Page 1

TM

IRM-5000P

INSULATION RESISTANCE METER

USER’S MANUAL

Vanguard Instruments Company, Inc.

1520 S. Hellman Ave.

Ontario, California 91761, USA

TEL: (909) 923-9390

FAX: (909) 923-9391

May 2010

Revision 2

Page 2

IRM-5000P USER’S MANUAL REV 2

SAFETY SUMMARY

FOLLOW EXACT OPERATING PROCEDURES

Any deviation from the procedures described in this User’s Manual may create one or more

safety hazards, may damage the IRM-5000P, or cause errors in the test results. Vanguard

Instruments Company, Inc. assumes no liability for unsafe or improper use of the IRM-5000P.

All safety precautions provided in this manual must be observed during all phases of testing

including test preparation, test lead connection, actual testing, and test lead disconnection.

SAFETY WARNINGS AND CAUTIONS

All devices under test shall be off-line and fully isolated.

The area around the IRM-5000P’s charging circuits and test terminals must be kept clean and

dry to prevent high-voltage leakage paths which can cause hazardous conditions or erroneous

measurements. Failure to heed these precautions may result in unsafe operating conditions,

cause erroneous test results, and will void the manufacturer’s warranty.

DO NOT MODIFY TEST EQUIPMENT

To avoid the risk of introducing additional or unknown hazards, do not install substitute parts or

perform any unauthorized modification to any IRM-5000P test unit. To ensure that all designed

safety features are maintained, it is highly recommended that repairs be performed only by

Vanguard Instruments Company factory personnel or by an authorized repair service provider.

Unauthorized modifications can cause safety hazards and will void the manufacturer’s

warranty.

WARNING

Do not remove test leads during a test. Failure to heed this warning can result in electrical

shock to personnel and damage to the equipment.

i

Page 3

REV 2 IRM-5000P USER’S MANUAL

TABLE OF CONTENTS

CONVENTIONS USED IN THIS DOCUMENT ..................................................................................... 1

1.0 INTRODUCTION .................................................................................................................. .. 2

1.1 General Description and Features ................................................................................... 2

1.2 Furnished Accessories ...................................................................................................... 4

1.3 Technical Specifications ................................................................................................... 5

1.4 IRM-5000P Controls and Indicators ................................................................................. 6

2.0 PRE-TEST SETUP ................................................................................................................... 8

2.1 Operating Voltages .......................................................................................................... 8

2.2 LCD Screen Contrast Control ............................................................................................ 9

2.3 Printer Paper Control ....................................................................................................... 9

2.4 Printer Paper .................................................................................................................... 9

3.0 OPERATING PROCEDURES ................................................................................................. 11

3.1 Performing Tests ............................................................................................................ 11

3.1.1. Entering Test Record Header Information ............................................................. 11

3.1.2. Performing an Insulation Resistance Test .............................................................. 14

3.1.3. Performing a Polarization Index Ratio (PI) Test ..................................................... 22

3.1.4. Performing a Step Voltage (SV) Test ...................................................................... 28

3.1.5. Performing a Dielectric Discharge (DD) Test .......................................................... 34

3.2 Working With Test Records ........................................................................................... 40

3.2.1. Saving a Test Record ............................................................................................... 40

3.2.2. Restoring a Test Record From Flash EEPROM ........................................................ 41

3.2.3. Printing a Test Record from the Working Memory ................................................ 42

3.2.4. Printing a Directory of Test Records Stored in the IRM-5000P’s Memory ............ 44

3.2.5. Erasing Test Records From the Flash EEPROM ...................................................... 46

4.0 CHANGING SETUP PARAMETERS ....................................................................................... 48

4.1 Setting the Clock ............................................................................................................ 48

4.2 Setting the Frequency .................................................................................................... 49

4.3 Setting the Temperature Units of Measure ................................................................... 50

4.4 Enabling the Computer Interface .................................................................................. 51

APPENDIX A - DIELECTRIC DISCHARGE RATIO TEST DESCRIPTION ............................................... 52

APPENDIX B - GUARD TERMINAL APPLICATION ........................................................................... 53

ii

Page 4

IRM-5000P USER’S MANUAL REV 2

LIST OF TABLES

Table 1. IRM-5000P Technical Specifications ................................................................................. 5

Table 2. Functional Descriptions of IRM-5000P Controls and Indicators ....................................... 7

Table 3. Voltage Selection Jumper Settings .................................................................................... 8

Table 4. PI Ratio Table ....................................................................................................... ............ 27

LIST OF FIGURES

Figure 1. IRM-5000P Controls and Indicators ................................................................................. 6

Figure 2. 100-120 Vac Jumper Settings ........................................................................................... 8

Figure 3. 200-240 Vac Jumper Settings ........................................................................................... 8

Figure 4. Resistance Test Results Report Printout ........................................................................ 20

Figure 5. Resistance Plot from a Resistance Test ......................................................................... 20

Figure 6. Current Plot from a Resistance Test .............................................................................. 21

Figure 7. Polarization Index Test Results Report Printout ............................................................ 26

Figure 8. Polarization Index Test Resistance Plot ......................................................................... 27

Figure 9. Polarization Index Test Current Plot .............................................................................. 27

Figure 10. Step Voltage Test Results Report Printout .................................................................. 32

Figure 11. Step Voltage Test Resistance and Current Plots .......................................................... 33

Figure 12. Dielectric Discharge Test Results Report Printout ....................................................... 37

Figure 13. Dielectric Discharge Test Resistance Plot .................................................................... 38

Figure 14. Dielectric Discharge Test Current Plot ......................................................................... 39

Figure 15. Typical Test Record Directory Printout ........................................................................ 45

iii

Page 5

REV 2 IRM-5000P USER’S MANUAL

CONVENTIONS USED IN THIS DOCUMENT

This document uses the following conventions:

• A key or switch on the IRM-5000P is indicated as [KEY] and [SWITCH].

Menu options are referenced as (MENU OPTION).

•

Screen and menu names are referenced as “SCREEN/MENU NAME”.

•

The terms “test record” and “test shot” are used interchangeably.

•

• IRM-5000P LCD screen output is shown as:

1. OPTION 1

2. OPTION 2

3. OPTION 3

4. OPTION 4

• When instructions are provided, the menu item that should be selected is shown in bold as

shown below (option 3 should be selected):

1. OPTION 1

2. OPTION 2

3. OPTION 3

4. OPTION 4

• Warning messages are indicated as:

Warning message

WARNING

• Important notes are indicated as:

Note details

NOTE

1

Page 6

IRM-5000P USER’S MANUAL REV 2

1.0 INTRODUCTION

1.1 General Description and Features

The IRM-5000P is a microprocessor-based, high-voltage, insulation-test ohmmeter. The rugged

and portable IRM-5000P is ideal for use in electric utility substations and for industrial

applications.

This sophisticated insulation tester uses a dual-microprocessor design. One microprocessor is

dedicated to the control of the power supply and measuring circuitry, while the second is

dedicated to the user interfaces and printer control. To ensure operator safety, the

microprocessors communicate via an optical link, thus isolating the operator controls from the

dangerous high test voltages inside the unit.

The IRM-5000P measures the insulation resistance of a test material by applying a known test

voltage and measuring the resultant leakage current. The measured insulation resistance is

then displayed on the back-lit LCD screen. The IRM-5000P’s built-in 2.5-inch wide thermal

printer can print test reports in both tabular and graphic formats. Up to 100 test reports can be

stored in the unit’s internal memory. Test reports can also be transferred to a PC via the built-in

RS-232C interface. The IRM-5000P can automatically perform industry-standard tests such as

Polarization Index (PI) test, Step Voltage (ST) test, and Dielectric Discharge (DDS) test.

Test Voltage

The IRM-5000P can perform tests with preset voltages (500, 1000, 2500, 5000 Vdc), or with

user-selectable voltages ranging from 50 Vdc to 5000 Vdc with a ±2 Vdc resolution.

Insulation Resistance Test

The test voltage for an insulation resistance test can be user-selected, and the test duration can

range from 1 to 90 minutes. The IRM-5000P will then collect resistance readings throughout the

selected test period. The resistance value, test voltage, leakage current, and capacitance are

displayed on the back-lit LCD screen. The tabulated test report can be printed on the built-in

2.5-inch wide thermal printer. The report can also be printed as a graph of the resistance over

time.

Polarization Index (PI) Test

The Polarization Index (PI) measures the ratio of insulation resistance after one minute and

then after ten minutes. The Polarization Index is derived from a ratio of the two periods, where

the resistance value at ten minutes is divided by the resistance value at one minute.

PI tests can be run at preset voltages (500, 1000, 2500, 5000 Vdc) or at a user-specified voltage

from 50 Vdc to 5000 Vdc. Test results can be printed in both tabular and graphic formats.

Step Voltage (SV) Test

The Step Voltage test is based on an ideal insulator producing the same resistance

measurement at all voltages. As an example, an insulator that is over-stressed will measure

lower resistance values at higher voltages. Accordingly, the resistances measured on an overstressed insulator at increasingly higher voltages (steps) will produce decreasingly lower

resistance values.

2

Page 7

REV 2 IRM-5000P USER’S MANUAL

The SV test measures insulation resistances in five equal voltage steps up to a final test voltage

of 2500 Vdc or 5000 Vdc. The voltage is stepped up in 1/5 increments of the final test voltage

every one minute, five minutes, or other user-defined time interval.

Dielectric Discharge (DDS) Test

The DDS test measures the dielectric absorption of an insulator. This test can be used to

diagnose an insulation problem in cases where multi-layered insulation is used. The default test

requires 30 minutes of applying full voltage followed by a one minute discharging of the Device

Under Test (DUT). The DD value is then calculated using the formula:

DD Ratio = Current after 1 minute (mA) / (Test Voltage X Capacitance)

Capacitor Discharge

After each test, the IRM-5000P automatically discharges any test voltage left on the test

material. An audible alarm and a message on the screen warn the operator of the shock hazard

during each discharging period.

Capacitance Display

The IRM-5000P automatically measures the capacitance of the device being tested. The

capacitance-measuring range is from 0.01 µF to 10.0 µF.

Volt Meter

The IRM-5000P can also be used to measure voltages. Measurable input voltage ranges from 50

V to 1250 V, AC or DC.

User Interface

The IRM-5000P features a back-lit LCD screen (20 characters by 4 lines) that is viewable in both

bright sunlight and low-light levels. A rugged, 16-key, membrane keypad is used to control the

unit.

Built-in Thermal Printer

The IRM-5000P’s built-in 2.5-inch wide thermal printer can print the test reports in both tabular

and graphic formats.

Internal Test Record Storage

The IRM-5000P can store up to 100 test records in Flash EEPROM. Test records can be retrieved

and printed on the built-in thermal printer, or they can be transferred to a PC via the unit’s RS232C interface.

Computer Interface

The IRM-5000P can be computer-controlled via its RS-232C interface. A Windows® XP/Vistabased analysis software application is provided with each unit. Using this software, test records

can be retrieved from the IRM-5000P and then stored on the PC for future analysis and report

generation. A special feature of the software can overlay several resistance curves on-screen

and can be used to monitor the resistance deterioration of a test material over time.

Additionally, test records can be exported in Microsoft® Excel format for further analysis.

3

Page 8

IRM-5000P USER’S MANUAL REV 2

Temperature Probe

A non-contacting, infrared, temperature sensor is provided with each unit for recording test

material temperatures.

Power Source

The IRM-5000P can operate continually for up to 6-hours using its internal rechargeable SLA

batteries, or it can be operated with an external power source.

1.2 Furnished Accessories

The IRM-5000P comes furnished with the following:

• One 6-foot cable set

• One 15-foot cable set

• One RS-232C Cable

• One power cord

• Cable carrying duffel bag

4

Page 9

REV 2 IRM-5000P USER’S MANUAL

1.3 Technical Specifications

Table 1. IRM-5000P Technical Specifications

TYPE Insulation resistance meter

PHYSICAL SPECIFICATIONS 19”W x 7”H x 15”D, (48 cm x 17 cm x 38 cm); Weight: 24lbs (10.9 kg)

INPUT POWER 100 – 120 Vac or 220 – 240 Vac (selectable), 50/60Hz

RESISTANCE READING

RANGE

(0°C to +30°C)

TEST VOLTAGE Selectable from 50Vdc – 5 KVdc, in 2 Vdc steps

OUTPUT VOLTAGE

ACCURACY

(0°C to +30°C)

SHORT CIRCUIT CURRENT 2 mA max

CURRENT READING RANGE

(0°C to +30°C)

CAPACITANCE READING

RANGE

(0°C to +30°C)

VOLTAGE READING RANGE

(0°C to +30°C)

CAPACITOR DISCHARGE Less than 2 Sec/μF, automatic at the end of test

HUM REJECTION 1mA per 1kv of test voltage, 2mA rms maximum

BATTERIES Two 12V, 2.0 Ah sealed lead acid batteries. Battery life: typical 6 hrs,

PRINTER Built-in 2.5-inch wide thermal printer can print test results in both tabulated

COMPUTER INTERFACE One RS-232C port

INTERNAL TEST RECORD

STORAGE

SAFETY UL Certified (UL 61010A-1), CAN/CSA Certified (C22.2 No. 1010.1-92)

ENVIRONMENT Operating: -10˚ to 50˚ C (15˚ to +122˚ F); Storage: -30˚ C to 70˚ C (-22˚ to

HUMIDITY (MAX) 90% RH @ 40˚ C (104˚ F) non-condensing

ALTITUDE (MAX) 2000m (6562 ft) to fully safety specifications

CABLES One 6-foot cable set, one 15-foot cable set, ground cable, power cord, cable

OPTIONS

WARRANTY One year on parts and labor

100 K-ohms – 1 M-ohm ±20%,

1 M-ohm – 1 T-ohm ±5%,

1 T-ohm – 5 T-ohm ±20% , 5kV

100 K-ohms – 1 M-ohm ±20%,

1 M-ohm – 100 G-ohms ±5%,

100 G-ohms – 500 G-ohms ±5%, 500 V

1 M-ohm – 10 G-ohms ±5%, 50 V

±2%, ±1v of selected voltage with load resistance greater than 100 MΩ

0.03 nA – 2 mA; Accuracy: ±5% ±0.2 nA

0.01 μF – 10.0 μF (Test voltage greater than 100V); Accuracy: ±5% ±0.03 μF

50 – 1250 Vac (rms) or dc; Accuracy: ±5%, ±1V

continuous testing. The IRM-5000P can be used while charging.

and graphic formats

Store up to 100 test records in Flash EEPROM

+158˚ F)

bag

Transportation Case

The above specifications are valid at nominal operating voltage and at a

temperature of 25°C (77°F). Specifications may change without prior notice.

NOTE

5

Page 10

IRM-5000P USER’S MANUAL REV 2

1.4 IRM-5000P Controls and Indicators

The IRM-5000P’s controls and indicators are shown in Figure 1 below. A leader line with an

index number points to each control and indicator, which is cross-referenced to a functional

description in Table 2. The table describes the function of each item on the control panel. The

purpose of the controls and indicators may seem obvious, but users should become familiar

with them before using the IRM-5000P. Accidental misuse of the controls will usually cause no

serious harm. Users should also be familiar with the safety summary found on the front page of

this User’s Manual.

Figure 1. IRM-5000P Controls and Indicators

6

Page 11

REV 2 IRM-5000P USER’S MANUAL

Table 2. Functional Descriptions of IRM-5000P Controls and Indicators

Item

Number

1

2

3

4

5

6

7

8

9

10

11

Panel Markings Functional Description

RS-232C RS-232C PC interface.

110-120 Vac, 2A,

50-60Hz

Fuse: 250Vac, 3A

Fast-Blow

HIGH VOLTAGE

PRESENT

CHARGE Battery charging indicator.

Built-in 2.5-inch wide thermal printer.

POWER Power switch.

Rugged alpha-numeric keypad.

NEG Negative test lead terminal.

GUARD Guard test lead terminal.

POS Positive test lead terminal.

Power plug and fuse holder.

Test voltage presence indicator.

Back-lit LCD Screen (20 characters by 4 lines). Viewable in both bright sunlight

and low-light levels.

7

Page 12

IRM-5000P USER’S MANUAL REV 2

2.0 PRE-TEST SETUP

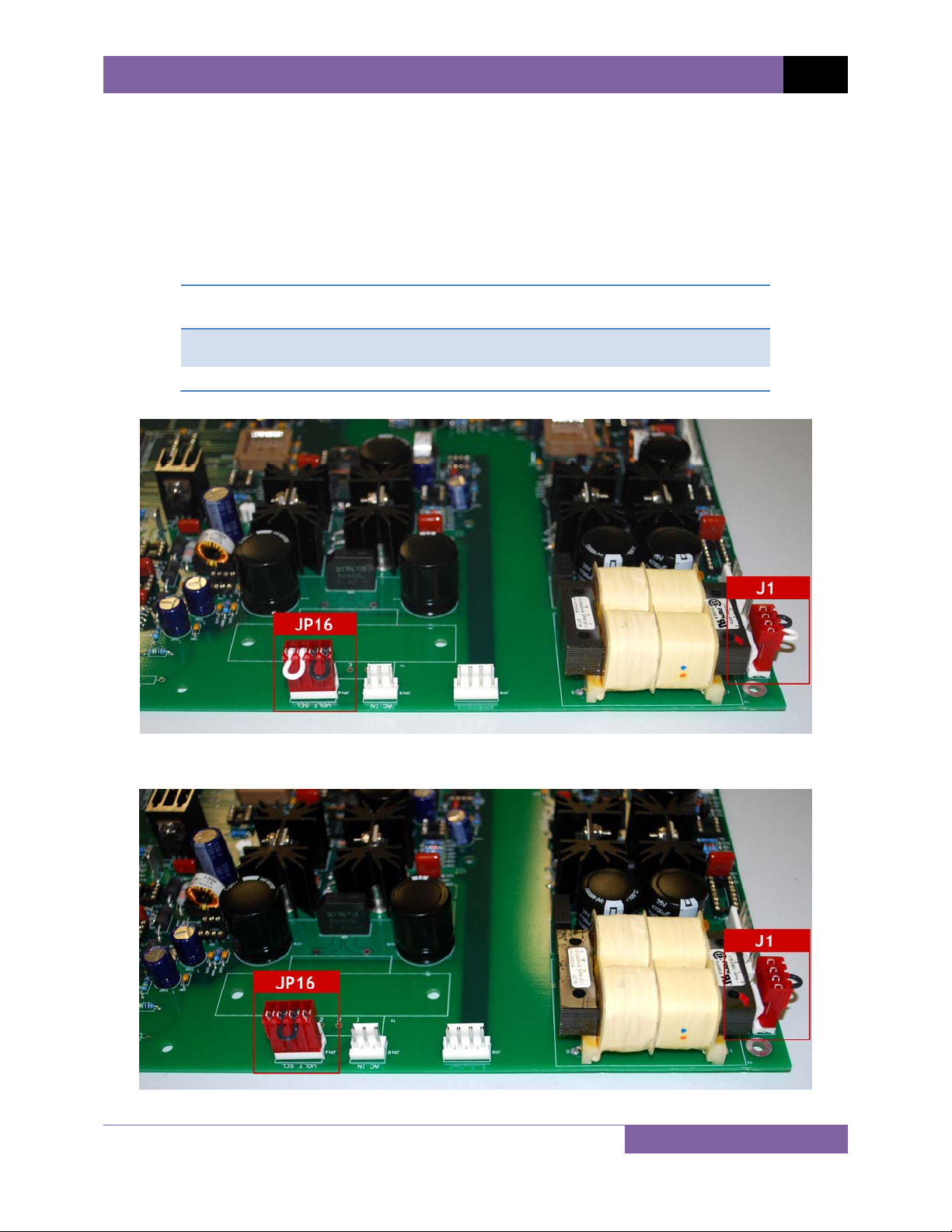

2.1 Operating Voltages

The IRM-5000P’s operating voltage is preset at the factory and is selectable between 100-120

Vac, 50/60 Hz or 200-240 Vac, 50/60 Hz. The voltage is set by placing jumpers at the JP16 and J1

jumper blocks on the main board as listed in Table 3 and illustrated in Figure 2 and Figure 3.

Table 3. Voltage Selection Jumper Settings

Voltage

Selection

100 – 120 Vac

200 – 240 Vac

JP16 Settings

Jumper Pin 1 and 2

Jumper Pin 3 and 4

Jumper Pin 2 and 3 Jumper Pin 2 and 3

Figure 2. 100-120 Vac Jumper Settings

J1 Settings

Jumper Pin 1 and 2

Jumper Pin 3 and 4

Figure 3. 200-240 Vac Jumper Settings

8

Page 13

REV 2 IRM-5000P USER’S MANUAL

2.2 LCD Screen Contrast Control

To increase the LCD screen contrast, press and hold the [PAPER ∧ Contrast] key for two

seconds. Release the button when the desired contrast level has been reached.

To decrease the LCD screen contrast, press and hold the [PAPER ∨ Contrast] key for two

seconds. Release the button when the desired contrast level has been reached.

2.3 Printer Paper Control

To advance the thermal printer paper, press and release the [PAPER ∧ Contrast] key.

To retract the thermal printer paper, press and release the [PAPER ∨ Contrast] key.

2.4 Printer Paper

The IRM-5000P’s built-in thermal printer uses 2.5-inch wide thermal paper for printing test

results. To maintain the highest print quality and to avoid paper jams, the use of thermal paper

supplied by Vanguard Instruments Company is highly recommended. Additional paper can be

ordered from the following sources:

Vanguard Instruments Co, Inc.

1520 S. Hellman Avenue

Ontario, CA 91761

Tel: 909-923-9390

Fax: 909-923-9391

Part Number: VIC TP-3 paper

BG Instrument Co.

13607 E. Trent Avenue

Spokane, WA 99216

Tel: 509-893-9881

Fax: 509-893-9803

Part Number: VIC TP-3 paper

9

Page 14

IRM-5000P USER’S MANUAL REV 2

2.5 Replacing the Thermal Printer Paper

The roll of thermal paper is housed inside a dispenser underneath the printer cover. To replace

the paper, follow the steps below:

• Unscrew the two large printer cover screws and remove the printer cover.

• Remove the leftover thermal paper roll from the paper holder.

• Unroll the new thermal paper roll.

• Feed the thermal paper into the slot between the paper pocket and the rubber roller.

The printer will automatically pull the paper under the thermal head.

• Place the paper roll into the paper holder.

• Lift the thermal head and align the thermal paper if necessary.

• Re-install the printer cover.

Thermal paper has a chemical coating on one side of the paper. This side should be

facing the thermal print head. Incorrect paper loading may result in blank output on

NOTE

the thermal paper.

The thermal paper will show a red stripe to indicate that the roll is about to run out

of paper.

10

Page 15

REV 2 IRM-5000P USER’S MANUAL

3.0 OPERATING PROCEDURES

3.1 Performing Tests

3.1.1. Entering Test Record Header Information

You can enter the test record header information before performing tests. The record header

includes identifying information such as company, location, test description, etc. Once the

header information has been entered, it will apply to all subsequent test records. To enter the

header information:

a. When the unit is turned on, you will be presented with the “START-UP” menu:

1. RUN TEST 05/05/10

2. UTILITIES 10:10:15

Bat:

TERMINAL VTG: 1 V

NOTES

• If the IRM-5000P is running on battery power, the battery icon will be

displayed on the LCD screen as shown above. The icon also represents the

charge level of the battery.

If the IRM-5000P is plugged in, a plug icon will be displayed on the LCD

screen as shown below:

1. RUN TEST 05/05/10

2. UTILITIES 10:10:15

Bat:

TERMINAL VTG: 1 V

• The test terminal voltage is displayed at the bottom of the LCD screen. The

IRM-5000P can be used as a voltmeter by connecting the positive and

negative leads to a voltage source. The voltage measurement range is

from 50-1250 V(AC/DC).

Press the [2] key (UTILITIES).

b. The following screen will be displayed:

1.PRINT 2.SAVE/RES

3.SETUP

TERMINAL VTG: 1 V

Press the [3] key (SETUP).

11

Page 16

c. The following screen will be displayed:

1.TEST ID 2.CLOCK

3.COMP INT 4.50/60Hz

5.°C/°F

TERMINAL VTG: 1 V

Press the [1] key (TEST ID).

d. The following screen will be displayed:

COMPANY

_

ENTER to Confirm

TERMINAL VTG: 1 V

Type the company name using the alpha-numeric keypad.

When pressing a key, the corresponding number on the key will be displayed first.

Pressing the key again will display the first letter on the key. Pressing the key again will

display the second letter on the key. For example, to type the letter “A”, you must press

the [2] key twice. To erase the character at the cursor position, press the [CLEAR] key.

Press the [PAPER ∧ Contrast] key to move to the next character. Press the [PAPER

∨ Contrast]

key to move to the previous character. Press the [ENTER] key when you

are done typing the company name.

IRM-5000P USER’S MANUAL REV 2

e. The following screen will be displayed:

LOCATION

_

ENTER to Confirm

TERMINAL VTG: 1 V

Type the location name using the alpha-numeric keypad and then press the

key.

f. The following screen will be displayed:

TEST DESCRIPTION

_

ENTER to Confirm

TERMINAL VTG: 1 V

Type the test description using the alpha-numeric keypad and then press the

key.

g. The following screen will be displayed:

[ENTER]

[ENTER]

12

Page 17

REV 2 IRM-5000P USER’S MANUAL

OPERATOR

_

ENTER to Confirm

TERMINAL VTG: 1 V

Type the operator’s name using the alpha-numeric keypad and then press the [ENTER]

key. All header information will be saved, and you will be returned to the “START-UP”

menu.

13

Page 18

IRM-5000P USER’S MANUAL REV 2

3.1.2. Performing an Insulation Resistance Test

The insulation resistance test measures the insulation resistance at selected voltages. Since the

insulation resistance is continuously monitored during each test, users can plot the resistance

or current values versus time. Use the steps below to perform an insulation resistance test:

a. Start from the “START-UP” menu:

1. RUN TEST 05/05/10

2. UTILITIES 10:10:15

Bat:

TERMINAL VTG: 1 V

Press the [1] key (RUN TEST).

If you had previously performed a test and had not saved the test results, the

following screen will be displayed:

NOTE

Test Not Saved!

“Enter” To continue

TERMINAL VTG: 1 V

Press the [ENTER] key if you do not want to save the results from the

previous test. Continue to step b.

Press any other key if you would like to save the results from the previous test.

You will be returned to the “START-UP” menu. Please see section 3.2.1 for

instructions on how to save test results to the IRM-5000P’s Flash EEPROM.

b. The following screen will be displayed:

1. R 2. PI

3. DD 4. SV

TERMINAL VTG: 1 V

Press the [1] key (R).

14

Page 19

REV 2 IRM-5000P USER’S MANUAL

c. The following screen will be displayed:

1. 1 Min 2. 10 Min

3. 30 Min 4. Custom

TERMINAL VTG: 1 V

1. 1 Min

Press the [1] key to select the 1 minute test duration. Continue to step d.

2. 10 Min

Press the [2] key to select the 10 minute test duration. Continue to step d.

3. 30 Min

Press the

[3] key to select the 30 minute test duration. Continue to step d.

4. Custom

Press the

[4] key to enter a custom test duration in minutes. The following

screen will be displayed:

Test Time (Minutes):

0 Minutes

TERMINAL VTG: 1 V

Type the desired test duration in minutes using the numeric keypad, and then

press the [ENTER] key. Continue to step d.

d. The following screen will be displayed:

1. 500V 2. 1000V

3. 2500V 4. 5000V

5. Custom

TERMINAL VTG: 1 V

1. 500V

Press the

[1] key to select 500V for the test voltage. Continue to step e.

2. 1000V

Press the [2] key to select 1000V for the test voltage. Continue to step e.

3. 2500V

Press the

4. 5000V

Press the [4] key to select 5000V for the test voltage. Continue to step e.

15

[3] key to select 2500V for the test voltage. Continue to step e.

Page 20

5. Custom

Press the [5] key to enter a custom test voltage value. The following screen will

be displayed:

Test Voltage (50-5K)

0 Volts

TERMINAL VTG: 1 V

Type the desired test voltage (between 50 V – 5000 V) using the numeric keypad,

and then press the [ENTER] key. Continue to step e.

e. The following screen will be displayed:

ENTER D.U.T. TEMP?

1. YES 2. NO

TERMINAL VTG: 1 V

1. YES

IRM-5000P USER’S MANUAL REV 2

Press the [1] key (YES) if you would like to enter the Device Under Test (D.U.T.)

temperature. The following screen will be displayed:

ENTER TEMP (0-254 F)

°F

TERMINAL VTG: 1 V

Type the D.U.T. temperature using the numeric keypad. The screen will be

updated as shown:

ENTER TEMP (0-254 F)

120 °F

TERMINAL VTG: 1 V

Press the [ENTER] key and continue to step f.

2. NO

Press the [2] key (NO) if you do not want to enter the Device Under Test (D.U.T.)

temperature. Continue to step f.

16

Page 21

REV 2 IRM-5000P USER’S MANUAL

f. The following screen will be displayed:

PRINT DURING TEST?

1. YES 2. NO

TERMINAL VTG: 1 V

1. YES

Press the [1] key (YES) to print the resistance readings on the IRM-5000P’s builtin thermal printer. If this option is selected, the resistance values will be printed

at every second, starting at 10 seconds. Continue to step g.

2. NO

Press the

[2] key (NO) if you do not want to print the resistance readings.

Continue to step g.

g. The following screen will be displayed if the IRM-5000P needs to perform self-

calibration:

CALIBRATING

PLEASE WAIT 25

TERMINAL VTG: 1 V

The remaining calibration time is displayed in seconds. When the calibration is

completed, the following screen will be displayed:

“ENTER” TO START!

R 5000V 10Min

TERMINAL VTG: 1 V

Press the

[ENTER] key to start the test.

h. The following screen will be displayed while the test is being performed:

Bat: Time: 09:51

Resistance: 983.8 M

Current: 47 uA

TEST VOLTAGE: 4999V

The resistance value symbols are:

T = Tera-ohm

NOTE

G = Giga-ohm

M = Mega-ohm

K = Kilo-ohm

17

Page 22

IRM-5000P USER’S MANUAL REV 2

The LCD screen will be dynamically updated displaying the remaining time along with

the resistance, current, and test voltage values. When the test is completed, the results

will be displayed as shown:

Res=989.7M 4.87uA

5000V 0.0uF 10:00

TERMINAL VTG: 1 V

Press any key to continue.

If you had entered a D.U.T. temperature in step e, the following screen will be

displayed:

NOTE

D.U.T. TEMP: 200°F

EQ R @ 40°C: 399.6G

TERMINAL VTG: 1 V

This screen shows the equivalent resistance value at 40°C. The equivalent

resistance value is automatically calculated by the IRM-5000P based on the

D.U.T. temperature entered in step e.

Press any key to continue. The following screen will be displayed:

D.U.T. TEMP: 200°F

EQ R @ 20°C: 1.599T

TERMINAL VTG: 1 V

This screen shows the calculated equivalent resistance value at 20°C. Press any

key to continue.

i. The following screen will be displayed:

PRINT REPORT?

1.YES 2.NO

TERMINAL VTG: 1 V

Press the [1] key (YES) to print the test report (See Figure 4 for a sample test report

printout).

j. The test report will be printed on the built-in thermal printer, and then the following

screen will be displayed:

18

Page 23

REV 2 IRM-5000P USER’S MANUAL

SAVE TEST?

1.YES 2.NO

TERMINAL VTG: 1 V

Press the [1] key (YES) to save the test results.

k. The following screen will be displayed:

TEST NUMBER 1

HAS BEEN SAVED!

TERMINAL VTG: 1 V

Press any key to continue.

l. The following screen will be displayed:

REPEAT TEST?

1.YES 2.NO

TERMINAL VTG: 1 V

Press the [2] key (NO). You will be returned to the “START-UP” menu.

Please see section 3.2.3 for instructions on how to print test results graphs.

NOTE

19

Page 24

IRM-5000P USER’S MANUAL REV 2

Figure 4. Resistance Test Results Report Printout

Figure 5. Resistance Plot from a Resistance Test

20

Page 25

REV 2 IRM-5000P USER’S MANUAL

Figure 6. Current Plot from a Resistance Test

21

Page 26

IRM-5000P USER’S MANUAL REV 2

3.1.3. Performing a Polarization Index Ratio (PI) Test

The polarization index (PI) is derived from the ratio of the insulation resistance at ten minutes

divided by the insulation value at one minute. For a typical insulation, the resistance value

increases as time increases during a test.

Standard voltages of 500 V, 1000 V, or 5000 V can be used, or the user can enter a custom test

voltage value from 50 V to 5000 V. The default test duration is ten minutes, but a custom test

duration can be set from 10 to 99 minutes. Follow the steps below to perform a PI test:

a. Start from the “Start-Up” menu:

1. RUN TEST 05/05/10

2. UTILITIES 10:10:15

Bat:

TERMINAL VTG: 1 V

Press the [1] key (RUN TEST).

b. The following screen will be displayed:

1. R 2. PI

3. DD 4. SV

TERMINAL VTG: 1 V

Press the [2] key (PI).

c. The following screen will be displayed:

1. 10 Min (Default)

2. Custom

TERMINAL VTG: 1 V

1. 10 Min (Default)

Press the

[1] key to select the default test duration of 10 minutes. Continue to

step d.

2. Custom

Press the [2] key to enter a custom test duration (between 10 to 99 minutes).

The following screen will be displayed:

NON-STANDARD Time?

“ENTER” to continue

TERMINAL VTG: 1 V

Press the

[ENTER] key to continue.

22

Page 27

REV 2 IRM-5000P USER’S MANUAL

If you press any other key besides the [ENTER] key, you will be

returned to the beginning of step c.

NOTE

The following screen will be displayed:

Test Time (Minutes):

0 Minutes

TERMINAL VTG: 1 V

Enter the test duration using the numeric keypad and then press the [ENTER]

key. Continue to step d.

d. The following screen will be displayed:

1. 500V 2. 1000V

3. 2500V 4. 5000V

5. Custom

TERMINAL VTG: 1 V

Select the desired test voltage by pressing the corresponding key ([1], [2], [3], [4], or

[5]).

e. The following screen will be displayed:

ENTER D.U.T. TEMP?

1. YES 2. NO

TERMINAL VTG: 1 V

1. YES

Press the

[1] key (YES) if you would like to enter the Device Under Test (D.U.T.)

temperature. The following screen will be displayed:

ENTER TEMP (0-254 F)

°F

TERMINAL VTG: 1 V

Type the D.U.T. temperature using the numeric keypad. The screen will be

updated as shown:

ENTER TEMP (0-254 F)

120 °F

TERMINAL VTG: 1 V

Press the [ENTER] key and continue to step f.

23

Page 28

2. NO

Press the [2] key (NO) if you do not want to enter the Device Under Test (D.U.T.)

temperature. Continue to step f.

f. The following screen will be displayed:

PRINT DURING TEST?

1. YES 2. NO

TERMINAL VTG: 1 V

1. YES

Press the [1] key (YES) to print the resistance readings on the IRM-5000P’s builtin thermal printer. If this option is selected, the resistance values will be printed

at every second, starting at 10 seconds. Continue to step g.

2. NO

Press the [2] key (NO) if you do not want to print the resistance readings.

Continue to step g.

IRM-5000P USER’S MANUAL REV 2

g. The following screen will be displayed:

CALIBRATING

PLEASE WAIT 25

TERMINAL VTG: 1 V

The IRM-5000P will perform self-calibration, and then the following screen will be

displayed:

“ENTER” TO START!

PI 350V 10Min

TERMINAL VTG: 1 V

Press the

[ENTER] key to start the test.

h. The following screen will be displayed while the test is being performed:

Bat: Time: 09:43

Resistance: 2.517 M

Current: 98.16 uA

TEST VOLTAGE: 350 V

24

Page 29

REV 2 IRM-5000P USER’S MANUAL

The LCD screen will be dynamically updated displaying the remaining time along with

the resistance, current, and test voltage values. When the test is completed, the results

will be displayed as shown:

Res= 40.81MK PI=7.7

350V 99.37uF 10:00

TERMINAL VTG: 3 V

Press any key to continue.

If you had entered a D.U.T. temperature in step e, the IRM-5000P will calculate

the equivalent resistance values at 40°C and 20°C and display them on the LCD

NOTE

screen.

i. The following screen will be displayed:

PRINT REPORT?

1.YES 2.NO

TERMINAL VTG: 1 V

Press the [1] key (YES) to print the test report (See Figure 7 for a sample test report

printout. See Table 4 for an interpretation of).

j. The test report will be printed on the built-in thermal printer, and then the following

screen will be displayed:

SAVE TEST?

1.YES 2.NO

TERMINAL VTG: 1 V

Press the

[1] key (YES) to save the test results.

k. The following screen will be displayed:

TEST NUMBER 8

HAS BEEN SAVED!

TERMINAL VTG: 1 V

Press any key to continue.

25

Page 30

l. The following screen will be displayed:

REPEAT TEST?

1.YES 2.NO

TERMINAL VTG: 1 V

Press the [2] key (NO). You will be returned to the “START-UP” menu.

Please see section 3.2.3 for instructions on how to print test results graphs.

NOTE

IRM-5000P USER’S MANUAL REV 2

Figure 7. Polarization Index Test Results Report Printout

26

Page 31

REV 2 IRM-5000P USER’S MANUAL

Figure 8. Polarization Index Test Resistance Plot

Figure 9. Polarization Index Test Current Plot

Table 4. PI Ratio Table

PI Ratio Insulation Condition

Less than 1.0

1.0 to 2.0

2.0 to 4.0

Above 4.0

* A PI ratio between 1.0 and 2.0 is satisfactory for a load with low capacitance, such as short runs.

** A dry, brittle insulation may show a good PI reading but may fail under shock conditions.

Unsatisfactory

Questionable *

Good

Very Good **

27

Page 32

IRM-5000P USER’S MANUAL REV 2

3.1.4. Performing a Step Voltage (SV) Test

The step voltage (SV) test measures insulation resistances in five equal voltage steps up to a

final test voltage of 2500 Vdc, 5000 Vdc, or a user-defined voltage value. The voltage is stepped

up in 1/5 increments of the final test voltage every one minute, five minutes, or other userdefined time interval. Follow the steps below to perform a step voltage test:

a. Start from the “START-UP” menu:

1. RUN TEST 05/05/10

2. UTILITIES 10:10:15

Bat:

TERMINAL VTG: 1 V

Press the [1] key (RUN TEST) to start a test.

b. The following screen will be displayed:

1. R 2. PI

3. DD 4. SV

TERMINAL VTG: 1 V

Press the [4] key (SV).

c. The following screen will be displayed:

1. 5 Min (Default)

2. Custom

TERMINAL VTG: 1 V

Press the [1] key (5 Min).

d. The following screen will be displayed:

1. 2500V 2. 5000V

3. Custom

TERMINAL VTG: 1 V

Select the maximum test voltage by pressing the corresponding key (

[1], [2], or [3]).

28

Page 33

REV 2 IRM-5000P USER’S MANUAL

e. The following screen will be displayed:

ENTER D.U.T. TEMP?

1. YES 2. NO

TERMINAL VTG: 1 V

1. YES

Press the [1] key (YES) if you would like to enter the Device Under Test (D.U.T.)

temperature. The following screen will be displayed:

ENTER TEMP (0-254 F)

°F

TERMINAL VTG: 1 V

Type the D.U.T. temperature using the numeric keypad. The screen will be

updated as shown:

ENTER TEMP (0-254 F)

120 °F

TERMINAL VTG: 1 V

Press the [ENTER] key and continue to step f.

2. NO

Press the [2] key (NO) if you do not want to enter the Device Under Test (D.U.T.)

temperature. Continue to step f.

f. The following screen will be displayed:

CALIBRATING

PLEASE WAIT 25

TERMINAL VTG: 1 V

The IRM-5000P will perform self-calibration, and then the following screen will be

displayed:

“ENTER” TO START!

SV 2500V 5Min

TERMINAL VTG: 1 V

Press the [ENTER] key to start the test.

29

Page 34

IRM-5000P USER’S MANUAL REV 2

g. The following screen will be displayed while the test is being performed:

Bat: Time: 04:59

Resistance: 10.002 G

Current: 50.2 nA

TEST VOLTAGE: 498 V

The LCD screen will be dynamically updated displaying the remaining time along with

the resistance, current, and test voltage values. When the test is completed, the results

for the first time interval and voltage step will be displayed as shown:

9.952G@ 01:00, 499V

2500V 0.00uF 05:00

TERMINAL VTG: 1 V

Press any key to continue. The results for the second time interval and voltage step will

be displayed:

9.973G@ 02:00, 1002V

2500V 0.00uF 05:00

TERMINAL VTG: 1 V

Press any key to continue. The results for the third time interval and voltage step will be

displayed:

9.851G@ 03:00, 1503V

2500V 0.00uF 05:00

TERMINAL VTG: 1 V

Press any key to continue. The results for the fourth time interval and voltage step will

be displayed:

9.847G@ 04:00, 2000V

2500V 0.00uF 05:00

TERMINAL VTG: 1 V

Press any key to continue. The results for the final time interval and voltage step will be

displayed:

9.863G@ 05:00, 2500V

2500V 0.00uF 05:00

TERMINAL VTG: 1 V

Press any key to continue.

h. The following screen will be displayed:

30

Page 35

REV 2 IRM-5000P USER’S MANUAL

PRINT REPORT?

1.YES 2.NO

TERMINAL VTG: 1 V

Press the [1] key (YES) to print the test report (See Figure 10 for a sample test report

printout).

i. The test report will be printed on the built-in thermal printer, and then the following

screen will be displayed:

SAVE TEST?

1.YES 2.NO

TERMINAL VTG: 1 V

Press the [1] key (YES).

j. The following screen will be displayed:

TEST NUMBER 9

HAS BEEN SAVED!

TERMINAL VTG: 1 V

Press any key to continue.

k. The following screen will be displayed:

REPEAT TEST?

1.YES 2.NO

TERMINAL VTG: 1 V

Press the

NOTE

[2] key (NO). You will be returned to the “START-UP” menu.

Please see section 3.2.3 for instructions on how to print test results graphs.

31

Page 36

IRM-5000P USER’S MANUAL REV 2

Figure 10. Step Voltage Test Results Report Printout

32

Page 37

REV 2 IRM-5000P USER’S MANUAL

Figure 11. Step Voltage Test Resistance and Current Plots

33

Page 38

IRM-5000P USER’S MANUAL REV 2

3.1.5. Performing a Dielectric Discharge (DD) Test

The dielectric discharge (DD) test measures the dielectric absorption of a tested material. A

typical DD test is timed for 30 minutes. Follow the steps below to perform a dielectric discharge

test:

a. Start from the “START-UP” menu:

1. RUN TEST 05/05/10

2. UTILITIES 10:15:15

Bat:

TERMINAL VTG: 1 V

Press the [1] key (RUN TEST).

b. The following screen will be displayed:

1. R 2. PI

3. DD 4. SV

TERMINAL VTG: 1 V

Press the [3] key (DD).

c. The following screen will be displayed:

1. 30 Min (Default)

2. Custom

TERMINAL VTG: 1 V

Press the [1] key (30 Min).

d. The following screen will be displayed:

1. 500V

2. Custom

TERMINAL VTG: 1 V

Press the

[1] key to select 500V or press the [2] key to enter a custom test voltage

value.

34

Page 39

REV 2 IRM-5000P USER’S MANUAL

e. The following screen will be displayed:

ENTER D.U.T. TEMP?

1. YES 2. NO

TERMINAL VTG: 1 V

1. YES

Press the [1] key (YES) if you would like to enter the Device Under Test (D.U.T.)

temperature. The following screen will be displayed:

ENTER TEMP (0-254 F)

°F

TERMINAL VTG: 1 V

Type the D.U.T. temperature using the numeric keypad. The screen will be

updated as shown:

ENTER TEMP (0-254 F)

120 °F

TERMINAL VTG: 1 V

Press the [ENTER] key and continue to step f.

2. NO

Press the [2] key (NO) if you do not want to enter the Device Under Test (D.U.T.)

temperature. Continue to step f.

f. The following screen will be displayed:

CALIBRATING

PLEASE WAIT 25

TERMINAL VTG: 1 V

The IRM-5000P will perform self-calibration, and then the following screen will be

displayed:

“ENTER” TO START!

DD 200V 30Min

TERMINAL VTG: 1 V

Press the [ENTER] key to start the test.

35

Page 40

IRM-5000P USER’S MANUAL REV 2

g. The following screen will be displayed while the test is being performed:

Bat: Time: 29:57

Resistance: 1.802 M

Current: 0.105 mA

TEST VOLTAGE: 200 V

The LCD screen will be dynamically updated displaying the remaining time along with

the resistance, current, and test voltage values. When the test is completed, the results

will be displayed as shown:

R= 2.179M DD=5.8

200V 3.85uF 30:00

TERMINAL VTG: 1 V

Press any key to continue.

h. The following screen will be displayed:

PRINT REPORT?

1.YES 2.NO

TERMINAL VTG: 1 V

Press the [1] key (YES) to print the test report (See Figure 12 for a sample test report

printout).

i. The test report will be printed on the built-in thermal printer, and then the following

screen will be displayed:

SAVE TEST?

1.YES 2.NO

TERMINAL VTG: 1 V

Press the [1] key (YES).

j. The following screen will be displayed:

TEST NUMBER 10

HAS BEEN SAVED!

TERMINAL VTG: 1 V

Press any key to continue.

36

Page 41

REV 2 IRM-5000P USER’S MANUAL

k. The following screen will be displayed:

REPEAT TEST?

1.YES 2.NO

TERMINAL VTG: 1 V

Press the [2] key (NO). You will be returned to the “START-UP” menu.

Please see section 3.2.3 for instructions on how to print test results graphs.

NOTE

37

Figure 12. Dielectric Discharge Test Results Report Printout

Page 42

IRM-5000P USER’S MANUAL REV 2

Figure 13. Dielectric Discharge Test Resistance Plot

38

Page 43

REV 2 IRM-5000P USER’S MANUAL

39

Figure 14. Dielectric Discharge Test Current Plot

Page 44

IRM-5000P USER’S MANUAL REV 2

3.2 Working With Test Records

3.2.1. Saving a Test Record

After performing a test, the test results are temporarily stored in the IRM-5000P’s working

memory. At the end of the testing procedure, the user is presented with an option to save the

test results to the unit’s Flash EEPROM. If the results are not saved during the testing

procedure, they can still be saved as long as another test has not been performed. To save the

test results from the last test performed:

a. Start from the “START-UP” menu:

1. RUN TEST 05/05/10

2. UTILITIES 10:15:15

Bat:

TERMINAL VTG: 1 V

Press the [2] key (UTILITIES).

b. The following screen will be displayed:

1.PRINT 2.SAVE/RES

3.SETUP

TERMINAL VTG: 1 V

Press the [2] key (SAVE/RES).

c. The following screen will be displayed:

1.SAVE 2.RESTORE

3.ERASE 4.DIRECTORY

TERMINAL VTG: 1 V

Press the

[1] key (SAVE).

d. The test record will be saved in the IRM-5000P’s Flash EEPROM. The test record number

will be automatically assigned by the IRM-5000P. The following screen will be displayed

when the test record has been saved:

TEST NUMBER 11

HAS BEEN SAVED!

TERMINAL VTG: 1 V

Press any key to return to the “START-UP” menu.

40

Page 45

REV 2 IRM-5000P USER’S MANUAL

3.2.2. Restoring a Test Record From Flash EEPROM

You can restore a test record from the IRM-5000P’s Flash EEPROM to the working memory. You

can then print the restored test record on the unit’s built-in thermal printer (see section 3.2.3

for printing instructions). To restore a test record:

a. Start from the “START-UP” menu:

1. RUN TEST 05/05/10

2. UTILITIES 10:15:15

Bat:

TERMINAL VTG: 1 V

Press the [2] key (UTILITIES).

b. The following screen will be displayed:

1.PRINT 2.SAVE/RES

3.SETUP

TERMINAL VTG: 1 V

Press the [2] key (SAVE/RES).

c. The following screen will be displayed:

1.SAVE 2.RESTORE

3.ERASE 4.DIRECTORY

TERMINAL VTG: 1 V

Press the [2] key (RESTORE).

d. The following screen will be displayed:

RECALL TEST

NUMBER:

TERMINAL VTG: 1 V

Type the test record number that you would like to restore and then press the

[ENTER] key. If you do not know the record number, you can first print a test record

directory using the instructions in section 3.2.4.

e. The selected test record will be restored to the working memory and the following

screen will be displayed:

TEST NUMBER 8

RESTORED!

TERMINAL VTG: 1 V

Press any key to return to the “START-UP” menu.

41

Page 46

IRM-5000P USER’S MANUAL REV 2

3.2.3. Printing a Test Record from the Working Memory

After performing a test, the results are stored in the IRM-5000P’s working memory. The

tabulated results, resistance plot, and current plot can then be printed. Also, if a record is

restored from the unit’s Flash EEPROM to the working memory, the test results can be printed

on the thermal printer. Use the steps below to print a test record from the working memory:

a. Either perform a test or restore a test record from the Flash EEPROM. Then start from

the “START-UP” menu:

1. RUN TEST 05/05/10

2. UTILITIES 15:15:15

Bat:

TERMINAL VTG: 1 V

Press the

[2] key (UTILITIES).

b. The following screen will be displayed:

1.PRINT 2.SAVE/RES

3.SETUP

TERMINAL VTG: 1 V

Press the

[1] key (PRINT).

c. The following screen will be displayed:

1.PLOT R 2.PLOT I

3.PLOT R,I 4.SUMMARY

TERMINAL VTG: 1 V

1. PLOT R

Press the

[1] key (PLOT R) to print the resistance versus time graph. The graph

will be printed on the thermal printer and you will be returned to the “STARTUP” menu.

2. PLOT I

Press the [2] key (PLOT I) to print the current versus time graph. The graph will

be printed on the thermal printer and you will be returned to the “START-UP”

menu.

3. PLOT R,I

Press the

[3] key (PLOT R,I) to print both the resistance versus time graph and

the current versus time graph. The graphs will be printed on the thermal printer

and you will be returned to the “START-UP” menu.

42

Page 47

REV 2 IRM-5000P USER’S MANUAL

4. SUMMARY

Press the [4] key (SUMMARY) to print the tabulated test results. The summary

report will be printed on the thermal printer and you will be returned to the

“START-UP” menu.

43

Page 48

IRM-5000P USER’S MANUAL REV 2

3.2.4. Printing a Directory of Test Records Stored in the IRM-5000P’s Memory

You can print a directory of all the test records stored in the IRM-5000P’s Flash EEPROM using

the steps below:

a. Start from the “START-UP” menu:

1. RUN TEST 05/05/10

2. UTILITIES 15:15:15

Bat:

TERMINAL VTG: 1 V

Press the [2] key (UTILITIES).

b. The following screen will be displayed:

1.PRINT 2.SAVE/RES

3.SETUP

TERMINAL VTG: 1 V

Press the [2] key (SAVE/RES).

c. The following screen will be displayed:

1.SAVE 2.RESTORE

3.ERASE 4.DIRECTORY

TERMINAL VTG: 1 V

Press the [4] key (DIRECTORY).

d. The following screen will be displayed:

TEST DIRECTORY

1.FULL 2.BRIEF

TERMINAL VTG: 1 V

1. FULL

Press the

[1] key (FULL) to print a directory of all the test records stored in the

IRM-5000P’s Flash EEPROM. A sample test record directory printout is shown in

Figure 15.

2. BRIEF

Press the

[2] key (BRIEF) to print a directory of the last 15 test records stored in

the IRM-5000P’s Flash EEPROM. A sample test record directory printout is shown

in Figure 15.

44

Page 49

REV 2 IRM-5000P USER’S MANUAL

45

Figure 15. Typical Test Record Directory Printout

Page 50

IRM-5000P USER’S MANUAL REV 2

3.2.5. Erasing Test Records From the Flash EEPROM

You can erase individual or all test records stored in the IRM-5000P’s Flash EEPROM. To erase a

test record:

a. Start from the “START-UP” menu:

1. RUN TEST 05/05/10

2. UTILITIES 15:15:15

Bat:

TERMINAL VTG: 1 V

Press the [2] key (UTILITIES).

b. The following screen will be displayed:

1.PRINT 2.SAVE/RES

3.SETUP

TERMINAL VTG: 1 V

Press the [2] key (SAVE/RES).

c. The following screen will be displayed:

1.SAVE 2.RESTORE

3.ERASE 4.DIRECTORY

TERMINAL VTG: 1 V

Press the [3] key (ERASE).

d. The following screen will be displayed:

1. ERASE SINGLE TEST

2. ERASE ALL TESTS

TERMINAL VTG: 1 V

1. ERASE SINGLE TEST

Press the

[1] key if you would like to erase a single test record from the IRM-

5000P’s Flash EEPROM. The following screen will be displayed:

ERASE TEST

NUMBER:

TERMINAL VTG: 1 V

Press the [STOP] key If you selected the erase option by mistake or

do not wish to erase a test record. You will be returned to the “START-

NOTE

UP” menu.

46

Page 51

REV 2 IRM-5000P USER’S MANUAL

Type the test number that you would like to erase and then press the [ENTER]

key. If you do not know the test number, you can first print a test record

directory using the instructions in section 3.2.4.

The following screen will be displayed while the test record is being deleted:

ERASING TEST

PLEASE WAIT...

TERMINAL VTG: 1 V

The following screen will be displayed when the test record has been completely

deleted:

TEST NUMBER 1

ERASED!

TERMINAL VTG: 1 V

Press any key to return to the “START-UP” menu.

2. ERASE ALL TESTS

Press the [2] key to erase all test records from the IRM-5000P’s Flash EEPROM.

The following screen will be displayed:

ERASE ALL TESTS?

1.NO 2.YES

TERMINAL VTG: 1 V

Press the [1] key if you do NOT want to erase all the test records. You will be

returned to the “START-UP” menu.

Press the [2] key if you would like to erase all the test records. The following

screen will be displayed while the test records are being deleted:

ERASING TESTS

PLEASE WAIT...

TERMINAL VTG: 1 V

The following screen will be displayed when all test records have been

completely deleted:

ERASE COMPLETE!

TERMINAL VTG: 1 V

Press any key to return to the “START-UP” menu.

47

Page 52

4.0 CHANGING SETUP PARAMETERS

4.1 Setting the Clock

To set the IRM-5000P’s internal clock:

a. Start from the “START-UP” menu:

1. RUN TEST 05/05/10

2. UTILITIES 15:15:15

Bat:

TERMINAL VTG: 1 V

Press the [2] key (UTILITIES).

b. The following screen will be displayed:

1.PRINT 2.SAVE/RES

3.SETUP

TERMINAL VTG: 1 V

IRM-5000P USER’S MANUAL REV 2

Press the [3] key (SETUP).

c. The following screen will be displayed:

1.TEST ID 2.CLOCK

3.COMP INT 4.50/60Hz

5.°C/°F

TERMINAL VTG: 1 V

Press the [2] key (CLOCK).

d. The following screen will be displayed:

ENTER

MM-DD-YY HH:MM:SS

_

Enter the month, date, time, hours, minutes, and seconds (in 24-hour format) using the

alpha-numeric keypad. When the last digit is entered, the clock will be set and you will

be returned to the “START-UP” menu.

48

Page 53

REV 2 IRM-5000P USER’S MANUAL

4.2 Setting the Frequency

To set the frequency:

a. Start from the “START-UP” menu:

3. RUN TEST 05/05/10

4. UTILITIES 15:15:15

Bat:

TERMINAL VTG: 1 V

Press the

[2] key (UTILITIES).

b. The following screen will be displayed:

1.PRINT 2.SAVE/RES

3.SETUP

TERMINAL VTG: 1 V

Press the

[3] key (SETUP).

c. The following screen will be displayed:

1.TEST ID 2.CLOCK

3.COMP INT 4.50/60Hz

5.°C/°F

TERMINAL VTG: 1 V

Press the [4] key (50/60Hz).

d. The following screen will be displayed:

1. 60 Hz

2. 50 Hz

TERMINAL VTG: 1 V

Press the

[1] key (60 Hz) to set the frequency to 60 Hz, or press the [2] key (50 Hz). The

setting will be stored and you will be returned to the “START-UP” menu.

49

Page 54

IRM-5000P USER’S MANUAL REV 2

4.3 Setting the Temperature Units of Measure

When performing tests, you can provide the Device Under Test (D.U.T.) temperature and the

IRM-5000P will automatically calculate the equivalent resistance values at 40°C and 20°C. You

can select the preferred units of measure for entering the D.U.T. temperature by using the

steps below:

a. Start from the “START-UP” menu:

1. RUN TEST 05/05/10

2. UTILITIES 15:15:15

Bat:

TERMINAL VTG: 1 V

Press the [2] key (UTILITIES).

b. The following screen will be displayed:

1.PRINT 2.SAVE/RES

3.SETUP

TERMINAL VTG: 1 V

Press the [3] key (SETUP).

c. The following screen will be displayed:

1.TEST ID 2.CLOCK

3.COMP INT 4.50/60Hz

5.°C/°F

TERMINAL VTG: 1 V

Press the [5] key (

d. The following screen will be displayed:

1. °C

2. °F

TERMINAL VTG: 1 V

Press the [1] key (°C) or the [2] key (°F) to select the corresponding units of measure.

The D.U.T. temperature units of measure will be set and you will be returned to the

“START-UP” menu.

°C/°F

).

50

Page 55

REV 2 IRM-5000P USER’S MANUAL

4.4 Enabling the Computer Interface

The IRM-5000P can be connected to a PC via its RS-232C (serial) computer interface port. The

RS-232C port is controlled by the main microprocessor board and is optically isolated from the

high-voltage generator board. A Windows-based software package is provided with the IRM5000P that can be used to retrieve test records from the IRM-5000P. In order to use the

software with the IRM-5000P, you must first connect the unit to the PC via the RS-232C port

and then enable its computer interface. Follow the steps below to enable the computer

interface:

a. Start from the “START-UP” menu:

1. RUN TEST 05/05/10

2. UTILITIES 15:15:15

Bat:

TERMINAL VTG: 1 V

Press the [2] key (UTILITIES).

b. The following screen will be displayed:

1.PRINT 2.SAVE/RES

3.SETUP

TERMINAL VTG: 1 V

Press the [3] key (SETUP).

c. The following screen will be displayed:

1.TEST ID 2.CLOCK

3.COMP INT 4.50/60Hz

5.°C/°F

TERMINAL VTG: 1 V

Press the

d. The computer interface will be enabled and the following screen will be displayed:

You can now use the provided software to retrieve test records from the IRM-5000P.

Please refer to the IRM-5000P Software User’s Manual for further instructions.

[3] key (COMP INT).

COMPUTER INTERFACE

MODE

Press the [STOP] key to disable the computer interface and return the IRM-5000P to

stand-alone mode. You will be returned to the “START-UP” menu.

51

Page 56

IRM-5000P USER’S MANUAL REV 2

APPENDIX A - DIELECTRIC DISCHARGE RATIO TEST DESCRIPTION

When a dielectric is subjected to a voltage gradient, some charge will slowly permeate into the

dielectric. The effect is referred to as Dielectric Absorption. Since the dielectric is by intent an

insulator, one can imagine that the movement of these small charges has a very long time

constant. While virtually all dielectrics exhibit the effect to some extent, poorer dielectrics or

dielectrics that have undergone degradation will absorb more charge.

The IRM-5000P’s Dielectric Discharge test uses a standard test voltage of 500V and a standard

test duration of 30 minutes. During the testing period some charge migrates into the dielectric

material under test, as described above. At the completion of the test, the insulation system is

discharged to zero potential. At the zero point, the absorbed charge will start to migrate out of

the insulator’s dielectric. After discharging the dielectric for one minute, the Dielectric

Discharge current flow is measured. As can be seen in the equation below, the Dielectric

Discharge Ratio is proportional to the current measured:

RATIO DD

=

In general, higher ratios indicate a poorer insulation system. As one would expect, a higher test

voltage will produce a higher electric field across the insulator’s dielectric material, and more

charge can be expected to be absorbed by the dielectric. Thus, doubling the test voltage can be

expected to double both the absorbed charge as well as the discharge current measured at the

end of the test. To make the Dielectric Discharge Ratio independent of this natural

phenomenon, the formula for the Dielectric Discharge Ratio is divided by the test voltage.

An insulation system that has longer lengths of insulated conductors can naturally be expected

to absorb more charge, due to the longer length of the conductors and dielectric. Of course,

such systems will also have a higher capacitance, as the capacitance of a pair of conductors in a

cable is proportional to the length of the cable. Thus, a system with twice as much cable will

absorb, in general, twice as much charge, but will also have twice as much capacitance.

Dividing the discharge current by the measured capacitance in the DD Ratio formula above will

normalize the effect.

×

(mA) minute 1 after Current

eCapacitanc Voltage Test

52

Page 57

REV 2 IRM-5000P USER’S MANUAL

APPENDIX B - GUARD TERMINAL APPLICATION

When testing an insulation system, there may be times where the measured leakage current is

not necessarily a function of a poor insulation system, but rather of contamination at the

connection point, which allows leakage currents to flow along the surface of the connection

point. These readings can cause the test operator to incorrectly assume that the insulation

system under test has failed and must be replaced.

To exclude these surface effects and get an accurate measurement of the insulation system

itself, it is often advisable to perform the Insulation Test with a guard terminal attached as

shown in the figure below.

Surface leakage currents, which may flow along the surface of the exposed wires, will flow from

the Positive HV Test lead to the Guard lead. These currents are not measured by the IRM5000P. The cable itself will also have some inherent leakage current that will flow from the

Positive HV lead, through the cable, and out the Negative HV lead. The current that will be

used for the Insulation Resistance measurements.

The guard terminal is at very nearly the same voltage potential as the Negative Test lead. For

the same reason, the guard connection should be positioned to avoid arcing from the Positive

Test lead. As shown in the illustration, by placing the guard near the Negative Test lead, the risk

of arching can be avoided.

53

Page 58

1520 S. Hellman Ave • Ontario, CA 91761 • USA

Phone: 909-923-9390 • Fax: 909-923-9391

www.vanguard-instruments.com

Copyright © 2010 by Vanguard Instruments Company, Inc.

IRM-5000P User’s Manual • Revision 2.0 • May 19, 2010 • TA

Loading...

Loading...