Page 1

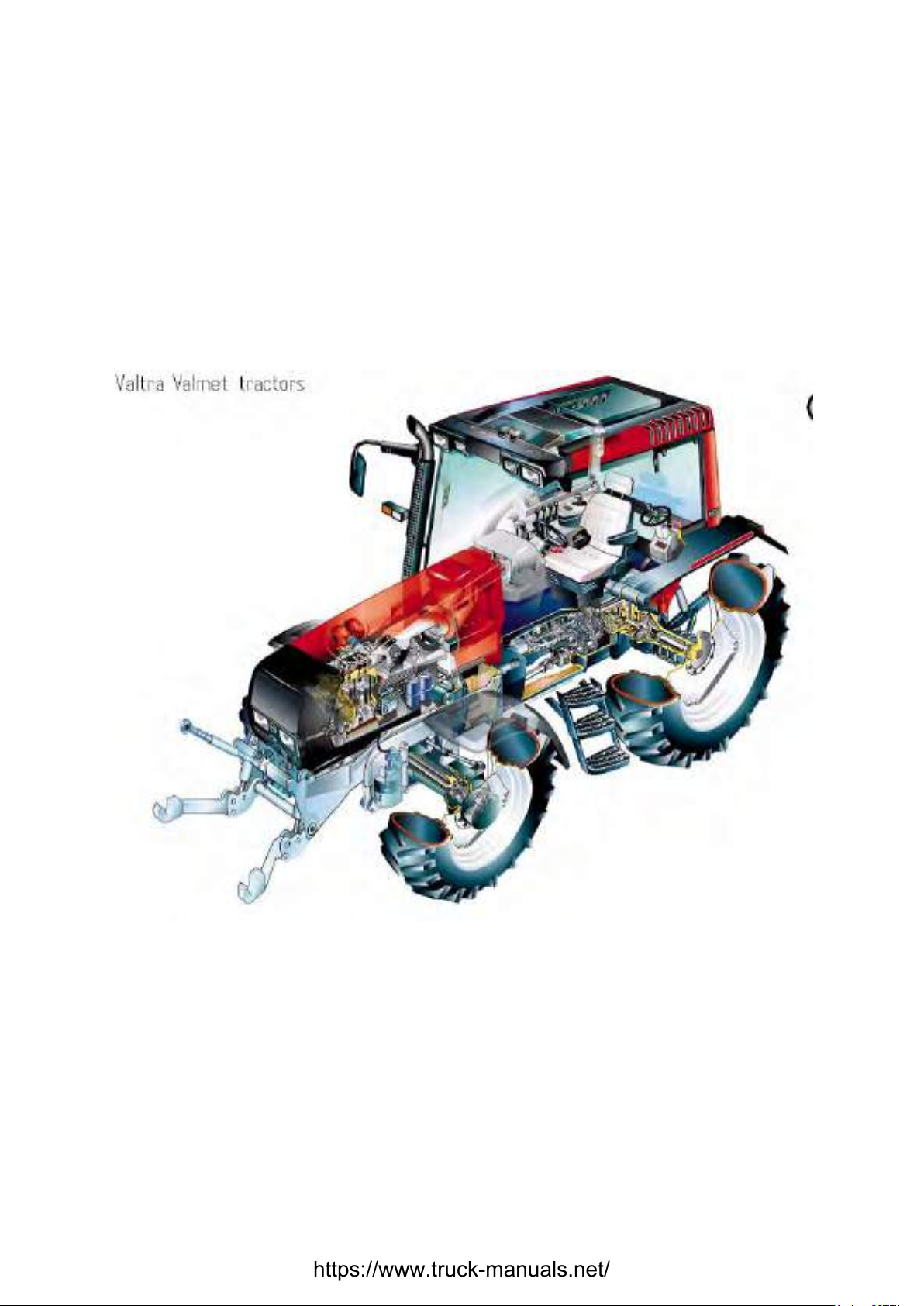

VALTRA – VALMET

MEGA MEZZO HI-TEC

WORKSHOP MANUAL

Page 2

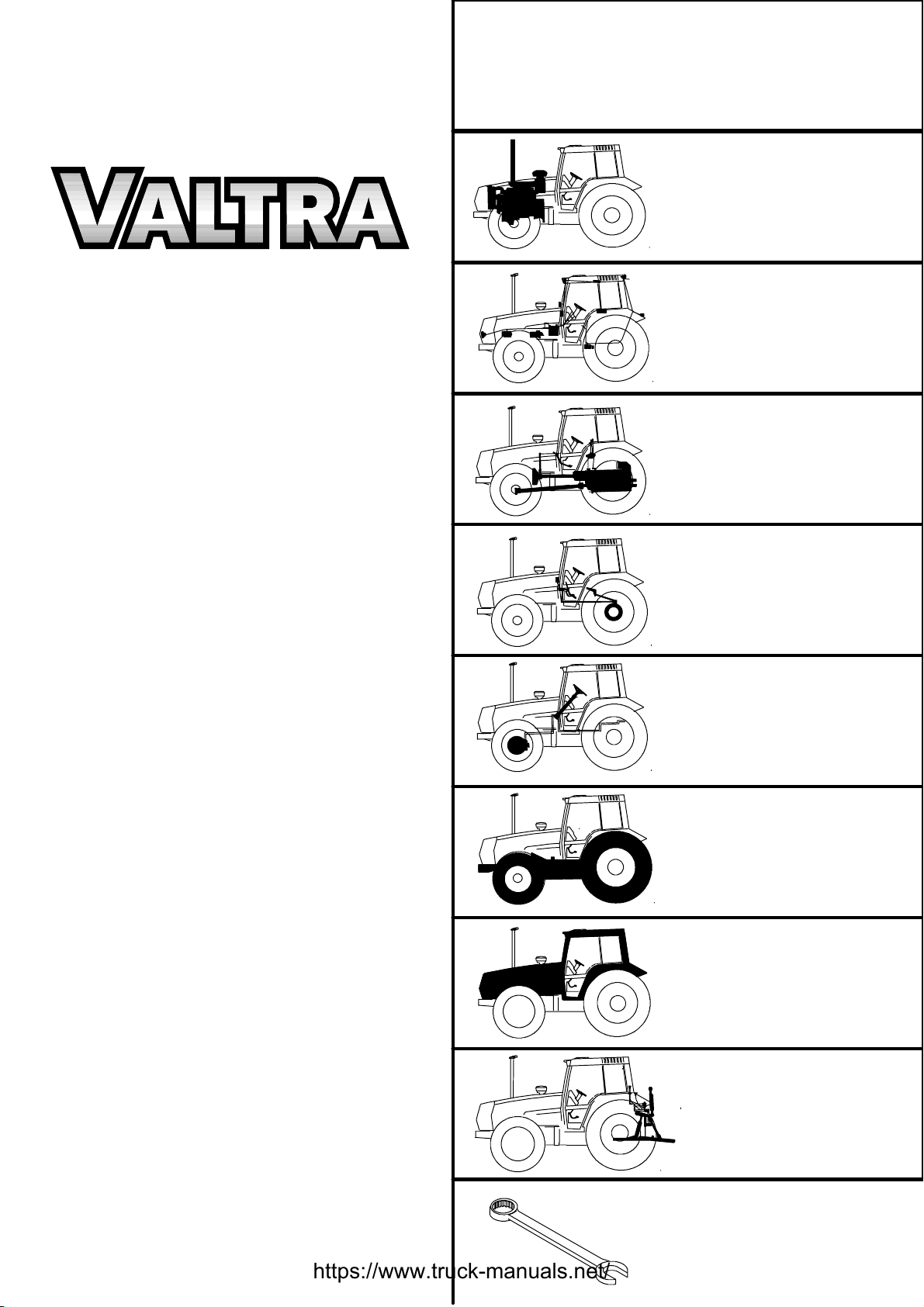

10

General

6000, 6100, 6200

6250, 6300, 6350

6400, 6550, 6600

6650, 6800, 6850

6900, 8000, 8100

8200, 8400, 8050

20

30

40

50

Engine

Electrical

system

Power

transmission

Brake

system

8150, 8450, 8550

8750, 8950

6600E---8750E

Service Manual

Tractors

Groups 10---100

60

70

80

Steering system and Front

axle

Frame and

Wheels

Cab and

Shields

Valtra Inc.

44200 Suolahti, Finland

90

100

Hydraulics

Tools

Page 3

Order no 39 210 211

ENGLISH

Page 4

10. General

11. Layout

12. Repairs

13. Maintenance

Page 5

2

Page 6

To t he re a d e r

The Service Manual for the Valmet tractors is intended to be a practical reference source to be used in workshop. The repair instructions in the manual are based on methods which have been worked out in practice

during normal workshop conditionsand which are based on the use of special tools from the manufacturer

when stated in the instructions. The manual also contains descriptions of the design and function of the

components.

Detailed maintenance instructions can be found in Operator’s Manual.

The Service Manual will be continually updated with new revised pages which should be inserted in the

manual. Alterations and additions will first appear as service bulletins.

Only genuine Valmet spare parts should be used to ensure the best possible function of the machine. Certain operations should be carried out with the aid of special tools designed by Valmet.

Valmet Trac tors Inc.

Tra ct o r Serv ic e

3

Page 7

4

Page 8

1. 8. 2000

11. General

The following supplements have been published for the Valmet 6000 ---8950 Service Manual:

1. 9. 2002

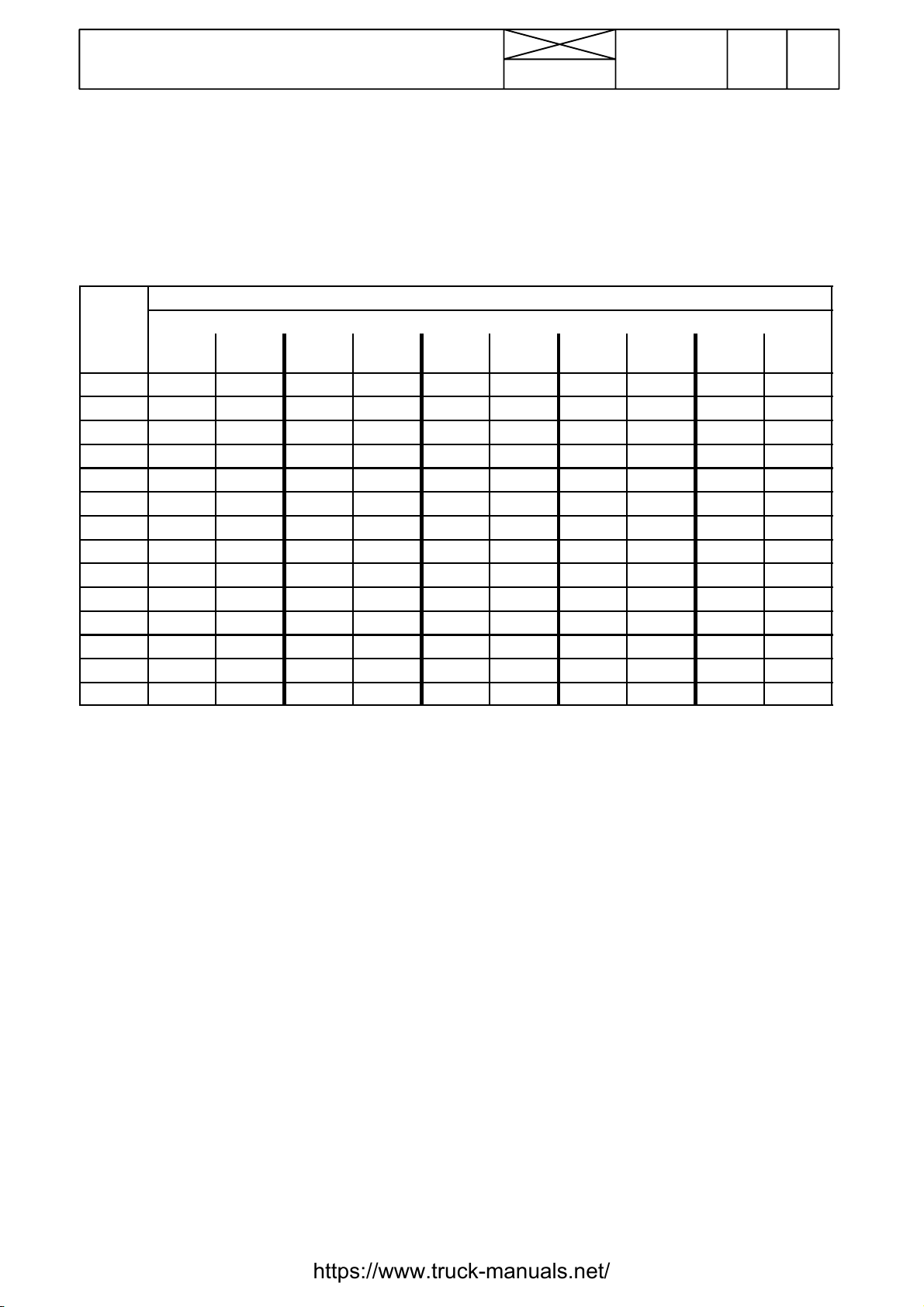

Model Code Page

6000--8950 110 0

Ordering number

39 256 211

39 256 212

39 256 213

39 256 214

39 256 215

39 256 216

39 256 217

39 256 218

39 256 219

39 260 211

39 260 212

39 260 213

39 260 214

39 260 215

Supplement no. 39 256 211 (15. 6. 1992)

Includes:

--- A ut o co n t r o l I I I

--- air conditioning

--- tractor 8000

--- amendments

Supplement no. 39 256 212 (1. 9. 1992)

Includes:

--- 20 --- s e ri e s en g in e s

--- amendments

Supplement no. 39 256 213 (15. 5. 1993)

Includes:

--- De l ta P ow e rs h if t

--- tractor 8400

--- amendments

--- the latest fitting instructions of optional equipment

Supplement no. 39 256 214 (1. 1. 1994)

Includes:

--- tractors 6000 and 8200

--- A ut o co n t r o l I I

--- A ut o co n t r o l I V

--- S i g e --- a x l e d if f e re n ti a l lo c k

--- in d u st r ia l f ro n t a x l e

--- latest air conditioning

--- amendments

Supplement no. 39 256 215 (1. 1. 1995)

Includes:

--- amendments

--- the latest fitting instructions of optional equipment

Supplement no. 39 256 216 (15. 4. 1995)

Includes:

--- engine intake air system and cooling system, modifications

--- A ut o co n t r o l 2 . 1

--- A gr o da t a --- i n s t r u m en t

--- hydraulic type clutch release mechanism

--- DP S , m o d i fi c at i on s

Date Notes

15. 6. 1992

1. 9. 1992

15. 5. 1993

1. 1. 1994

1. 1. 1995

15. 4. 1995

15. 5. 1996

1. 4. 1997

1. 8. 1998

1. 11. 1998

1. 6. 1999

1. 10. 1999

1. 8. 2000

1. 9. 2002

--- H i Sh i ft

--- amendments

--- the latest fitting instructions of optional equipment

Supplement no. 39 256 219 (1. 8. 1998)

Includes:

--- F ie l dM a s te r

--- pressure air brakes for trailer (optional)

--- latest fitting instructions for optional equipment

--- amendments

--- new folder,new index leaves (10 ---30 and40 ---100) and new

spine labels.

Supplement no. 39 260 211 (1. 11. 1998)

Includes:

--- HiTech reverse shuttle

--- Autocontrol V

--- N ew 5 0 --- se r ie s m od e ls

--- Front axle air suspension

--- E --- e ng i n e s

--- A mendments

Supplement no. 39 260 212 (1. 6. 1999)

Includes:

--- Autocontrol 2.2

--- amendments (e.g. for AC V)

--- fitting instructions for optional equipment

Supplement no. 39 260 213 (1. 10. 1999)

Includes:

--- Carraro 20.29 front axle

--- amendments (e.g. version 42 of AC V)

Supplement no. 39 260 214 (1. 8. 2000)

Includes:

--- H i Tec h g en . 2 , A C --- 5 . 2

--- front PTO on 6250H---6850Hi tractors

--- modified lubricating oil pump for 6---cyl. engines

--- new rear axle housing for transmissions 650/550

--- amendments

--- updated fitting instructions for optional equipment

Supplement no. 39 256 217 (15. 5. 1996)

Includes:

--- tractor 6800

--- tractors 8050 ---8750

--- amendments

Supplement no. 39 256 218 (1. 4. 1997)

Includes:

--- tractors 6200 and 8000R

--- f r o n t P T O

--- Ca r e Te l

Supplement no. 39 260 215 (1. 9. 2002)

Includes:

--- transmission and final drives 700

--- A gr o li n e --- i n s tr u m e n t

--- technical modifications

Page 9

6

Page 10

Model Code Page

11. Layout

8. 11. 1990

6000--8750 110 1

Layout of Service Manual

1. Division into groups

The manual is divided into groups (10 ---100) which are based on the make ---up of the tractor.The groups are listed on the first index

leaf.

Example. 10. General

20. Engine, fuel and cooling systems

30. Electrical system

40. Power transmission

a.s.o.

The number designation for each group is given in the top left box of the respective pages (and the first figure in the code designation)

Code

410 1

Page

50

60

70

80

90

100

2. Division into components or sub ---groups

Each group is further divided into components or sub---groups. The number and the name of each component is given in the top

left box on each page (and comprise the two first figures in the code designation).

Example. 41. Clutch

42. Gearbox

44. Quick ---shift gear

45. Final drives etc.

7

Page 11

Model Code Page

11. Layout

8. 11. 1990

6000--8750 110 2

3. Code designation

Three---digit code designations are used to distinguish the different document groups for the respective components. The same

code is also used in the Time List as a reference to the text in this Manual. The code designation numbers appear both in the box at

thetopofthepageandalsointheheadings.

Example: Code 410:

--- Group: Power transmission (4)

--- Component: Clutch (41)

--- Document group: General (410)

4. Page numbers

The instructions for all components are numbered in consecutive order in the right---hand box at the top of the page. The page

numbers begin with page 1 for each component.

Page

41. Clutch

8. 11. 1990

15. 5. 1993

Model Code

6100--- 8400 410 1

5. D a te

At the top of each page there are two boxes for dates. In the case of a revised issue, the date of the earlier issue is printed in the

crossed---overboxandthedateofthecurrentissueisprintedinthe”real”datebox.

6. Mo del

At the top of each page the tractor model for which the page is valid is indicated.

7. Additions and amendments of the service manual

New and up -- -dated pages will be continually added to the service manual. The new pages should be inserted as indicated by the

code: the first digit (also the first digit on the index leaf) indicated the group:

--- the two first digits indicate the component or sub --- group

--- the third digit indicates the document group for the respective components

--- the page number indicates the definite position of the page within the service manual

If there are two pages with the same code and page number the page with the later date in the date box (and the old date in the

crossed--- over box) is valid (or the current page).

N.B. Fitting instructions for extra equipment are inserted into the service manual at the end of group concerned (E.g. code 39 is

inserted at the end of group 30).

8

Page 12

11. Layout

Code designation in the Service Manual

10. General

110 Layout

120 Repairs

130 Maintenance

20 Engine

21. Engine

210 Technical data, tools, description

211 Cylinder block and flywheel housing

212 Cylinder head and valve mechanism

213 Crank mechanism

214 Timing gears

215 Lubrication system and oil sump

216 Induction and exhaust system, turbocharger

219 Removing and fitting engine

22. Fuel system

220 Technical data, tools, description

222 Fuel feed pump and fuel filters

223 Injection pump and injectors

8. 11. 1990

1. 4. 1997

Model Code Page

6000--8750 110 3

23. Cooling system

230 Technical data, tools, description

231 Thermostat and coolant pump

30. Electrical system

310 Specifications, wiring diagrams

311 Autocontrol II

312 Autocontrol 2.1

313 Sigma ---power

320 AC power lift

321 ACD power lift

330 Agrodata

331 AD---instrument

340 Autocontrol ---III

350 Autocontrol IV

360 CareT el

40. Power transmission

41. Clutch

410 Technical data, tools, description

411 Clutch assembly and pedal rods

412 Hydraulic coupling

42. Gearbox

420 Technical data, tools, description

421 Selector forks

422 Gear shift levers

423 Shafts and gear wheels

424 Differential

44. Quick--- shift gear, DPS, reverse shuttle, 4WD clutch

440A Quick ---shift gear , technical data, tools, description

440B Reverse shuttle, technical data, tools, description

440C 4WD clutch, technical data, tools, description

441 Quick--- shift gear, repair instructions

442 Reverse shuttle, repair instructions

443 4WD clutch, repair instructions

444 DPS, repair instructions

45. Final drives

450 Technical data, tools, description

451 Final drives, repair instructions

4 6 P o w e r t a k e --- o f f

460 Technical data, tools, description

461 Power take---off, repair instructions

463 Front PTO, repair instructions

9

Page 13

11. Layout

50. Brakes

510 Technical data, description

511. Service brakes

520 Parking brake

60. Steering system and front axle

61. Steering system

610 Technical data, tools, description

611 Steering valve

612 Priority valve

613 Steering cylinder

614 Adjustment

64. Powered front axle

640 Technical data, tools, description

641 Front axle housing and front axle suspension

643 Hubs

644 Differential

645 Industrial front axle

70 Frame and wheels

710 Tractor frame

720 T yres and wheel discs

8. 11. 1990

1. 4. 1997

Model Code Page

6000--8750 110 4

80 Cab and shields

810 Cab

820 Shields

830 Air conditioner

90 Hydraulics

910 Technical data, tools, description

911 Pump and pipes

912 Working hydraulics

913 Three---point linkage, towing hook

920 AC power lift

100. Special tools

101 Special tools (ETV)

102 Locally manufactured tools

Note! Separate fitting instructions for the optional equipments are inserted into the Service Manual. These instructions are positioned to the end of each main group. E.g. code 39 are placed to the end of group 30.

10

Page 14

Model Code Page

12. Repairs

8. 11. 1990

6000--8750 120 1

General instructions for repairs

Outer oil seals

The Service Manual contains instructions for changing all outer oil seals, (e.g. oil seals on the PTO shaft end, on the output shaft

to the front wheel drive and on the pinion shaft on the powered front axle, and so on).

Sealing compound and glue

If sealing compounds or glue are required for the repair work, the instructions will specify a sealing compound or glue which is

readily available through specialist dealers. Some seals should be greased before fitting and the space between the lips of the

seal should be filled with universal grease. If the seal is to be pushed over splines or sharp edges the seal should be protected

with for example a thin plastic foil.

Tightening torques and setting values

All necessary tightening torques and setting values for each repair operation are given at the beginning of each repair section

under the heading Technical Data. The most important values can also be found in the repair instructions.

Table 1 later gives the tightening torques in order of dimension, quality and surface treatment. The values given in the table should

be used if the tightening torque is not given in the repair instructions.

Safety

Always bear safety in mind when repairing or servicing the tractor. Use tools and lifting devices in the correct way . When you

are removing tractor components or splitting the tractor,every tractor part must be supported in such a way,that no risk of accident

exists. Avoid working under the supported tractor part if it is not absolutely necessary. When supporting the tractor the centre of

gravity of the frame part must always be checked. For instance the wedges must always be fitted between front axle and engine

to prevent axle oscillation when splitting the front frame of the tractor.

Trouble ---shooting

The following procedure, combined with the information contained in the workshop manual will be helpful in tracing faults accurately. It consists of following a number of logical steps to locate and correct the problem:

a) Determine the problem

b) List possible causes

c) Differentiate the causes

d) Conduct checks in logical order to determine the exact cause

e) Consider approximate remaining service life against cost of parts and labour..

f) Make any necessary repairs.

g) Recheck the parts and functions for correct operation

11

Page 15

12. Repairs

8. 11. 1990

Model Code Page

6000--8750 120 2

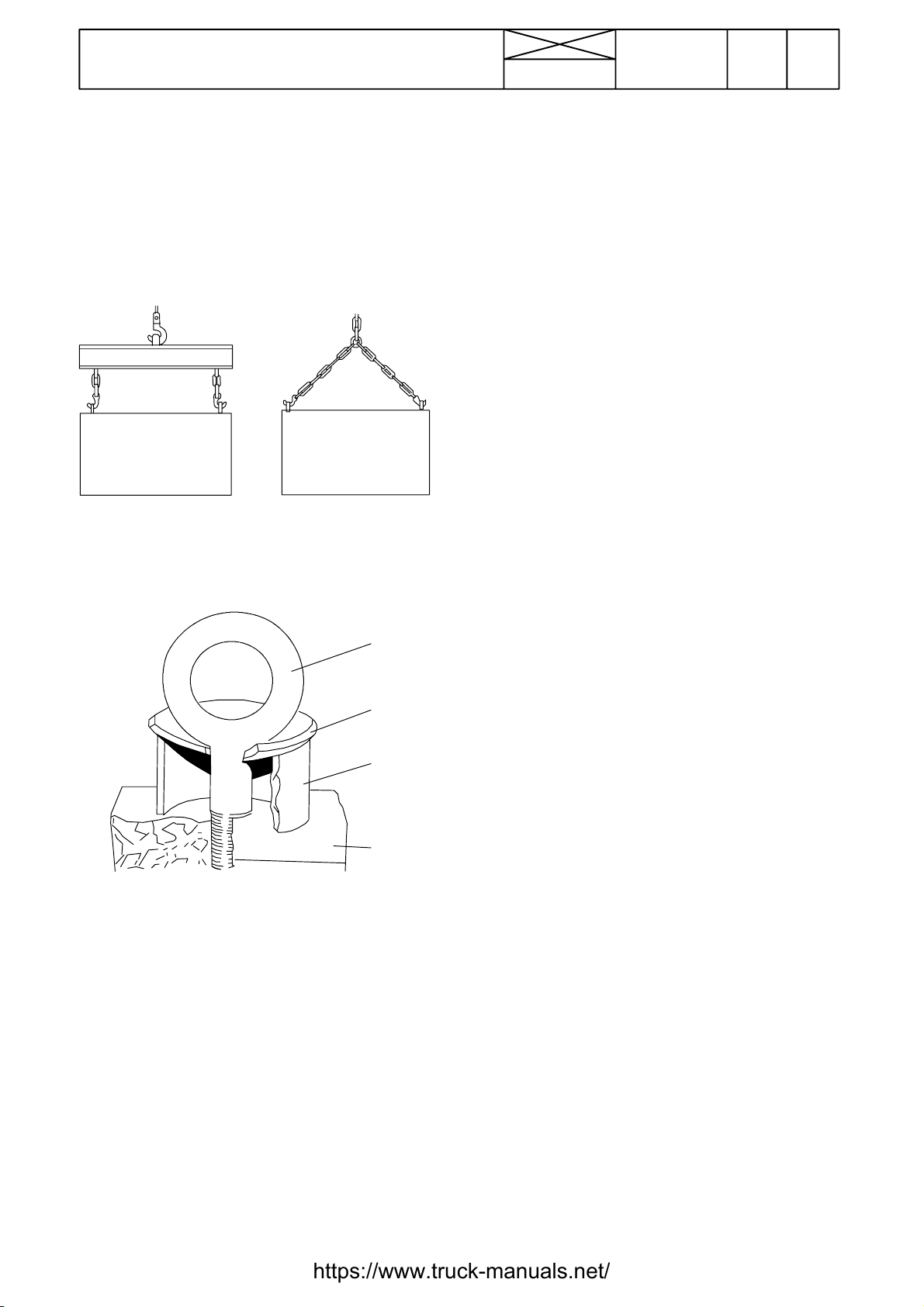

Handling of heavy components

Unless otherwise specified, all removals should be accomplished using adjustable lifting equipment. All supporting

slings must be parallel to each other and as near vertical as

possible in relation to the object being lifted. However, where

slings are of a far greater capacity than the weight of the load

to be fitted, a triangular lifting arrangement may be used.

Oikein

Rätt

Right

Richtig

Giusto

When removing a component at an angle, remember that the

capacity of an eyebolt is reduced when the angle between the

supporting members and the object becomes less than 90˚.

Correct

Teisingai

Väärin

Fel

Wrong

Falsch

Sbagliato

Mauvais

Neteisingai

B

Cleanliness

To ensure longlife of a machine, it is important to keep dirt and

foreign material out of its vital working components. Precautions must be taken to safeguard against this. Enclosed compartments, seals and filters have been provided to keep the

supply of air, fuel and lubricant clean. These protective devices must not be removed.

Whenever hydraulic, fuel, lubricating oil or lines are disconnected, clean the point of disconnectionand the surrounding

area. As soon as a line has been disconnected, cap, plug or

tape the line or opening to prevent the ingress of foreign material.

The samecleaning and covering precautionsshould be taken

when access covers or inspection plates are removed.

Clean and inspect all parts. Make sure that all passages and

holes are clear. Cover all parts to keep them clean. Make sure

parts are clean when they are reassembled. Leave new parts

in their wrapping until they are actuallyneeded for reassembly

Assembly

When reassembling a machine, complete each step in sequence. never partially assemble one part then start to assemble another. Make all recommended adjustments. Al ways check the job on completion to ensure that nothing has

been overlooked. Recheck the various adjustments before

putting the machine back into service.

C

D

A

Forged eyebolt support

A. Load

B. Lifting shackle

C. Shackle retaining plate ( 3 mm thick)

D. Sleeve

When necessary the forged eyebolt can be supported in the

way shown in figure above. Sleeve D may or may not be

welded to plate.

Warning! If a part resistsremoval, check that all nuts andbolts

have been removed and that there is no interference from adjacent parts.

Note! Before fitting new parts, remove rust preventative compound from all machined surfaces (usually ”peel --- off substances).

Lubrication

Where applicable, fill the compartments of repaired or renewed components with the quantity, type and grade of clean

lubricantrecommended in the routine maintenance sectionof

the Operator’s Manual.

Shims

When shims are removed, tie them together and identify their

location. Keep shims clean and take care not to bend them

before refitting them.

Gaskets

Make sure that the holes in gaskets line up with lubricating oil

passages in the mating parts. If gaskets have to be made, use

material of the correct type and thickness. Make sure that

holes are punched in the right places.

Incorrectly punched gaskets can cause serious damage.

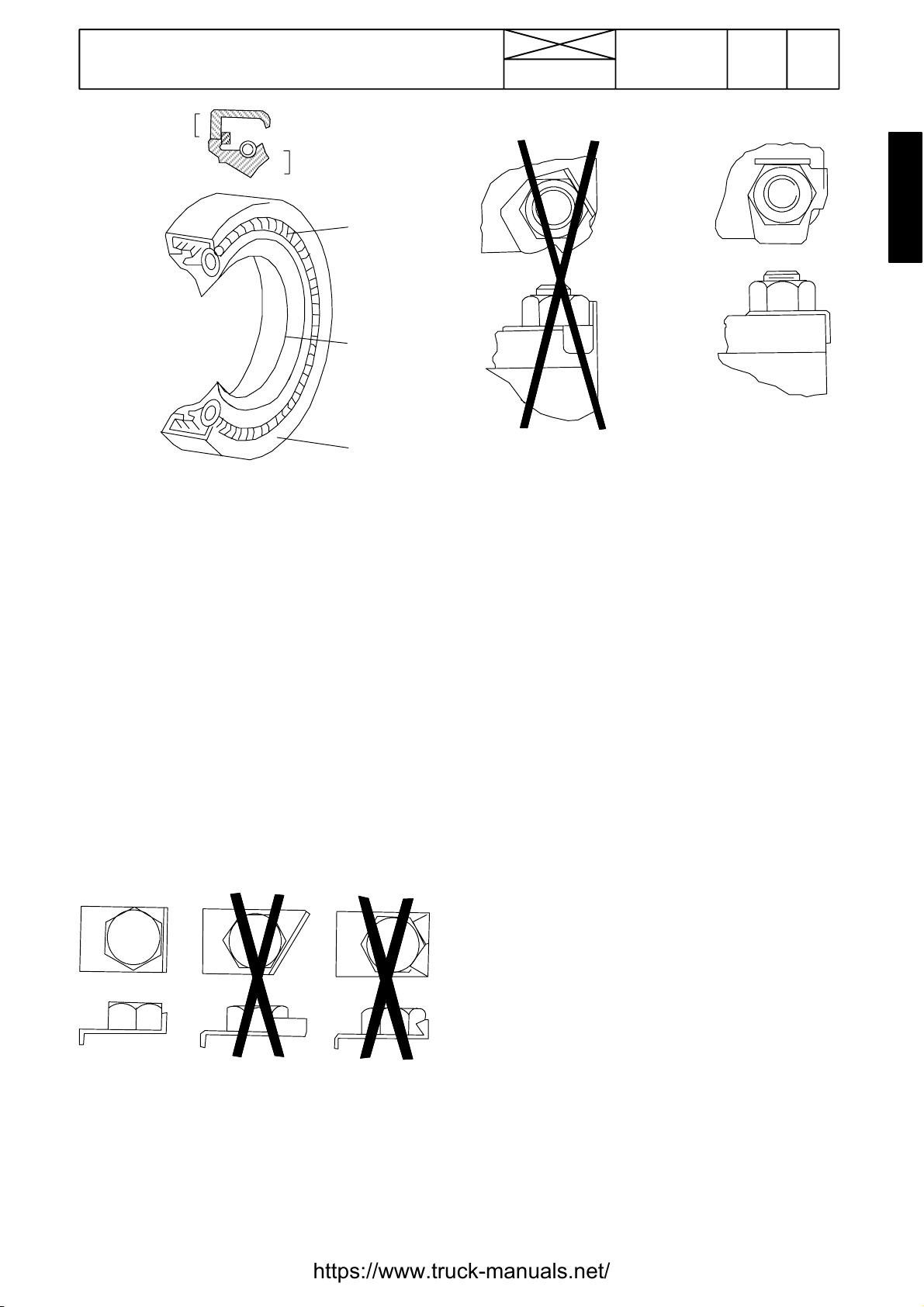

Lip type rubber seals

Lubricate the lips of lip---type rubber seals with oil before fitment. Do not use grease on seals, except for grease seals.

12

Page 16

12. Repairs

4

Model Code Page

8. 11. 1990

6000--8750 120 3

5

3

2

1

The main parts of lip --- type seal:

1. Case

2. Sealing element

3. Ring spring

The figure above shows the constructionof a simple lip ---type

seal. The cross section shows the heel (4) and the toe (5),

used to identify the sides of a single element seal. With a few

exceptions, the toe of a single - --lip is located on the lubricant

side. Some seals have a second auxiliary lip which has no

spring.

Cables and wires

When removing or disconnecting a group of cables or wires,

label each one to ensure correct refitment.

Locking devices

Correct and incorrect method of fitting and bending locking

tabs.

Slackening of nuts and bolts is prevented by mechanical

means such as lockwashers, tab washers and cotter pins, or

by Loctite---type locking agents.

Flat retainers must be installed properly to be effective. Bend

one end of the retainer against the edge of the part. Bend the

other end against one of the nut or bolt head.Always fit new

retainers in compartments which house moving parts. When

fitting lockwashers on aluminium housings, place a flat

washer between the lockwasher and the housing.

Note!

1) Never fit a lockwasher (Grower, fan, spring, etc.)under a nut

or bolt to which a specified torque has to be applied.

2) Always thoroughly degrease components before applying

Loctitetypelockingagents.

Bushes and press fits

Do not fit bushes with a hammer alone. Use a suitable fitting

tool and a hammer or, better still, a press if possible..

Correct and incorrect use of retainers

When using a press, ensure that pressure is applied directly

in line with the bore. If the ring has an oil hole, take care to align

it with the oil hole in the mating part. When press fitting a part

into anotherpart, lubricate the mating surfaces. Tapered parts

should be assembled dry. Before assembly, check that the

tapers are dry and free from burrs.

Fitting bolts in blind holes

Use bolts of the correct length. A bolt which is too long may

”bottom” before the head comes into contact with the part it

is to hold: this will cause damage to the threads. If a bolt is too

short, there may not be enough threads engaged to hold the

part securely.

13

Page 17

Model Code Page

12. Repairs

8. 11. 1990

6000--8750 120 4

Tab l e

Ta b l e 1 . Tightening torques, metric standard thread (ISO)

Tightening torques Nm1)

Dim. Quality, surface treatment, material and so on

8.8

lubr.

M4 --- --- --- --- --M5 6,4 0,6 5,7 0,5 --- 9 1 11 1

M6 11 1 10 1 12 1,2 15 1,5 18 2

M8 25 2 23 2 30 3 35 4 45 5

M10 50 5 45 5 60 5 70 7 90 10

M12 90 10 80 8 100 10 125 10 151 15

M14 140 15 125 10 160 15 200 20 240 20

M16 220 20 195 20 250 25 300 30 370 40

M18 300 30 270 30 350 35 430 40 510 50

M20 430 40 380 40 480 50 600 60 720 70

M22 570 60 500 50 650 65 800 80 970 100

M24 740 70 660 70 830 80 1030 100 1250 120

M27 1100 100 950 100 1200 120 1500 150 1800 180

M30 1500 150 1300 130 1600 160 2040 200 2500 250

tol.±

8.8

Zne

2

) tol±

8.8

3

Znk

) tol. ±

10.9

lubr.

tol. ±

12.9

lubr

tol. ±

1

) 1 Nm=0,102 kpm

2

) Zne=zinc electroplating

3

)Znk=hotgalvanized

If the bolts differs from the standard range the values in the

table must not be used.

14

Page 18

12. Repairs

8. 11. 1990

Conversion table for common units

Quantities and units Conversion factors

Overall and detail dimensions millimetres (mm) 100 mm=3,94 inches

1 inch=25,4 mm

Short distances e.g. turning circles metres (m) 1 m=3,28 ft

1 ft=0,305 m

Travel distances kilometres 1 km=0,62 mile

1 mile=1,61 km

Tractor weights, axle loadings kilograms (kg) 1 kg=2,2 lbs

1 lb=0,454 kg

Travel speed kilometres per h (km/h) 1 km/h=0,62 mph

1mph=1,61km/h

Drawbar pull kilonewtons (kN) 1 kN=224,8 lbs

1 lb=4,448 N

Power (identified by such terms as crankshaft power, 1 kW=1,34 hp

pto power, belt power, drawbar power, indicating 1 hp=0,746 kW

the point at which the measurement was taken)

kilowatts (kW)

Model Code Page

6000--8750 120 5

Engine torque newton metres (Nm) 1 Nm=0,74 ft lb

1 ft lb=1,356 Nm

Fuel consumption by weight (kilograms per hr, kg/h) 1 kg/h=2,2 lb/hr

(by volume) litres per hr (l/h) 1 lb=0,454 kg

1l/h=0,22gal/hr

1gal=4,54l

Fuel economy (specific fuel consumption) 304 g/kWh=0,5 lb/hp hr

grams per kilowatt hr (g/kWh)

Engine displacement litres (l) 1 l=61,02 m cu in

100 cu in=1,639 l

Hydraulic pump 1 MPa=145 psi

pressure---mecapascal (MPa) 1000 psi=6,9 MPa

delivery ---millimetres per sec (ml/s) 100 ml/s=1,32 gpm

1 gpm=75,77 ml/s

Tyre

pressure---kilopascal (kPa) 100 kPa=14,5 psi

1psi=6,9kPa

Area acres---hectare To convert multiply by

0,404686

Volume bushel---litre To convert multiply by

39,3687

Quantity pound per acre---kilogram per hectare Multiply by 1,12085

Volume Multiply by

superficial foot ---cubic metre 0,002360

15

Page 19

16

Page 20

13. Maintenance

Maintenance Valmet 6000---8750

N.B. Detailed maintenance instructions, see Operator’s Man-

ual.

1. 1. 1994

15. 5. 1996

Model Code Page

6000--8750 130 1

Greasing lubricating points fitted with

grease nipples

General

Correct maintenance at the right time is a basic condition for

reliable operation of the tractor. Maintenance costs are small

compared with any repair costs resulting from lack of maintenance. The most important measures are those which you

carry out yourself and which include lubrication and various

checks and adjustments.

The serviceintervals shown apply for normal operating conditions but in more severe conditions servicing should be carried out more frequently.

General instructions concerning oil

checks and oil filling

--- Alwaysstoptheenginebeforestartingwork

--- Apply the parking brake to ensure the tractor cannot

move. If the ground is uneven the wheels should be

scotched

--- W ashdown the tractor first so that the work can be done

more easily and quickly.

--- Always observe the utmost cleanliness in all maintenance work. Thoroughly wipe off filler caps and plugs as well

as surrounding parts of the tractor before filling up with fuel

or oil.

--- Inspect the oil and filters when changing. Large

amounts of dirt (e.g. heavily clogged filters) can point to a

fault which could cause extensive and costly repairs if not

corrected in time.

---When carrying out checks the tractor should stand on level

ground.

--- Levels should be checked in the morning when the oil

is cold and has had time torun down to the bottom of the unit

concerned.

--- When changing the oil, bear in mind that the oil can be

very hot when it drains from the tractor. Waste oil and oil

filtersshouldbehandledcarefullyanddisposedofproperly

--- After completion of the service work always replace all

safety covers etc.

--- Always clean the grease nipples before applying the

grease gun.

--- Apply grease through the nipples until clean grease

oozes out (unless otherwise instructed).

--- Wipe away superfluous grease which has been

pressed out at the lubricating point.

--- Preferably carry out lubrication with bearing points and

joints unloaded and with the bearings in different positions.

Lubrication and maintenance schedule

All intervals are countedfrom zerohours on the hour recorder.

For example, 1000 hours service is carried out every 1000

(yearly), 2000 hours (every other year) etc. even if the guarantee service has been carried out.

Example: The 1000 hour service contains all items mentioned

under 10 h/Daily, 50 h/once a week, 250 h, 500 h and 1000 h.

17

Page 21

13. Maintenance

Maintenance schedule

18

7

4

15. 5. 1996

1. 4. 1997

Model Code Page

6000--8750 130 2

14

5

11 12 1415

14

15

6

1

2

6

4

5

16 17

Daily/every 10 hours

1. Check engine oil level

2. Check coolant level and radiator fins

3. Check for leakage

Weekly/every 50 hours

4. Grease three ---point linkage and towing hook

5. Grease brake mechanism (EP grease)

6. Grease front axle brackets (also nipples on steering system

andonnon---poweredfrontaxle)

7. Check oil level in transmission and hydraulics

8. Clean air filter cyclone (tractors with a horizontally fitted air

filter and an ejector pipe; clean suction housing hole plate)

9. Check fan belt tightness

10.Check water trap (on 6--- cylinder engines. On other mo-

dels on the other side. On models 8200, 8400 and

8050---8750 also under both fuel filters)

11.Check electrolyte level in battery

8910

6

15

14

66

6084--- 67

Every 250 hours

12. Clean engine air filter

13. Grease door and window hinges and locks

14. Change engine oil and filter

15. Grease front axle joints (powered axle)

16. Change pressure filters. First change at 100 hours warranty service,then at 250 hours and after that at 500 hours

and then at intervals of 500 running hours.

17. Check brake fluid level (and clutch fluid level,

668103---)

18. Clean cab ventilation air filter

19. Check wheel nuts and bolts and tyre pressures

18

Page 22

13. Maintenance

1. 4. 1997

1. 11. 1998

Model Code Page

6000--8750 130 3

25

27 30 25 34 22 27 29 31 36 28 33

26

24

39

35

36 32

30 25 38 21 23 37 20 41 33

Every 500 hours

20. Clean water trap (fuel system) (on 6 ---cylinder engines.

On the other models on the other side. On models

8200, 8400 and 8050---8750 also under the fuel filters).

Does not concern 6200 and 8000R tractors.

21. Check brake pedal free travel

22. Check clutch pedal free travel, ---668102.

23. Change pressure filters (transmission and hydraulics)

24. Check oil level in front axle differential and hubs

24a. Calibrate first time gaspedal on HiTech models. Later at

intervals of 1000 running hours.

Every 1000 hours/yearly

25. Change oil in transmission/hydraulic s and clean suc-

tion strainer

26. Change oil in front axle differential and hubs

27. Change cab ventilation air filter and wash cab recirculation filter, if fitted.

28. Change fuel filters. 6200, 8000R: change also the water

trap filter

29. Change safety filter (in engine air filter)

30. Greasereardriveaxlebearings

31. Grease flywheel ring gear

32. Check, grease and adjust front wheel bearings on

non---powered front axle

33. Check/adjust front wheel toe---in

34. Clean fuel tank

35. Adjust valves

35a Calibrate gas pedal on HiTech models

24

42 40 43 33 32

26

6084--- 68

Every 2000 hours/every other year

36. Change engine coolant

37. Change brake fluid (and clutch fluid, 668103--- )

38. Change transmission housing breather

39. Check and clean injectors

40. Check alternator

41. Check starter motor

Every 4000 hours

42. Check function of turbocharger at authorized workshop (if

fitted)

43. Change engine rubber vibration damber on 6---cyl.

engines (not 8200 and 8450 ---8750)

19

Page 23

Model Code Page

C

G

10W/30+30

C

20CCH---4

Coolingsystem

:

ater+ant

e

ezeag

ent(stand

ardiA

S

water+ant

i

freezeagent(standardiASTM

)

6000--8950 130 4

13. Maintenance

1. 8. 2000

1. 9. 2002

Recommended fuel and lubricants (all capacities are incl. of filters)

Part of machine S A E --- g r a d e AP I --- g r a d e Capacity (litres)

Engine:

--- 6100 (3 ---cyl.)

--- 6000, 6200 ---6650Hi, 6800 ---6850Hi (4 ---cyl.)

-- 6900, 8000, 8100, 8200, 8400, 8050--8950Hi (6--cyl.)

Hydraulics/transmission HT 60: ---30˚C...+30˚C

Powered front axle:

--- differential, Dana / ind. Carraro

--- hubs, Dana 80W/90 GL---5 (LS) 2x1

--- hubs, ind. front axle Dana+Carraro 2x1,5

Fuel tank:

--- 6000--- 8000 Hi Trol, 6250Hi---6650Hi HiTrol

--- o th e r mo d el s

--- extra fuel reservoir, metallic / plastic +82 / +121

Cooling system:

--- 6100 (with larger radiator) 13,5 (17,5)

--- 6000, 6200 ---6600 (with openable front grille) 15,5 (17)

--- 6250 Hi ---6650 Hi 17

--- 6800 / 6850 Hi

--- 8000- --8400 (with openable front grille)

--- 8200, 8400, 8050, 8150 with expansion tank

--- 8050 Hi and 8150 Hi 28

--- 8450, 8550 / 8450 Hi, 8550 Hi 25 / 27

--- 8750 / 8950Hi 31 / 31

Brake fluid reservoir/Clutch fluid resesvoir brake fluid SAE J1703 0,3 / 0,2

Window washer reservoir washer fluid 3

Oils in front PTO units see page 463/9.

*) Tractor frame numbers, see page 450/6.

**) Tractor frame numbers, see page 450/8.

15W40 +40˚C... ---10˚C

HT 100: ---10˚C...+40˚C

diesel fuel

w

D3306---86a tai BS 6580:1985)

i---fr

---

˚

˚

...---

˚

---

˚

--- 4

CH --- 4

GL---4

(G 2 --- 9 8)

TM

10

13

19

34 (43 max/HiTech, 8050---,

J02316---: 45 max)

(extra max 50/HiTech,

8050---, J02316---: extra max

6200---8950 *): min 45, max

55, extra max 65.

8950Hi **): min 45, max 55,

extra max. 65.

8/6

158

165

22 / 22

24 (25)

28 (8400, model 2001:

30)

53).

Oil qual ity and capacity in fluid couplings (Hi --- Trol)

Vo i t h T D --- V A coupling used up to serial no 658205 and V o i t h T D --- F V A 1 from serial no 666066. Engine oil SAE 10W/30 year

around or automatic transmission fluid ATF which meets standards: GM type A Suffix A, GM Dexron II (e.g. Neste ATF --- X):

--- 6000, 6100 --- 7,20 litres

--- 6200, 6300 7,4 litres 6200: 7,35 litres. 6300: 7,45 litres. 6250Hi: 7,40 litres. 6350Hi: 7,80 litres.

--- 6400 7,6 litres 7,85 litres. 6550Hi: 7,90 litres.

--- 6600 7,8 litres 7,90 litres. 6650Hi: 8,00 liter

--- 6800, 8000R, 8000 6800: 8,40 litres. 6900, 8000: 8,00 litres. 6850Hi: 8,00 litres.

Tra ns f l u i d ---coupling with effect from tractor serial no 658206 up to tractor serial no 666065. Engine oil SAE 10W/30 year around

or automatic transmission fluid ATF which meets standards: GM type A Suffix A, GM Dexron II (e.g. Neste ATF ---X):

--- 6100 5,2 l 6,4 l

--- 6300 5,4 l 6,6 l

--- 6400 5,6 l 6,8 l

--- 6600, 8000 5,8 l 7,0 l

*

) Check the manufacturing date of the coupling. If it is 1292 or later, use larger filling quantities.

---658205 666066 ---

658206--- 659409 ---666065

659408

*

)

4

Page 24

20. Engine

21. Engine

22. Fuel system

23. Cooling system

21

Page 25

22

Page 26

Model Code Page

21. Engine

15. 6. 1992

1. 9. 1992

Contents

General ( Op. no. 210):

Specifications 3...................................................................

Special tools 10....................................................................

Engine, description 12..............................................................

Repair instructions

Cylinder block and flywheel housing (Op. no. 211):

1. Cylinder block and cylinder liners:

A. Measuring cylinder liner wear 1...................................................

B. Removing cylinder liners 1........................................................

C. Checking cylinder block 1........................................................

D. Changing camshaft bushing 1....................................................

E. Oversize bushings for camshaft 2.................................................

F. Fitting plug at rear end of camshaft 3...............................................

G. Fitting pipe for oil dipstick 4......................................................

H. Fitting cylinder liners 4...........................................................

6000--8750 210 1

2. Flywheel housing:

A. Fitting flywheel housing 6........................................................

B. Changing crankshaft rear oil seal 6................................................

C. Changing flywheel starter gear 7..................................................

D. Fitting flywheel 7................................................................

Cylinder head and valve mechanism (Op. no. 212):

1. Cylinder head:

A. Removing cylinder head 1........................................................

B. R emoving valves 1..............................................................

C. Checking cylinder head 1........................................................

D. Changing valve guides 2.........................................................

E. Machining valve seat 2...........................................................

F. Changing valve seat inserts 3.....................................................

G. Grinding valves 3...............................................................

H. Fitting valves 3.................................................................

I. Fitting cylinder head 4............................................................

2.Valve mechanism:

A. Reconditioning rocker arm mechanism 5...........................................

B. Changing camshaft/camshaft gear 5...............................................

C. Adjusting valve clearance 6.......................................................

Crank mechanism (Op. no. 213):

1. Crankshaft:

A. Removing crankshaft 1..........................................................

B. Checking crankshaft 1...........................................................

C. Changing crankshaft gears 1.....................................................

D. Changing crankshaft ring gear (420---engines) 2.....................................

E. Fitting crankshaft 2..............................................................

2. Connecting rods and pistons:

A. Removing piston together with connecting rod 3.....................................

B. Changing connecting rod bearings 3...............................................

C. Checking connecting rod 3.......................................................

23

Page 27

21. Engine

15. 6. 1992

1. 9. 1992

D. Connecting rods, weight classes 4.................................................

E. Changing piston rings 5..........................................................

F. Ch e ck i ng p i st o n 6...............................................................

G. Fitting piston pin 6..............................................................

H. Fitting piston together with connecting rod 6........................................

3. Balancer unit, 420 ---engines:

A. Removing and dismantling balancer unit 7..........................................

B. Reconditioning balancer unit 7....................................................

C. Fitting balancer unit 8............................................................

Model Code Page

6000--8750 210 2

Engine timing gears (Op. no. 214)

A. Removing timing gear casing 1...................................................

B. Reconditioning idler gear 1.......................................................

C. Fitting timing gear casing 2.......................................................

Lubrication system and o il sump (Op. no. 215):

A. Reconditioning oil relief valve for lubrication oil pressure 1.............................

B. Removing and dismantling lubricating oil pump 1....................................

C. Assembling and fitting lubricating oil pump 2.......................................

D. Fitting oil sump gasket 2.........................................................

E. Lubricating oil quality requirements 3..............................................

Inlet and exhaust system, turbocharger (Op. no. 216):

A. Checking air filter 1..............................................................

B. Checking inlet and exhaust system 1...............................................

C. Checking turbocharger 1.........................................................

D. Reconditioning turbocharger 3....................................................

E. Fitting turbocharger 5............................................................

Working orders (Op. no. 219) 1................................................

24

Page 28

21. Engine

1. 8. 2000

1. 9. 2002

Model Code Page

6000--6800 210 3

Specifications

Engine designations

1. Basic markings: 320, 420, 620 and 634. The first digit indicates the number of cylinders and the two last digits the stroke

(---20=120 mm, ---34=134 mm).

2. Letters after the basic markings:

--- D=diesel engine

--- S=turbocharger (Schwitzer)

--- W=by--pass turbocharger, Delta turbo

--- B=Bosch P in---line pump

Note! R 24 , E 77 a n d EPA --- h o mo l og a ti o ns h a s b e e n ma d e f o r E --- e ng i n es .

Tractor 6000 6100 6200 6200 6250 Hi 6300 6300

Designation 420D 320 DS 420DSRE 420DSRE 420DSRE 420 DS 420DS

Turbocharger no yes yes yes yes yes yes

Noofcylinders434444 4

Displacement (litres) 4,4 3,3 4,4 4,4 4,4 4,4 4,4

Cyl. bore (mm) 108 108 108 108 108 108 108

Stroke (mm) 120 120 120 120 120 120 120

Compr. ratio 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1

Output (kW/r/min DIN) 55/2300 58/2300 59/2225 59/2200 59/2200 62,5/2225 66/2200

Torque (Nm/r/min DIN) 290/1450 310/1550 320/1400 360/1400 360/1400 330/1550 360/1400

Momentrise%2728,527414123 25

Low idling (r/min) 750 800 750 750 850 750 750

Compr. press

Max. no--load revs (r/min) 2500 2500 2425 2400 2400 2425 2400

1

) (bar) 24 24 24 24 24 24 24

(Schwitzer S1BG or S2BG)

(---K41123) (K41124--- ) (K41309 ---

--- R=distributor pump (Stanadyne)

--- I=intercooler

--- E=low emission engines (E---engines)

--- C=emission tested engines (certificated).

---L23437)

Tractor 6300 6350 Hi 6400 6400 6400 6400

(L23438---) (J17109---) (K41106---) (L23506---)

(Delta) (Delta)

Designation 420DSRE 420DSRE 420 DS 420 DW 420DW 420DWRE

Turbocharger yes yes yes yes yes yes

Noofcylinders444444

Displacement (litres) 4,4 4,4 4,4 4,4 4,4 4,4

Cyl. bore (mm) 108 108 108 108 108 108

Stroke (mm) 120 120 120 120 120 120

Compr. ratio 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1

Output (kW/r/min DIN) 66/2200 66/2200 70/2225 70/2225 73,5/2200 73,5/2200

Torque (Nm/r/min DIN) 400/1400 400/1400 365/1550 390/1550 415/1400 430/1400

Momentrise%393922313035

Low idling (r/min) 750 850 750 750 750 750

Compr. press

Max. no--load revs (r/min) 2400 2400 2425 2425 2400 2400

Tractor 6550 Hi 6600 6600E 6650 Hi 6750Hi*) 6800 6800E

Designation 420DWRE 420 DS 420 DS 420DWRE 420DWRIE 420 DWI 420DWI

Turbocharger yes yes yes yes yes (+interc..) yes (+interc..) yes (+interc..)

Noofcylinders444444 4

Displacement (litres) 4,4 4,4 4,4 4,4 4.4 4,4 4,4

Cyl. bore (mm) 108 108 108 108 108 108 108

Stroke (mm) 120 120 120 120 120 120 120

Compr. ratio 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1

Output (kW/r/min DIN) 73,5/2200 77/2225 77/2225 81/2200 77/1800 85/2225 85/2225

Torque (Nm/r/min DIN) 430/1400 405/1550 405/1550 460/1400 530/1150 440/1550 440/1550

Momentrise%352222312921 21

Low idling (r/min) 850 850 850 850 800 850 850

Compr. press

Max. no--load revs (r/min) 2400 2425 2425 2400 2000 2425 2425

1

) (bar) 24 24 24 24 24 24

1

) (bar) 24 24 24 24 24 24 24

1

) Minimum value at operating temperature and starting revs. Max permitted difference between cylinders 3,0 bar.

*)Lowrevsengine.

E = AC- --4, Control system for tractor.

Hi =HiTech.

5

Page 29

21. Engine

1. 8. 2000

1. 9. 2002

Model Code Page

6800--8400 210 3A

Specifications

Tractor 6800 6850 Hi 6900 8000 8050 8050

(L23517---) (---L23317) (L23318---)

Designation 420 DWRIE 420 DWRIE 620 DRE 620 D 620 DSR 620DSRE

Turbocharger yes (+interc..) yes (+interc..) no no yes yes

Noofcylinders446666

Displacement (litres) 4,4 4,4 6,6 6,6 6,6 6,6

Cyl. bore (mm) 108 108 108 108 108 108

Stroke (mm) 120 120 120 120 120 120

Compr. ratio 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1

Output (kW/r/min DIN) 88/2200 88/2200 75/2225 73,5/2225 81/2200 81/2200

Torque (Nm/r/min DIN) 490/1400 490/1400 390/1400 380/1550 490/1300 490/1400

Momentrise%282821203921

Low idling (r/min) 850 850 750 750 750 850

Compr. press

Max. no--load revs (r/min) 2400 2400 2425 2425 2400 2425

Tractor 8050 Hi 8100 8100E 8150 8150E 8150 8150 Hi

Designation 620DSRE 620 D 620 D 620 DSR 620 DSR 620DSRE 620DSRE

Turbocharger yesnonoyesyesyesyes

Noofcylinders6666666

Displacement (litres) 6,6 6,6 6,6 6,6 6,6 6,6 6,6

Cyl. bore (mm) 108 108 108 108 108 108 108

Stroke (mm) 120 120 120 120 120 120 120

Compr. ratio 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1

Output (kW/r/min DIN) 81/2200 88/2225 88/2225 92/2200 92/2200 92/2200 92/2200

Torque (Nm/r/min DIN) 490/1400 455/1550 455/1550 540/1300 540/1300 540/1400 540/1400

Momentrise%39212135353535

Low idling (r/min) 750 750 750 750 750 750 750

Compr. press

Max. no--load revs (r/min) 2400 2425 2425 2400 2400 2400 2400

1

) (bar) 24 24 24 24 24 24

(---L24138) (L24139--- )

1

) (bar) 24 24 24 24 24 24 24

Tractor 8200 8200E 8350Hi*) 8400 8400E 8400 8400

(---K34331) (K32135--- (L23130---)

---L33320)

Designation 634 D 634 D 620DSRIE 620 DS 620 DS 620 DS 620 DSIE

Turbocharger no no yes (+interc..) yes yes yes yes (+interc..)

Noofcylinders6666666

Displacement (litres) 7,4 7,4 6,6 6,6 6,6 6,6 6,6

Cyl. bore (mm) 108 108 108 108 108 108 108

Stroke (mm) 134 134 120 120 120 120 120

Compr. ratio 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1

Output (kW/r/min DIN) 95,5/2225 95,5/2225 99/1800 103/2200 103/2200 110/2200 118/2200

Torque (Nm/r/min DIN) 490/1550 490/1550 650/1100 520/1550 520/1550 625/1400 650/1400

Momentrise%20202316163027

Low idling (r/min) 750 750 800 750 750 750 750

Compr. press

Max. no--load revs (r/min) 2425 2425 2000 2400 2400 2400 2400

1

) Minimum value at operating temperature and starting revs. Max permitted difference between cylinders 3,0 bar.

*)Lowrevsengine.

E = AC ---4, Control system for tractor.

Hi =HiTech.

1

) (bar) 24 24 24 24 24 24 24

6

Page 30

21. Engine

1. 8. 2000

1. 9. 2002

Model Code Page

8450--8950 210 3B

Specifications

Tractor 8450 8450E 8450 8450 Hi 8550 8550E 8550

(---L24134) (L24135---) (--- L24115) (L24116--- )

Designation 620 DWR 620 DWR 620 DWRE 620DWRE 634 DSR 634 DSR 634DSRE

Turbocharger yes yes yes yes yes yes yes

Noofcylinders6666666

Displacement (litres) 6,6 6,6 6,6 6,6 7,4 7,4 7,4

Cyl. bore (mm) 108 108 108 108 108 108 108

Stroke (mm) 120 120 120 120 134 134 134

Compr. ratio 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1 16,5:1

Output (kW/r/min DIN) 103/2200 103/2200 103/2200 103/2200 118/2200 118/2200 118/2200

Torque (Nm/r/min DIN) 580/1450 580/1450 615/1400 615/1400 650/1450 650/1450 650/1400

Momentrise%30303838272727

Low idling (r/min) 750 750 750 750 750 750 750

Compr. press

Max. no--load revs (r/min) 2400 2400 2400 2400 2400 2400 2400

Tractor 8550 Hi 8750 8750E 8950 Hi

Designation 634DSRE 634 DS 634 DS 634 DSBIE

Turbocharger yes yes yes yes (+interc..)

No of cylinders 6 6 6 6

Displacement (litres) 7,4 7,4 7,4 7,4

Cyl. bore (mm) 108 108 108 108

Stroke (mm) 134 134 134 134

Compr. ratio 16,5:1 16,5:1 16,5:1 16,5:1

Output (kW/r/min DIN) 118/2200 118/140/2200 118/140/2200 118/147/2200

Torque (Nm/r/min DIN) 650/1400 650/1450 650/1450 650/820/1400

Moment rise % 27 27 27 27/28

Low idling (r/min) 750 750 750 750

Compr. press

Max. no--load revs (r/min) 2400 2400 2400 2400

1

) (bar) 24 24 24 24 24 24 24

(---J32215)

1

) (bar) 24 24 24 24

1

) Minimum value at operating temperature and starting revs. Max permitted difference between cylinders 3,0 bar.

E = AC ---4, Control system for tractor.

Hi =HiTech.

Valves, rockers and tappets

With a valve clearance of 1,0 mm:

--- in l e t v a lv e o pe n s 0˚±2˚ B.T.D.C...............................................................

--- in l e t v a lv e c lo s e s 16˚±2˚ A.B.D.C..............................................................

--- exhaust valve opens 39˚±2˚ B.B.D.C...........................................................

--- exhaust valve closes 1˚±2˚ A.T.D.C...........................................................

Valve clearance cold and hot:

--- in l e t v a lv e 0,35 mm....................................................................

--- exhaust valve 0,35 mm.................................................................

Angle of valve seat in cylinder head:

--- in l e t v a lv e 35˚+20’....................................................................

--- exhaust valve 45˚+20’.................................................................

Width of valve seat in cylinder head:

--- in l e t v a lv e 2,9...3,7 mm....................................................................

--- exhaust valve 1,3...2,3 mm.................................................................

Angle of valve face:

--- in l e t v a lv e 35˚--- 2 0 ’....................................................................

--- exhaust valve 45˚--- 2 0’.................................................................

Outside diameter of valve head:

--- in l e t v a lv e 48 mm....................................................................

--- exhaust valve 41 mm.................................................................

Max valve movement:

--- in l e t v a lv e 10,9 mm....................................................................

--- exhaust valve 12,1 mm.................................................................

Inlet valve stem diameter 8,960...8,975 mm..........................................................

Exhaust valve stem diameter 8,925...8,940 mm......................................................

Inlet valve stem clearance 0,025...0,055 mm.........................................................

--- R ej e c t l i mi t 0,30 mm...................................................................

Exhaust valve stem clearance 0,060...0,090 mm......................................................

--- R ej e c t l i mi t 0,35 mm...................................................................

7

Page 31

21. Engine

1. 1. 1994

1. 8. 1998

Inside diameter of valve guide before fitting 9,000...9,015 mm..........................................

Outside diameter of valve guide 16,028...16,039 mm....................................................

Diameter of valve guide bore in cylinder head 16,000...16,018 mm........................................

Protrusion of valve guide top above cylinder head surface 21 mm..............................

Depth of valve face below cylinder head surface:

--- in l e t v a lv e 0,7±0,05 mm....................................................................

--- exhaust valve 0,6±0,05 mm.................................................................

Valvespringfreelength 69,8mm...........................................................

Spring pressure when spring compressed to a length of:

--- 48 , 6 mm 327±17 N.....................................................................

--- 37 , 4 mm 500±23 N.....................................................................

Rocker arm shaft diameter 19,959...19,980........................................................

Inside diameter of rocker arm bearing bush:

--- (when fitted in position) 19,990...20,010 mm.........................................................

Outside diameter of rocker arm bearing bush 23,035...23,075 mm........................................

Diameter of rocker arm bore 23,000...23,021 mm.......................................................

Max. permissible push rod deflection (when free) 0,4 mm.....................................

Free length of rocker arm spring 80 mm...................................................

Spring pressure when spring compressed to a length 58 mm 80...100 N...........................

Outside diameter of tappet 29,939...29,960 mm........................................................

Diameter of tappet bore in cylinder block 30,000...30,043 mm............................................

Engines from week 34 1996:

Rocker arm shaft diameter 22,970...22,990 mm........................................................

Diameter of rocker arm bore 23,000...23,021 mm.......................................................

Model Code Page

6000--8750 210 4

Camshaft

Diameter of camshaft bearing journal no 1 49,925...49,950 mm...........................................

Diameter of camshaft bearing journals (others that no 1) 49,885...49,910 mm...............................

Diameter of camshaft bearing journals nos 2, 3 and 4 (620/634--- engines) 49,865...49,890 mm................

Inside diameter of camshaft bearing bushes (when fitted in position) 50,010...50,070 mm.....................

Diameter of camshaft bearing bores (others than no 1) 50,000...50,025 mm................................

Camshaft clearance in bearing bush no 1 0,060...0,145 mm............................................

Camshaft clearance in bearing bushes (others than no 1) 0,090...0,140 mm..............................

Camshaft clearance in bearing bushes nos 2, 3 and 4 (620/634 ---engines) 0,110...0,160 mm................

Bearing bush tolerance in block (press fit) 0,025...0,080 mm...........................................

Diameter of bearing bush bore in block 55,620...55,650 mm

Camshaft end play with 0,5 mm gasket between cylinder block and timing gear

housing and between timing gear housing and front cover 0,5...1,0 mm.............................

Cam height (distance between back of cam and tip of cam):

--- inlet valve 41,180...41,430 mm......................

--- exhaust valve 40,080...40,330 mm...................

Cam lift:

--- inlet valve 7,38 mm......................

--- exhaust valve 8,28 mm...................

Camshaft max permissible deflection (total indicator reading) 0,03 mm...........................

Cylinder liners

Protrusion of cylinder liner above cylinder block top face 0,030...0,080 mm...............................

Max. permissible height difference between liners (under same head) 0,02 mm....................

Outer diameter of cylinder liner guide:

--- at upper end of liner 124,475...124,500 mm..............

--- at lower end of liner 122,961...122,986 mm..............

Liner bore 108,000...108,022 mm........................

Height of cylinder liner flange 9,03...9,05 mm........

Height of cylinder liner flange, 1st oversize, part no 8366 47933 9,08...9,10 mm.........................

Height of cylinder liner flange, 2nd oversize, part no 8366 47934 9,13...9,15 mm........................

Height of cylinder liner flange, 3rd oversize, part no 8366 47935 9,23...9,25 mm.........................

Outer diameter of cylinder liner flange 131,700...131,800 mm.

Piston, rings and gudgeon pin

Minimum distance between piston and cylinder head (measured with a piece

of lead wire thought the injector location hole) 0,900...1,150 mm........................................

Piston diameter:

--- 17 mm from lower edge (320, 420, 620- --engines) 107,873...107,887 mm..................................

--- 19 mm from lower edge (634 --- engines) 107,883...107,897 mm...........................................

26

Page 32

21. Engine

15. 5. 1996

1. 4. 1997

Pinboreinpiston 40,003...40,009 mm................................................................

Piston pin diameter 39,991...40,000 mm..............................................................

Width of ring grooves:

--- 1st groove (right---angled ring; 6000, 6200, 6300, 8000R, 8000, 8100, 8050, 8150) 2,560...2,580 mm.......

--- 2n d g ro v e 2,520...2,540 mm....................................................................

--- 3r d g ro o v e 4,040...4,060 mm....................................................................

Side clearance of piston rings in their grooves:

--- 1st ring (right---angled ring; 6000, 6200, 6300, 8000R, 8000, 8100, 8050, 8150) 0,07...0,102 mm..........

--- 2n d r in g 0,03...0,062 mm......................................................................

--- 3r d r in g 0,05...0,082 mm......................................................................

--- re j e ct l im i t 0,15 mm....................................................................

Piston ring height (in direction of cylinder):

--- 1st ring (right---angled ring; 6000, 6200, 6300, 8000R, 8000, 8100, 8050, 8150) 2,478...2,490 mm..........

--- 2n d r in g 2,478...2,490 mm......................................................................

--- 3r d r in g 3,975...3,990 mm......................................................................

Piston ring gap (with piston fitted in cylinder)

--- 1st ring (wedge shaped ring; 6100, 6400, 6600, 6800, 8200, 8400, 8450, 8550, 8750) 0,40...0,55 mm.....

--- 1st ring (right---angled ring; 6000, 6200, 6300, 8000R, 8000, 8100, 8050, 8150) 0,30...0,45 mm..........

--- 2n d r in g 0,60...0,80 mm......................................................................

--- 3r d r in g 0,30...0,60......................................................................

--- re j e ct l im i t 1,0 mm....................................................................

Model Code Page

6000--8750 210 5

Max. permissible weight difference between pistons in same engine 25 g.....................

Piston to be heated up to 100˚C before fitting gudgeon pin.

Piston position in cylinder: combustion chamber of piston to face towards injector.

Connecting rod

Inside diameter of piston pin bush (with bush pressed into connecting rod) 40,025...40,040 mm...............

Outside diameter of piston pin bush 44,082...44,120 mm................................................

Interference fit: connecting rod small end bushing ---connecting rod 0,057...0,120 mm......................

Connecting rod small end bore 44,000...44,025....................................................

Connecting rod big end bore 71,730...71,749 mm......................................................

Bigendbearingshellthickness:

--- st a n d a r d 1,835...1,842 mm.....................................................................

--- 1st undersize 0,25 mm 1,960...1,967 mm.........................................................

--- 2nd undersize 0,50 mm 2,085...2,092 mm.........................................................

--- 3rd undersize 1,00 mm 2,335...2,342 mm.........................................................

--- 4th undersize 1,50 mm 2,585...2,592 mm.........................................................

Big---end bearing clearance 0,046...0,098 mm.......................................................

End float (side clearance) at big---end on crankshaft 0,200...0,410 mm...................................

Piston pin bushing location perpendicular to longitudinal axis of connecting

rod to be within 0,15:100..................................................................

Piston pin bushing location and big ---end bearing location to be parallel to within 0,05:100..........

Weight marking (letter) at lower end.

Max. permissible weight difference between connecting rods in the same engine 20 g..........

Position of connecting rod; order no at valve mechanism side

(away from the combustion chamber in the piston)

Crankshaft

Crankpin diameter:

--- st a n d a r d 67,981...68,000 mm.....................................................................

--- 1. undersize 0,25 mm 67,731...67,750 mm..........................................................

--- 2. undersize 0,50 mm 67,481...67,500 mm..........................................................

27

Page 33

21. Engine

8. 11. 1990

1. 9. 1992

--- 3. undersize 1,00 mm 66,981...67,000 mm..........................................................

--- 4. undersize 1,50 mm 66,481...66,500 mm..........................................................

Crankpin length 40,000...40,160 mm.................................................................

Main bearing journal diameter:

--- st a n d a r d 84,985...85,020 mm.....................................................................

--- 1st undersize 0,25 mm 84,735...84,770 mm.........................................................

--- 2nd undersize 0,50mm 84,485...84,520 mm.........................................................

--- 3rd undersize 1,00 mm 83,985...84,020 mm.........................................................

--- 4th undersize 1,50 mm 83,485...83,520 mm.........................................................

Main bearing location diameter (in cylinder block) 91,000...91,025 mm.....................................

Main bearing shell thickness:

--- st a n d a r d 2,955...2,965 mm.....................................................................

--- 1st undersize 0,25 mm 3,080...3,090 mm.........................................................

--- 2nd undersize 0,50 mm 3,205...3,215 mm.........................................................

--- 3rd undersize 1,00 mm 3,455...3,465 mm.........................................................

--- 4th undersize 1,50 mm 3,705...3,715 mm.........................................................

Main bearing clearance 0,050...0,127 mm...........................................................

Length of thrust bearing journal (journal nearest to flywheel):

--- standard (2 standard thrust plates) 45,000...45,080 mm...............................................

--- 1st oversize (one std and one 0,1 mm overthick thrust plate) 45,100...45,180 mm.........................

--- 2nd oversize (one std and one 0,2 mm overthick thrust plate) 45,200...45,280 mm.........................

--- 3rd oversize (one 0,1 mm and one 0,2 mm overthick thrust plate) 45,300...45,380 mm.....................

--- 4th oversize (two 0,2 mm overthick thrust plates) 45,400...45,480 mm...................................

Model Code Page

6000--8750

210 6

Other crankshaft journals may not be ground longer.

Crankshaft end float 0,100...0,380 mm..............................................................

Max. permissible ovality and other deformity of crankpins or journals 0,03 mm....................

Crankshaft unbalance 1,0 Ncm Max.............................................................

Balancing unit ring gear location, diameter (420 engines) 150,220...150,260 mm..............................

Balancing unit ring gear I.D. (420 engines) 150,000...150,040 mm...........................................

Flywheel

Flywheel ring gear no. of teeth 133 pcs.....................................................

Interference fit between ring gear ---flywheel 0,425...0,600 mm..........................................

Before fitting the ring gear, heat up to a temperature of 150...200˚C................................

Flywheel unbalance 1,0 Ncm Max..............................................................

Max permissible axial wobble of flywheel clutch face, measured at inner edge

of clutch face on diameter 200 0,06:ø200.....................................................

Timing gears

Tooth backlash:

Crankshaft---idler gear 0,05...0,25 mm............................................................

Idler gear--- camshaft gear 0,05...0,25 mm.........................................................

Idler gear--- fuel injection pump gear 0,05...0,25 mm................................................

Max. permissible side wobble of gears 0,05 m m..............................................

Idler gear shaft, diameter 54,951...54,970 mm..........................................................

Inner diameter of idler gear bushing (fitted) 55,000...55,030 mm..........................................

Inner diameter of Idler gear hole 60,000...60,030 mm...................................................

Camshaft gear hole diameter 32,000...32,025 mm......................................................

Camshaft end diameter 32,043...32,059 mm...........................................................

28

Page 34

21. Engine

1. 1. 1994

1. 8. 1998

Timing marks:

Timing marks on gears are in alignment when the 1st cylinder piston is at its top dead centre between

compression and power strokes.

On crankshaft gear 2 dots on tooth...............................................................

On idler gear:

--- against crankshaft gear mark 0 on tooth....................................................

--- against camshaft gear mark 1 dot on tooth.....................................................

--- against fuel injection pump gear mark 1 dot on notch............................................

On camshaft gear 1 dot on notch................................................................

On injection pump gear 1 dot on tooth...........................................................

Model Code Page

6000--8750

Cylinder block

Holes for guide pins 13,250...13,320 mm..............................................................

Main bearing location diameter 91,000...91,025 mm....................................................

Main bearing location (with bearings 8361 40950) 92,000...92,025 mm.....................................

Cylinder liner location, diameter:

--- u p p e r en d 124,514...124,554 mm....................................................................

--- lo w er e n d 123,000...123,040 mm....................................................................

Inner diameter of camshaft bushing (fitted) 50,010...50,070 mm..........................................

Cylinder block height 428,170...428,430 mm.............................................................

210 7

Distance between piston and top dead centre at different crank shaft angles

Grad 320, 420, 620mm634

mm

6˚

10˚

11˚

12˚

13˚

14˚

15˚

16˚

17˚

18˚

19˚

20˚

0,423

1,173

1,418

1,686

1,976

2,289

2,625

2,983

3,363

3,765

4,188

4,633

0,485

1,344

1,624

1,931

2,264

2,623

3,007

3,417

3,852

4,312

4,797

5,307

Grad 320, 420, 620mm634

mm

21˚

22˚

23˚

24˚

25˚

26˚

27˚

28˚

29˚

30˚

5,100

5,587

6,095

6,624

7,173

7,742

8,331

8,939

9,567

10,213

5,841

6,399

6,980

7,585

8,214

8,865

9,539

10,235

10,952

11,692

Cylinder head

Height of cylinder head 104,800...105,000 mm...........................................................

Height (min.) of cylinder head after repair grinding 104,000 mm....................................

Cylinder head straigthness:

--- in lateral direction 0,05 mm..............................................................

--- in longitudinal direction 0,10 mm.........................................................

Valve guide inner diameter (not fitted) 9,000---9,015 mm...............................................

Valve guide outer diameter 16,028...16,039 mm........................................................

Valve guide bore diameter in cylinder head 16,000...16,018 mm..........................................

Height of valve guide upper end from cylinder head surface 21 mm............................

Valve head depth from cylinder head surface:

--- in l e t v a lv e 0,7±0,05 mm (max. 1,70 mm)....................................................................

--- exhaust valve 0,6±0,05 mm (max. 1,60 mm).................................................................

Valve sealing surface angles:

--- in l e t v a lv e 35˚

--- exhaust valve 45˚

Valve sealing surface width:

--- in l e t v a lv e 2,9...3,7 mm....................................................................

--- exhaust valve 1,3...2,3 mm.................................................................

Diameter of exhaust valve seat insert 44,070...44,132 mm................................................

Diameter of exhaust valve seat insert location 44,000...44,025 mm........................................

Diameter of exhaust valve seat insert (repair part 8366 52269) 44,270...44,332 mm..........................

Diameter of exhaust valve seat insert location (repair part 8366 52269) 44,200...44,225 mm...................

....................................................................

.................................................................

+20’

+20’

Diameter of inlet valve seat insert (8366 47936) 48,570...48,632 mm.......................................

Diameter of inlet valve seat insert location 48,500...48,525 mm............................................

Diameter of inlet valve seat insert (repair part 8368 55347) 48,770...48,832 mm.............................

Diameter of inlet valve seat insert location (repair part 8368 55347) 48,700...48,725 mm......................

29

Page 35

21. Engine

Lubricating system

1. 9. 1992

1. 1. 1994

Model Code Page

6000--8750

210 8

Oil pressure at normal running temperature:

--- at idling speed (min.) 100 kPa (1,0 kp/cm

--- at running speed 250---400 kPa (2,5---4,0 kp/cm

Free length of oil pressure valve spring 80 mm..............................................

Spring pressure when valve spring is compressed to a length of 52 mm 54+5 N (5,4+0,5 kp)..................

Diameter of oil pressure valve plunger 19,602...19,635 mm..............................................

Diameter of oil pressure valve cylinder 19,700...19,752 mm..............................................

Oil filter by---pass valve opens at a pressure difference of 2±0,5 kp/cm

..............................

2

)...........................................................

2

Oil pump (320, 420 engines)

Backlash between gears when crankshaft lies firmly against the lower side of main bearings:

--- crankshaft gear---lubricating oil pump gear 0,05...0,25 mm........................................

--- between the pump gears 0,16...0,26 mm.......................................................

Diameter of drive shafts:

--- at bearings for body and cover 17,966...17,984 mm..................................................

--- at gear wheel pressed on shaft 18,099...18,109 mm..................................................

Diameter of shaft holes on body and cover 18,000...18,018 mm..........................................

Diameter of gear wheel holes 18,060...18,078 mm......................................................

Drive shaft gear (press fit), distance between side gear (thread side) and first shoulder 14,80...15,20 mm.....

Fixed shaft, diameter 18,028...18,039 mm.............................................................

Protrusion of fixed shaft end below pump body face 0,5...1,0 mm...................................

Thickness of cover gasket 0,06...0,08 mm.........................................................

Outside diameter of gear 43,486...43,525 mm..........................................................

Housing diameter 43,650...43,750 mm................................................................

Thickness of gears 24,000...24,027 mm...............................................................

End play of gears 0,03...0,11 mm................................................................

Depth of housing 24,000...24,043 mm................................................................

Number of teeth on drive gear (320 engines) 51 pcs.........................................

Number of teeth on drive gear (420 engines) 46 pcs.........................................

2

)..............................................................

Oil pump (620, 634 engines)

Backlash between gears when crankshaft lies firmly against the lower side of main bearings:

--- crankshaft gear---lubricating oil pump gear 0,05...0,25 mm........................................

--- between the pump gears 0,16...0,26 mm.......................................................

Diameter of drive shafts

--- at bearings for body and cover 17,966...17,984 mm..................................................

--- at gear wheel pressed on shaft 18,099...18,109 mm..................................................

Diameter of drive shaft bearing hole on body and cover 18,000...18,018 mm................................

Hole diameter of gear pressed on drive shaft 18,060...18,078 mm.........................................

Drive shaft gear (press fit), distance between side gear (thread side) and first shoulder 16,5±0,2 mm.....

Diameter of fixed shaft at gear wheel 17,966...17,984 mm................................................

Inner diameter of bearing for gear wheel which rotates on fixed shaft 18,000...18,018 mm....................

Fixed shaft in pump body, diameter 20,035...20,048 mm.................................................

Protrusion of fixed shaft end below pump body face 0,5+0,5 mm...................................

Thickness of cover gasket 0,06...0,08 mm.........................................................

Outer diameter of gear wheels (620 engines) 43,486...43,525 mm.........................................

Outer diameter of gear wheels (634 engines) 55,824...55,870 mm.........................................

Housing diameter (620 engines) 43,650...43,750 mm...................................................

Housing diameter (634 engines) 56,000...56,120 mm...................................................

Thickness of gears 32,000...32,027 mm...............................................................

End play of gears 0,03...0,11 mm................................................................

Depth of housing 32,000...32,043 mm................................................................

Number of teeth on drive gears 46 pcs....................................................

30

Page 36

21. Engine

1. 6. 1999

1. 10. 1999

Model Code Page

6000--8950

Balancing unit (420 engines)

Tooth backlash:

--- crankshaft ring gear --- balancer weight gear wheel 0,1...0,3 mm..................................

--- between the balancer weights gear wheels 0,05...0,250 mm........................................

Balancing weights end float 0,1...0,5 mm.......................................................

Shaft diameter at bearing surfaces 36,000...36,016 mm.................................................

Bearing bushing inner diameter (fitted) 36,050...36,075 mm..............................................

Diameter of holes in body for shafts, rear end 36,058...36,083 mm........................................

Diameter of holes in body for shafts, front end 35,958...35,983 mm........................................

Shim thickness, cylinder block---balancer unit 0,2 mm........................................

Turbocharger

Schwitzer S1A ( 320 DS engines)

Shaft end float max 0,14 mm..................................................................

Shaft radial clearance

Turbine housing attaching bolts 22 Nm....................................................

Nutatendofshaft 6,8 Nm...............................................................

Schwitzer S1B (420 DS engines) and S1BG by --pass turbo (420DW engines)

Shaft end float max 0,14 mm...................................................................

Shaft radial clearance

Turbine housing attaching bolts 22 Nm....................................................

Nutatendofshaft 8,1 Nm...............................................................

By---pass passage opening pressure (S1BG) 1,035 bar.........................................