Valor VENTANA Series, VENTANA 1200NCK, VENTANA 1200PCK Installation Instructions Manual

VENTANA

Gas Conversion Kit

1200PCK/NCK

Use with with Valor Models 1200 Heater ONLY

Installation Instructions

This appliance is certifi ed for use from 0–4500 feet. For

altitudes above 4500 feet, see local codes.

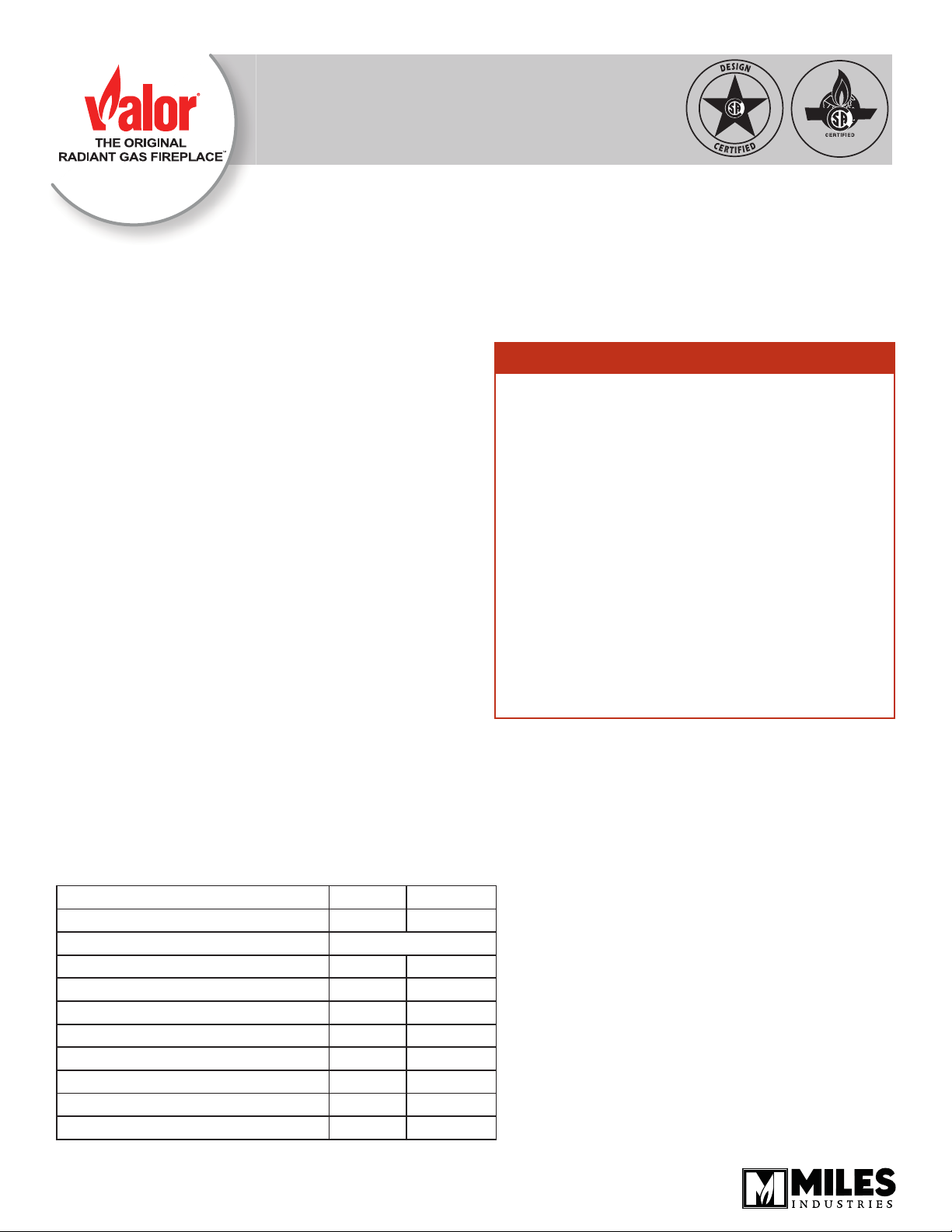

Kit Contents

1 Main burner

1 Pilot injector—see chart for identifi cation

1 Main burner elbow injector—see chart for

identifi cation

1 Minimum rate by-pass screw—see chart for

identifi cation

1 Set of conversion labels

1 Ceramic middle log (NG 4001370; LPG 4001534)

Tools Required

Wrenches, to disconnect gas line

•

• Phillips (+) screwdriver, to remove burner module

• Small (jewelers size) fl at blade screwdriver, to set

pressure

• Small fl at blade screwdriver, to release pressure tap

on valve

• Nut driver 8 mm or 5/16”, to remove burner nuts

• Needle nose pliers, to remove by-pass screw

• Hex (Allen) wrench, 4 mm or 5/32”, to remove pilot

injector

• Manometer, to set pressure when regulator is integral

with valve

WARNING

This conversion kit shall be installed by a

qualifi ed service agency in accordance with

the manufacturer’s instructions and all applicable codes and requirements of the authority

having jurisdiction. If the information in these

instructions is not followed exactly, a fi re, ex-

plosion or production of carbon monoxide may

result causing property damage, personal injury or loss of life. The qualifi ed service agency

is responsible for the proper installation of this

kit. The installation is not proper and complete

until the operation of the converted appliance

is checked as specifi ed in the manufacturer’s

instructions supplied with the kit.

Use this manual in conjunction with the installation manual supplied with the appliance.

Specifi cations

Model

Gas Natural Propane

Altitude (Ft.)* 0-4,500 feet*

Input Maximum (Btu/h) 36,000 31,000

Input Minimum (Btu/h) 15,000 15,000

Manifold Pressure (in w.c.) 3.6 10.5

Minimum Supply Pressure (in w.c.) 5.0 11.0

Maximum Supply Pressure (in w.c.) 11.0 14.0

Main Burner Injector Marking 82-1200 92-360

Pilot Injector Marking 62 30

Min. Rate By-Pass Screw 190 125

4001533-04

© Copyright Miles Industries Ltd., 2014.

1200NG 1200LPG

General Notes Regarding Conversion

The Ventana can be converted before or after installation into a wall. If converting after the fi replace is installed and

enclosed into the wall, the access to the minimum rate by-pass screw will require the removal of the burner module.

As well, the earlier version of the burner fi xing method to the burner module will require that the burner module be

removed—see section Burner.

There are two versions of the Ventana fi replace with respect to the manifold pressure regulation. Earlier versions

have a separate, convertible regulator that does not require a gas supply or a manometer to convert. Later versions

have a regulator integral with the control valve and require a gas supply and manometer to complete the conversion.

See section Manifold Pressure to determine which version you have.

Conversion Procedure

The conversion procedure will vary according to three factors.

• Whether the heater is already installed or not;

• Whether the burner mounting is considered an earlier model or later model;

• Whether the heater has a separate convertible regulator or a regulator integral to the valve.

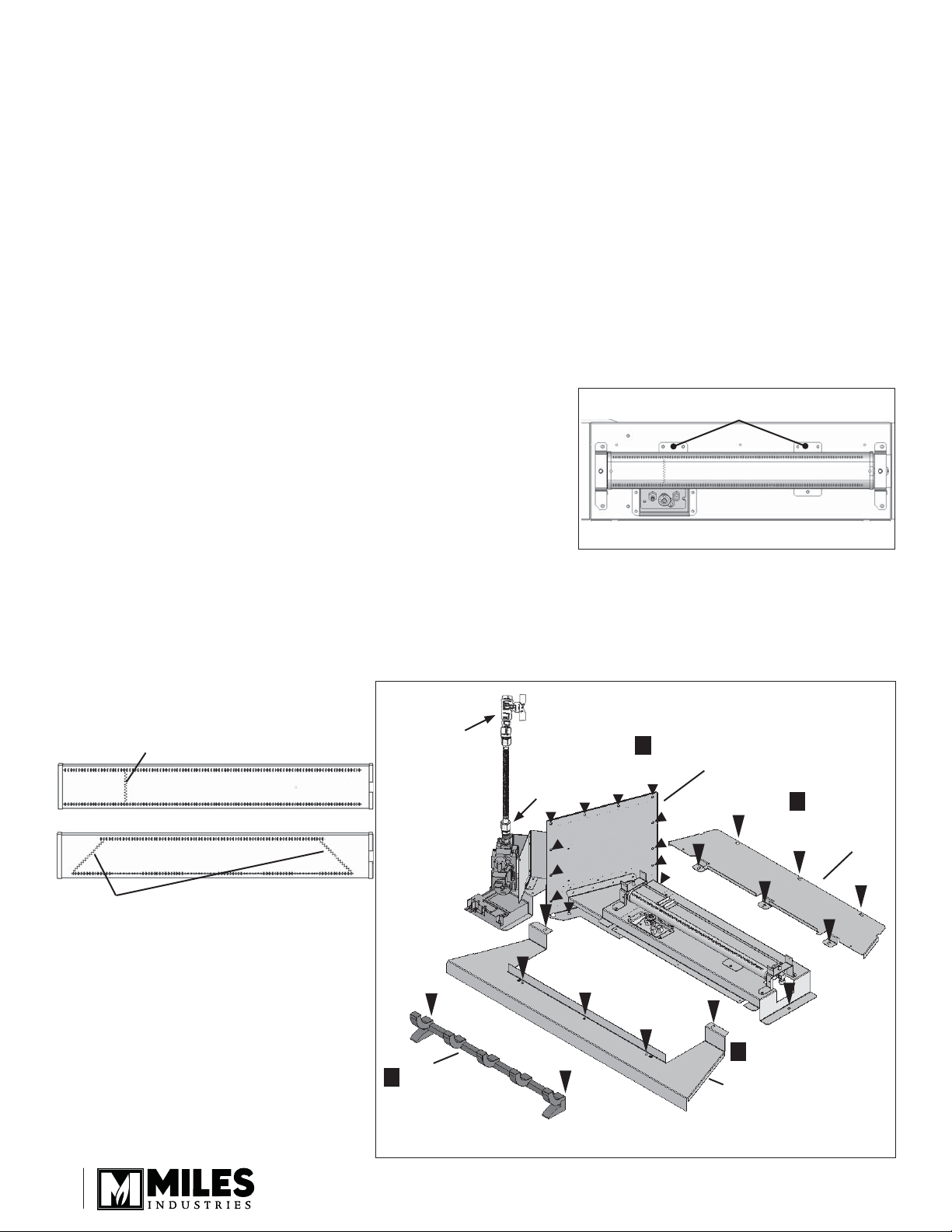

The burner module assembly does not need to be removed from the

Burner Supports

fi xed from top

heater in the following case:

• The conversion is done before the heater installation, AND

• The burner mounting is a later model (fi xed to the burner tray from

the top side).

In ALL other cases, the burner module must be removed to proceed to

the conversion.

1. Remove the window, logs/pack and ceramic bricks (if installed) from the fi rebox.

2. Shut-off gas if unit is already installed and disconnect gas line at the regulator or valve depending on model.

3. If the burner needs to be removed, remove the cast fret, front and rear brick supports—see fi gure 1.

4. Proceed to the following sub-sections.

Shut-off

Gas Supply

NG burner—cross-lighting ports

here

Disconnect

Gas Line

here

Remove Burner Module (12

4

screws + 1 at right hand side)

Burner

Top View

Remove

3

Rear Brick

Support (6

screws)

LPG burner—cross-lighting ports

2

Remove

1

Cast Fret

(2 screws)

Figure 1

2

Remove Front

Brick Support

(5 screws)

Burner

Early models—Burner fi xing nuts

accessible from underside of module

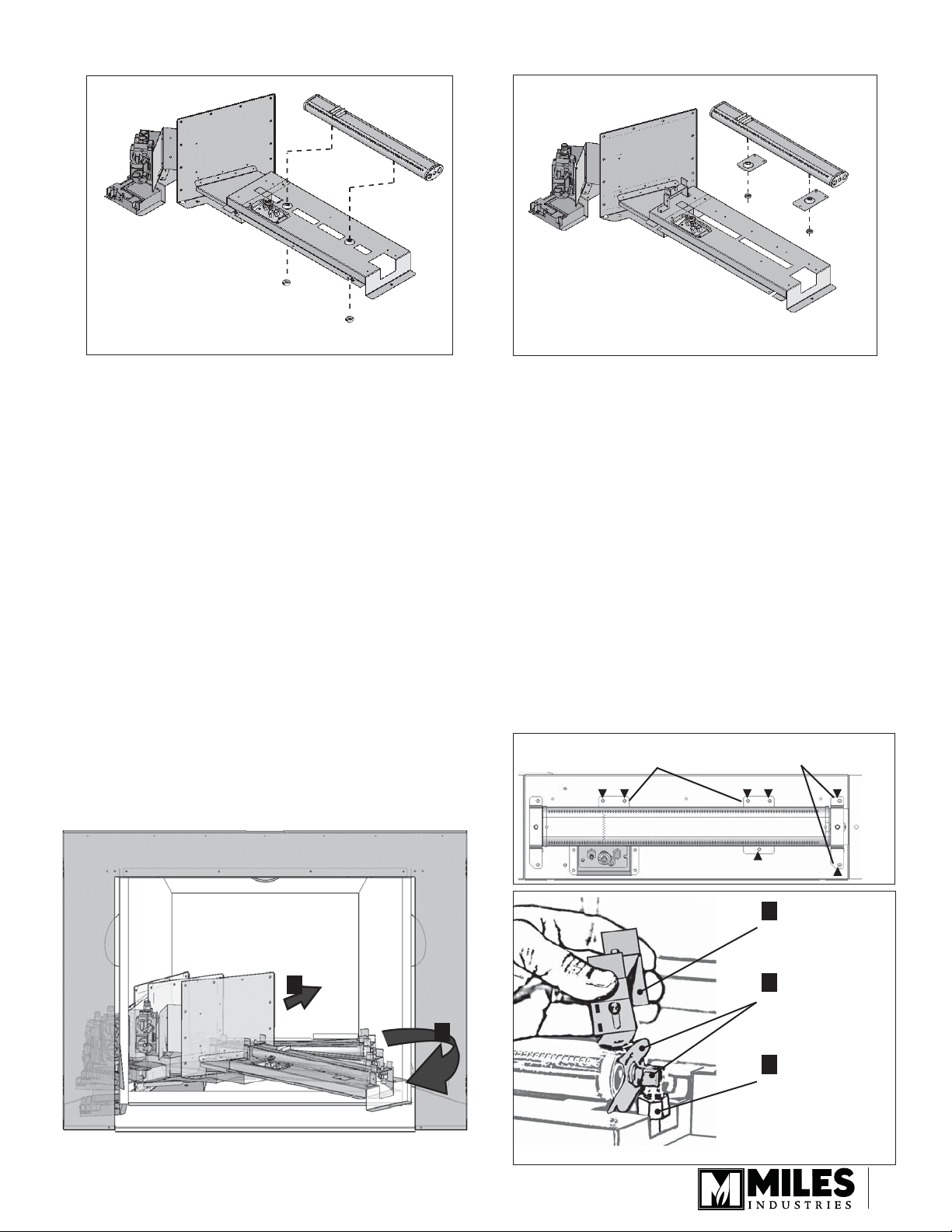

Early models: The burner fi xing points are under the

burner module tray and the burner module assembly

must be removed. Proceed as follows:

1. Remove the screw retaining burner module tray on

the right hand side as well as the 12 screws retaining

the module plate at the left side wall of the fi rebox—

see fi gure 1.

2. Grab the burner module assembly, lift it slightly, twist

it upward and slide it towards the right and out to

allow the valve and receiver attached to the module

end plate through the left inner fi rebox wall as shown

below.

3. Remove the front log retaining bracket from the

burner top at the right hand side and the injector

elbow with air shutter (NG) from the end of the

burner. Note that there is no air shutter on the LPG

burner. Unscrew the pipe nut while holding the

injector elbow with a wrench—see fi gure 2.

4. Remove the main burner by removing the two nuts

from the underside of the burner tray.

5. Replace the main burner by the appropriate fuel

burner fi xing it back to the burner tray with the two

nuts.

Later models—Burner fi xing supports

accessible from the top of module

Later models: The burner is fi xed to the burner tray

through two supports. The conversion can be done

without removing the burner module assembly from the

fi rebox.

1. Remove the front log retaining bracket from the

burner top at the right hand side.

2. Remove the injector elbow with air shutter (NG)

from the end of the burner. Note that there is no air

shutter on the LPG burner. Unscrew the pipe nut

while holding the injector elbow with a wrench—see

fi gure 2.

3. Remove the main burner by removing the fi ve

screws retaining the burner supports to the burner

tray.

4. Detach the main burner from its supports and attach

the supports to the replacing burner.

5. Refi t the new main burner to its position by fi xing the

burner supports back to the tray with the fi ve screws

previsously removed.

Remove burner from

tray (5 screws)

Remove front log retaining

bracket (2 screws)

1

Removing burner module from fi rebox

(fi rebox front transparent for clarity)

1

Remove front log

retaining bracket

3

Unscrew injector

elbow with air

2

shutter (NG) from

end of burner

2

Unscrew pipe

nut while holding

injector elbow

with wrench

Figure 2

3

Injector Elbow

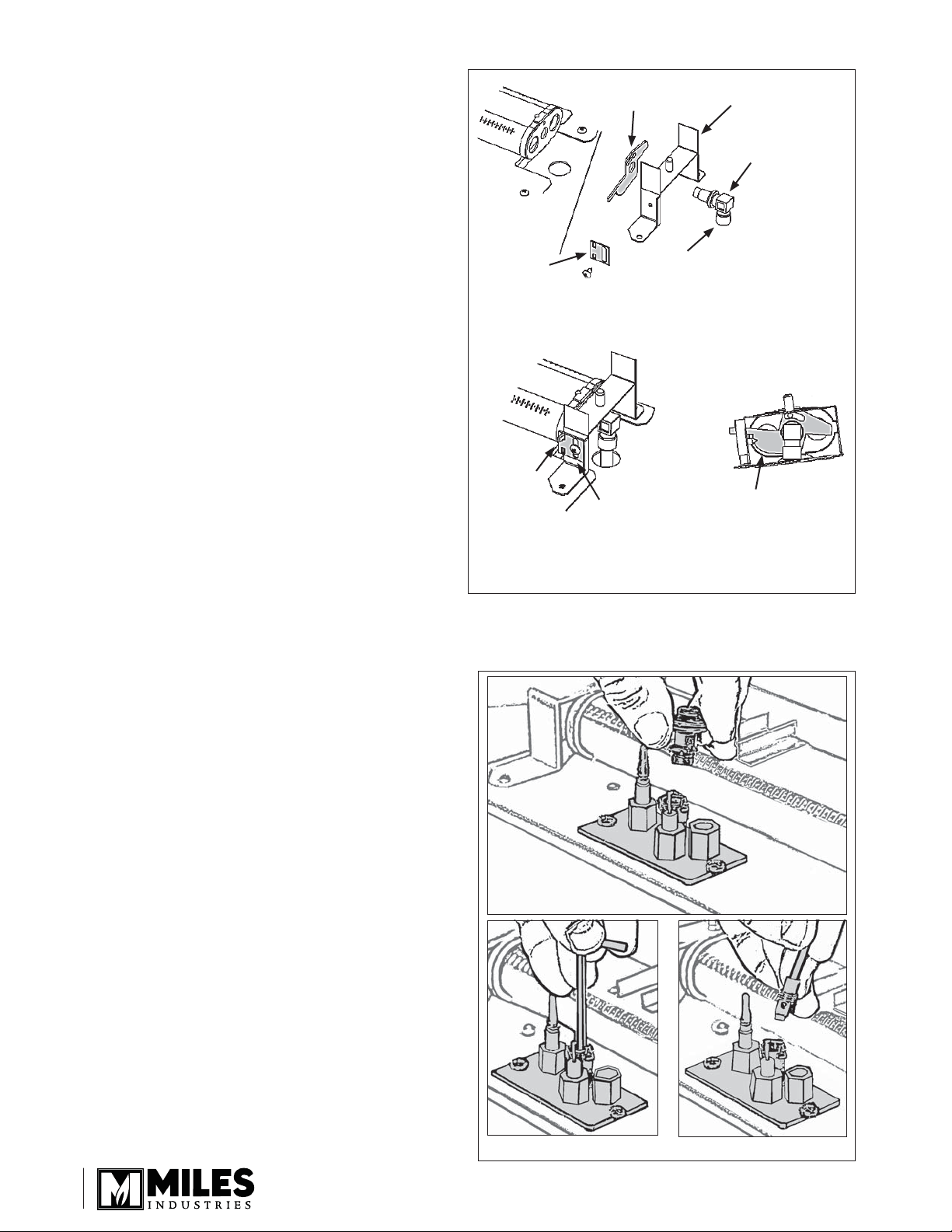

Reinstall the main burner injector elbow—see fi gure

3. Ensure the proper injector for the desired fuel type.

Note the catalogue number from the Specifi cations

table on page 1 and the same number stamped on the

side of the injector elbow.

• If converting to a LPG burner, DO NOT reinstall the

air shutter.

• If converting to a NG burner, install the air shutter

supplied with this kit as shown in fi gure 3.

Install air

shutter

slider (NG

units only)

Insert air

shutter

tab into

top hole

of slider

Install air shutter on

NG units only

Reconnect to pipe and

ensure it is gas-tight

Tighten screw

with slider at

mid-point in

slot

Re-install

log retaining

bracket

Thread injector

elbow through

air shutter (if

used) into end

of burner

Suggested air shutter

setting (NG units only)

Suggested NG

air shutter setting

Pilot Injector

1. Remove the pilot hood by pulling on it.

2. Unscrew the pilot injector using an Allen key. Discard

the pilot injector.

3. Replace with the appropriate pilot injector—see

Specifi cations table on page 1. Screw the new

injector.

4. Refi t the pilot hood by pushing down on it.

Figure 3

Figure 4

4

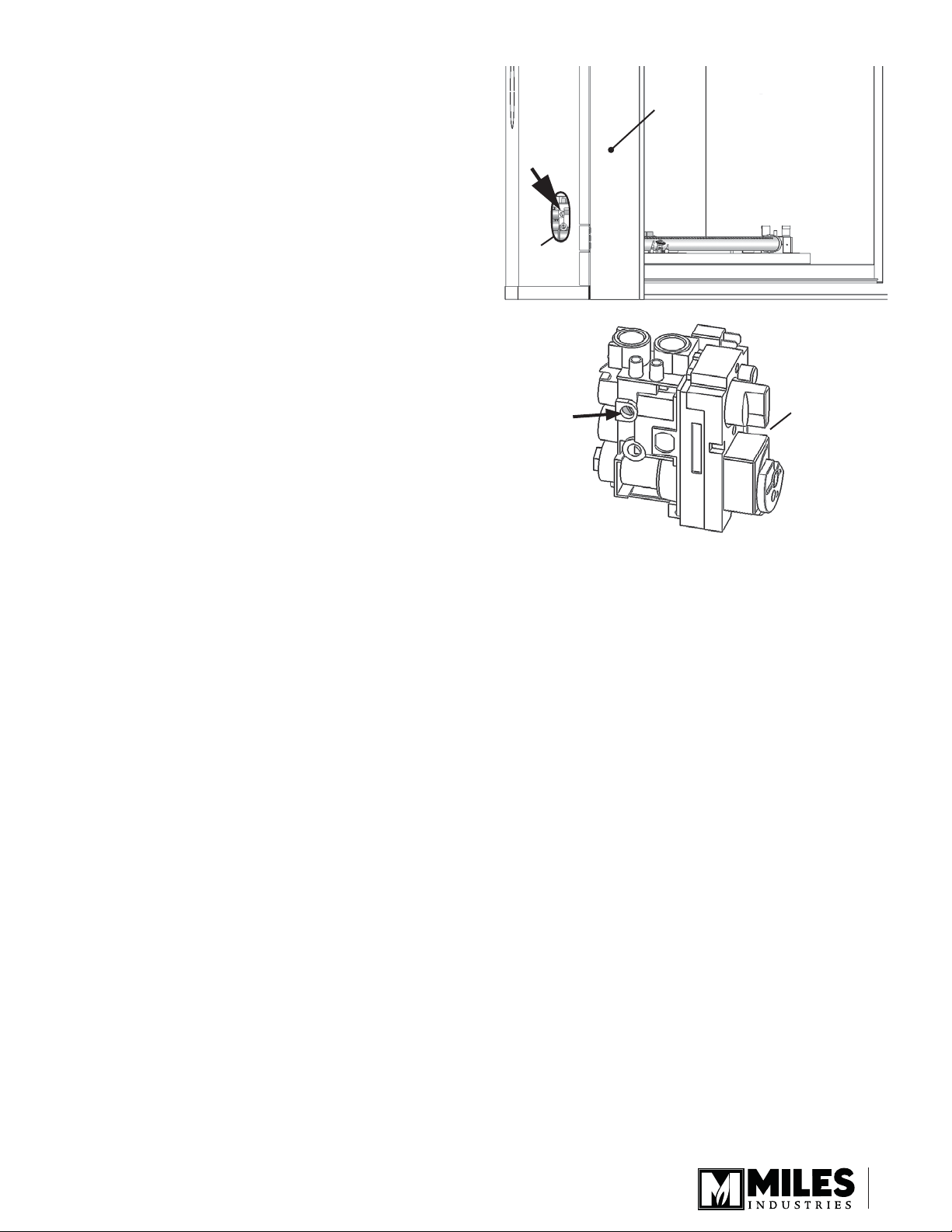

Minimum Rate By-Pass Screw

Convert the minimum rate by-pass screw accessing the

valve either when the burner is out of the fi rebox or from

the bottom hole of the exterior wall of the fi rebox, on the

left hand side of the fi rebox.

1. Remove the screw from the valve and discard. The

by-pass screw has a rubber O-ring and may need to

be pulled out using pliers after unscrewing.

2. Insert the replacement minimum rate by-pass screw

and hand tighten using a screwdriver. Refer to the

Specifi cations table on page 1 for proper by-pass

screw. Note that the number is stamped on the barrel

of the screw.

Firebox

left side

Opening

to access

the valve

Minimum rate

by-pass screw

location

Firebox

front

Front of

valve

Burner Reinstallation & Check

1. Reinstall the burner module if removed for

conversion.

2. Reinstall the rear brick support, the front brick support

and the cast grate.

3. Reconnect the gas line and the open shut-off valve.

Check for leaks.

5

Loading...

Loading...