Valor Ultimate Turbochim BR517R, Superflame RF BR517R, ULTIMATE TURBOCHIM 517RF, SUPERFLAME 517RF Installer's Manual

INSTALLER GUIDE

MODEL BR517R

(G.C. 32-032-11)

ULTIMATE TURBOCHIM*

&

SUPERFLAME RF*

Rear Fan Flued

Inset Gas Fires

*Covered b y GB Patent 2.202.622B

Please ke e p in a safe p l ac e for fut ur e r e fe r e n c e

600B 208/02

Please leave this Installer Guide with the user

As supplied, this appliance is for use with natural gas

(G20)

When converted using Valor conversion kit no.591149

this appliance is for use with propane gas (G31)

This appliance is for use in the United Kingdom (GB)

and the Republic of Ireland (IE) only.

CUSTOMER CARE

This Installer Guide gives sufficient details to enable the appliance to be installed

and maintained. If further information is required, our Valor AdviceLine will

be pleased to hel p.

Please telephone 0345 626341 (Local call rates apply)

2

CONTENTS

Page

Appliance data 4

General in s tallation requiremen t s 5

Contents of pack 9

Preparing applian c e f o r installation 10

Wall preparation 11

• General

• Brick et c . building. Appliance in front of wall

• Brick et c . building. Appliance recess e d in wall

• Timber frame buildin g. Applianc e in front o f wall

Electrical in s tallation 16

Installing ap plian c e 17

Electrical tests 18

Terminal guard, front s urroun d & gas s upply

installation

Ceramic coals & walls inst allat ion 21

Full operatin g c h e c ks 22

Final review 24

Servicing & parts replacem ent 25

• Burner plaques replace ment

• Front surround rem o val

• Pilot unit removal

• Burner un it c omplete removal

• Gas tap/F.S.D. & solenoid assembly removal

• Piezo ge n erator rem o val

• Main burner in jector re m oval

• Fan switch re moval

• Electrical control components access

• Distribution block removal

• Air press u re switch rem o val

• Fan removal

Short list of spares 30

11

11

12

14

19

25

26

26

26

27

27

27

27

28

28

28

29

3

PART1: APPLIANCE DATA

This pro duct u ses fu el effect pieces. It makes sen se to ta ke care when ha ndling

these articles to ensure that the release of dust is kept to a minimum

This appliance does not contain any component manufactured from asbestos or

asbestos related prod ucts.

The appliance data label and wiring diagram are on a tie below the burner and

are visible when the bottom front cover is removed.

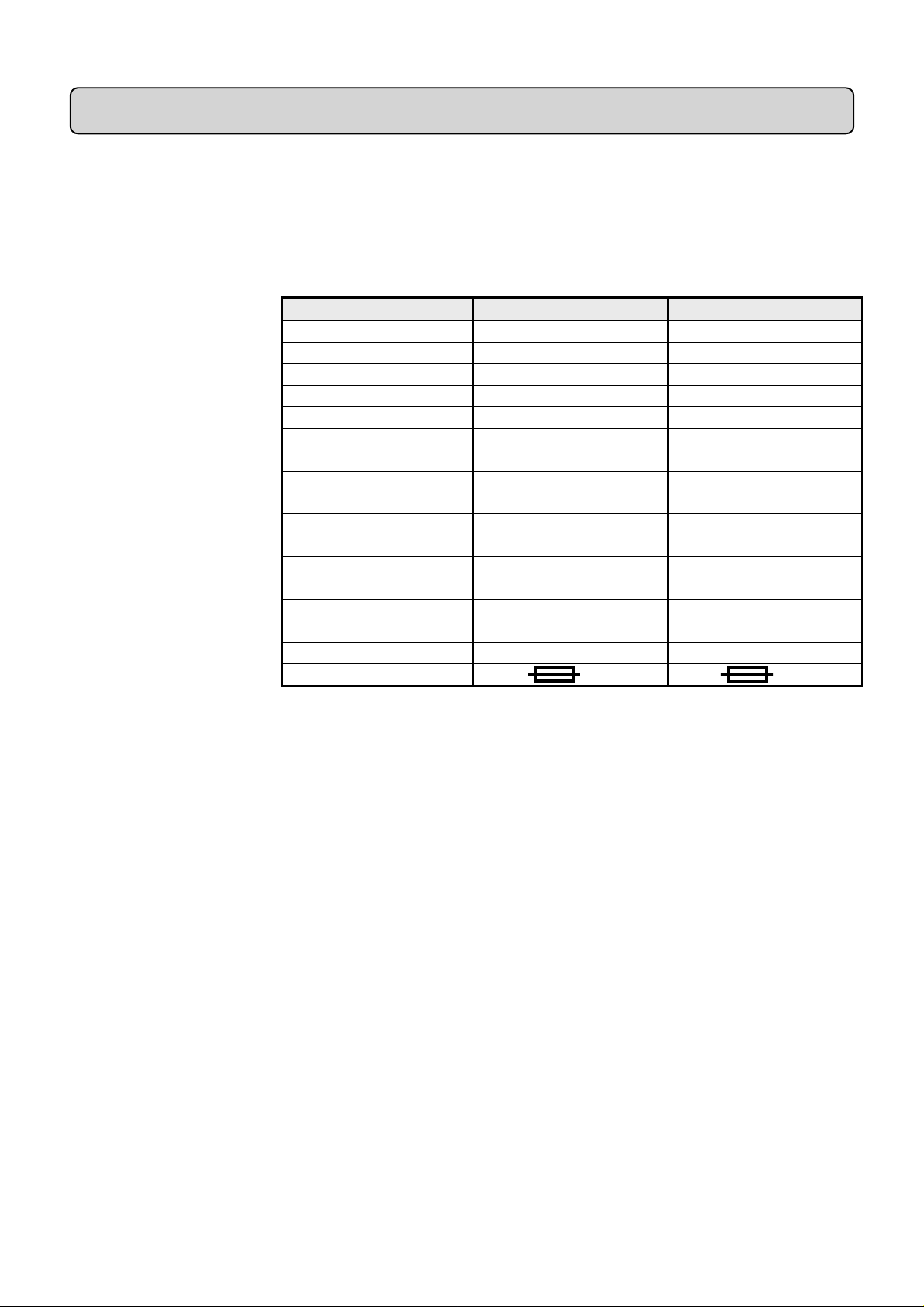

Gas Natural (G20) Propane (G31)*

Inlet P ressure 20mbar 37mbar

Input - Max. (Gr os s ) 6.0kW (20,500B t u/h) 6.1kW (20,800B t u/h)

Input - Min. ( Gro s s) 2.2kW (7,500Btu/h) 3.6kW (12,280B t u/h)

Output - Max. 3.12kW (10,600B t u/h) 3.6kW (12,280B t u/h)

Output - Min 1.1kW (3,750Btu/h) 1.8kW (6,140Btu/h)

Burner Test Pressure

(Cold)

Gas Connection 8mm pipe 8mm pipe

Burner Inje ct or Bray Cat. 18 Size 360 Bray Cat. 18 Size 170

Pilot & Atmosphere

Sensing De vice

Ignition Piezo Electric. Integral

Aeration Non-adjustable Non-adjustable

Electrical supply 230V ~ 50Hz AC 230V ~ 50Hz AC

Fan motor rati ng 55W 55W

Fuse rating 3A 3A

18.2±0.75mbar

(7.3±0.3in w.g.)

SIT Ref. OP9044 SIT Ref. OPLPG9222

with Gas Tap

35.6±0.75mbar

(14.3±0.3in w.g.)

Piezo Electric. Integral

with Gas Tap

.

*When converted using kit 591149

4

PART2:GENERAL INSTALLATION REQUIREMENTS

2.1 The installation must be in accordance with these instructions.

For the user’s protection, in the United Kingdom it is the law that all gas

appliances are installed by competent persons in accordance with the current

edition of the Gas Safety (Installation and Use) Regulations. Failure to install

the appliance correctly could lead to prosecution. The Council for the

Registration of Gas Installers (CORGI) re quires its members to work to

recognised standard s.

In the United Kingdom, all electrical supply installation must be installed in

accordance with t he cur rent edit ion of the IEE Wiring Regulations (BS7671).

In the United Kingdom the installation must also be in accordance with:

a) All the relevant parts of local regulations.

b) The current edition of the Building Regulations issued by the Department

of the Environment and the Welsh Office or the Building Standards

(Scotland) Regulations issued by the Scottish Development Departme nt.

.All relevant codes of practice.

c)

d) The relevant parts of the current editions of the following British

Standards:BS 5440 Part 1

BS 5871 Part 2

BS 6891

In the republic of Ireland the installation must also conform with:

a) The current editions of:-

IS 813

ICP3

IS327

b) All relevant national and local rules in force.

c) The current ETCI National Rules for Electrical Installation.

2.2 Electrical isolation of the unit should be by means of a switched fuse

spur that should be readily accessible to the user, easily identifiable and

preferably sited adjacent to the appliance. It should only connect this appliance.

2.3 This fire is a fan flued appliance for installation on an outward facing wall

of a conventional home which does not have a purpose built flue or chimney.

2.3.1 As supplied, the appliance is suitable for homes constructed of brick,

stone, etc. For homes constructed of brick, stone, etc. the appliance can be

installed into walls up to a maximum thickness as shown below.

If the convecti o n bo x is recessed into the wall: 413mm (16¼ in) max.

If the convection box is i n fr ont of t he finished wall surface: 305mm (12in)

max.

These dimensions are fr om the finished inter na l w all surface (including a n y sur r ound

material) to the external wall surface.

2.3.2 For timber framed build ings, the opti onal clearance bo x p ar t no. 517TFK

must be installed. For timber framed buildings, the appliance is suitable for

walls up to 292mm (11½” ) maximum thickness measured from the external

wall surface to the internal plaste rboard (or similar) wall surface.

Installation to a timber framed building should be in accordance with the

relevant sections of The Institute of Gas Engineers publication IGE/UP/7 “Gas

installations in timber frame buildings”. Please note that advice should be sought

before installing in a timber frame building since the alterations required may

5

nullify any NHBC cover relating to the property. If in doubt, guidance should be

requested from your local authority planning o r building departme nt.

2.4 This appl iance must be mounted wi t h a no n-co m b ust ible hea rt h (n.b

conglomera t e marble hearths are considered as non-combusti b le). The fire box

and fan box m ust b e mounted o n a non-co m b us t ible surface. The he a r t h m ust

project at least 345mm forward of the convection box front and b e at least

620mm wide (See illustrations in “wall preparation” section. The hearth

material must be at least 12mm thick. The periphery of the hearth (or fender)

should be at least 50mm above floor level to discourage the placing of carpets or

rugs over it. For timber framed buildings the hearth must be at least 50mm deep

over all its area so that the clearance box can be satisfactorily installed.

The surface of the hearth must be sufficiently flat to enable the bottom of the

front surround, the burner bracket and the bottom front cover casting to be

aligned horizonta lly. Any excessive unevenness (uneven til es, Cotswol d stone,

etc.) should be rectified.

The appliance must not stand on combustible materials or carpets.

2.5 The appliance must not be fitted directly against a combustible

wall. If the appliance i s to be fitted against a wall with combustible cladd ing or

skirting board, such materials must be removed from the area covered by the

metal outer surround of the appliance. We suggest that the actual surround is

used as a template to mark the area for combustible cl ad d ing removal.

The appli a nce can be fitte d t o a pur po se made propr ietary class “O ” 150° C

surround.

2.6 The opening in the surround or wall recess for the convection box must

be within the limits shown in figure 1(c)

2.7 The minimum allowable distance from the outside edge of the metal

front surround of the appliance to a corner wall having combustible materials is

178mm at either side.

2.8 The front face of the wall should be reasonabl y flat over the area which

will be covered by the convection box top and side flanges to ensure a good

seal.

2.9 The minimum height from the top surface of the hearth to the underside

of any shelf made from wood or other combustible material s is as

follows:-

• For a shelf up to 150mm deep

• Minimum height = 750mm .

• For a shelf deeper than 150mm

• Minimum height = 750m m + 12.5mm for every 25mm d epth over

150mm.

2.10 Note that soft wall coverings (e.g. embossed vinyl, etc.) are easily affected

by heat. They may scorch or become discoloured when close to a heating

appliance. Please bear this in mind when installing.

2.11 The appliance must not be installed in any room which contains a bath or

shower or where steam is regularly present.

6

2.12 An extractor fan may only be used in the same room as this appliance, or

in any area from which ventilation for the appliance is taken, if it does not affect

the safe performance of the appliance. Note the spillage test requirements

detailed further on in this manual. If the fan is likely to affect the appliance, the

appliance must not be installed unles s t he fan is perm a nently dis c onnected.

2.13 A fan-powered flue system t ends to de p ressurise t he room containi ng t he

appliance. Normally no additional ventilation should be required. In

exceptional circumstances, however the spillage check (See further on in this

guide) may indicate a need for further ventilation in order to ensure that there is

adequate air replacement. If necessary seek expert advice.

In the Republic of Ireland (IE), permanent ventilation must comply with the

rules currently in force.

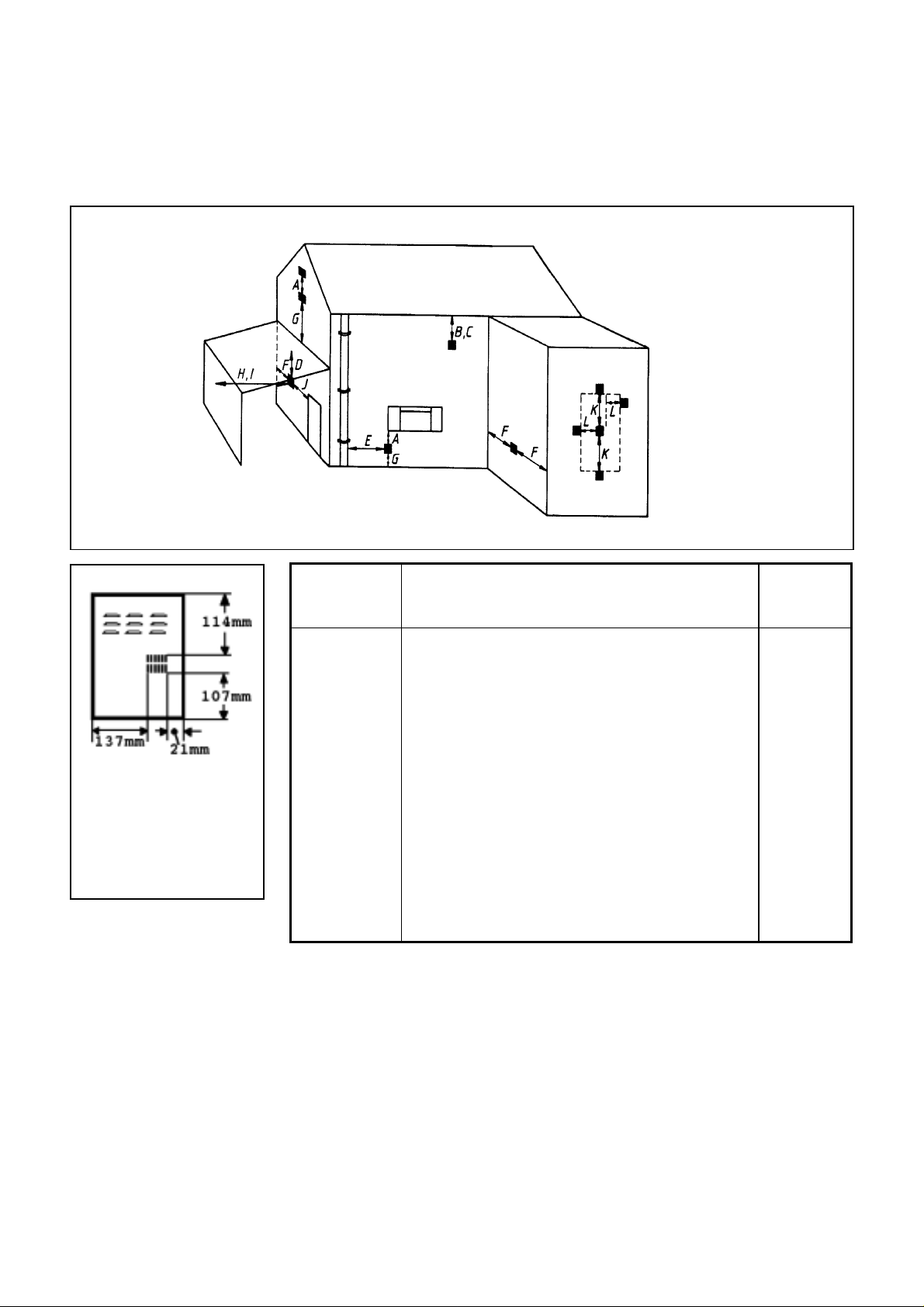

Figure 1

(a) Appliance Dimensions (b) Shelf & Corner Wall Clearances

(c) Opening Requ ir em ents

7

2.14 The flue terminal should be located so that the wind can blow freely

across it at all tim es and where a n y b lo c k a g e du e to lea v es , s n o w , et c . is unlikely.

The minimum allowable distances from the terminal are shown in the

following table and figure 2. Note: The distances are from the edge of the vertical exit

slots in the terminal not from the edges of the rectangular box (See figure 2a).

Figure 2 Terminal positions & minimum distances

Minimum distances for

terminal positions shown

in the table are from slot

openings

Figure 2a

Dimension Terminal Position Minimu

m

Distance

A Directly below an opening, air brick, windows,

300mm

etc.

B Below gutters, soil pipes or drain pipes 75mm

C Bel ow eaves 200mm

D Below balconies or car por t r oo f 200mm

E From a vertical drain pipe or soil pi pe 75mm

F From an internal o r external corne r 200mm

G Above ground, roof or b alcony leve l 300mm

H From a surface facing the t erminal 600mm

I From a terminal facing the terminal 1200mm

J From an opening in a car port (e.g. door,

1200mm

window) into dwelling

K Verticall y from a t erminal on the sa m e wall 1500mm

L Horizontally from a t erminal on the sa m e wall 300mm

M P roje cti on outwards from wall 15mm

2.15 This appliance is suppl ied with a terminal guard . In England and Wales,

the Building Regulations require that the terminal guard is fitted if the flue

terminal can come in contact with people near the buildi ng or be subject to

damage. Even if the regulations do not demand it, we recommend that the

guard is fitted to prevent damage or blockage of the flue system by leaves etc.

2.16 A concealed gas supply conne ct ion can be mad e through the right side

panel or near the right cor ner of the rear p a nel. Visi b le front connect ion can be

from the l eft or right s ide.

2.17 Electrical connection is from the left side.

8

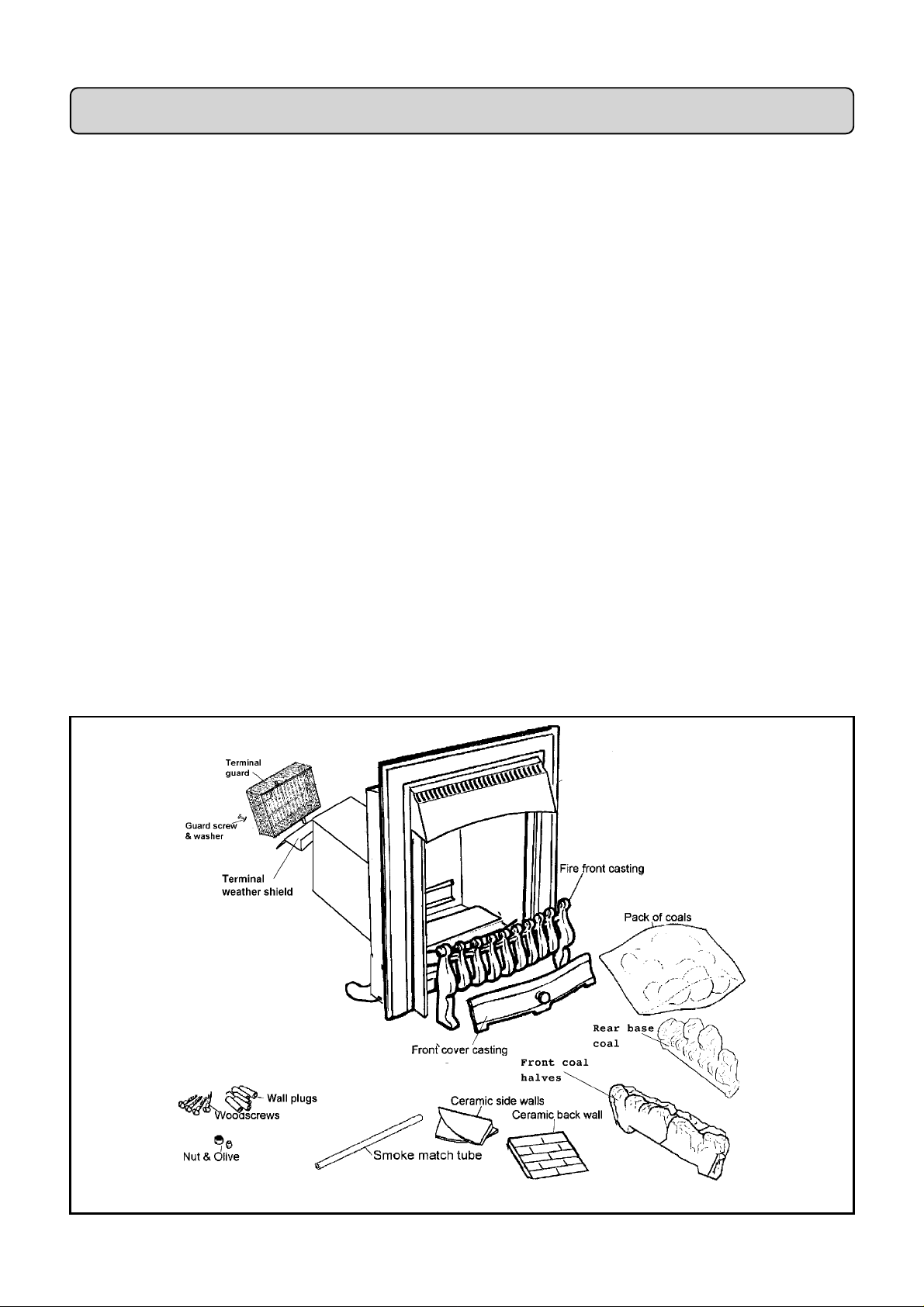

PART3: UNPACKING

The fire front will be one of the following options:

Ultimate black & brass surround

Ultimate all bl ack suerround

Superflame.

The pack contains:

1 Burner & convection box unit fitted with front surround and fanned flue

unit

1 Nut & olive for 8mm inlet pipe

1 Ceramic back wall

1 Pair of ceramic side walls

1 Front base coal left & right halves

1Rear base coal

1 Pack of 5 loose coals

1Template

1 Smoke match tube

1 Terminal weather shield

1Terminal guard

2 Screws & washers for terminal guard

6 Wall plugs

6 Woodscrews

1 Fire front casting

1 Bottom front cover casting

2 Finials for front cover casting (Superflame only)

1 Literature pack

Carefu lly remove the con tents. Take special c are in ha ndling th e ceramic wa lls

and the coals.

Check that all the listed parts are present and in good condition.

Figure 3 Pack contents

9

PART4:PREPARING APPLIANCE FOR INSTALLATION

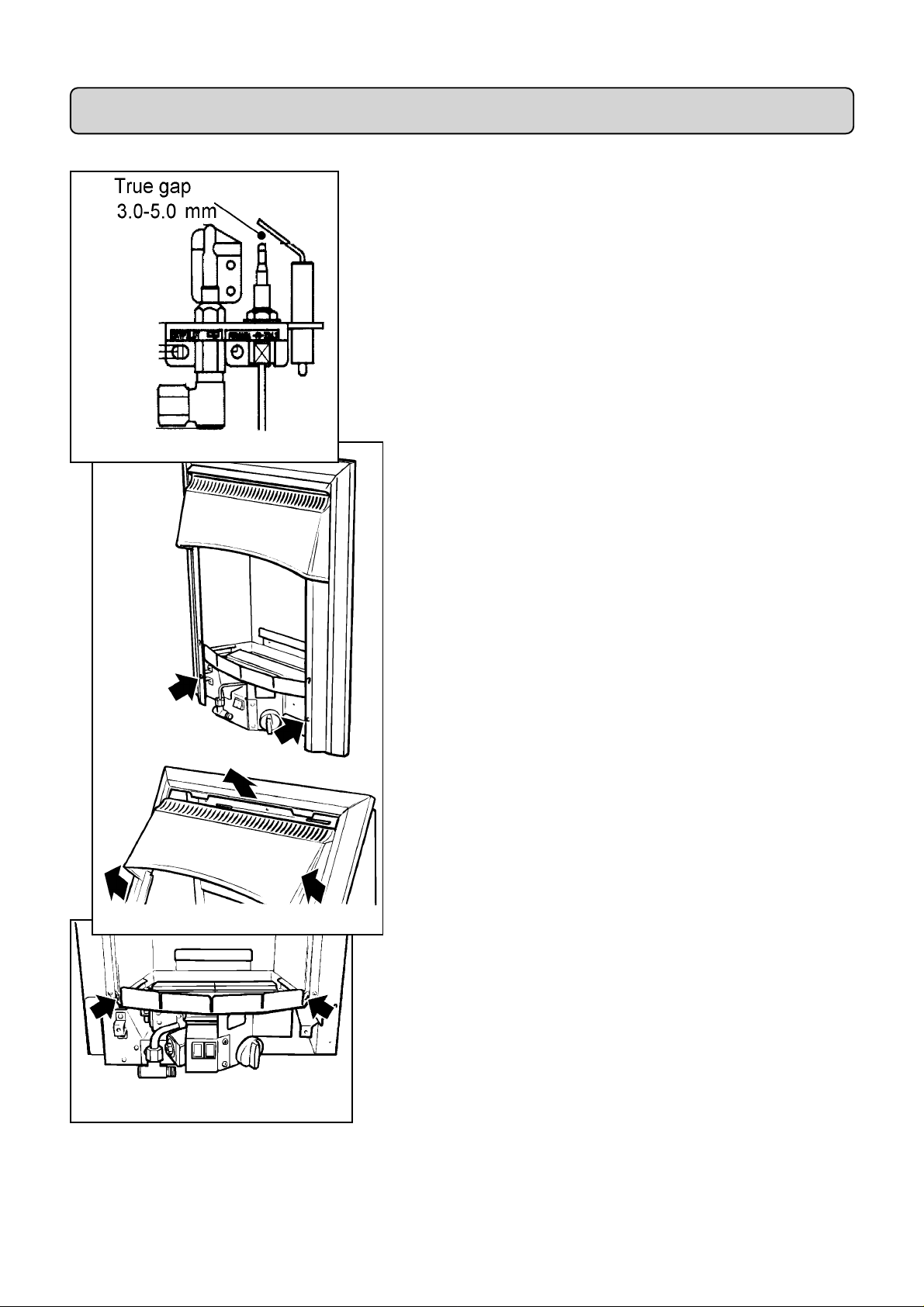

4.1 Check ignition spark

Before attempting to install, it is worth checking that the piezo electric

spark ignition system operates satisfactoril y.

To initiate the spark, depress the control knob and while keeping it

depressed, turn anticlockwise through approximately 60° to the

“PILOT/IGN” position. A spark should track from the electrode pin to

the thermocouple tip. If there is no spark or incorrect tracking, check

the spark gap between the electrode wire and thermocouple tip (see

figure 4). If the spark gap is correct, check the ignition wiring.

Figure 4 Pilot Ignition System

4.2 Remove the two screws securing the bottom of the front

surround to the sides of the convection box. Raise the front

surround to allow the retaining lugs at the top to clear the slots in

the convection box hood and then lift clear (see figure 5).

Figure 5 Front Surround Removal

Figure 6 Burner Removal P oints

4.3 In the majority of cases (Fixing the appliance to th e floor,

removal of mains cable for ease of connection to isolating

switch ), the b urn er u nit w ill need t o b e det ach ed. D etac h the bu rn er

unit from the convection box by removing two screws (see figure 6).

10

Loading...

Loading...