Page 1

INSTALLATION MANUAL

SWING GATE

AUTOMATION

Page 2

CENTURIONSYSTEMShasbeen manufacturingautomaticgate systems since 1987, andis committed to

providingreliable,costeffectivesolutionsin thefieldof accessautomation.

CENTURIONstrivestogiveserviceand backup second to none. Ourengineersareavailableto give sales

support,installationtraining,andanswersto technicalorinstallationproblems.

Theequipmentisinstalledworldwideandis availablethroughanetworkof distributors.

CENTURIONisanISO9001 - 2000 registered company,continually looking at updating its products in line

withworldtrendstoensurethatitsproductswillprovidecustomersatisfaction.

Furtherinformationis availableonour websitewww.centsys.co.za

©CENTURIONSYSTEMS (PTY) LTD

CenturionSystems(Pty)Ltd. reservestheright tomakechangesto theproductsdescribed inthismanualwithout noticeandwithout obligation

of Centurion Systems (Pty) Ltd. to notify any persons of any such revisions or changes. Additionally, Centurion Systems (Pty) Ltd. makesno

representationsorwarrantieswithrespectto thismanual.

Nopart ofthisdocument maybe copied, storedin aretrievalsystem ortransmittedin anyformor byany meanselectronic,mechanical,optical

orphotographic,withouttheexpressprior writtenconsentofCenturionSystems(Pty) Ltd.

Company Profile

Company Profile

Pag e 2

Page 3

Page 3

Table of Contents

Table of Contents

Important Safety Instructions...........................................................4

General Description..................................................................5

Icons Used In This Booklet.............................................................5

Specifications . . . . ...................................................................6

Package Contents....................................................................9

Required Tools & Equipment ..........................................................13

Site Considerations .................................................................14

Cabling Requirements...............................................................17

Operator Installation.................................................................18

Inward swing gates..................................................................22

Outward swing gates ................................................................24

Electrical Set-up....................................................................26

Control box Installation...............................................................26

Additional Features. .................................................................28

Menu navigation map................................................................29

Controller Features ..................................................................31

Factory Defaults Schedule............................................................39

Description of terminal functions.......................................................41

LED Indicator Lights.................................................................43

Buzzer Feedback...................................................................43

Charger & pillar ligh connections.......................................................44

Determine Gate Swing Angle..........................................................45

Wiring Diagram for Motor M (MTR M) ...................................................46

Wiring Diagram for Motor S (MTR S) ....................................................47

Wiring Diagram for Safeties...........................................................48

Wiring Diagram for Other Inputs........................................................50

Allowable Wind Loading..............................................................52

Installation Handover................................................................53

Page 4

Important Safety Instructions

Important Safety Instructions

Page 4

To ensure the safety of people,it is important that you readall the following

instructions. Incorrect installation or incorrect use of the product could

causeseriousharmto people.

Theinstaller, being eitherprofessionalor DIY, isthelast person onthesite that canensurethat the operatorissafely

installed,andthat thewholesystemcanbeoperatedsafely.

MOVING GATE CAN CAUSE

SERIOUS INJURY OR DEATH

KEEP CLEAR. GATE MAY MOVE AT

ANY TIME. DO NOT ALLOW

CHILDREN TO PLAY IN AREA OR

OPERATE GATE .

WAR NI NG

ATTENTION

WARNINGS FOR THE INSTALLER

1. CAREFULLYREAD AND FOLLOWALL INSTRUCTIONS 14. Safety devicesmust be fitted to the installation to guard

beforebeginningtoinstalltheproduct. against mechanical movement risks such as crushing,

draggingandshearing.

2. All installation, repair, and service work to this product

mustbedone byasuitably qualifiedperson. 15. It is recommended that at least one warning indicator

lightbefitted toeverysystem.

3. Do not activate your gate opener unless you can see it

and can determine that its area of travel is clear of 16. Always fit the warning signs visibly to the inside and

people,pets,or otherobstructions. outsideofthe gate.

4. NO ONEMAY CROSS THEPATHOF A MOVING GATE. 17. The installer must explain and demonstrate the manual

Always keep people and objects away from the gate operationof thegate incase ofan emergency,and must

anditsarea oftravel. handtheUser/Warningsguideover totheuser.

5. NEVER LET CHILDRENOPERATE OR PLAYWITH THE 18. Explain these safety instructions to all persons

GATE CONTROLS, and do not allow children or pets authorized to use this gate, and be sure that they

nearthegate area. understand the hazards associated with automated

gates.

6. Securealleasilyaccessedgate openercontrolsin order

topreventunauthorizeduse ofthegate. 19. Do not leave packing materials (plastic, polystyrene,

etc.) within reach of children as such materials are

7. Do not in any way modify the components of the

potentialsourcesofdanger.

automatedsystem.

20. Dispose of all waste products like packaging materials,

8. Do not install the equipment in an explosive

wornoutbatteries,etc,accordingtolocal regulations.

atmosphere:the presenceof flammablegasor fumesis

aseriousdanger tosafety. 21. Always check the obstruction detection system, and

safetydevicesforcorrectoperation.

9. Beforeattemptingany workon thesystem, cutelectrical

poweranddisconnectthe batteries. 22. CenturionSystems does not acceptany liability caused

byimproperuse oftheproduct,orfor useotherthan that

10. Themainspower supply of theautomated system must

forwhichthe automatedsystemwasintended.

be fitted with an all-pole switch with contact opening

distanceof3mm orgreater. Useof a5A thermalbreaker 23. This product was designed and built strictly for the use

withall-polecircuitbreak isrecommended. indicated in this documentation. Any other use, not

expresslyindicatedhere, couldcompromisethe service

11. Make sure that an earth leakage circuit breaker with a

life/operation of the product and/or be a source of

thresholdof30mAisfittedupstreamof thesystem.

danger.

12. Nevershort circuitthe battery anddo nottryto recharge

24. Everything not expressly specified in these instructions

the batteries with power supply units other than that

isnotpermitted.

suppliedwiththeproduct,orbyCenturion Systems.

13. Make sure that the earthing system is correctly

constructed, and that all metal parts of the system are

suitablyearthed.

Page 5

Page 5

The Vector operator has been designed to safely and cost-effectively automate a wide variety of swing

gates, from single light domestic swing gates to heavy industrial double swing gates.

The fail-safe and fully redundant position and collision detection system has been designed and tested

to set the standard in safety of operation and to provide an unparalleled level of reliability and durability

in operation.

The gate travel limits are managed by a sealed double-redundant opto-electronic system that has been

designed not only to ensure ultra-reliable operation, but also to ensure precise position and trajectory

control. This enables very accurate and reliable collision detection to ensure safe operation even under

trying conditions.

A novel, adaptive, parabolic ramping algorithm also ensures smooth and quiet gate starting and

stopping irrespective of the gate condition, even after many years in service.

The Vector control card has been designed to be easy and intuitive to use with helpful instructions on

the status of the operation during and after the installation. It also has a built-in diagnostic procedure

that can verify every aspect of the control card on site.

Some of the advanced features offered by the Vector controller are:

• Fully automated single button limit-setup for single and double swing gates.

• Full graphics LCD display to simplify the installation process with easily understood icons indicating

the controller state.

• Intuitive user interface with built-in diagnostics to speed up and simplify the installation process.

• Separate safety inputs for sensitive edges or beams on both the closing and opening directions of

the gate.

• Advanced closed-loop speed control to maintain safe and reliable operation on inclined gates

under windy conditions.

• Selectable and adjustable auto-close with pushbutton override.

• Pedestrian (Partial) opening with automatic closure.

• Positive close mode.

• Advanced and proven lightning/surge protection.

• Solenoid lock drive output up to 2A.

• A status LED output to indicate the gate status remotely.

• Leaf delay selectable for either gate leaf.

Lightning Protection

The Vector electronic controller utilizes the same proven surge protection philosophy that is used in all

Centurion products. While this does not guarantee that the unit will not be damaged in the event of a

lightning strike or power surge, it greatly reduces the likelihood of such damage occurring. The earth

return for the surge protection is provided via the mains power supply earth. In order to ensure that the

surge protection is effective, it is essential that the unit is properly earthed.

General Description

General Description

Indicates tips and other information that could be useful during the installation.

Notes indicate variations and other aspects that should be considered during the installation.

Cautions are critical aspects that must be adhered to, to prevent personal injury.

Icons Used In This Booklet

Icons Used In This Booklet

Page 6

Page 6

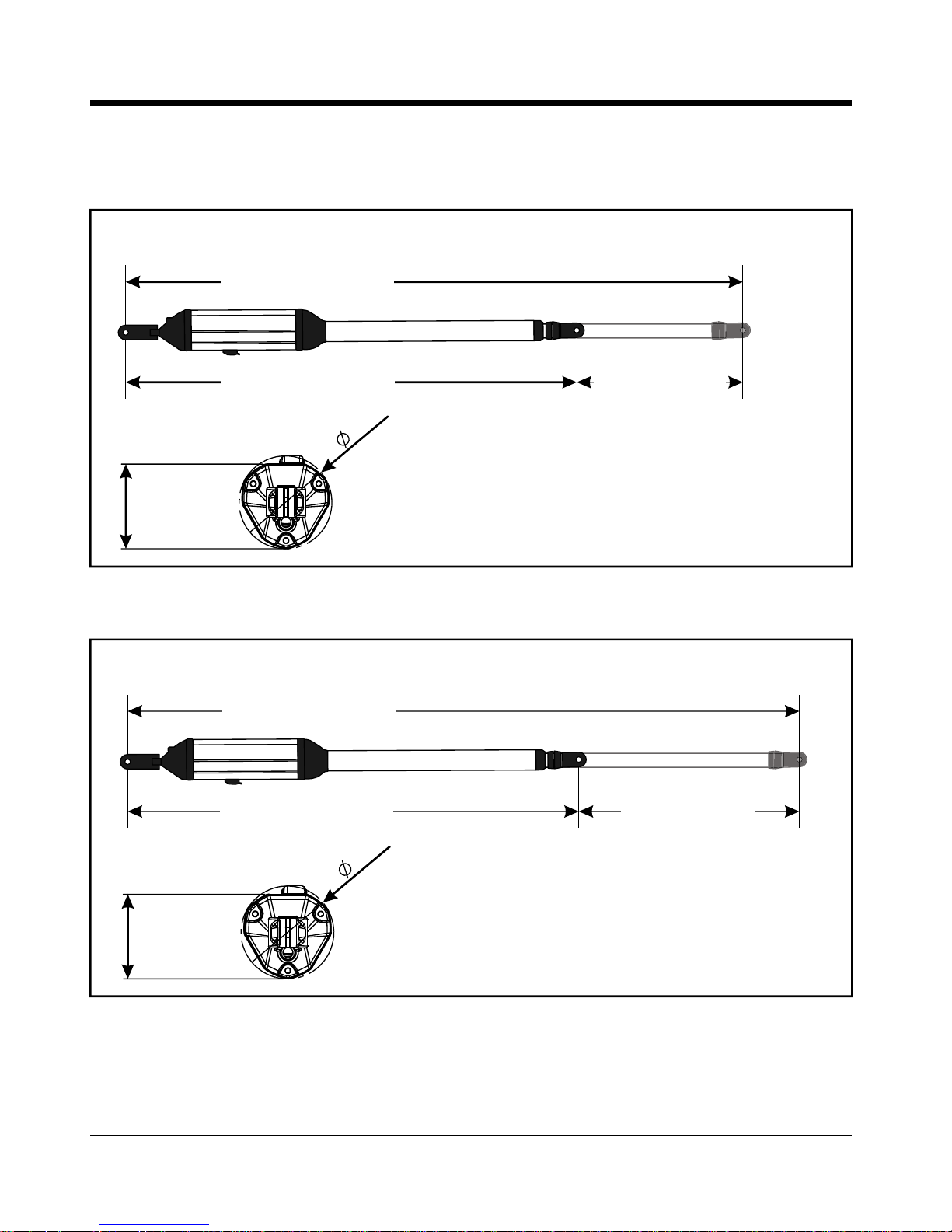

Overall Dimensions

1400mm Extended

1400mm Extended

1000mm Retracted

1000mm Retracted

400mm Stroke

400mm Stroke

Model V400

100

95mm

All dimensions shown in millimetres

Model V500

1600mm Extended

1600mm Extended

1100mm Retracted

1100mm Retracted

100

95mm

All dimensions shown in millimetres

500mm Stroke

500mm Stroke

Figure 1 O verall Dimensions

Specifications

Specifications

Page 7

Power Configurations:

Extention/retraction

(no load):

Max. Output Force:

Max. Operations (day):

Max. Number of

continuous Operations:

Standby Operations:

Standby period:

½ day

1 day

2 days

Typical Gate Opening/

Closing Time:

Operating Temp. Range:

Housing Protection:

Mass of Operator:

Operator Stroke:

DC Current Draw (Max):

Nominal Input Voltage:

12V DC

15A

27mm/sec

250kgf

V400: 5.5kg

V500: 5.9kg

V400: 400mm

V500: 500mm

V400: <14 Sec

V500: <17.5 Sec

-20°C to +60°C

IP55

Unlimited

Battery 40AH <900 cycles

Battery 40AH <880 cycles

Battery 40AH <840 cycles

Battery 7AH <115 cycles

Battery 7AH <85 cycles

Battery 7AH <7 cycles

NA

Battery 40AH <850 cycles

Battery 40AH <770 cycles

Battery 40AH <620 cycles

100*

12V DC

15A

27mm/sec

250kgf

200

Unlimited

V400: <14 Sec

V500: <17.5 Sec

V400: 5.5kg

V500: 5.9kg

V400: 400mm

V500: 500mm

-20°C to +60°C

IP55

7AH, 12V, CP84E

(Domestic)

7AH, 12V, CP84SM

(Light Industrial)

Standby period:

½ day

1 day

2 days

D ouble kit inc controller only

Battery 7AH <140 cycles

Battery 40AH <880 cycles

Battery 40AH <840 cycles

Battery 7AH <75 cycles

D ouble kit inc controller and 2 sets sa fety beam s

Operator V400/V500

*

Limited by the charging rate

Higher capacity battery can also be used must be housed separately e.g. 40AH.

Page 7

12V Single or Double

15A (fused)

18V DC

48mA

2A DC

3A (PTC)

Current Sense & Redundant Optical

Redundant Optical

-20°C to +60°C

Max. Motor Current Per Channel:

Max. Input Voltage:

Standby Current Draw:

Max. Solenoid Current Draw:

Max. Aux Output Current:

Collision Detection:

Position & Trajectory:

Temperature Range:

Control Card

Page 8

Page 8

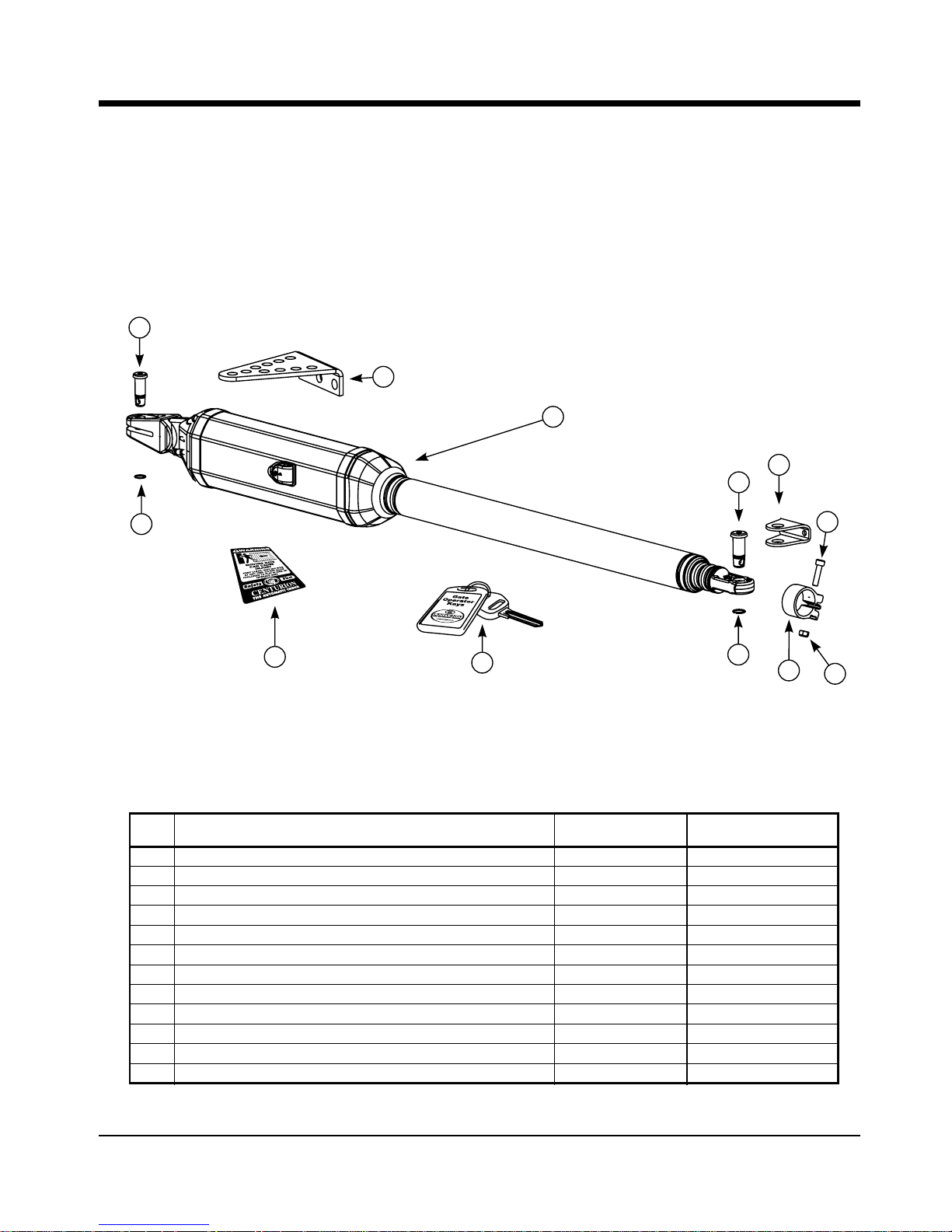

Allowable Gate Mass

Maximum allowable gate mass for V400 operator:

Gate swing angle Up to Up to Up to Up to Up to Up to

1.5m 2m 2.5m 3m(#1) 3.5m(#1) 4m(#1)

90° 500kg 500kg 500kg 360kg 260kg 200kg

100° 500kg 500kg 388kg 160kg 190kg 150kg

110° 500kg 306kg 198kg 130kg

120° 180kg 100kg 65kg

(#1 - an electric lock must be fitted to secure gate in closed position)

NOT RECOMMENDED

Maximum allowable gate mass for V500 operator:

Gate swing angle Up to Up to Up to Up to Up to Up to

1.5m 2m 2.5m 3m(#1) 3.5m(#1) 4m(#1)

90° 750kg 750kg 750kg 550kg 410kg 310kg

100° 750kg 750kg 600kg 420kg 310kg 230kg

110° 750kg 500kg 320kg 220kg

120° 310kg 170kg 110kg

(#1 - an electric lock must be fitted to secure gate in closed position)

NOT RECOMMENDED

Allowable Wind Loading

For wind loading tables see page 52.

7AH, 12V, CP84SM

(Light Industrial)

Boxed Shipping Weight

(Excluding Batteries):

Protection Level:

2.7kg

7AH, 12V, CP84E

(Domestic)

7AH, 12V, CP84SM

(Light Industrial)

IP55

2.6kg

IP55

Power Supply, Wall Box and Control Card Assembly

Power Supply

Nominal Input Voltage:

AC Current Draw (Max):

Temperature Range:

Max. Continuous

Charging Current:

170mA60mA

220V AC ±10% @ 50Hz220V AC ±10% @ 50Hz

-20°C to +60°C

-20°C to +60°C

0,8A @ 13,8V 2,5A @ 13,8V

7AH, 12V, CP84E

(Domestic)

Page 9

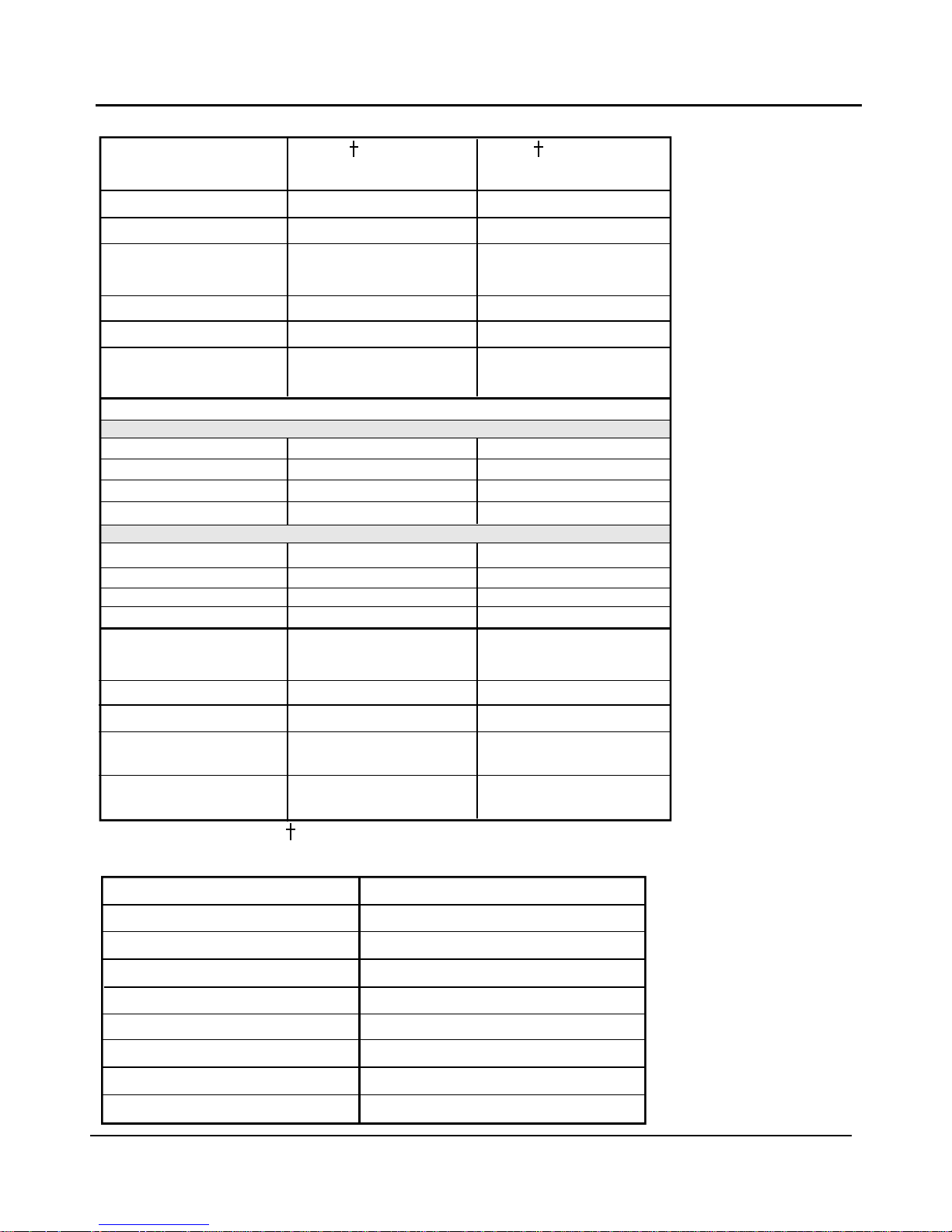

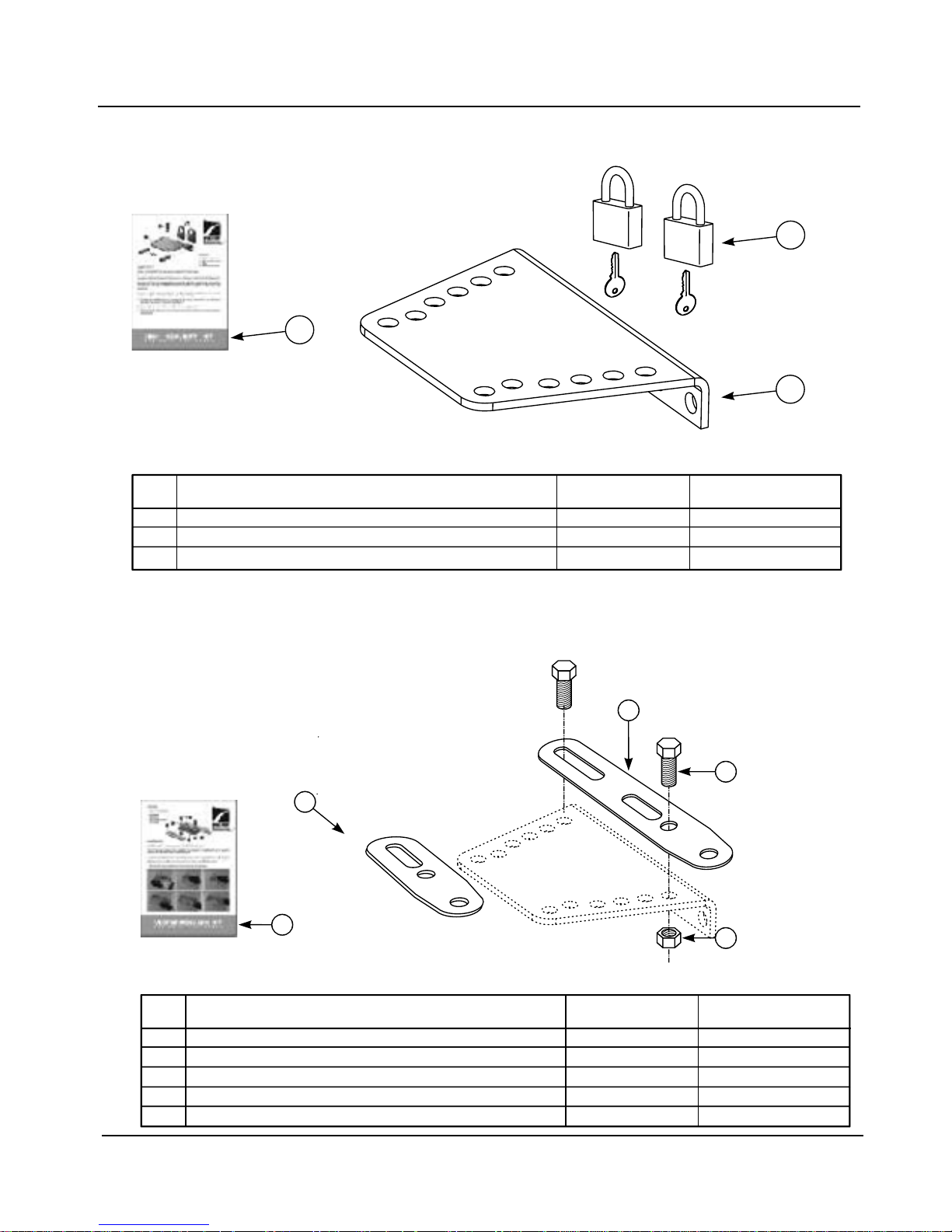

Item Description Qty. Part No.

1 Vector gate operator 1 1050M00000

2 Wall bracket (standard) 1 1050M20000

3 Wall bracket pin 1 DOMCEN0069

4 Gate Bracket 1 1050M27000

5 Gate bracket pin 1 1050M05000

6 Origin body 1 1050M0161M

7 Gate operator keys 1 GTKEYTG01

8 Gate warning decal 2 LABELGATE1

9 Cap screw M6 x 25 1 B124106025

10 14mm snap ring 1 F1400SNAPR

11 12mm snap ring 1 F1200SNAPR

12 M6 nut 1 N120206000

Figure 2 Standard P ackage C ontents

Page 9

11

1

2

3

5

4

6

8

7

10

12

9

Package Contents

Package Contents

For standard V400 and V500 operators

(VEC40000V2 & VEC50000V2)

Page 10

Page 10

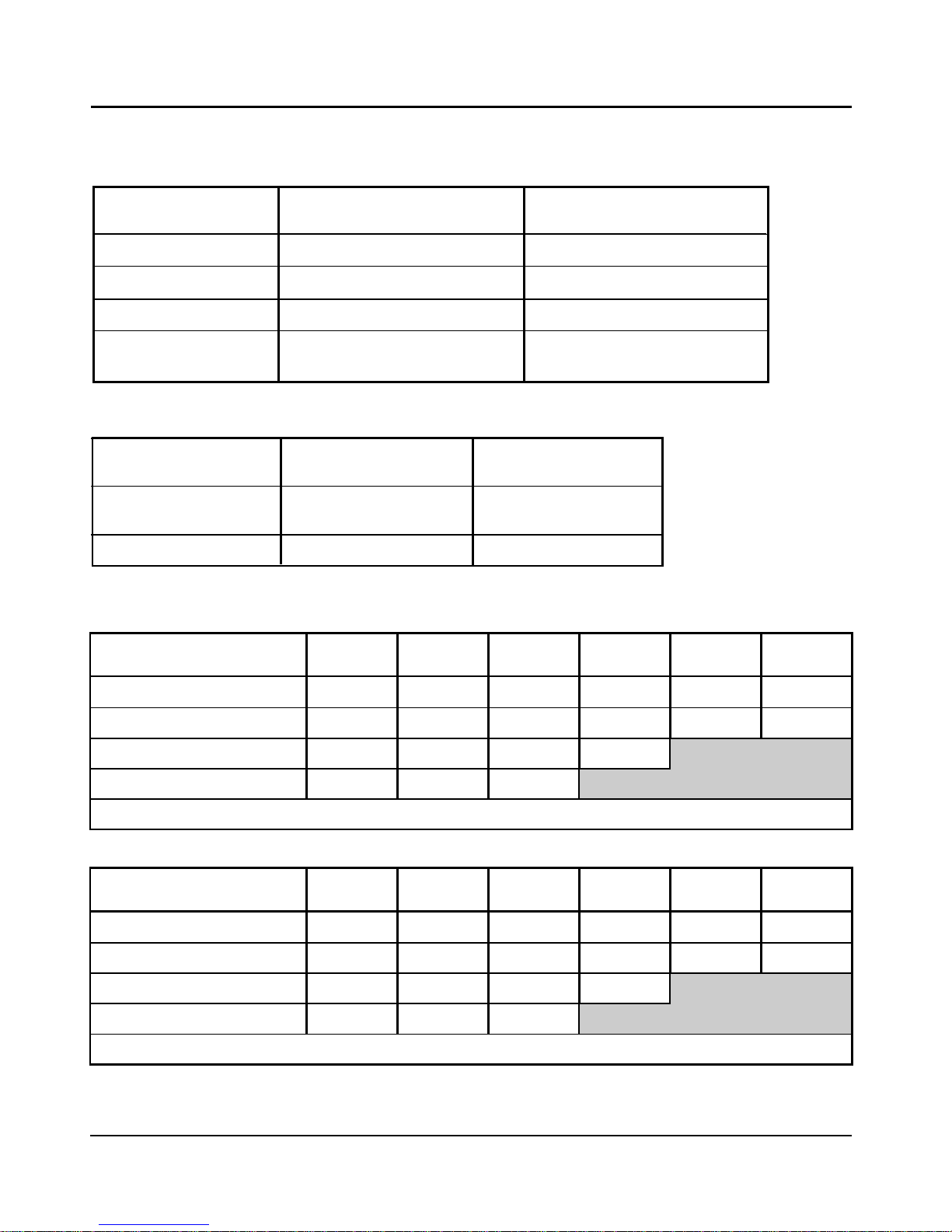

Control box including charger & controller (Domestic)

VECCAD00V2 / (Light Industrial) VECCAD01V2

Figure 3 Optional A ccesso ries continued.

Item Description Qty. Part No.

1 Wall adaptor plate 2 1050M34000

2 M10x20 Countersunk screw 2 B123201025

3 M10 Hexnuts 2 N120110000

4 Vector wall adaptor kit packing leaflet 1 DOC1050D06

Wall adaptor kit (optional) VECWAK00V1

3

1

2

4

1

2

7

4

5

6

3

1

2

3

4

5

6

7

1

1

1

1

1

2

1

1

1

1

1

1

VECC-D00V2

CP84E V2

Misc parts

DOC1050D01

TBA

TX4NV2433

CP4C

Vector Control Card Version 2 built in Rx

CP84E Charger

Wall box

User Guide

Installation Manual

NOVA 4 button transmitters

12V 7.0AH Battery (User supplied - not part of kit)

Item

Description Qty QtyDomestic

VECC-D01V2

CP84SM2A0

Misc parts

DOC1050D01

TBA

CP4C

Light Ind

Page 11

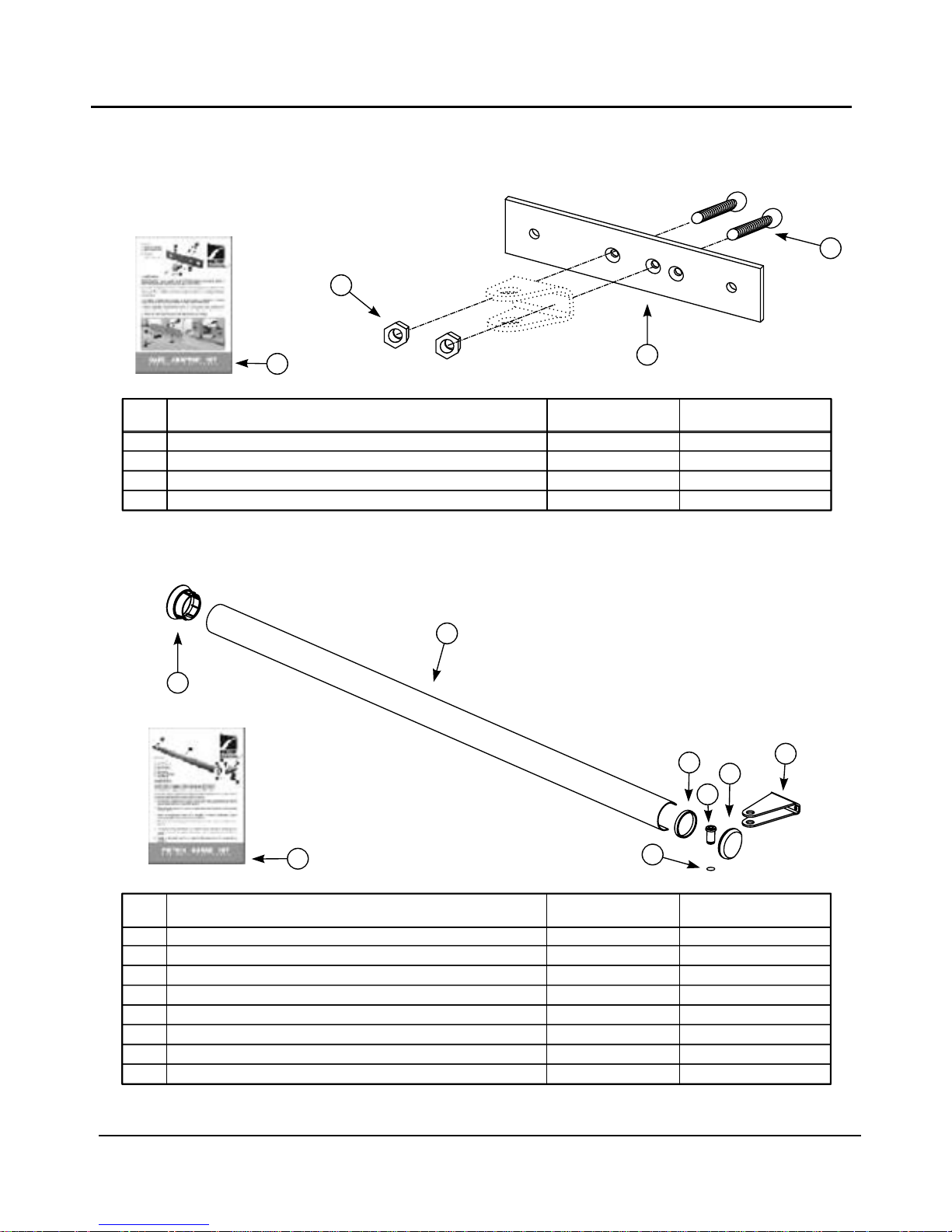

Item Description Qty. Part No.

1 Wall bracket (high security) 1 1050M3000D

2 Padlock 2 M-PLTRI263

4 Vector high security kit packing leaflet 1 DOC1050D05

High security kit (optional) VECHSK00V1

Page 11

1

2

3

Item Description Qty. Part No.

1 Vector securing plate (short) 1 1050M3200D

2 Vector securing plate (long) 1 1050M3300D

3 M10x20 Bolt 2 B121210020

4 M10 Hexnut 2 N120110000

5 Vector mechano kit packing leaflet 1 DOC1050D08

Mechano kit (optional) VECMAK00V1

1

2

3

4

5

Page 12

Page 12

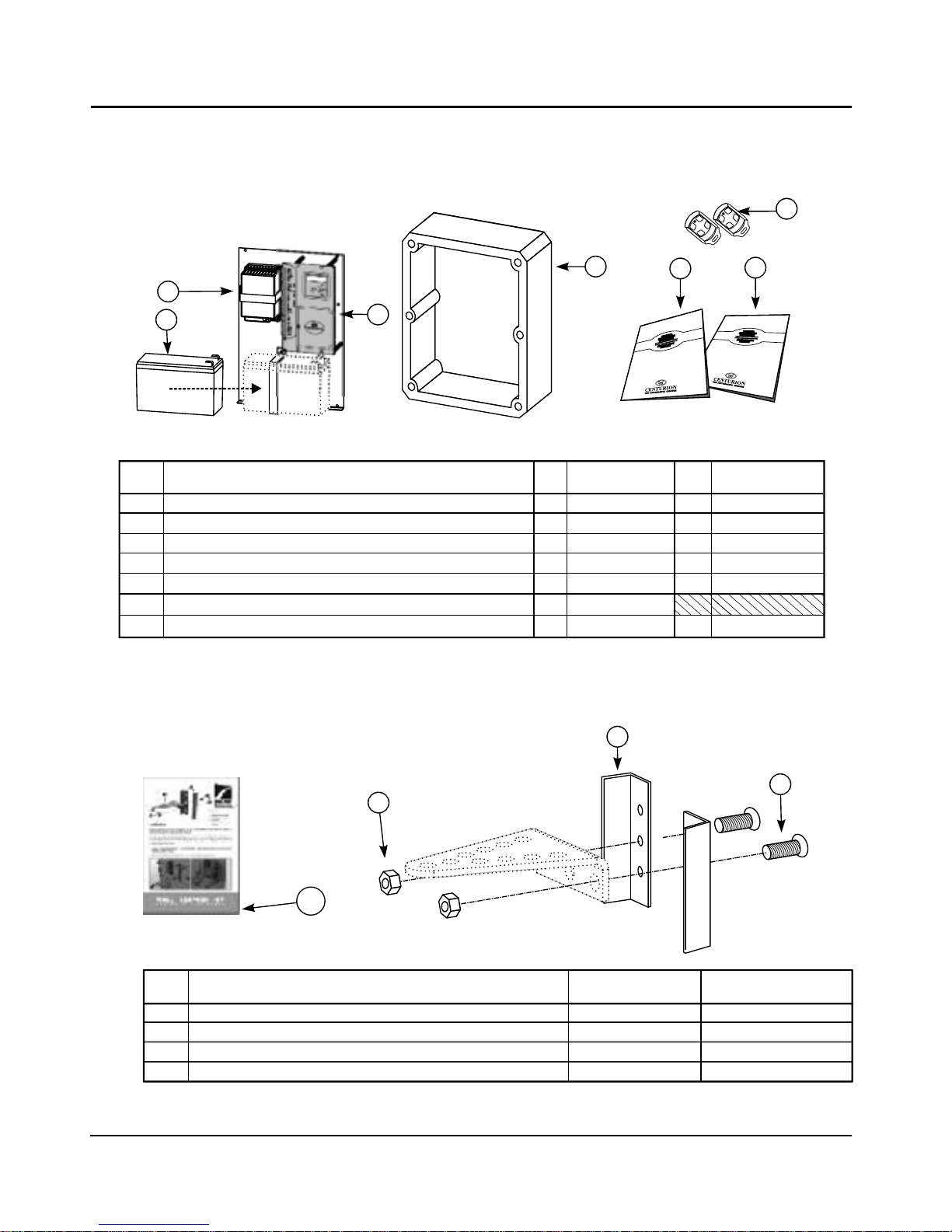

Item Description Qty. Part No.

1 Gate bracket spreader plate 1 1050M03500

2 M6x12 Countersunk screw 2 B123206010

3 M6 Hexnuts 2 N1202060SS

4 Vector gate adaptor kit packing leflet 1 DOC1050D07

Gate adaptor kit (optional) VECGAK00V1

1

2

3

4

Item Description Qty. Part No.

1 Piston guard 1 1050M0321P

2 Guard retainer 1 DOMCEN0070

3 Guard sleeve 1 DOMCEN0070

4 Guard cap 1 DOMCEN0070

5 Guard pin 1 1050M35000

6 Guard gate bracket 1 1050M2400D

7 14mm snap ring 1 F1400SNAPR

8 Piston guard kit packing leaflet 1 DOC1050D04

Figure 3 Optional A ccesso ries

Piston guard kit (optional) VEC4PG00V1

1

2

3

4

5

7

6

8

Page 13

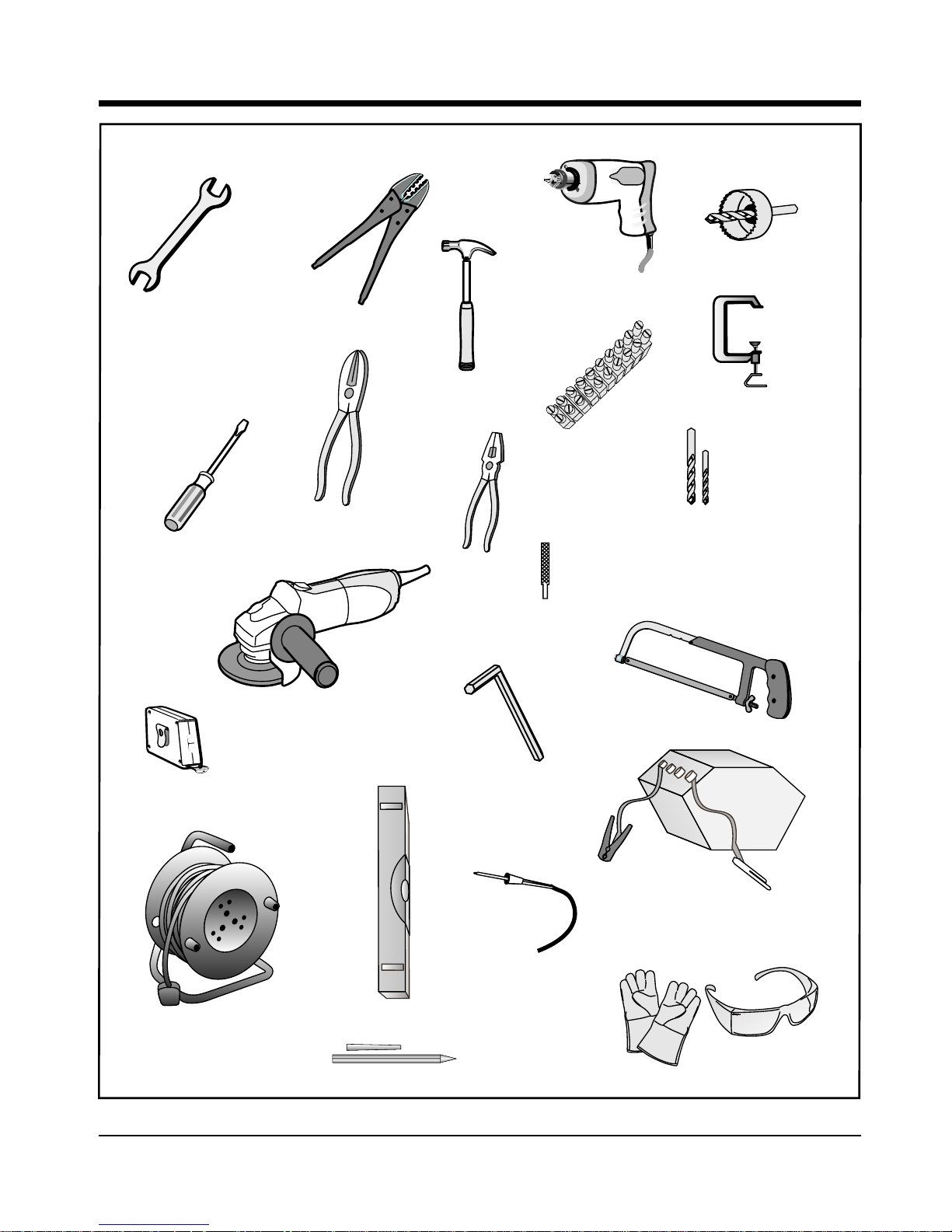

Required Tools & Equipment

Required Tools & Equipment

Figure 4 R equired Tools and E quipm ent

Spanner

17mm, 15m m

Preferably Socket Set

Screw Drivers

6mm Philips

3.5 Flat

Crimping Tool

and Pin Lugs

Pliers

Side Cutters

Hammer

2 X G-Clam ps

Electric

Drilling

M achine

M easuring Tape

H acksaw

Angle

Grinder

Spirit

Level

Marking pen/Chalk

5m m A llen Key

20mm Hole Saw

Connector block

Safety Equipm ent

G oggles, gloves, etc.

Welding M achine

(including consum ables

& safety equipm ent)

Soldering Iron

M asonry Bits - 12m m

10mm For Wall M ount Brackets

Steel Bits 6.5mm/10.5m m

6mm Pin Punch

Extension Cord

SFW

Page 13

Page 14

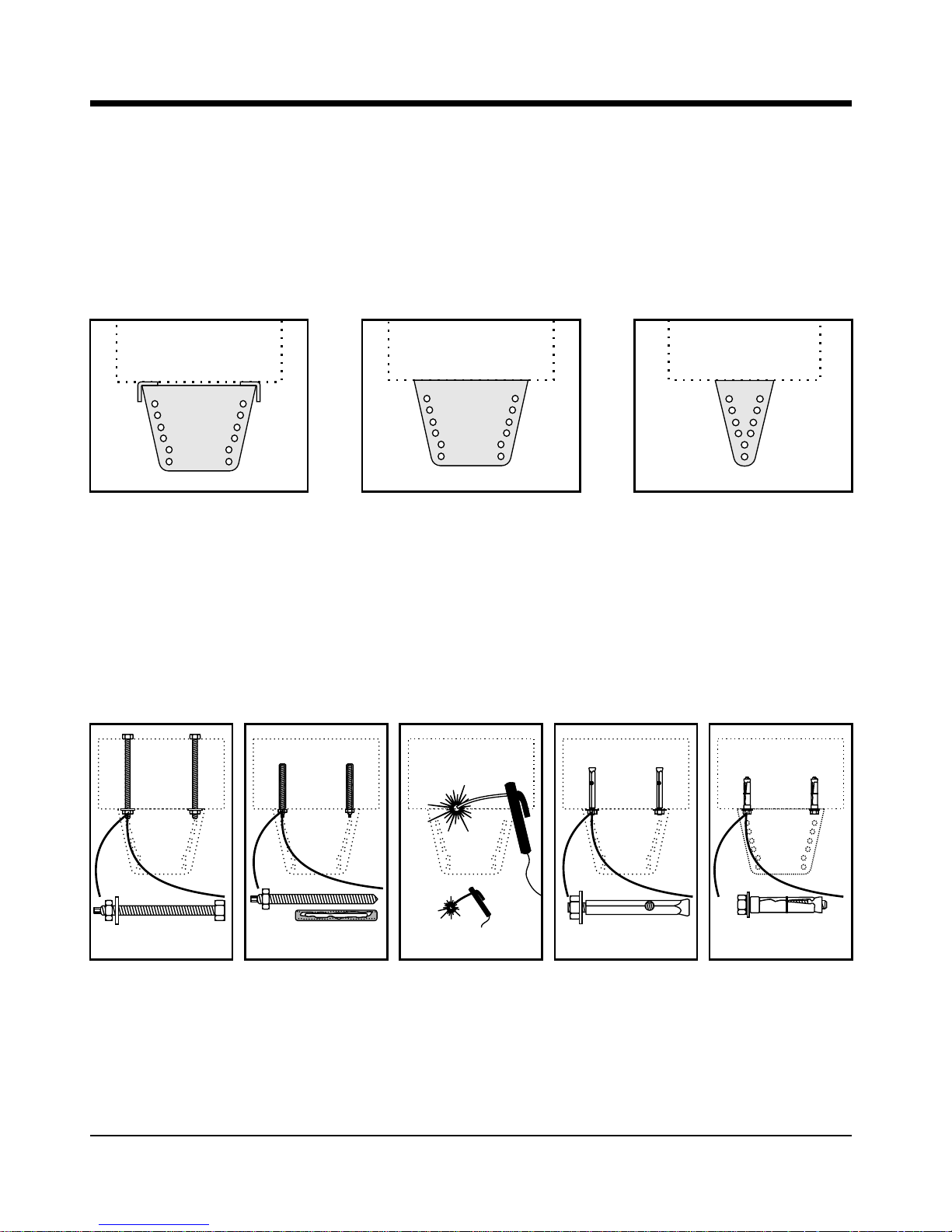

Site Considerations

Site Considerations

Page 14

Inordertoensureareliableand durableinstallationthoughtshould begivento:

Strengthofthepillar

For reliable operation it is important to ensure that the way the operator is secured to the wall takes into

accountthestrengthofthepillar, thesizeofthegate,andhowfrequentlythe gatewouldbeused:

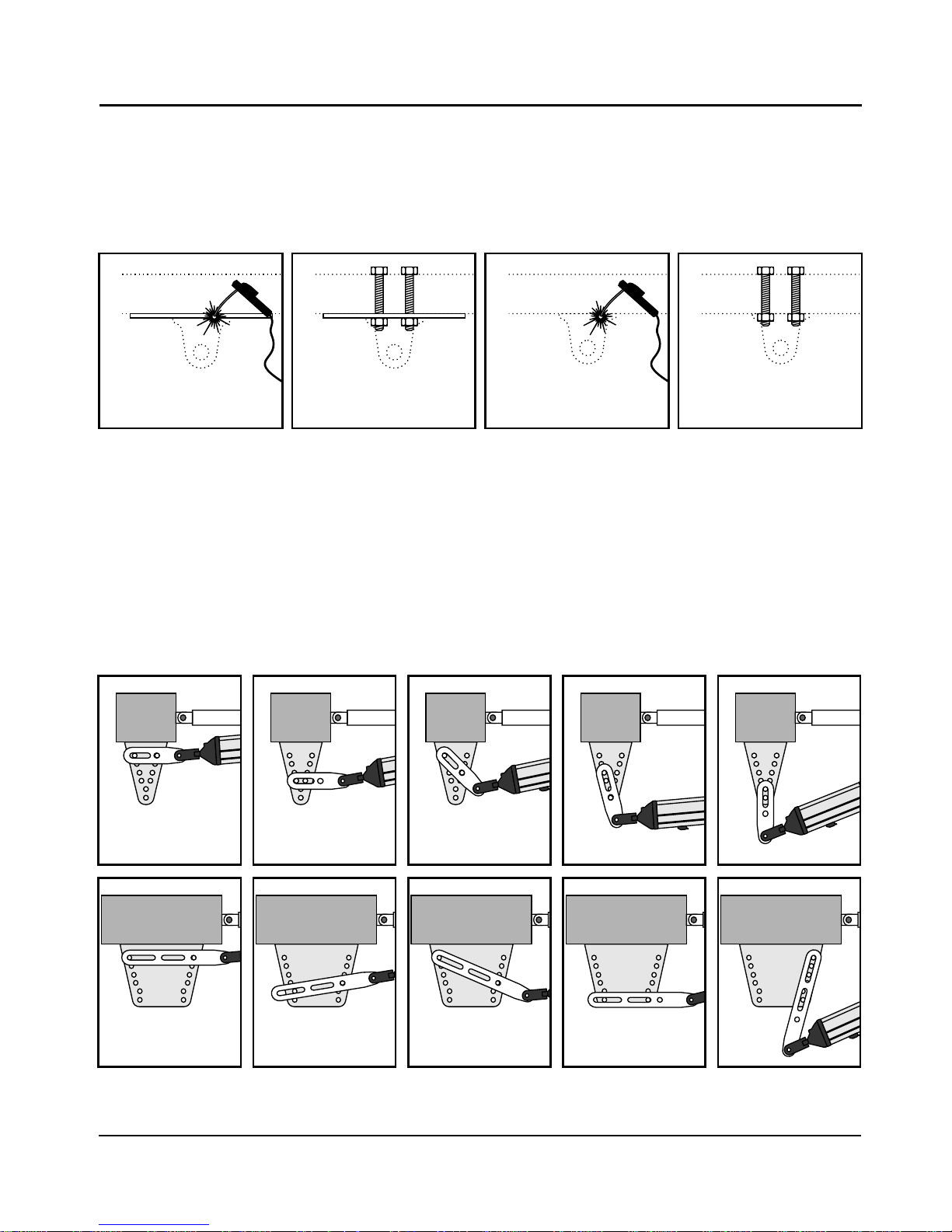

PILLARPILLAR

PILLAR

This mounting works well for

heavy gates shorter than

about 2m in single household domestic applications.

Alternatively it should be

considered for use on pillars

of low or unknown strength.

This mounting means is

typically used on light to

medium weight domestic

gates that are about 1.5m

long, and that is mounted on

pillars of average strength.

This mounting is highly

recommended for all light

industrial gates, or for heavy

gates of any length.

Alternatively it should be

considered for use on pillars

of low or unknown strength.

Standard bracketHigh security kit

High security kit

together with a

Wall adaptor kit

BEST WORKS WELL GOOD

Asimportantasthebracketishow thebracketissecured tothepillar:

Applications:

• Prefabricated

walling

• For heavy gates

operating

frequently

PILLAR PILLAR

STEEL

PILLAR

PILLAR PILLAR

Applications:

• Masonry pillars

• Frequent use

Applications:

• Lighter gates

• Domestic

Applications:

• Light gates

• Domestic

Applications:

• Very light

• Very domestic

Through wall

Chemical

anchors

Welding

Sleeve

anchors

RAWL Bolts

BEST WORKS WELL WORKS WELL OK

NOT

RECOMMENDED

Page 15

Page 15

Strengthofthegateand gatebracket

The gate adaptor kit both strengthens the connection to the gate, and also allows for more flexibility when

mountingthebrackettothegate:

TheMechanokit

This kit is useful when fitting VECTORS to existing installations, and also makes adjustments easier when

doingnewinstallations.

Applications:

• Light industrial

• Heavy gates

• Frequent use

Applications:

• Domestic

• Medium gates

• Frequent use

Applications:

• Domestic

• Light gates

• Infrequent use

Welding

Gate adaptor kit

Through bolts

Gate adaptor kit

Welding

Through bolts

(High tensile)

FAIRGOODVERY GOODBEST

Tex screws and mild steel bolts are not recommended

Page 16

Figure 5 Minimum Installation Requirem en ts

Installthegateoperatoronlyif:

1. Itwillnotposea hazardtothe public.

2. Thereissufficientclearanceto aroadwayand/or publicthoroughfares.

3. Theinstallationwillmeetall municipaland/orlocal authorityrequirementsonce completed.

4. Thegatemass,lengthand applicationiswithin theoperatorspecifications (seepage8).

5. Thewindloadingspecificationsare notexceeded(see page42).

6. Thegateisingood workingorder,vertically hungandswings freely.

7. Itcanbeinstalledtohave sufficient clearance between moving parts whenopeningandclosingtoreducethe

riskof personalinjuryand entrapment.

8. Pushbuttons or key switches, when required, must be positioned so that the gate is in line of sight of the

operator.

Generalconsiderationsfortheinstallation:

1. Always recommend the fitment of additional safety equipment such as safety edges and safety beams, for

additionalprotection againstentrapmentor othermechanicalrisks.

2. Checkthatnopipesor electricalcablesare intheway oftheintendedinstallation.

3. Checkthatenoughspaceis availableforthe gateoperatorwith thegateintherequiredopenposition.

(Seediagram below).

4. Checkthestrengthofthe mountingpillarand fitawall adaptorkit whereneeded.

5. Iftheswinggateleaf islongerthan 2.5m,ensure thatalockcanbefitted.

6. Neverfittheoperatorontheoutsideofthegate,wherethepublichasaccesstoit. (Followtheinstructionsfor

anoutward openingswinggate, ifrequired.)

7. Forgreater securityconsiderfittinganoptionalhighsecuritykit.

8. Consider where the gate bracket will be mounted. It might simplify the installation to fit the optional gate

adaptorkit.

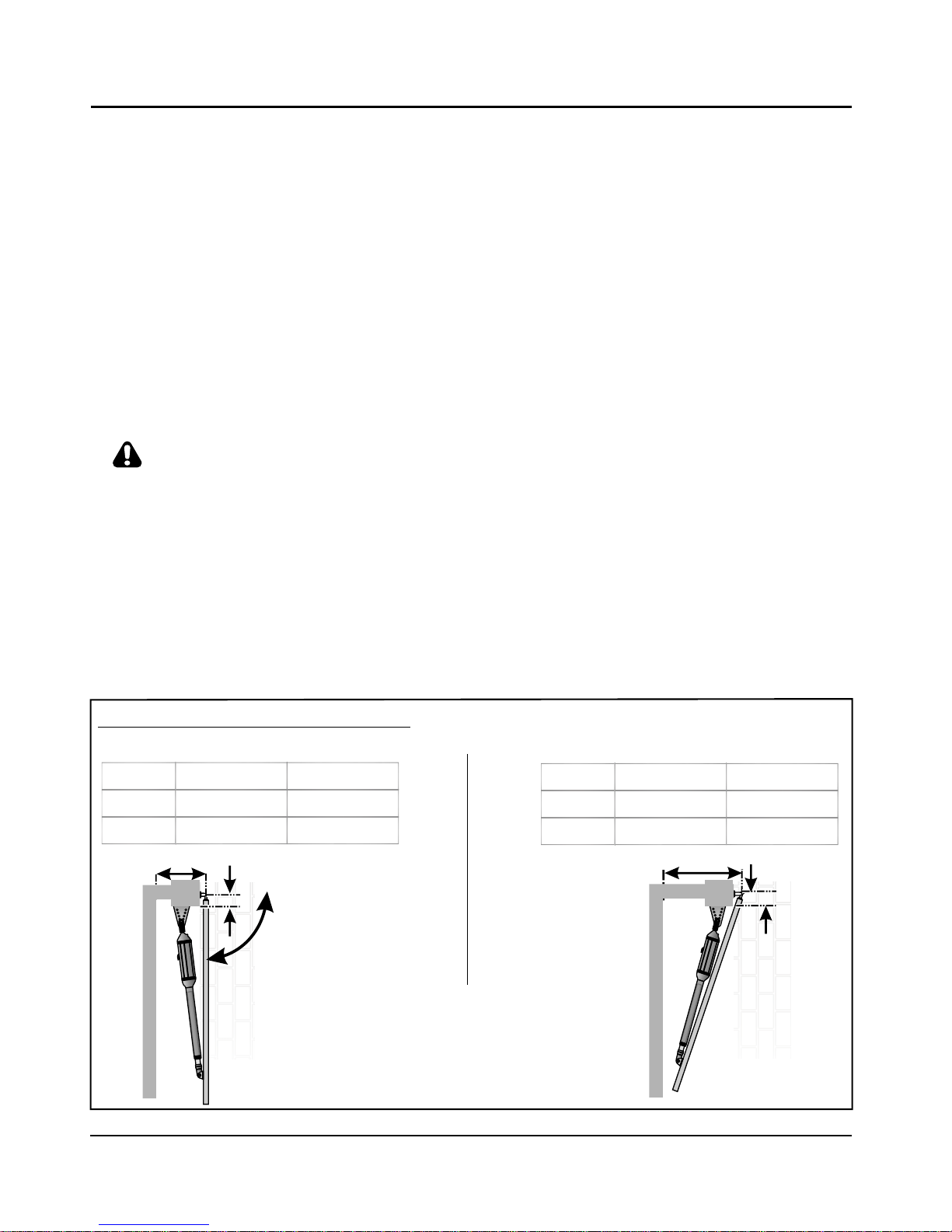

Page 16

There must be 2 sets of beams. One across the driveway when the gate is closed and one when the gate is open.

Gate opening

90° or less

Pillar (Max.) *

Wall (Min.) #

Wall (Min.) *

Gate opening

110°

Gate opening 90° or less

Operator

V400

150mm

150mm 250mm

V500

335mm

Wall (Min.) # Pillar (Max.)*

Gate opening 110°

Operator

V400

150mm

150mm 145mm

V500

210mm

Wall (Min.) # Pillar (Max.)*

Minimum Installation Requirements

(Tables are based on gates shorter than 2.5m.

• For gates 2.5m to 3.0m long, reduce the maximum pillar thickness by 20mm.

• For gates 3.0m to 3.5m long, reduce the maximum pillar thickness by 40mm.

• For gates 3.5m to 4.0m long, reduce the maximum pillar thickness by 60mm.)

# - The typical minimum wall clearance required to fit the operator.

* - The maximum allowable pillar thickness on which to fit the operator.

Pillar (Max.) #

Page 17

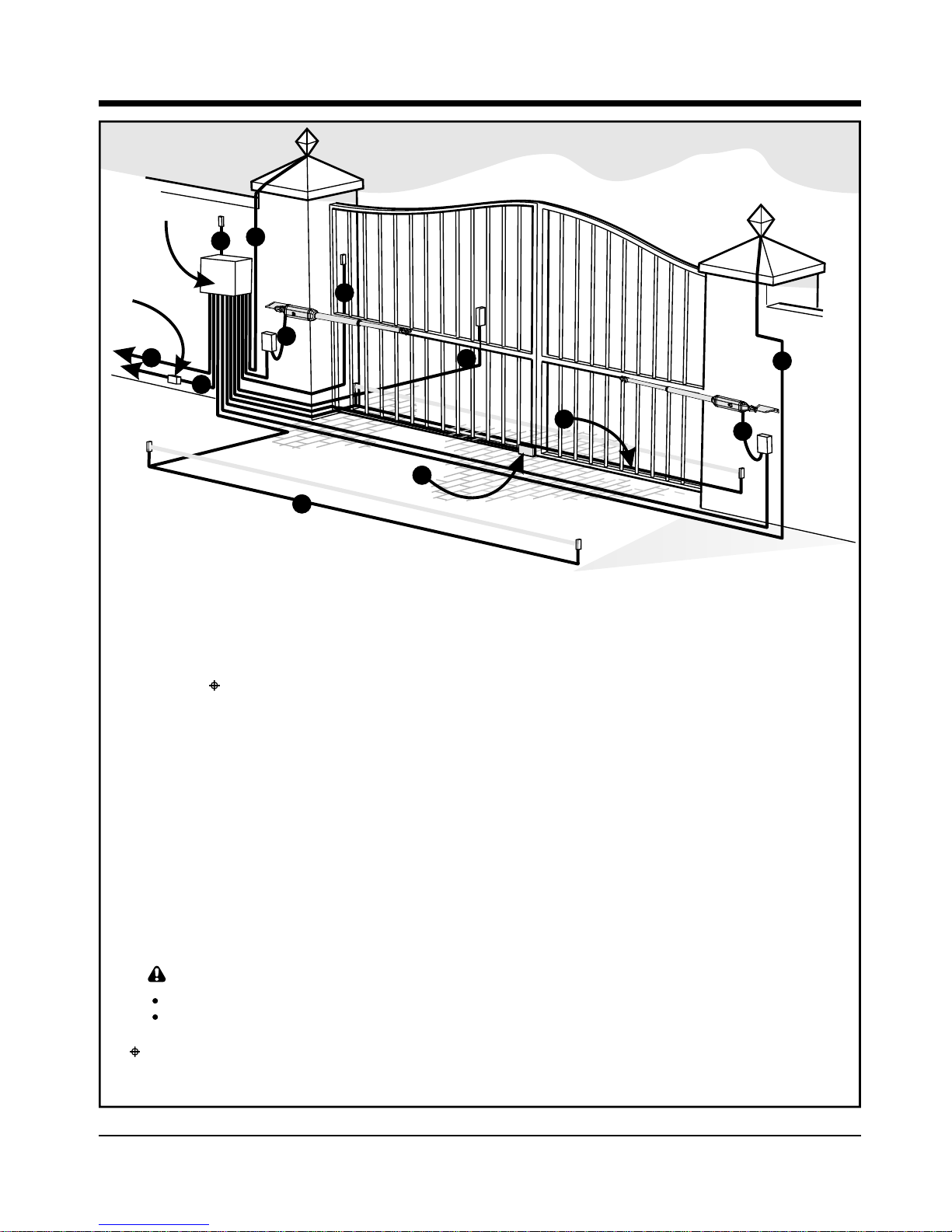

Cabling Requirements

Cabling Requirements

Figure 6 C abling Requirem en ts

Page 17

1. 220V AC mains cable via mains isolator Or

switch (3 core LNE 0,5mm²)*,

Optional keypad (if required, 3 core

2

Or

0,5mm multi-stranded).

Low voltage 16V AC battery charger

6. Optional infrared beams or safety edge

2

supply (2 core 1,5mm²).

(if required, 3 core 0,5mm multistranded or 4 core 0.5mm² for CE

2. Intercom cable (n1 + 6 core) to house.

compliance.)

3. MOTOR M (MTR M) or MOTOR S

7. Optional intercom cable (n2+2 core

(MTR S) cable (if required minimum,

0,5mm²multi-stranded) to gate station

2

2 core 2mm + 4 core 0,5mm² multistranded) ¥

8. Optional electric lock. (2 core 0.5mm²)

See page 8.

4. Optional radio receiver cable (3 core

2

0,5mm multi-stranded, optional) # 9. Optional pillar light cable (3 core, size

according to power reg.)

5. Optional pedestrian key switch (if

2

required, 2 core 0,5mm multi-stranded).

†

To dw elling

Mains

iso lator

sw itch

C ontro l

box

4

5

7

6

n1 = number of cores required by intercom. n2 = number of cores required by intercom.

2

LEGEND

1

8

9

9

3

3

6

†

Mains isolator must be fitted less than 1m from controller

* Increase cable thickness if pillar lights are to be installed.

Screened cable is always recommended to provide better protection against lightning earth one end of screening.

Domestic charger only.

# For optimum range an external receiver can be mounted on the wall.

¥ Centurion has available customer VECTOR cable order reference: CABLEVEC68

Page 18

1. Determinegate opening angle and directionof

operator(inwardoroutward).

Alternatively the swing angle can be determined more accurately with the process

detailedonpage37.

120°

100°

110°

90°

80°

70°

60°

OPEN

CLOSED

E

L

G

N

A

G

N

I

W

S

E

T

A

M

I

T

S

E

2. Determine a suitable height for the wall

bracket.

Wall Bracket

85m m

Gate Bracket

Minimum 125m m

3. Determinewhere to put the bracket according

toAandBvaluesinthetablesonpages23and

25.

B

A

120°

110°

100°

90°

80°

70°

60°

Gate opening angle

0°

120°

110°

100°

90°

80°

70°

60°

Gate opening angle

0°

For tables see page 23 or 25

.

or

or

USE MECHANO KIT CUT THE BRACKET

CAUTION:

Take care to shorten

the wall bracket to

prevent interference

with the operator

Operator Installation

Operator Installation

Page 18

The gate bracket must fit to a sturdy point on

the gate.

Consider using the optional gate adaptor kit.

OPERATOR MUST NOT FOUL AGAINST BRACKET

Page 19

4. Secure the bracket to the wall with the most

appropriate means.

See page 14 for site considerations.

5. Fitthegatebrackettotheoperator.

1 OR 2 TURNS

6. Fit the motor end of the operator to the wall

bracket.

7. Open the gate fully and temporarily clamp the

gatebrackettothegate.

Determine the gate bracket position

Page 19

The gate bracket must fit to a sturdy point on

the gate.

Consider using the optional gate adaptor kit.

Start with the operator fully retracted.

Turn out the actuator tube one or two turns.

Page 20

or

or

8. Unlock the operator and swing the gate

closed.

9. Remove the pin and the operator from the

bracket,checkthat there are at leastoneortwo

turnsof theactuatorbeforeitisfullyextended.

10. Secure the gate bracket using the most

appropriate means.

11. Fitoperator, wallbracketpinsandsnaprings.

Fasten gate bracket to gate

Page 20

See page 14 for site considerations.

If it becomes obvious that the operator does not

have enough stroke, reduce either the A or B

distances by moving the wall bracket.

Be sure not to make the A and B values less than

allowed for in the installation tables on page 23.

In general:

• Large B distances give good security and

good closing push force.

• Small A and small B will increase the speed.

or

As an alternative to the snap ring, fit a

padlock.

Page 21

or

13.Unlock the operator and open the gate fully

14. Slide the origin clamp along the actuator

tube, right up to the operator.

Secure in place with an allen key tighten

properly.

15.Attachwarningdecalstothegateasshown.

2

1

Adjust origin clamp

(NB - Not required for outward swinging gates)

Page 21

open

12. Fitoperator, gatebracketpinsandsnaprings

As an alternative to the snap ring, fit a

padlock.

The mechanical part of the installation is now complete.

Page 22

Figure 7 Position Inw ard Opening Gates

Page 22

Operator Installation

Operator Installation

B

A

Inward Swing Gate Setup

B

A

For gates opening 90° or less:

For gates opening m ore than 90°:

Ensurethatthe gate does notexceed the

gatem assspecifications on page 8.

For bestsecurity(butslow er operation)

installwithlarge B value

For fast operation (but less security)

installwithsmallA andsm allB values

GATE OPEN

GATE OPEN

GATE CLOSED

Page 23

Alternative positions

A and B must each be greater than

Gate swing A+B should Up to Up to Up to Up to Up to Up to

angle not exceed 1.5m 2m 2.5m 3m 3.5m 4m

60° - 90° or less 465mm

100° 400mm

110° 340mm

120° 285mm

Recommended positions

(Only for a 2.5m gate or shorter)

A value B value

90° or less 220 220

100° 190 190

110° 150 150

120° 135 135

Alternative positions

Gate swing A+B should Up to Up to Up to Up to Up to Up to

angle not exceed 1.5m 2m 2.5m 3m 3.5m 4m

60° - 90° or less 380mm

100° 325mm

110° 275mm

120° 230mm

A and B must each be greater than

Recommended positions

(Only for a 2.5m gate or shorter)

A value B value

90° or less 150 150

100° 155 155

110° 125 125

120° 110 110

120°

100°

110°

90°

80°

70°

60°

Gate opening angle

0°

120°

100°

110°

90°

80°

70°

60°

Gate opening angle

0°

1400mm Extended

1400mm Extended

1000mm Retracted

1000mm Retracted

1600mm Extended

1600mm Extended

1100mm Retracted

1100mm Retracted

For V400 (400mm operator)

For V500 (500mm operator)

100mm 100mm 100mm

120mm

140mm 160mm

NOT RECOMMENDED

100mm 100mm 100mm

120mm

140mm 160mm

NOT RECOMMENDED

NOTE:

100m m for A or B w ould ensure a 10mm clearance betw een the operator and gate if the gate is 50mm thick

NOTE:

100m m for A or B w ould ensure a 10mm clearance betw een the operator and gate if the gate is 50mm thick

Page 23

Gate swing

angle

Gate swing

angle

Page 24

Outward Swing Gate Setup

B

A

make up bracket

to suit

For gates opening 90° or less:

B

A

make up bracket

to suit

For gates opening m ore than 90°:

Figure 8 Position Outward Opening Gates

Page 24

Ensurethatthe gate does notexceed the

gatem assspecifications on page 8.

Outward opening swing gates m usthave

physical end stops fitted inthe open

position.

Originclam ps m ust N O T be

fitted.

For bestsecurity(butslow er operation)

installwithlarge B value

For fast operation (but less security)

installwithsmallA andsm allB values

GATE CLOSED

GATE OPEN

GATE OPEN

End stop see

Caution Note

CAUTION:

Page 25

Page 25

Alternative positions

A and B must each be greater than

Gate swing A+B should Up to Up to Up to Up to Up to Up to

angle not exceed 1.5m 2m 2.5m 3m 3.5m 4m

60° - 90° or less 465mm

100° 400mm

110° 340mm

120° 285mm

Recommended positions

(Only for a 2.5m gate or shorter)

A value B value

90° or less 220 220

100° 190 190

110° 150 150

120° 135 135

Alternative positions

Gate swing A+B should Up to Up to Up to Up to Up to Up to

angle not exceed 1.5m 2m 2.5m 3m 3.5m 4m

60° - 90° or less 380mm

100° 325mm

110° 275mm

120° 230mm

A and B must each be greater than

Recommended positions

(Only for a 2.5m gate or shorter)

A value B value

90° or less 150 150

100° 155 155

110° 125 125

120° 110 110

120°

100°

110°

90°

80°

70°

60°

Gate opening angle

0°

120°

100°

110°

90°

80°

70°

60°

Gate opening angle

0°

1400mm Extended

1400mm Extended

1000mm Retracted

1000mm Retracted

1600mm Extended

1600mm Extended

1100mm Retracted

1100mm Retracted

For V400 (400mm operator)

For V500 (500mm operator)

100mm 100mm 100mm

120mm

140mm 160mm

NOT RECOMMENDED

100mm 100mm 100mm

120mm

140mm 160mm

NOT RECOMMENDED

NOTE:

100m m for A or B w ould ensure a 10mm clearance betw een the operator and gate if the gate is 50mm thick

NOTE:

100m m for A or B w ould ensure a 10mm clearance betw een the operator and gate if the gate is 50mm thick

Gate swing

angle

Gate swing

angle

Page 26

Electrical Set-up

Electrical Set-up

WARNING

1. Alwayscheckthattheisolatorin the mains supplytothegateisinthe OFF position,beforedoingany

work.

2. Ensure that all low voltage systems (Less than 42.4V) are suitably protected from damage, by

disconnectingallsourcesof powersuchas chargersandbatteriesbeforedoing anywork.

3. Allelectricalworkmustbe carried out accordingto the requirements of all applicable local electrical

codes. (Itisrecommendedthatalicensedelectricalcontractorperformsuchwork.)

Page 26

1. Secure the control box to wall using the most

appropriatemeans.

Secure control box to wall

p 1

CONTROL BOX

PREFERABLY MOUNTED

AT EYE LEVEL

Be sure to position the wall box so as not to

cause any hazards during and after the

installation.

Preferably mount the wall box:

• Out of direct sunlight

• At a comfortable working height

• Away from garden sprinklers etc.

• To allow easy access even when the

gate is open

2. Connect all the cables as required to the

controlcard.Seepage46andpage47.

3. When wiring each operator back to the

controller housing, it is recommended to

mount a small junction box adjacent each

operator. Terminate the cable provided on the

operatorinto this junction boxand then routea

new cable from the junction box to the

controllerhousing.

Connect all wiring

For wiring diagram see page 46/47

Page 27

Page 27

Light

Light

Batt +

Batt MTR M+

MTR M MTR S+

MTR S -

Com

FRX

LIT

LED

Com

Aux 12V

Com Saf

Sol

4. Check that the charger and battery are

connectedtothecontroller.

Ensurethebatterypolarityiscorrect.

5. Switchonthemainssupply(viaisolator).

6. Ensurethat both the controller and charger are

effectively earthed for improved lightning

protection.

Settingthelimits

7. Check that the origin has been correctly set.

(Seepage 21)

open

8. Checkthatthegateis closedandtheoperatoris

locked.

9. Push and hold the SETUP button ( ) for 3

seconds. Select the “limits” menu by pressing

the ENTER button ( ). The Limit setup

wizard will now begin. Follow the on-screen

instructions to complete the setup procedure.

SSens1

SSens2

M Sens1

M Sens2

Sens+

Sens-

Safe CLS

Safe OPN

Com

LCK/STP

TRG

PED

33333

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

AutoCloseAutoCloseAutoCloseAutoCloseAutoClose

Page 28

Figure 10 provides the full menu of features that can be setup on the system. Explanation of each

feature is provided in the section “CONTROLLER FEATURES”.

When setting up the VECTOR system via the LCD display, all the steps that have to be followed are

clearly provided via the display. It is only necessary to note the following:

? To get into setup mode, press the (oblong) button for 3 seconds and follow the instructions

provided from there.

? The buttons provided on the controller for navigating the system, are not marked because at each

step during the setup, the function given to each button is provided on the display.

? When not in setup mode, ie normal mode, the (round) button is used as a TEST button for

operating the system. The up/down buttons are not used unless the diagnostic screens have been

selected to appear in normal mode, in which case these buttons allow switching from one screen

to the next.

For each feature, a factory default setting has been programmed into the controller. The defaults have

been determined to suit a typical domestic swing gate installation. It is only necessary to change a

feature where the default does not suit the installation being carried out. When selecting any feature in

the menu, details of the current setting stored in the controller are displayed.

Page 28

Figure 9 View of C ontroller

S Sens1

S Sens2

M Sens1

M Sens2

Sens+

Sens-

Safe CLS

Safe OPN

Com

LCK/STP

TRG

PED

Com

FRX

33333

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

AutoCloseAutoCloseAutoCloseAutoCloseAutoClose

Menu Level

Menu Level

How to set up additional features

on the Vector Controller

How to set up additional features

on the Vector Controller

Page 29

Menu Navigation Map

Menu Navigation Map

Page 29

Figure 10 Part A of “M enu Navigation M ap”

SETTING LIMITS: 1

SAFETY: 2

AUTOCLOSE: 3

MODES OF OPERATION: 4

RUN PROFILE: 5

IR BEAMS: 6

Setup Wizard

MTRM Collision Force: 2.1

MTRS Collision Force: 2.2

Collision Count: 2.3

Autoclose Status: 3.1

Autoclose Time: 3.2

Autoclose Override Time: 3.3

Autoclose Advanced Options: 3.4

Operating Mode

Positive Close: 5.1

Leaf Delay: 5.2

Pre-Open Delay: 5.3

Pre-Close Delay: 5.4

Opening Speed: 5.5

Closing Speed: 5.6

Ramp up Distance: 5.7

Ramp down Distance: 5.8

Crawl Distance: 5.9

Torque Limit: 5.10

MTRM Opening Collision Force

MTRM Closing Collision Force

MTRS Opening Collision Force

MTRS Closing Collision Force

Autoclose on Open: 3.4.1

Autoclose on Partly Open: 3.4.2

Autoclose on Partly Closed: 3.4.3

Standard Mode

Condominium Mode

Reversing Mode

Positive Close Status: 5.1.1

Positive Close Type: 5.1.2

Positive Close Short Stop Value: 5.1.3

Positive Close Push Force: 5.1.4

Leaf Delay Status: 5.2.1

Leaf Delay Value: 5.2.2

Short Stop

MTRM Only

MTRS Only

MTRM & MTRS

PIRAC Control: 6.1

SAF Output Status: 6.2

IRBO = IRBC

IR Beam Alarms: 6.3

PIRAC Status: 6.1.1

Stop On Open: 6.1.2

Ambush Alarm: 6.3.1

Break in Alarm Status: 6.3.2

Stop On Open Status: 6.1.2.1

Stop Distance: 6.1.2.2

Ambush Alarm Status: 6.3.1.1

IRB Broken time: 6.3.1.2

Page 30

Page 30

Figure 10 Part B of “M enu Navigation M ap”

Pedestrian Open Position: 7.1

Pedestrian Autoclose Time: 7.2

Pedestrian Pre-Open Delay: 7.3

Pedestrian Pre-Close Delay: 7.4

Lock Enabled Status: 8.1

Lock Type: 8.2

Release Time: 8.3

Pre-Release Time: 8.4

Lock Location: 8.5

Lock Drive (AC/DC): 8.6

Courtesy Light Time: 9.1

Light Profile: 9.2

Operating Standard: 10.1

Reset Options: 10.2

Diagnostic Screen Status: 10.3

Test Button Disabled Status: 10.4

Press Master Button

If m enu locke d

ADD Remotes: 11.1

DELETE Remotes: 11.2

EDIT Remotes: 11.3

Remotes Menu Locked Status: 11.4

Courtesy Light

Pre Flash A

Pre Flash B

Pre Flash C

Factory Default: 10.2.1

Delete All Remotes: 10.2.2

Reset All: 10.2.3

Delete Remote By ID: 11.2.1

Delete Remote Button: 11.2.2

Delete Remote By Button: 11.2.3

Delete All Remotes: 11.2.4

PEDESTRIAN: 7

GATE LOCK: 8

COURTESY LIGHT: 9

GENERAL: 10

REMOTES: 11

§ Refer to Table 1 on page 39 for Schedule of Factory Defaults for each feature.

Page 31

Page 31

§ Refer to Table 1 on page 39 for Schedule of Factory Defaults for each feature described below.

Controller Features

Controller Features

SAFETY (COLLISION FORCE) - MENU 2

MTRM/S COLLISION FORCE

If the gate is obstructed, the internal collision circuitry will activate. The response of the

system to a collision will vary, depending on the Operating Standard (eg CE, UL325)

selected. Responses can vary from one or both gates stopping, to one or both gates

reversing. The collision force can be set from Min to Max in 5 discrete steps.

A sixth step will disable collision sensing entirely, allowing MAXIMUM force to be

achieved. Under this condition, the motors will continue running until they stall, at which

point a collision will be detected. NB:This level should only be used if additional safety

measures are taken. (e.g.: Infrared beams, sensitive edge etc.)

Collision force can be set independently per motor, as well as per direction of travel.

COLLISION COUNT

A counter monitors the number of collisions that the gate experiences before both gates

reach the fully closed position. If the value exceeds the value set in the MULTIPLE

COLLISION COUNTER the controller shuts down until the next valid trigger is received.

As indication, the STATUS LED will flash 4 times every second. The multiple collision fault

indication will continue to flash indefinitely or until a valid trigger has been received.

AUTO-CLOSE – MENU 3

AUTO-CLOSE STATUS

The Auto-close feature when turned on, has the function of automatically closing the gate

after a preset auto-close time. The AUTO-CLOSE feature is automatically turned on when

the controller is set for CONDOMINIUM mode of operation.

AUTO-CLOSE TIME

The auto-close time can be set anywhere from 1 to 255 seconds.

AUTO-CLOSE OVERRIDE

It is possible for the user to temporarily turn off auto-close when the mode of operation is

STANDARD or REVERSING. To activate AUTO-CLOSE OVERRIDE, the TRG input must

be activated and maintained for a period longer than the time set for the AUTO-CLOSE

OVERRIDE TIME, after which the input can be cleared ie press and hold the button of

the remote that operates the gate.

The gate response will be to start opening on the first TRG trigger, and then to stop as

soon as the AUTO-CLOSE OVERRIDE feature is activated. On clearing of the TRG input,

the gate will continue opening until fully open. The AUTO-CLOSE feature is now off and

the gate will remain open indefinitely.

The next signal received on TRG will clear the AUTO-CLOSE OVERRIDE feature, close

the gate, and set the AUTO-CLOSE feature back to normal.

AUTO-CLOSE ADVANCED OPTIONS

The conditions under which the gate will auto close can be set within the Advanced

Autoclose options menu.

1

2

Page 32

Page 32

3

4

Page 33

If “Short Stop” is correctly set, PCM will cut off

when gates reach closed position, in line

Line of gates when closed

M gate closes

slightly behind

S Gate (Leaf delay)

S Gate closes first

Mechanical lip

1

*

M Gate continues to close

“Short Stop”

S Gate stops slightly before closed position

2

*

*

Mechanical lip on

M Gate engages with S Gate

With PCM, M Gate continues closing,

pushing the S Gate with it

3

4

Page 33

Page 34

Page 34

5

Inside

closing beam

O utside

closing beam

TYPIC A L C LO SIN G B EAM INSTALLATIO N

G ates w ill not close

Page 35

Page 35

Outside closing beam

Inside closing beam

Opening beam

IRBO = IRBC

(Combine inside closing beam with opening beam = save on one beam )

Intruder breaks beam while loitering at gate

==

Alarm

Adjustable

beam broken time

==

Alarm

++

Intruder blocks

beam

Page 36

Page 36

7

8

6

Page 37

Page 37

9

Page 38

Page 38

10

Page 39

Factory Defaults Schedule

Factory Defaults Schedule

Page 39

Table 1 Factory Defaults Schedule

PARAMETER DESCRIPTION

UNIT

MIN

DEFAULT

MAX

South African Standard Profile

Auto-Close Enabled

Auto-Close Time

Mode of Operation

Motor M Opening Force

PCM Enabled

Leaf Delay Enabled

Motor M Closing Force

PCM Type

Leaf Delay

Motor S Opening Force

PCM Stop Short Distance

Motor S Closing Force

PCM Force

Max. No. Collisions

Collision Alarm Output

Auto-Close Override Time

Auto-Close from Fully Open

Auto-Close from Partly Open

Auto-Close from Partly Closed

YES/NO

mm:ss

S,R,C

Level

YES/NO

YES/NO

Level

M,S,M & S,SS

mm

Level

mm

Level

% (A)

Collisions

B,C,P,S,L

s

00:00*

1

NO

NO

1

1

1

1

1

3*

0

1

Max (6)

YES

YES

Max (6)

Max (6)

40

Max (6)

15

255

2*

0:15

Standard

3

NO

NO

3

Master Only

10*

250*

3

5

3

3

4

Buzzer

3

04:00*

15*

NO

NO

YES

YES

YES/NO

YES/NO

YES/NO

* -Settings are fixed across standards

** -Settings are not configurable via the GUI

Table continue on next page.

Opening Speed

Closing Speed

Ramp Up Distance

Ramp Down Distance

Crawl Distance

Torque Limit

mm/s

mm

(A)

10

10

20

20

5

4

Max

Max

400

400

400

15

30

30

30

30

10

11

mm/s

mm

mm

Pre-Close Delay Time

Pre-Open Delay Time

s

s

00

0

196

196

Page 40

Page 40

PARAMETER DESCRIPTION

UNIT

MIN

DEFAULT

MAX

PED Open Distance

Gate Lock Enabled

PIRAC Enabled

IRB Ambush Alarm Enabled

IRBO Starts Wire-Less**

Courtesy Light Time

Diagnostic Screen Enabled

Remote Menu Locked

Gate Lock Type

SAF Common Enabled

IRB Ambush Alarm Hold-Off Time

IRBC Starts Wire-Less**

Courtesy Light Profile

Test Push-Button Enabled

Helix Mode Disabled**

Gate Lock Pre-Release Time

SAF Common Tests which Beams

IRB Break-In Alarm Enabled

LCK Starts Wire-Less**

Gate Lock Release Time

IRBO acts as IRBC

IRB Alarms Output

Gate Lock Location

Gate Lock Drive Type

PED Auto-Close Time

PED Pre-Open Delay Time

PED Pre-Close Delay Time

% (Full Open)

YES/NO

YES/NO

YES/NO

YES/NO

YES/NO

Minutes

YES/NO

YES/NO

B,C,P,S,L

h:mm:ss

YES/NO

YES/NO

M,S

Crt,A,B,C

YES/NO

YES/NO

s

s

C,O,C & O

C,O,C & O

YES/NO

YES/NO

AC,DC

NO

NO

NO

1

0:00:04*

NO

NO

24.0*

YES

YES

YES

255

YES

YES

9:59:59*

24.0*

NO

NO

YES

YES

0:02:00

NO

NO

Striker

NO

1

YES

Courtesy

YES

YES

0.0

IRBC Only

NO

YES

1.0

0.1*

0.1*

NO

BUZZER

Close Only

AC

30

100

240

240

240

10

0

0

0

0

2

5

s

s

s

* -Settings are fixed across standards

** -Settings are not configurable via the GUI

South African Standard Profile Continue

Table 1 Factory Defaults Schedule

Page 41

Page 41

Description of Terminal Functions

Description of Terminal Functions

Page 42

Page 42

Page 43

Page 43

LED Indicator Lights

LED Indicator Lights

The controller is fitted with diagnostic lights (LEDs) that assist with the set-up and maintenance of the gate.

Table 2providesa descriptionandpurpose oftheindicator lights.Referto figure11below forlocation.

During Normal Operation

ON

OFF

SLOW REGULAR FLASH = Gate is opening

FAST REGULAR FLASH = Gate is closing

1 FLASH EVERY 2 SECONDS = Courtesy light latched on

2 FLASHES EVERY 2 SECONDS = Mains failure

3 FLASHES EVERY 2 SECONDS = Battery low

4 FLASHES EVERY 2 SECONDS = Collision shutdown

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

NAME STATUS

S Sens2

M Sens1

M Sens2

Light

Light

Batt +

Batt -

Sens+

Sens-

Safe CLS

Safe OPN

Com

LCK/STP

TRG

PED

Com

FRX

LIT

LED

Com

Aux 12V

Safe Com

Sol

Table 2 D escription of LED indicators

Figure 11 LED positions

= Gate open

= Gate closed

= Signal present

= No signal

= Opening Safeties clear

= Opening Safeties obstructed

= Closing Safeties clear

= Closing Safeties obstructed

= Signal present

= No signal

= Signal present

= No signal

= System ready to operate

= System locked

= Signal present

= No signal

STATUS

LED

TRG

Saf OPE

Saf CLO

FRX

PED

LCK/STP

LIT

Buzzer Feedback

The VECTOR 2 controller is equipped with an onboard buzzer which is used for various features and

functions on the controller. One of the functions it provides is audible diagnostic feedback as detailed

in the table below:

Multiple collision condition

Battery low condition

Holiday lock-out enabled

Buzzer emits a pulsed tone for a 5 second duration,

after the controller is activated in a battery low

condition.

Buzzer emits a continuous pulsed tone as soon as

a multiple collision shutdown is activated. The tone

will cease as soon as a valid trigger input is activated.

Buzzer emits a pulsed tone for a 5 second duration

when the controller is activated with this feature

enabled.

PARAMETER DESCRIPTION

Page 44

Charger and Pillar Light Connections

Charger and Pillar Light Connections

Page 44

Thefollowingprotectionfusesareprovidedonthesystem:

Fuse Protection

Item

MAIN CONTROLLER

Motor Circuit - fuse per channel

Light circuit

Auxiliary supply

CHARGER

Mains input

Type

Automotive Fuse (25X7)

5X20mm

Electronic fuse - not replaceable

5X20mm

Rating

15A

3A Fast Blow

3A

250mA Fast Blow

S Sens1

S Sens2

MSens1

MSens2

Light

Light

Batt +

Batt MTR M+

MTR M MTR S+

MTR S -

Sens+

Sens-

Safe CLS

Safe OPN

Com

LCK/STP

TRG

PED

Com

FRX

LIT

LED

Com

Aux 12V

Safe Com

Sol

220V AC

Mains in

E

N

L

L

Protection fuse on

mains input to

charger (rating:

250mA slow blow)

Auxiliary supply

Pillar

light

NEUTRAL

LIVE

N

N

L

L

E

E

N

N

L

L

E

E

N

N

L

L

E

E

N

N

L

L

E

E

N

N

L

L

E

E

N

N

L

L

E

E

N

N

L

L

E

E

N

N

L

L

E

E

N

N

L

L

E

E

N

N

L

L

E

E

N

N

L

L

E

E

N

N

L

L

E

E

N

N

L

L

E

E

N

N

L

L

E

E

N

N

L

L

E

E

Figure 12 C harger and pillar light connections

Page 45

Usethisproceduretoaccuratelydeterminethegateopeningangle:

Determine Gate Swing Angle

Determine Gate Swing Angle

USE GATE SW ING ANGLE OF

90 Degrees

100 Degrees

110 Degrees

120 Degrees

60 Degrees

70 Degrees

80 Degrees

1 351mm

1 474mm

1 587mm

1 687mm

1 000mm

VALUE Z FRO M ...

1 075mm

1 218mm

1 587mm

1 687mm

1 732mm

1 075mm

...TO

1 218mm

1 351mm

1 475mm

Step 3

1m

Open the gate and measure a

distance along the gate a

distance of 1m from the

centreline of the gate hinge.

Make a mark on the ground.

Measure the distance on the

ground between the two marks

(Z). Using this Z value, read off

the gate opening angle from the

table below.

Step 2

1m

Close the gate and measure a distance

of 1m from the centreline of the gate hinge.

Make a mark on the ground.

Step 1

Page 45

Page 46

Figure 13 Wiring Diagram for Motor M

MASTER

SLAVE

BLACK

BLACK

RED

RED

BLUE

BLUE

PURPLE

PURPLE

BLACK

BLACK

RED

RED

BLUE

BLUE

PURPLE

PURPLE

S Sens1

S Sens2

M Sens1

M Sens2

Light

Light

Batt +

Batt MTR M+

MTR M MTR S+

MTR S -

Sens+

Sens-

Safe CLS

Safe OPN

Com

LCK/STP

TRG

PED

Com

FRX

LIT

LED

Com

Aux 12V

Safe Com

Sol

THIN PURPLE

THIN RED / GREY

THICK BLUE

THICK BLACK

THIN BLUE / ORANGE

THIN BLACK

MOTOR M (MTR M)

MOTOR M (MTR M)

Page 46

Wiring Diagram for MOTOR M

(MTR M) Operator

Wiring Diagram for MOTOR M

(MTR M) Operator

Page 47

Figure 14 Wiring Diagram for Motor S

15

15

15

15

S Sens1

S Sens2

MSens1

M Sense2

Sens+

Sens-

Saf CLO

Saf OPE

Com

LCK/STP

TRG

PED

Com

FRX

LIT

LED

Com

Aux 12V

Com Saf

Sol

Light

Light

Batt +

Bat -

MTR M+

MTR —

MTR S+

MTR S-

BLACK

BLACK

RED

RED

BLUE

BLUE

PURPLE

PURPLE

PURPLE

PURPLE

BLUE

BLUE

S Sens1

S Sens2

M Sens1

M Sens2

Light

Light

Batt +

Batt MTR M+

MTRMMTR S+

MTRS-

Sens+

Sens-

Safe CLS

Safe OPN

Com

LCK/STP

TRG

PED

Com

FRX

LIT

LED

Com

Aux 12V

Safe Com

Sol

THIN PURPLE

THIN RED / GREY

THICK BLUE

THICK BLACK

THIN BLUE / ORANGE

THIN BLACK

MOTOR S (MTR S)

MOTOR S (MTR S)

Page 47

Wiring Diagram for MOTOR S

(MTR S) Operator

Wiring Diagram for MOTOR S

(MTR S) Operator

Page 48

COM

NC

NO

O PEN ING

BEA M

+12V/24V

COM

NC

NO

IRB RECEIVER

- 12V/24V

12V or 24V

IRB Tx

CLO SIN G

BEA M

+12V/24V

IRB RECEIVER

- 12V/24V

12V or 24V

IRB Tx

Wiring Diagram for Safety Beams

Wiring Diagram for Safety Beams

(for CE compliance)

(for CE compliance)

Page 48

Page 49

Page 49

S Sens1

S Sens2

M Sens1

M Sens2

Light

Light

Batt +

Batt MTR M+

MTR M MTR S+

MTR S -

Sens+

Sens-

Safe CLS

Safe OPN

Com

LCK/STP

TRG

PED

Com

FRX

LIT

LED

Com

Aux 12V

Safe Com

Sol

Page 50

Wiring diagram for other inputs

Wiring diagram for other inputs

NEG

+12V/24V

COM

NC

NO

RADIO RECEIVER

REMOTE CONTROL CIRCUITRY

NEG

+12V

COM

NC

NO

LOOP

LOOP DETECTOR

FREE EXIT CIRCUITRY

HOLIDAY LOCKOUT

KEYSWITCH

(normally CLOSED)

PILLAR LIGHT

PUSHBUTTON

(normally OPEN)

PEDESTRIAN

KEYSWITCH

(normally OPEN)

SOLENOID

LED

STATUS

LED

Page 50

*

*

Only applicable if external radio receiver is being used

Page 51

Page 51

SOLENOID

OR STRIKE

LOCK

S Sens1

S Sens2

M Sens1

M Sens2

Light

Light

Batt +

Batt MTR M+

MTR M MTR S+

MTR S -

Sens+

Sens-

Safe CLS

Safe OPN

Com

LCK/STP

TRG

PED

Com

FRX

LIT

LED

Com

Aux 12V

Safe Com

Sol

Page 52

Page 52

Wind speeds for which operator will still operate the gate (for V400 or V500 operators)

For a 25% covered gate: (Palisades, etc.) x 1.8m high

Value of Gate lengths:

A or B dimension Up to Up to Up to Up to Up to Up to

once installed. #1 1.5m 2m 2.5m 3m(#2) 3.5m(#2) 4m(#2)

100mm 94km/h 66km/h 48km/h 44km/h 41km/h 37km/h

140mm 119km/h 85km/h 65km/h 57km/h 51km/h 46km/h

180mm 138km/h 101km/h 78km/h 67km/h 60km/h 53km/h

220mm 156km/h 114km/h 89km/h 76km/h 67km/h 60km/h

260mm 171km/h 126km/h 99km/h 84km/h 74km/h 65km/h

300mm 186km/h 137km/h 108km/h 91km/h 80km/h 71km/h

340mm 199km/h 147km/h 116km/h 98km/h 86km/h 76km/h

(#1 See page 18 or 20 for installation details) (#2 - an electric lock must be fitted)

Wind speeds for which operator will still operate the gate (for V400 or V500 operators)

For a 100% covered gate: (Fully clad gates, etc.) x 1.8m high

Value of Gate lengths:

A or B dimension Up to Up to Up to Up to Up to Up to

once installed. #1 1.5m 2m 2.5m 3m(#2) 3.5m(#2) 4m(#2)

100mm 47km/h 33km/h 24km/h 22km/h 20km/h 19km/h

140mm 59km/h 43km/h 32km/h 28km/h 26km/h 23km/h

180mm 69km/h 50km/h 39km/h 34km/h 30km/h 27km/h

220mm 78km/h 57km/h 44km/h 38km/h 34km/h 30km/h

260mm 86km/h 63km/h 49km/h 42km/h 37km/h 33km/h

300mm 93km/h 68km/h 54km/h 46km/h 40km/h 35km/h

340mm 100km/h 74km/h 58km/h 49km/h 43km/h 38km/h

(#1 See page 18 or 20 for installation details) (#2 - an electric lock must be fitted)

Allowable Wind Loading

Allowable Wind Loading

Page 53

Page 53

Installation Handover

Installation Handover

Once the installation has been successfully completed and tested, it is important for the installer to

explaintheoperation and safetyrequirementsofthesystem.

NEVERASSUMETHEUSERKNOWS HOW TO SAFELYOPERATEANAUTOMATEDGATE.Evenifthe

user has used one before, it does not mean he knows how to SAFELY operate it. Make sure that the user

fullyunderstandsthefollowingsafetyrequirementsbefore finallyhandingoverthe site.

Ensurethattheuserfullyunderstands:

!

Howtooperatethemanualreleasemechanism. (Bydemonstration)

!

Howtheobstructiondetectionandallothersafetyfeatureswork. (Bydemonstration)

!

All the safety considerations associated with operating an automated gate, and that he

understands that he is responsible for explaining these safety instructions to all other users of

theautomatedsystem:

1. Do not activate your gate operator unless you can see it and can determine that its area of

travelisclearofpeoplepets,orotherobstructions.

2. NO ONE MAY CROSS THE PATH OF A MOVING GATE. Always keep people and objects

awayfromthegateanditsarea oftravel.

3. NEVER LET CHILDREN OPERATE OR PLAY WITH THE GATE CONTROLS, and do not

allowchildrenorpetsnearthegate area.

4. Be careful with moving partsandavoidcloseproximity to areas where fingers or handscould

bepinched.

5. Secure all easilyaccessed gate operator controls in order toprevent unauthorized use of the

gate.

6. Keep the automated gate system properly maintained, and ensure that all working areas are

freeofdebrisandotherobjectsthatcouldaffectthegate operationandsafety.

7. On a monthly basis, check the obstruction detection system and safety devices for correct

operation.

8. Allrepairandservice worktothisproduct mustbedonebyasuitablyqualifiedperson.

9. This product was designed and builtstrictly for theuse indicated in this documentation. Any

other use, not expressly indicated here, could compromise the good condition/operation of

theproductand/orbeasourceof danger.

10.Centurion Systems (Pty) Ltd does not accept any liability caused by improper use, of the

product,orforuseotherthanthat forwhichtheautomated systemwasdesigned.

11.Ensure that the customer is in possession of the User Guide and also complete the installationdetailsinthebackofthe UserGuide.

Page 54

Sharecall 0860-CENTURION

(Sharecall number applicable when dialed from within South Africa only)

(Omit (0) when dialing from outside South Africa)

or visit www.centsys.co.za

for details of your nearest agent

For technical support, contact:

South A frican B ranches and Regional D istributors:

O ther C ountries:

Johannesburg Central/West Rand.........................................011-699-2400

Johannesburg East-Rand ...............................................011-397-6401

Durban.............................................................. 031-701-9583

Nelspruit ........................................................... 013-752-8074/5

Pretoria..............................................................012-349-1745

Cape Town ...........................................................021-552-9425

Port Elizabeth .......................................................041-581-6994/5

East London ..........................................................043-743-4923

Bloemfontein .........................................................051-448-1714

Kimberly.............................................................053-832-3231

Vereeniging ..........................................................016-422-5667

Please refer to our website: www.centsys.co.za

Centurion Systems (Pty) Ltd Head Office:

Tel: +27 (0)11-699-2400, Fax: +27 (0)11-704-3412 or (0)11-462-6669

148 Epsom Avenue, North Riding

P.O. Box 506, Cramerview, 2060

South Africa

Latest Revision: 10.10.2008

Docum ent Ref.: 1050.D .01.0009_14

M aster address page: 0000.D.01.0004_5

© 2007 Centurion System s (Pty) Ltd.

Product C ode: DO C 1050D01

Product C ode: DC P70R 507

Loading...

Loading...