Page 1

VC-EVCC-P

Technical Reference

Version 2.2.0

Authors

Vector Informatik GmbH

Status

Released

Page 2

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 2

based on template version 6.0.2

Document Information

History

Author

Date

Version

Remarks

ssm

2020-07-07

1.0.1

Change Authors’ information

Add Document information

ssm

2020-07-15

1.0.2

Chapter 1: Update graphic

Chapter 2: Update System Overview

vml/ssm

2020-08-04

1.1.0

Chapter “Delivery Content” added

ssm

2020-08-27

1.2.0

Chapter “Industrialization” added

dim

2020-09-24

2.0.0

Updated for SW release 3.0.0:

Chapter 2 “System Architecture” updated (RMP architecture

added)

Chapter 4.14 “Charging Arbitration” added

dim

2020-11-24

2.0.1

Chapter 3.2: Connector description updated

ssm

2021-02-03

2.1.0

Chapter 7.5 “Quality Documents” added

dim

2021-03-31

2.2.0

Chapter 4.8 Remark about HSOUT added

Reference Documents

No.

Source

Title

[1]

OppCharge

Network and application protocol specification for Siemens – Volvo

OppCharge implementation, Version 1.3.0

[2]

Vector

TechnicalReference_CAN-WiFi-GW

[3]

DIN

DIN 70121:2014-12

[4]

DIN

DIN EN 61851-23 - Konduktive Ladesysteme für Elektrofahrzeuge

- Teil 23 Gleichstromladestationen für Elektrofahrzeuge (IEC 61851-

23:2014)

[5]

DIN

DIN EN 61851-23 Berichtigung 1 - Konduktive Ladesysteme für

Elektrofahrzeuge - Teil 23 Gleichstromladestationen für

Elektrofahrzeuge (IEC 61851-23:2014/COR1:2016)

[6]

Vector

User Manual

[7]

ISO

ISO 15118-2:2014(E)

Page 3

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 3

based on template version 6.0.2

Safety Instructions

Caution

To avoid personal injuries and damage to property you have to read and understand

the following safety instructions and hazard warnings prior to installation and use of this

ECU. Keep this documentation always near the ECU.

Proper Use and Intended Purpose

Caution

The ECU may only be operated according to the instructions and descriptions of this

manual. The ECU is exclusively designed for use by skilled personnel as its operation

may result in serious personal injuries and damage to property. Therefore, only those

persons may operate the ECU who have understood the possible effects of the actions

which may be caused by the ECU. Users have to be specifically trained in the handling

(e.g. calibration) with the ECU, the applied embedded software and the system

intended to be influenced. Users must have sufficient experience in using the ECU

safely.

Hazard Warnings

Caution

The ECU may control and/or otherwise influence the behavior of control systems and

electronic control units. Serious hazards for life, body and property may arise, in

particular without limitation, by interventions in safety relevant systems (e.g. by

deactivation or otherwise manipulating the engine management, steering, airbag and/or

braking system) and/or if the ECU is operated in public areas (public traffic). Therefore,

you must always ensure that the ECU is used in a safe manner. This includes inter alia

the ability to put the system in which the ECU is used into a safe state at any time (e.g.

by “emergency shutdown”), in particular without limitation in the event of errors or

hazards. Furthermore, all technical safety and public law directives which are relevant

for the system in which the ECU is used must apply. Provided that serious hazards for

life, body and property may occur and before the use in public areas the system in

which the ECU is used must be tested according to recognized rules of engineering in

a non-public area.

Page 4

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 4

based on template version 6.0.2

Contents

1 General .......................................................................................................................... 7

2 System Architecture ..................................................................................................... 8

2.1 OppCharge Architecture ..................................................................................... 8

2.2 Roof-Mounted Pantograph Architecture ............................................................. 9

2.3 Supported Peripherals ....................................................................................... 9

3 ECU ................................ .............................................................................................. 10

3.1 ECU Overview ................................................................................................. 10

3.2 Key ECU Characteristics .................................................................................. 11

4 Functional Overview ................................................................................................... 12

4.1 CP Communication .......................................................................................... 12

4.2 WiFi Communication (OppCharge only) ........................................................... 12

4.3 Power Line Communication ............................................................................. 13

4.3.1 Low Level communication with EVSE .............................................. 13

4.3.2 DC Charging with High Level Communication .................................. 13

4.4 Stop Button ...................................................................................................... 14

4.5 StopCharge CAN Signal .................................................................................. 14

4.6 Clamp 15 Signal Input ...................................................................................... 14

4.7 Status LEDs ..................................................................................................... 14

4.8 High Side Outputs ............................................................................................ 14

4.9 Reprogramming of the ECU Software .............................................................. 15

4.10 Self-Diagnostics ............................................................................................... 15

4.11 ECU State Handling ......................................................................................... 15

4.12 Vehicle Immobilization (OppCharge only) ........................................................ 16

4.13 Configuration of Software ................................................................................. 16

4.14 Charging Arbitration ......................................................................................... 16

5 Qualification ................................ ................................................................................ 17

5.1 Configuration ................................................................................................... 17

5.2 Electrical Tests ................................................................................................. 17

5.3 EMC Test ......................................................................................................... 18

5.4 Climatic Tests ................................................................................................... 18

5.5 Mechanical Tests ............................................................................................. 19

5.6 Life Tests.......................................................................................................... 19

5.7 Chemical Tests................................................................................................. 19

6 Industrialization .......................................................................................................... 21

Page 5

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 5

based on template version 6.0.2

7 Delivery Content ......................................................................................................... 22

7.1 ECU ................................................................................................................. 22

7.2 Packaging ........................................................................................................ 22

7.3 Software .......................................................................................................... 23

7.4 Technical Documents ....................................................................................... 23

7.5 Quality Documents ........................................................................................... 23

8 Glossary and Abbreviations ...................................................................................... 25

Page 6

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 6

based on template version 6.0.2

Illustrations

Figure 1-1 VC-EVCC-P ................................................................................................ 7

Figure 2-1 System Overview OppCharge (Inverted Pantograph) ................................. 8

Figure 2-2 System Overview Roof-Mounted Pantograph (RMP) .................................. 9

Figure 3-1 VC-EVCC-P Interfaces ............................................................................. 10

Figure 7-1 VC-EVCC-P packed in Cardboard Package ............................................. 22

Tables

Table 1-1 Delivery Content ......................................................................................... 7

Table 3-1 VC-EVCC-P Key Characteristics .............................................................. 11

Table 4-1 Low Level Communication – Duty Cycle of CP PWM ............................... 13

Table 5-1 Qualification Configuration ........................................................................ 17

Page 7

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 7

based on template version 6.0.2

1 General

The Vector Controller - Electric Vehicle Communication Controller for Pantograph (VC-

EVCC-P) is a generic ECU for 24V environments.

It realizes electrical charging according to OppCharge V1.3.0 (see [1]) in combination with

an additional CAN-WiFi-Gateway for communication with the charging infrastructure.

In addition, charging with a roof-mounted pantograph is supported.

The hardware is the VC36PLC-24 with an integrated flash bootloader. VC-EVCC-P includes

a modern MICROSAR stack with all relevant application modules to realize electrical

charging communication.

Figure 1-1 VC-EVCC-P

The following parts are included in the delivery:

Part

Description

VC-EVCC-P

ECU with integrated software

Documentation

Customer receives a Technical Reference (this

document) as well as a User Manual and

Charging Sequence Diagrams

Remaining Bus Simulation

CANoe bus simulation for the VC-EVCC-P for

bus test and evaluation purposes

CAN database description (dbc)

Diagnostic description file (cdd)

Table 1-1 Delivery Content

Page 8

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 8

based on template version 6.0.2

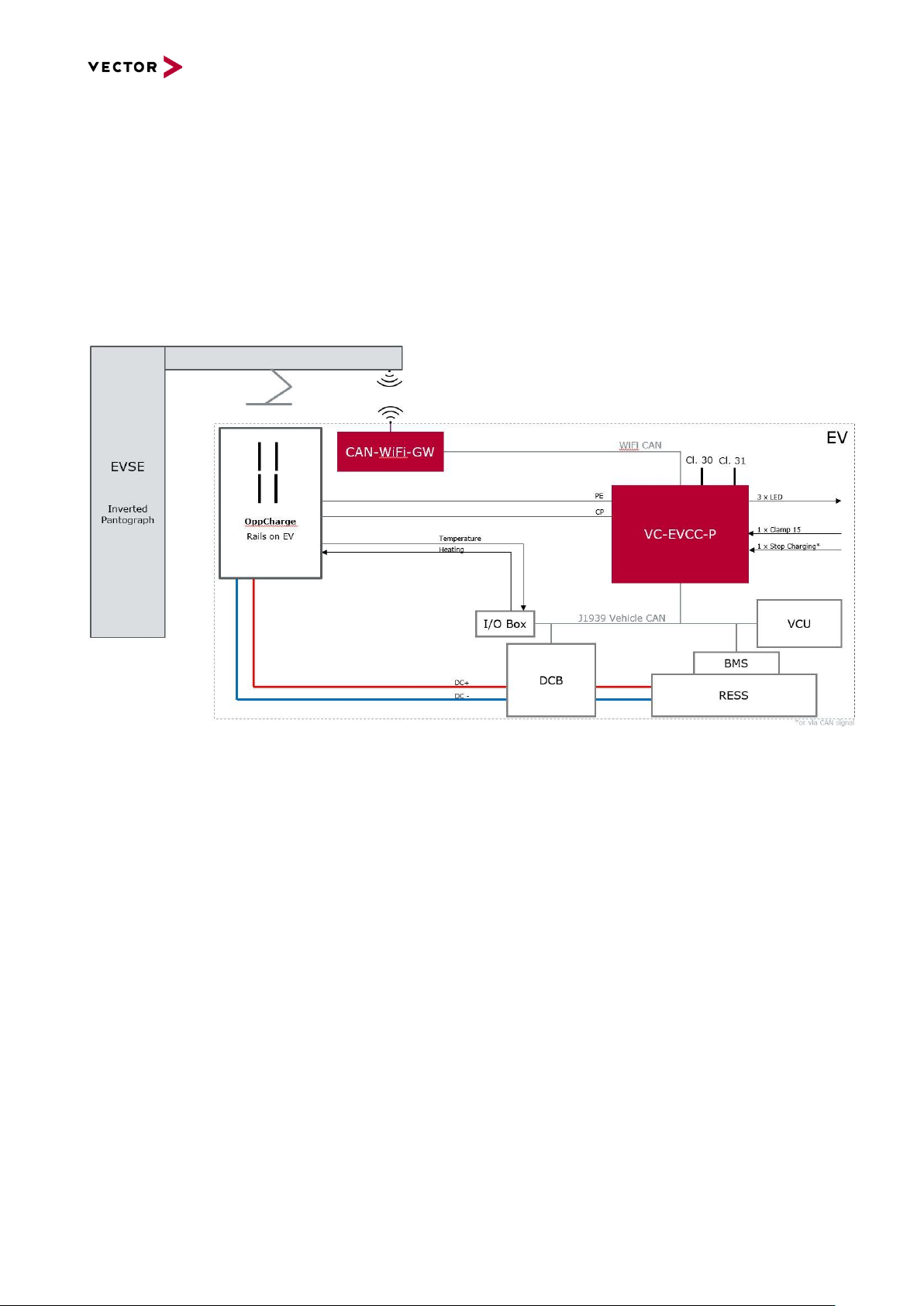

2 System Architecture

The VC-EVCC-P is designed to be integrated into the vehicle with one of the following

system architectures.

2.1 OppCharge Architecture

Figure 2-1 System Overview OppCharge (Inverted Pantograph)

Red components are in focus of VC-EVCC-P system context and are provided by Vector.

Non-red components, e.g. CAN-I/O Interface, have to be supplied alternatively in case

Temperature or Heater control shall be implemented.

Page 9

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 9

based on template version 6.0.2

2.2 Roof-Mounted Pantograph Architecture

Figure 2-2 System Overview Roof-Mounted Pantograph (RMP)

Red components are in focus of VC-EVCC-P system context and are provided by Vector.

Non-red components, e.g. CAN-I/O Interface, have to be supplied alternatively in case

Temperature or Heater control shall be implemented.

2.3 Supported Peripherals

Supported peripherals of the VC-EVCC-P:

> CAN-WiFi-Gateway (Vector article no.: 180109):

Due to radio admission restrictions the CAN-WiFi-Gateway is only available for the

European Market. For further information about restrictions of usage see [2].

Page 10

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 10

based on template version 6.0.2

3 ECU

This chapter contains an overview about the VC-EVCC-P. A detailed description of the

electronics and housing can be found in the User Manual of the VC-EVCC-P.

3.1 ECU Overview

The following diagram and tables give an abstract overview of the interfaces of the hardware.

Note

There are many different configuration options for the hardware of the VC-EVCC-P.

The following figure shows the configuration of the VC-EVCC-P.

Figure 3-1 VC-EVCC-P Interfaces

Page 11

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 11

based on template version 6.0.2

3.2 Key ECU Characteristics

Parameter

Description

CPU

SPC564B74L7, 120MHz

Memory

3,0 MB Code-Flash, 4x16 kB Data-Flash, 192

kB RAM

Voltage range

10V … 32V (ISO 16750, Code E)

Connector

Molex CMC36 Hybrid Sealed (36 Pins)

Communication

3x CAN 2.0B (incl. shielding)

1x PLC – Power Line Communication based on

IEC61851

I/O

Extensive Inputs and Outputs typically needed

for in vehicle powerline charging systems

Temperature Range

-35°C … +85°C (ISO 16750, Code H)

Typical Current Consumption without loads

150mA

Quiescent Current

114µA

Weight

560 g

IP protection

IP6K6K / IP6K7 / IP6K9K (not valid for

unsealed housing

Functional Safety

Not considered, development based on QM

process

Table 3-1 VC-EVCC-P Key Characteristics

Page 12

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 12

based on template version 6.0.2

4 Functional Overview

4.1 CP Communication

The CP connection to rails is detected by measurement of CP voltage.

4.2 WiFi Communication (OppCharge only)

The VC-EVCC-P controls DC charging communication between EV and EVSE according to

OppCharge V1.3.0 [1] communication via an additional CAN-WiFi-Gateway [2].

The DC charging via ACD (inverted pantograph) is done according to the following

sequence:

WiFi Communication Setup

Setup of High Layer Communication

Charge Parameter Discovery

Cable Check incl. ACD connection, isolation measurement and immobilization of the

vehicle

Pre-Charge

Power Delivery True

Current Demand incl. monitoring of charging progress

Power Delivery False

Session Stop incl. retraction of ACD to home position and mobilization of the vehicle

Stop Communication Session

Caution

Plug and Charge is not supported by the VC-EVCC-P.

Page 13

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 13

based on template version 6.0.2

4.3 Power Line Communication

4.3.1 Low Level communication with EVSE

According to [4] and [5] a low-level communication via PWM on the CP pin is supported.

The following PWM duty cycles are valid:

Duty Cycle of CP PWM

Description

0% <= DC < 3%

No charging allowed

3% <= DC <= 7%

Usage of high-level protocol according to ISO

15118 and DIN 70121. Charging without this

high-level protocol is not possible.

7% < DC < 8%

No charging allowed

8% < DC < 10%

Max current consumption is 6A

10% <= DC <= 85%

Available current = Duty Cycle * 0,6A

85% < DC <= 96%

Available current = (Duty Cycle – 64) * 2,5A

96% < DC <= 97%

Max current consumption is 80A

97% < DC <= 100%

No charging allowed

Table 4-1 Low Level Communication – Duty Cycle of CP PWM

4.3.2 DC Charging with High Level Communication

According to [3] and [7], high level communication for DC charging is supported. The

supported charging profile is EIM (External Identification Means).

Caution

Plug and Charge is not supported by the VC-EVCC-P.

The DC charging is done in the following sequence:

> Get charging clearance from vehicle

> Session setup with EVSE

> Parameter exchange with EVSE (charging mechanism, schedule tables…)

> Isolation measurement with EVSE

> Start pre-charge

> Start charging

> Continuously monitoring of charging progress

> Vehicle state monitoring; Stop button monitoring; Temperature monitoring; EVSE

communication; Self-diagnostic of actuators/sensors

> Stop charging

Page 14

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 14

based on template version 6.0.2

Note

For detailed information, please refer to the DC Charging diagram.

The first schedule table from EVSE will always be accepted on the protocol layer but

ignored in the application (charging will start immediately, independent from the received

schedule table).

4.4 Stop Button

The button is monitored continuously when the VC-EVCC-P is active. If the button is

pressed, the charging is stopped.

Alternatively, the VC-EVCC-P checks a CAN signal for charge abortion information.

In case of an error during ACD retraction the VC-EVCC-P disables immobilization of the

vehicle after driver confirmation of full clearance of the vehicle via pushing the Stop Button.

4.5 StopCharge CAN Signal

The StopCharge CAN Signal is monitored continuously when the VC-EVCC-P is active and

the feature is activated. If the StopCharge CAN Signal is set to pressed, the charging is

stopped.

4.6 Clamp 15 Signal Input

For a discrete wakeup of the ECU instead of a CAN network wakeup the Clamp 15 signal

input may be used to wake the ECU and keep it awake. Clamp 15 has to be available during

the whole OppCharge sequence.

4.7 Status LEDs

The charging status can be displayed via three LEDs which can be controlled via CAN

messages by an external ECU. For more details please refer to the User Manual of the VC-

EVCC-P.

4.8 High Side Outputs

Caution

If the VC-EVCC-P suffers from an unintentional GND contact loss, the freewheeling

diode inside HSOUT4 may lead to an unexpected flow of current from HSOUT4 via its

external load to GND.

As this may lead to undefined behavior of the external load (e.g. a BMS relay), the

usage of HSOUT4 must be considered with care.

If in doubt, please contact the Vector support.

Page 15

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 15

based on template version 6.0.2

Three High Side Outputs are available for general purposes which can be controlled via

CAN signals by an external ECU. For more details please refer to the User Manual of the

VC-EVCC-P.

Caution

If the High Side Outputs of the VC-EVCC-P are used, measures must be taken to

ensure a load current greater than 15mA (HSOUT0, HSOUT1) respectively 330mA

(HSOUT4).

An appropriate load resistor must be calculated depending on the supply voltage.

Otherwise, the VC-EVCC-P will detect an OpenLoad error which leads to a switch-off

of the respective High Side Output.

4.9 Reprogramming of the ECU Software

Reprogramming will be done via diagnostic CAN (CAN0). Therefore, the ISO 14229 UDS

protocol will be used. The following reprogramming features are supported:

Download of one logic block of application and basic software

Download of one logic block of Ethernet transceiver firmware

Download of CWG software

Security via CRC (no signature)

Updater for the flash bootloader itself is not supported

4.10 Self-Diagnostics

The VC-EVCC-P continuously monitors all relevant inputs and outputs. The information is

available in the self-diagnostic messages of the outputs.

In addition to that the self-diagnostic also includes faults during charging or in case of internal

faults.

4.11 ECU State Handling

An ECU wakeup is performed due to following reasons:

Clamp 15 signal

CAN wakeup

Stop button pressed

Control Pilot Pin active

Wake up from real time clock

Page 16

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 16

based on template version 6.0.2

If the ECU is active there are the following awake reasons possible to stay active:

Clamp 15 signal

Control Pilot activity

CAN active

Active Diagnostic session

Active OppCharge charging session

In all other cases, the VC-EVCC-P will go to sleep.

4.12 Vehicle Immobilization (OppCharge only)

The VC-EVCC-P starts immobilization of the vehicle as soon as the EVSE is requested to

start movement of the ACD. The immobilization of the vehicle is kept active until the EVSE

is requested to retract the ACD and the EVSE successfully responds about the ACD back

at its home position.

In case of errors during ACD movement the VC-EVCC-P keeps the vehicle immobile and

indicates an error value via CAN (see dbc. for details). In this case the driver has to confirm

safe position of the ACD via pushing the Stop Button.

4.13 Configuration of Software

The VC-EVCC-P allows configurations of the firmware on the diagnostic channel:

Baudrate adjustment between 250 kBaud, 500 kBaud and 1 MBaud on the J1939 CAN

Automatic switch of high side output to wakeup other ECUs

Charging stop user interaction via charging stop button or dedicated CAN message

Configurable message cycle times of several messages

Security Key Constant

4.14 Charging Arbitration

The charging arbitration enables the operation of a VC-EVCC-P together with a VC-VCCU

on the same CAN channel. It targets use cases which require two charging options

(pantograph and charging inlet) per vehicle but only one option is used at a time.

For charging arbitration, the VC-EVCC-P provides the following configurations on the

diagnostic channel:

> Configuration of Primary Source Address

> Configuration of Secondary Source Address

> Activation/Deactivation of Charging Arbitration

For more details, please refer to the User Manual of the VC-EVCC-P [6].

Page 17

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 17

based on template version 6.0.2

5 Qualification

This section describes the qualification of the VC-EVCC-P. The qualification of Vector ECUs

is executed by accredited test labs according to international standards. Documents with

detailed test specification and test results are not provided. Further details on the performed

tests could be available on individual request.

5.1 Configuration

The qualification of the VC-EVCC-P design has been performed in the following

configuration of the hardware.

Feature

Configuration

High-speed CAN

Channel

Termination

Ground coupling

CAN0

not populated

capacitive (100nF)

CAN1

120Ω

directly connected

CAN2

120Ω

capacitive (100nF)

20mA LED Output

> PWM dimming

200mA High-Side Output

> Static digital

5A High-Side Output

> Freewheeling diode

> Static digital

5A H-Bridge

> Static digital

IP Protection Class

> Housing sealed

Table 5-1 Qualification Configuration

5.2 Electrical Tests

The following electrical tests have been performed:

E-01 Overvoltage

E-05 Load dump

E-06 Superimposed alternating voltage

E-07 Slow decrease and increase of supply voltage

E-08 Slow decrease, quick increase of the supply voltage

E-08 Reset behavior at voltage drop

E-10 Short interruptions

E-11 Starting profile

Page 18

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 18

based on template version 6.0.2

E-12 Voltage curve with interactive generator regulation

E-13 Single line interruption

E-14 Multiple line interruption

E-15 Reversed voltage

E-16 Ground reference and supply offset

E-17 Short circuit protection

E-19 Quiescent current

E-22 Overcurrent

E-23 Direct current supply voltage

E-24 Voltage transient to engine rpm steps

E-25 Momentary drop in supply voltage

5.3 EMC Test

The following tests have been performed:

EMC1 - RF-emissions - Measurements at the artificial network (AN-Test, CISPR

25:2008-03)

EMC2 - RF-emissions – Measurements with antennas (RE-Test, CISPR 25: 2008-03)

EMC7 - Transient emissions on supply cables (CTE-Test, ISO 7637-2: 2011-03)

EMC9 - RF-immunity to interference – Bulk current injection (BCI-Test, ISO/DIS 11452-

4: 2010-01)

EMC10 - RF-immunity to interference – Using antennas (ALSE-Test, ISO 11452-2:

2004-11)

EMC14 - Transients on supply lines (TSUP-Test, ISO 11452-2: 2004-11)

EMC15 - Transients on lines except supply lines (TOL-Test, ISO 7637-3: 2007-07)

EMC16 - Electrostatic discharge – Handling Test (ESDH, ISO 10605: 2008-07)

EMC17 - Electrostatic discharge – Direct discharge (ESDD, ISO 10605: 2008-07)

EMC18 - Electrostatic discharge – Indirect discharge (ESDI, ISO 10605: 2008-07)

5.4 Climatic Tests

The following climatic tests have been performed:

K-01 High / Low temperature storage test

K-02 Temperature step test

K-03 High / Low temperature operation test

K-05 Rapid change of temperature with specified transition duration

Page 19

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 19

based on template version 6.0.2

K-06 Salt spray tests - Leakage and function test

K-07 Salt spray tests - Corrosion test

K-09 Humid heat, cyclic test - Composite temperature/humidity cyclic test

K-10 Protection against water

K-11 Steam jet test

K-12 Ice water shock test - Splash water test

K-13 Ice water shock test - Submersion test

K-14 Damp heat, steady-state test

K-15 Humid heat, cyclic test - Dewing test

K-19 Temperature cycle with specified change rate

5.5 Mechanical Tests

The following mechanical tests have been performed:

M-01 Free fall

M-03 Dust test

M-04 Vibration test (Profile D)

M-06 Mechanical shock (Severity II, Drivers door)

5.6 Life Tests

The following life tests have been performed:

L-02 High temperature endurance test

L-03 Alternating temperature endurance test

Assumed Life time: 50,000h / 15 Years

5.7 Chemical Tests

The following chemical tests have been performed:

AA - Diesel fuel

BA - Engine oil

BE - Greases

BF - Silicone oil

CC - Antifreeze fluid

CD - Urea

CG - Protective lacquer remover

Page 20

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 20

based on template version 6.0.2

CA - Battery fluid

CE - Cavity protection

CF - Protective lacquer

DF - Cold cleaning agent

DJ - Ammonium containing cleaner

EB - Transpiration

ED - Refreshment containing caffeine and sugar

EF - Cream, coffee whitener

DB - Vehicle washing chemicals

DC - Interior cleaner

DD - Glass cleaner

DE - Wheel cleaner

EE - Runway de-icer

AE - Methanol

DG - Acetone

DH - Cleaning solvent

DK - Denatured alcohol

Page 21

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 21

based on template version 6.0.2

6 Industrialization

This section describes the elements of the VC-EVCC-P industrialization, which are installed

and released by Vector:

> Production engineering

> Production requirements

> Quality requirements

> Control plan

> P-FMEA

> D-FMEA

> Production installation

> Series Production line for electronic parts

> Automated Optical Inspection (AOI)

> In Circuit Test (ICT)

> Production line for mechanical assembly

> Leakage test

> Generic End of Line Test (EOL)

> Production Specification

> The common part of production is described in the Production Specification and is

released by Vector.

Note

The documents listed in this chapter are for internal documentation of processes only.

They are not released for external use or delivery to Customer.

Page 22

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 22

based on template version 6.0.2

7 Delivery Content

The VC-EVCC-P hardware is packed in a single packaging and shipped as off-the-shelf

product from Vector warehouse. The standard delivery for software and documents takes

place via download link as ZIP file from the Vector homepage.

7.1 ECU

Based on the offer and order the customer will receive an off-the-shelf product:

> VC-EVCC-P Series (No.: 89518)

> VC-EVCC-P Evaluation (No.: 89519)

The ECUs are stored inside the cardboard package. The goods will be extracted from the

stock as per ordered quantity and packed individually within our logistics department in

Stuttgart.

7.2 Packaging

The VC-EVCC-P is packed in a single box (non ESD) with the following description:

> Approximate sizing of a single package: 250 mm x 191 mm x 64 mm (L x W x H,

approximately)

> Approximate weight: 0,74 kg (approximately, Cardboard 0,18 kg + ECU 0,56 kg)

Figure 7-1 VC-EVCC-P packed in Cardboard Package

Several ECUs in one shipment are packed in overpacks, e.g.:

> 5 ECUs: Approximately 450 x 320 x 320 mm, 5 kg

> 10 ECUs: Approximately 560 x 360 x 310 mm, 10 kg

> 25 ECUs: Approximately 800 x 600 x 400 mm, 25 kg

Page 23

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 23

based on template version 6.0.2

7.3 Software

> VC-EVCC-P for vFlash package (.vflashpack)

> CANoe project (.cfg)

> CAN J1939 communication matrix (.dbc)

> WiFi CAN communication matrix (.dbc)

> Diagnosis CAN communication matrix (.dbc)

> Diagnosis description file for CANdela Studio (.cdd)

7.4 Technical Documents

> Release Notes VC-EVCC-P (.pdf)

> Technical Reference VC-EVCC-P (.pdf)

> Technical Reference CAN-WiFi-Gateway (.pdf)

> User Manual VC-EVCC-P (.pdf)

> User Manual CAN-WiFi-Gateway (.pdf)

> Charging Sequence Description OppCharge (.pdf)

> Charging Sequence Description Roof-mounted Pantograph (.pdf)

> Envelope model 3D (STEP)

> VC-EVCC-P technical drawing (2D)

> VV-Report VC36PLC-24 (.pdf)*

7.5 Quality Documents

The following quality documents can be made accessible to a customer representative

remotely:

> PFMEA (Top 10)

> Control Plan

Page 24

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 24

based on template version 6.0.2

*will be provided if required

Page 25

Technical Reference VC-EVCC-P

© 2021 Vector Informatik GmbH Version 2.2.0 25

based on template version 6.0.2

8 Glossary and Abbreviations

Term

Description

AC

Alternating Current

ACD

Automatic Connection Device

AUTOSAR

AUTomotive Open System ARchitecture

CAN

Controller Area Network

.cdd

CANdela Diagnostic Description File

CP

Control Pilot

CPU

Central Processing Unit

CRC

Cyclic Redundancy Check

CWG

CAN-WiFi-Gateway

DC

Direct Current

DCB

Disconnecting Circuit Breaker

ECU

Electronic Control Unit

EV

Electric Vehicle

EVSE

Electric Vehicle Supply Equipment

LED

Light Emitting Diode

PLC

Power Line Communication

PE

Physical Earth

PP

Proximity Pin / Plug Present

PWM

Pulse-Width Modulation

QM

Quality Management

RAM

Random Access Memory

RESS

Rechargeable Energy Storage System

RMP

Roof-mounted Pantograph

UDS

Unified Diagnostic Services

V2G

Vehicle-to-Grid

VAS

Value Added Services

VC-EVCC-P

Vector Controller – Electric Vehicle Communication Controller for

Pantograph

VDV

Verband Deutscher Verkehrsunternehmen

WiFi

Wireless communication according to IEEE-802.11

Loading...

Loading...