Page 1

WRM-10P and WRM-40

TRANSFORMER WINDING RESISTANCE METERS

USER’S MANUAL

Vanguard Instruments Company, Inc.

1520 S. Hellman Ave.

Ontario, California 91761, USA

TEL: (909) 923-9390

FAX: (909) 923-9391

November 2009

Revision 3

Page 2

WRM-10P AND WRM-40 USER’S MANUAL REV 3

SAFETY SUMMARY

NOTICE

This manual applies to both the WRM-10P and WRM-40 transformer winding resistance

meters. The operating procedures are virtually the same for both models, and any differences

are clearly described where applicable.

FOLLOW EXACT OPERATING PROCEDURES

Any deviation from the procedures described in this User’s Manual may create one or more

safety hazards, may damage the WRM-10P/40, damage the test transformer, or cause errors in

the test results. Vanguard Instruments Company, Inc. assumes no liability for unsafe or

improper use of the WRM-10P/40.

All safety precautions provided in this manual must be observed during all phases of testing

including test preparation, test lead connection, actual testing, and test lead disconnection.

SAFETY WARNING AND CAUTIONS

The WRM-10P/40 shall be used only by trained operators. All transformers under test shall be

off-line and fully isolated.

DO NOT MODIFY TEST EQUIPMENT

To avoid the risk of introducing additional or unknown hazards, do not install substitute parts or

perform any unauthorized modification to any WRM-10P/40 test unit. To ensure that all

designed safety features are maintained, it is highly recommended that repairs be performed

only by Vanguard Instruments Company factory personnel or by an authorized repair service

provider. Unauthorized modifications can cause safety hazards and will void the manufacturer’s

warranty.

WARNING

Do not remove test leads during a test. Failure to heed this warning can result in lethal

electrical shock to personnel and damage to the equipment.

i

Page 3

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

TABLE OF CONTENTS

CONVENTIONS USED IN THIS DOCUMENT ..................................................................................... 1

1.0 INTRODUCTION .................................................................................................................. .. 2

1.1 General Description and Features ................................................................................... 2

1.2 Technical Specifications ................................................................................................... 4

1.2.1. WRM-10P Technical Specifications .......................................................................... 4

1.2.2. WRM-40 Technical Specifications ............................................................................ 5

1.3 WRM Controls and Indicators .......................................................................................... 6

2.0 PRE-TEST SETUP ................................................................................................................. 10

2.1 Operating Voltages ........................................................................................................ 10

2.2 LCD Screen Contrast Control .......................................................................................... 12

2.3 Printer Paper Control ..................................................................................................... 12

2.4 Printer Paper .................................................................................................................. 12

2.5 Replacing the Thermal Printer Paper ............................................................................. 13

3.0 OPERATING PROCEDURES ................................................................................................. 14

3.1 WRM Cable Connections ............................................................................................... 14

3.2 General Procedures ....................................................................................................... 16

3.3 Entering Test Record Header Information ..................................................................... 17

3.4 Performing a Resistance Test ......................................................................................... 20

3.5 Performing a Load Tap Changer / Voltage Regulator Resistance Test .......................... 29

3.6 Performing a Special Resistance Test ............................................................................ 36

3.7 Performing a Transient Test .......................................................................................... 41

3.8 Performing a Diagnostic Test ......................................................................................... 44

3.9 Working with Test Records ............................................................................................ 45

3.9.1. Restoring a Test Record for Review or Printing ..................................................... 45

3.9.2. Reviewing or Printing a Restored Test Record ....................................................... 48

3.9.3. Printing a Test Record Directory ............................................................................ 49

3.9.4. Erasing Test Records ............................................................................................... 51

3.10 Enabling the Computer Interface .................................................................................. 53

3.11 Setting the Date and Time ............................................................................................. 54

4.0 WRM-10P/40 SPECIAL FEATURES ...................................................................................... 55

4.1 Bypassing Resistance Reading Delay ............................................................................. 55

4.2 Converting Resistance Measurements .......................................................................... 56

5.0 Troubleshooting Guide ...................................................................................................... 57

ii

Page 4

WRM-10P AND WRM-40 USER’S MANUAL REV 3

LIST OF FIGURES

Figure 1. WRM-10P Controls and Indicators .................................................................................. 6

Figure 2. WRM-40 Controls and Indicators .................................................................................... 8

Figure 3. 100 – 120 Vac Jumper Settings ...................................................................................... 10

Figure 4. 200 – 240 Vac Jumper Settings ...................................................................................... 10

Figure 5. WRM-10P Relay Location ............................................................................................... 11

Figure 6. WRM-40 Relay Location ................................................................................................. 11

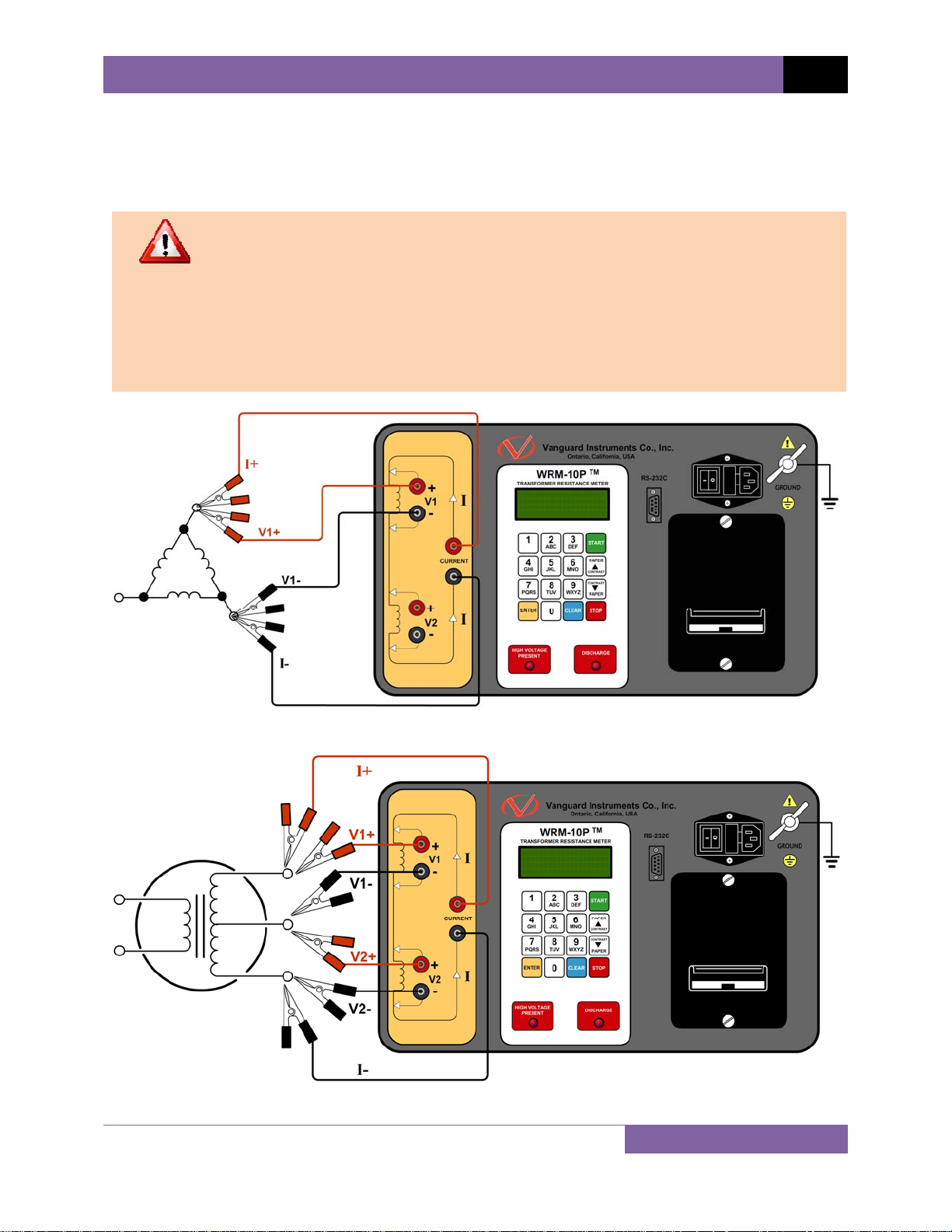

Figure 7. Typical WRM Connections Diagram #1 .......................................................................... 14

Figure 8. Typical WRM Connections Diagram #2 .......................................................................... 14

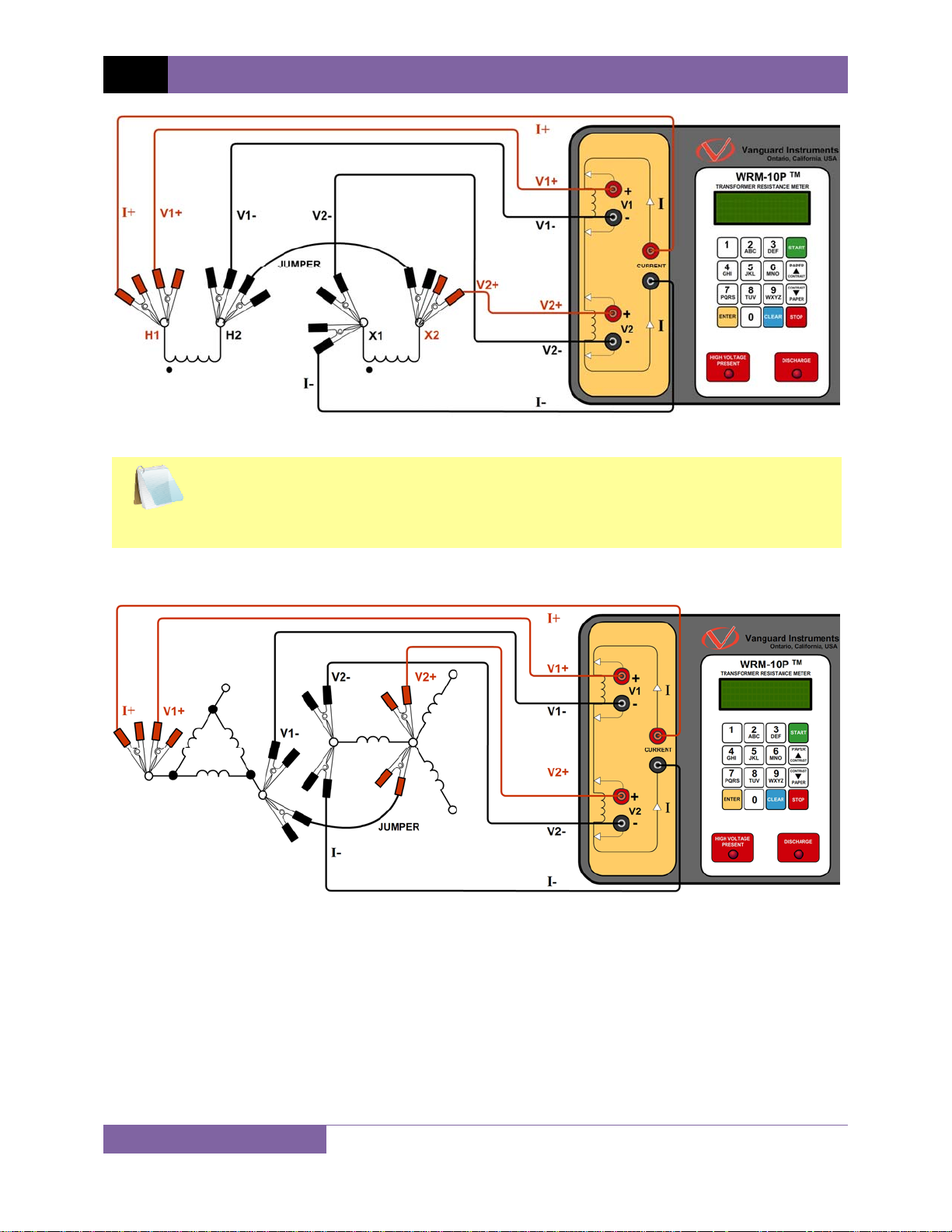

Figure 9. Typical WRM Connections Diagram #3 .......................................................................... 15

Figure 10. Typical WRM Connections Diagram #4 ........................................................................ 15

Figure 11. Typical V1 Test Report Printout ................................................................................... 26

Figure 12. Typical V1 and V2 Test Report Printout ....................................................................... 27

Figure 13. Typical V1 and V2 Test Report Printout with Multiple Readings ................................ 28

Figure 14. Typical LTC/Voltage Regulator Test Report Printout ................................................... 35

Figure 15. Typical Five Minute Special Test Report Printout ........................................................ 40

Figure 16. Typical Transient Test Report ...................................................................................... 43

Figure 17. Typical Test Record Directory Printout ........................................................................ 50

LIST OF TABLES

Table 1. WRM-10P Technical Specifications ................................................................................... 4

Table 2. WRM-40 Technical Specifications ..................................................................................... 5

Table 3. Functional Descriptions of WRM-10P Controls and Indicators ........................................ 7

Table 4. Functional Descriptions of WRM-40 Controls and Indicators .......................................... 9

Table 5. Voltage Selection Jumper Settings .................................................................................. 10

iii

Page 5

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

CONVENTIONS USED IN THIS DOCUMENT

This document uses the following conventions:

• Both the WRM-10P and WRM-40 are simply referred to as “WRM” in this manual. The exact

model number is used only in cases where differences between the units are discussed.

• A key, switch, or knob on the WRM is indicated as [KEY], [SWITCH], [KNOB].

Menu names are referenced as “MENU NAME”

•

• WRM LCD screen output is shown as:

1. OPTION 1

2. OPTION 2

3. OPTION 3

4. OPTION 4

• Warning messages are indicated as:

Warning message

WARNING

• Important notes are indicated as:

Note details

NOTE

1

Page 6

WRM-10P AND WRM-40 USER’S MANUAL REV 3

1.0 INTRODUCTION

1.1 General Description and Features

The WRM-10P is designed to accurately measure the winding resistance of highly inductive

power transformers. The unit’s dual resistance-reading input channels can measure two

winding resistances simultaneously, and four-wire (Kelvin) connections provide high accuracy

and require no lead compensation. The WRM-10P provides stable resistance readings of very

large transformers by utilizing a 36 Vdc power supply capable of outputting up to 10 Amperes.

The resistance reading of a 100MVA transformer can be achieved in 5 minutes or less. The

unit’s power supply is cooled by heavy-duty fans designed for continuous operation. For greater

flexibility in the field, the WRM-10P comes with a built-in 2.5-inch wide thermal printer used for

printing test reports.

Since the WRM-10P can accurately measure resistances ranging from 1 micro-ohm to 2,000

ohms, it can also be used to measure EHV circuit-breaker contact resistance, motor winding

resistance, or any low resistance. If the transformer winding temperature is entered, the WRM10P can calculate the equivalent resistance value of the winding material (aluminum or copper)

at any standard reference temperature. Also, a special test mode can run a test for up to 45

minutes while saving resistance readings at one-minute intervals. In addition to measuring the

resistance value, the WRM-10P also checks the “make-before-break” tap-switching sequences

of voltage regulators and load tap changers.

The WRM-10P can store test results in Flash EEPROM. Test results can be printed on the built-in

2.5-inch wide thermal printer or can be transferred to a PC via the RS-232C interface port.

The WRM-40 has all the features of the WRM-10P, but is capable of outputting up to 40

Amperes. The WRM-10P has a resistance reading range of 1 micro-ohm to 2,000 ohms while

the WRM-40 has a resistance reading range of 1 micro-ohm to 500 ohms.

The WRM-10P and WRM-40 come furnished with three 50-foot test cables. Each test cable lead

is terminated with a quick-disconnect test clip.

Built-in Safety Features

At the end of each test, the WRM automatically dissipates the stored energy in the transformer.

This discharge circuit will continue to work even if the supply voltage is lost. For added safety,

the unit’s power supply is thermally protected from over-load damage.

User Interface

The WRM features a back-lit LCD screen (20 characters by 4 lines) that is viewable in both bright

sunlight and low-light levels. A rugged, alpha-numeric, membrane keypad is used to control the

unit.

2

Page 7

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

Internal Test Record Storage

The WRM can store 63 test records (up to 48 readings per test record) in Flash EEPROM. Test

records can be retrieved and printed on the built-in thermal printer or can be transferred to a

®

PC via the RS-232C interface port. A Windows

XP/Vista-based software application is provided

with each WRM. This software can be used to retrieve test records from the WRM and can also

be used to export records in Microsoft® Excel format.

3

Page 8

WRM-10P AND WRM-40 USER’S MANUAL REV 3

1.2 Technical Specifications

1.2.1. WRM-10P Technical Specifications

Table 1. WRM-10P Technical Specifications

TYPE Portable transformer winding resistance meter

PHYSICAL SPECIFICATIONS 16.8”W x 12.6”H x 10.6”D (42.6 cm x 32.0 cm x 26.9 cm); Weight: 27 lbs

(12.2 kg)

INPUT POWER 100 – 120 Vac or 200 – 240 Vac (factory pre-set), 50/60 Hz

(Please see the voltage setting notes in section 2.1)

RESISTANCE READING

RANGE

ACCURACY 1 – 19,999 micro-ohms: ±0.5% reading, ±1 count;

TEST VOLTAGE 36 Vdc max

TEST CURRENT RANGE Auto range, 10 Amperes max

DISPLAY Back-lit LCD Screen (20 characters by 4 lines); viewable in bright sunlight

PRINTER 2.5-inch wide built-in thermal printer

KEYPAD Rugged membrane keypad (10 alpha-numeric keys, 6 function keys)

INTERNAL TEST RECORD

STORAGE

COMPUTER INTERFACE One RS-232C (19,200 Baud) port

PC SOFTWARE Windows® XP/Vista-based software is included with purchase price

SAFETY Designed to meet IEC61010 (1995), UL61010A-1, CSA-C22.2 standards

ENVIRONMENT Operating: -10˚C to 50˚ C (15˚F to +122˚ F); Storage: -30˚ C to 70˚ C (-

CABLES Three 50-foot test cables, ground cable, power cord and cable bag

OPTIONS Transportation case

WARRANTY One year on parts and labor

1 micro-ohm – 2,000 ohms

20 – 999 milliohms: ±1% reading, ±1 count;

1 – 2,000 ohms: ±1.5% reading, ±1 count

and low-light levels

Stores 63 test records of 48 readings each

22˚F to +158˚ F)

The above specifications are valid at nominal operating voltage and at a

temperature of 25°C (77°F). Specifications may change without prior notice.

NOTE

4

Page 9

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

1.2.2. WRM-40 Technical Specifications

Table 2. WRM-40 Technical Specifications

TYPE Portable transformer winding resistance meter

PHYSICAL SPECIFICATIONS 25”W x 8.5”H x 20”D (63.5 cm x 21.6 cm x 50 cm); Weight: 44 lbs (20 kg)

INPUT POWER 100 – 120 Vac or 200 – 240 Vac (factory pre-set), 50/60 Hz

(Please see the voltage setting notes in section 2.1)

RESISTANCE READING

RANGE

ACCURACY 1 – 19,999 micro-ohms: ±0.5% reading, ±1 count;

TEST VOLTAGE 36 Vdc max

TEST CURRENT RANGE Auto range, 40 Amperes max

DISPLAY Back-lit LCD Screen (20 characters by 4 lines); viewable in bright sunlight

PRINTER 2.5-inch wide built-in thermal printer

KEYPAD Rugged membrane keypad (10 alpha-numeric keys, 6 function keys)

INTERNAL TEST RECORD

STORAGE

COMPUTER INTERFACE One RS-232C (19,200 Baud) port

PC SOFTWARE Windows® XP/Vista-based software is included with purchase price

SAFETY Designed to meet IEC61010 (1995), UL61010A-1, CSA-C22.2 standards

ENVIRONMENT Operating: -10˚C to 50˚ C (15˚F to +122˚ F); Storage: -30˚ C to 70˚ C (-

CABLES Three 50-foot test cables, ground cable, power cord and cable bag

OPTIONS Transportation case

WARRANTY One year on parts and labor

1 micro-ohm – 500 ohms

20 – 999 milliohms: ±1% reading, ±1 count;

1 – 500 ohms: ±1.5% reading, ±1 count

and low-light levels

Stores 63 test records of 48 readings each

22˚F to +158˚ F)

The above specifications are valid at nominal operating voltage and at a

temperature of 25°C (77°F). Specifications may change without prior notice.

NOTE

5

Page 10

WRM-10P AND WRM-40 USER’S MANUAL REV 3

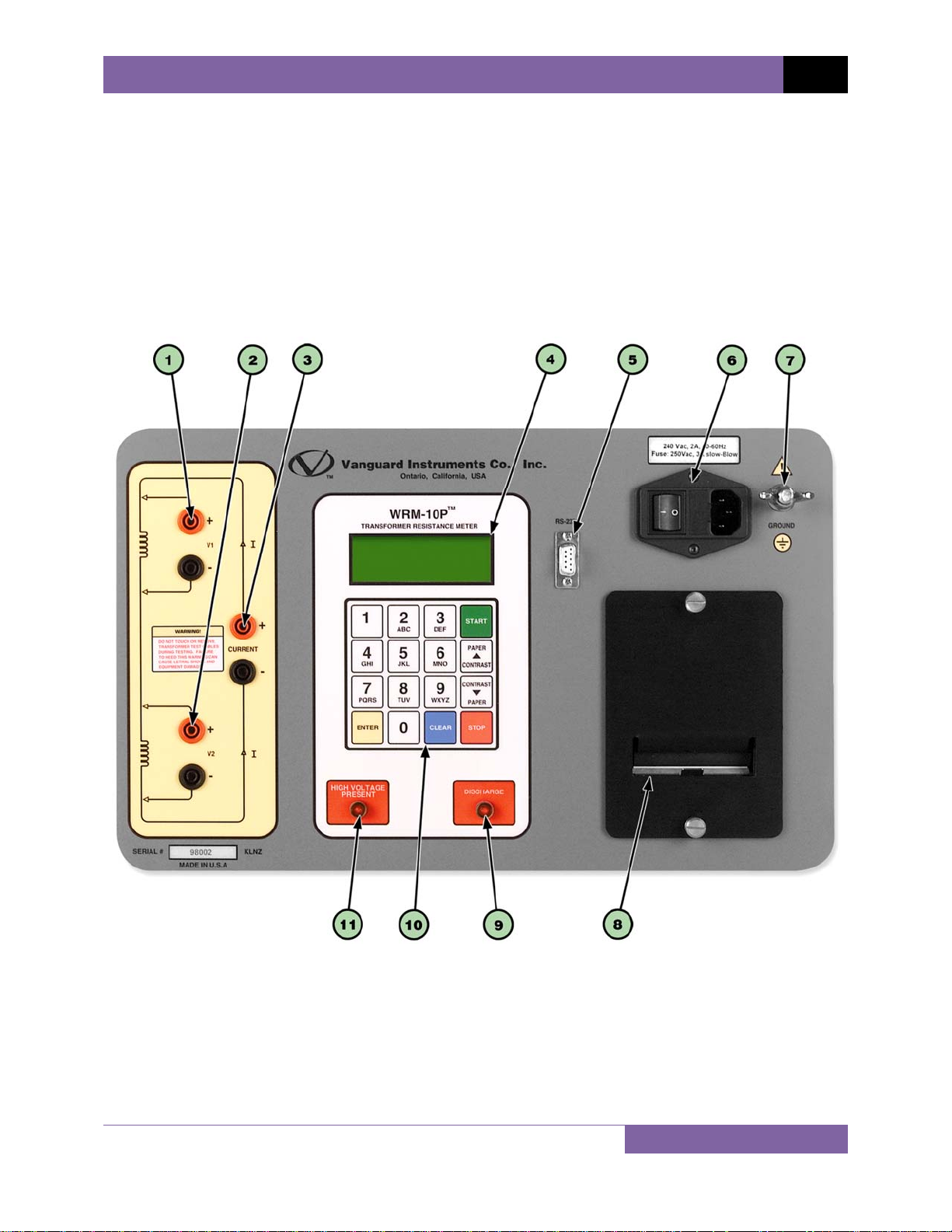

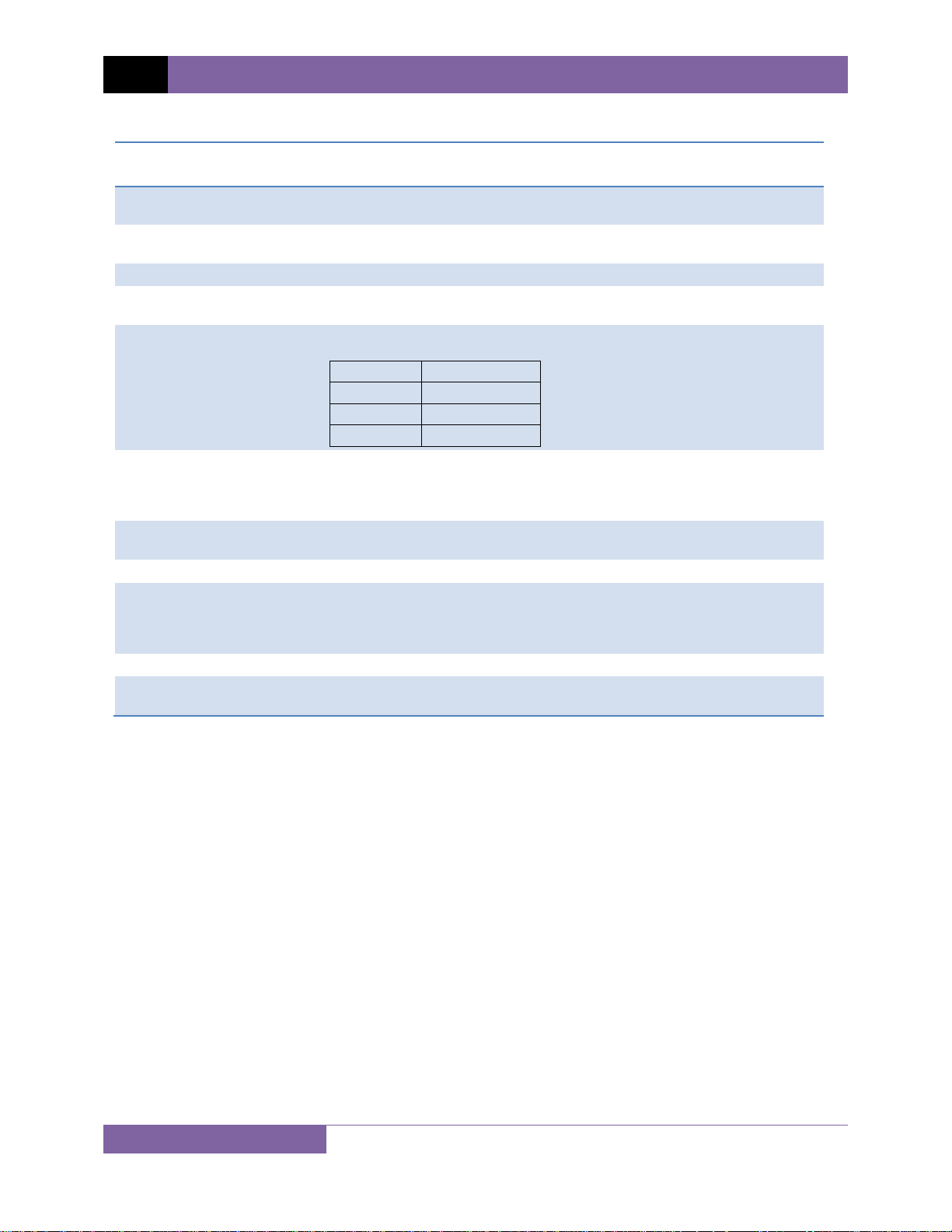

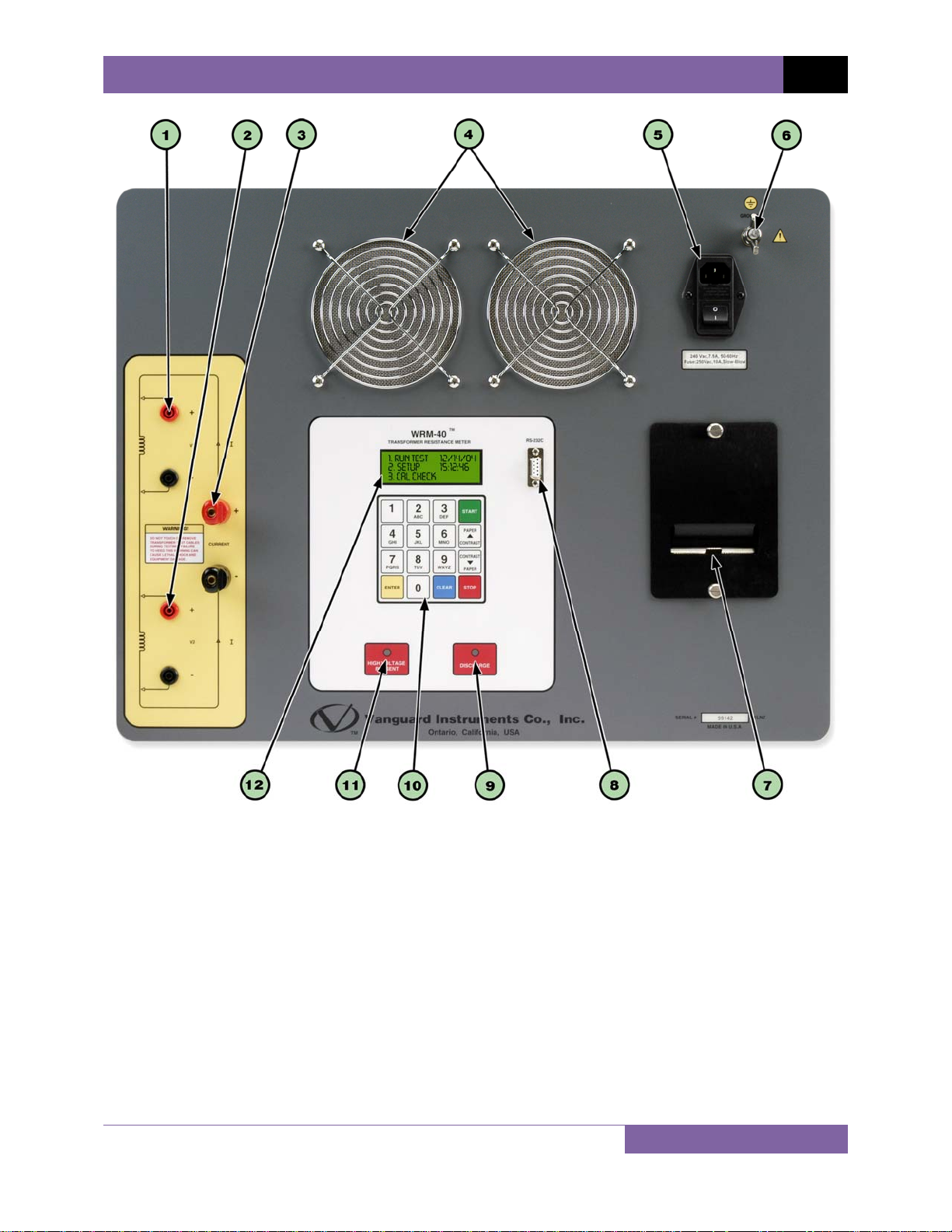

1.3 WRM Controls and Indicators

The WRM-10P and WRM-40’s controls and indicators are shown in Figure 1 and Figure 2,

respectively. A leader line with an index number points to each control and indicator, which is

cross-referenced to a functional description in Table 3 for the WRM-10P and Table 4 for the

WRM-40. The tables describe the function of each item on the control panel. The purpose of

the controls and indicators may seem obvious, but users should become familiar with them

before using the WRM. Accidental misuse of the controls will usually cause no serious harm.

Users should also be familiar with the safety summary found on the front page of this User’s

Manual.

Figure 1. WRM-10P Controls and Indicators

6

Page 11

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

Table 3. Functional Descriptions of WRM-10P Controls and Indicators

Item

Number

1

2

3

4

5

6

7

8

9

10

11

Panel Markings Functional Description

V1

V2

CURRENT Current Output. Female test connector ja cks fo r conn ecting cu rrent te st leads.

RS-232C

240 Vac 2A,

50-60 Hz

Fuse: 250 Vac,

3A Slow Blow

GROUND

Built-in 2.5-inch wide thermal printer.

DISCHARGE

Rugged membrane keypad.

HIGH VOLTAGE

PRESENT

Voltage sensing channel #1. Female test connector jacks for connecting

voltage-sensing test leads.

Voltage sensing channel #2. Female test connector jacks for connecting

voltage-sensing test leads.

Back-lit LCD screen (4 lines by 20 characters). Visible in bright light and low light conditions.

9-pin RS-232C interface port; female DB type. Data rate is set to 19,200 baud,

1 start bit, 2 stop bits, 8 data bits and no parity bit.

Pin Signal

2 RX

3 TX

5 Signal Ground

Input power connector with third-wire safety ground. On/Off rocker toggle

switch with built-in fuse protection.

Safety ground. This must be connected to station ground before connected the

WRM test leads to the transformer.

Red LED warning indicator light. This LED is illuminated when the WRM is

discharging the stored energy from the transformer. Do NOT disconnect test

leads when this light is on. Failure to heed this warning can result in

shock to personnel.

Red LED warning indicator light. This LED is illuminated when there is a

possibility that voltage exists across the test leads.

7

Page 12

WRM-10P AND WRM-40 USER’S MANUAL REV 3

Figure 2. WRM-40 Controls and Indicators

8

Page 13

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

Table 4. Functional Descriptions of WRM-40 Controls and Indicators

Item

Number

1

2

3

4

5

6

7

8

9

10

11

12

Panel Markings Functional Description

V1

V2

CURRENT Current Output. Female test connector ja cks fo r conn ecting cu rrent te st leads.

240 Vac 2A,

50-60 Hz

Fuse: 250 Vac,

3A Slow Blow

GROUND

Built-in 2.5-inch wide thermal printer.

RS-232C

DISCHARGE

Rugged membrane keypad.

HIGH VOLTAGE

PRESENT

Voltage sensing channel #1. Female test connector jacks for connecting

voltage-sensing test leads.

Voltage sensing channel #2. Female test connector jacks for connecting

voltage-sensing test leads.

Air intake cooling fans. The air intake cooling fans maintain the internal

temperature. There is an output air fan on the side of the case.

Input power connector with third-wire safety ground. On/Off rocker toggle

switch with built-in fuse protection.

Safety ground. This must be connected to station ground before connected the

WRM test leads to the transformer.

9-pin RS-232C interface port; female DB type. Data rate is set to 19,200 baud,

1 start bit, 2 stop bits, 8 data bits and no parity bit.

Pin Signal

2 RX

3 TX

5 Signal Ground

Red LED warning indicator light. This LED is illuminated when the WRM is

discharging the stored energy from the transformer. Do NOT disconnect test

leads when this light is on. Failure to heed this warning can result in

shock to personnel.

Red LED warning indicator light. This LED is illuminated when there is a

possibility that voltage exists across the test leads.

Back-lit LCD screen (4 lines by 20 characters). Visible in bright light and low light conditions.

9

Page 14

WRM-10P AND WRM-40 USER’S MANUAL REV 3

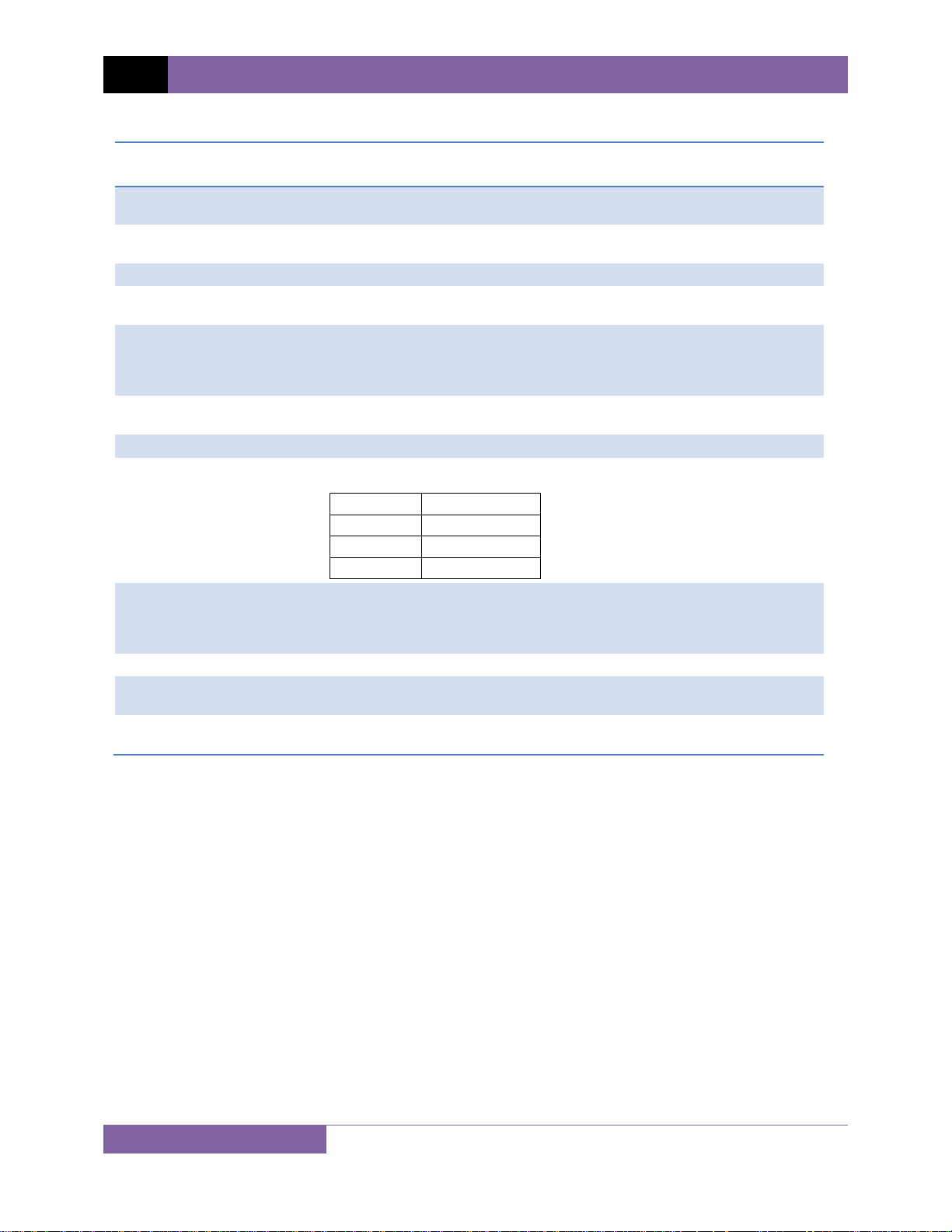

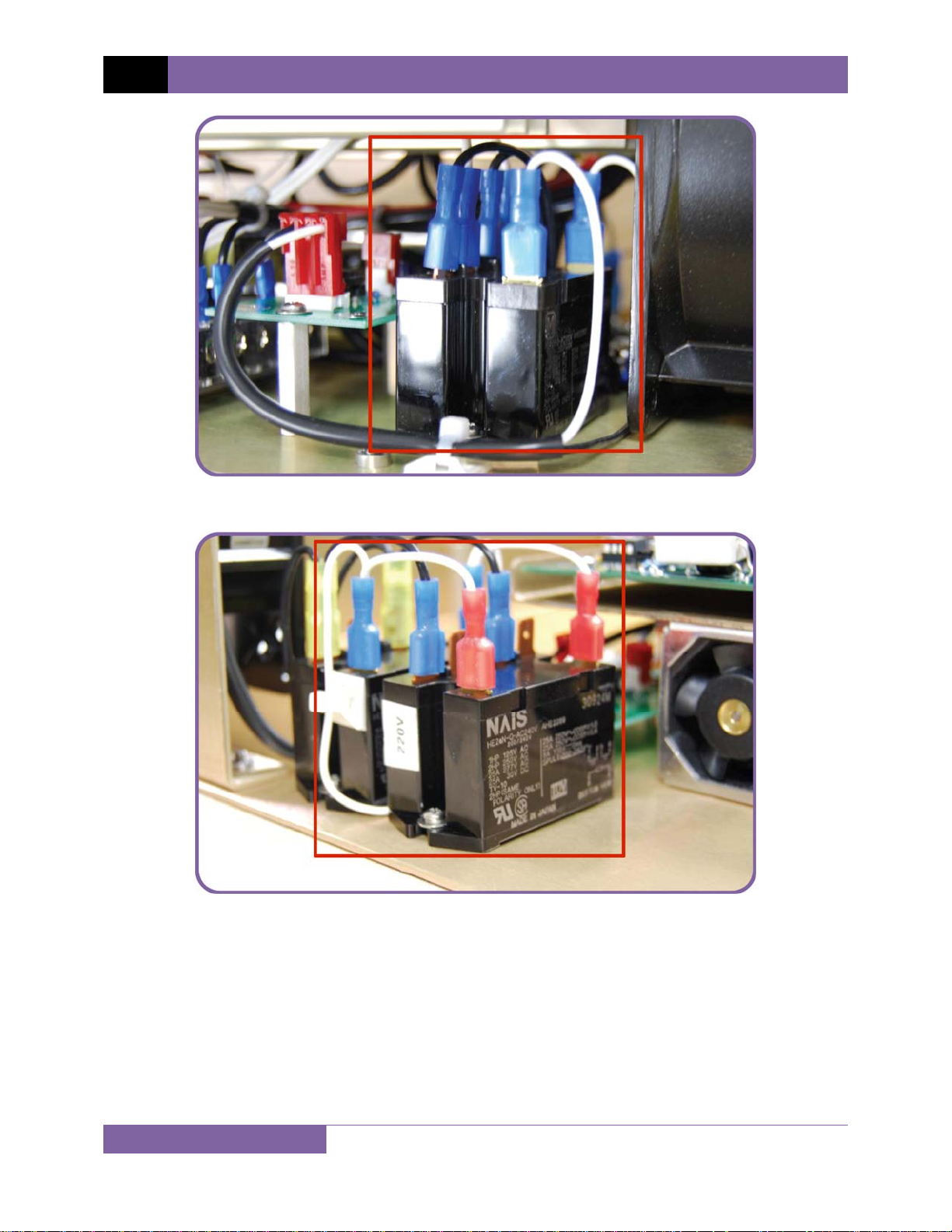

2.0 PRE-TEST SETUP

2.1 Operating Voltages

The WRM’s operating voltage is preset at the factory and is selectable between 100-120 Vac,

50/60 Hz or 200-240 Vac, 50/60 Hz. The voltage is set by placing jumper(s) on the power

terminal block as listed in Table 5 and illustrated in Figure 3 and Figure 4. The relay must also be

changed if the voltage settings are changed. Please see Figure 5 and Figure 6 for the location of

the relays.

Table 5. Voltage Selection Jumper Settings

Voltage

Selection

100 – 120 Vac

200 – 240 Vac

Terminal Block Jumpers

Brown to Blue and Yellow to Green HE2aN-Q-AC120V

Blue to Yellow HE2aN-Q-AC-240V

Figure 3. 100 – 120 Vac Jumper Settings

Relay

Part Number

Figure 4. 200 – 240 Vac Jumper Settings

10

Page 15

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

Figure 5. WRM-10P Relay Location

11

Figure 6. WRM-40 Relay Location

Page 16

WRM-10P AND WRM-40 USER’S MANUAL REV 3

2.2 LCD Screen Contrast Control

To increase the LCD screen contrast, press and hold the [PAPER ∧ Contrast] key for two

seconds.

To decrease the LCD screen contrast, press and hold the [PAPER ∨ Contrast] key for two

seconds.

2.3 Printer Paper Control

To advance the WRM printer paper, press and release the [PAPER ∧ Contrast] key.

To retract the WRM printer paper, press and release the [PAPER ∨ Contrast] key.

2.4 Printer Paper

The WRM’s built-in thermal printer uses 2.5-inch wide thermal paper for printing test results.

To maintain the highest print quality and to avoid paper jams, the use of thermal paper

supplied by Vanguard Instruments Company is highly recommended. Additional paper can be

ordered from the following sources:

Vanguard Instruments Co, Inc.

1520 S. Hellman Avenue

Ontario, CA 91761

Tel: 909-923-9390

Fax: 909-923-9391

Part Number: VIC TP-3 paper

BG Instrument Co.

13607 E. Trent Avenue

Spokane, WA 99216

Tel: 509-893-9881

Fax: 509-893-9803

Part Number: VIC TP-3 paper

12

Page 17

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

2.5 Replacing the Thermal Printer Paper

The roll of thermal paper is housed inside a dispenser underneath the printer cover. To replace

the paper, follow the steps below:

• Unscrew the two large printer cover screws and remove the printer cover.

• Remove the leftover thermal paper roll from the paper holder.

• Unroll the new thermal paper roll.

• Feed the thermal paper into the slot between the paper pocket and the rubber roller.

The printer will automatically pull the paper under the thermal head.

• Place the paper roll into the paper holder.

• Lift the thermal head and align the thermal paper if necessary.

• Re-install the printer cover.

Thermal paper has a chemical coating on one side of the paper. This side should be

facing the thermal print head. Incorrect paper loading may result in blank output on

NOTE

the thermal paper.

The thermal paper will show a red stripe to indicate that the roll is about to run out

of paper.

13

Page 18

WRM-10P AND WRM-40 USER’S MANUAL REV 3

3.0 OPERATING PROCEDURES

3.1 WRM Cable Connections

Typical WRM connection diagrams are shown in Figure 7, Figure 8, Figure 9, and Figure 10.

• Do not touch or disconnect any test lead that is connected to a transformer

WARNINGS

terminal while high current is being conducted during a test. Failure to heed

this warning can result in lethal electric shock to personnel and/or damage

to the equipment.

• Disconnect the test clips from the transformer bushing only after the WRM

has completely discharged the transformer. Always disconnect the test clips

slowly from the transformer bushing to prevent an accidental flash-over.

Figure 7. Typical WRM Connections Diagram #1

Figure 8. Typical WRM Connections Diagram #2

14

Page 19

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

Figure 9. Typical WRM Connections Diagram #3

The above figure illustrates the simultaneous testing of both the high and low

windings on a single-phase transformer. When measuring two channels, the above

NOTE

cable connection is recommended since it will speed up the testing process.

Figure 10. Typical WRM Connections Diagram #4

15

Page 20

WRM-10P AND WRM-40 USER’S MANUAL REV 3

3.2 General Procedures

The main steps for using the WRM are outlined below:

a. Ground the WRM to the substation ground.

Always connect the WRM to the substation ground before connecting any

test lead to any transformer bushing. Failure to follow this procedure may

WARNING

damage the WRM.

b. Plug the WRM power cable into a power outlet.

c. Insert current-cable plugs and voltage-sensing cable plugs into the corresponding

control panel jacks.

d. Attach the test cable clamps to the transformer terminal for the winding that is to be

measured.

e. Turn on the WRM by pressing [I] on the power rocker switch.

f. The unit will self-calibrate, and then you will be presented with the “START-UP” menu as

shown below:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

16

Page 21

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

3.3 Entering Test Record Header Information

You can enter the test record header information before performing tests. The record header

includes identifying information such as the company, station, circuit, model number, etc. Once

the header information has been entered, it will apply to all subsequent test records. To enter

the header information:

a. Start from the “START-UP” menu:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

Press the [2] key (SETUP).

b. The following screen will be displayed:

1. ENTER XFMR ID

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the [1] key (ENTER XFMR ID).

c. The following screen will be displayed:

COMPANY:

UP/DOWN TO POSITION

“ENTER” TO ACCEPT

Type the company name using the alpha-numeric keypad.

When pressing a key, the corresponding number on the key will be displayed first.

Pressing the key again will display the first letter on the key. Pressing the key again will

display the second letter on the key. For example, to type the letter “A”, you must press

the [2] key twice. To erase the character at the cursor position, press the [CLEAR] key.

Press the

∨ Contrast]

[PAPER ∧ Contrast] key to move to the next character. Press the [PAPER

key to move to the previous character. Press the [ENTER] key when you

are done typing the company name.

d. The following screen will be displayed:

STATION:

UP/DOWN TO POSITION

“ENTER” TO ACCEPT

Type the station name using the alpha-numeric keypad and then press the [ENTER]

key.

17

Page 22

e. The following screen will be displayed:

CIRCUIT:

UP/DOWN TO POSITION

“ENTER” TO ACCEPT

Type the circuit information using the alpha-numeric keypad and then press the

[ENTER] key.

f. The following screen will be displayed:

MANUFACTURER:

UP/DOWN TO POSITION

“ENTER” TO ACCEPT

Type the manufacturer name using the alpha-numeric keypad and then press the

[ENTER] key.

g. The following screen will be displayed:

WRM-10P AND WRM-40 USER’S MANUAL REV 3

MODEL:

UP/DOWN TO POSITION

“ENTER” TO ACCEPT

Type the model information using the alpha-numeric keypad and then press the

[ENTER] key.

h. The following screen will be displayed:

SERIAL NUMBER:

UP/DOWN TO POSITION

“ENTER” TO ACCEPT

Type the serial number using the alpha-numeric keypad and then press the

key.

i. The following screen will be displayed:

KVA RATING:

UP/DOWN TO POSITION

“ENTER” TO ACCEPT

[ENTER]

Type the transformer’s KVA rating using the alpha-numeric keypad and then press the

[ENTER] key.

18

Page 23

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

j. The following screen will be displayed:

OPERATOR:

UP/DOWN TO POSITION

“ENTER” TO ACCEPT

Type the operator’s name using the alpha-numeric keypad and then press the [ENTER]

key.

All header information will be saved, and you will be returned to the “START-UP” menu.

19

Page 24

3.4 Performing a Resistance Test

a. Start from the “START-UP” menu:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

Press the [1] key (TEST XFMR).

b. The following screen will be displayed:

1. V1 & V2 TEST

2. V1 ONLY TEST

3. SPECIAL TEST V1,V2

4. SPECIAL TEST V1

Press the [1] key (V1 & V2 TEST) if you would like to perform a V1 & V2 test.

Press the [2] key (V1 ONLY TEST) if you would like to perform a V1 test only.

Please see section 3.5 for information about performing special tests.

WRM-10P AND WRM-40 USER’S MANUAL REV 3

The test current is 10 Amps for the WRM-10P and 40 Amps for the WRM-40.

NOTE

c. The following menu will be displayed:

LTC or VTG REG?

1. YES

2. NO

Press the [2] key (NO).

d. The following screen will be displayed:

CONVERT READINGS

TO STANDARD TEMP?

1. YES

2. NO

1. YES

Press the

[1] key (YES) if you wish to convert readings to standard temperature.

The following screen will be displayed:

WINDING MATERIAL:

1. COPPER, Tk=234.5

2. ALUMINUM, Tk=225

3. MANUALLY ENTER Tk

20

Page 25

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

Press the [1] key (COPPER, Tk=234.5) to select copper as the winding material.

Continue to step d.

Press the [2] key (ALUMINUM, Tk=225) to select aluminum as the winding

material. Continue to step d.

Press the [3] key (MANUALLY ENTER Tk) to manually enter the Tk value. The

following screen will be displayed:

Tk:

230.0°C

↑↓ to adjust Tk

“ENTER” to accept

You can increase the Tk value by 0.5°C increments by pressing the [PAPER ∧

Contrast]

key.

You can decrease the Tk value by 0.5°C increments by pressing the [PAPER ∨

Contrast]

key.

Press the [ENTER] key to confirm the temperature setting. Continue to step e.

2. NO

Press the [2] key (NO) if you do NOT wish to convert readings to standard

temperature. Continue to step e.

e. The following screen will be displayed:

D.U.T. TEMP

25.0°C 77.0°F

↑↓ to adjust temp

“ENTER” to accept

Use the

[PAPER ∧ Contrast] and [PAPER ∨ Contrast] keys to adjust the D.U.T.

(Device Under Test) temperature.

Press the [ENTER] key to confirm the D.U.T. temperature setting.

f. The following screen will be displayed:

REFERENCE TEMP:

85.0°C 185.0°F

↑↓ to adjust temp

“ENTER” to accept

Use the [PAPER ∧ Contrast] and [PAPER ∨ Contrast] keys to adjust the

reference temperature.

Press the

[ENTER] key to confirm the reference temperature setting.

21

Page 26

WRM-10P AND WRM-40 USER’S MANUAL REV 3

The WRM will calculate the equivalent resistance value at this new

temperature. Please see section 4.2 for further information about how this

NOTE

value is calculated.

g. The following warning screen will be displayed:

********WARNING******

DANGEROUS FLASH-OVER

WILL OCCUR IF CABLES

ARE DISCONNECTED!

This warning is a reminder that the next sequence of test steps will run current through

the test load.

Press any key to continue.

h. The following screen will be displayed:

- V1 & V2 TEST –

“START” TO RUN TEST

OR

“STOP” TO ABORT

Press the

[START] key to run the test.

i. The following screen will be displayed momentarily:

CALIBRATING

PLEASE WAIT...

After the WRM finishes its internal calibration, the following screen will be displayed:

XFMR CHARGING

PLEASE WAIT…

* XFMR ENERGIZED! *

This is only an informational screen to remind the operator that a test is in progress. The

display duration of this message depends on the size of the winding’s inductance.

You can bypass this delay and observe the resistance value immediately. See

section 4.1 for instructions on how to select this option.

NOTE

22

Page 27

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

j. The WRM determines when the resistance reading is stable and displays the resistance

values on the LCD screen as shown below:

TEST IN PROGRESS

I=9.79A R1=499μΩ

R2=105μΩ

* XFMR ENERGIZED! *

The WRM will continue the test and update the resistance values on the LCD screen.

While the test is in progress, you can press the [ENTER] key to save the current

readings from the LCD screen to the WRM’s internal working memory. This process can

be repeated as needed for a maximum of 48 times per test.

Although this process can be used to store multiple readings when testing a

Load Tap Changer (LTC) or Voltage Regulator, a more convenient method is

NOTE

also available. Please see section 3.5 for information about performing an

LTC or Voltage Regulator test.

If the [ENTER] key is pressed, the data is saved and the following screen will be

displayed on the LCD screen:

TEST IN PROGRESS

I = 1.09A R1=499μΩ

SAVING TEST

* XFMR ENERGIZED! *

Once the data is saved, the following screen will be displayed:

TEST IN PROGRESS

I = 1.09A R1=499μΩ

TEST SAVED

* XFMR ENERGIZED! *

Press the

[STOP] key to stop running the test. The test results will be displayed as

shown:

TEST RESULTS

I = 1.09A R1=499μΩ

TEST SAVED

Press any key to continue to the next step.

23

Page 28

k. The following screen will be displayed:

PRINT TEST RESULTS?

1. YES

2. NO

1. YES

Press the [1] key (YES) to print the test results on the built-in thermal printer.

The last test results displayed on the LCD screen will be printed. Typical WRM

test reports are shown in Figure 11, Figure 12, and Figure 13. Continue to step l.

2. NO

Press the [2] key (NO) to bypass printing of the test results. Continue to step l.

l. The following screen will be displayed:

KEEP THIS READING?

1. YES

2. NO

WRM-10P AND WRM-40 USER’S MANUAL REV 3

1. YES

Press the [1] key (YES) to save the reading. One of the following screens will be

displayed:

The following screen will be displayed if there is no previous data in the memory:

TEST SAVED

The following screen will be displayed if previous data for the same test type is

stored in the memory:

PREVIOUS DATA IN BUF

11/05/09 10:49:08

1. APPEND PREV. DATA

2. CLEAR PREV. DATA

The WRM retains the current test results in its working memory. When a test is

finished, the user can append the new test results to the previous test results in

the working memory, as long as the unit’s power has not been turned off

between tests.

Press the [1] key (APPEND PREV. DATA) to append the current test results to the

previous test results in the working memory.

Press the [2] key (CLEAR PREV. DATA) to only save the current test results and

discard any previous data from the working memory.

24

Page 29

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

In either case, press any key and continue to step m.

2. NO

If you do not wish to save the reading, press the [2] key (NO) and continue to

step m.

m. The following screen will be displayed:

RUN ANOTHER TEST?

1. YES

2. NO

Press the [1] key (YES) to run another test. Return to step b.

Press the [2] key (NO) if you do not want to run another test. Continue to step n.

n. The following screen will be displayed:

SAVE THIS RECORD?

1. YES

2. NO

1. YES

Press the [1] key (YES) to save the test record. Continue to step o.

2. NO

Press the [2] key (NO) if you do not want to save the test record. The following

screen will be displayed:

ARE YOU SURE?

DATA WILL BE LOST!

1. DO NOT SAVE RECORD

2. SAVE RECORD

Press the

[1] key (DO NOT SAVE RECORD) if you do not want to save the record.

You will be returned to the “START-UP” menu.

Press the [2] key (SAVE RECORD) to save the record. Continue to step o.

25

Page 30

WRM-10P AND WRM-40 USER’S MANUAL REV 3

o. The following screen will be displayed:

RECORD NUMBER 01

HAS BEEN SAVED!

NOTE

The record number is automatically assigned and incremented by the WRM.

Press any key to return to the “START-UP” menu.

Figure 11. Typical V1 Test Report Printout

26

Page 31

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

Measured Resistance

Equivalent Resistance at

Figure 12. Typical V1 and V2 Test Report Printout

27

Page 32

WRM-10P AND WRM-40 USER’S MANUAL REV 3

Figure 13. Typical V1 and V2 Test Report Printout with Multiple Readings

28

Page 33

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

3.5 Performing a Load Tap Changer / Voltage Regulator Resistance Test

The Load Tap Changer/Voltage Regulator Resistance Test can be used to conveniently measure

the resistance at each tap position. Once the number of taps has been entered, the WRM will

request the user to set the tap position, starting with the lower taps, then to neutral, and then

to the raise taps. At each tap position, the resistance is measured, displayed on the LCD screen,

and stored. The WRM then instructs the user to change to the next tap position and repeat the

testing process.

Use the steps below to perform an LTC/Voltage Regulator Test:

a. Start from the “START-UP” menu:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

Press the [1] key (TEST XFMR).

b. The following screen will be displayed:

1. V1 & V2 TEST

2. V1 ONLY TEST

3. SPECIAL TEST V1,V2

4. SPECIAL TEST V1

Press the [1] key (V1 & V2 TEST) if you would like to perform a V1 & V2 test.

Press the [2] key (V1 ONLY TEST) if you would like to perform a V1 test only.

c. The following screen will be displayed:

LTC or VTG REG?

1. YES

2. NO

Press the [1] key (YES).

d. The following screen will be displayed

ENTER # OF RAISE

TAPS, NOT COUNTING

NEUTRAL (1-23):

Type the number of taps the LTC or Voltage Regulator has using the alpha-numeric

keypad, and then press the

29

[ENTER] key. We will enter “3” for our example.

Page 34

e. The following screen will be displayed:

3 LOWER,N,3 RAISE

IS THIS CORRECT?

1. YES

2. NO

If the tap information is correct, press the [1] key (YES) and continue to step f.

If the tap information is incorrect, press the [2] key (NO) and return to step d.

f. The following screen will be displayed:

CONVERT READINGS

TO STANDARD TEMP?

1. YES

2. NO

1. YES

Press the [1] key (YES) if you wish to convert readings to standard temperature.

The following screen will be displayed:

WRM-10P AND WRM-40 USER’S MANUAL REV 3

WINDING MATERIAL:

4. COPPER, Tk=234.5

5. ALUMINUM, Tk=225

6. MANUALLY ENTER Tk

Press the [1] key (COPPER, Tk=234.5) to select copper as the winding material.

Continue to step g.

Press the [2] key (ALUMINUM, Tk=225) to select aluminum as the winding

material. Continue to step g.

Press the [3] key (MANUALLY ENTER Tk) to manually enter the Tk value. The

following screen will be displayed:

Tk:

230.0°C

↑↓ to adjust Tk

“ENTER” to accept

You can increase the Tk value by 0.5°C increments by pressing the

Contrast]

key.

You can decrease the Tk value by 0.5°C increments by pressing the

Contrast]

key.

[PAPER ∧

[PAPER ∨

Press the [ENTER] key to confirm the temperature setting. Continue to step g.

2. NO

Press the [2] key (NO) if you do NOT wish to convert readings to standard

temperature. Continue to step g.

30

Page 35

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

g. The following screen will be displayed:

D.U.T. TEMP

25.0°C 77.0°F

↑↓ to adjust temp

“ENTER” to accept

Use the [PAPER ∧ Contrast] and [PAPER ∨ Contrast] keys to adjust the D.U.T.

(Device Under Test) temperature.

Press the [ENTER] key to confirm the D.U.T. temperature setting.

h. The following screen will be displayed:

REFERENCE TEMP:

85.0°C 185.0°F

↑↓ to adjust temp

“ENTER” to accept

Use the [PAPER ∧ Contrast] and [PAPER ∨ Contrast] keys to adjust the

reference temperature.

Press the [ENTER] key to confirm the reference temperature setting.

The WRM will calculate the equivalent resistance value at this new

temperature. Please see section 4.2 for further information about how this

NOTE

value is calculated.

i. The following screen will be displayed:

********WARNING******

DANGEROUS FLASH-OVER

WILL OCCUR IF CABLES

ARE DISCONNECTED!

Press any key to continue.

j. The following screen will be displayed:

SET TAP TO 3 LOWER

“START” TO RUN TEST

OR

“STOP” TO ABORT

Set the LTC or Voltage Regulator tap position as indicated on the LTC screen and press

[START] key.

the

31

Page 36

WRM-10P AND WRM-40 USER’S MANUAL REV 3

k. The following screen will be displayed momentarily:

CALIBRATING

PLEASE WAIT...

After the WRM finishes its internal calibration, the following screen will be displayed:

XFMR CHARGING

PLEASE WAIT…

I = 0.03A

* XFMR ENERGIZED! *

l. The WRM determines when the resistance reading is stable and displays the resistance

values on the LCD screen as shown below:

TEST IN PROGRESS 21

I=0.01A R1=997.4μΩ

R2=0μΩ

* XFMR ENERGIZED! *

Press the [ENTER] key to accept and save the readings.

m. The following screen will be displayed:

TEST IN PROGRESS 21

I=0.01A R1=997.4μΩ

SAVING TEST

* XFMR ENERGIZED! *

Once the reading has been saved, the following screen will be displayed momentarily:

TEST IN PROGRESS 21

I=0.01A R1=997.4μΩ

TEST SAVED

* XFMR ENERGIZED! *

n. After saving the readings, the following screen will be displayed:

SET 2L THEN “START”

* XFMR ENERGIZED! *

Set the LTC or Voltage Regulator tap position to the position indicated on the LCD screen

and press the [START] key.

The WRM will continue the test and display the results as in step l. Repeat steps l

through m for all “Lower” positions and then through all “Raise” positions.

32

Page 37

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

o. The following screen will be displayed after the last “Raise” position’s resistance reading

is stored:

PRINT RECORD?

1. YES

2. NO

1. YES

Press the [1] key (YES) to print the test results on the built-in thermal printer. A

Typical LTC/Voltage Regulator test report is shown in Figure 14. Continue to step

p.

2. NO

Press the [2] key (NO) to bypass printing of the test results. Continue to step p.

p. The following screen will be displayed:

SAVE THIS RECORD?

1. YES

2. NO

1. YES

Press the [1] key (YES) to save the test record. The following screen will be

displayed:

RECORD NUMBER 01

HAS BEEN SAVED!

Press any key to return to the “START-UP” menu.

2. NO

If you do not wish to save the test record, press the

[2] key (NO). The following

screen will be displayed:

ARE YOU SURE?

DATA WILL BE LOST!

1. DO NOT SAVE RECORD

2. SAVE RECORD

Press the

[1] key (DO NOT SAVE RECORD) to NOT save the test record. You will

be returned to the “START-UP” menu.

33

Page 38

WRM-10P AND WRM-40 USER’S MANUAL REV 3

Press the [2] key (SAVE RECORD) to save the test record. The following screen

will be displayed:

RECORD NUMBER 01

HAS BEEN SAVED!

Press any key to return to the “START-UP” menu.

34

Page 39

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

Figure 14. Typical LTC/Voltage Regulator Test Report Printout

35

Page 40

WRM-10P AND WRM-40 USER’S MANUAL REV 3

3.6 Performing a Special Resistance Test

The Special Resistance Test is used to conduct a resistance test for a pre-defined period ranging

from 1 to 45 minutes. The resistance data is recorded at one minute intervals. Use the steps

below to perform a Special Resistance Test:

a. Start from the “START-UP” menu:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

Press the [1] key (TEST XFMR).

b. The following screen will be displayed:

1. V1 & V2 TEST

2. V1 ONLY TEST

3. SPECIAL TEST V1,V2

4. SPECIAL TEST V1

Press the [3] key (SPECIAL TEST V1, V2) to perform a V1 and V2 special resistance test.

Press the [4] key (SPECIAL TEST V1) to perform a V1 special resistance test.

c. The following screen will be displayed:

ENTER SPECIAL TEST

TIME MINUTES (1-45):

_

Enter the test time (between 1 to 45 minutes) using the alpha-numeric keypad, and

then press the [ENTER] key.

d. The following screen will be displayed:

CONVERT READINGS

TO STANDARD TEMP?

1. YES

2. NO

1. YES

Press the

[1] key (YES) if you wish to convert readings to standard temperature.

The following screen will be displayed:

WINDING MATERIAL:

1. COPPER, Tk=234.5

2. ALUMINUM, Tk=225

3. MANUALLY ENTER Tk

36

Page 41

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

Press the [1] key (COPPER, Tk=234.5) to select copper as the winding material.

Continue to step d.

Press the [2] key (ALUMINUM, Tk=225) to select aluminum as the winding

material. Continue to step d.

Press the [3] key (MANUALLY ENTER Tk) to manually enter the Tk value. The

following screen will be displayed:

Tk:

230.0°C

↑↓ to adjust Tk

“ENTER” to accept

You can increase the Tk value by 0.5°C increments by pressing the [PAPER ∧

Contrast]

key.

You can decrease the Tk value by 0.5°C increments by pressing the [PAPER ∨

Contrast]

key.

Press the [ENTER] key to confirm the temperature setting. Continue to step e.

2. NO

Press the [2] key (NO) if you do NOT wish to convert readings to standard

temperature. Continue to step e.

e. The following screen will be displayed:

D.U.T. TEMP

25.0°C 77.0°F

↑↓ to adjust temp

“ENTER” to accept

Use the

[PAPER ∧ Contrast] and [PAPER ∨ Contrast] keys to adjust the D.U.T.

(Device Under Test) temperature.

Press the [ENTER] key to confirm the D.U.T. temperature setting.

f. The following screen will be displayed:

REFERENCE TEMP:

85.0°C 185.0°F

↑↓ to adjust temp

“ENTER” to accept

Use the [PAPER ∧ Contrast] and [PAPER ∨ Contrast] keys to adjust the

reference temperature.

Press the

[ENTER] key to confirm the reference temperature setting.

37

Page 42

WRM-10P AND WRM-40 USER’S MANUAL REV 3

g. The following warning screen will be displayed:

********WARNING******

DANGEROUS FLASH-OVER

WILL OCCUR IF CABLES

ARE DISCONNECTED!

This warning is a reminder that the next sequence of test steps will run current through

the test load.

Press any key to continue.

h. The following screen will be displayed:

- V1 ONLY TEST –

“START” TO RUN TEST

OR

“STOP” TO ABORT

Press the [START] key to run the test.

i. The following screen will be displayed momentarily:

CALIBRATING

PLEASE WAIT...

After the WRM finishes its internal calibration, the following screen will be displayed:

XFMR CHARGING

PLEASE WAIT…

* XFMR ENERGIZED! *

This is only an informational screen to remind the operator that a test is in progress. The

display duration of this message depends on the size of the winding’s inductance.

You can bypass this delay and observe the resistance value immediately. See

section 4.1 for instructions on how to select this option.

NOTE

j. The WRM determines when the resistance reading is stable and shows the resistance

value on the LCD screen as shown below (the first line shows the remaining test time):

REMAINING TIME=10:00

I=10.01A R1=499 μΩ

R2=501 μΩ

* XFMR ENERGIZED! *

38

Page 43

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

When the pre-defined test time has elapsed, the following screen will be displayed:

TEST RESULTS

I=10.01A R1=499 μΩ

R2=501 μΩ

Press any key to continue.

k. The following screen will be displayed:

SAVE THIS RECORD?

1. YES

2. NO

1. YES

Press the [1] key (YES) to save the test record. Continue to step l.

2. NO

Press the [2] key (NO) if you do not want to save the test record. The following

screen will be displayed:

ARE YOU SURE?

DATA WILL BE LOST!

1. DO NOT SAVE RECORD

2. SAVE RECORD

Press the [1] key (DO NOT SAVE RECORD) if you do not want to save the record.

You will be returned to the “START-UP” menu.

Press the [2] key (SAVE RECORD) to save the record. Continue to step l.

l. The following screen will be displayed:

RECORD NUMBER 02

HAS BEEN SAVED!

• The record number is automatically assigned and incremented by the WRM.

• Once the test record has been saved, it can be recalled and printed (see

NOTES

section 3.9.1 for further information). Figure 15 shows a typical Special Test

report printout.

Press any key to return to the “START-UP” menu.

39

Page 44

WRM-10P AND WRM-40 USER’S MANUAL REV 3

Figure 15. Typical Five Minute Special Test Report Printout

40

Page 45

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

3.7 Performing a Transient Test

The transient test verifies that a regulating switch in a Voltage Regulator or Load Tap Changer

changes contacts through its selection range without a break in the circuit. This is an important

test because in actual use, any break in current in a regulating tap switch generates large

reactive voltage spikes that are hazardous and exceed the switch’s voltage ratings, thus causing

irreparable damage.

By connecting the WRM continuity test input across the switching input and running the

regulator switch through all the contacts in its range, any breaks in continuity caused by faulty

tap switching can be detected. Please note that the transient test is applicable for the V1

channel only.

Use the steps below to perform a Transient Test:

a. Start from the “START-UP” menu:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

Press the [2] key (SETUP).

b. The following screen will be displayed:

1. ENTER XFMR ID

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the [4] key (NEXT PAGE).

c. The following screen will be displayed:

1. COMPUTER CONTROL

2. SET TIME

3. TRANSIENT TEST

Press the

[3] key (TRANSIENT TEST).

d. The following warning screen will be displayed:

********WARNING******

DANGEROUS FLASH-OVER

WILL OCCUR IF CABLES

ARE DISCONNECTED!

Press any key to continue.

41

Page 46

WRM-10P AND WRM-40 USER’S MANUAL REV 3

e. The following screen will be displayed:

TRANSIENT TEST

“START” TO RUN TEST

OR

“STOP” TO ABORT

Press the [START] key.

f. The following screen will be displayed:

*XFMR CHARGING*

PLEASE WAIT…

* XFMR ENERGIZED! *

g. The test begins as the magnetic field in the transformer ramps up to a stable plateau.

The following screen will be displayed when the transformer current stabilizes:

VOLTAGE REG TEST

RUN TAPS NOW...

* XFMR ENERGIZED! *

h. Manually run the regulator switch through all the contacts in its range. Press the

[STOP] key to end the test.

The following screen will be displayed if no transient is detected:

NO TRANSIENT

DETECTED.

The following screen will be displayed if a switch break is detected:

TRANSIENT DETECTED!

Press any key to continue.

i. The following screen will be displayed:

PRINT TEST RESULTS?

1. YES

2. NO

42

Page 47

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

Press the [1] key (YES) to print the test results. The test results will be printed, and you

will be returned to the “START-UP” menu. A typical voltage regulator test report is

shown in Figure 16.

Press the [2] key (NO) if you do not want to print the test results. You will be returned

to the “START-UP” menu.

Figure 16. Typical Transient Test Report

43

Page 48

WRM-10P AND WRM-40 USER’S MANUAL REV 3

3.8 Performing a Diagnostic Test

In diagnostic mode, the WRM can run a resistance test, display the sense voltages, and test

current on the WRM. This feature can be used to verify the WRM’s voltage and current

readings against an external meter. Use the steps below to perform a diagnostic test:

a. Start from the “START-UP” menu:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

Press the [3] key (USER DIAG).

b. The following warning screen will be displayed:

********WARNING******

DANGEROUS FLASH-OVER

WILL OCCUR IF CABLES

ARE DISCONNECTED!

Press any key to continue.

c. The following screen will be displayed:

- USER DIAG TEST –

“START” TO RUN TEST

OR

“STOP” TO ABORT

Press the [START] key.

d. The V1, V2, and test current (I) will be displayed as shown below:

V1 = 28.13 mV

V2 = 09.23 mV

I = 1.091 A

* XFMR ENERGIZED! *

Press the

[STOP] key to end the test and return to the “START-UP” menu.

44

Page 49

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

3.9 Working with Test Records

3.9.1. Restoring a Test Record for Review or Printing

Use the steps below to restore a test record from the WRM’s Flash EEPROM to the unit’s

working memory:

a. Start from the “START-UP” menu:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

Press the

[2] key (SETUP).

b. The following screen will be displayed:

1. ENTER XFMR ID

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the

[3] key (RESTORE RECORD).

c. The following screen will be displayed:

1. RESTORE RECORD

2. DIRECTORY

3. ERASE RECORDS

Press the [1] key (RESTORE RECORD).

d. The following screen will be displayed:

RESTORE RECORD

1. ENTER RECORD NUMBR

2. SCROLL TO SELECT

1. ENTER RECORD NUMBER

Press the [1] key (ENTER RECORD NUMBER) if you know the record number that

you would like to restore. The following screen will be displayed:

RESTORE RECORD

NUMBER:

Type the record number using the alpha-numeric keypad, and then press the

[ENTER] key.

45

Page 50

WRM-10P AND WRM-40 USER’S MANUAL REV 3

The following screen will be displayed:

RECORD RESTORED!

Press any key. Continue to step e.

2. SCROLL TO SELECT

Press the [2] key (SCROLL TO SELECT) to scroll through the WRM’s record

directory and find the record that you would like to restore. The following screen

will be displayed:

RECORDS DIRECTORY

“UP” TO SCROLL FWD

“DWN” TO SCROLL RVS

Press either the [PAPER ∧ Contrast] or [PAPER ∨ Contrast] key to scroll

through the test record directory. The header for each test record will be

displayed as shown:

#1 11/06/09 09:30

NUM OF TESTS: 3

ABB

Continue to press the [PAPER ∧ Contrast] or [PAPER ∨ Contrast] key

until you have located the test record that you would like to restore. Press the

[ENTER] key. The following screen will be displayed:

RECORD RESTORED!

Press any key. Continue to step e.

46

Page 51

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

e. The following screen will be displayed:

REVIEW RECORD

1. SCROLL TEST RECORD

2. PRINT TEST RECORD

1. SCROLL TEST RECORD

Press the [1] key (SCROLL TEST RECORD) to view the test record on the LCD

screen. Use the [PAPER ∨ Contrast] key to scroll to the next page. Press the

[STOP] key when you are done viewing the test record, and you will be

returned to the “START-UP” menu.

2. PRINT TEST RECORD

Press the [2] key (PRINT TEST RECORD) to print the restored record. The test

record will be printed on the built-in thermal printer, and you will be returned to

the “START-UP” menu.

Once a test record has been restored to the working memory, it can be

reviewed or printed at the time it is restored or at a later time. To review or

NOTE

print a restored test record at a later time, please see the instructions in

section 3.9.2.

47

Page 52

WRM-10P AND WRM-40 USER’S MANUAL REV 3

3.9.2. Reviewing or Printing a Restored Test Record

Once you have restored a test record to the working memory (see section 3.9.1), you can print

or review it at the time it was restored or at a later time. Follow the steps below to review or

print a test record after it has been restored to the working memory:

a. Start from the “START-UP” menu:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

Press the [2] key (SETUP).

b. The following screen will be displayed:

1. ENTER XFMR ID

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the [2] key (REVIEW RECORD).

c. The following screen will be displayed:

REVIEW RECORD

1. SCROLL TEST RECORD

2. PRINT TEST RECORD

1. SCROLL TEST RECORD

Press the [1] key (SCROLL TEST RECORD) to view the test record on the LCD

screen. Use the [PAPER ∨ Contrast] key to scroll to the next page. Press the

[STOP] key when you are done viewing the test record, and you will be

returned to the “START-UP” menu.

2. PRINT TEST RECORD

Press the [2] key (PRINT TEST RECORD) to print the restored record. The test

record will be printed on the built-in thermal printer, and you will be returned to

the “START-UP” menu.

48

Page 53

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

3.9.3. Printing a Test Record Directory

A directory of all the test records stored in the WRM’s Flash EEPROM can be printed on the

built-in thermal printer using the steps below:

a. Start from the “START-UP” menu:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

Press the [2] key (SETUP).

b. The following screen will be displayed:

1. ENTER XFMR ID

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the [3] key (RESTORE RECORD).

c. The following screen will be displayed:

1. RESTORE RECORD

2. DIRECTORY

3. ERASE RECORDS

Press the [2] key (DIRECTORY).

d. The following screen will be displayed:

PRINT DIRECTORY

1. FULL DIRECTORY

2. SHORT DIRECTORY

Press the

[1] key (FULL DIRECTORY) to print the entire directory of test records. After

the directory is printed, you will be returned to the “START-UP” menu.

Press the [2] key (SHORT DIRECTORY) to print a short directory. This lists the last 10

records stored in the WRM’s memory. After the directory is printed, you will be

returned to the “START-UP” menu.

A typical test record directory printout is shown in Figure 17.

49

Page 54

WRM-10P AND WRM-40 USER’S MANUAL REV 3

Figure 17. Typical Test Record Directory Printout

50

Page 55

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

3.9.4. Erasing Test Records

Follow the steps below to erase a single test record or the entire directory of test records from

the WRM’s Flash EEPROM:

a. Start from the “START-UP” menu:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

Press the [2] key (SETUP).

b. The following screen will be displayed:

1. ENTER XFMR ID

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the [3] key (RESTORE RECORD).

c. The following screen will be displayed:

1. RESTORE RECORD

2. DIRECTORY

3. ERASE RECORDS

Press the [3] key (ERASE RECORDS).

d. The following screen will be displayed:

ERASE RECORD

1. ERASE SINGLE REC.

2. ERASE ALL RECORDS

You can cancel the erase process by pressing the [STOP] key.

NOTE

1. ERASE SINGLE REC.

Press the [1] key (ERASE SINGLE REC.) to erase a single record. The following

screen will be displayed:

51

ERASE RECORD

NUMBER:

Page 56

WRM-10P AND WRM-40 USER’S MANUAL REV 3

Type the record number that you would like to erase, and then press the

[ENTER] key. The following screen will be displayed:

RECORD NUMBER 1

ERASED!

Press any key to return to the “START-UP” menu.

2. ERASE ALL RECORDS

Press the [2] key (ERASE ALL RECORDS) to erase all records stored in the WRM’s

Flash EEPROM. The following screen will be displayed:

ERASE ALL RECORDS!

Are you sure?

“ENTER” TO CONTINUE

If you would like to cancel the process, press the [STOP] key.

Press the [ENTER] key to erase all test records. The following screen will be

displayed when all the test records have been erased:

RECORDS ERASED!

Press any key to return to the “START-UP” menu.

52

Page 57

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

3.10 Enabling the Computer Interface

The Computer Interface Mode is used to transfer test records from the WRM’s Flash EEPROM

to a PV via the RS-232C port. To use this mode, first run the provided PC software and then

connect the PC to the RS-232C port on the WRM. Then follow the steps below to enable the

WRM’s computer interface:

a. Start from the “START-UP” menu:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

Press the [2] key (SETUP).

b. The following screen will be displayed:

1. ENTER XFMR ID

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the [4] key (NEXT PAGE).

c. The following screen will be displayed:

1. COMPUTER CONTROL

2. SET TIME

3. VOLTAGE REG. TEST

Press the [1] key (COMPUTER CONTROL).

d. The following screen will be displayed, indicating that the WRM’s computer interface is

enabled:

COMPUTER ITF MODE

Press the

[STOP] key to disable the computer interface mode and return to the

“START-UP” menu.

53

Page 58

3.11 Setting the Date and Time

To set the date and time:

a. Start from the “START-UP” menu:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

WRM-10P AND WRM-40 USER’S MANUAL REV 3

Press the

[2] key (SETUP).

b. The following screen will be displayed:

1. ENTER XFMR ID

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the

[4] key (NEXT PAGE).

c. The following screen will be displayed:

1. COMPUTER CONTROL

2. SET TIME

3. VOLTAGE REG. TEST

Press the [2] key (SET TIME).

d. The following screen will be displayed:

ENTER

MM-DD-YY HH:MM:SS

Type in the date and time using the alpha-numeric keypad. When the complete date

and time has been entered, you will be immediately returned to the “START-UP” menu.

54

Page 59

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

4.0 WRM-10P/40 SPECIAL FEATURES

4.1 Bypassing Resistance Reading Delay

When the WRM first applies the test voltage to the transformers winding, the current is

increased slowly until the transformer’s winding reaches saturation. During this period, the

resistance value varies substantially and the readings may appear unstable to the operator. The

WRM has a built-in 3 minute delay between the start of the test and when the resistance value

is displayed on the LCD. This feature eliminates the possibility of early erroneous readings.

Depending on the transformer size, the delay may be shorter or longer than 3 minutes.

The operator can bypass this delay and observe the test results immediately. To bypass this

delay:

Start at the “START-UP” menu:

1. TEST XFMR 11/02/09

2. SETUP 12:33:01

3. USER DIAG

Press the numbers [9], [8], and [7] in sequence. The following screen will be displayed

momentarily:

QUICK DISPLAY MODE

SET!

You will then be returned to the “START-UP” menu.

Once the Quick Display Mode has been set, the WRM will display resistance values as soon as

measurements are made. This bypass setting will remain active until the unit is turned off.

When the unit is turned on again, it will use the default 3 minute delay before displaying

resistance values.

55

Page 60

WRM-10P AND WRM-40 USER’S MANUAL REV 3

4.2 Converting Resistance Measurements

The WRM can convert the resistance reading of the device under test at its present

temperature to the equivalent resistance value at a different temperature. The conversion is

accomplished by the following formula:

Rs = Rm (Ts + Tk) / (Tm + Tk)

Where:

Rs is the resistance at desired temperature

Rm is the measured resistance

Ts is the desired reference temperature

Tm is the temperature at which the resistance was measured

Tk is the constant used for the winding material

Tk = 234.5 for copper

Tk = 240.0 for aluminum

56

Page 61

REV 3 WRM-10P AND WRM-40 USER’S MANUAL

5.0 Troubleshooting Guide

PROBLEM DESCRIPTION Probable Cause Suggested Solution

No current displayed on

the LCD screen when

performing a test.

Resistance reading is zero

or invalid while current

value is displayed on the

LCD screen.

• Opened current cable connection.

Opened transformer windings.

•

• Opened sense leads connection.

• Sense leads problem.

• Check current cable connection.

• Perform a quick test using a shunt

or a piece of aluminum bar.

• Check sense leads connection to

D.U.T.

• Check sense leads using an

ohmmeter.

• Perform a diagnostic test. See

section 3.8.

57

Page 62

1520 S. Hellman Ave • Ontario, CA 91761 • USA

Phone: 909-923-9390 • Fax: 909-923-9391

www.vanguard-instruments.com

Copyright © 2009 by Vanguard Instruments Company, Inc.

WRM-10 User’s Manual • Revision 2.0 • June 5, 2009 • TA

Loading...

Loading...