Page 1

TM

WRM-10

TRANSFORMER WINDING RESISTANCE METER

USER’S MANUAL

Vanguard Instruments Company, Inc.

1520 S. Hellman Ave.

Ontario, California 91761, USA

TEL: (909) 923-9390

FAX: (909) 923-9391

June 2009

Revision 2

Page 2

WRM-10 USER’S MANUAL REV 2

SAFETY SUMMARY

FOLLOW EXACT OPERATING PROCEDURES

Any deviation from the procedures described in this User’s Manual may create one or more

safety hazards, may damage the WRM-10, damage the test transformer, or cause errors in the

test results. Vanguard Instruments Company, Inc. assumes no liability for unsafe or improper

use of the WRM-10.

All safety precautions provided in this manual must be observed during all phases of testing

including test preparation, test lead connection, actual testing, and test lead disconnection.

SAFETY WARNING AND CAUTIONS

The WRM-10 shall be used only by trained operators. All transformers under test shall be offline and fully isolated.

DO NOT MODIFY TEST EQUIPMENT

To avoid the risk of introducing additional or unknown hazards, do not install substitute parts or

perform any unauthorized modification to any WRM-10 test unit. To ensure that all designed

safety features are maintained, it is highly recommended that repairs be performed only by

Vanguard Instruments Company factory personnel or by an authorized repair service provider.

Unauthorized modifications can cause safety hazards and will void the manufacturer’s

warranty.

WARNING

Do not remove test leads during a test. Failure to heed this warning can result in lethal

electrical shock to personnel and damage to the equipment.

i

Page 3

REV 2 WRM-10 USER’S MANUAL

TABLE OF CONTENTS

CONVENTIONS USED IN THIS DOCUMENT ..................................................................................... 1

1.0 INTRODUCTION .................................................................................................................. .. 2

1.1 General Description and Features ................................................................................... 2

1.3 Technical Specifications ................................................................................................... 3

1.4 WRM-10 Controls and Indicators .................................................................................... 4

2.0 PRE-TEST SETUP ................................................................................................................... 6

2.1 Operating Voltages .......................................................................................................... 6

3.0 OPERATING PROCEDURES ................................................................................................... 9

3.1 WRM-10 Cable Connections ............................................................................................ 9

3.2 General Procedures ....................................................................................................... 11

3.3 Performing Transformer Tests ....................................................................................... 12

3.3.1. Performing a Single Resistance Test ...................................................................... 12

3.3.2. Performing a Voltage Regulator Test ..................................................................... 14

3.4 User Diagnostic Mode .................................................................................................... 16

LIST OF FIGURES

Figure 1. WRM-10 Controls and Indicators .................................................................................... 4

Figure 2. 100 – 120 Vac Jumper Settings ........................................................................................ 6

Figure 3. 200 – 240 Vac Jumper Settings ........................................................................................ 6

Figure 4. Relay Location .................................................................................................................. 7

Figure 5. Typical WRM-10 Connections Diagram #1 ...................................................................... 9

Figure 6. Typical WRM-10 Connections Diagram #2 .................................................................... 10

Figure 7. Typical Dual Winding Connections Diagram .................................................................. 10

LIST OF TABLES

Table 1. WRM-10 Technical Specifications ..................................................................................... 3

Table 2. Functional Descriptions of WRM-10 Controls and Indicators .......................................... 5

Table 3. Voltage Selection Jumper Settings .................................................................................... 6

ii

Page 4

WRM-10 USER’S MANUAL REV 2

CONVENTIONS USED IN THIS DOCUMENT

This document uses the following conventions:

• The WRM-10’s control knob is referenced as [CONTROL KNOB]

Menu names are referenced as “MENU NAME”

•

• WRM-10 LCD screen output is shown as:

MAIN MENU

<RUN TEST>

• Warning messages are indicated as:

Warning message

WARNING

• Important notes are indicated as:

Note details

NOTE

1

Page 5

REV 2 WRM-10 USER’S MANUAL

1.0 INTRODUCTION

1.1 General Description and Features

The WRM-10 is designed to accurately measure the winding resistance of highly inductive

power transformers. The unit’s dual resistance-reading input channels can measure two

winding resistances simultaneously. Four-wire (Kelvin) connections provide high accuracy

voltage reading and require no lead compensation. The WRM-10 provides stable resistance

readings of very large transformers by utilizing a 36 Vdc power supply capable of outputting up

to 10 Amperes. The resistance reading of a 100MVA transformer can be achieved in 5 minutes

or less. The unit’s power supply is cooled by heavy-duty fans designed for continuous

operation.

Since the WRM-10 can accurately measure resistances ranging from 1 micro-ohm to 2,000

ohms, it can also be used to measure EHV circuit-breaker contact resistance, motor winding

resistance, or any low resistance. In addition to measuring the resistance value, the WRM-10

also checks the “make-before-break” tap-switching sequences of voltage regulators and load

tap changers.

The WRM-10 is furnished with three 50-foot test cables, a ground cable, a power cord, and a

cable carrying bag. Each test cable lead is terminated with a quick-disconnect test clip.

1.2 Functional Description

The WRM-10’s operation is based on the electrical relationship described by Ohm’s law: R=V/I,

where I is a known current and V is the DC voltage measured across the unknown resistance.

The value of the unknown resistance is calculated by dividing the measured voltage by the

current which is calculated by the microprocessor. Calculated resistance readings are then

displayed on the unit’s back-lit LCD screen.

A special current source allows the WRM-10 to output up to 10 Amperes of test current. The

test current is automatically adjusted depending on the load resistance. For added safety, the

current source circuit is thermally protected. Also, a built-in discharge circuit automatically

discharges the stored energy in the transformer at the end of each test.

2

Page 6

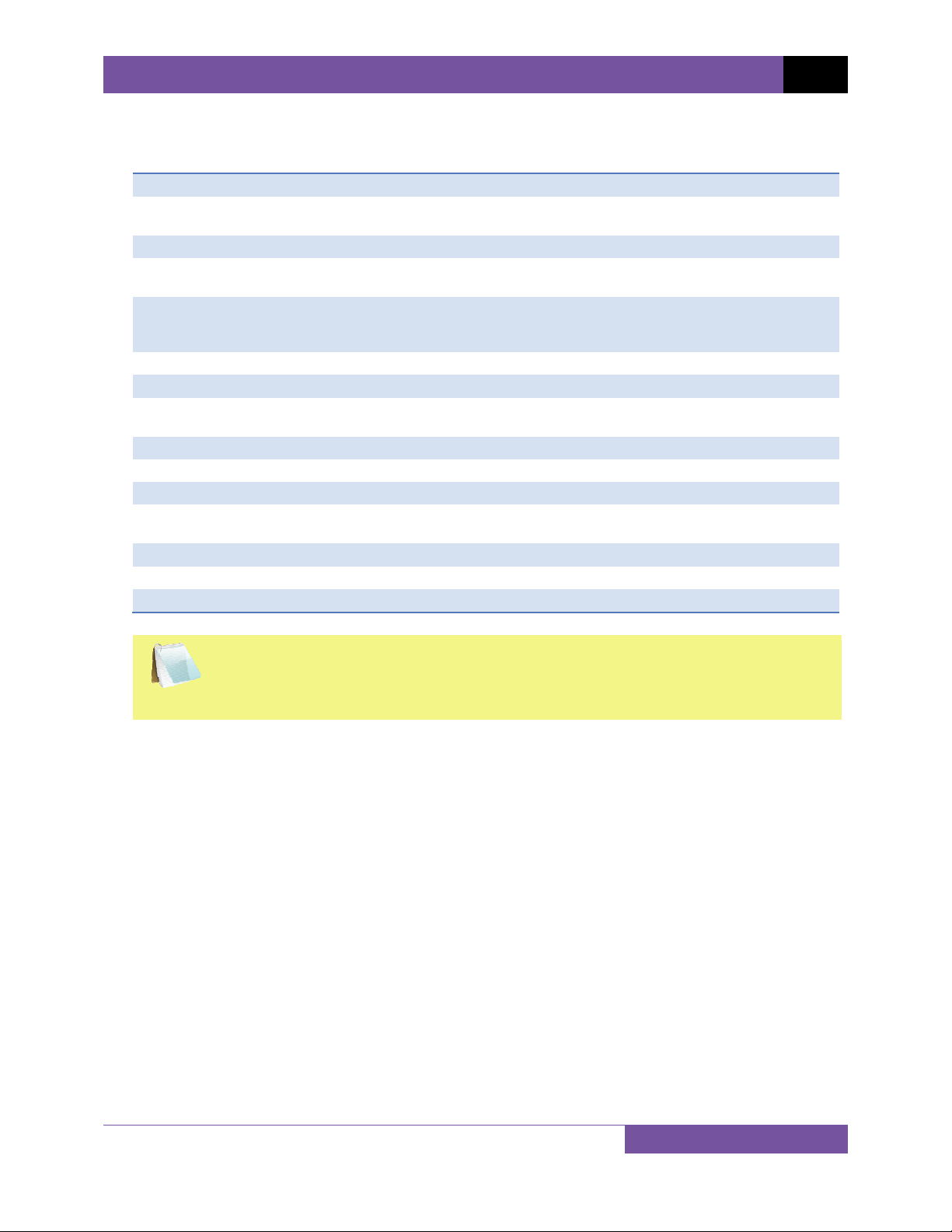

1.3 Technical Specifications

Table 1. WRM-10 Technical Specifications

TYPE Portable transformer winding resistance meter

PHYSICAL SPECIFICATIONS 16.8”W x 12.6”H x 10.6”D (42.6 cm x 32.0 cm x 27 cm); Weight: 27 lbs

(12.2 kg)

INPUT POWER 100 – 120 Vac or 200-240 Vac (factory pre-set), 50/60 Hz

RESISTANCE READING

RANGE

ACCURACY 1 – 19,999 micro-ohms: ±0.5% reading, ±1 count

TEST VOLTAGE 36 Vdc max

TEST CURRENT RANGE Auto range, 10 Amperes max

DISPLAY Back-lit LCD Screen (16 characters by 2 lines); viewable in bright sunlight

CONTROL Single “turn-and-push” knob

COMPUTER INTERFACE RS-232C port (19,200 baud) used for factory calibration and diagnostics

SAFETY Designed to meet IEC61010 (1995), UL61010A-1, CSA-C22.2 standards

ENVIRONMENT Operating: -10˚C to 50˚ C (15˚F to +122˚ F); Storage: -30˚ C to 70˚ C (-

CABLES Three 50-foot test cables, ground cable, power cord and cable bag

OPTIONS Transportation case

WARRANTY One year on parts and labor

1 micro-ohm – 2,000 ohms

20 – 999 milli-ohms: ±1% reading, ±1 count;

1 – 2,000 ohms: ±1.5% reading, ±1 count

and low-light levels

22˚F to +158˚ F)

WRM-10 USER’S MANUAL REV 2

NOTE

The above specifications are valid at nominal operating voltage and at a

temperature of 25°C (77°F). Specifications may change without prior notice.

3

Page 7

REV 2 WRM-10 USER’S MANUAL

1.4 WRM-10 Controls and Indicators

The WRM-10’s controls and indicators are shown in Figure 1 below. A leader line with an index

number points to each control and indicator, which is cross-referenced to a functional

description in Table 2. The table describes the function of each item on the control panel. The

purpose of the controls and indicators may seem obvious, but users should become familiar

with them before using the WRM-10. Accidental misuse of the controls will usually cause no

serious harm. Users should also be familiar with the safety summary found on the front page of

this User’s Manual.

4

Figure 1. WRM-10 Controls and Indicators

Page 8

WRM-10 USER’S MANUAL REV 2

Table 2. Functional Descriptions of WRM-10 Controls and Indicators

Item

Number

1

2

3

4

5

6

7

8

9

10

Panel Markings Functional Description

V1

I Current output. Female connector jacks used for connecting current test leads.

None

GROUND

100-120 Vac. 2A,

50-60 Hz

Fuse: 250 Vac, 3A

Slow-Blow

RS-232C

DISCHARGE

CHANGE

“PUSH” TO

SELECT

HIGH VOLTAGE

PRESENT

V2

Voltage sensing input channel #1. Female connector jacks used for connecting

voltage-sensing test leads.

Back-lit LCD screen (16 characters by 2 lines); viewable in bright sunlight and

low-light levels.

Safety ground terminal. 5/16-18 threaded stud with hand-turned wing nut. This

must be connected to the station ground before connecting any WRM-10 test

leads to the transformer.

Input power connector with third-wire safety ground. On/Off rocker toggle switch

with built-in fuse protection.

9-pin RS-232C interface port; female DB type. Data rate is set to 19,200 baud,

1 start bit, 2 stop bits, 8 data bits and no parity bit.

Pin Signal

2 RX

3 TX

5 Signal Ground

Red LED indicator light. This warning indicator is lit when the WRM-10 is

discharging the stored energy in the transformer. Do NOT disconnect the test

leads when this light is on. Failure to heed this warning can result in

shock and/or fatal injury to personnel.

Single turn-and-press control knob used to operate the WRM-10. You can scroll

through different menu options by turning this knob, and you can select a

function by pressing the knob.

Red LED indicator light. This warning light is illuminated when there is a

possibility of high voltage across the test leads. Do NOT disconnect the test

leads when this light is on. Failure to heed this warning can result in

shock and/or fatal injury to personnel.

Voltage input sensing channel #2. Female connector jacks used for connecting

voltage-sensing test leads.

5

Page 9

REV 2 WRM-10 USER’S MANUAL

2.0 PRE-TEST SETUP

2.1 Operating Voltages

The WRM-10’s operating voltage is preset at the factory and is selectable between 100-120

Vac, 50/60 Hz or 200-240 Vac, 50/60 Hz. The voltage is set by placing jumper(s) on the power

terminal block as listed in Table 3 and illustrated in Figure 2 and Figure 3. The relay must also be

changed if the voltage settings are changed. Please see Figure 4 for the location of the relay.

Table 3. Voltage Selection Jumper Settings

Voltage

Selection

100 – 120 Vac

200 – 240 Vac

Terminal Block Jumpers

Brown to Blue and Yellow to Green HE2aN-Q-AC120V

Blue to Yellow HE2aN-Q-AC-240V

Figure 2. 100 – 120 Vac Jumper Settings

Relay

Part Number

6

Figure 3. 200 – 240 Vac Jumper Settings

Page 10

WRM-10 USER’S MANUAL REV 2

Figure 4. Relay Location

7

Page 11

REV 2 WRM-10 USER’S MANUAL

2.2 LCD Screen Contrast Control

To adjust the LCD screen’s contrast:

a. Start from the “MAIN MENU”:

MAIN MENU

<RUN TEST>

Turn the [CONTROL KNOB] till the following screen is displayed:

MAIN MENU

<ADJ CONTRAST>

Press the [CONTROL KNOB].

b. The following screen will be displayed:

ADJ CONTRAST

“PUSH” = DONE

Turn the [CONTROL KNOB] clockwise to increase the contrast (darken the screen).

Turn the [CONTROL KNOB] counter-clockwise to decrease the contrast (lighten the

screen).

Press the [CONTROL KNOB] when you are done adjusting the contrast level. You will

be returned to the “MAIN MENU”.

8

Page 12

WRM-10 USER’S MANUAL REV 2

3.0 OPERATING PROCEDURES

3.1 WRM-10 Cable Connections

Typical WRM-10 connections diagrams are shown in Figure 5 and Figure 6. A typical dual

winding connections diagram is shown in Figure 7.

Do not touch or disconnect any test lead that is connected to a transformer

terminal while high current is being conducted during a test. Failure to heed this

WARNING

warning can result in lethal electric shock to personnel and/or damage to the

equipment.

WARNING

Figure 5. Typical WRM-10 Connections Diagram #1

Disconnect the test clips from the transformer bushing only after the WRM-10

has completely discharged the transformer. Always disconnect the test clips

slowly from the transformer bushing to prevent an accidental flash-over.

9

Page 13

REV 2 WRM-10 USER’S MANUAL

Figure 6. Typical WRM-10 Connections Diagram #2

The above figure illustrates the simultaneous testing of both the high and low

windings on a single-phase transformer. When measuring two channels, the above

NOTE

cable connection is recommended since it will speed up the testing process.

Figure 7. Typical Dual Winding Connections Diagram

10

Page 14

WRM-10 USER’S MANUAL REV 2

3.2 General Procedures

The main steps for using the WRM-10 are outlined below:

a. Ground the WRM-10 to the substation ground.

Always connect the WRM-10 to the substation ground before connecting

any test lead to any transformer bushing. Failure to follow this procedure

WARNING

may damage the WRM-10.

b. Plug the WRM-10 power cable into a power outlet.

c. Insert current-cable plugs and voltage-sensing cable plugs into the corresponding

control panel jacks.

d. Attach the test cable clamps to the transformer terminal for the winding that is to be

measured.

e. Turn on the WRM-10 by pressing [I] on the power rocker switch.

f. The unit will self-calibrate, and then you will be presented with the “MAIN MENU” as

shown below:

MAIN MENU

<RUN TEST>

11

Page 15

REV 2 WRM-10 USER’S MANUAL

3.3 Performing Transformer Tests

3.3.1. Performing a Single Resistance Test

a. Start from the “MAIN MENU”:

MAIN MENU

<RUN TEST>

Press the [CONTROL KNOB].

b. The following screen will be displayed:

RUN TEST

<V1 & V2>

Turn the [CONTROL KNOB] till the following screen is displayed:

RUN TEST

<V1 ONLY>

Press the [CONTROL KNOB].

c. The following screen will be displayed:

FLASH-OVER IF

CABLES REMOVED!

Press the [CONTROL KNOB].

d. The following screen will be displayed:

“PRESS” TO START

“TURN” TO ABORT

Press the

[CONTROL KNOB].

[CONTROL KNOB] to start the test. You can abort the test by turning the

e. The following screen will be displayed:

*XFMR CHARGING

The above screen will continue to display while the WRM-10 is performing the test (the

lightning bolts will be flashing). When the WRM-10 has determined that the resistance

readings are stable, the test results will be displayed as shown:

R1 = 10.0 mΩ

R2 = 10.5 mΩ

12

Page 16

WRM-10 USER’S MANUAL REV 2

The WRM-10 will continue to apply the test voltage on the transformer’s windings and

update the resistance values on the LCD screen. Press the [CONTROL KNOB] to stop

the test.

f. The WRM-10 will automatically discharge the transformer and display the following

screen during the discharging process:

DISCHARGE XFMR!

PLEASE WAIT...

After the transformer is discharged, the test results will be displayed on the screen as

shown:

R1 = 10.0 mΩ

R2 = 10.5 mΩ

Press the [CONTROL KNOB]. You will be returned to the “MAIN MENU”.

13

Page 17

REV 2 WRM-10 USER’S MANUAL

3.3.2. Performing a Voltage Regulator Test

The Voltage Regulator Test verifies that a regulating switch in a primary voltage tap regulator

changes contacts through its selection range without a break in the circuit. This test is

important because in actual use, any break in the current in a regulating tap switch generates

large reactive voltage spikes that are hazardous and may exceed the switch’s voltage ratings,

thus causing irreparable damage. By connecting the WRM-10’s continuity test input across the

switching input and running the regulator switch through all the contacts in its range, any break

in continuity caused by faulty tap switching can be detected.

To perform a voltage regulator test:

a. Start from the “MAIN MENU”:

MAIN MENU

<RUN TEST>

Press the [CONTROL KNOB].

b. The following screen will be displayed:

RUN TEST

<V1 & V2>

Turn the [CONTROL KNOB] till the following screen is displayed:

RUN TEST

<VTG REG>

Press the [CONTROL KNOB].

c. The following screen will be displayed:

FLASH-OVER IF

CABLES REMOVED!

Press the [CONTROL KNOB].

d. The following screen will be displayed:

VTG REG TEST

“PUSH” TO START

Press the

[CONTROL KNOB] to start the test.

14

Page 18

WRM-10 USER’S MANUAL REV 2

e. The following screen will be displayed while the test is being performed:

*XFMR CHARGING*

After the transformer has been charged, the following screen will be displayed:

V REG. TEST

RUN TAPS NOW

Run the voltage regulator tap switch.

f. If no transient is detected as the taps are switching:

1. The screen display will not change

2. Turn or press the [CONTROL KNOB] to end the test. The following screen will

be displayed:

NO TRANSIENT

DETECTED

If a switch break is detected:

1. The following message will be displayed:

TRANSIENT

DETECTED

2. Turn or press the [CONTROL KNOB] to end the test.

15

Page 19

REV 2 WRM-10 USER’S MANUAL

3.4 User Diagnostic Mode

The user diagnostic mode can be used to monitor the V1 and V2 voltages and the test current

on the WRM-10’s LCD screen. To use the WRM-10 in user diagnostic mode:

a. Connect the WRM-10 to the test transformer, and then start from the “MAIN MENU”:

MAIN MENU

<RUN TEST>

Turn the [CONTROL KNOB] till the following screen is displayed:

MAIN MENU

<USER DIAG>

Press the [CONTROL KNOB].

b. The following screen will be displayed:

RUN TEST

<V1 & V2>

Turn the [CONTROL KNOB] till the following screen is displayed:

FLASH-OVER IF

CABLES REMOVED!

Press the [CONTROL KNOB].

c. The following screen will be displayed:

“PRESS” TO START

“TURN” TO ABORT

Press the

[CONTROL KNOB] to start the test.

d. The following screen will be displayed momentarily:

CALIBRATING

PLEASE WAIT...

The WRM-10 will then alternate between displaying the following screens:

V1 = 1.03V

I = 00.005A

V2 = 1.03V

I = 00.005A

e. Press or turn the [CONTROL KNOB] to end the test. You will be returned to the

“MAIN MENU”.

16

Page 20

1520 S. Hellman Ave • Ontario, CA 91761 • USA

Phone: 909-923-9390 • Fax: 909-923-9391

www.vanguard-instruments.com

Copyright © 2009 by Vanguard Instruments Company, Inc.

WRM-10 User’s Manual • Revision 2.0 • June 5, 2009 • TA

Loading...

Loading...