CAN module

CANBUS USER MANUAL

1.1.

REQUIREMENTS

1.1.1. PHYSICAL REQUIREMENTS

The module shall be compatible with various types of power supply for different commercial vehicles,

mainly 12V and 24V.

Normal operating conditions:

• Operating temperature: -40℃—+85℃;

• Relative humidity: 45%—75%;

• Pressure: 86Kpa—106Kpa(absolute pressure value);

• Storage temperature range:-40℃—+85℃.

1.1.2. FUNCTION REQUIREMENT

CAN module shall be able to receive, process, analyze, store and transmit data from the sensors and the

tool. Its main functions are as follows:

• Reliable data receiving: the receiving rate shall > 90%

• Time setting

• Data storage

• Serial Port data transmission

• Sensor ID registration

The module communicates with TPMS Smart Tool and realizes ID LEARNING. After TPMS is started, the

CAN module will transmit its ID to TPMS Smart Tool by RF. Then the Sensor ID of each tire will be learned

by TPMS Smart Tool. All the Sensors ID and CAN module ID in the TPMS Smart Tool are transmitted to

CANBUS again for registration. Besides, the data of pressure and temperature of tires will be transmitted

by CANBUS, not by RF.

1.1.3. PROPERTIES REQUIREMENT

• Reverse polarity requirements: after one-minute connection of reverse polarity, the product shall

be able to function properly with normal power supply;

• Receiver’s contact discharge level is 8KV, air discharge level is 15KV.

1.2. CAN MODULE PRINCIPLE

CAN module is used to receive wireless information, and appropriately process and display information.

Main parts and functions of CAN module are:

• R/F receiver module decodes high frequency signal transmitted by tractor’s transmitting module

and transceiver module; then it sends the data package to MCU through SPI port.

• MCU analyzes data information in the data package. In the case of tire pressure sensor signal,

sensor ID will be analyzed. If sensor ID is the same with its predetermined ID information, its

temperature and pressure information will be collected and processed; once sensor ID is different with its

predetermined ID information, the data will not be considered as that vehicle’s tire data and will not be

processed.

• Power system will change 12V or 24V vehicle power supply into normal operating voltages for

different modules.

1

CAN module

• Memory module records tire information stored by the receiver (if any abnormality occurred in

any tire, the tire information will be immediately stored), the data can be downloaded to a computer

through Serial Port or wirelessly for analysis.

1.3. CAN MODULE PERFORMANCE DISCRIPTION

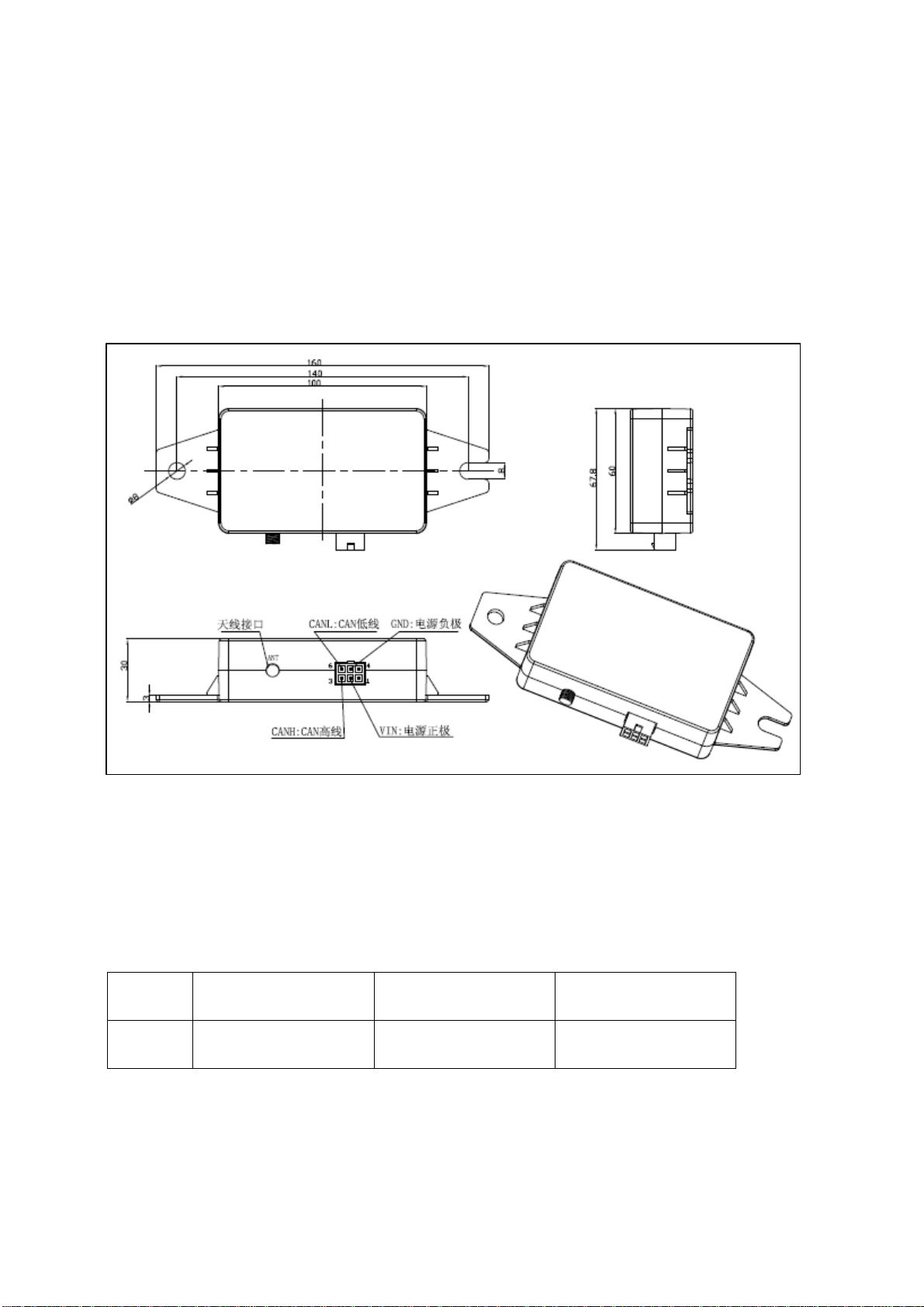

1.3.1. MODULE INTERFACE CIRCUIT AND INSTALLATION DIMENSION

Note: ANT is antenna interface. Wire is extended to vehicle chassis. Le ngth of wire is defined by vehicle

manufacturer according to different vehicle models.

1.3.2. DEFINITION OF PORT

z CAN BUS port:

Socket type: MOLEX 39-01-2060 or 5569-06AIS(corresponding plug model as 39-01-2060 or

5557-06R) 6pin

Definition of pin:

5 pin 2 pin 3 pin 6pin

GND

(black)

z RF port:

REVERSE SMA port (90° angle)

2

VIN(DC24/12V

compatible, red)

CANH(yellow)

CANL(green)

CAN module

1.3.3. FUNCTIONS

1.3.3.1.

When tire pressure is≥10.8Bar(8.3*1.3), high pressure warning level two, potential risky status, driver

shall stop the vehicle and adjust tire pressure immediately.

When tire pressure is≥9.5Bar(8.3*1.15), high pressure warning level one, it calls driver’s attention to

tire pressure and adjust tire pressure accordingly.

HIGH PRESSURE WARNING

1.3.3.2. LOW PRESSURE WARNING

When tire pressure is < 7.4Bar(8.3*0.9), low pressure warning level one, it calls driver’s attention to

tire pressure and adjust tire pressure accordingly.

When tire pressure is< 6.6Bar(8.3*0.8), low pressure warning level two, potential risky status, driver

shall stop the vehicle and adjust tire pressure immediately.

1.3.3.3. HIGH TEMPERATURE WARNING:

When tire pressure is≥80℃, it gives out high temperature warni ng, driver shall stop the vehicle and

lower the temperatu re of the tire.

1.3.3.4. FAST LEAKAGE WARNING:

When the tire pressure loss is ≥0.33Bar within 16s, it gives out fast leakage warning, driver shall stop the

vehicle and make appropriate treatment.

1.3.3.5. NON-RECEIVING DATA WARNING:

When the system does not receive tire pressure information for more than 20 minutes, it gives out nonreceiving data warning.

1.3.3.6. CAN BUS COMMUNICATIONS

When any of the above 5 kinds of information is received, the system will send data to ICM through CAN

BUS for processing.

1.3.3.7. DATA STORAGE

The system can store 4300 of tire information. Under norm al conditions, data shall be stored every 30

minutes; under abnormal condition, data shall be stored every 10s. When abnormality occurs in any tire,

the stored information shall be reviewed. The function is similar to Black Box.

1.3.3.8. ID LEARNING

The module communicates with TPMS Smart Tool and realizes ID LEARNING;

To make integration of TPMS to vehicles simple, save installation time, our proposed installation process is

as follows:

3

CAN module

g

T

T

g

st

ar

t

Sensors

preparati

on

Use tool, read

tire ID,

establish oneto-one

relationship

between tire

ID and tire

location

Sensor

installed

onto

wheels

ires

installati

on

write tire ID and

location into

receivin

by TPMS smart

tool

module

Receivin

g

module

installati

on

wirin

Test

ires

installation

line

Chassis

installatio

n line

End

Body

instal

lation

line

1.3.3.9. CAN BUS COMMUNICATIONS PROTOCOL

• CAN BUS communications protocol is based on J1939

• Transmission rate: 250Kbits/S

• CAN2.0B, Extended Super Frame

• Recommend circuit:

Note:The load resistor (marked R223)whether to need depends on the CAN bus design.

• Communications time sequence:

1)Under normal conditions: All tire data are transmitted every 10S after the first data is received; the

time interval between every two tires is 100ms.

4

CAN module

2)Under abnormal conditions: When an abnormal data is received, it will be transferred through CAN

BUS immediately.

3)Under abnormal conditions: All abnormal tire data are transmitted every 10S, the time interval

between every two tires is 100ms.

5

CAN module

r

a

l

g

i

o

n

e

m

N

warning

hi

h

warning

Explanation

The low order 4 bits represent a

position number, counting left to

right when facing in the

direction of normal vehicle

travel (forward).

The high order 4 bits represent a

position number, counting front

to back on the vehicle.

Examples: 0x23 would be right

outside rear rear on a 3-axle

tractor with dual axle per

side(3rd axle,4th tire)

Pressure at which air is

contained in cavity formed by

tire and rim, 5.5kpa/bit

Example:0x79(Hex)means the

pressure:

121(Dec)

*5.5=665Kpa=6.65Bar=6.6Bar

Temperature at the surface of the

tire sidewall, 0.03125℃/bit

Example:Byte3:0x8D(HEX);

Byte4:0x24(HEX)

0x248D(HEX),Dec value:9357;

absolute temperature:

9357*0.03125=292.4

Celsius degree:292.4-273=19.4℃

00=Normal, 01=Not receive the

tire signal in the past 20

minutes, Others=Rev.

00=Normal

01=Leakage

Others=Rev.

00=Normal

01=high temperature warning

Others=Rev.

The pressure loss rate of a tire.

Example:Byte6:0x8D;Byte7:0x24

0x248D(HEX),dec value 9357;

Leakage rate:

9357*0.1=935.7Pa/s=9.35Kpa/s=0.09

Bar/s Pressure warning range

000=Over high pressure, P≥

10.8Bar;

001=High pressure,9.5Bar≤P<

10.8Bar;

010= Normal:7.4Bar≤P<9.5Bar

011= Low pressure:6.6Bar≤P<

7.4Bar;

Unavail

Data

Data

Physical

Physica

Er

Def

able

maximum

minimum

maximum

minimum

value

or

ult

value

value

value

value

255

Offset

Ratio

factor

Unit

th

Len

n

t

locati

StartB

8

1.1

250

0

1000

0

0

5.5

kPa

8

2.1

64255

0

1735

-273

-273

0.03125

degC

16

3.1

2

5.5

2

5.3

2

5.1

64255

0

6425.5

0

0

0.1

Pa/s

16

6.1

100=Over low pressure:P<6.6Bar

3

8.6

Sig

Truans

Signal

Parameter

Period

BCM_Gat

CAN ID

PGN

name

0x18FEF433

65268

Tire

Condition

0x18FEF433

65268

Tire

Condition

0x18FEF433

65268

Tire

Condition

0x18FEF433

0x18FEF433

0x18FEF433

65268

65268

65268

Tire

Tire

Condition

Tire

Condition

Condition

0x18FEF433

65268

Tire

Condition

0x18FEF433

65268

Tire

Condition

(ms)

al

typ

SPN

eway

Node

itting

on

descripti

Signal name

Tire

10000

929

ICM

TPMS

position

Tire Location

Tire

10000

241

ICM

TPMS

pressure

Tire Pressure

10000

242

ICM

TPMS

re

Tire

temperatu

Tire

Temperature

10000

10000

10000

1697

1698

1699

ICM

ICM

ICM

TPMS

TPMS

TPMS

g

on-

data

Leakage

receiving

Fault

Electrical

CTI Wheel End

CTI Tire Status

re

warning

temperatu

CTI Wheel

Sensor Status

10000

2586

ICM

TPMS

rate

leakage

Pressure

Tire Air

Leakage Rate

10000

2587

ICM

TPMS

level

warning

Pressure

Threshold

Detection

Tire Pressure

6

CAN module

1.4. TECHNICAL PARAMETERS

1.4.1. OPERATING CONDITIONS

Normal operating conditions

• Operating Temperature: -40℃—+85℃;

• Relative humidity: 45%—75%;

• Pressure: 86Kpa—106Kpa(absolute pressure value)

• Storage temperature range: -40℃—+85℃.

1.4.2. PROPERTIES PARAMETER

• Voltage supply: 12V or 24V

• Receiving sensitivity: -95dbm~-105dbm

1.5. FCC'S AUTHENTICATION ANNOUNCEMENT

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device ma y not cause harmful inter f erence, and (2) thi s device must a cc ept any interference

received, including interference that may cause un desired operat ion.

This equipment has been tested and found to comply with the limits for a Class B digital devi ce, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment gene rates uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. You can test that if this equipment does cause harmful interference to radio or television

reception by turning the equipment off and on.

Caution content: changes or modifications not expressly approved by the party responsible for compliance

could void the user's author ity to operat e the equipment.

7

Loading...

Loading...