changing mode.

Vertical Bar

resolution)

Small Digits

Right (OPTION)

Display and Operation

Idle display (no button pressed for 30

sec.): Not visible.

Loop display: Bar at 1 = Loop 1, Bar at

2 = Loop 2, etc

Display of

setpoint, clock

or parameter

number.

Display of

output value.

(Scrolls

up/down, 10%

Increase SET POINT

(Parameter setting:

SCROLL menu options

Select Control Loop

(Parameter setting: ESCAPE

menu option, discard

Press < 2 sec.: Toggle OccupiedUnoccupied mode or switch from

OFF to ON

Press > 2 sec.: Turn unit OFF.

(Parameter setting: ENTER to

select menu option, accept

parameter change)

Press < 2 sec.: Select Control Loop

Press > 2 sec.: Enter set-up

CLOCK, SCHEDULES, H/C

(Parameter setting: ENTER to

select menu option, accept

parameter change)

Decrease SET POINT

(Parameter setting: SCROLL menu

options and parameters)

Idle display

The idle display is activated when no key has been pressed for 30 seconds.

The contents of the idle display are selectable through parameters UP08 to UP14.

Setting UP08 to OFF will disable idle display. Last active control loop or manual output will remain displayed.

Display of control loop

Active when changing set points. Large digits show input value. Small digits show set point. Horizontal bars top left show which

loop is being displayed.

Override of secondary set point in cascade control

If cascade control is active (with VAV for example) the user can override the primary loop and manually select the set point of the

secondary loop (the loop is then changed to constant air volume mode). This function is helpful for tuning the VAV system. This

feature may be disabled by setting UP02 to OFF.

While the secondary loop is displayed change the set point with UP/DOWN. The hand symbol appears.

Change setpoint again to cancel cascade override. The hand symbol disappears.

Delay on enable function

During a pending delay the hand symbol will be shown. For example the condition to activate the controller with 1FU is met, but a

startup delay is specified. The controller will remain switched off and show the hand symbol until the delay expired.

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 5

Page 6

TCX2 Universal Controller

OPERATION

Press OPTION > 2 sec. SEL and current time displayed

Press OPTION < 2 sec. to change time,

Minutes blink: UP/DOWN to change, OPTION to save,

Hours blink: UP/DOWN to change, OPTION to save,

DAY1 blinks: UP/DOWN to change, OPTION to save weekday

Day of month blinks, UP/DOWN to change, OPTION to save

Month blinks, UP/DOWN to change, OPTION to save

Year blinks, UP/DOWN to change, OPTION to save

Press ESC or POWER to return

SEL

00:00

DAY1 (Mon)

01.01.

2014

Press OPTION > 2 sec. current time and SEL displayed

Press UP:

PRO and SEL displayed

Press OPTION:

Time schedule status displayed OFF or ON ( )

Press OPTION to toggle OFF/ON

SEL

PRO

Pro

OFF/ON

Press UP while PRO-ON displayed:

Press UP or DOWN to SCROLL Pr01 through Pr12,

Press OPTION to select desired schedule (e.g. Pr01),

00:00 blinks

Press UP/DOWN to select Pr01 switching time from 00:00–23:45

Press OPTION to save switching time (bar appears indicating step 1 complete): DAY 1 blinks

08:00

Pr01

While Pr01 is displayed and DAY1 is blinking: If 365 is shown, press DOWN key. After this DAY 1 will show.

Press UP:

Activate Pr01 switching time for DAY1 (triangle appears on 1),

Press DOWN:

Deactivate Pr01 switching time for DAY1 (triangle disappears)

Press OPTION to save Pr01 DAY1 (2nd bar indicates step 2 complete):

Repeat for DAY2 – DAY7

DAY1

Pr01

1 2 3 4 5 6 7

The selection of switching time and weekdays for this time schedule is now completed.

Press POWER to come to desired action for Pro1. The following options appear in this order:

no = switching time not active

OP = operation mode (ON, OFF, OCCUPIED, UNOCCUPIED)

LP = set point

AO = Position of analog output (output must be in manual mode by parameter setting)

FAN = Fan state (output must be in manual mode by parameter setting)

do = Position binary output – digital, 3-point or PWM (output must be in manual mode by parameter

setting).

Hday/ON = Annual time schedule: Holiday starts

Hday/OFF = Annual time schedule: Holiday ends

Press UP/DOWN to scroll through the possible events(3nd bar indicates step 3 complete)

LP

Pr01

Status LED

A status LED is located on the upper left side of the controller housing. During normal operation the LED blinks briefly once every

5 seconds. It will blink every second in case there is an alarm or fault condition.

Power Failure

All parameters and set points are memorized and do not need to be re-entered.

Upon return of power: Based on UP05 the controller will start in OFF, occupied or the same mode as before.

Clock and time schedule settings are retained for 48 hours (after being powered for at least 10 hours).

Error messages

Err1: Communication error

Err2: Internal data corrupt. Replace product.

Err3: Initial power up after firmware update or internal error. Re-start product. If error reappears, replace product.

Err4: Configuration error. Parameter settings are conflicting. Verify control setup; make sure all assigned inputs are enabled

and functioning.

Err5: Parameter copy mode: Copy error – if external module is addressed, communication error with external product.

Err6: Parameter copy mode: Check sum mismatch of eeprom data. Data in external eeprom corrupt.

Err7: Lead/Lag function error. At least one assigned lead/lag module is not assigned or failed.

Clock operation

The controller contains a quartz clock with battery back-up. Up to 12 schedules based on time and day of the week may be

programmed (Pr01 through Pr12). Schedules may change controller operation mode (on, off, occupied, unoccupied), change fan

state, directly position an output, or change a loop set point. A blinking clock indicates that the time has not been set or the unit

was without power for longer than 48 hours. The time needs to be set to allow time schedules to operate. Summer / winter time

changeover may be activated using user parameters.

Clock setup

Enable/disable time schedules

Creating weekly time schedules

Step 1: Select a switching time (Up to 12, Pr01–Pr12)

Step 2: Apply selected switching time (Pr01) to DAY1 (Mon) – DAY 7 (Sun) or 365 days (Annual schedule)

Step 3: For weekly schedules: Select action for switching time (Pr01+Days)

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 6

Page 7

TCX2 Universal Controller

OPERATION

Press Option to complete selection of event

For all non-operation mode changes, it is required to select the output or control loop in this step.

For example for setpoint LP1, LP2, etc. or for an output the number of the output that should be changed.

Press UP/DOWN to select, OPTION to complete

LP01

Pr01

Choose operation mode, setpoint or position of output

Characteristics of action (e.g. 0–100% for A1) appear (5th bar indicates step 5 complete)

Press UP/DOWN to select, OPTION to complete

25%

Pr01

Press UP while PRO-ON displayed:

Press UP or DOWN to SCROLL Pr01 through Pr12,

Press OPTION to select desired schedule (e.g. Pr01),

00:00 blinks

Press UP/DOWN to select Pr01 switching time from 00:00–23:45

Press OPTION to save switching time (bar appears indicating step 1 complete): DAY 1 blinks

08:00

Pr01

This parameter is not used for annual time schedules.

While Pr01 is displayed and DAY1 is blinking:

Press OPTION repeatedly to step through this mode or on TCX2-OP, press POWER.

Day1

Pr01

1 2 3 4 5 6 7

Press POWER to come to desired action for Pro1. The following options appear in this order:

no = switching time not active

OP = operation mode (ON, OFF, OCCUPIED, UNOCCUPIED)

LP = set point

AO = Position of analog output (output must be in manual mode by parameter setting)

FAN = Fan state (output must be in manual mode by parameter setting)

do = Position binary output – digital, 3-point or PWM (output must be in manual mode by parameter

setting).

Hday/ON = Annual time schedule: Holiday starts

Hday/OFF = Annual time schedule: Holiday ends.

Press UP/DOWN to scroll through the possible events(3nd bar indicates step 3 complete)

Press Option to complete selection of event

Hday

Pr01

Select month 1 for January and 12 for December. Month is blinking.

Press UP/DOWN to select, OPTION to complete

24.08

Pr01

Select day of month to complete event (1-31). Day is blinking.

Press UP/DOWN to select, OPTION to complete

5th bar indicates step 5 complete.

24.08

Pr01

Step 4: Select ID (For example: LP01 or FAN2)

Step 5: Complete switching event

Creating annual time schedules (only for V1.3 and later)

Annual schedules have priority over other schedules. While an annual schedule is active, the weekly schedules will be inactive.

Step 1: Select a switching time (Up to 12, Pr01–Pr12)

Step 2: Apply selected switching time (Pr01) to DAY1 (Mon) – DAY 7 (Sun)

Step 3: For annual schedules: Select start or end of holidays

Step 4: Select month (For example: 1-12)

Step 5: Select day and Complete switching event

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 7

Page 8

TCX2 Universal Controller

OPERATION

Press OPTION > 2 sec. SEL and current time displayed

Press UP/DOWN

Until small digits display H-C:

Press OPTION

Currently active Heat or Cool optional with fan symbol or Auto are displayed:

Press OPTION again to toggle Heating only, cooling only, fan only in heating mode or cooling mode or auto in

the following order:

Auto: heating and cooling change automatically based on demand. This must be setup with FU3.

Heat: Heating only. The controller stays in heating mode and will not switch to cooling.

Heat & Fan: The controller is in fan only mode. The fan will activate based on heating sequence.

Cool: Cooling only. The controller stays in cooling mode and will not switch to heating.

Cool & Fan: The controller is in fan only mode. The fan will activate based on cooling sequence.

H-C

SEL

Press OPTION > 2 sec. SEL and current time displayed

Press UP/DOWN

Until small digits display SEL, Large digits show:

UI = universal inputs

AO = Analog outputs

FAN = Fan outputs

do = Binary, 3-point or PWM outputs

Press OPTION to display state of In- or Output

UI

SEL

Press UP/DOWN to step through the number of available in- or outputs

Large digits show in-output type & number, Small digits show value

UI 01

25%

While in binary output mode,

Press OPTION key to display the total number of hours the binary output has been ON.

Large digits show in-output type & number, Small digits show running time in hours.

If the running time is larger than 9999 hours, 10000 hours are shown as level on the vertical bar.

The example on the right equals 50345h running time.

(Maximum runtime is 65535h = 7.5 years)

do 01

345h

New Feature with V1.3: Heat – Cool - Fan only – Auto selection

Display of in- and output states

Step 1: Select type or in- or output

Step 2: Select number of in- or output

Step 3: Display total run time for binary outputs

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 8

Page 9

TCX2 Universal Controller

SETUP AND CONFIGURATION

Parameter

Description

Range

Default

UP 00

Enable access to operation modes

ON/OFF

ON

UP 01

Enable access to set points

ON/OFF

ON

UP 02

Enable manual control in cascade and for fan speeds

ON/OFF

ON

UP 03

Enable change of heating/cooling mode

ON/OFF

ON

UP 04

Enable access to time programs:

ON/OFF

ON

UP 05

State after power failure:

0= off, 1= on, 2= state before power failure

0, 1, 2

2

UP 06

Enable unoccupied Mode: Shift the setpoint to a lower temperature in winter or higher

temperature in summer in order to save energy. Unoccupied mode may be activated through

the POWER button, or with the external input (typically for key card switches, occupancy

sensors in combination with door contacts for hotels or meeting rooms.)

ON/OFF

OFF

UP 07

Celsius or Fahrenheit: ON= Fahrenheit, OFF= Celsius

ON/OFF

OFF (Celsius)

UP 08

Show idle display while no key is pressed

ON/OFF

ON

UP 09

Select type of content for large digits (00= OFF):

0–6

1

00 = OFF

01 = Input

02 = Control loop setpoint

03 = Analog output

04 = Fan

05 = Binary output

06 = Clock

UP 10

Select content source for large digits (0= OFF):

0–12

1

Input:

1 = UI1

2 = UI2

3 = UI3

4 = UI4

5 = UI5

6 = UI6

7 = UI7

8 = UI8

9 = VI1

10 = VI2

11 = VI3

12 = VI4

Set point:

1 = LP1

2 = LP2

3 = LP3

4 = LP4

Analog output:

1 = AO1

2 = AO2

3 = AO3

Fan

1 = Fan 1

2 = Fan 2

Binary output:

1 = DO1

2 = DO2

3 = DO3

4 = DO4

5 = DO5

6 = DO6

UP 11

Select type of content for small digits (same options as UP09)

0–6

2

UP 12

Select content source for small digits (same options as UP10)

0–10

1

UP 13

Select type of content for vertical bar display (same options as UP09)

0–6

3

UP 14

Select content source for vertical bar (same options as UP10)

0-10

1

UP 15

OFF = Do not show heating & cooling state, ON = Display heating & cooling state

ON/OFF

ON

UP 16

OFF = Alarms display only while active, ON = Alarms display until confirmed,

ON/OFF

ON

UP 17

Clock display type (12/24): OFF= 24-hr ON= 12-hr (AM/PM)

ON/OFF

OFF(24hr)

UP 18

Reset timer for manual override in time schedule mode.

0 = Reset of override mode is not active. Time schedules overridden manually will be switched

back to scheduled mode at next switching event.

1…255 = Delay for the controller to go back to the scheduled OFF or unoccupied operation

mode if the operation mode is changed manually to occupied.

0–255 Min

60(Min)

UP 19

Constant backlight for display:

OFF = The backlight is only on when a key has been pressed

ON = The backlight is constantly on

ON/OFF

OFF

UP 20

New Feature: Do not show input value in loop display

OFF = Input value is shown

ON = Only setpoint is shown. Input value is not visible in loop display

ON/OFF

OFF

UP 21

New Feature: Enable daylight savings mode. If enabled, internal real time clock will be

advanced by one hour in summer and delayed one hour in winter

ON/OFF

OFF

UP 22

New Feature: TCX2 is in no-reply-mode for OPU2-VC communication

OFF = TCX2 is in normal mode for communication with OPU2-VC

ON = TCX2 is in no-reply-mode for communication with OPU2-VC

No-reply-mode: This mode allows connecting one operation terminal to multiple controllers.

One controller must be in normal operation mode and all the others must be set to no-replymode. The controllers set to no-reply-mode will follow each command issued by the operation

terminal. They will not send responses and their alarm conditions are not monitored by the

operation terminal.

Setting a controller with only one operation terminal to no-reply-mode will result in

communication error on the operation terminal. In this case parameter UP22 can still be

changed to 0 through the operation terminal.

ON/OFF

OFF

UP 23

New Feature: Wink function: the LED on top lights up constantly if ON

ON/OFF

OFF

User and display parameters (Password 009)

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 9

Page 10

TCX2 Universal Controller

SETUP AND CONFIGURATION

OFF = LED has normal function ON = LED is constantly active

UP 24

New Feature: Summer / winter mode. Used for control loops, to select the corresponding

setpoint limits. Set in xL28

OFF = Summer mode (cooling), ON = Winter mode (heating)

ON/OFF

OFF

Module

Description

PW

UP

User and display parameters

009

LP

Control loops Lp1 to Lp4

241

UI

Input configuration: 1U to 8U,

AL

Alarm configuration: 1AL to 8AL

FU

Special functions Fu1 to Fu5

AO

Analog output configuration, AO1 to AO3

FAN

Fan output configuration FAN1 to FAN2

DO

Binary output configuration, do1 to do6

Co

Communication setup (refer to separate communication brochure)

COPY

copy mode to copy full parameter sets between run, default and external memory

with up to 4 saving locations (AEC-PM1)

Setting parameters to configure the controller

TCX2 is an intelligent controller with the flexibility to fit a wide range of applications. The control operation is defined by

parameters set using the standard operation terminal. There are two levels:

1. User/display parameters (password 0009)

2. Control parameters (password 0241)

Recommended set-up procedure:

1. Set jumpers on the back of the controller for inputs and outputs

2. Connect power supply and inputs

3. Make sure Celsius – Fahrenheit settings are correct (UP07)

4. Program input parameters

5. Program control parameters

6. Program output parameters

7. Program auxiliary functions and user settings

8. Test function of unit

9. Switch off power

10. Connect outputs

11. Reconnect power

12. Test control loop

Parameters are grouped according to modules:

How to change parameters

1. Press UP/DOWN buttons simultaneously for three seconds. The display will show firmware version and revision number.

Press the OPTION button to start login.

2. CODE is shown in small display. Select 241 or the number provided by your supplier using the UP or DOWN button. These

are the default access numbers, your supplier may have changed those numbers or blocked access to the parameters

completely. Parameters should only be changed by authorized personnel.

3. Press OPTION after selecting the correct code. The user/display parameters are displayed immediately.

4. Once logged in with 241 control modules are displayed (UI, AL, LP, AO, FAN, DO, CO etc.) – select with UP/DOWN and open

with OPTION. Then select the ID with UP/DOWN keys: 1U, 2U, 3U etc., open with OPTION. As soon as the module is open its

parameters are displayed.

5. Select the parameters with the UP/DOWN buttons. Change a parameter by pressing the OPTION button. Three arrows are

displayed to indicate that the parameter may be modified. Use UP/DOWN buttons to adjust the value.

6. After you are done, press OPTION to save the new value and return to the selection level (arrows disappear when selection is

saved). Pressing left hand POWER button without pressing OPTION will discard the value and return without saving.

7. Press POWER to leave parameter selection and return to control module selection.

8. Press the POWER to leave the menu. The unit will return to normal operation, if no button is pressed for more than 5

minutes.

How to select active alarms on outputs and special functions

1. Select the parameter as described above

2. Press OPTION to start selecting alarms. AL 1 is now shown in the large digits.

3. Press UP to select the alarm 1, press DOWN to deselect the alarm 1. A selected alarm is visible by a dark triangle on the

bottom line of the LCD. The output or function will activate if the corresponding alarm is triggered.

4. Press OPTION to step to alarm 2. Repeatedly press OPTION key to step through all available alarms and select or deselect

them by pressing UP or DOWN.

5. Press POWER to leave the alarm selection routine and return to the parameter selection level.

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 10

Page 11

TCX2 Universal Controller

SETUP AND CONFIGURATION

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 11

Page 12

TCX2 Universal Controller

SETUP AND CONFIGURATION

Copying and restoring the entire parameter set

It is possible to backup and refresh the entire parameter set to a second onboard memory (default memory) or a plug-in memory.

This simplifies substantially the programming of multiple controllers with identical parameter sets.

Removable plug-in memory AEC-PM1

The plug-in memory is an accessory that can be plugged in on the right side of the TCX2. Once connected, the power LED on the

AEC-PM1 lights up. The memory can hold up to 4 individual parameter sets. It is easy for a site engineer to update a variety of

standard installations or for an OEM to program his standard setup based on application.

Auto-load

While copying a parameter set to eeprom, the user may choose the auto-load feature. With this feature set, the parameters load

automatically when powering up the controller. It is thus possible for a non-technical person to perform a parameter update by

simply powering up the controller with the AEC-PM1 plugged in.

Procedure to copy parameter sets

1. Login to engineering parameters as described above.

2. Press UP or DOWN until COPY is selected

3. Press the OPTION key. Select copy source: These are the options:

4. Press OPTION key. Now select copy destination: These are the options:

5. Press OPTION key. Your selection is shown on the large digits: source ID to target ID. For example run time memory to

6. Press the OPTION key to conclude the selection. The Data LED on the AEC-PM1 plug-in blinks to indicate data

Exchanging parameter sets with a computer

Through a USB/RS485 converter it is possible to read and write parameter sets to a computer by the use a free program called

EasySet. The EasySet tool may be downloaded from the vectorcontrols.com website.

To exchange parameter sets, install the EasySetTM configurator program and plug in the USB/RS485 converter to your computer.

Connect the RS485 converter to the OP3 (+) and OP4 (-) terminal of the TCX2 using a twisted pair wire. If an OPU2-VC is

connected, you must first unplug it. In order to use EasySet, select the port of your USB converter first.

Parameter sets may now be read out from the TCX2 to the PC and written back to the TCX2. This makes it possible to keep a

parameter library on computer, exchange parameter sets through emails or keep a log file of all the projects completed.

0. CLR The copy destination will be erased

1. RUN Run time memory

2. DFLT Default: On board backup memory

3. EEP1 External memory folder 1 on AEC-PM1

4. EEP2 External memory folder 2 on AEC-PM1

5. EEP3 External memory folder 3 on AEC-PM1

6. EEP4 External memory folder 4 on AEC-PM1

1. RUN Run time memory

2. DFLT Default: On board backup memory

3. EEP1 External memory folder 1 on AEC-PM1

4. EEP2 External memory folder 2 on AEC-PM1

5. EEP3 External memory folder 3 on AEC-PM1

6. EEP4 External memory folder 4 on AEC-PM1

eep1 is shown as 1to3. After confirming the selection, choose YES or AUTO to start the copy process. Select NO to abort.

AUTO s only available if the target is the external plug in. By selecting AUTO: The parameters will load automatically

when the controller is powered up while the AEC-PM1 is plugged in. If one plug-in has several parameter folders with the

AUTO flag set the one with the smallest index will be loaded.

New Feature for products with a communication plug-in. Selecting CO15 = 01 will write back an increased address

to the AEC-PM1 after a successful copy. This way it is easier to configure large projects.

communication in case it is copied to or from. PEND is shown while the copy process takes place.

There are several possibilities for the result:

Good: The copy process was successful

Fail: Err5, Communication problem. The plug in module is either damaged or missing

Fail: Err6, Checksum mismatch. The checksum of the source data was incorrect. Data corruption. This may

happen if the plug-in has not been written to before or data corruption took place.

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 12

Page 13

TCX2 Universal Controller

INPUT & ALARM CONFIGURATION

Parameter

Description

Range

Default

01 u0

For universal inputs: 1U to 8U: Signal type (0= not active):

1= 0-10V or 0-20mA

2= 2-10V or 4-20mA

3= NTC

4 = open contact direct (contact open = 100%, closed = 0%)

5 = open contact reversed (contact open = 0%, closed = 100%)

6 = potentiometer input, assign to setpoint selection of control loop

7 = light control mode: toggle and dimmer switch

8 = pulse counting input.

0–8

1

01 u1

Display minimum value. See note below about display resolution.

For potentiometer input: lower range limit of potentiometer in 100 Ohm steps

New feature: only if xxu0 = 1, 2 or 6:

if minimum value is higher than maximum value, the input signal is reversed. 0%

input = 100% signal, 100% input = 0% signal

-50–205

0

01 u2

Display maximum value. See note below about display resolution.

For potentiometer input: Upper range limit of potentiometer in 100 Ohm steps

New feature: only if xxu0 = 1, 2 or 6:

if minimum value is higher than maximum value, the input signal is reversed. 0%

input = 100% signal, 100% input = 0% signal

-50–205

100

01 u3

Range of universal inputs (For analog inputs only: 1u0 = 1,2)

0 – 5

0

0 = x1

1 = x10

2 = x100

3 = square root

4 = square root x 10

5 = square root x 100

01 u4

Analog input unit: 0= no unit, 1= %, 2= °C /°F, 3= Pa

0–3

1

01 u5

When 01u0 = 1-5: Select number of samples taken for low pass filter: Filtering

prevents unwanted fluctuation of sensor signals. The controller measures signal inputs

every second and calculates the input signal based on a number of measured values

and a digital low pass filter. Take into account that signal reaction delays as the number

of samples taken for the filter increases.

Note: changing this value will as well change 01u8

0–100

3

01 u6

Sensor calibration

Per input range

0.0

01 u7

Calculate mathematical function over multiple inputs (0=not active):

1= average, 2= minimum, 3= maximum, 4= differential UI(n) – UI(n-1)

0–4

0

01 u8

New Feature:

When 01u0 = 7 (light switch), select auto switch off time. Set to 0, if output should not

automatically switch off.

Note: Shared value: changing this value will as well change 01u5

00:00s...15:10h

MM:SS...HH:MM

00:15

MM:SS

Input & alarm/interlock configuration

Universal inputs (analog, binary or passive)

Set jumpers on the back of the controller: 0–10VDC (default), 0–20mA, or RT/DI (passive temperature or binary)

Match sensor range to input display. With a differential pressure transmitter having 0–200 Pa measuring range set 01U1

display minimum to 0 and 01U2 display maximum to 200. The allowable range value of -50–205 may be adjusted with

multipliers in 01U3. The largest displayable values are -990–9999.

Passive temperature input is NTC 10k@25°C (77°F). Specified accuracy can only be guaranteed using Vector Controls Sxx-

Tn10 sensors. Range values described above also apply to temperature inputs.

Display resolution (01u1 and 01u2)

Limiting the display range increases set point resolution. A range <25 provides set point steps of 0.1°C (0.2°F). A range

<125 provides set point steps of 0.5°C(0.1°F). Larger ranges increase by 1 step. Square root input range (0xu3) has no

influence.

Note: Fahrenheit and differential steps are doubled.

New Feature: open contact as input type (01u0 = 4 or 5): For an open contact input set the jumper to RT/DI and

parameter 01u0 to open contact (4 or 5). If set to 4 (open contact direct), an open contact reads as a high value (100%), a

closed contact as a low value (0%). If set to 5 (open contact reversed), an open contact reads as low value (0%) and a

closed contact as high value (100%). Note: sensor calibration does not work for binary inputs.

New Feature: potentiometer input (01u0 = 6). A potentiometer may be connected to a passive input to control the

setpoint of a control loop. With the input display minimum and maximum values the range of the potentiometer can be

defined in 100 ohms steps. For example setting the 1u01 to 50 and 1u02 to 120 represents a potentiometer from 5k to 12k

Ohm. The resistance is measured and calculated into a 0-100% value. Based on the potentiometer input, the setpoint will

now be moved between the upper and lower setpoint limits of the control loop. There are other uses for the potentiometer

input. For example, the controller can be enabled and disabled remotely with a potentiometer using an input in

potentiometer mode assigned to the Auxiliary Function Enable/Disable (1FU). Or use Alarm/Interlocks assigned to the

potentiometer input to activate or deactivate outputs. With the potentiometer fully on, for example, another interlock could

activate a boost mode. The potentiometer could then read OFF (65°F) to Full (85°). Add one more wire connected to a 10k-2

resistor and measure the room temperature as well. Thus with 3 wires in total ( potentiometer, common, room temperature)

a well-functioning low cost operation terminal may be realized.

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 13

Page 14

TCX2 Universal Controller

INPUT & ALARM CONFIGURATION

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 14

Page 15

TCX2 Universal Controller

INPUT & ALARM CONFIGURATION

01 u0

For universal inputs: 1U to 8U: Signal type (0= not active):

1= 0-10V or 0-20mA

2= 2-10V or 4-20mA

3= NTC

4 = open contact direct (contact open = 100%, closed = 0%)

5 = open contact reversed (contact open = 0%, closed = 100%)

6 = potentiometer input, assign to set point selection of control loop

7 = light control mode: toggle and dimmer switch

8 = pulse counting input.

0–8

8

01 u1

Not used

-50–205

0

01 u2

Value to be added with each pulse. For single pulse counting set to 1.

This value will only be used if u7 = 0.

-50–205

1

01 u3

Range of universal inputs

0 = x1

1 = x10

0 – 1

0

01 u4

Analog input unit: 0= no unit, 1= %, 2= °C /°F, 3= Pa

0–3

1

01 u5

Save value to eeprom, only after every n sample will the data be saved to eeprom.

The eeprom allows for 100’000 guaranteed saves. In order to guarantee reliable

operation this multiplier should be set to prevent premature aging of the controller.

0 = 1 every sample is saved.

1 = 10 after 10 samples data is saved to the eeprom

2 = 100 after 100 samples data is saved to eeprom

3 = 1000 after 1000 samples data is saved to eeprom

0..3

0

01 u6

Reset counter: any value other than 0 will reset the counter.

Once this value is set to 1 and saved, the counter will be reset to 0 immediately.

0...255

0

01 u7

Select Input whose value is used to be added with each pulse.

0–12

0

New Feature: light control mode: toggle and dimmer switch (01u0 = 7): Manage lighting with TCX2 and special

functions such as alarms, time schedules and automatic occupied/unoccupied mode switch can be used for occupant

convenience and to reduce lighting costs. With this feature building light is controlled by using push-button switches in the

room connected to passive inputs on TCX2. A passive input is assigned directly to an output connected to a relay for the light.

This is achieved by setting xd01 to 9. An analog output is assigned directly to an input by assigning xA00 to 7. Use binary

outputs for on/off lights or add an analog output for dimming. Pressing the push-button switch for less than 2 seconds will

toggle the binary output. For dimming, pressing the push-button switch for longer than 2 seconds will change the input value

by 10% per second from 0% to 100% and again back to 0%.

Pulse counting mode

New Feature: pulse counting mode: (01u0 = 8): With this feature it is possible to count pulses from a water or energy

meter and summarize a constant value or the result of an input.

For frequent pulses the summary option of u5 is recommended. This will save only every 10

and keep the values until then in RAM. This bears the risk that those values will not be remembered after a power failure.

With u07 the value of two inputs may be used in conjunction with the Pulse Counting Input to calculate energy consumption.

For example, apply the Mathematical Function-Differential to supply and return water temperature for a heating system. The

calculated value of a series of inputs is shown on the input with the higher number. When UI1 supply water temperature and

UI2 return water temperature both have Mathematical Function-Differential parameter selected the difference between

supply and return temperature will be shown on UI2. When the Pulse Counting input parameter u07 is set to 2, the

difference between supply and return temperature is added to the total at each pulse of the flow meter. This total then

represents energy consumption.

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 15

th

or 100th pulse to the eeprom

Page 16

TCX2 Universal Controller

INPUT & ALARM CONFIGURATION

01 u0

For virtual inputs: 9U to 12U: Select signal source

1 = Operation terminal OPU2-VC, OPU2-2TH-VC, etc.

2 = Bus module: AEX-MOD (Modbus), AEX-BAC (BACnet)

0–2

0

01 u1

Display minimum value

-50–205

0

01 u2

Display maximum value

-50–205

100

01 u3

Range of universal inputs (For analog inputs only)

0 – 2

0

0 = x1

1 = x10

2 = x100

01 u4

Analog input unit of measure: 0= no unit, 1= %, 2= °C /°F, 3 = Pa

0–3

2

01 u5

Not used for virtual inputs. Do not change

0–100

12

01 u6

Sensor calibration

Per input range

0.0

01 u7

Calculate mathematical function over multiple inputs (0=not active):

1= average, 2= minimum, 3= maximum, 4= differential UI(n) – UI(n-1)

0–4

0

01 u8

New Feature:

Select timeout: If the value is not updated within the specified time period, the input

will be disabled. If the input is assigned to an active control loop or a function

configuration error Err4 is shown.

00:00s...15:10h

MM:SS...HH:MM

01:00

MM:SS

Virtual input configuration

Virtual inputs may originate from a remote operation terminal such as the OPU2-VC or from a bus master if a communication

module such as the AEX-MOD for MODBUS or AEX-BAC for BACnet is present.

The remote input has a selectable timeout. If the value is not updated within this timeout, the input will be disabled and the

configuration error Err4 is shown. Rewriting the input value will re-enable the input but will not clear Err4. Err4 can only be

cleared by acknowledgement through the right key. Setting the timeout to 0 disables its function. For control functions, the

timeout should not be disabled.

While no additional setup is required on the OPA2, the bus master needs to write its value to the correct address for the

input within the timeout period. Details are described in the documentation of the communication module.

Inputs of OPU2-VC:

The OPU2-VC has one temperature input. This input is assigned to the first virtual input. For the TCX2-40863 this would be

input 9. To use the temperature input of OPU2-VC, set 09u0 = 1.

Inputs of OPU2-2TH-VC:

The OPU2-2TH-VC has a temperature input, a humidity input and 2 binary inputs. These inputs are assigned to following

virtual inputs:

1. VI1 = UI9 = temperature input

2. VI2 = UI10 = humidity input

3. VI3 = UI11 = passive input 1

4. VI4 = UI12 = passive input 2

Mathematical functions on inputs

Square root calculation on input values: The input signal maybe subjected to the square root function prior to calculating the

display values. The square root is calculated from the input signal and the result is again conditioned to 10bit resolution. The

square root function is useful when airflow needs to be calculated from differential pressure, as in VAV systems for example.

Calculate mathematical functions over multiple inputs for loop control or display with xxU7. In order to calculate average,

minimum or maximum between several inputs, make sure all the inputs are of identical type and range and then activate the

same function on xxU7 on all the selected inputs. The largest input of the group selected will carry the calculated value. For

example: When average is activated on 02U7 and 01U7 = 1, the average is carried on universal input 2.

UI2 may now be used as input for control loops and it will show the average value of UI1 and UI2 combined.

It is possible to use different functions on different inputs. For example: minimum of UI1 and UI3 and maximum of UI2 and

UI4.

The differential function may only be calculated on subsequent inputs. Such as UI2-UI1. The function must only be activated

on the minuend (a number from which another number is subtracted) – UI2 in this example. The displayed value of the

minuend will change into the difference: UI2 in – UI1 = UI2 out. It is possible to have multiple differentials on one controller.

It is not possible to reverse the subtraction: UI1-UI2.

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 16

Page 17

TCX2 Universal Controller

INPUT & ALARM CONFIGURATION

Priority for output control

1. Alarm level low

2. Alarm level high

3. Operation mode OFF

4. Control function

Alarm function

Number of available alarms.

8 alarms are available. The highest priority alarm is alarm 1, the lowest one is alarm 8.

The following alarm functions are available.

They are described in greater detail in the following pages:

o High or low limit alarm configuration

o Alarm based on maximum set point deviation of control loop

o Maintenance alarm based on run time counters

o Feedback or output alarms

o Alarms based on control loop sequence

o New Feature: Timeout or cycle mode for outputs

Operating the interlock in off mode:

Normally an interlock should not operate while the controller is in OFF mode. However, there are exceptions. To activate an

interlock in OFF mode, set its AL4 value to ON. Make sure AL4 is set to OFF if it should not activate an output in OFF mode.

Alarm automatic reset or acknowledge only (AL4).

Certain alarms should automatically reset once the condition is removed, but still keep the end user informed that the alarm

condition occurred: A typical example is a frost alarm. If the temperature drops too low, the heat should come on and it

should stop again once the frost protection reset temperature is reached.

If an alarm indicates a failure of system equipment that would endanger the operation of a device, the alarm should not

automatically reset. For example, when a fan fails to come on or a pump does not operate. In this case the alarm situation

needs to be resolved before restarting the outputs.

By setting AL3 to ON the engineer determines that the alarm must be reset manually before normal operation can continue.

Alarm delay, alarm limit and alarm reset:

For the above alarms, an activation delay, a limit and a reset (where applicable) may be defined. The reset determines when

the alarm condition will return to normal. It is used with input limit alarms, in frost protection for example. The frost

protection alarm is activated once the temperature drops below 5°C (41°F), the alarm reset is set to 5K. The room is now

heated until the temperature reaches 5°C (41°F) + 5K = 10°C (50°F). Once this temperature is reached the alarm will switch

off, it will remain blinking until acknowledged.

Alarm Settings on Outputs

The position of an output in the event of an alarm may be defined for each

output and each alarm individually. The output can be switched on (100%) or off

(0%).

Additionally, analog outputs may now as well be set to a predefined value. To

achieve this, the same alarm needs to be selected in the ON and OFF register. An

additional parameter is provided to choose the desired alarm level.

The alarm takes precedence over operating state and control signal. For interlocks, its operation during OFF mode is defined

through parameter AL4.

Two parameters define the behavior of the output based on an alarm: One parameter defines which alarm deactivates the

output (0%); the other parameter defines which alarm activates the output to 100%. Each alarm can be individually selected.

Multiple alarms can be assigned to one output. Should an alarm be active simultaneously in the parameter to activate and

another one to deactivate the output, the one to de-activate has precedence.

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 17

Page 18

TCX2 Universal Controller

INPUT & ALARM CONFIGURATION

1AL 0

Select alarm type:

0 = Alarm is not active

1 = Input high or low limit (Select input in AL 2)

2 = Max. set point deviation of control loop (select loop in AL 1)

3 = Maintenance alarm from run time counters (select counter in AL 1)

4 = Feedback or output alarm for fan, supervise fan state (Select fan in AL 1)

5 = Feedback or output alarm for binary output (select output in AL 1)

6 = Feedback or output alarm for analog output (select output in AL 1)

7 = Level alarm or interlock for PI-sequence of control loop (select output in AL 1)

8 = Timeout or cycle mode for outputs. (select type in AL 2 and ID in AL 1)

0…8

0

1AL 1

Not used

0…8

0

1AL 2

Select supervised input if 1AL0 = 1

0 = not active, 1 = UI1 to 12 = VI02

0…12

0

1AL 3

Alarm or interlock mode

OFF = Alarm mode active: Icon and the words ALA# on the small digits indicating

active alarm will appear on display, reset option in 1AL4 applies.

ON = Interlock mode: Outputs revert to normal operation when alarm condition is

no longer present, Icon and text indicating active alarm will not appear.

OFF, ON

OFF

(Alarm)

1AL 4

Automatic reset or acknowledge to reset (only if AL3 = OFF)

OFF = Alarm condition resets automatically. After alarm condition is no longer

present, outputs will revert to normal operation, but alarm Icon will continue

to blink on display until acknowledged with Option key.

ON = Alarm condition must be reset manually. After alarm condition is no longer

present, outputs will remain in alarm setting, and Icon will continue to show

on display, until acknowledged with Option key.

Note: All alarms operate as well if the controller is in OFF mode.

OFF, ON

OFF

(Automatic

reset)

Select if interlock is active in OFF mode (only if AL3 = ON)

OFF = Interlock is not active while controller is in off mode or disabled

ON = Interlock is active independent of controller state

1AL 5

Delay until alarm is active

00:00s...15:10h

MM:SS...HH:MM

00:00

MM:SS

1AL 6

Type of alarm (applies only if AL0 = 1, 7)

OFF = Low limit alarm

ON = High limit alarm

OFF, ON

OFF

1AL 7

Alarm limit for input based alarms (applies only if AL0 = 1, 4 to 6 in feedback mode)

Note: shared value. Changing this input will as well change 1AL9

Per input range

10%

1AL 8

Hysteresis for alarm setback for input based alarms (applies only if AL0 = 1)

Note: shared value. Changing this input will as well change 1ALA

Per input range

5%

1AL 9

Not used

0...100%

8%

1AL A

Not used

0...100%

4%

High or low limit alarm configuration

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 18

Page 19

TCX2 Universal Controller

INPUT & ALARM CONFIGURATION

1AL 0

Select alarm type:

0 = Alarm is not active

1 = Input high or low limit (Select input in AL 2)

2 = Max. set point deviation of control loop (select loop in AL 1)

3 = Maintenance alarm from run time counters (select counter in AL 1)

4 = Feedback or output alarm for fan, supervise fan state (Select fan in AL 1)

5 = Feedback or output alarm for binary output (select output in AL 1)

6 = Feedback or output alarm for analog output (select output in AL 1)

7 = Level alarm or interlock for PI-sequence of control loop (select output in AL 1)

8 = Timeout or cycle mode for outputs. (select type in AL 2 and ID in AL 1)

0…8

2

1AL 1

Select control loop if 1AL 0 = 2,7,

Note: max deviation limit is defined in control loop parameters

0 = all active control loops (not valid if 1AL0 = 7)

1 = loop 1 to 4 = loop 4

0…8

1

1AL 2

Not used

0…12

0

1AL 3

Alarm or interlock mode

OFF = Alarm mode active: Icon and the words ALA# on the small digits indicating

active alarm will appear on display, reset option in 1AL4 applies.

ON = Interlock mode: Outputs revert to normal operation when alarm condition is

no longer present, Icon and text indicating active alarm will not appear.

OFF, ON

OFF

(Alarm)

1AL 4

Automatic reset or acknowledge to reset (only if AL3 = OFF)

OFF = Alarm condition resets automatically. After alarm condition is no longer

present, outputs will revert to normal operation, but alarm Icon will continue

to blink on display until acknowledged with Option key.

ON = Alarm condition must be reset manually. After alarm condition is no longer

present, outputs will remain in alarm setting, and Icon will continue to blink on

display, until acknowledged with Option key.

Note: All alarms operate as well if the controller is in OFF mode.

OFF, ON

OFF

(Automatic

reset)

Select if interlock is active in OFF mode (only if AL3 = ON)

OFF = Interlock is not active while controller is in off mode or disabled

ON = Interlock is active independent of controller state

1AL 5

Delay until alarm is active

00:00s...15:10h

MM:SS...HH:MM

00:00

MM:SS

1AL 6

Not used

OFF, ON

OFF

1AL 7

Not used

Per input range

10%

1AL 8

Not used

Per input range

5%

1AL 9

Not used

0...100%

8%

1AL A

Not used

0...100%

4%

Alarm based on maximum set point deviation of control loop

*See maximum control loop set point deviation parameter xL26

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 19

Page 20

TCX2 Universal Controller

INPUT & ALARM CONFIGURATION

1AL 0

Select alarm type:

0 = Alarm is not active

1 = Input high or low limit (Select input in AL 2)

2 = Max. set point deviation of control loop (select loop in AL 1)

3 = Maintenance alarm from run time counters (select counter in AL 1)

4 = Feedback or output alarm for fan, supervise fan state (Select fan in AL 1)

5 = Feedback or output alarm for binary output (select output in AL 1)

6 = Feedback or output alarm for analog output (select output in AL 1)

7 = Level alarm or interlock for PI-sequence of control loop (select output in AL 1)

8 = Timeout or cycle mode for outputs. (select type in AL 2 and ID in AL 1)

0…8

3

1AL 1

Select run time counter of which binary output if AL 0 = 3,

0 = all binary outputs

1 = Digital output 1 to 6 = Digital output 6

0…8

0

1AL 2

Not used

0…12

0

1AL 3

Alarm or interlock mode

OFF = Alarm mode active: Icon and the words ALA# on the small digits indicating

active alarm will appear on display, reset option in 1AL4 applies.

ON = Interlock mode: Outputs revert to normal operation when alarm condition is

no longer present, Icon and text indicating active alarm will not appear.

OFF, ON

OFF

(Alarm)

1AL 4

Automatic reset or acknowledge to reset (only if AL3 = OFF)

OFF = Alarm condition resets automatically. After alarm condition is no longer

present, outputs will revert to normal operation, but alarm Icon will continue

to blink on display until acknowledged with Option key.

ON = Alarm condition must be reset manually. After alarm condition is no longer

present, outputs will remain in alarm setting, and Icon will continue to blink on

display, until acknowledged with Option key.

Note: All alarms operate as well if the controller is in OFF mode.

OFF, ON

OFF

(Automatic

reset)

Select if interlock is active in OFF mode (only if AL3 = ON)

OFF = Interlock is not active while controller is in off mode or disabled

ON = Interlock is active independent of controller state

1AL 5

Delay until alarm is active

00:00s...15:10h

MM:SS...HH:MM

00:00

MM:SS

1AL 6

Not used

OFF, ON

OFF

1AL 7

Not used

Per input range

10%

1AL 8

Not used

Per input range

5%

1AL 9

Not used

0...100%

8%

1AL A

Not used

0...100%

4%

Maintenance alarm based on run time counters*

* See digital output parameters xd09 and xd10

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 20

Page 21

TCX2 Universal Controller

INPUT & ALARM CONFIGURATION

1AL 0

Select alarm type:

0 = Alarm is not active

1 = Input high or low limit (Select input in AL 2)

2 = Max. set point deviation of control loop (select loop in AL 1)

3 = Maintenance alarm from run time counters (select counter in AL 1)

4 = Feedback or output alarm for fan, supervise fan state (Select fan in AL 1)

5 = Feedback or output alarm for binary output (select output in AL 1)

6 = Feedback or output alarm for analog output (select output in AL 1)

7 = Level alarm or interlock for PI-sequence of control loop (select output in AL 1)

8 = Timeout or cycle mode for outputs. (select type in AL 2 and ID in AL 1)

0…8

4 - 6

1AL 1

Select fan, binary or analog output if 1AL 0 = 4, 5, 6, 8

0 = Interlock or alarm not active

1..x = selected output

0…8

1

1AL 2

Select supervised input or activate output alarm if 1AL0 = 4, 5, 6:

0 = Output alarm, 1 = UI1 to 12 = VI02

0…12

0

1AL 3

Alarm or interlock mode

OFF = Alarm mode active: Icon and the words ALA# on the small digits indicating active

alarm will appear on display, reset option in 1AL4 applies.

ON = Interlock mode: Outputs revert to normal operation when alarm condition is no

longer present, Icon and text indicating active alarm will not appear.

OFF, ON

OFF

(Alarm)

1AL 4

Automatic reset or acknowledge to reset (only if AL3 = OFF)

OFF = Alarm condition resets automatically. After alarm condition is no longer present,

outputs will revert to normal operation, but alarm Icon will continue to blink on

display until acknowledged with Option key.

ON = Alarm condition must be reset manually. After alarm condition is no longer present,

outputs will remain in alarm setting, and Icon will continue to blink on display, until

acknowledged with Option key.

Note: All alarms operate as well if the controller is in OFF mode.

OFF, ON

OFF

(Automatic

reset)

Select if interlock is active in OFF mode (only if AL3 = ON)

OFF = Interlock is not active while controller is in off mode or disabled

ON = Interlock is active independent of controller state

1AL 5

Delay until alarm is active

00:00s...15:10h

MM:SS...HH:MM

00:00

MM:SS

1AL 6

Type of feedback (applies only if AL0 = 4, 5, 6, 8)

OFF = Direct: Output on, feedback high

ON = Reverse: Output on, feedback low

OFF, ON

OFF

1AL 7

Alarm limit for input based alarms (applies only if AL0 = 1, 4 to 6 in feedback mode)

Note: shared value. Changing this input will as well change 1AL9

Per input range

10%

1AL 8

Hysteresis for alarm setback for input based alarms (applies only if AL0 = 1)

Note: shared value. Changing this input will as well change 1ALA

Per input range

5%

1AL 9

Alarm limit for sequence based alarms (applies only if AL0 = 4 to 6 in output mode, 7)

Note: shared value. Changing this input will as well change 1AL7

0...100%

8%

1AL A

Hysteresis for alarm setback for sequence based alarms (applies only if AL0 = 4 to 6 in

output mode or 7)

Note: shared value. Changing this input will as well change 1AL8

0...100%

4%

Feedback or output alarms

Feedback alarms for fans, binary and analog outputs (AL0 = 4-6):

Feedback alarms are deployed to make sure a device is operating correctly. For example, to supervise a fan feedback from a

pressure switch may be used. While the fan is in operation, the pressure should be high, if the fan is off, the pressure should

be low. If any of these conditions is amiss, after the delay time defined in AL5 expired, an alarm needs to be generated.

Feedback alarms normally should not reset themselves automatically, therefore set AL4 = ON.

New Feature: Output alarms for fans, binary and analog outputs (AL0 = 4-6):

Output alarms or interlocks can be used to activate an interlock based on the activation of, or exceeding the limit of, an

output. A feedback alarm with no input assigned (AL2 = 0) will work as an output alarm or interlock.

For fan output alarms, each fan speed has a value of 10%. So speed 1 = 10%, speed 2 = 20% and speed 3 = 30%. To

trigger an interlock or alarm based on fan speeds, the appropriate limits will have to be set using AL9 and AL10.

For binary outputs, the level is 100% when on and 0% when the output is off.

Analog outputs are according to their actual output level in % of the full span.

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 21

Page 22

TCX2 Universal Controller

INPUT & ALARM CONFIGURATION

1AL 0

Select alarm type:

0 = Alarm is not active

1 = Input high or low limit (Select input in AL 2)

2 = Max. set point deviation of control loop (select loop in AL 1)

3 = Maintenance alarm from run time counters (select counter in AL 1)

4 = Feedback or output alarm for fan, supervise fan state (Select fan in AL 1)

5 = Feedback or output alarm for binary output (select output in AL 1)

6 = Feedback or output alarm for analog output (select output in AL 1)

7 = Level alarm or interlock for PI-sequence of control loop

8 = Timeout or cycle mode for outputs. (select type in AL 2 and ID in AL 1)

0…8

0

1AL 1

Select control loop if 1AL 0 = 2,7,

Note: max deviation limit is defined in control loop parameters

0 = all active control loops (not valid if 1AL0 = 7)

1 = loop 1 to 4 = loop 4

0…8

0

1AL 2

Select sequence if 1AL0 = 7

0 = heating or reverse

1 = cooling or direct

2 = heating and cooling or reverse and direct

0…12

0

1AL 3

Alarm or interlock mode

OFF = Alarm mode active: Icon and the words ALA# on the small digits indicating

active alarm will appear on display, reset option in 1AL4 applies.

ON = Interlock mode: Outputs revert to normal operation when alarm condition is

no longer present, Icon and text indicating active alarm will not appear.

OFF, ON

OFF

1AL 4

Automatic reset or acknowledge to reset (only if AL3 = OFF)

OFF = Alarm condition resets automatically. After alarm condition is no longer

present, outputs will revert to normal operation, but alarm Icon will continue

to blink on display until acknowledged with Option key.

ON = Alarm condition must be reset manually. After alarm condition is no longer

present, outputs will remain in alarm setting, and Icon will continue to blink on

display, until acknowledged with Option key.

Note: All alarms operate as well if the controller is in OFF mode.

OFF, ON

OFF

Select if interlock is active in OFF mode (only if AL3 = ON)

OFF = Interlock is not active while controller is in off mode or disabled

ON = Interlock is active independent of controller state

1AL 5

Delay until alarm is active

00:00s...15:10h

MM:SS...HH:MM

00:00

MM:SS

1AL 6

Type of alarm (applies only if AL0 = 1, 7)

OFF = Low limit alarm

ON = High limit alarm

OFF, ON

OFF

1AL 7

Not used

Per input range

10%

1AL 8

Not used

Per input range

5%

1AL 9

Alarm limit for sequence based alarms (applies only if AL0 = 4 to 6 in output mode, 7)

Note: shared value. Changing this input will as well change 1AL7

0...100%

8%

1AL A

Hysteresis for alarm setback for sequence based alarms (applies only if AL0 = 4 to 6 in

output mode or 7)

Note: shared value. Changing this input will as well change 1AL8

0...100%

4%

Alarms based on control loop sequence

Alarms or interlocks for PI sequences of control loops (AL0 = 7)

Set an alarm or interlock if a sequence of a control loop exceeds a certain level. This may be used to control an output

through several control conditions in parallel when applied as interlock, or to indicate a malfunctioning control setup when

used as alarm. Use limits AL9 and ALA to define limit and hysteresis for alarms or interlocks for PI sequences.

Alarm notification or interlock (AL3):

Low or high limits of inputs may be used to supervise operating conditions when an output should be switched on or off

independent of control situations. In this case an alarm display may be unwanted. The display of an alarm can be suppressed

by converting the alarm to an interlock by setting AL3 to ON.

Doc: 70-07-0174, V1.3R0, 20170131, Subject to alteration © Vector Controls GmbH, Switzerland, www.vectorcontrols.com Page 22

Page 23

TCX2 Universal Controller

INPUT & ALARM CONFIGURATION

1AL 0

Select alarm type:

0 = Alarm is not active

1 = Input high or low limit (Select input in AL 2)

2 = Max. set point deviation of control loop (select loop in AL 1)

3 = Maintenance alarm from run time counters (select counter in AL 1)

4 = Feedback or output alarm for fan, supervise fan state (Select fan in AL 1)

5 = Feedback or output alarm for binary output (select output in AL 1)

6 = Feedback or output alarm for analog output (select output in AL 1)

7 = Level alarm or interlock for PI-sequence of control loop (select output in AL 1)

8 = Timeout or cycle mode for outputs.

0…8

0

1AL 1

Select fan, binary or analog output if 1AL 0 = 4, 5, 6, 8

0 = Interlock or alarm not active

1..x = selected output

0…8

0

1AL 2

Select type of device for timeout detection if 1AL0 = 8

0 = Operation mode, Active if operation mode is OFF. (revert using AL6)

1 = fan, Active if fan is off

2 = binary output

3 = analog output

0…12

0

1AL 3

Alarm or interlock mode

OFF = Alarm mode active: Icon and the words ALA# on the small digits indicating

active alarm will appear on display, reset option in 1AL4 applies.

ON = Interlock mode: Outputs revert to normal operation when alarm condition is

no longer present, Icon and text indicating active alarm will not appear.

OFF, ON

OFF

1AL 4

Automatic reset or acknowledge to reset (only if AL3 = OFF)

OFF = Alarm condition resets automatically. After alarm condition is no longer

present, outputs will revert to normal operation, but alarm Icon will continue

to blink on display until acknowledged with Option key.

ON = Alarm condition must be reset manually. After alarm condition is no longer

present, outputs will remain in alarm setting, and Icon will continue to blink on

display, until acknowledged with Option key.

Note: All alarms operate as well if the controller is in OFF mode.

OFF, ON

OFF

Select if interlock is active in OFF mode (only if AL3 = ON)

OFF = Interlock is not active while controller is in off mode or disabled

ON = Interlock is active independent of controller state

1AL 5

Timeout period: time while the output is off. This time will be reset if the output

activates.

00:00s...15:10h

MM:SS...HH:MM

00:00

MM:SS

1AL 6

Type of feedback (applies only if AL0 = 4, 5, 6, 8)

OFF = Direct: Output on, feedback high

ON = Reverse: Output on, feedback low

OFF, ON

OFF

1AL 7

Run time in cycle mode. (applies only if AL0 = 8)

Interlock or alarm will be activated for the run time specified here.

00:00s...15:10h

MM:SS...HH:MM

00:00

1AL 8

Activation in cycle mode. (applies only if AL0 = 8)

0 = function is active independent of operation mode

1 = function is active only in ON mode

2 = function is active only in OFF mode

3 = function is active only in disabled mode

4 = function is active only in OFF and disabled mode.

0…4

0

1AL 9

Not used

0...100%

8%

1AL A

Not used

0...100%

4%

AL4 = OFF

AL4 = ON

AL8 = 0

Only active in on mode

Always active

AL8 = 1

Only active in on mode