Valor President 520AN, President 520AP Installation & Operation Manual

GAS FIRED VENTED ROOM HEATERS

ine or other flammable

vapors and liquids in the vicinity of this or any

Do not touch any electrical switch; do not use

pplier from a

neighbor’s phone. Follow the gas supplier’s

If you cannot reach your gas supplier, call the

Installation and service must be performed by a

qualified installer, service agency or the gas

he information in this manual is

not followed exactly, a fire or explosion may result

causing property damage, personal injury or loss of

MODEL 520AN

For Natural Gas

MODEL 520AP

For L P G (Propane) Gas

President

WARNING: If t

life.

− Do not store or use gasol

other appliance.

− WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

•

• Immediately call your gas su

•

−

supplier

This appliance is a domestic room heater. It must not

be used for any other purpose such as drying clothes etc.

any phone in your building.

instructions.

fire department.

INSTALLATION & OPERATION MANUAL

Please read this manual before installing and operating your heater.

Please keep this manual for future reference.

(Vous pourrez vous procurer un manuel en langue Française chez votre concessionaire)

600A671/02

CONTENTSCONTENTS

Safety information 3

Installation instructions 4

• General

• Rates

• Orifice data

• Clearances

• Floor requirements

• Draft hood

• Venting

• Optional accessories

• Possible installations

• Contents of packs

• Assembling outer cast-iron case

• Heater preparation

• Ignition spark check

• Gas supply connection

• Log installation

• Operation check

• System pressure check

• Venting check

• Aeration adjustment

• Completion of assembly

• Final checks

Operating procedure 14

• Lighting if igniter fails

• Safety warnings

• Lighting instructions

Cleaning 17

Periodic checks 17

Calling for service 17

Servicing information for qualified engineer 18

• Burner tube removal

• Electrode removal

• Pilot & cross lighting burner removal

• Pilot jet removal

• Regulator removal

• Control valve & ignition generator removal

• Thermocouple removal

Page

4

4

4

5

5

5

5

5

5

6

6

7

8

8

9

10

10

10

11

11

13

14

15

16

18

18

18

18

19

19

19

2

SAFETY INFORMATIONSAFETY INFORMATION

Due to high temperatures, the appliance should be

located out of traffic and away from furniture and

draperies.

Children and adults should be alerted to the hazards of

high surface temperatures and should stay away to

avoid burns or clothing ignition.

Young children should be carefully supervised when

they are in the same room as the appliance.

Clothing or other flammable material should not be

placed on or near the appliance.

The glass window unit must be put back in place prior

to operating the appliance if it has been removed for

servicing or cleaning.

Never operate with broken or damaged window glass.

This appliance should be installed and repaired by a

qualified service person.

The appliance should be inspected before use and at

least annually by a professional service person. More

frequent cleaning may be required due to excessive

lint from carpeting, bedding material, etc. It is

imperative that control compartments, burners and

circulating air passageways of the appliance are kept

clean.

Keep curtains, clothing, furniture and other flammable

materials at least 36ins (900mm) from the front and top

of the appliance

When operating your new room heater for the first time, some vapors may be released which may cause a slight odor and could possibly set off any

smoke detection alarms in the immediate vicinity. These vapors are quite normal on new appliances. They are totally harmless and will disappear after a

few hours use.

Keep the appliance area well clear and free from

combustible materials, gasoline and other flammable

vapors and liquids.

If any changes are made to the room construction in

the vicinity of the appliance after installation (e.g.

additional mantle etc.) make sure that the changes

conform to the installation requirements in this manual.

Never attempt to burn paper or any other material in

the appliance.

Keep the base of the appliance below the ashlip and

the area between the outer case and the wall clear to

prevent obstruction of air flow to the appliance.

This appliance must be properly connected to a

venting system. The appliance is equipped with a vent

safety shutoff system designed to protect against

improper venting. Operating when not connected to a

properly installed and maintained venting system or

tampering with the shutoff system can result in carbon

monoxide (CO) poisoning and possible death.

The venting system should be checked periodically.

Recent trends in home improvement and new tighter

construction techniques have contributed to problems

with venting. If you suspect that your appliance is not

venting properly, do not operate. Seek expert advice.

Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

NOTE

3

INSTALLATION INSTRUCTIONS

1. GENERAL

This appliance is certified by International Approval

Services for use in Canada and the USA.

The installation must conform with local codes or, in the

absence of local codes, with the current

CAN/CGA-B149 installation code in Canada or the current

National Fuel Gas Code, ANSI Z223.1 in the USA. Only

qualified licensed or trained personnel should install the

appliance.

The appliance rating plate is on the inner face of the back

panel at the left side.

Burner Type: Aerated front and rear simplex tubes with

combined pilot and cross lighting burner.

Gas Connection: A 3/8" N.P.T elbow connector is provided

for connection to the appliance inlet pipe located at the

center back.

Rates (Btu/h)

Natural Gas

Altitude

Max. Min.

(Ft)*

Input 0-2000 20,000 7,700

2000-4500 17,800 7,000

Output 0-2000 15,000 5,300

2000-4500 12,500 4,900

* Altitudes above 2000ft require conversion kit 525HACK

Propane

Altitude (Ft) Max. Min.

Input 0-4500 17,000 8,750

Output 12,750

Orifice Data

For verification only. Do not attempt to drill or otherwise

modify appliance output.

Gas Type No of

Dia (ins)

holes

Natural Pilot AMAL 40 1 0.022

Front Cat 18-

300

Rear Cat 99-

230

Propane Pilot Cat 960-

10

Front Cat 960-

110

Rear Cat 960-

100

7 0.025

7 0.022

1 0.0094

1 0.035

1 0.034

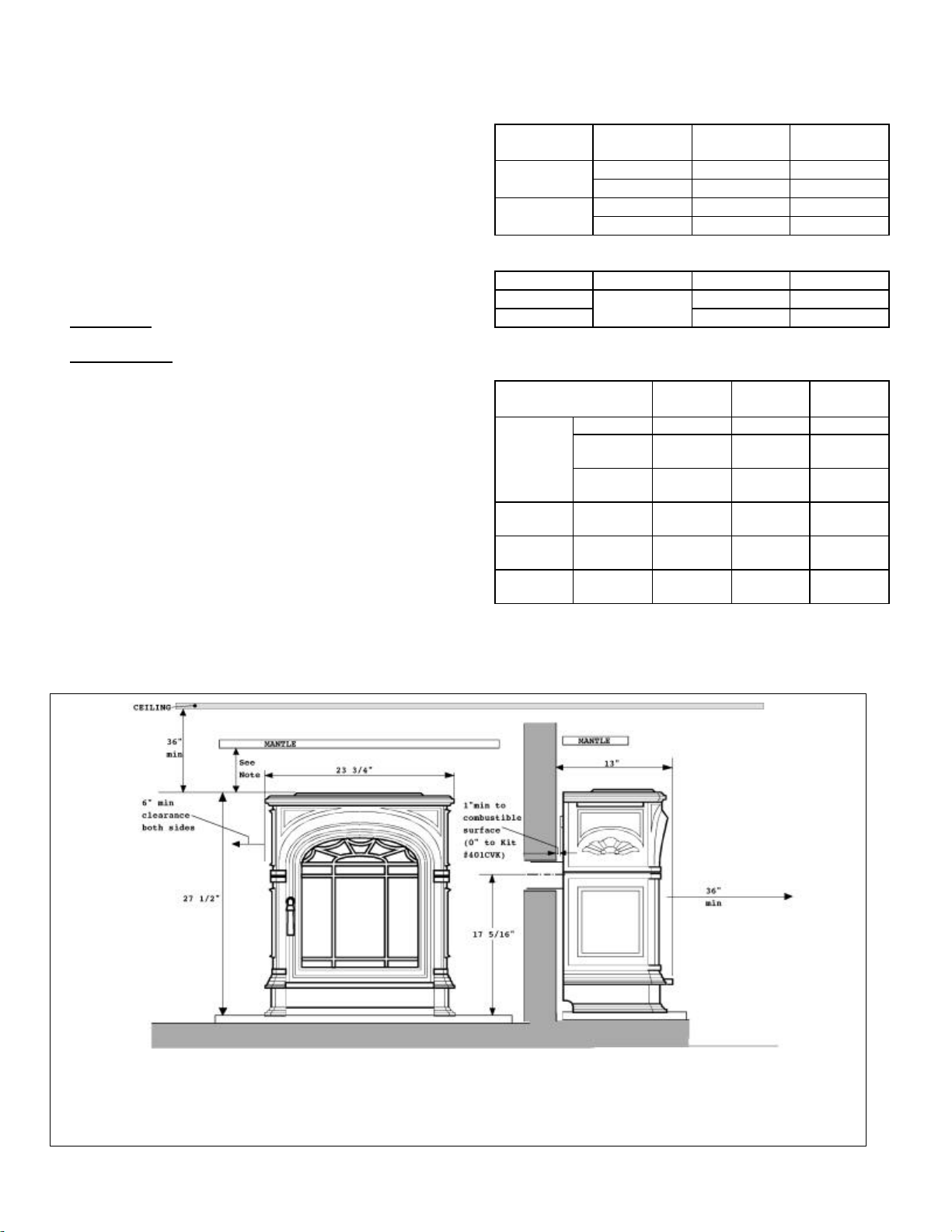

Mantles: For a mantle not more than 7” deep - minimum clearance is 6” above extreme top surface of heater. For mantle of greater depth

add 1/2” extra clearance for each extra 1” of mantle depth.

Fig.1 Dimensions & clearances

4

1.1 CLEARANCES:

Make sure that the minimum clearances to combustible materials

are maintained during installation including adequate space for

the proper operation and servicing of the heater. The minimum

clearances from the heater to combustible materials are shown in

figure 1. The combustion air opening below the ashlip assembly

and the clearance at the sides of the case rear must not be

obstructed.

1.2 FLOOR:

Do not place the heater on carpeting, vinyl or other soft surfaced

floor coverings. Install only on hard surfaced materials.

It is recommended for aesthetic considerations and ease of

maintenance that the heater is installed on a hearth finished with

brick, ceramic tile, marble etc. Raising the hearth slightly will help

to minimize dust and lint accumulation under the unit. The

recommended minimum hearth size is 32” wide x 15” deep.

If however, the heater is installed directly on flooring of

combustible material other than wood, it must be installed on a

metal or wood panel extending the full width and depth of the

heater.

1.3 DRAFT HOOD:

This heater has a draft hood built into its back and draws its air

from either side. It must not be altered or obstructed. The draft

hood must be in the same atmospheric pressure zone as the

combustion air inlet to the heater.

1.4 VENTING:

This heater is a vented appliance and must be connected to a

chimney or flue in accordance with the national and local codes.

For added safety, this heater is equipped with a vent sensor system

which will react to incorrect venting by shutting down the gas

supply. The thermally activated sensor switch is located within

the draft hood to detect either a blocked or disconnected vent.

Certain backdraft conditions may also activate the switch.

1.5 OPTIONAL ACCESSORIES:

The following kit can be used with this appliance:#401CVK Concealed Vent Kit required for use with a new zero

clearance type installation. It allows the heater to be installed with

type B metal vent concealed behind a wall or partition and/or in a

chase.

Full installation and operating instructions are supplied with the

kit.

For full details above this kit, contact your dealer.

1.6 POSSIBLE INSTALLATIONS

This appliance can be installed:

1. As a retrofit

a. To an existing masonry fireplace and chimney

b. To an existing factory built zero clearance type fireplace with a

factory built chimney.

The fireplace must be built in accordance with the national, state,

provincial or territorial building code recognized by the authority

having jurisdiction, or the National Fire Protection Association

code in the USA

Any flue damper must be removed or locked open.

The chimney must be swept and both chimney and fireplace

checked for soundness before installation of the heater.

If local codes dictate or if condensation is a problem, a flue liner

must be installed. Use a flue liner that is approved by the

enforcing authority and that is installed in accordance with the

manufacturers instructions. If a flexible liner system is used,

5

ensure that no sags or dips are allowed to occur where the liner

connects to the heater (figure 2).

2. Free standing with connection to an approved chimney or vent

maintaining the clearances shown in figure 1.

3. As a zero clearance installation fitted with the optional

#401CVK Concealed Venting Kit.

This kit allows the heater to be installed with a type B metal vent

concealed behind a wall or partition and/or in a chase. The

venting kit is designed for a 4” round flue. The kit is shown in

figure 3.

Clearances to combustible materials are: Outside edges of

framing plate = 0”. From any part of the flue adapter box

= 1”. Clearances from the connecting elbow are

determined by local codes or, in the absence of local codes,

with the current CAN/CGA1-B149 Installation Code in

Canada or the current National Fuel Gas Code, ANSI

Z223.1 in the USA

Fig. 2 Flexible chimney liner

Fig. 3 Concealed vent kit installation

2. UNPACKING THE HEATER AND CASE

CONTENTS OF THE PACKAGES

Box 1 of 3 (Heat engine)

The carton contains the following:1 Heater assembly

3 Ceramic logs (packed in the heater)

1 Flue collar

1 Flue collar extension

1 Wall spacer

1 Smoke channel (Venting check)

1 Control knob

1 Control shaft

8 Threadcutting screws for flue collar & smoke channel

2 Plastic caps for foot screws

1 Caution/Instruction position label

2 Nuts and lockwashers for wall spacer

2 Flat washers and machine screws for

arched lintel fixing

Box 2 of 3 (Outer case)

2 Side Panels (outer case)

1 Door assembly (outer case)

Box 3 of 3 (Outer case)

1 Top Plate (outer case)

1 Arched lintel (outer case)

1 Ashlip/front feet assembly (outer case).

Remove the contents carefully to prevent damage. Some items

may be contained in

the packaging

fitments - Examine

carefully before

discarding. Check

that all the items are

present and

undamaged.

Note the weight of

the component on

the outside of each

box.

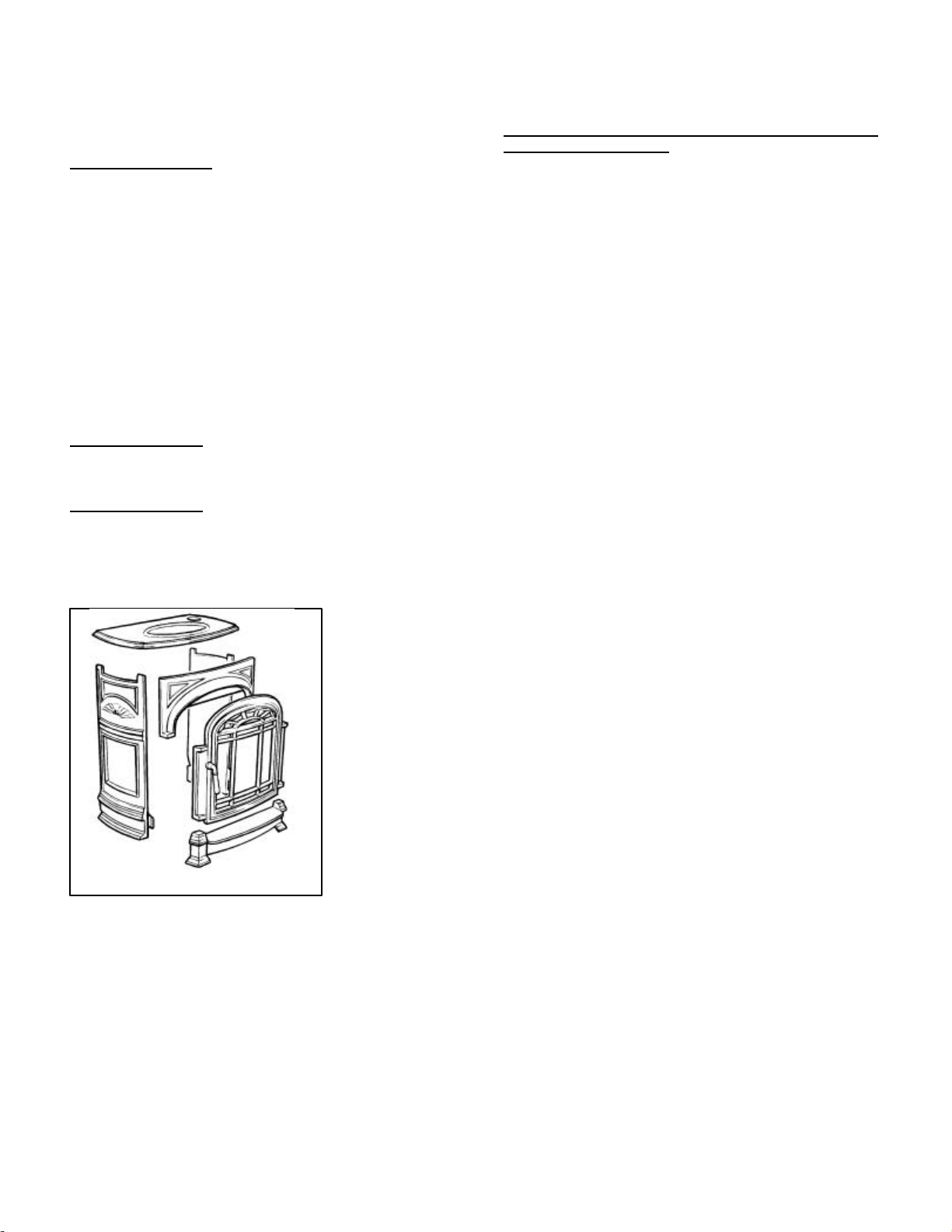

3. ASSEMBLING THE CAST IRON OUTER CASE

Please read these instructions fully before attempting to install the

Outer Case for the first time.

THE OUTER CASE COMPONENTS ARE HEAVY

The cast-iron outer case supplied with President is a high quality

casting weighing around 120lbs in total, therefore it is supplied as

individual components that are easily assembled together to form a

whole. The weight of the heaviest piece is 28 lb. If you have any

doubt of your ability to easily assemble these components, you

should ask someone to assist.

Remove the outer case components from Boxes 2 and 3, identify

each part, and check for transit damage. Note there are two Side

Panels (left and right), a lower ashlip/front feet assembly, an

Arched Lintel component, a Door, and a Top Plate. See exploded

diagram below (Figure 4).

The outer case components comprise:2 Left and right side panels with leveling feet.

1 Ashlip/front feet assembly

1 Arched lintel assembly

1 Door assembly

1 Top plate

Identify the two Side Panels. Take the left panel and observe the

leveling feet. The leveling feet are precision-machined to a high

finish to avoid scratching the hearth.

Offer up the panel to the vertical plane of the fireplace back panel

and observe that the panel sits level on the hearth leaving no

discernible vertical gap against the fireplace. Adjust the leveling

feet to eliminate any such gap.

Place to one side. Similarly adjust the right hand panel for level.

Place to one side.

Fig. 4 Outer case components

6

Loading...

Loading...