Page 1

THE PROGRAMMABLE

CONTROL SYSTEM

MK-IV

User’s Manual

Page 2

Page 3

General descriptions

MODES

The system contains six different modes:

1. MANUAL MODE: The mode when the mixer is operated like a manual controlled mixer. Instead of executing a programmed recipe, the

mixer is started and operated until it is manually shut off.

2. PROGRAMMING MODE: The mode where all programming and

editing takes place.

3. PROGRAM MODE: The mode where all programmed recipes are

executed.

4. FIXED MODE: A pure executional mode , mixer will only run the programmed recipes. Neither editing or speed/time overwriting can take

place. Manual mode is void.

5. RPMMODE: Computer displays the speed in actual R.P.M.

6. SPEED MODE: Computer displays the speed.

(speed 1, 2, 3 and 4)

1

Page 4

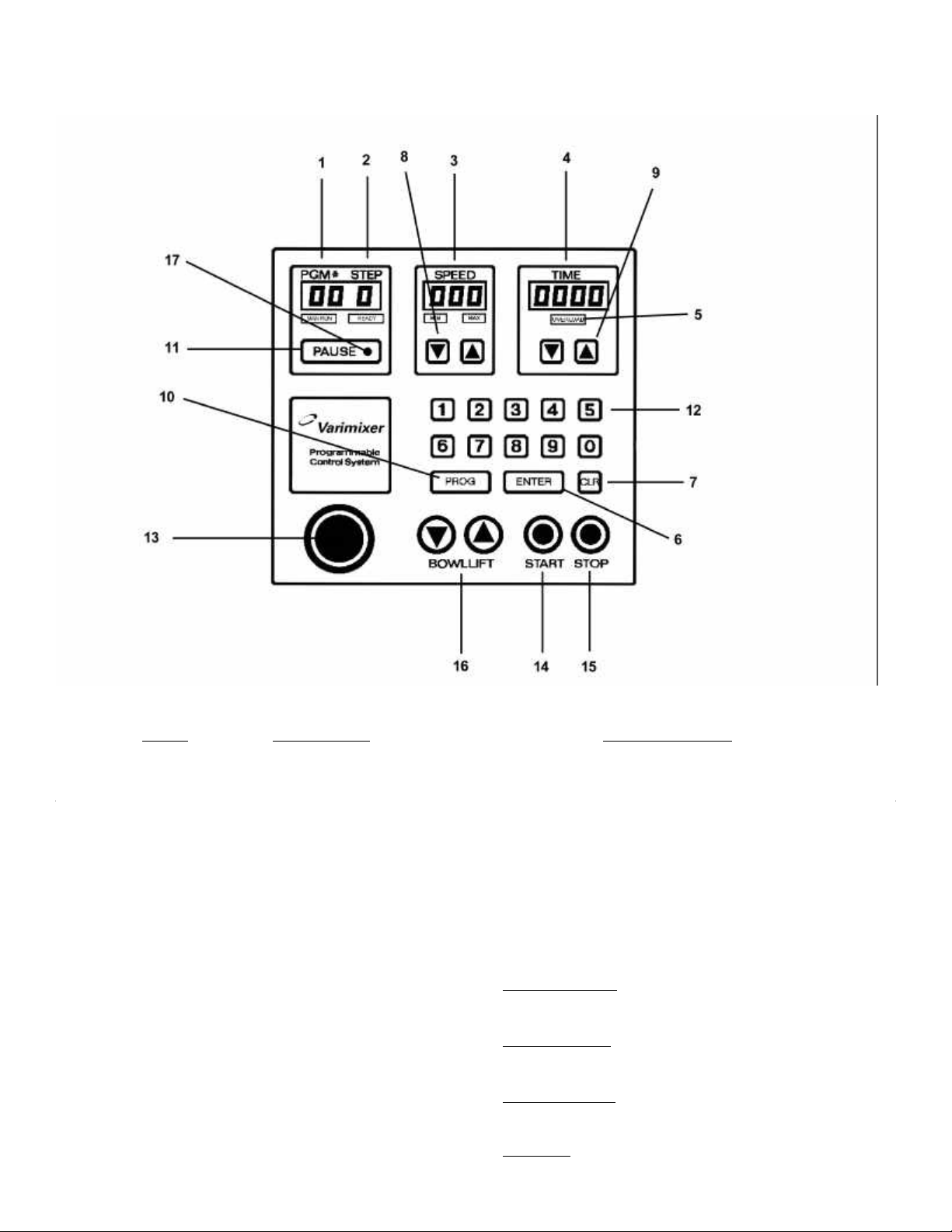

The Keypad

The Keypad is used for entering data to the system.

displays

MIxer cannot maintain set speed,

The mixer is running at absolute

The mixer is ready to start.

ITEM FUNCTION EXPLANATION

1. Program No. Displays the program Number being executed.

2. Step Displays the step number being executed.

3. Speed Displays the set-speed.

4. Time Displays the elapsed time since start or

the remaining time to shut down.

5. Text Area

OVERLOAD:

too much mix or speed set too high.

MIN SPEED: The mixer is running at absolute

minimum speed.

MAX SPEED:

maximum speed.

READY:

2

Page 5

ITEM FUNCTION EXPLANATION

6. Enter Used for stepping through a program.

7. CLR

8. Speed up/down arrows.

9. Time up/down arrows.

10. Program

11. Pause

12. Numeric keys

13. Emergency Stop

14. Start

15. Stop

16. Bowl Lift

17. Green L.E.D.

Clears a flashing display.

Used for adjusting the the speed while the mixer

is running.

Used for adjusting the the time.

Used to enter/exit program-programming mode.

Pauses the mixer without losing recipe.

Used for setting time and speed.

Stops the mixer instantly.

Starts the mixer.

Stop and reset key - reduces the speed to

minimum and stops the mixer.

If available, used for raising and lowering the

mixing bowl.

Lights up when mixer is paused.

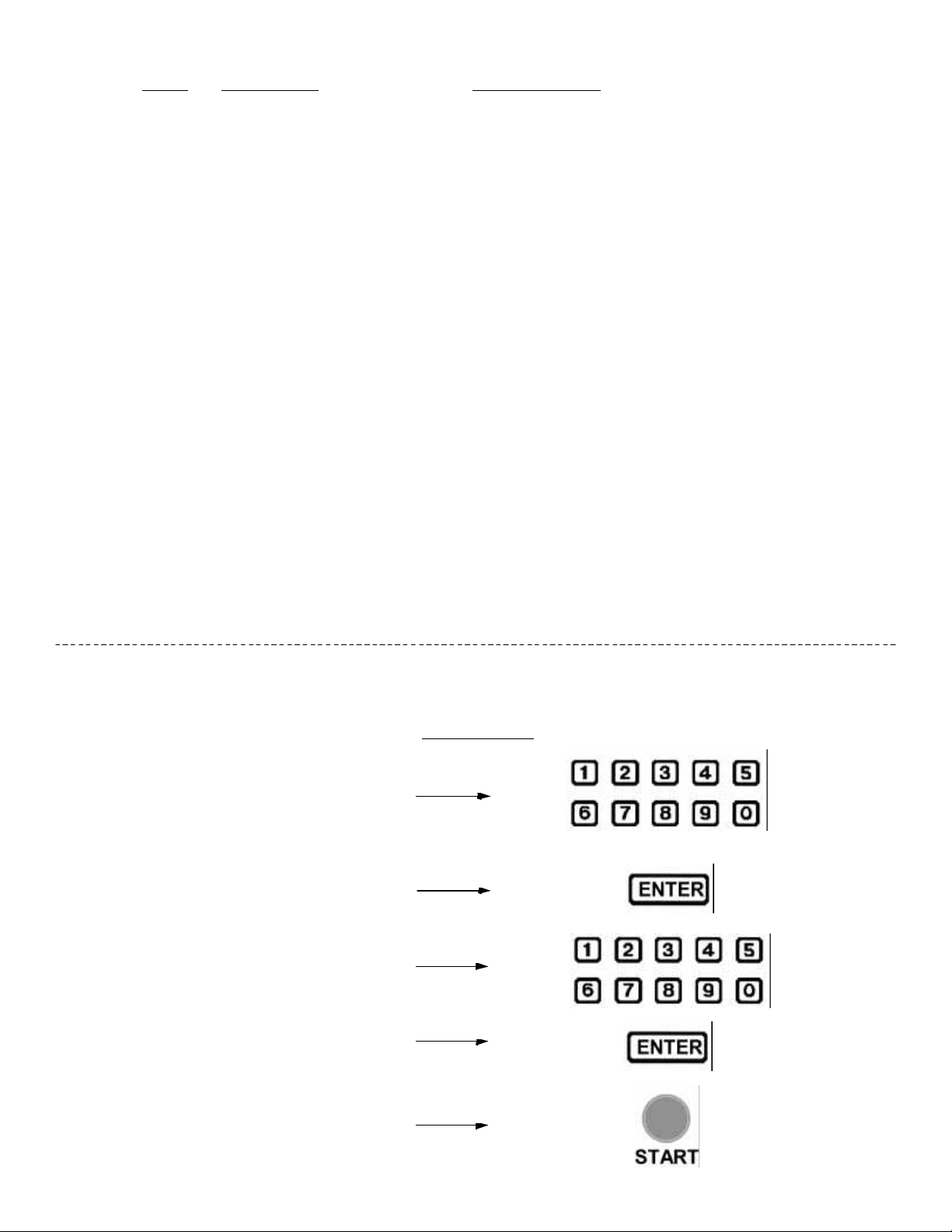

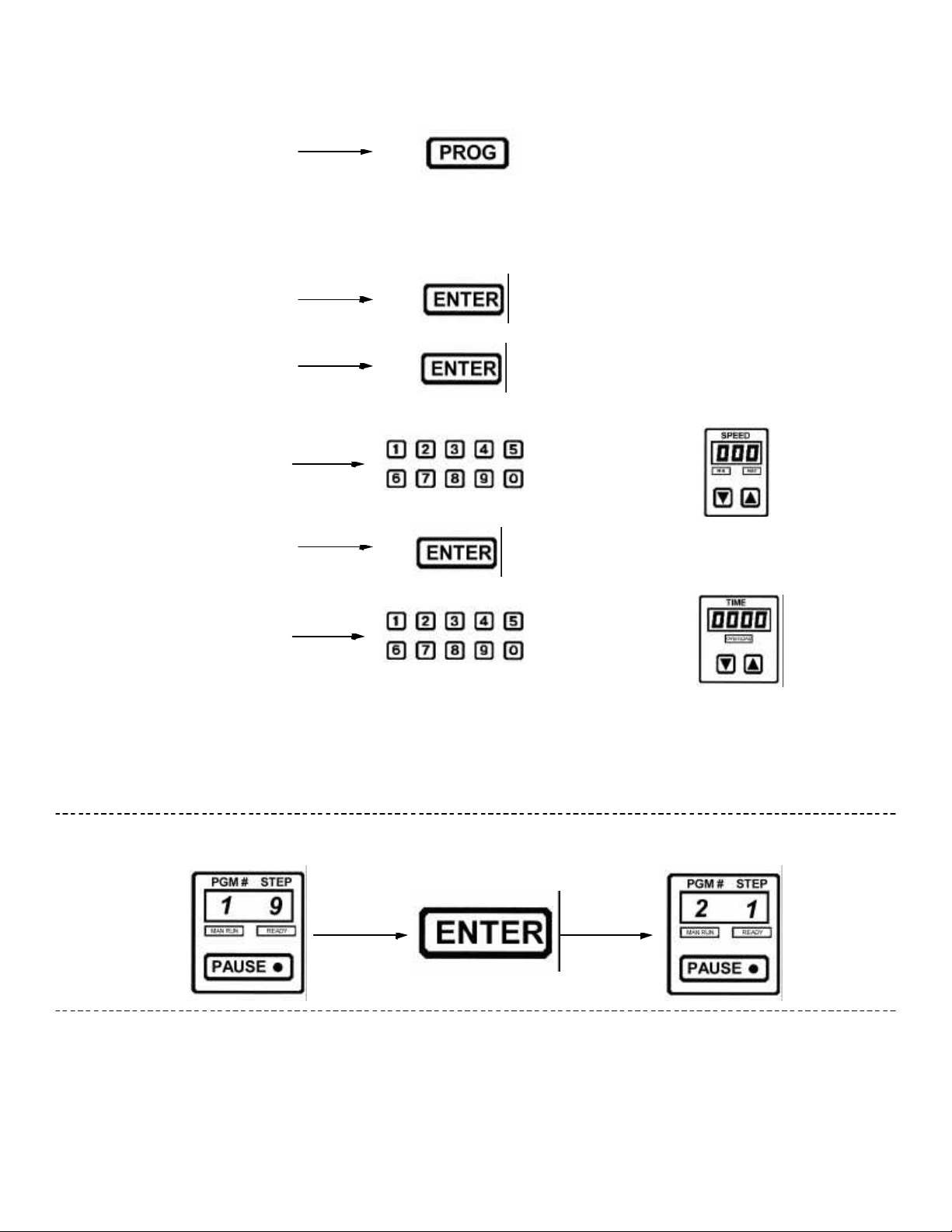

Enter the speed desired.

Push

Enter the time desired.

Push

Push

How to run the mixer manually.

R.P.M. Mode.

3

Page 6

Enter the speed desired.

A flashing display indicates that it is expecting the operator to key in a value.

An example is 100 R.P.M. for 5:00 minutes or 0 R.P.M. for 15 seconds (which is a 15 second pause)

start automatically after a pause, the start button must be pushed

is mandatory. The control system will read it as a “end of pro

-

Push

Enter the time desired.

Push

Push

How to run the mixer manually.

SPEED Mode.

How to input a program.

A step is always a combination of speed and time.

Please note that the mixer will not

to proceed to the next step.

Up to 25 programs , each constisting of 9 steps , can be stored in memory.

A Sample Program

Program Number

1

“0” Speed and “0” Time in the last step

gram” mark.

Step

1

2

3

4

5

6

Speed Time

60

200

0

110

180

0

1:00

5:00

:20

4:00

2:00

0:00

4

Page 7

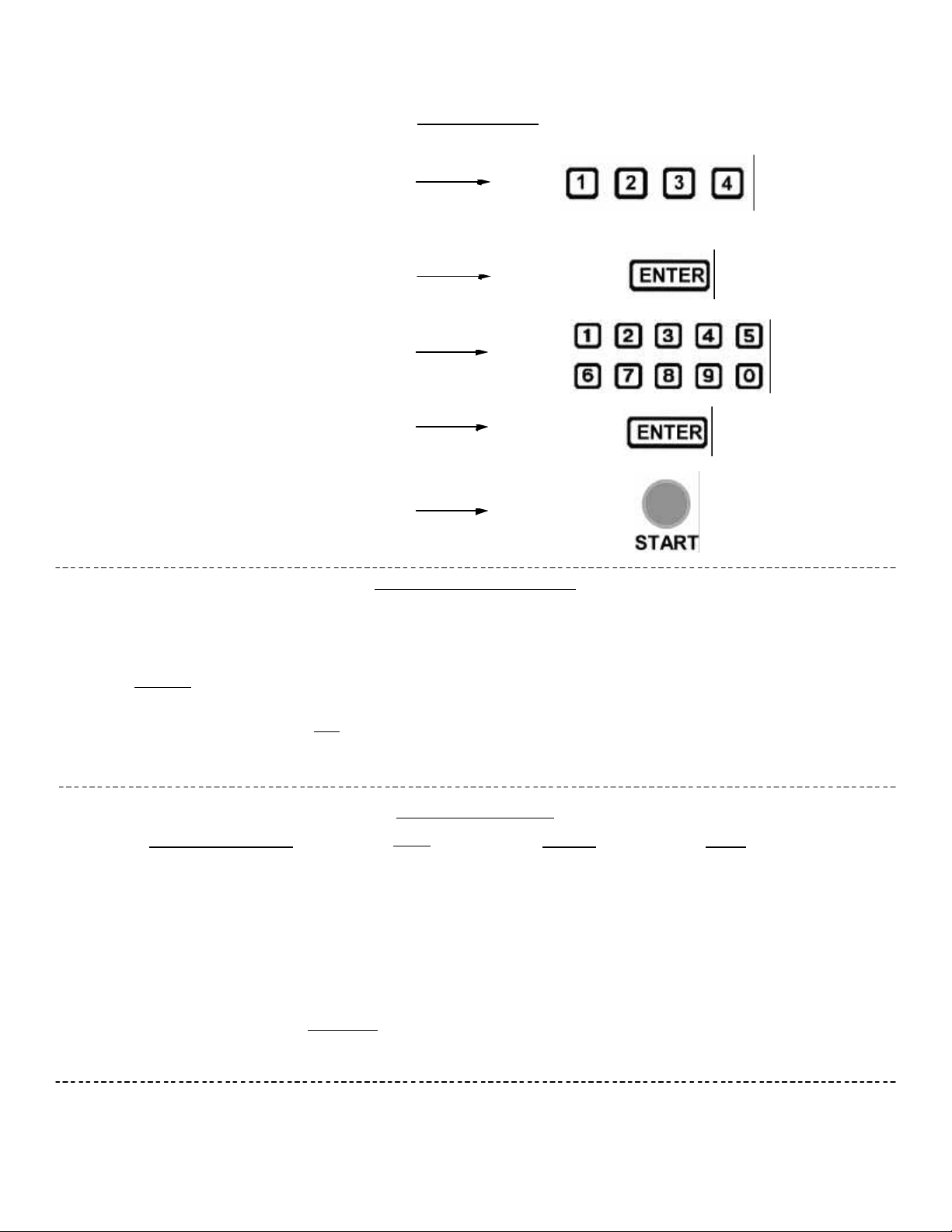

Push

-

To delete a recipe, use the same step above to enter the programming mode, then push “ENTER” to

Push

Push

Enter the speed desired.

To program a recipe.

“HOLD FOR 3SECONDS”

Push

Enter the time desired.

Repeat this process for as many as 9 steps per program, after the 9th step , the next program num

ber will display, ready to enter a new recipe.This will continue up to 25 programs.

Example

To edit a recipe or to correct mistakes, use the same step above to enter the programming mode,

then push “ENTER” to reach the program/step that you wish to edit.

reach the program/step that you wish to erase. Enter “0” in speed and “0” in time in all steps.

5

Page 8

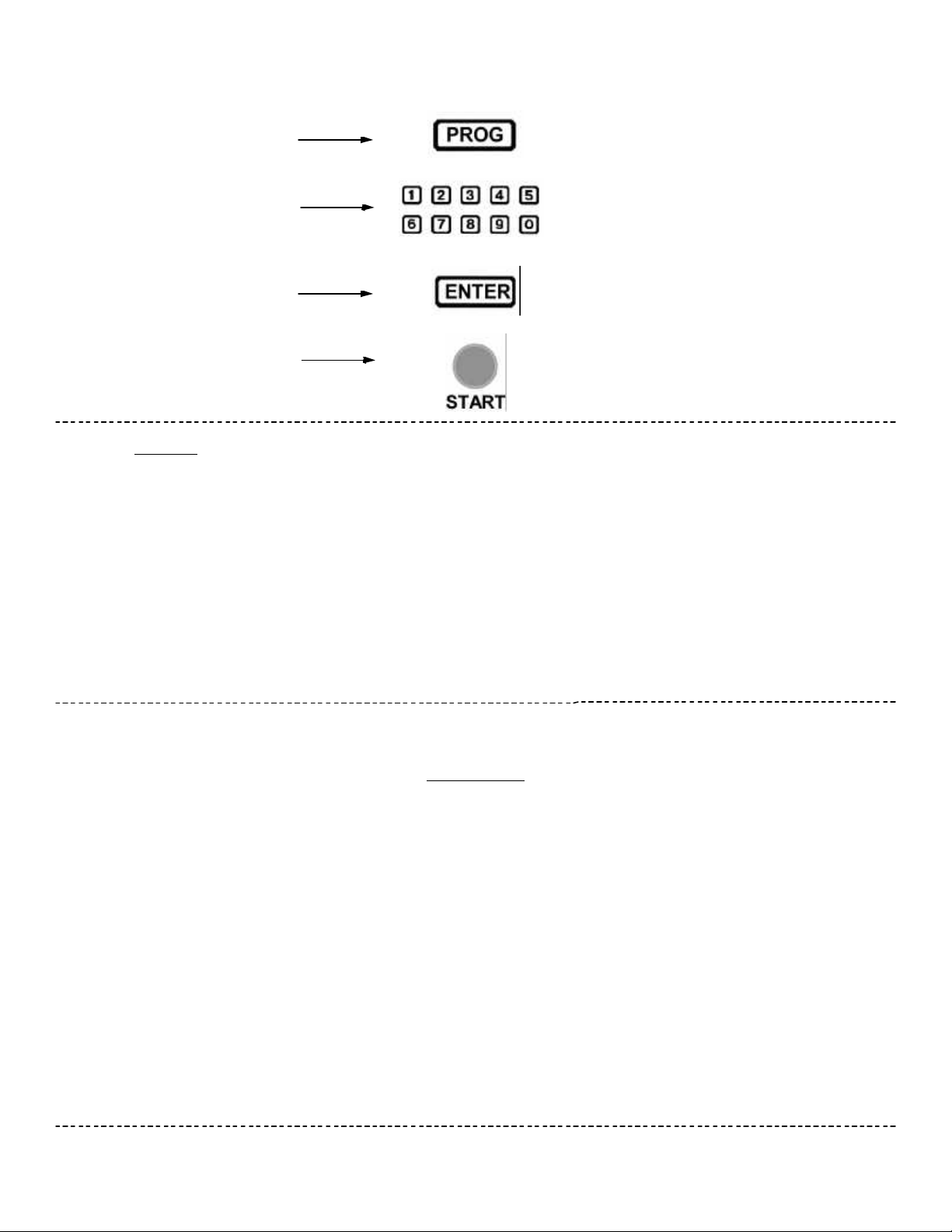

To run a programmed recipe.

-

Push

Enter the Program number.

Push

Push

After the ENTER key has been pushed, the data in step 1 will be displayed along with the program

number.

After the last program step has been executed, the mixer will slow to minimum speed and shut off.

The mixer can be stopped at any time during a recipe by using the “PAUSE” button, the mixer will

slow to stop and the recipe will not be lost. To continue on with the same recipe, push “START”.

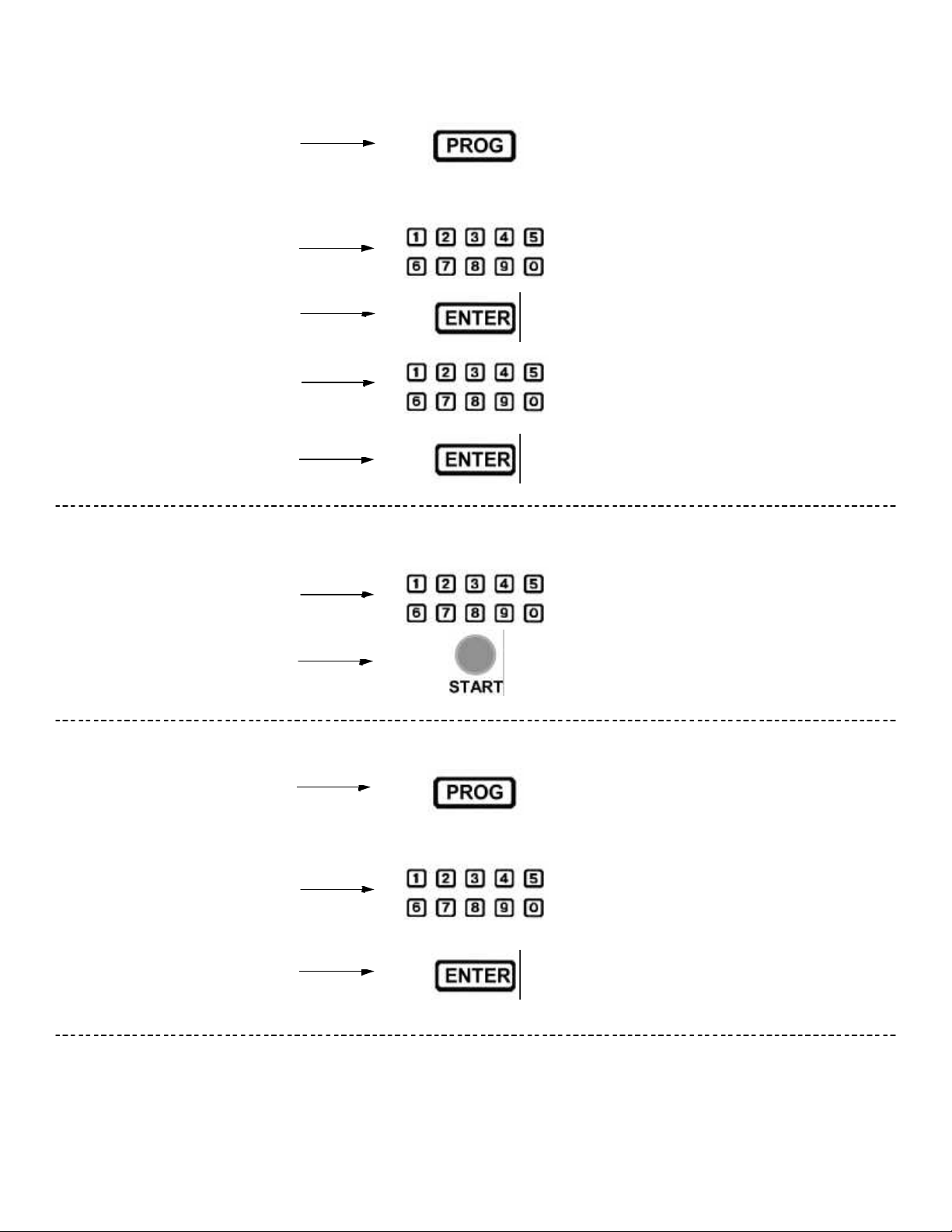

Fixed Mode

Fixed mode is basically designed for users who operate the same recipes over and over again with

out frequent updating.

The maximum numbers of programs available in fixed mode is reduced from 25 to 10.

Fixed mode is a purely executional mode, its not possible to adjust the speed or time while in this

mode.

The mixer will only run recipes that are programmed.

The advantage to this mode is that no one can “cheat” the programmed recipe.

The only applicable keys are START, STOP, PAUSE,BOWL LIFT, emergency stop and numeric

keys.

6

Page 9

Push

Push “99”

Push

Push “1 2 3 4”

Push

To enter “FIXED MODE”

“HOLD FOR 3 SECONDS”

Push the program number.

Push

Push

Push “1 2 3 4”

Push

To exit “FIXED MODE”

“HOLD FOR 3 SECONDS”

7

Page 10

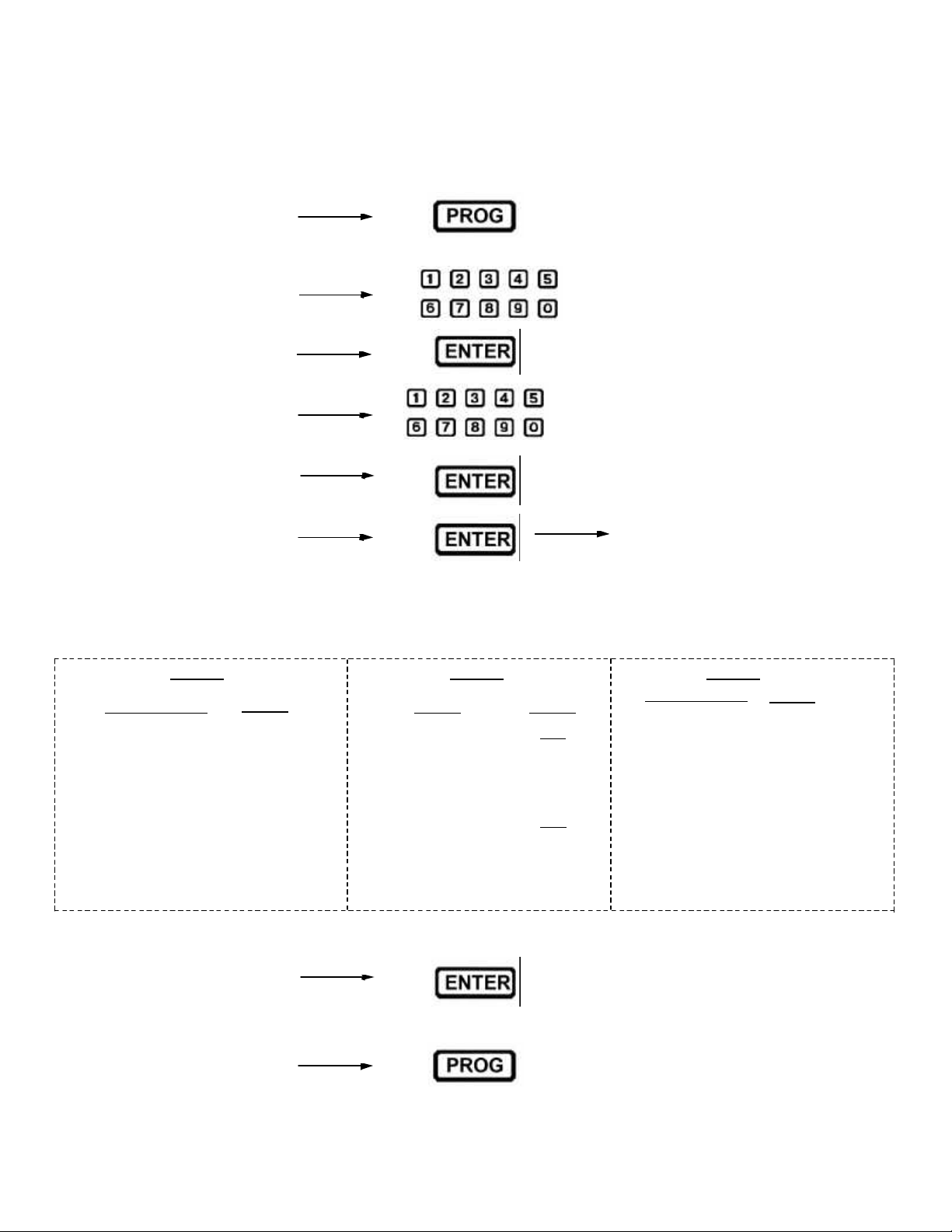

Control Data for Program 26

Program 26 contains the control data required by the computer to operate. This data differs from

model to model.

To access Program 26.

Push

“HOLD FOR 3 SECONDS”

Push “26”

Push

Push “1 2 3 4”

Push

Push

Enter the value on the following chart that matches the mixer model. Repeat for step 8 and 9.

Step 7

Mixer Model

W30

W40

W60

W80

W100

W150

Cinnabon 40

Cinnabon 60

Push

Value

30

40

60

80

100

150

401

601

“RPM” MODE :00

(Speeds RPM)

“SPEED MODE” :02

(Speeds 1-4)

Step 8

Mode Value

OR

until you reach Step 7.

Step 9

Mixer Model

W30

W40

W60

W80

W100

W150

Krispy Kreme

Cinnabon 40

Cinnabon 60

Value

369

390

375

422

422

422

425

737

660

Push

8

Page 11

D

In the electronics fail.

A

B

C

It is possible to bypass the control system if the electronics fail.

Please note, when the system is bypassed, the safety devices do not operate. Extreme care should

be taken when operating the mixer.

1. Switch off the main power.

2. Open the top lid, flip the dip switch (B) on the back of the computer control from “Auto” to

“Manual”.(NOTE: The front L.E.D. lights will not display in “Manual” mode)

3. Disconnect the “Speed Reg” Harness(C).

4. Disconnect the servo motor by removing the cotter pin (A) the the clevis pin.

5. Remove the round black plug button on the right side of the mixer, and insert the auxillary speed

lever (D) into the slotted shaft.

6. Close the lid, turn on the power.

7. Only 2 buttons will function, the START key and emergency stop button. Start the mixer and use

the auxillary lever to adjust the speed.

9

Page 12

Error Codes

The servo motor block actuator (B) did not contact the minimum speed microswitch (A) after

this unless the microswitch is contacted by the block mounted on the speed adjustment shaft.

A error in the mixer will trigger an ERROR code in the time display. See the chart below for an

explanation of error codes and the procedure for correcting them.

E:401 E:301

E:201

HOT

E:201

the stop button was pushed or the programmed recipe completed.

The computer is programmed to slow the mixer down to low speed before shutting off. It will not do

To correct this error:

1) Check the microswitch (A) to see if it is working by manually pushing it, when pushed, the “MIN”

light should energize on the control panel. If it does not, the microswitch is faulty.

2) The actuator (B) is not contacting the switch, adjust the switch up by loosening the screws (C).

3) The servo motor is not moving at all. check the fuses in the rear of the control , if blown, replace

,if not blown ,check the voltage (31 VDC) at the servo motor while the mixer is running. If voltage is

present, the servo is faulty.

Min

B

A

Max

C

10

Page 13

E:301 There is no signal from the speed pickup (hall effect sensor).

2) Inspect the three wires between the sensor and the plug. Replace the sensor if wires are broken.

To correct this error:

1) Check that the sensor (D) is centered directly above the track of the 3 magnets (F) on the pulley

and the gap between the sensor and magnets is 1/16”. If not , bend and / or move the bracket (I)

holding the sensor.

3) Insure the aluminum disc (E) is tight on the pulley.

Side View

D

E

E

Top View

F

I

D

HOT The thermal overload has tripped because of excessive amp draw or heat.

The overload will automatically reset after it has cooled. This function is to protect the mixer.

To correct this error:

1) Have a service technician inspect all wiring, contactor and overload for faults.

2) Monitor the amp draw while the unit is operating. If excessive, the drive motor may be failing.

1.5 Amp

11

Page 14

E:4:01 The values in program 26 steps 7, 8 and 9 are missing or incorrect.

To correct this error:

light: When activated, mixer will lower speed 20% until it can maintain a steady speed.

1. Too much dough in the bowl (overloading) or speed set to high. Lower dough amount and speed.

Push

“HOLD FOR 3 SECONDS”

Push “26”

Push

Push “1 2 3 4”

Push

Push

Enter the value on the following chart that matches the mixer model. Repeat for step 8 and 9.

Step 7

Mixer Model

W30

W40

W60

W80

W100

W150

Cinnabon 40

Cinnabon 60

Push

Value

30

40

60

80

100

150

401

601

“RPM” MODE :00

(Speeds RPM)

“SPEED MODE” :02

(Speeds 1-4)

Step 8

Mode Value

OR

until you reach Step 7.

Step 9

Mixer Model

W30

W40

W60

W80

W100

W150

Krispy Kreme

Cinnabon 40

Cinnabon 60

Value

369

375

390

422

422

422

425

737

660

Push

OVERLOAD

2. V-belts slipping , tighten belts or replace as needed.

3. Drive pin in motor pulley sheared, replace.

4. Hall effect sensor out of adjustment or magnet disc loose. (See E:301)

12

Page 15

MAINTENANCE AND ADJUSTMENTS

Fuse data and component location

Computer Control

2 Fuses: 8 Amp

6.3 x 32 MM

P.N. 20E-418.1

Hall Effect Sensor

P.N. 30E-500M

Bowl Lift Servo Motor

(If equipped)

P.N. 100N-86.02

Speed Servo Motor

P.N. 60E-517.02

Power Supply

1 Fuse:1.5 Amp

6.3 x 32 MM

P.N. 20E-418

13

Bowl Lift

Microswitches

(PN 61-522) Each

Page 16

Bowl adjustments

Models W30, W40, W40P, W60,W60P

W30 = 6 3/8”

W40 = 6 3/8”

W60 = 7”

14

Page 17

Bowl adjustments

Models W80, W100, W150N

W80 = 9 1/8”

W100 = 11 5/8”

W150 = 11 7/8”

15

Page 18

Lubrication

White Lithium Grease (IE Lubriplate )

Nye Fluorocarbon Gel 868VH

Order from authorized service agent

Part number: WHITE GREASE

16

Page 19

Belt adjustments

off of shaft.

..

NEVER move the base for motor (R)(in the oblong

holes) , this is a factory setting and is NOT used to

tighten the belts.If the entire unit is to be

exchanged, reference the below table.

Models W30-W40(P) Distance (B) 11 1/2 inches

Models W60-W150 Distance (B) 12 1/4 inches

1. Start by tightening the V-belts (C).

1.A) Loosen the bolts (D) and the jam nut (E).

1.B) Tighten the bolt (F) until the V-belts are tight,

........tighten the the 2 bolts (D).

...C) Back bolt (F) out away from arm. DONOT

........LEAVE AGAINST ARM.

2. If the main vari belt (A) appears loose when the

....unit is running.

...A) Remove nut (J) and washers (H).

...B) Pry upper spring fork assembly (N)

...C) Remove 1 or 2 washers from (G).

...D) Reinstall spring fork assembly (N) , washers

.......(H) and nut. (J). DO NOT TIGHTEN NUT.

...E) Start the mixer and tighten nut (J) until snug.

3. Now turn to Page 20 and follow the instructions

...“Adjustment of low (min) and high (max) speed

....microswitches”.

17

Page 20

Belt Exchange

1. Loosen Bolt (J) and remove washers (H).

2

2. Remove cotterpin (T) and dowel pin (E) from servo linkage.

2 .

3. Remove vari drive belt (A) from pulleys.

2

4. Remove Hall Effect sensor (X) from the rear of the computer.

3

5. Loosen bolts (D) and remove the front v-belts (C) by tilting the center pul

....ley assembly (L) forward and rolling the belts (C) off the front pulley one

....at a time. The belts can now be threaded between the lower fork (M) and

....the lower movable pulley.

3 3 3

3 Installing and tightening of V-belts

3

6. Install the V-belts (C) on the center pulley assembly and front pulley.

3

7. Tighten the two bolts (D).

3

8. Tighten the bolt (F) until the V-belts are tight, then tighten the the 2 bolts

....(D).Back bolt (F) out away from arm. DO NOT LEAVE AGAINST ARM.

9.

9. Install the Hall Effect sensor (X) onto the computer and align.

....(See page 11)

.

10. Measure the distance (B) to insure it is within tolerance...

......Models W30-W40(P) Distance (B) 11 1/2 inches

......Models W60-W150 Distance (B) 12 1/4 inches

.

11. If the measurement is out of spec, the motor assembly should be moved

......by loosening the four bolts (P) on the motor mount plate, sliding the

......motor until it is within the proper distance, and retighten bolts (P).

.

12. Install the vari drive belt. (A)

.

13. Install fork assembly.

.

14. Install washers (G) and nut. (J) DO NOT TIGHTEN NUT.

.

15. Start the mixer and tighten nut. (J)

16. Follow the instructions on Page 20,.“Adjustment of min and max speed

......microswitches”.

18

Page 21

Belt Exchange

19

Page 22

Adjustment of low and high speed microswitches.

20

Page 23

Adjustment of low and high speed microswitches.

21

Page 24

Speed Servo System

Figure Number Description

1..........................Sensor..........................30E-500M.........................30E-500M

2..........................Bolt M6.................. ......STA 5432.........................STA 5432

3..........................Magnets.......................30E-515M.........................30E-515M

4..........................Screw...........................STA 5011..........................STA 5011

5..........................Speed Microswitch.... ...30E-507............................30E-507

5A .................... ...Speed Micro w/roller....30E-508...........................30E-508

7..........................Shaft ...........................30E-47M...........................60E-47M

8..........................Snap Ring....................STA 3414 ................... ......STA 3414

9..........................Bushing .......................20-310 .............................20-310

10.........................Screw...........................STA 5636 .........................STA 5636

11.........................Bolt...............................STA 5432..........................STA 5432

12.........................Nut...............................STA 5819..........................STA 5819

13.........................Servo Arm 12MM I.D...30E-543............................60E-543

13.........................Servo Arm 1/2” I.D.......30E-543............................60E-543.1

W30, W40 , W40P

W80, W100 , W150

ITEM

13

I.D.

ITEM

18

Measure I.D. of hole

OR O.D. of Pin.to

determine correct

part number.

O.D.

17.........................Plug Button..................30E-47.12.........................30E-47.12

16.........................Speed Servo Motor......60E-517.02.......................60E-517.02

18.........................Servo Pin 12MM O.D...60E-70..............................60E-70

18.........................Servo Pin.1/2” O.D. .60E-70.2...........................60E-70.2

19.........................Cotter Pin....................STA 6205..........................STA 6205

20.........................Control Assembly.........20E-604M.........................20E-604M

21.........................Emergency Stop..........20E-615M.........................20E-615M

22.........................Retrofit Handle.............20E-47.1M........................20E-47.1M

22

Page 25

Speed Servo System

23

Page 26

Power Supply

Figure Number Description All Models

1..........................Transformer..............................................................60E-430

2..........................Filter..........................................................................20E-419

3..........................Relay 24VDC............................................................140E-420

4..........................Fuse Holder..............................................................20E-416.1

5..........................Fuse..........................................................................20E-418

6..........................Compression Fittings ...............................................STA 3000

7..........................Thermal Overload................................................... ..20-88.24

8..........................Contactor ............................................................... ..100-88.5

9..........................Auxilliary Switch...................................................... ..20-88.47

10.........................Grey Harness............................................................60E-428

11.........................Computer Harness....................................................60E-542.1

24

Page 27

Power Supply

11

1

10

2

3

4

5

6

9

8

252627

7

Page 28

Page 29

Page 30

Power Supply Wiring Diagram

1.5 Amp

28

Page 31

Page 32

5489 Campus Drive

Shreveport LA 71129

(800) 222-1138

(318) 635-3131 Fax

Loading...

Loading...