VANDER-LIFT™

MODELS 450, 600 & 1000

MAINTENANCE

MANUAL

ALL VANCARE PRODUCTS

ARE MADE IN THE U.S.A.

VANCARE,Inc. Phone: (800) 694-4525

1515 First Street Fax: (402) 694-3994

Aurora, Nebraska 68818 Email: LQIR@YDQFDUH.FRP

VANDER-LIFT

April 2014

For your nearest Distributor, call 1-800-694-4525

2

MODELS 450, 600 * 1000

MAINTENANCE MANUAL

TABLE OF CONTENTS

VANDER-LIFT DIAGRAM OF PARTS AND DESCRIPTIONS

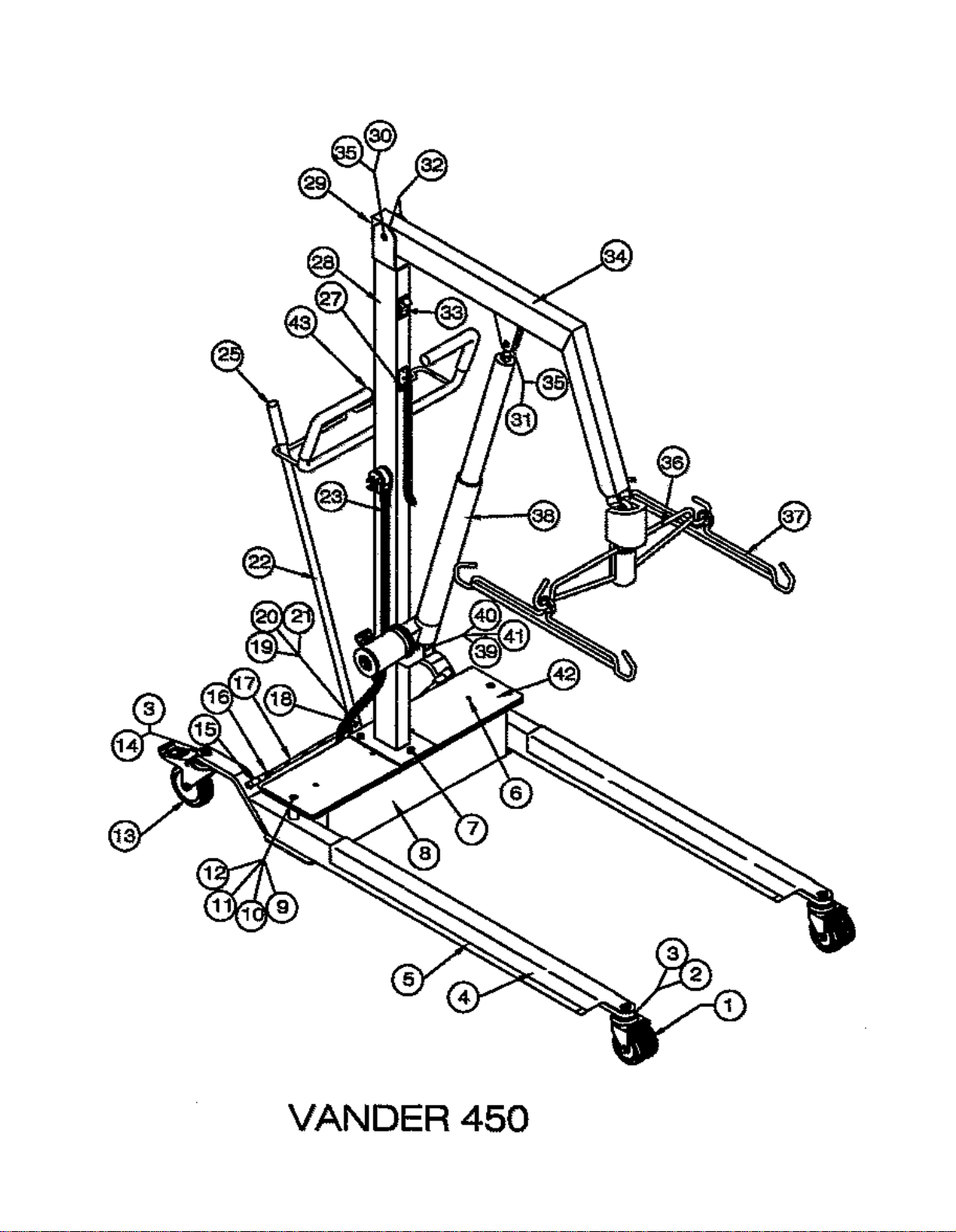

Vander-Lift 450 diagram, part numbers and descriptions Page 3-4

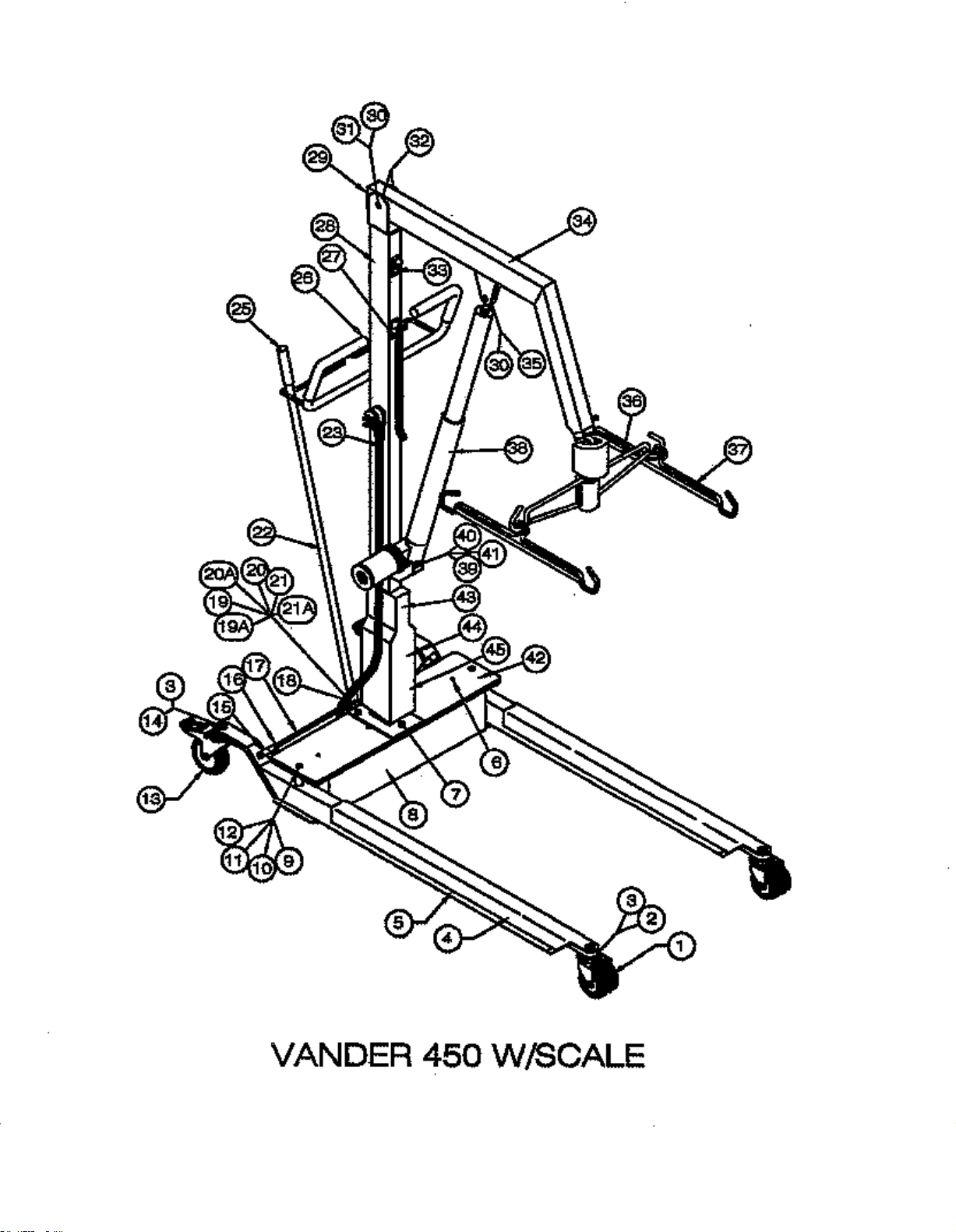

Vander-Lift 450 w/scale diagram, part numbers and descriptions Page 5-6

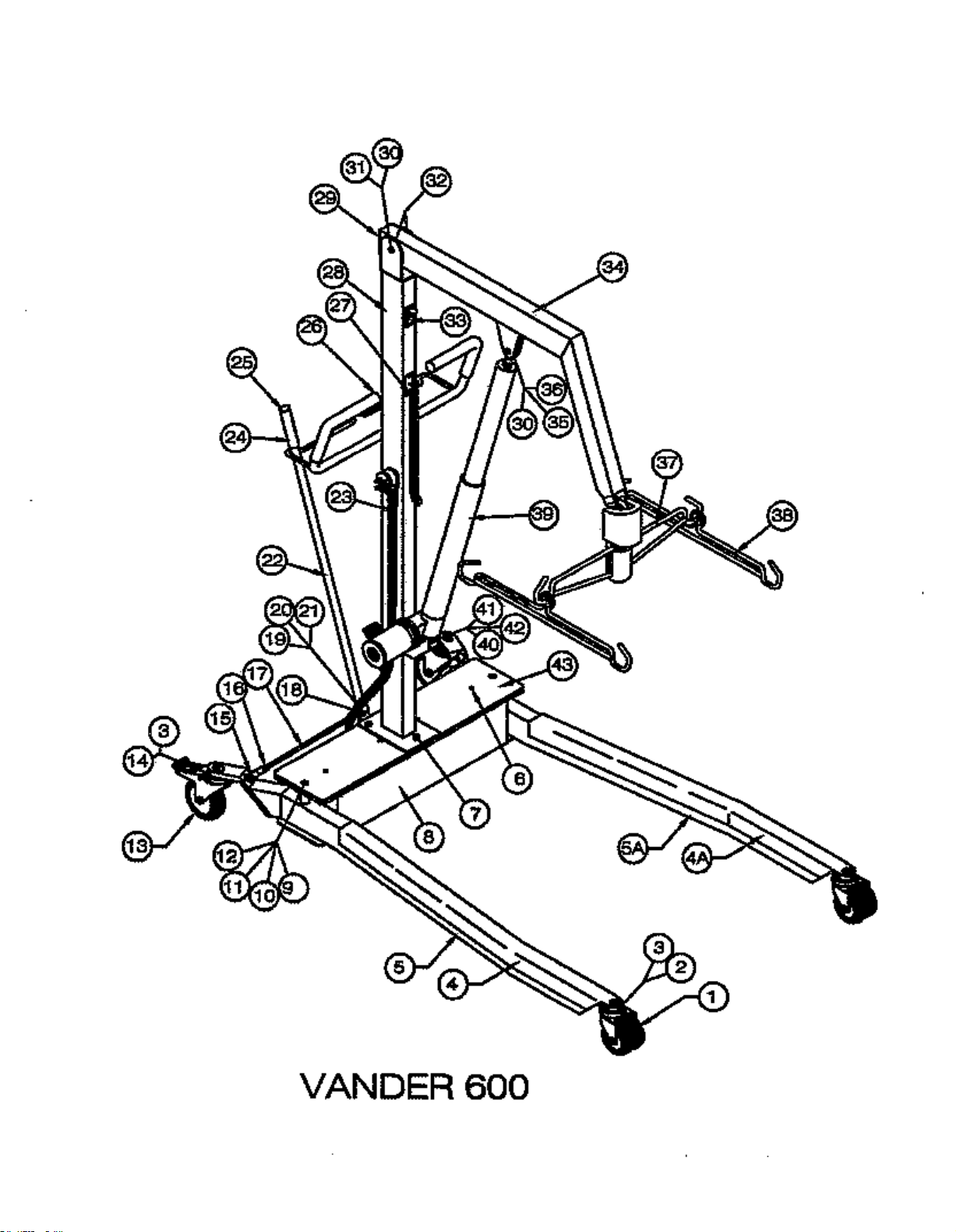

Vander-Lift 600 diagram, part numbers and descriptions Page 7-8

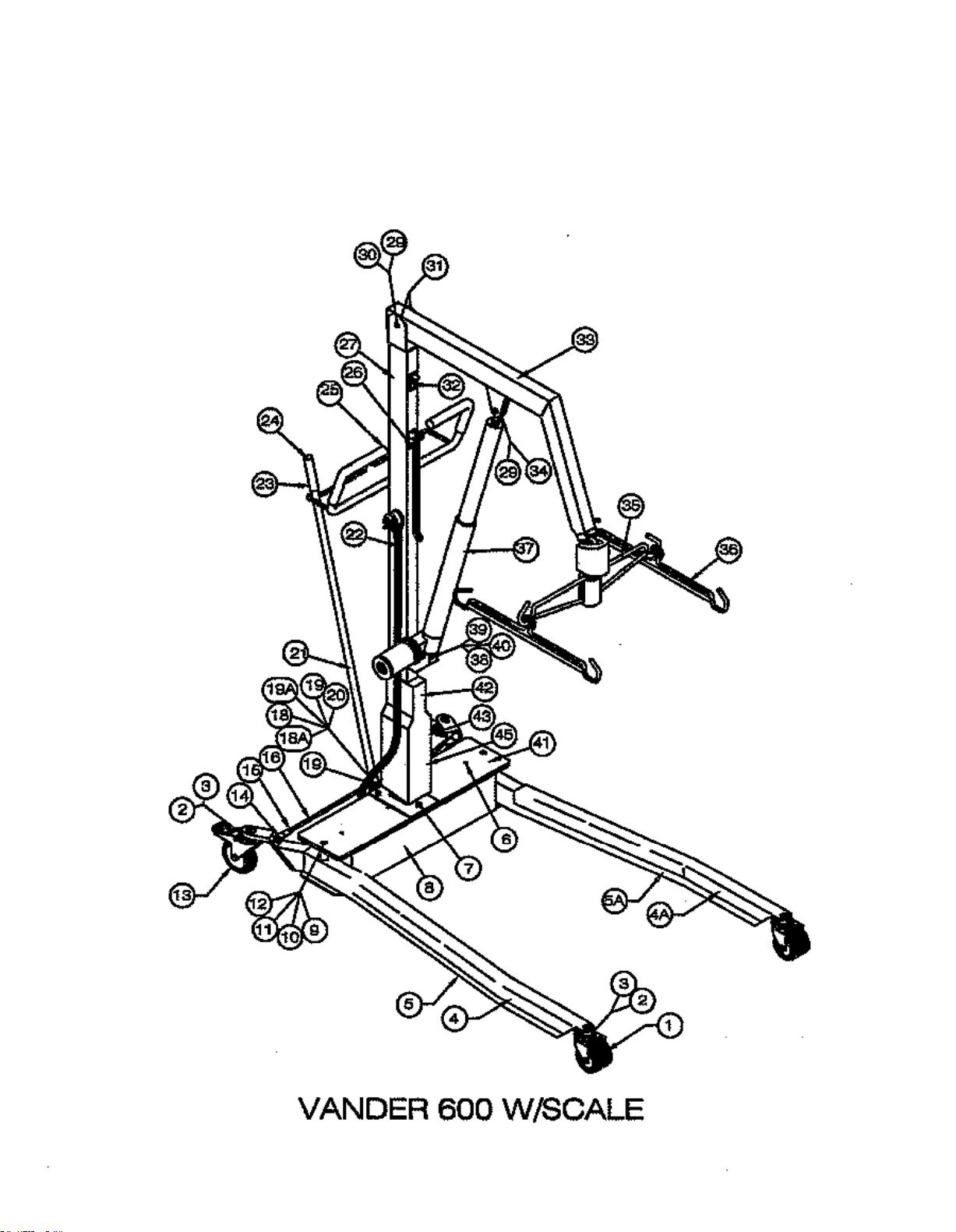

Vander-Lift 600 w/scale diagram, part numbers and descriptions Page 9-10

Vander-Lift 1000 diagram, part numbers and descriptions Page 11-12

ASSEMBLING LIFT

Tools needed to assemble your lift Page 13

Assembly Procedure Page 13-14

TROUBLE SHOOTING GUIDE

Problems, Solutions & Diagrams Page 15-22

MONTHLY VANDER-LIFT SLING INSPECTION SHEET Page 24

MONTHLY VANDER-LIFT INSPECTION SHEET Page 26

QUARTERLY MAINTENANCE CHECK

Tools needed for quarterly maintenance check Page 28

Quarterly Maintenance Page 28-29

For your nearest Distributor, call 1-800-694-4525

1

April 2014

For your nearest Distributor, call 1-800-694-4525

3

V-L LEG PROTECTORS CLEAR

OPTIONAL

VANDERLIFT 450

April 2014

For your nearest Distributor, call 1-800-694-4525

4

REF # PART # DESCRIPTION QTY REF # PART # DESCRIPTION QTY

1 MFG-9-523190 CASTER 3" NON-LOCK 2 35 MFG-6-000350 INDEX ARM (ZI

2 MFG-9-238120 3/8-16X1.25 F

3 MFG-9-263820 3/8-16 NYLON LOCKNUT 4 23 MFG-6-000055 HOSP PLUG W/AC CORD 1

4 MFG-4-900615

5 MFG-4-100010 V-

FG-

M

4-200010 V-L LEG (BLUE) 2

6 MFG-9-225750 1/4-20 X 3/

7 MFG-9-238100 3/8-16 X 1 GR 5 B0LT 3 28 MFG-4-100030 V-L TOWER (WHITE) 1

8 MFG-4-100020 V-L BASE (WHITE) 1 MFG-4-200030 V-L TOWER (BLUE) 1

MFG-4-200020 V-L BASE (BLUE) 1 *28 MFG-9-322039 VC CORD ASSEM (TAN) 1

*8 MFG-6-008000 24V CONTROL BOARD 1 *28 MFG-9-336450 E-STOP WIRE HARNESS 1

*8 MFG-9-270463 4-40X5/8 SH CAP (SS) 2 *28 MFG-9-370650 POWER CORD (MOTOR) 1

*8 MFG-9-270625 6-32X1/4 BH SH (SS) 2 *28 MFG-9-398956 WIRE 5&6 MICRO SWTCH 1

*8 MFG-9-270838 #8-32 X 3/8" PH-PH 2 *28 MFG-9-542400 1/2" GROMMET 5

*8 MFG-9-271075 #1O-24 X 3/4 MS 1

*8 MFG-9-290650 #6 INT

7 MFG-9-293807 3/8" SPLIT LOCK WASH 5 32

*

*

8 MFG-9-320650 CORD RESTRAINT 1 33

8 MFG-9-321510 BATTERY 12 VOLT 2 34 1

*

*8 MFG-9-351600 JUMPERS (BATTERY) 1

*

8 MFG-9-386630 FLAG TERM. .250 1

*8 MFG-9-386710 RING TERMINAL (BLUE) 2 35 MFG-9-265005 1/2 -20 JAM NUT 2

*8 MFG-9-387100 SPADE CONN

*8 MF

*8 MFG-9-570850 BATTERY PAD (UPPER) 1 38 MFG-4-520151 ACTUATOR, V-L 24V 1

*8 MFG-9-570860 BATTERY PAD (LOWER) 1 *38 MFG-4-930145 CRANK - EMERGENCY DN 1

*8 MFG-9-570870 BOARD PAD 1 *38 MFG-9-370660 MIC SWITCH/DOOR&LIFT 1

*8 SEW -6-000089 BATTERY STRAPS 1 *38 SEW -4-900171 V-L BOOT (BLK) 1

9 MFG-9-250050 1/2-13 X 5 1/4 HH G5-LEG 2 39 MFG-9-238125 3/8 X 1 1/4 SH BOLT 1

10 MFG-9-295040 WASHER .040/SS 2 40 MFG-9-263118 5/16-18 HEX NUT 1

11 MFG-9-295062 WASHER .062/SS 2 41 MFG-9-645500 HOSE 4 ACT. BUSHING 1

12 MFG-9-265008 1/2-13 NYLON JAM NUT 2 42 MFG-6-000522 PLASTIC LIDS 2

13 MFG-9-523120 CASTER 4" LOCKING 2 * MFG-9-261024 #10-24 LOCK NUT 2

14 MFG-9-238153 3/8-16X 1.5 FH SH/SS 2 * MFG-9-672020 PLASTIC MOUNT-MICRO 1

15 MFG-6-583650 CUT TIE ROD ENDS 2 * SEW-6-001048 SLING/BELT BAG 1

16 MFG-9-263824 3/8-24 N.F. NUT-ZN 6 *

17 MFG-6-000366 TIE ROD - CHROMED 2

18 MFG-9-583600 TIE ROD END 2 * NOT PICTURED

19

20 MFG-9-592300 WASHER 5/8" BLK FIBE 1 MFG-4-401200 IMS HANGING SCALE 1

G-9-542400 1/2" GROMET 1 37 MFG-4-910120 HANGER ROD COMPLETE 2

MFG-9-266311 LOC NUT 5/8-11 1

L LEG (WHITE) 2 25 MFG-9-633820 7/8" END CAP-RUBBER 3

H-SH/SS 2 22 MFG-6-

2

4 FH PH 4 27 MFG-6-008025 PENDANT SWITCH-CON/B 1

ERNAL LOCK/WSH 2 31

-MALE (BL) 1 36 MFG-4-910130 COMP/HANGER BAR(G

43

573300 SHIFT BAR (33 3/

MFG-9-250155 1/2-20X 1 1/2 HH

MFG-9-624110 BRONZE BUSHING 3/4"

MFG-9-370690 EMERGENCY STOP SW TCH

MFG-4-100070 LIFT ARM (WHITE)

MFG-4-200070 LIFT ARM (BLUE)

MFG-9-225020

MFG-9-621000 1" LOCKING PLUG 2

3/4 PLASTIC CAPS

NC) 1

4") 1

1

2

1

1

RAY) 1

4

For your nearest Distributor, call 1-800-694-4525

April 2014

For your nearest Distributor, call 1-800-694-4525

5

REF #

PART # DESCRIPTION QTY

1

MFG-9-523190 CASTER 3" NON-LOCK 2

2

MFG-9-238120 3/8-16X1.25 FH-SH/SS 4

3

MFG-9-263820 3/8-16 NYLON LOCKNUT 4

4

MFG4-900615

V-L LEG PROTECTORS CLEAR

5

6

MFG-9-225750 1/4-20 X 3/4 FH PH 4

MFG-9-238100 3/8-16 X 1 GR 5 B0LT 3

MFG-9-290650 #6 INTERNAL LOCK/W SH 2

MFG-9-293807 3/8" SPLIT LOCK WASH 5 MFG-4-100037 V-L/SCALE TOWER-WHITE 1

8

MFG-4-200021 V-L BASE/SCALE BLUE 1

MFG-9-320650 CORD RESTRAINT 1

MFG-6-008000 24V CONTROL BOARD 1

MFG-9-336450 E-STOP WIRE HARNESS 1

MFG-9-261024 #10-24 LOCK NUT 2

MFG-9-398956 WIRE 5&6 MICRO SWTCH 1

MFG-9-270463 4-40X5/8 SH CAP (SS) 2

MFG-9-542400 1/2" GROMET 1

MFG-9-270625 6-32X1/4 BH SH (SS) 2

MFG-9-270838 #8-32 X 3/8" PH-PH 2

MFG-9-265005 1/2-20 NYLON JAM NUT 2

MFG-9-250250 1/2-20 X 2 1/2 HH 1

MFG-9-271075 #1O-24 X 3/4 MS 1

MFG-9-624110 BRONZE BUSHING 3/4" 2

MFG-9-321510 BATTERY 12 VOLT 2

MFG-9-370690 EMERGENCY STOP SWTCH 1

MFG-9-351600 JUMPERS (BATTERY) 1

MFG-4-200070 LIFT ARM (BLUE) 1

MFG-9-386630 FLAG TERM. .250 1 MFG-4-100070 LIFT ARM (WHITE) 1

MFG-9-386710 RING TERMINAL (BLUE) 2

1/2-20X 1 1/2 HH 1

MFG-9-387100 SPADE CONN-MALE (BL) 1 2

MFG-9-570850

BATTERY PAD (UPPER) 1

MFG-4-910130

MFG-9-570860 BATTERY PAD (LOWER) 1

MFG-4-910120 HANGER ROD COMPLETE 2

MFG-9-570870 BOARD PAD 1

MFG-4-520151 ACTUATOR, V-L 24V 1

SEW-6-000089 BATTERY STRAPS 1

MFG-4-930145 CRANK - EMERGENCY DN 1

MFG-9-250050 1/2-13 X 5 1/4 HH G5-LEG 2

MFG-9-370660 MIC SWITCH/DOOR&LIFT 1

MFG-9-295062 WASHER .062/SS 3

MFG-9-238125 3/8 X 1 1/4 SH BOLT 1

MFG-9-265008 1/2-13 NYLON JAM NUT 2

MFG-9-263118 5/16-18 HEX NUT 1

MFG-9-523120 CASTER 4" LOCKING 2

MFG-9-645500 HOSE 4 ACT. BUSHING 1

MFG-9-238153 3/8-16X 1.5 FH SH/SS 2

MFG-6-000522 PLASTIC LIDS 2

MFG-6-583650 CUT TIE ROD ENDS 2

MFG-4-200047 V-L/S CELL MOUNT-BL 1

MFG-9-263824 3/8-24 N.F. NUT-ZN 6 MFG-4-100047 V-L/S CELL MOUNT-WHITE 1

MFG-9-583600 TIE ROD END 2 MFG-4-100057 V-L/S CELL HSING-WHITE 1

MFG-5-704000 1" GREEN SPRING/DANLY 1

MFG-9-238107 3/8-16 X 1 FH SH(SS) 2

MFG-6-542211 .078 THRUST BEARING 1

MFG-6-771017 MAST/SCALE LOAD CELL 1

MFG-6-542212 .060 RACE 2

*

MFG-6-771007 MAST/SCALE METER(SS) 1

MFG-6-542470 INDEX ARM-2 1

SEW-4-900171 V-L BOOT (BLK) 1

MFG-6-542575 INDEX GUIDE BOLT 1

SEW-6-001048 SLING/BELT BAG 1

VANDERLIFT 450 W/SCALE

April 2014

For your nearest Distributor, call 1-800-694-4525

6

*8

*8

*8

*8

*8

*8

*8

*8

*8

*8

9

10

11

12

13

14

15

16

17

18

19

19A

20

20A

21

MFG-4-200010 V-L LEG (BLUE) 2

MFG-4-100010 V-L

7

*8

*7

MFG-4-100021 V-L BASE/SCALE WHITE 1

*8

*8

*8

*8

*8

MFG-9-295040 WASHER .040/SS 2

MFG-6-000366 TIE ROD - CHROMED 2

LEG (WHITE) 2

REF #

*21A

21A

22

2

23

25

26 MFG-9-621000 1" LOCKING PLUG 2

27

28

*28

*28

*28

*28

*28

30

31

32

33

34

35

36

37

38

*38

*38

*38

39

40

41

42

43

*28

*44

45

*38

*

*

* NOT PICUTRED

PART # DESCRIPTION QTY

MFG-9-265010 1/2-13 HEX NUT -ZN 2

MFG-9-250047 1/2-13 X 4 SH CS -SS 1

MFG-6-573290 SHIFT BAR-2 (29") 1

MFG-6-000055 HOSP PLUG W/AC CORD 1

MFG-9-633820 7/8" END CAP-RUBBER 1

MFG-6-008025 PENDANT SWITCH-CON/B 1

MFG-4-200037 V-L/SCALE TOWER-BLUE 1

MFG-9-322039 VC CORD ASSEM (TAN) 1

MFG-9-265005

COMP/HANGER BAR(GREY)

MFG-9-672020 PLASTIC MOUNT-MICRO 1

MFG-4-200057 V-L/S CELL HSING-BLU 1

MFG-9-225020 3/4 PLASTIC CAPS 4

April 2014

For your nearest Distributor, call 1-800-694-4525

7

600 LEG PROT (RIGHT) CLEAR

VANDERLIFT 600

April 2014

For your nearest Distributor, call 1-800-694-4525

8

REF # PART # DESCRIPTION QTY REF # PART # DESCRIPTION QTY

1 MFG-9-523190 CASTER 3" NON-LOCK 2 21 MFG-9-592300 WASHER 5/8" BLK FIBE 1

2 MFG-9-238120 3/8-16X1.25 FH-SH/S

3 MFG-9-263820 3/8-16 NYLON LOCKNUT 4 23 MFG-6-000055 HOSP PLUG W/AC CORD 1

4 MFG-4-900617

4A MFG-4-

5 MFG-4-100602 600 LEG (RI

5A MFG-4-100601 600 LEG (LEFT) WHITE 1 28 MFG-4-100030 V-L TOWER (W HITE) 1

6 MFG-9-225750 1/4-20 X 3/4 FH PH 4 *28 MFG-9-322039 VC CORD ASSEM (TAN) 1

7 MFG-9-238100 3/8-16 X 1 GR 5 B0LT 3 *28 MFG-9-336450 E-STOP WIRE HARNESS 1

*7 MFG-9-293807 3/8" SPLIT LOCK WASH 5 *28 MFG-9-370650 POWER CORD (MOTOR) 1

8 MFG-4-100020 V-L BASE (WHITE) 1 *28 MFG-9-398956 WIRE 5&6 MICRO SWTCH 1

*8 MFG-6-008000 24V CONTROL BOARD 1 29 MFG-9-672010 PLASTIC PLUG 2.5X1.5 1

*8 MFG-9-270463 4-40X5/8 SH CAP (SS) 2 30 MFG-9-265005 1/2-20 NYLON JAM NUT 2

*8 MFG-9-270625 6-32X1/4 BH SH (SS) 2 31 MFG-9-250250 1/2-20X2 1/2 HH 1

*8 MFG-9-270838 #8-32 X 3/8" PH-PH 2 32 MFG-9-624110 BRONZE BUSHING 3/4" 2

*8 MFG-9-271075 #1O-24 X 3/4 MS 1 33 MFG-9-370690 EMERGENCY STOP SWTCH 1

*8 MFG-9-320650 CORD RESTRAINT 1 34 MFG-4-100070 LIFT ARM (WHITE) 1

*8 MFG-9-321510 BATTERY 12 VOLT 2 MFG-4-200070

*8 MFG*8 MFG-9-386630 FLAG TERM. .250 1 36 MFG-9-295012 WASHER- 1/2 X 1 O.D. 2

*8 MFG-9-386710 RING TERMINAL (BLUE) 2 37 MFG-4-910130 COMP/HANGER BAR(GREY) 1

*8 MFG-9-387100 SPADE CONN-MALE (BL) 1 38 MFG-4-910120 HANGER ROD COMPLETE 2

*8 MFG-9-570850 BATTERY PAD (UPPER) 1 39 MFG-4-520151 ACTUATOR, V-L 24V 1

*8 MFG-9-570860 BATTERY PAD (LOWER) 1 *39 MFG-4-930145 CRANK - EMERGENCY DN 1

*8 MFG-9-570870 BOARD PAD 1 *39 MFG-9-290650 #6 INTERNAL LOCK/W SH 2

*8 SEW -6-000089 BATTERY STRAPS 1 *39 MFG-9-370660 MIC SWITCH/DOOR&LIFT 1

9 MFG-9-250050 1/2-13 X 5 1/4 HH G5-LEG 2 *39 MFG-9-672020 PLASTIC MOUNT-MICRO 1

10 MFG-9-295040 WASHER .040/SS 2 *39 SEW-4-900171 V-L BOOT (BLK) 1

11 MFG-9-295062 WASHER .062/SS 2 40 MFG-9-238125 3/8 X 1 1/4 SH BOLT 1

12 MFG-9-265008 1/2-13 NYLON JAM NUT 2 41 MFG-9-645500 HOSE 4 ACT. BUSHING 1

13 MFG-9-523120 CASTER 4" LOCKING 2 42 MFG-9-263118 5/16-18 HEX NUT 1

14 MFG-9-238153 3/8-16X 1.5 FH SH/SS 2 43 MFG-6-000522 PLASTIC LIDS 2

15 MFG-6-583650 CUT TIE ROD ENDS 2 * MFG-9-261024 #10-24 LOCK NUT 2

16 MFG-9-263824 3/8-24 N.F. NUT-ZN 6 * SEW -6-001048 SLING/BELT BAG 1

17 MFG-4-900605 600 TIE ROD-CHROMED 2

18

19 MFG-6-000350 INDEX ARM (ZINC) 1 * NOT PICTURED

20 MFG-9-266311 LOC NUT 5/8-11 1

900616 600 LEG PROT (LEFT) CLEAR 1 25 MFG-9-633820 7/8" END CAP-RUBBER 1

GHT

MFG-4-200602 600 LEG (RIGHT) BLUE 1 27 MFG-6-008025 PENDANT SWITCH-CON/B 1

MFG-4-200601 600 LEG (LEFT) BLUE 1 MFG-4-200030 V-L TOWER (BLUE) 1

MFG-4-200020 V-L BASE (BLUE) 1 *28 MFG-9-542400 1/2" GROMMET 1

9-351600 JUMPERS (BATTERY)

MFG-9-

583600 TIE ROD END 2

S 2 22 MFG-6-573300 SHIF

1

) WHT 1 26 MFG-9-621000 1" LOCKING PLUG 2

1 35 MFG-

* MFG-9-225020 3/4 PLAST

9-250155 1/2-20X1 1/2 HH 1

MFG-4-401200 IMS HANGING SCALE 1

T BAR (33 3/4") 1

LIFT ARM (BLUE) 1

IC CAPS 4

OPTIONAL

April 2014

For your nearest Distributor, call 1-800-694-4525

9

REF #

PART # DESCRIPTION QTY

QTY

1

MFG-9-523190 CASTER 3" NON-LOCK 2

1

2

MFG-9-238120 3/8-16X1.25 FH-SH/SS 4

2

3

MFG-9-263820 3/8-16 NYLON LOCKNUT 4

1

4

MFG-4-900617

600 LEG PROT (RIGHT) CLEAR

1

5

MFG-4-200602 600 LEG-RIGHT (BLUE) 1

MFG-4-200601 600 LEG-LEFT (BLUE) 1

6

MFG-9-225750 1/4-20 X 3/4 FH PH 4

1

7

MFG-9-238100 3/8-16 X 1 GR 5 B0LT 3

1

8

MFG-4-200021 V-L BASE/SCALE BLUE 1

1

1

MFG-6-008000 24V CONTROL BOARD 1

1

MFG-9-261024 #10-24 LOCK NUT 2

MFG-9-270463 4-40X5/8 SH CAP (SS) 2

MFG-9-265005 1/2-20 NYLON JAM NUT

MFG-9-270625 6-32X1/4 BH SH (SS) 2

MFG-9-250250 1/2-20-2 1/2 HH

MFG-9-270838 #8-32 X 3/8" PH-PH 2

MFG-9-624110 BRONZE BUSHING 3/4"

MFG-9-271052 #10-24-1/2 BH SH-SS 2

MFG-9-370690 EMERGENCY STOP SWTCH

MFG-9-271075 #1O-24 X 3/4 MS 1

MFG-4-200070 LIFT ARM (BLUE)

1

MFG-9-321510 BATTERY 12 VOLT 2

MFG-4-100070 LIFT ARM (WHITE)

1

MFG-9-351600 JUMPERS (BATTERY) 1

1

MFG-9-386630 FLAG TERM. .250 1

MFG-9-386710

RING TERMINAL (BLUE) 2

MFG-4-910130

1

MFG-9-387100 SPADE CONN-MALE (BL) 1

MFG-4-910120 HANGER ROD COMPLETE 2

MFG-9-542400 1/2" GROMET 1

MFG-4-520151 ACTUATOR, V-L 24V 1

MFG-9-570850 BATTERY PAD (UPPER) 1

MFG-4-930145 CRANK - EMERGENCY DN 1

MFG-9-570860 BATTERY PAD (LOWER) 1

MFG-9-290650 #6 INTERNAL LOCK/W SH 2

SEW-6-000089 BATTERY STRAPS 1

MFG-9-672020 PLASTIC MOUNT-MICRO 1

MFG-9-250050 1/2-13 X 5 1/4 HH G5-LEG 2

MFG-9-238125 3/8 X 1 1/4 SH BOLT 1

MFG-9-295040 WASHER .040/SS 2

MFG-9-263118 5/16-18 HEX NUT 1

MFG-9-295062 WASHER .062/SS 3

MFG-9-645500 HOSE 4 ACT. BUSHING 1

MFG-9-265008 1/2-13 NYLON JAM NUT 2

MFG-6-000522 PLASTIC LIDS 2

MFG-9-523120 CASTER 4" LOCKING 2

MFG-6-771017 MAST/SCALE LOAD CELL 1

2

6

MFG-9-238107 3/8-16 X 1 FH SH(SS) 2

2

MFG-4-200047 V-L/S CELL MOUNT-BL 1

2 MFG-4-100047 V-L/S CELL MOUNT-WHITE 1

1

MFG-6-771007 MAST/SCALE METER(SS) 1

1

SEW-4-900171 V-L BOOT (BLK) 1

MFG-6-542212 .060 RACE 2

*

SEW-6-001048 SLING/BELT BAG 1

MFG-6-542470 INDEX ARM-2 1 * MFG-9-225020 3/4 PLASTIC CAPS 4

MFG-6-542575 INDEX GUIDE BOLT 1

VANDERLIFT 600 W/SCALE

April 2014

For your nearest Distributor, call 1-800-694-4525

10*April 2014

4A

MFG-4-900607 600 LEG PROT (LEFT) CLEAR 1

MFG-4-100602 600 LEG-RIGHT (W HITE) 1

5A

MFG-4-100601 600 LEG-LEFT (W HITE) 1

*7

MFG-9-293807 3/8" SPLIT LOCK WASH 5

MFG-4-100021 V-L BASE/SCALE WHITE 1

*8

*8

*8

*8

*8

*8

*8

*8

*8

*8

*8

*8

*8

*8

*8

*8

MFG-9-570870 BOARD PAD 1

*8

9

10

11

12

13

REF #

20

20A

21

1

22

24

25

26

27

*27

*27

*27

*27

*27

*27 MFG-4-200057 V-L/S CELL HOUSING-BLU 1

*27 MFG-4-100057 V-L/S CELL HOUSING-WHITE 1

29

30

31

32

33

34

35

36

37

*37

*37

*37

*37

38

39

40

41

42

PART # DESCRIPTION

MFG-9-250047 1/2-13 X 4 SH CS -SS

MFG-9-265010 1/2-13 HEX NUT -ZN

MFG-6-573290 SHIFT BAR-2 (29")

MFG-6-000055 HOSP PLUG W/AC CORD

MFG-9-633820 7/8" END CAP-RUBBER 1

MFG-9-621000 1" LOCKING PLUG

MFG-6-008025 PENDANT SWITCH-CON/B

MFG-4-200037 V-L/SCALE TOWER-BLUE

MFG-4-100037 V-L/SCALE TOWER-WHITE

MFG-9-320650 CORD RESTRAINT

MFG-9-322039 VC CORD ASSEM (TAN) 1

MFG-9-336450 E-STOP WIRE HARNESS

MFG-9-370650 POWER CORD (MOTOR)

MFG-9-398956 WIRE 5&6 MICRO SWTCH

MFG-9-250155 1/2 X 20 1 1/2" HH

COMP/HANGER BAR(GREY)

MFG-9-370660 MIC SWITCH/DOOR&LIFT 1

2

2

1

1

2

1

2

1

14

MFG-6-583650 CUT TIE ROD ENDS

15

MFG-9-263824 3/8-24 N.F. NUT-ZN

16

MFG-4-900605 600 TIE ROD-CHROMED

17

MFG-9-583600 TIE ROD END

18

MFG-5-704000 1" GREEN SPRING/DANLY

18A

19

19A

20

MFG-6-542211

.078 THRUST BEARING

*44

45

*

*37

* NOT PICTURED

For your nearest Distributor, call 1-800-694-4525

11

600 LEG PROT (RIGHT) CLEAR

VANDERLIFT 1000

April 2014

For your nearest Distributor, call 1-800-694-4525

12

REF # PART # DESCRIPTION QTY REF # PART # DESCRIPTION19 QTY

1 MFG-9-523190 CASTER 3" NON-LOCK 2

2 MFG-9-238153 3/8-16X 1.5 FH SH/SS 4 20 MFG-9-266311 LOC NUT 5/

3 MFG-9-263820 3/8-16 NYLON LOCKNUT 4 21 MFG-6-573300 SHIFT BAR (33 3/4") 1

4 MFG-4-900617

4A MFG-4-900618 600 LEG PROT (LEFT) CLEAR 1

5 MFG-4-

5A MFG-4-101001 1000 LEG-LH (WHT) 1 26 MFG-6-008025 PENDANT SWITCH-CON/B 1

6 MFG-9-225750 1/4-20 X 3/4 FH PH 4 MFG-4-201030 1000 TOWER (BLUE) 1

7 MFG-9-238122 3/8-16 X 1 1/4 HH-G5 3 *27 MFG-9-322039 VC CORD ASSEM (TAN) 1

*7 MFG-9-293807 3/8" SPLIT LOCK WASH 5 *27 MFG-9-336450 E-STOP WIRE HARNESS 1

8 MFG-4-101020 1000 BASE (WHT) 1 *27 MFG-9-370650 POWER CORD (MOTOR) 1

*8 MFG-6-008000 24V CONTROL BOARD 1

*8 MFG-9-270463 4-4

*8 MFG-9-270625 6-32X1/4 BH SH (SS) 2 30 MFG-9-250250 1/2-20-2 1/2 HH 1

*8 MFG-9-270838 #8-32 X 3/8" PH-PH 2 31 MFG-9-624110 BRONZE BUSHING 3/4" 2

*8 MFG-9-271075 #1O-24 X 3/4 MS 1 32 MFG-9-370690 EMERGENCY STOP SWTCH 1

*8 MFG-9-320650 CORD RESTRAINT 1 33 MFG-4-101070 1000 ARM (W HT) 1

*8 MFG-9-321510 BATTERY 12 VOLT 2 MFG-4-201070

*8 MFG-9-351600 JUMPER

*8 MFG-9-386630 FLAG TERM. .250 1

*8 MFG-9-386710 RING TERMINAL (BLUE) 2 35 MFG-4-910110 1000# HANGER BAR/

*8 MFG-9-387100 SPADE CONN-MALE (BL) 1 *35 MFG-9-261024 #10-24 LOCK NUT 2

*8 MFG-9-570850 BATTERY PAD (UPPER) 1 37 MFG-4-551000 1000# ACTUATOR ASSY 1

*8 MFG-9-570860 BATTERY PAD (LOWER) 1 *37 MFG-4-930145 CRANK - EMERGENCY DN 1

*8 MFG-9-570870 BOARD PAD 1 *37 MFG-9-290650 #6 INTERNAL LOCK/W SH 2

*8 SEW -6-000089 BATTERY STRAPS 1 *37 MFG-9-370660 MIC SWITCH/DOOR&LIFT 1

9 MFG-9-250058 1/2 X 5 1/2 HH G8 2 *37 MFG-9-672020 PLASTIC MOUNT-MICRO 1

10 MFG-9-295040 WASHER .040/SS 2 *37 SEW-4-900171 V-L BOOT (BLK) 1

11 MFG-9-295062 WASHER .062/SS 2 38 MFG-9-238125 3/8 X 1 1/4 SH BOLT 1

12 MFG-9-265008 1/2-13 NYLON JAM NUT 2 39 MFG-9-263118 5/16-18 HEX NUT 1

13 MFG-9-523120 CASTER 4" LOCKING 2 40 MFG-9-645500 HOSE 4 ACT. BUSHING 1

14 MFG-6-583650 CUT TIE ROD ENDS 2 41 MFG-6-000522 PLASTIC LIDS 2

*15 MFG-9-263824 3/8-24 N.F. NUT-ZN 6 * SEW -6-001048 SLING/BELT BAG 1

16 MFG-4-900605 600 TIE ROD-CHROMED 2

17 MFG-9-583600 TIE ROD END 2

18 MFG-6-000350 INDEX ARM (ZINC) 1 * NO

101002 1000 LEG-RH (WHT) 1 24 MFG-9-633820 7/8"

-4-201002 1000 LEG-RH (BLUE) 1 25 MFG-9-621000 1" LOCKING PLUG 2

NFG

MFG-4-201001 1000 LEG-LH (BLUE) 1 27 MFG-4-101030 1000 TOWER (WHT) 1

MFG-4-201020 1000 BASE (BLUE) 1 *27

0X5/8 SH CAP (SS) 2 29 MFG-9-265005 1/2-20 NYLON JAM NUT 2

S (BATTERY) 1 34 MFG-9-250155 1/2-20X1 1/2 HH 1

1 22 MFG-6-000055 HOSP PLUG W/AC CORD 1

19 MFG-9-592300 W ASHER 5/8" BLK FIBE 1

8-11 1

END CAP-RUBBER 3

MFG-9-398956 WIRE 5&6 MICRO SWTCH 1

*27 MFG-9-542400 1/2" GROMMET 1

1000 ARM (BLUE) 1

COM 1

36 MFG-4-910100 1000# HANGER ROD-COM 2

* MFG-9-225020 3/4 PLASTIC CAPS 4

T PICTURED

OPTIONAL

MFG-4-901145 1000 HANGING SCALE 1

TOOLS NEEDED TO ASSEMBLE YOUR LIFT

April 2014

For your nearest Distributor, call 1-800-694-4525

13

¾ “Wrenches (2) Standard Screw Driver

9/16” Wrench 3/8” Wrench

½” Wrench

Phillips head screw driver

Apply 1-2 drops of Loctite to all nuts and bolts

ASSEMBLY PROCEDURE

FOLLOW STEPS ONE THROUGH TEN

Numbers coincide with pictorial on following page

Step 1) Remove mast with pendant switch, arm assembly, hanger bar with pads, hanger rods and small

cardboard box containing batteries, 10 x 24 nut and bolt, 2 1/2" mast bolt and bottom actuator

bolt, (3)

Step 2) Remove the base

Step 3) Using Phillips screwdriver, remove plastic lids from base assembly.

Step 4) Place mast over base assembly. Connect all wire connectors numbered 1 through 6 and gently

guide wires into base being carful not to pinch any wires when the mast is put on the base.

The number 4 tan wire plugs directly into the control board inside base at phone jacks.

Step 5) Align the three (3) holes in the mast with the three (3) holes in the base. Apply 1-2 drops of

Loctite to the three (3) 3/8” bolts and three (3) 3/8” lock washers; do not tighten them

completely at this time.

Step 6) Place shift bar through shift bar guide on the right end of the mast over the index arm on the

base assembly. (Loosen the three (3) 3/8” bolts on mast if needed.) When shift bar is in place

then tighten the three (3) 3/8” bolts in mast firmly.

Step 7) Place the two batteries inside the base and hook together the battery wire connection. Place

the two black lids back on base and tighten down.

Step 8) Hang hospital grade plug with coil cord on mast before assembling tie rods to index arm. Left

tie rod goes to the bottom hole of the index arm and right tie rod goes to the top hole of the

index arm. Place 3/8” lock washers and 3/8” nut to each tire rod and tighten firmly.

Step 9) Place actuator cover on actuator then align upper arm into mast bracket using ½ x 2 ½ HH bolt.

At this time apply 1-2 drops of Loctite then tighten the ½-20 Jam nut. Align lower arm bracket

holes with top of

inserting ½

Jam nut. Place ¾” plasti

Step 10) Place hanger bar with pads on end of arms assembled and insert 10 x 24 bolt and tighten 3/8”

nut firmly. Place hanger rods on hanger assembly.

3/8” bolts, and (3) 3/8” l

assembly from box.

e actuator, and install 2 3/4" plastic nut covers before

th

- 20 x 1 ½” HH bolt. At th

c caps over nut and bolt on top of the actuator.

ock washers.

is time apply 1-2 drops of Loctite then tighten the ½”-20

April 2014

For your nearest Distributor, call 1-800-694-4525

14

April 2014

For your nearest Distributor, call 1-800-694-4525

15

April 2014

For your nearest Distributor, call 1-800-694-4525

16

TAN PHONE

April 2014

For your nearest Distributor, call 1-800-694-4525

17

CONNECTION

WHITE

MOTOR

POWER CORD

EMERGENCY

STOP SWITCH

BLACK

WHITE

BLACK

BLACK

BLACK W/ RED

24V

T2

RLUPA

P8

T1

P9

PEND

RLWNA

DN

UP

24V

P2

RLUPB

P3

SPARE

P11

P5 P10

2

2

2

P4

RLDWNB

P1

P7

BLUE

F2 F1

P6

BLUE

BRN

BLUE

BRN

WHITE

RED

NOT USED

T1

BRN

BATTERY

MICRO SWITCH

EMERGENCY DOWN

DN BLU

UP

WHT

UP/DOWN

AUXILLARY

T2 BLU

NOT USED

SWITCH

Part #6-008000

24 VOLT CONTROL BOARD

DIAGRAM 1A

BLACK

110 VAC

WHT

INPUT

BATTERY

CHARGER

GRN

BRN

SWITCH

EMERGENCY STOP

NEGATIVE Probe to Blue Wire Side

POSTIVE Probe to Brown Wire Side

4

April 2014

For your nearest Distributor, call 1-800-694-4525

18

9

TAN PHONE

CONNECTION

11

10

1

WHITE

8 Remove/Replace

BLACK

T2

T1

PEND

DN

UP

24V

SPARE

8 Remove/Replace

BLUE

2

2

2

F2 F1

NOT USED

T1

BRN

DN BLUE

UP

WH

T2 BLUE

NOT USED

MOTOR

POWER CORD

EMERGENCY

STOP SWITCH

WHITE

BLACK

3

Part #6-008000

Part #9-378100

Lower PC (Logic Board)

24 VOLT CONTROL BOARD

8

BLACK

BLACK W/ RED

24V

RLUPA

P8

P9

RLWNA

P2

RLUPB

P3

P11

BATTERY

CHARGER

P5 P10

P4

RLDWNB

P1

P7

P6

BLUE

BRN

SWITCH

UP/DOWN

AUXILLARY

BLUE

BRN

WHITE

RED

BATTERY

MICRO SWITCH

EMERGENCY DOWN

62 5

BRN

SWITCH

lower PC board (logic Board)

* Careful to align 6 gold pegs into socket on

EMERGENCY STOP

8 Remove/Replace

8 Remove/Replace

DIAGRAM 1B

3. Using 5/8" wrench, remove auxiliary switch.

4. Remove tan wire connection #4 from phone

jack on control board.

5. Remove control board from base.

6. Remove top PC board (relay board).

To remove top PC board, while pressing

1. Remove black lids using Phillips screwdriver.

2. Unplug & remove batteries.

BLACK

down on white pegs, lift top PC board

teach corner.

connection numbers on through six.

7. Unplug wires from base at

noted on diagram.

8. Remove remaining four connections

WHT

110 VAC

GRN

INPUT

completely disconnected & removed

board), #7 through #12 as per diagram.

screws located one at each corner and

remove old lower PC board (logic board).

board), careful not to tighten to tight

very careful not to press hard when making

connections.

white pegs. Carefully align white pegs and

11. With Phillips screwdriver remove 4 Phillips

12. Screw down new lower PC board (logic

13. Replace connections #7 through #12 being

14. Put the new top PC board (relay board) on

9. Top PC board (relay board) should be

six gold pegs.

10. Remove wires from lower PC board (logic

*Note diagram

disconnected.

15. Replace all connections previously

16. Put control board back into lift base being

careful with wire connections.

Tighten with 5/8" wrench.

17. Reinsert auxiliary switch into back of base.

Probe Here

April 2014

For your nearest Distributor, call 1-800-694-4525

19

Negative (-)

Black

Positive (+)

Probe Here

Red

Probe Here

Negative (-)

Black

Positive (+)

Probe Here

Red

Part #9-321510

(2) 12 VOLT BATTERIES

Here

Connect Jumper

RED WIRE

BLACK WIRE

BATTERY POST HERE

Here

Connect Jumper

BATTERY POST HERE

Diagram 1C

TAN PHONE

April 2014

For your nearest Distributor, call 1-800-694-4525

20

CONNECTION

WHITE

BLUE

P5 P10

2

2

2

P4

RLDWNB

P1

P7

F2 F1

BLUE

BRN

BLUE

BRN

P6

WHITE

RED

PEND

T2

RLUPA

P8

T1

RLWNA

P9

BLACK

MOTOR

WHITE

POWER CORD

BLACK

BLACK

EMERGENCY

STOP SWITCH

24V

SPARE

DN

UP

24V

P2

RLUPB

P3

P11

NOT USED

T1

BRN

UP

WHT

AUXILLARY

BATTERY

DN Bue

T2

Blue

NOT USED

SWITCH

UP/DOWN

MICRO SWITCH

EMERGENCY DOWN

BLK W/ RED TAPE

BRN

Part #6-008000

BATTERY

CHARGER

SWITCH

EMERGENCY STOP

24 VOLT CONTROL BOARD

BLACK

DIAGRAM 2A

U S E E X T R E M E C A U T I O N ! ! !

GRN

Disconnect from

WHT

INPUT

110 VAC

coil cord here

4

April 2014

For your nearest Distributor, call 1-800-694-4525

21

TAN PHONE

CONNECTION

1

WHITE

8 Remove/Replace

8 Remove/Replace

BLACK

T2

T1

PEND

DN

UP

24V

SPARE

BLUE

2

2

2

F2 F1

NOT USED

T1

BRN

DN BLUE

WHT

UP

T2 BLUE

NOT USED

MOTOR

POWER CORD

EMERGENCY

STOP SWITCH

WHITE

BLACK

3

Part #6-008000

Part #9-378200

Lower PC (Logic Board)

24 VOLT CONTROL BOARD

BLACK

BLK W/ RED TAPE

24V

RLUPA

P8

P9

RLWNA

P2

RLUPB

P3

P11

BATTERY

CHARGER

P5 P10

P4

RLDWNB

P1

P7

P6

BLUE

BRN

SWITCH

UP/DOWN

AUXILLARY

BLUE

BRN

WHITE

RED

BATTERY

MICRO SWITCH

EMERGENCY DOWN

62 5

BRN

SWITCH

lower PC board (logic Board)

* Careful to align 6 gold pegs into socket on

EMERGENCY STOP

8 Remove/Replace

8 Remove/Replace

DIAGRAM 5B

3. Using 5/8" wrench, remove auxiliary switch.

4. Remove tan wire connection #4 from phone

jack on control board.

5. Remove control board from base.

6. Remove top PC board (relay board).

To remove top PC board, while pressing

1. Remove black lids using Phillips screwdriver.

2. Unplug & remove batteries.

BLACK

down on white pegs, lift top PC board

teach corner.

connection numbers on through six.

7. Unplug wires from base at

noted on diagram.

8. Remove remaining four connections

WHT

110 VAC

GRN

INPUT

completely disconnected & removed

white pegs. Carefully align white pegs and

9. Top PC board (relay board) should be

six gold pegs.

10. Put the new top PC board (relay board) on

*Note diagram

disconnected.

11. Replace all connections previously

12. Put control board back into lift base being

careful with wire connections.

Tighten with 5/8" wrench.

13. Reinsert auxiliary switch into back of base.

Place Negative Probe

April 2014

For your nearest Distributor, call 1-800-694-4525

22

Place Positive Prode

@ white Wire

@ Black Wire

Be sure connection is

BLACK

secure when finished

PEND

T2

T1

TAN PHONE

CONNECTION

WHITE

DN BLUE

UP

T2 BLUE

NOT USED

DN

UP

24V

SPARE

BLUE

2

2

2

F2 F1

NOT USED

T1

BRN

WHT

MOTOR

WHITE

POWER CORD

EMERGENCY

STOP SWITCH

Part #6-008000

BLACK

BLACK

BLK W/ RED TAPE

24V

RLUPA

P8

P9

RLWNA

P2

RLUPB

P3

P11

BATTERY

CHARGER

P5 P10

P4

RLDWNB

P1

P7

P6

BLUE

BRN

BLUE

BRN

WHITE

RED

BRN

UP/DOWN

AUXILLARY

BATTERY

MICRO SWITCH

EMERGENCY DOWN

SWITCH

EMERGENCY STOP

SWITCH

24 VOLT CONTROL BOARD

DIAGRAM 8A

BLACK

110 VAC

GRN

WHT

INPUT

April 2014

For your nearest Distributor, call 1-800-694-4525

23

MONTHLY VANDER-LIFT™ SLING INSPECTION CHECKLIST

April 2014

For your nearest Distributor, call 1-800-694-4525

24

INSTRUCTIONS: All slings in the facility must be checked monthly. Slings that are damaged or excessively worn must be removed

from service and replaced with undamaged slings. Check each blank as that item is inspected. Note the date inspected, the initials of

the nurse or professional rehabilitation department staff member who performed the inspection, and action taken, if any, in the

“CORRECTIVE ACTION” column.

YEAR

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC CORRECTIVE ACTION

Total number of slings.

Is loose and/or missing

stitching present?

On slings with safety

belts, does Velcro or

plastic connector fasten

securely?

Are tears present?

Is excessive wear

present?

Is color fading on

stabilizing handles?*

Is the padding inside the

leg straps smooth?**

*If the color is fading on the stabilizing handles, this indicates the sling is being laundered with bleach or with a har sher detergent than is recommended. The s li ng must be

removed from service immediately and discarded as bleach or harsh detergent can weaken the fabric and stitching.

**If the padding inside the leg straps is bunched (no longer smooth), this indicates the sling has been dried in a hot dryer. The sling must be removed from service immediately

and discarded as too much heat can damage the sling.

April 2014

For your nearest Distributor, call 1-800-694-4525

25

MONTHLY VANDER-LIFT™ INSPECTION CHECKLIST

April 2014

For your nearest Distributor, call 1-800-694-4525

26

HANGER ROD DIAGRAM

Grommets

Hanger rod

Verify grommets and hanger rods are present and in working condition.

INSTRUCTIONS: Use one page for each VANDER-LIFT™. Check each blank as that item is inspected. Note date inspected, initials of

maintenance staff member who performed inspection and repairs or adjustments made in the “COMMENTS” column.

Serial Number of Lift

Year

JAN

Check nuts & bolts for

tightness

Inspect welds for cracks,

rusting & damage

Inspect hanger bar

welds & tolerance

(see diagram below)

Remove lids & inspect

wire connections

Check casters for

tightness/lint

Check battery voltage

while lift is in operation*

Check battery charger

output (27.6 volts + or-

.5 volts)

FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC COMMENTS

*13.2 volts if fully charged, approx. 12.0 volts if partially discharged (+ or - .5 volt). If voltage decreases by 4 – 5 volts, change the battery.

Please follow the maintenance and inspection procedures

outlined in the product manuals and record accordingly.

Based on institutional average usage data, Vancare

recommends that all lifts be replaced every ten years or

sooner based upon the facilities usage and the findings

during regular use, maintenance and inspections.

April 2014

For your nearest Distributor, call 1-800-694-4525

27

TOOL

April 2014

For your nearest Distributor, call 1-800-694-4525

28

S NEEDED FOR QUARTERLY MAINTENANCE CHECK

¾ “Wrenches (2) 9/16 “Wrench

½ “Wrench AC/DC Volt Meter

Phillips Head Screw Driver

Apply 1-2 drops of Loctite to all nuts and bolts

QUARTERLY MAINTENANCE

heck all nuts and bolts for tightness. If loose, apply 1 or 2 drops of

1.C

Loctite # 271.

2.

Visually inspect welds for cracks and/ or rusting.

3. Check hanger assembly (per diagram.) (VANDER-LIFT ONLY)

4. Check hanger rods (per diagram) Gromets installed & hanger rod clips installed.

5

. Remove lids and visually inspe

6.Check batteries for voltag

ct wire connections.

e (minimum 25 volt). Check each battery for voltage

(should be equal). If more then 3 volts difference replace low battery. This

should be done under load.

heck battery charger for output (26+ volts, maximum output 28 volts)

7.C

ANNUAL MAINTENANCE

(All of the above quarterly maintenance in addition to the items listed below)

A

pply 1.25% of weight capacity to lift and inspect for cracked or weak welds and

any irregular deformation of lift and lift attachments.

April 2014

For your nearest Distributor, call 1-800-694-4525

29

Loading...

Loading...