Page 1

Job __________________________

Item No ______________________

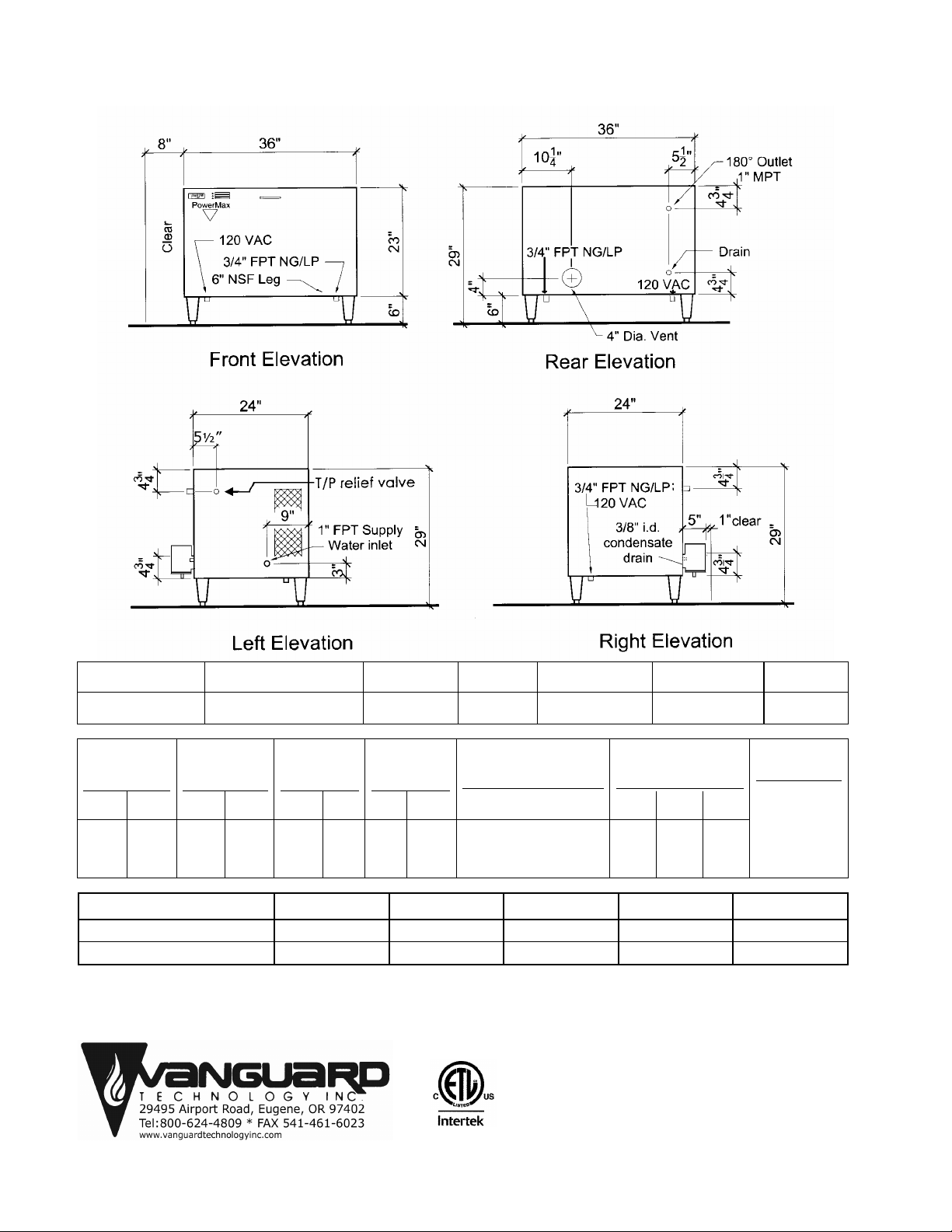

PowerMax200TM Gas Booster Heater

` Model: PM200N

Temperature Rise

Gallons per Minute

Gallons per Hour

FEATURES AND BENEFITS

• Single point water, gas and electrical connections

• Factory-provided pressure and temperature relief

valve

• Space saving design installs below dishtables

• Can be installed in a remote location up to 150

feet from the scullery

• All waterways constructed of stainless steel,

copper and brass for corrosion protection and

clean operation

• Simple, easy maintenance through front panel

• All stainless steel cabinet and frame

• Instant 1850F water provided consistently to

dishwasher rinse cycle

• Welded stainless steel accumulator (limited

lifetime warranty) maintains rinse water at 1850F

• Woven Fiber Power Burner

Printed in USA R06/15

400 Rise 500 Rise 600 Rise 700 Rise 1400 Rise

8.7 7.0 5.5 5.0 2.5

520 420 330 300 150

• Radial solid copper fin-tube heat exchanger for

3600 heat transfer

• Cleanable intake air filter

• Burners activated by water flow & temperature

• Advanced microprocessor controls

• Natural Gas or Liquid Propane 199,900 BTUH

• Can provide 100% of hot water requirement for

many restaurants

ACCESSORIES AND OPTIONS

(available at additional cost)

□ EZ-Vent Kit for Venting through dishwasher

ventilation system

□ Factory Authorized StartUp

□ Re-circulating kit required if booster is located

more than 5 ft from dishwasher rinse valve

□ ¾-1” for remote installations and/or single tank hot

water coil tank heat (also requires a CT-1 module)

□ 1-¼” for long distance remote installations and/or 2

tank hot water coil tank heat and/or 2 dishwasher

rinse service (also requires CT-2 module)

□ Wall Mount Kit

□ Water Hammer Arrester

□ Water Pressure Gauge

□ Water Temperature Gauge

□ Water Pressure/Temperature Gauge

□ High Pressure water pressure reducing valve

(needed if water supply pressure exceeds

80psi)

□ Low Pressure water pressure reducing valve

(for dishwasher rinse; installed after booster &

before D/W rinse)

□ Auxiliary PowerVent required for extended

flue lengths. Call factory

□ Stainless Steel Legs

□ Seismic Stainless Steel Legs

□ EZ Install Kit

□ Expansion Tank

TM

or PM200L

TM

Page 2

PowerMax200TM – High Output Gas Booster Heater

Model: PM200NTM or PM200L

TM

Model Number

PM200

Natural Gas

Pressure

WC @ Inlet

Min M ax Min Max Nat LP Min Max

7” 10.5” 10” 14”

Gallons Per Minute 8.7 7 5.5 5 2.5

*Contact factory if booster will be supplying dishwasher fill valves or tank heat.

TM

Temperature Rise 40oF 50oF 60oF 70oF 140oF

Gallons Per Hour 520 420 330 300 150

BtuH per burner

Natural or Propane

199,900 3/4" NPT 1" NPT

LP Gas

Pressure

WC @ Inlet

2.75”

Manifold

Pressure

WC

-

3.5”

6.5”

-

8”

Gas

Connection

Water

Pressure

(Flow)

40

psi

80

psi

Water

Supply

Dishwasher Rinse

Re-circulating

3/4" or 1" NPT*

Required if outlet is

more than 5 feet from

rinse valve of

dishwasher

Electrical

Connection

120V 1ph 6.2

amps

Loop

Gas Pressure

Regulators

One each

Supplied

Clearance From

Combustible

Surface

Side Top Rear

6” L

1” R

1”

6”**

Shipping

Weight

468 lbs

Vent Per

Local Code

Auxiliary

Power Vent

Required for

extended flue

lengths Call

factory

**1” from back of exhaust vent

Note: May be vented through the dishwasher canopy or pant-leg exhaust system per 1991

Uniform Mechanical Code Sec 916. & 917. Check with local authority

Printed in USA R07/15

Page 3

2 9 49 5 A ir po r t R oa d, E u g e n e, O R 9 7 4 0 2

T o ll F re e:

1 - 8 00 - 62 4 -4 8 0 9

T el:( 5 41 ) 4 6 1 -6 02 0 F ax :(5 4 1) 4 6 1 -6 0 23

PowerMax200

TM

Gas Booster Heater specification

Booster heater shall be a PowerMax200TM gas booster water heater, Model

PM200TM as manufactured by Vanguard Technology Inc., Eugene, OR 97402.

Booster to be fired by a 199,900 Btu woven fiber power burner, using natural gas

or liquid propane fuel. Burner to be ignited by means of a hot surface igniter and

a redundant intermittent pilot. Heat exchanger to be of heavy duty finned copper

tubing, .065” thickness and carry a 5 year limited warranty. Standard equipment

to include gas pressure regulating valve, internal bronze-stainless re-circulation

pump, integrated solid state temperature control, temperature and pressure relief

valve, cleanable intake air filter, and LED temperature display. Booster frame,

body panels, accumulator tank, and flue collar shall be of all stainless steel

construction. Unit shall stand on 6 inch adjustable stainless or composite NSF

approved legs. The 4.8 gallon accumulator tank shall carry a limited lifetime

warranty. Stainless steel front panel to be removable for access to all

components without disconnecting booster from its installed location. Booster

Heater shall produce 520 gph @ 40oF∆T; 300 gph @ 70oF∆T. Booster to be rated

at 88%-94% operating efficiency, minimum. The PM200TM can be installed up to

150 feet from the dishwasher rinse valve when equipped with a Vanguard

circulation kit. The circulation loop shall be 3/4" to 1-1/2" copper (see manual),

insulated to a minimum of R-4. Loop to be furnished and installed by others.

When installed with a remote circulation loop or with 1 or 2 tank dishwasher hot

water heating coils, PowerMaxTM Booster will also include a CT1-C or CT-2-C

return connection kit. PowerMaxTM Booster may be vented through wall or roof,

or with optional S. S. EZ-Vent Kit, may be vented through the dishwasher

condensate hood or cowl vent system.

Printed in USA R06/15

Loading...

Loading...