Page 1

Y

A

TEDD

US OPERATING INSTRUCTIONS

W5

Page 2

EXPLODED VIEW

No.... Description ............................................................................................................ Part No.

1 ...... Control button, l. and r. ........................................................................................... AR005-178-TZ005

2 ...... Base........................................................................................................................ AR005-022-TZ002

2.1 ... Fuse 5 A, slow, 110V .............................................................................................. AR005-418-00001

3 ...... Cover plate ............................................................................................................. AR005-347-TZ001

4 ...... Cable....................................................................................................................... AR005-193-TZ001

5 ...... Tilt Bearing, l. and r. ................................................................................................ AR005-337-TZ001

6 ...... Lid ........................................................................................................................... AR005-024-TZ002

7 ...... Intermediate shaft ................................................................................................... AR005-325-TZ001

8 ...... Upperpart ................................................................................................................ AR005-023-TZ002

9 ...... Lockpin ................................................................................................................... AR005-332-TZ001

10 .... Planetary Head ....................................................................................................... AR005-002-TS001

11..... Control board .......................................................................................................... AR005-378-TS001

12 .... Transformer 110V ................................................................................................... AR005-368-TZ001

13 .... Transmission and motor ......................................................................................... AR005-339-TZ001

13.1 . Poly-V belt............................................................................................................... AR005-090-TZ001

14 .... Release housing..................................................................................................... AR005-372-TS001

15 .... Weight Compensator .............................................................................................. AR005-352-TZ001

16 .... Attachment drive ..................................................................................................... AR005-010-TZ001

17 .... Machine feet ........................................................................................................... AR005-213-TZ001

18 .... Fixing of bowl .......................................................................................................... AR005-340-TZ001

13, 13.1

1

12

6

8

16

7

5

14

4

10

18

11

15

The mixer is equipped with a safety-timeout

that turns off the mixer after 45 minutes

continuous operation.

2, 2.1

3

9

17

Page 3

1

US

OPERATING INSTRUCTIONS

TEDDYTM W5A Food Mixer

with Att achment Drive

CONTENTS:

GUARANTEE: ...................................................................................................................................................... 1

AFETY: ....................................................................................................................................................... 1

S

INSTALLATION OF NEW MIXER: ................................................................................................................................ 1

CONNECTION TO POWER: ...................................................................................................................................... 2

INTRODUCTION TO THE MIXER:................................................................................................................................ 2

RECOMMENDED WORKING SPEEDS: ......................................................................................................................... 2

PERATION OF THE MIXER:.................................................................................................................................... 3

O

MAXIMUM CAPACITY OF THE MIXER:......................................................................................................................... 3

OVERLOAD: ....................................................................................................................................................... 3

CLEANING AND HYGIENE: ...................................................................................................................................... 3

MAINTENANCE:.................................................................................................................................................... 4

IST OF ERRORS AND POSSIBLE SOLUTIONS:............................................................................................................. 4

L

MOUNTING OF ACCESSORIES:................................................................................................................................. 4

RECOMMENDED SPEEDS FOR ATTACHMENT DRIVE:...................................................................................................... 4

GUARANTEE:

The guarantee does not cover faults resulting from faulty operation, overloading and lacking observance of directions of

maintenance.

In case of complaints, please contact your dealer.

In case you want further information, please state machine type

and serial number of the mixer.

SAFETY:

The safety of the user is achieved by:

• The mixer will only start when the upper part is lowered.

• The upper part can only be tilted up when the mixer is

stopped.

• Protection from excess current, excess voltage and too

low voltage.

• The mixer is provided with fixed bowl screen.

The mixer is designed for manufacture

of products which do not during processing cause reactions or emit substances

which may be detrimental to the user.

INSTALLATION OF NEW MIXER:

The following equipment is included:

√√

√ Cable

√√

√√

√ Beater

√√

√√

√ Ingredient chute

√√

Before taking the mixer into use, check that all parts are delivered.

Dimensions and weight:

TEDDY incl. equipment:

• Net weight with equipment: 44 Lbs.

• Outside dimensions of mixer: 18¼ “ x 9½ “ x 15¾ “

√√

√ Hook

√√

√√

√ Whip

√√

√√

√ Bowl

√√

√√

√ Lid for the bowl

√√

Putting your fingers in the bowl while the

mixer is running may cause injuries.

The mixer is listed by:

Location:

The mixer is to be placed on a stable and horizontal table.

5489 Campus Drive.

Shreveport La 71109

800 222-1138

www.varimixer.com

mix@varimixer.com

™TEDDY is a registered trademark belonging to A/S Wodschow & Co. 042005 US

Page 4

CONNECTION TO POWER:

The enclosed cable must be used.

The mixer

• Only single phase power supply with ground must be used

for the mixer. Use the enclosed cable.

• A plug with 2 pins + ground must be used.

• Check that the voltage of the power supply corresponds

the voltage printed on the rating plate placed in the bot-

tom of the mixer and stated on the packing.

• The mixer must be protected by a differential circuit

breaker and a fuse of max. 15Aps0 A.

A fuse is built into the cable plug.

The power characteristics of the mixer:

Supply Output Frequency Voltage Motor Power

voltage (V) (W) (Hz) (A) (HP)

115 300 60 3 0.4

must be connected to ground!

2

Equipment:

As standard the mixer comes with the following equipment:

• Bowl in stainless steel.

White plastic lid for bowl (lids in various colors are available).

•

• Ingredient chute.

• Dough hook in stainless steel for kneading of dough.

• Beater in stainless steel for mixing.

• Whip in stainless steel for whipping.

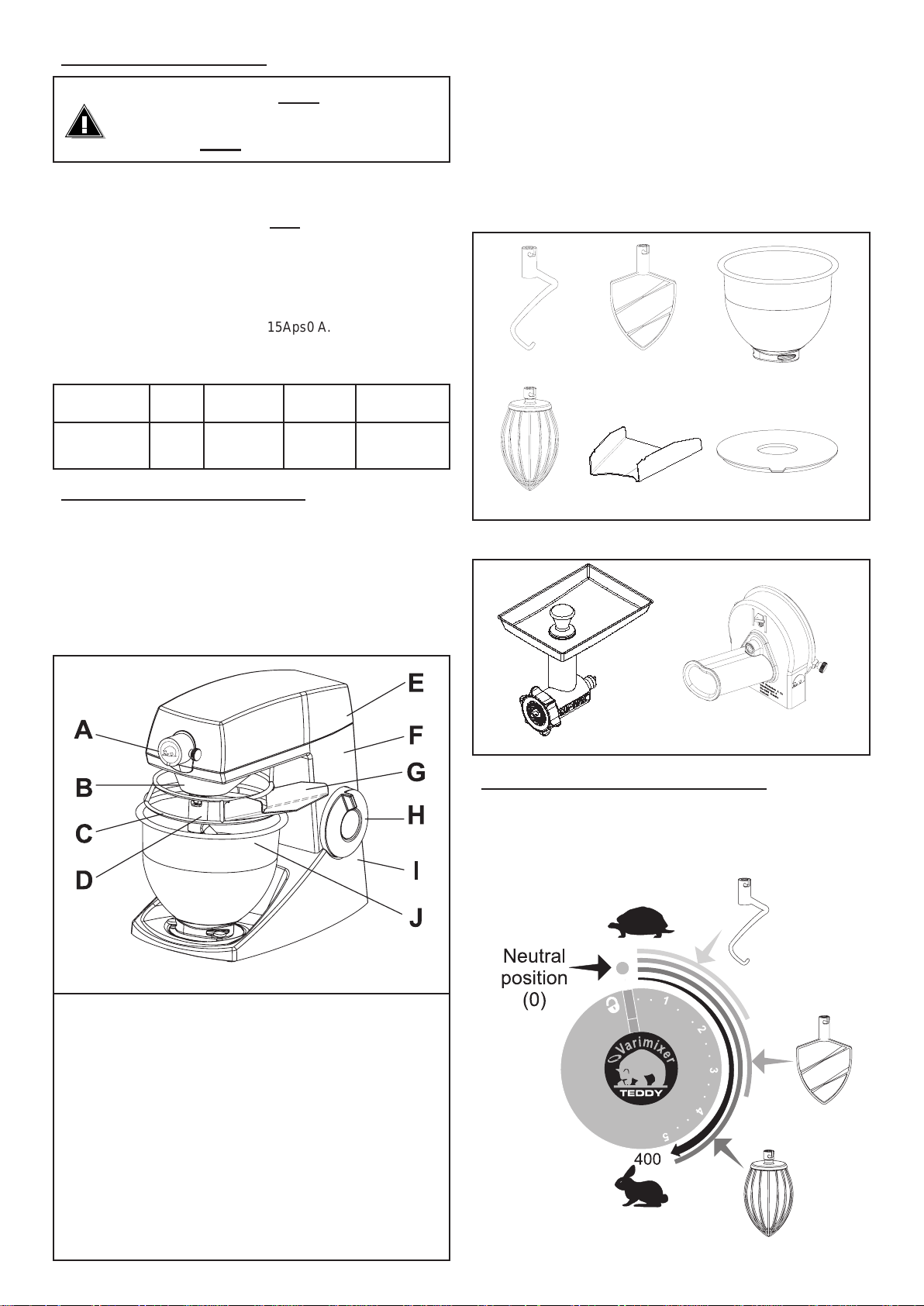

Hook Beater

Bowl

INTRODUCTION TO THE MIXER:

TEDDY is a small professional mixer for kneading, mixing and

whipping in bakeries, confectioneries or kitchens.

Any operation of the mixer is made by means of the rotary knobs

on the sides of the mixer. The two knobs can be used simultaneously or individually and are used both for speed regulation

and as opening/closing function.

The attachment hub A makes it possible to connect meat grinder

and vegetable slicer.

Whip

Extra equipment:

Meat grinder

Ingredient chute

Lid

Vegetable slicer

RECOMMENDED WORKING SPEEDS:

• Position 1-2: Low speed Kneading

• Position 1-3: Medium speed Mixing

• Position 1-5: High speed Whipping

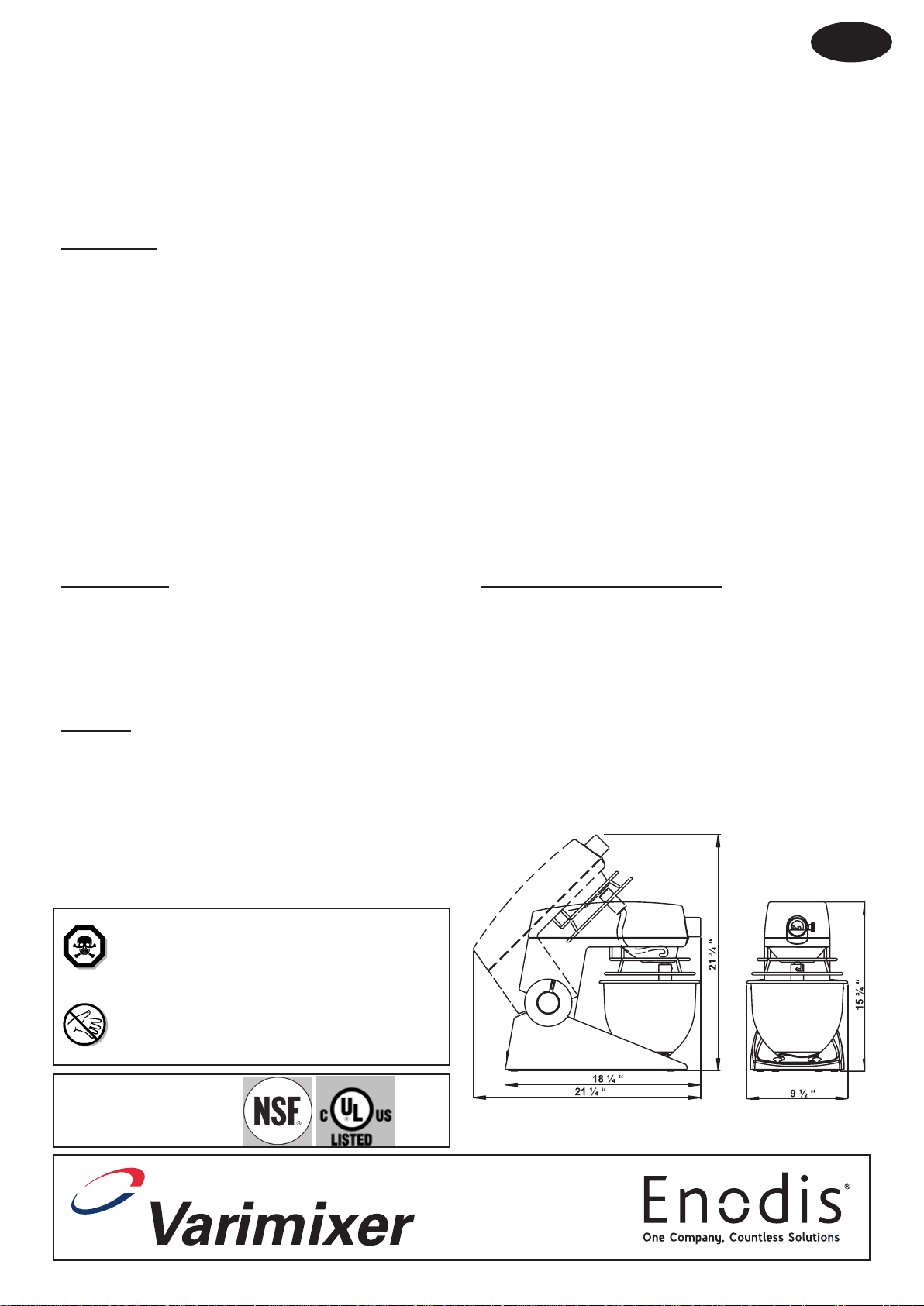

Fig. 1 The construction of the mixer

A Attachment hub

B Housing of the planetary gear

C Bowl screen in stainless steel

D Bayonet shaft

E Lid

F Upper part

G Ingredient chute

H Rotary knobs (two pcs.)

I Base

J Bowl in stainless steel, contents 5 quarts

Fig. 2 Recommended working speeds

Page 5

OPERATION OF THE MIXER:

The bowl must be mounted when the

mixer is started!

A. Turn the rotary knobs to the locking symbol (fig. 3A).

3

MAXIMUM CAPACITY OF THE MIXER:

The working capacity of the mixer depends of:

• The tool used.

• Sort and quantity of the raw materials.

• The optimum speed for a good result.

Too big quantities will always reduce the

quality of the product and the life of the mixer.

Overloading can also result in sudden stops.

US

A: Locking symbol B: Neutral position C: Speeds

Fig.3 The three positions of the rotary knobs.

B. Tilt backwards the upper part of the mixer.

C. Place a tool in the bayonet shaft and turn it counter-clock-

wise to lock it in position (fig. 4).

Fig. 4 Mounting of tool in the bayonet shaft.

D. Place the bowl between the three locking bolts in the foot

of the mixer and turn it clockwise until locked (fig. 5).

Product

Bread dough, 50% Lbs 5

Mashed potatoes Lbs 4

Whippe d cre a m Q t 1

Layer cake Lbs 6

Cake donuts Lbs 6

Raw

material

Approx. ma x.

quantity

OVERLOADING:

If the mixer is moving e.g. kneading dough, this is not due to

errors or overloading.

In case of overloading the electronic variator will reduce the

current to the motor and stop it.

In case of stop due to overloading, turn

the rotary button back to neutral position,

and the mixer can be started again.

If the motor stops after long time of operation, and cannot be

started immediately after, the thermosensor of the motor has

switched off the current, and the mixer needs to cool down before it can be re-started. This protects the motor from overheating.

The mixer contains two thermal cut-outs, which automatically

reconnect in case of previous disconnection by the thermosensor.

Locking bolts

Fig. 5 Place the bowl in the mixer and turn it to be fixed

in the locking bolts.

E. Fill the ingredients in the bowl.

F. Tilt the upper part of the mixer, including tool, down.

G. St art the mixer by turning the rotary knobs away from the

locking symbol and past 1. To avoid splashing and dust

from flour, it is recommended to increase the speed gradually until the required speed is obtained (fig. 3C), (see

fig. 2 for recommended working speeds).

H. S top the mixer by turning the rot ary knobs back to neutral

position (fig. 3B).

I. The upper part of the mixer can only be tilted backwards

when the rotary knobs is turned to the locking symbol

(fig. 3A).

CLEANING AND HYGIENE:

After use:

• Remove bowl and tools.

• Wash the bowl and the tools in hot water and detergent /

degreaser / disinfectant. Rinse with pure water and dry.

Do not spray water on the mixer

Tools and bowl can be cleaned in dishwasher.

• Wipe the housing of the planetary gear , the bayonet shaft

and the bowl screen. Use a damp sponge and a detergent / disinfectant. Rinse the parts with sponge and pure

water.

• Check that the various parts have been cleaned thoroughly.

• Do not use abrasive detergents, which could scratch the

surface.

• Use detergents suited for use on aluminium and plastic

(polycarbonate).

Page 6

MAINTENANCE:

The mixer requires no maintenance (motor and bearings for

the mechanical parts are greased for life).

Safety device:

Check the function of the safety device regularly:

• The motor

position (see fig. 3B).

must stop when the rotary knobs is in neutral

If the safety device does not function, do

not use the mixer. Contact your dealer.

LIST OF ERRORS AND POSSIBLE SOLUTIONS:

If the problem cannot be solved, contact

your dealer.

The mixer does not start:

Check that ...

• The upper part of the mixer is in its down position.

• The mixer is plugged in and connected to power.

• The electrical power supply is correct.

• The fuse in the cable plug (fig.6, 1) has not been burned.

If the fuse is defective, it can be replaced by the extra

fuse (fig.6, 2) that is also available in the cable plug.

1

4

MOUNTING OF ACCESSORIES:

The mixer is equipped with an attachment hub with variable speed,

and with the possibility of attaching the following equipment:

• Meat grinder , supplied with meat tray, stomper and set of

knives consisting of blade and plate 5/32”.

• Vegetable slicer mounted with discs for shredding, grating and cube cutting.

For further information regarding accessories, please see the special sheets following the accessories.

The mixer must always be disconnected

before mounting or dismantling of the accessory.

Mounting of accessories (fig. 7):

• Assemble the accessory in question.

• Stop the mixer.

• Turn the cover plate C away from the hole.

• When mounting the pre-mounted accessory A, the shaft

B is inserted into the attachment drive D of the mixer.

• By turning the accessory until the pin E is pointing towards the slot G a correct clutch is obtained.

• The accessory is pushed as far into the attachment hub D

as possible. (The pin E must be in the slot G, then the

shaft of the accessory is in a correct clutch with the attachment drive).

• The accessory is fastened by turning the knob H clockwise.

Dismantling of accessories (fig. 7):

• Stop the mixer.

• Turn the knob H counterclockwise until the locking screw

is free of the hole F.

• Take out the accessory of the attachment hub, dismantle

and clean it.

2

Fig. 6 Fuses in the cable plug.

The mixer stops during work:

• The mixer is overloaded due to too high speed or too

heavy loading. See the paragraph "Overloading".

In case of power failure set the rotary

button back to neutral position, and the

mixer can be started again.

The tool is stuck in the bayonet shaft:

This is normally due to insufficient cleaning or damaged hole in

the tool:

• When the tool is stuck, do not force it free. Apply a little

oil and let this work a couple of minutes.

• Turn the tool backwards and forwards until it can be removed.

Unnormal noise:

Metallic noise ...

• The tool is distorted and hits the bowl.

• The bowl has been damaged or is not in its proper position.

Fig. 7 Mounting of accessories.

RECOMMENDED SPEEDS FOR ATTACHMENT HUB:

Page 7

EQUIPMENT

STACKABLE BOWLS

WHIP HOOK BEATER

ANTISPLASH GUARD

LIDS FOR BOWL

MEAT GRINDER: ....................... 3MM

1

9

4

8

2

INGREDIENT CHUTE

V

EGETABLE SLICER:................... 3VC

4

2

3

8

6

1

6

45

3

SPARE PART LIST:

1. Stomper ............................................... AR005-364-TD001

2. Meat Tray ............................................. AR005-363-TD001

3. Ring ...................................................... AR005-355-TD001

4. Disc with 5/32” holes ......................... AR005-357-TD002

5. Cutter ................................................... AR005-358-TD001

6. Feed screw .......................................... AR005-356-TD001

7. Housing ............................................... AR005-359-TD002

8. Disc with 1/8” holes ........................... AR005-357-TD001

9. Disc with 5/16” holes ......................... AR005-357-TD003

7

10

11

5

12

7

9

SPARE PART LIST:

1. Back Mounted ...................................................3VC.381M

2. Friction bearing for back ................... AR005-362-TD001

3. Axle for ejector disc ............................................3VC.389

4. Ejector disc .......................................................... 3VC.384

5. Axle for cutter disc .............................................. 3VC.386

6. Friction bearing for front ....................................3VC.391

7. Screw M6x16 ....................................................... STA5563

8. Knifehouse ........................................................3VC.382M

9. Plunger.................................................................. 3VC.385

10. Grating disk 1/16” ................................................. 3VC.G2

11. Slicing disk 1/16”/ Shredding disk 1/8” ............ 3VC.S2R3

12. Julienne disk 5/16”x 5/16”(chips) ........................3VC.J8

13. Slicing disk 3/32”/ Shredding disk 3/16” ........3VC.S26R5

13

Page 8

5489 Campus Drive.

Shreveport La

71109

800 222-1138

www.varimixer.com

mix@varimixer.com

Loading...

Loading...