VAL Avionics COM 2000 Installation And Operator's Manual

VAL AVIONICS LTD

COM 2000

VHF Transceiver

Installation and Operator’s

Manual

Revision 3

March 2013

P/N 172200-3

I N S T A L L A T I O N A N D O P E R A T O R ’ S M A N U A L

C O M 2 0 0 0 – V H F T R A N S C E I V E R

V A L A V I O N I C S L T D

Revision History:

October 2010 – Initial Printing

May 2012 – Inserted section 1.4: FCC regarding FCC ID and emissions.

December 2012 – Updated Appendix A, table 4 with serial pin port. Spelling Corrections

March 2013 – Updated Appendix A for units with serial number 20720 to current.

Revision 3 Page 2 of 31

March 2013

I N S T A L L A T I O N A N D O P E R A T O R ’ S M A N U A L

C O M 2 0 0 0 – V H F T R A N S C E I V E R

V A L A V I O N I C S L T D

Table of Contents

1

2

3

4

5

6

7

8

Table 1: Specifications .................................................................................................................................. 6

Table 2: Equipment Supplied ........................................................................................................................ 7

Table 3: Equipment Not Supplied ................................................................................................................. 7

Table 4: Rear Connector Pin Functions ....................................................................................................... 17

Figure 1: Unit Controls ................................................................................................................................ 11

Figure 2: Physical Dimensions .................................................................................................................... 16

Figure 3: P1 Connector Pin Out................................................................................................................... 16

Figure 4: Panel Cut Out ............................................................................................................................... 16

Figure 5: Mounting Tray Assembly Exploded View................................................................................... 16

Figure 6: COM 2000 Basic Wiring Diagram................................................................................................ 18

Figure 7: Interface with AP100 .................................................................................................................... 18

SECTION I - GENERAL INFORMATION 4

1.1 INTRODUCTION...........................................................................................................................................4

1.2 SCOPE ............................................................................................................................................................4

1.3 EQUIPMENT DESCRIPTION.......................................................................................................................4

1.4 FCC Emission Band ........................................................................................................................................5

1.5 SPECIFICATIONS .........................................................................................................................................6

1.6 EQUIPMENT SUPPLIED ..............................................................................................................................7

1.7 EQUIPMENT REQUIRED BUT NOT SUPPLIED .......................................................................................7

1.8 LICENSE REQUIREMENTS.........................................................................................................................7

SECTION II - INSTALLATION 8

2.1 GENERAL INFORMATION .........................................................................................................................8

2.1.1 Scope .....................................................................................................................................................8

2.2 UNPACKING AND INSPECTION................................................................................................................8

2.3 EQUIPMENT INSTALLATION PROCEDURES .........................................................................................8

2.3.1 Cooling Requirements ...........................................................................................................................8

2.3.2 Mounting Requirements ........................................................................................................................8

2.3.3 Wire Harness Fabrication ......................................................................................................................9

2.3.4 COM 2000 Installation ..........................................................................................................................9

2.4 POST INSTALLATION CHECK...................................................................................................................9

2.4.1 Operational Check ...............................................................................................................................10

2.4.2 Final Inspection ...................................................................................................................................10

2.5 LIMITATIONS .............................................................................................................................................10

SECTION III - OPERATION 11

3.1 GENERAL INFORMATION .......................................................................................................................11

3.1.1 Scope ...................................................................................................................................................11

3.1.2 Display Functions ................................................................................................................................11

3.1.3 User Controls .......................................................................................................................................11

3.2 System Configuration....................................................................................................................................13

3.2.1 Accessing Setup Functions ..................................................................................................................13

SECTION IV - WARRANTY AND SERVICE 14

4.1 LIMITED WARRANTY ..............................................................................................................................14

4.2 SERVICE ......................................................................................................................................................14

Appendix A – INSTALLATION DRAWINGS AND CONNECTOR LAYOUT 15

Appendix B – WIRING DIAGRAMS 18

Appendix C – Certifications 19

7.1 TSO Certification: .........................................................................................................................................19

Appendix D – INSTRUCTIONS FOR CONTINUED AIRWORTHINESS 20

8.1 MAINTENANCE INSTRUCTIONS ............................................................................................................20

Revision 3 Page 3 of 31

March 2013

I N S T A L L A T I O N A N D O P E R A T O R ’ S M A N U A L

C O M 2 0 0 0 – V H F T R A N S C E I V E R

V A L A V I O N I C S L T D

1 SECTION I - GENERAL INFORMATION

1.1 INTRODUCTION

Thank you for purchasing our COM 2000 – VHF Transceiver. Here at Val Avionics Ltd., our core design

philosophy is based on the ease of installation and use. The COM 2000 represents 20 years of refinement in that

process, based on the feedback of customers that have used the COM 760. The COM 2000 takes the original idea of

the COM 760: a simple to use, reliable, and without the frills of other radios; Overhauled and incorporating new

and exciting features.

That design philosophy translates into the ease of installation and simple operation makes the COM 2000 – VHF

Transceiver a communication solution for a wide variety of aircraft panels, from the Homebuilt through heavy

twins. The COM 2000 satisfies the need for compact, fully intergraded, quality radio that can be counted on to

provide years of reliable service.

Before installing and /or using your new COM 2000 please read this manual completely. This will ensure proper

installation and familiarize you with all of the features your COM has to offer.

1.2 SCOPE

This manual will provide detailed information about the installation and operation of the COM 2000 – VHF

Transceiver. It will also provide equipment limitation information and instructions for continued airworthiness.

1.3 EQUIPMENT DESCRIPTION

The COM 2000 has been designed for simplicity. It is intuitive to install and operate. Using state of the art

technology Val Avionics Ltd. has created a radio that will provide the pilot with simple and easy to operate

communications.

The COM 2000 also has an enhanced display that features both active and standby frequency displays. As an added

feature from the classing COM 760, the unit now features non-volatile memory for both the active and standby

frequencies. No longer do you need a memory power line to maintain your frequencies. Also included is a

revolutionary 15 channel quick access memory (The largest in the industry). The display also incorporates the latest

in high intensity LED technology that provides excellent view ability even in direct sunlight.

The unit’s controls have been designed for simple user interface. The concentric knobs on the right side of the unit

select the standby frequency, with a push button flip-flop to load the standby frequency into the active window. The

inner concentric knob on the left side of the unit selects the volume. The outer left knob controls the squelch

allowing a pilot to quiet noisy channels, or receive weak signals, all from the twist of a knob. The push button on

the left side knob set lets the user select a previously stored channel in memory. A long push of the left button will

power the unit down.

The COM 2000 has one internal receiver. The internal receiver operating from 118.00 MHz to 137.975 MHz. This

receiver is capable of receiving down to 2µV with a 6dB signal to noise ratio.

The COM 2000 has many audio inputs and outputs to facilitate any installation. The unit has 2 capacitively coupled

audio inputs for adding a Nav receiver audio output or other such audio device. The COM also has a 5W speaker

output and 50mW headphone output.

Revision 3 Page 4 of 31

March 2013

I N S T A L L A T I O N A N D O P E R A T O R ’ S M A N U A L

C O M 2 0 0 0 – V H F T R A N S C E I V E R

V A L A V I O N I C S L T D

1.4 FCC

The COM 2000 transceiver is a Voice Modulated communications device utilizing Amplitude modulation,

with a maximum power of 10W, operating in the 6K00A3E emission designator, with a 25kHz channel spacing.

This unit has been tested and found to comply with the limits for a Class B receiver, pursuant to Part 15 of

the FCC rules, as well as the emission requirements set forth in Part 87 of the FCC rules. These limits are designed

to provide reasonable protection against harmful interference when it is operated in an aircraft environment. The unit

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions manual, may cause harmful interference to radio communications. Operation of the unit in a residential

area is likely to cause harmful interference in which case the user will be required to correct the interference at his

own expense.

FCC ID: EZN5PRCOM2000

Revision 3 Page 5 of 31

March 2013

I N S T A L L A T I O N A N D O P E R A T O R ’ S M A N U A L

C O M 2 0 0 0 – V H F T R A N S C E I V E R

V A L A V I O N I C S L T D

1.5 SPECIFICATIONS

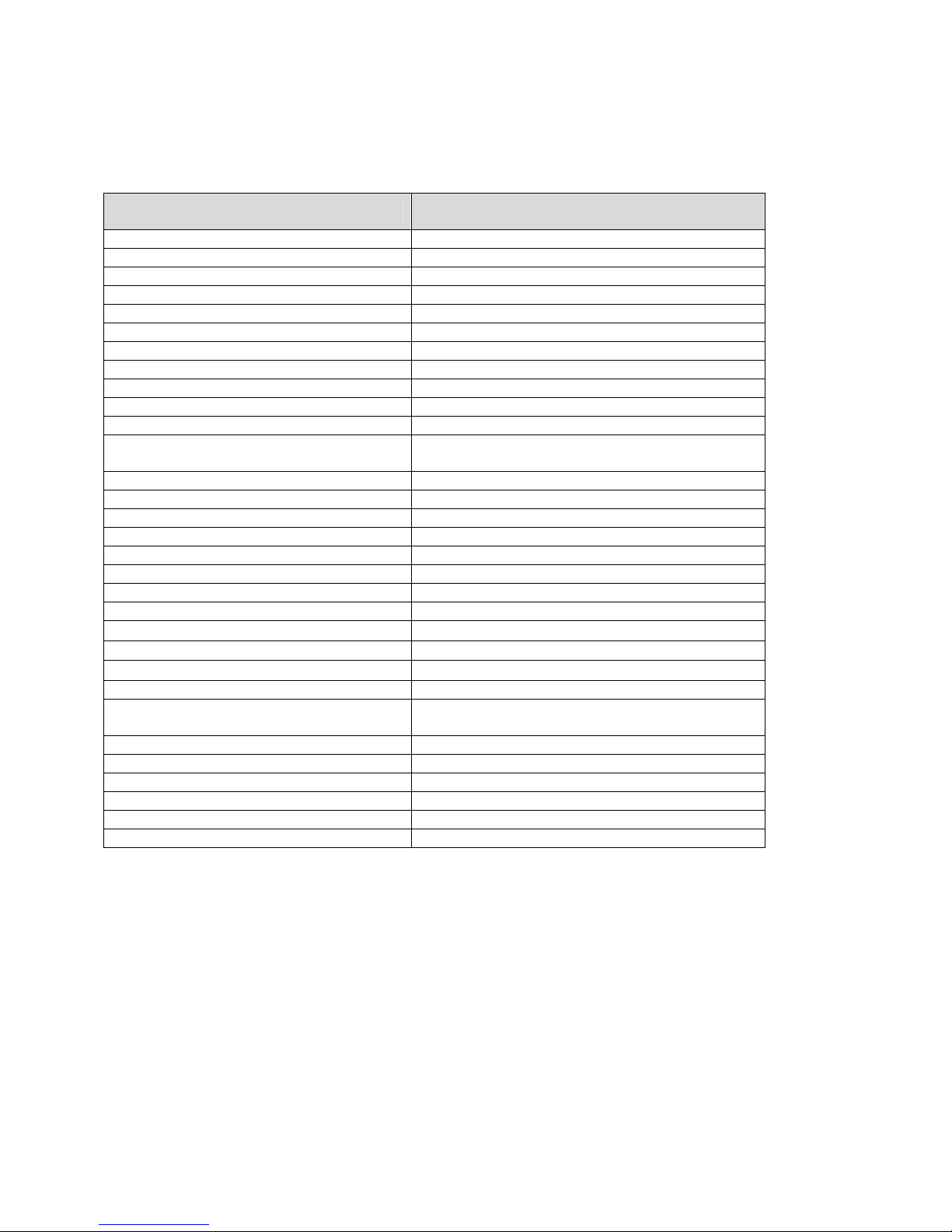

Table 1: Specifications

SPECIFICATIONS CHARACTERISTICS

Environmental: (RTCA/DO160D)

Minimum Performance Standard (RTCA/DO-186B)

Physical Dimensions:

Height 1.0 inches (2.54 cm)

Width 6.25 inches (15.88 cm)

Depth 9.0 inches (22.86 cm)

Weight: 3.25 pounds (1.5 kg)

Mounting: Panel mounted, no shock mounting required

Temperature Range: -20 to +55 Celsius with short time operations at

+70 Celsius

Power Requirements:

Voltage 11.0 to 30.0 VDC

Current 0.5 Amp Rec. 3 Amp max transmit

Receiver:

VHF Frequency 118.00 to 136.975 MHz

Sensitivity 2 µV to provide a 6dB S+N:N

Channel Spacing 25 kHz

Stability

Selectivity

Audio output

AGC Characteristics From 10 µV to 200 µV the audio level will not

Transmitter:

Carrier Power 8W nom. RMS

Duty Cycle 50%

Manufacturer’s Model Number

Part Number VPN 0800105

±.002%

≥60dB

5W to 4Ω Spk 50mW to 600Ω Phone

vary more than 3db.

COM 2000

Revision 3 Page 6 of 31

March 2013

I N S T A L L A T I O N A N D O P E R A T O R ’ S M A N U A L

C O M 2 0 0 0 – V H F T R A N S C E I V E R

V A L A V I O N I C S L T D

1.6 EQUIPMENT SUPPLIED

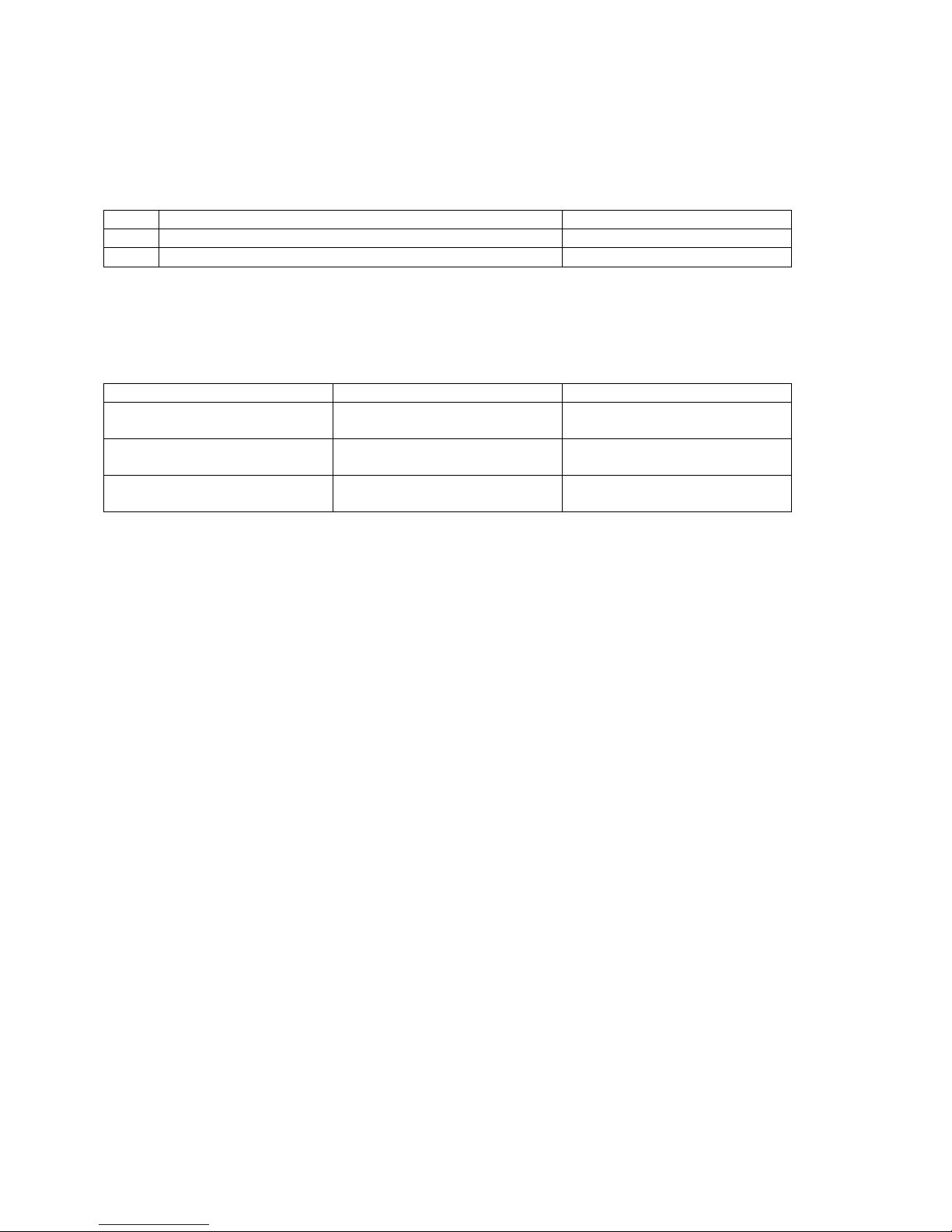

Table 2: Equipment Supplied

QTY DESCRIPTION PART NUMBER

1 COM 2000 – 760 Channel Radio

1 INSTALLATION KIT

0800105

651002

1.7 EQUIPMENT REQUIRED BUT NOT SUPPLIED

Table 3: Equipment Not Supplied

QTY DESCRIPTION PART NUMBER

1 Circuit Breaker 5 amp Potter & Brumsfield W58-2 (Ref

VPN 0331005)

1 Aircraft Cabin Speaker Ref aircraft parts manual for

specific part number

1 Contact Crimping Tool w/

Positioning Tool

AMP P/N 601966-1

AMP P/N 601699-5

1.8 LICENSE REQUIREMENTS

None

Revision 3 Page 7 of 31

March 2013

I N S T A L L A T I O N A N D O P E R A T O R ’ S M A N U A L

C O M 2 0 0 0 – V H F T R A N S C E I V E R

V A L A V I O N I C S L T D

2 SECTION II - INSTALLATION

2.1 GENERAL INFORMATION

2.1.1 Scope

This section of the manual will provide the needed information to successfully complete the installation of your new

COM 2000 – VHF Transceiver. Please read this section completely before proceeding with the installation process.

Although the COM 2000 installation procedures are designed with the do-it-yourselfer in mind, we at Val Avionics

Ltd. strongly suggest that you seek the advice of a qualified avionics installation facility before beginning this or any

other installation project. Qualified avionics installation technicians can offer good advice as to time-tested

installation practices and techniques that can save you many hours of time and frustration.

2.2 UNPACKING AND INSPECTION

Use care when unpacking the equipment. Inspect the unit and supplied parts for visual signs of damage during

shipment. Examine the unit for loose screws, dents, broken buttons and other signs of damage that may have

occurred during shipment. Verify the contents of the container with the list in section 1.5. If any damaged or missing

parts are discovered during the inspection save the shipping material and contact the freight carrier to file a claim. If

it is suspected that parts were omitted from the container please feel free to contact Val Avionics Ltd., to acquire the

missing items.

2.3 EQUIPMENT INSTALLATION PROCEDURES

2.3.1 Cooling Requirements

Forced air-cooling is not required for the COM 2000 – VHF Transceiver. However, when planning the location for

mounting, ensure adequate spacing from heat producing sources such as heating or defrosting ducts.

2.3.2 Mounting Requirements

The COM 2000 mounting tray should be rigidly mounted in the avionics stack using the hardware provided in the

installation kit. Ensure that the mounting location will provide easy access and a clear view of the equipment’s front

panel from the pilot’s position. Ensure that the mounting position will provide adequate clearance between the unit

and the associated wire harness and the aircraft controls. Bracing at the rear of the unit should be installed to ensure

rigidity in the panel. Consult FAA Advisory Circular AC 43.13-2A for acceptable practices and techniques.

Revision 3 Page 8 of 31

March 2013

I N S T A L L A T I O N A N D O P E R A T O R ’ S M A N U A L

C O M 2 0 0 0 – V H F T R A N S C E I V E R

V A L A V I O N I C S L T D

2.3.3 Wire Harness Fabrication

Val Avionics Ltd. Strongly recommends the use of a factory fabricated wire harness (VPN 751027) with your new

COM 2000 – VHF Transceiver. Use of the factory fabricated wire harness will ensure proper operation of the COM

2000, reduction in the occurrence of interfering signals and ground loops, greatly reduced installation time, and

provide prolonged trouble-free performance of your new equipment.

Although strongly recommended, it is not required to use the factory fabricated wire harness when installing the

COM 2000. A wiring harness can be fabricated in the field. Refer to appendix B of this manual for a complete

wiring diagram. The COM 2000 is connected to the aircrafts avionics bus via a 5 AMP circuit breaker. All wires

must be 22 AWG MIL-SPEC, unless otherwise noted in accordance with current regulations. Two and three

conductor shielded MIL-C-27500 or equivalent wire must be used where indicated. Use AMP Contact Crimping

Tool (AMP P/N 601966-1) with Positioning Tool (AMP P/N 601699-5) or equivalent to ensure good quality

contacts. Refer to FAA Advisory Circular AC 43.13-2A for acceptable practices and techniques.

2.3.4 COM 2000 Installation

2.3.4.1 Mounting

The COM 2000 is rigidly mounted in the aircrafts avionics stack. Once a location has been selected, a visual

inspection should be made of the area directly behind the panel which, will be occupied by the COM 2000 and

harness assembly for obvious obstructions such as heater ducts, control cables, fuel and oil lines or any other

obstruction. Pay particular attention to the control yoke assembly. It should be moved to the full limit of travel and

verified that sufficient clearance exists prior to beginning installation. Most aircraft instrument panels will already

have existing radio mounting cutouts. If the location you have selected requires that a mounting hole be cut, refer to

Figure 4: Panel Cut Out on Page 16 for the mounting template. Mark and cut the mounting holes as required.

Position the unit’s mounting tray in its upright position, and from the rear of the panel. With the unit held in place,

insert the two of the supplied 6-32 X 3/8” screws from the front and tighten as appropriate. The installing agency

must fabricate and attach rear support brackets to the aircraft structure behind instrument panel as appropriate to

support the rear of the COM 2000. Then, attach these brackets to the provided attachment points on the rear of the

unit with the supplied 6-32 1/4" Screws.

2.3.4.2 Antennas

One antenna is required for the COM 2000 installation. A standard COM antenna can be used with the unit such as a

COMANT CI-121 or equivalent. Follow the antenna manufacture’s installation Manual to ensure proper installation

of the antenna.

2.3.4.3 Audio

The COM 2000 has two auxiliary audio inputs and two audio outputs, Speaker audio and Headset audio. In

installations with two radio and/or more audio devices, it is strongly recommended that these audios be coupled to a

quality audio selector panel such as a Val Avionics AP 100. For complete details, refer to the interconnect wiring

diagrams in Appendix B.

2.4 POST INSTALLATION CHECK

Revision 3 Page 9 of 31

March 2013

I N S T A L L A T I O N A N D O P E R A T O R ’ S M A N U A L

C O M 2 0 0 0 – V H F T R A N S C E I V E R

V A L A V I O N I C S L T D

2.4.1 Operational Check

Refer to section three of this manual. Check all functions of the COM 2000 for proper operation. Check the

operational functions of other equipment installed in the aircraft in accordance with the individual manufacture’s

operation manuals to insure that no cross interference exists as a result of this installation.

2.4.2 Final Inspection

Verify that the wiring is bundled away from all controls and that no part of the installation interferes with the

movement of the aircraft controls. Move all of the aircraft controls through their full range of movement while

visually verifying that the installation does not mechanically interfere with the control movement. Verify that the

wiring harnesses are properly secured to the aircraft structure in accordance with accepted practices as described in

AC 43.13 and that adequate strain relief and service loops have been provided. Ensure that there are no kinks or

sharp bends in the wire harnesses. Verify that the wire bundles are not exposed to any sharp or abrasive surfaces.

Complete log book entries, FAA form 337, weight and balance computations and other documentations as required.

2.5 LIMITATIONS

There are no known limitations to the operation of the COM 2000. Instructions for Continued Airworthiness and

Return to Service Instructions can be found in Appendix C.

Revision 3 Page 10 of 31

March 2013

Loading...

Loading...