Valor PORTRAIT 575LFK Installation Instructions Manual

PORTRAIT

575LFK Lift Freestanding Kit

CSA approved for use with Valor Models 530I Heaters ONLY

Includes installation instructions for 576LCP and 578LF kits

Installation Instructions

INSTALLER

!

A barrier designed to reduce the risk of burns from the hot viewing

glass is provided with this appliance and shall be installed

for the protection of children and other at-risk individuals.

Notes: This kit must be installed or serviced by a qualifi ed

installer, service agency or gas supplier. These instructions are to

be used in conjunction with the main installation instructions

for the above listed heater models.

The application of this kit does not affect the venting

capabilities or method of preparation of the 530 heater as

described in the 530 heater installation manual.

WARNING

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

Leave this manual

with the appliance.

CONSUMER

Retain this manual

for future reference.

To complete the installation

of this kit you need the

following items:

• 530I Portrait Engine

• 575LFK Lift Freestanding

Kit

• 578LF Lift Front

• 576LCP Lower Cover

Panel

(optional)

530I—

Portrait Engine

578LF—Lift Front

Overview

4002695-06

© Copyright Miles Industries Ltd., 2013

(530I, 575LFK, 576LCP and 578LF sold separately)

576LCP—

Lower Cover

Panel

575LFK—Lift Freestanding Kit

(back panel comes with 578 kit)

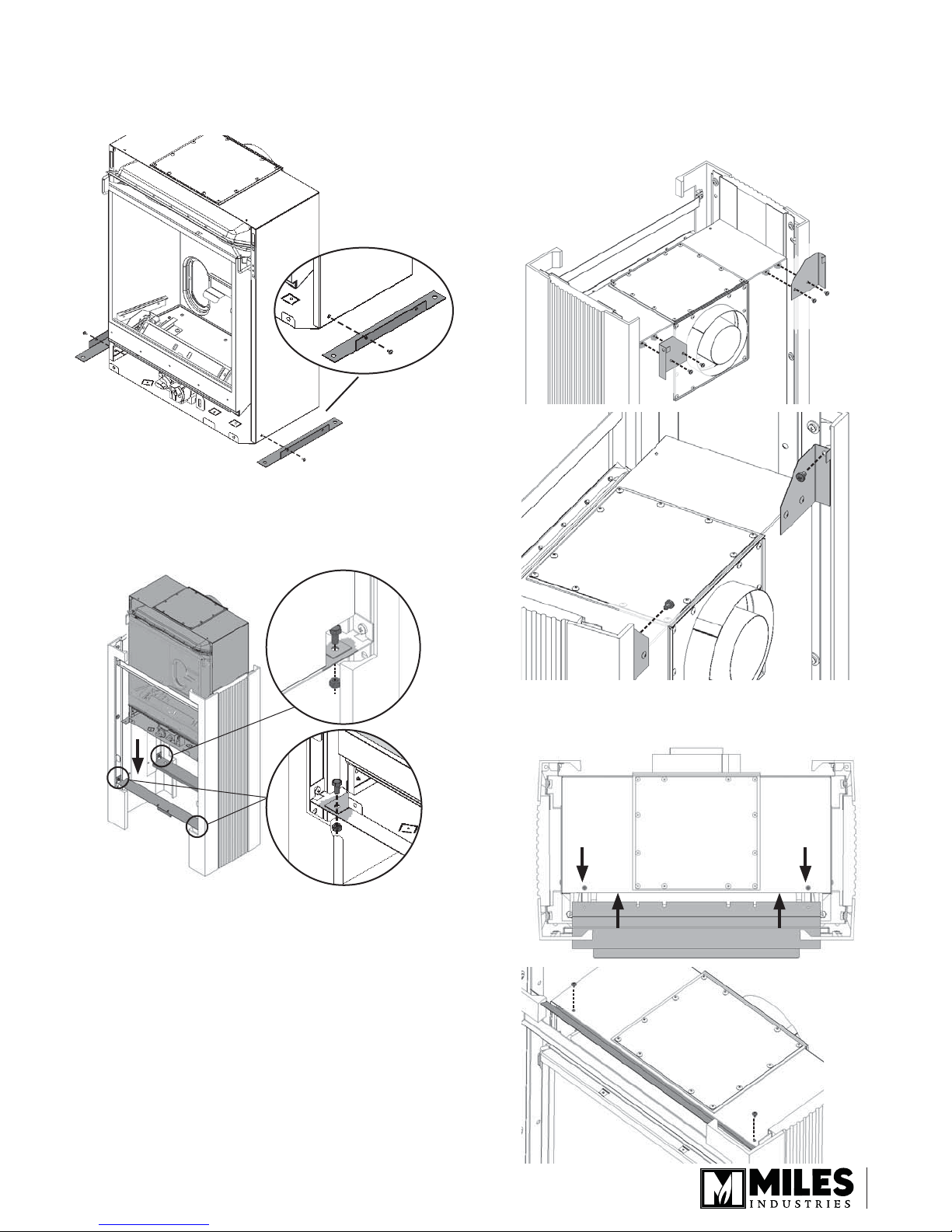

Basic Installation Sequence

• Assemble sides of casing, bottom and top front

brackets.

• Assemble bottom brackets to heater.

• Fit heater in casing and bolt in place.

• Assemble rear brackets to heater and fi x to casing.

• Gas fi t and vent heater.

• Hook the rear panel, the top panel and infi ll panel.

• Install fi rebox grille and complete installation of

heater as per heater installation instructions.

• Install bracket and place lower cover panel if used.

• Hook window frame cover and front.

Kits Contents

Tips

• Wear gloves or ensure to manipulate the cast

iron/concrete pieces with clean hands to avoid

any stain.

• Remove the 530 window and all items inside the

appliance before installing to lighten it.

• In steps 4, 5 and 7 in the following instruc-

tions, assemble the parts loosely, just enough

for them to hold together. This will allow you

to fi t all the parts more easily. Then, in step

10, after all the parts are fi tted together and

adjusted, tighten all the screws.

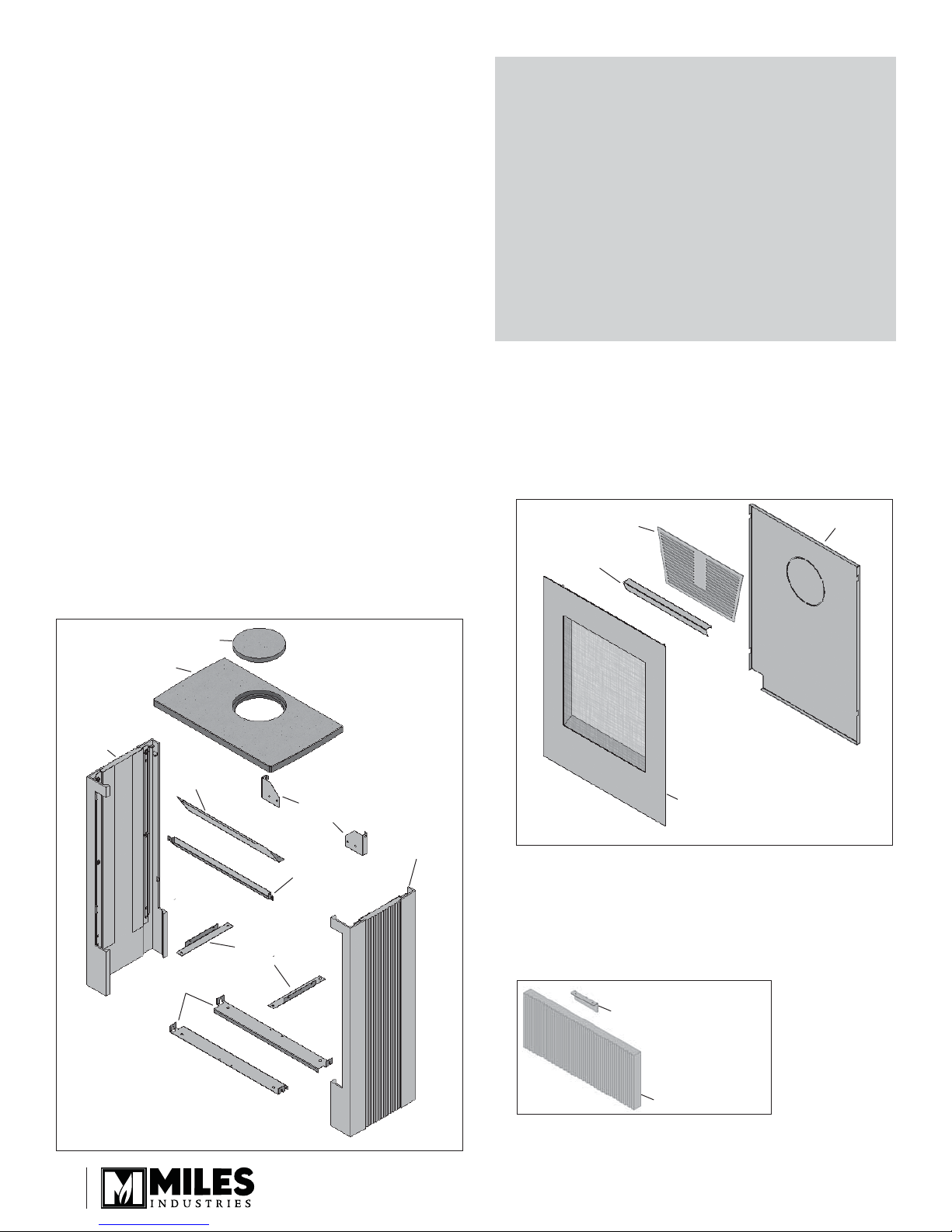

575LFK Lift Freestanding Kit (required)

• Casing left side

• Casing right side

• Top panel

• Top infi ll panel

• Convection baffl e

• Front hanging bracket

• Rear hanging brackets (2)

• Bottom support brackets (2)

• Engine brackets (2)

• Hardware

Top infi ll panel

Top panel

Casing left

hand side

Convection

baffl e

Engine

brackets

Bottom support

brackets

Rear

hanging

brackets

Front

hanging

bracket

Casing right

hand side

578LF Lift Front (required)

• Front trim with screen

• Window frame cover

• Back panel

• Firebox grille

Firebox grille

Window frame cover

Front trim

Back panel

576LCP Lower Cover Panel (optional)

• Lower cover panel

• Support bracket

• Hardware

Support bracket

2

Lower cover panel

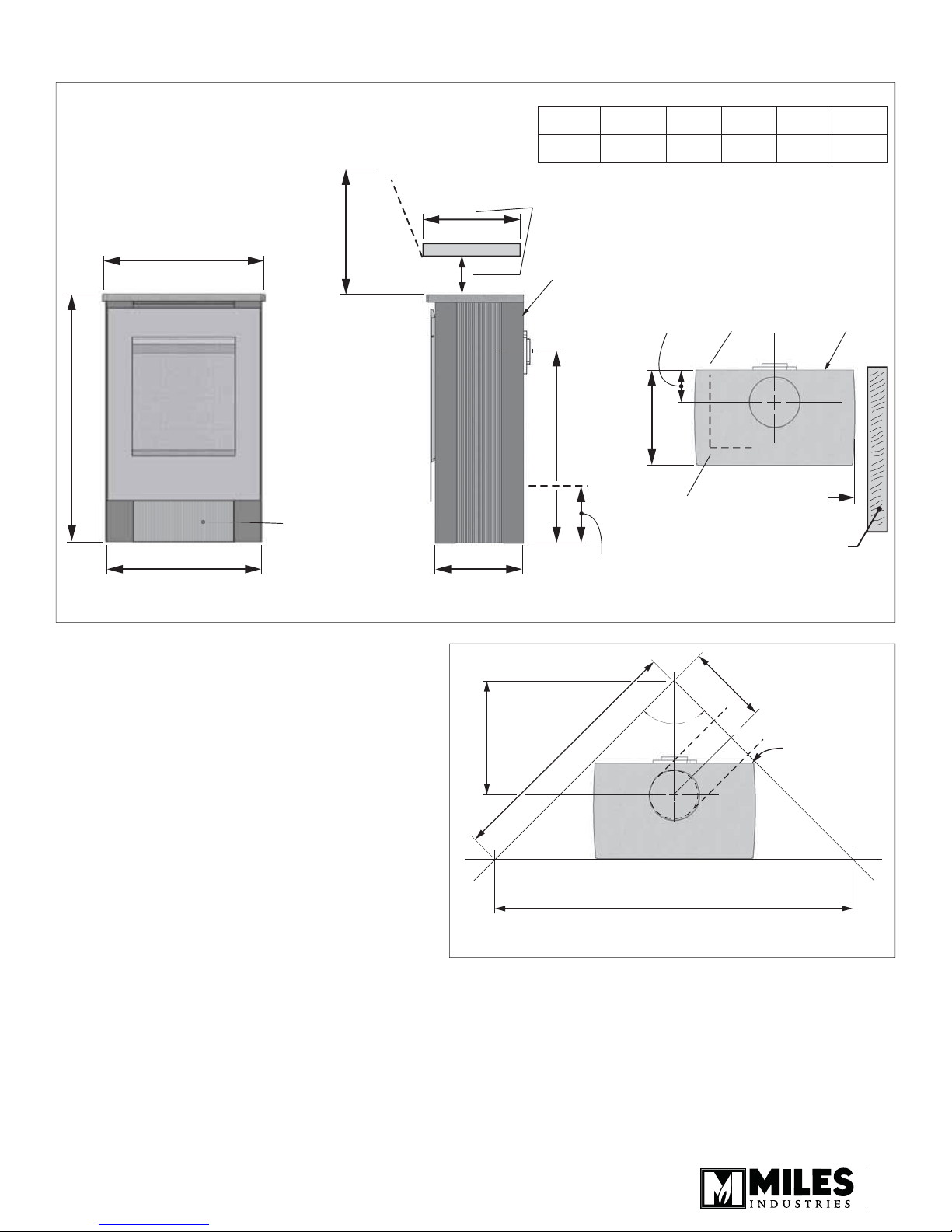

Dimensions & Clearances to Combustibles

Ceiling

Combustible Mantel Clearances

Mantel

Depth ‘A’

Mantel

Height ‘B’2”(51 mm)3”(76 mm)5”(127 mm)7”(178 mm)9”(229 mm)

0–15”

(0–381 mm)

16”

(406 mm)

18”

(457 mm)

20”

(508 mm)

22”

(559 mm)

36”

(914 mm)

576LCP

optional

panel

min.

24-5/8” (625 mm)

37-15/16” (964 mm)

23-11/16” (601.6 mm)

Front View Top ViewRight Side View

Casting Tolerances

Due to the nature of cast iron and concrete, dimensional consistency may vary from one unit to the

next and some variation in surface fi nish and fl at-

ness is to be expected. We have done our best to

control and make allowance for this; however some

variation is inevitable.

Floor Requirements

The 530 heater is approved for installation directly

on any combustible material other than soft fl ooring

material such as carpet or vinyl.

A

Mantel

B

13-5/16”

(338.5 mm)

17-1/4”

Minimum

See table

Zero clearance

29-1/8” (739.7 mm)

x

Gas line access

point 8-1/2” (216 mm)

(438.1 mm)

Minimum 38” (967.3 mm)

4-15/16”

(109.5 mm)

Gas line access

point through

casing

x

14-5/8” (371.5 mm)

Gas line connection

point 3/8” NPT FEMALE

at valve

Minimum

12-1/4”

(311.5 mm)

90°

x

Zero

clearance

3”

(76.2 mm)

min.

Sidewall

Zero clearance

Mobile Home Floor Fixing

The Lift FS must be fi xed to the fl oor through the

fl oor when used in a mobile home.

Mantel Requirements

The Lift FS may be installed with a combustible

mantel provided clearances are maintained as

indicated below. Be aware that although safe,

some combustible materials and fi nishes at the

listed clearances may, over time, discolor, warp,

or show cracks. Care should be taken when

choosing materials—consult your fi replace dealer.

Minimum 53-7/8” (1368.4 mm)

Corner Dimensions

3

Tip

In steps 4, 5 and 7 in the following instructions,

assemble the parts loosely, just enough for them

to hold together. This will allow you to fi t all the

parts more easily. Then, in step 10, after all the

parts are fi tted together and adjusted, tighten all

the screws.

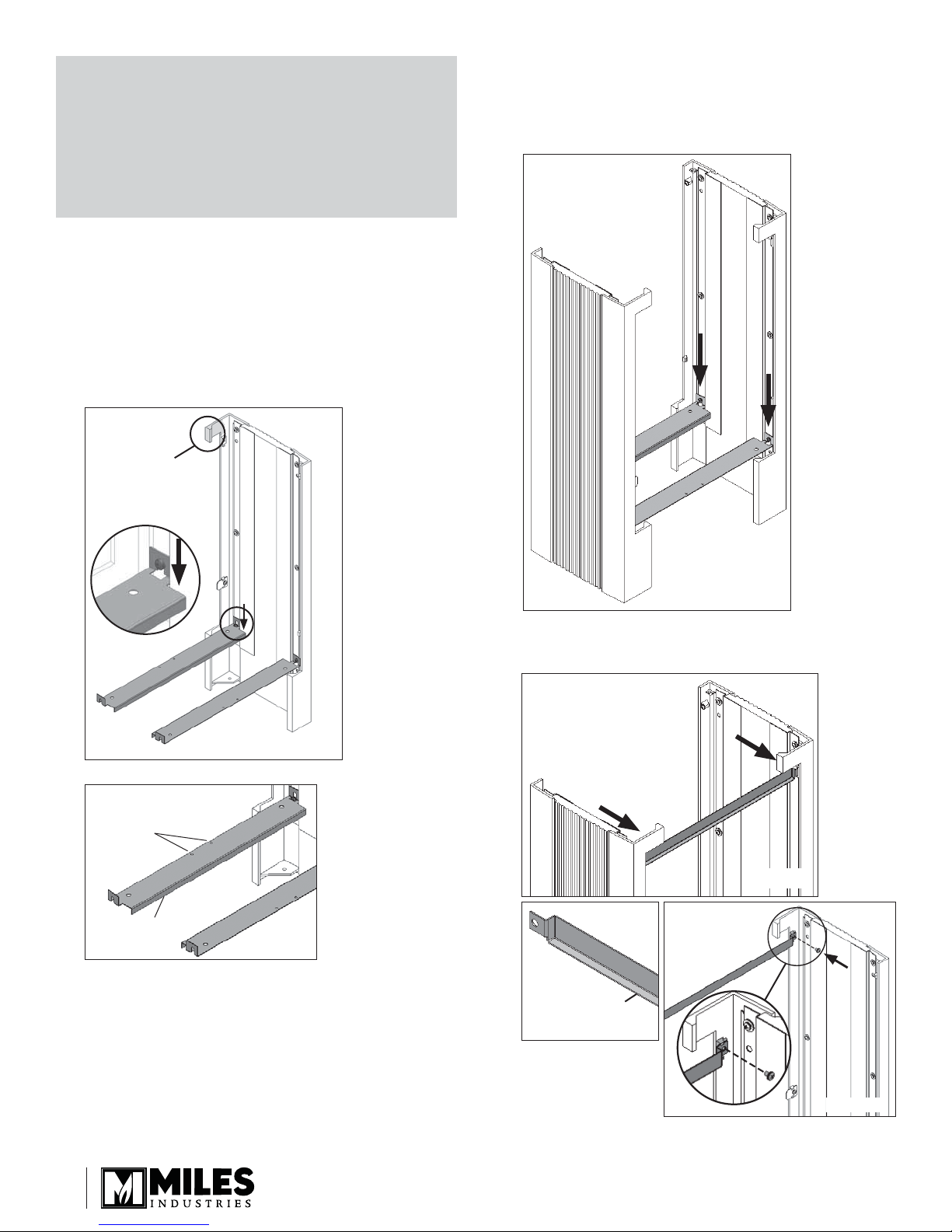

Installation

1. Identify the front and rear of one cast iron/concrete

side panel. The front of the panel has a protruding

piece at the top.

2. Install the bottom support brackets. Loosen off the

bottom screws and insert the screw heads in the

keyholes of the brackets as shown. Make sure the

brackets are oriented properly. Tighten the screws.

front

3. On the other side panel, loosen off the bottom

screws. Place the fi rst panel at the desired location.

Place the second panel as indicated and attach

the bottom support brackets sliding them over the

screw heads of the panel. Tighten the screws.

Bottom brackets orientation

outer edge with

two holes

inner edge with

downward lip

Front view

4. Loosely fi x the front hanging bracket to the side

panels with one black machine screw on each side.

Rear view

Front view

Top

Rear view

Bottom

Lip goes

to the front

Front view, left side

4

Rear view

5. Fix the engine brackets to the bottom of the

appliance with one machine screw on each side as

indicated. Either bracket can be used on either side

of the appliance.

6. Slide the appliance into the casing from the top.

Loosely fi x the appliance to the casing with a nut

and bolt on each side at the front and one nut and

bolt at the rear left-hand corner.

7. Remove two screws on each side of the back panel

of the appliance case. Secure the top rear support

brackets to the appliance case using the screws

previously removed. Loosely fi x the appliance to the

casing with one self-tapping screw per side.

8. Slide the convection baffl e under the top panel of

the appliance case. Fix the convection baffl e using

two machine screws provided.

5

Loading...

Loading...