Page 1

M212242EN-C

Installation Guide

CMS Industrial Cabinet

AB100

C

Page 2

PUBLISHED BY

Vaisala Oyj

Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

P.O. Box 26, FI-00421 Helsinki, Finland

+358 9 8949 1

Visit our Internet pages at w

© Vaisala 2020

No part of this document may be reproduced,

published or publicly displa

any means, electronic or mechanical (including

photocopying), nor may its contents be modified,

translated, adapted, sold or disclosed to a third

party without prior written permission of the

copyright holder. Translated documents and

translated portions of multilingual documents are

based on the original English versions. In

ambiguous cases, the English versions are

applicable, not the translations.

The contents of this document are subject to

change without prior notice.

Local rules and regulations may vary and they

shall take precedence over the information

contained in this document. Vaisala makes no

representations on this document’s compliance

ww.vaisala.com.

yed in any form or by

with the local rules and regulations applicable at

an

y given time, and hereby disclaims any and all

responsibilities related thereto.

This document does not create any legally

binding obligations for Vaisala towards customers

or end users. All legally binding obligations and

agreements are included exclusively in the

applicable supply contract or the General

Conditions of Sale and General Conditions of

Service of Vaisala.

This product contains software developed by

Vaisala or third parties. Use of the software is

governed by license terms and conditions

included in the applicable supply contract or, in

the absence of separate license terms and

conditions, by the General License Conditions of

Vaisala Group.

Page 3

Table of contents

Table of contents

1. About this document.......................................................................................

1.1 Version information.............................................................................................5

1.2 Related manuals.................................................................................................. 5

1.3 Documentation conventions..............................................................................6

1.4 Trademarks........................................................................................................... 7

2. Product overview.............................................................................................. 8

2.1 Overview of Vaisala CMS Industrial Cabinet CAB100..................................... 8

2.2 Basic features and options.................................................................................9

2.2.1 CAB100A models........................................................................................ 10

2.2.2 CAB100B models.........................................................................................10

2.3 Physical structure and components..................................................................11

2.3.1 Enclosures.................................................................................................... 14

2.4 Regulatory compliances....................................................................................15

3. Installing the enclosure................................................................................. 16

3.1 Installing CAB100A with mounting frame...................................................... 16

3.2 Installing CAB100B with mounting frame.......................................................19

3.3 Enclosure flanges..............................................................................................23

3.3.1 Leading cables through rubber flange.................................................... 24

3.3.2 Leading cables through stainless steel flange........................................ 25

4. Electrical installation..................................................................................... 27

4.1 Installation safety.............................................................................................. 27

4.1.1 ESD protection............................................................................................ 28

4.2 Connecting AC (mains) power........................................................................ 28

4.3 Connecting power over Ethernet to CAB100A..............................................32

4.4 Supplying power to external measurement device from CAB100B........... 32

5

5. Adding devices to CAB100A..................................................................... 35

5.1 Expanding PDT101 transmitter installation in CAB100A.............................. 35

5.2 Expanding safety barrier installation in CAB100A........................................38

5.3 Expanding galvanic isolator installation in CAB100A................................... 41

6. Adding devices to CAB100B..................................................................... 44

6.1 Adding PDT101 transmitters as new modules to CAB100B.........................44

6.2 Expanding PDT101 transmitter installation in CAB100B.............................. 50

6.3 Adding analog input channels to CAB100B.................................................. 56

6.3.1 Wiring and powering loop-powered measurement devices.................62

6.3.2 Wiring externally powered measurement devices.................................65

6.4 Adding safety barriers as new modules to CAB100B.................................. 69

6.5 Expanding safety barrier installation in CAB100B........................................78

6.6 Adding galvanic isolators as new modules to CAB100B............................. 85

6.7 Expanding galvanic isolator installation in CAB100B...................................93

6.8 Installing serial port server and Ethernet switch........................................ 100

7. Replacing devices.........................................................................................105

7.1 Replacing PDT101 transmitters in CAB100A and CAB100B.......................105

7.2 Replacing DL4000 data loggers in CAB100A and CAB100B....................109

8. Maintenance..................................................................................................... 114

8.1 PDT101 calibration............................................................................................ 114

8.2 PDT101 adjustment........................................................................................... 114

8.3 Cleaning.............................................................................................................115

1

Page 4

CAB100 Installation Guide M212242EN-C

9. Technical data..................................................................................................

116

9.1 CAB100 specifications..................................................................................... 116

9.1.1 Enclosure dimensions................................................................................118

9.2 Component specifications...............................................................................119

9.2.1 Vaisala Dierential Pressure Transmitter PDT101 specifications.......... 119

9.2.2 Vaisala DL4000 Universal Data Logger specifications......................... 121

9.2.3 Vaisala vNet PoE Data Logger Interface specifications....................... 123

9.2.4 Third-party component specifications................................................... 125

9.3 Spare parts and accessories...........................................................................126

Appendix A: Wiring diagrams.....................................................................128

A.1 CAB100A wiring diagrams.............................................................................

128

A.2 CAB100B wiring diagrams..............................................................................133

Appendix B: Layout diagrams.....................................................................138

B.1 CAB100A layout diagrams............................................................................. 138

B.2 CAB100B layout diagrams............................................................................. 143

Appendix C: Removing and recycling data logger battery.................149

Maintenance and calibration services........................................................ 151

Warranty............................................................................................................ 151

Technical support............................................................................................ 151

Recycling........................................................................................................... 151

2

Page 5

List of figur

es

List of figur

Figure 1 Cabinet models CAB100A (small) and CAB100B (large)........................ 8

Figure 2 Main components inside CAB100A, PDT101 model with

Figure 3 Main components inside CAB100A, PDT101 model with vNet PoE......12

Figure 4 Main components inside CAB100B, mixed model with

Figure 5 CAB100A enclosure dimensions................................................................... 14

Figure 6 CAB100B enclosure dimensions....................................................................14

Figure 7 CAB100A wall installation accessories........................................................ 17

Figure 8 CAB100B wall installation accessories.........................................................21

Figure 9 Stainless steel flange........................................................................................25

Figure 10 CAB100A enclosure dimensions..................................................................118

Figure 11 CAB100B enclosure dimensions.................................................................. 119

Figure 12 Wiring diagram for CAB100A PDT101 voltage model with

Figure 13 Wiring diagram for CAB100A PDT101 voltage model with

Figure 14 Wiring diagram for CAB100A analog channel model with

Figure 15 Wiring diagram for CAB100A safety barrier model with

Figure 16 Wiring diagram for CAB100A galvanic isolator model with

Figure 17 Wiring diagram for CAB100B PDT101 model...........................................133

Figure 18 Wiring diagram for CAB100B analog channel model with

Figure 19 Wiring diagram for CAB100B analog channel model with

Figure 20 Wiring diagram for CAB100B safety barrier model...............................136

Figure 21 Wiring diagram for CAB100B galvanic isolator model......................... 137

Figure 22 Main components inside CAB100A, PDT101 model with

Figure 23 Main components inside CAB100A, PDT101 model with vNet PoE...139

Figure 24 Main components inside CAB100A, analog channel model

Figure 25 Main components inside CAB100A, safety barrier model

Figure 26 Main components inside CAB100A, galvanic isolator

Figure 27 Main components inside CAB100B, mixed model with

Figure 28 Main components inside CAB100B, PDT101 model............................... 144

Figure 29 Main components inside CAB100B, analog channel model................145

Figure 30 Main components inside CAB100B, mixed model with

Figure 31 Main components inside CAB100B, safety barrier model....................147

Figure 32 Main components inside CAB100B, galvanic isolator model..............148

es

serial port serv

PDT101s, analog input channels, and safety barriers...............................13

serial port server and 24 VDC power supply........................................... 128

vNet PoE............................................................................................................ 129

serial port server and 24 VDC power supply...........................................130

serial port server and 24 VDC power supply............................................ 131

serial port server and 24 VDC power supply........................................... 132

loop-powered measurement devices........................................................134

externally powered measurement devices...............................................135

serial port server and 24 VDC power supply........................................... 138

with serial port server and 24 VDC power supply................................. 140

with serial port server and 24 VDC power supply.................................. 141

model with serial port server and 24 VDC power supply.................... 142

PDT101s, analog input channels, and safety barriers.............................143

PDT101s and safety barriers..........................................................................146

er and 24 VDC power supply..............................................11

3

Page 6

CAB100 Installation Guide M212242EN-C

List of tables

Table 1 Document versions (English).............................................................................5

Table 2 Related manuals.................................................................................................... 5

Table 3 CAB100 c

Table 4 Enclosure flanges and recommended use...................................................23

Table 5 CAB100 operating environment.................................................................... 116

Table 6 CAB100 powering specifications...................................................................116

Table 7 CAB100 mechanical specifications............................................................... 116

Table 8 CAB100 environmental compliance..............................................................117

Table 9 CAB100 EMC compliance.................................................................................118

Table 10 PDT101 models.................................................................................................... 119

Table 11 PDT101 measurement performance.............................................................. 119

Table 12 PDT101 operating environment..................................................................... 120

Table 13 PDT101 compliance...........................................................................................120

Table 14 PDT101 inputs and outputs...............................................................................121

Table 15 PDT101 mechanical specifications..................................................................121

Table 16 DL4000 general specifications...................................................................... 121

Table 17 DL4000 memory specifications....................................................................122

Table 18 DL4000 recording span.................................................................................. 123

Table 19 DL4000 current loop and voltage inputs...................................................123

Table 20 vNet operating environment..........................................................................123

Table 21 vNet inputs and outputs..................................................................................123

Table 22 vNet mechanical specifications.....................................................................124

Table 23 vNet general specifications............................................................................ 124

Table 24 Power supply module product information...............................................125

Table 25 Circuit breaker product information.............................................................125

Table 26 Safety barrier product information.............................................................. 125

Table 27 Galvanic isolator product information.........................................................125

Table 28 Serial port server product information........................................................126

Table 29 Ethernet switch product information.......................................................... 126

Table 30 CAB100 spare parts and accessories...........................................................126

onfiguration options..........................................................................9

4

Page 7

1. About this document

Version information

1.1

Chapter 1 – About this document

This document provides installation instructions and product specifica

Industrial Cabinet CAB100.

Table 1 Document versions (English)

Document code Date Description

M212242EN-C December 2020 New chapters in this revision:

• Supplying po

(page 32)

• Wiring externally powered measurement devices (page 65)

Updated chapters:

• Wiring and powering loop-powered measurement devices

(page 62)

• Vaisala Dierential Pressure Transmitter PDT101 specifications

(page 119)

• CAB100B wiring diagrams (page 133) (wiring diagram for externally

powered devices added)

M212242EN-B June 2020 New chapters in this revision:

•

All chapters describing the small cabinet model CAB100A

• Enclosure flanges (page 23)

Updated chapters:

• Installation safety (page 27)

• Installing serial port server and Ethernet switch (page 100)

• Spare parts and accessories (page 126)

wer to external measurement device from CAB100B

tions for Vaisala CMS

M212242EN-A October 2019 First version.

1.2 Related manuals

Table 2 Related manuals

Document code Name

M212262EN Vaisala CMS Industrial Cabinet CAB100 Assembling Analog Channel Terminal Block

T

echnical Note

M212294EN Vaisala CMS Industrial Cabinet CAB100 Wiring Diagrams Technical Reference

M212284EN Vaisala CMS Industrial Cabinet CAB100 Quick Guide

M211284EN Vaisala Dier

M211247EN Vaisala HUMICAP

ential Pressure Transmitter PDT101 Quick Guide

â

Humidity and Temperature Transmitter Series HMT120 Quick Guide

5

Page 8

CAB100 Installation Guide M212242EN-C

Document code Name

M211244EN Vaisala HUMICAP

M210566EN Vaisala HUMICAP

M010056EN Vaisala HUMICAP

M210483EN Vaisala Transmitter Series HMT360 Safety Guide

M211975EN Vaisala viewLinc Enterprise Server Version 5.0 User Guide

M211655EN Vaisala vNet PoE Network Interface Quick Start Guide

M211700EN Vaisala vNet PoE Network Interface User's Guide

90000687-88 DIGI PortServer

158962 / 900260

2300

S-SM-9160-06-

/2015

en-09

Stahl 9001 Series Single-channel Safety Barrier Operating Instructions

Stahl Type 9160/9163 Transmitter Supply Unit/Isolating Repeater Safety Manual

â

Humidity and Temperature Transmitter Series HMT120 User Guide

â

Humidity and Temperature Transmitter Series HMT330 User Guide

â

Humidity and Temperature Transmitter Series HMT360 User's Guide

â

TS Family Quick Start Guide

Documentation by third-party instrument manufacturers is provided as is.

1.3 Documentation conventions

WARNING!

Warning alerts y

instructions carefully at this point, there is a risk of injury or even death.

CAUTION!

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or important data

could be lost.

Note highligh

Tip giv

ts important information on using the product.

es information for using the product more eciently.

ou to a serious hazard. If you do not read and follow

6

Page 9

Lists tools needed to perform the task.

Indicates that you need to take some notes during the task.

1.4 Trademarks

Chapter 1 – About this document

Vaisalaâ is a r

HUMICAPâ is a registered trademark of Vaisala Oyj.

DIGI PortServerâ is a registered trademark of DIGI International Inc.

All other product or company names that may be mentioned in this publication are trade

names, trademarks, or registered trademarks of their respective owners.

egistered trademark of Vaisala Oyj.

7

Page 10

CAB100 Installation Guide M212242EN-C

2. Product overview

2.1 Overview of Vaisala CMS Industrial

Cabinet C

Vaisala CMS Industrial Cabinet CAB100 is an instrument cabinet designed to integrate

de

vices for measuring humidity, temperature, dierential pressure, and other parameters.

Combined with the Vaisala viewLinc Continuous Monitoring System, CAB100 is an

integrated solution for real-time monitoring of cleanrooms and industrial applications in

multiple industries.

CAB100 is available in 2 models, CAB100A (small enclosure) and CAB100B (large enclosure).

The cabinets can be configured according to application requirements, with options for

dierential pressure transmitters, analog input channels for the connection of remote

transmitters, and safety barriers or galvanic isolators for hazardous areas, used with

intrinsically safe devices.

AB100

Figure 1 Cabinet models CAB100A (small) and CAB100B (large)

8

Page 11

2.2 Basic features and options

Chapter 2 – Product overview

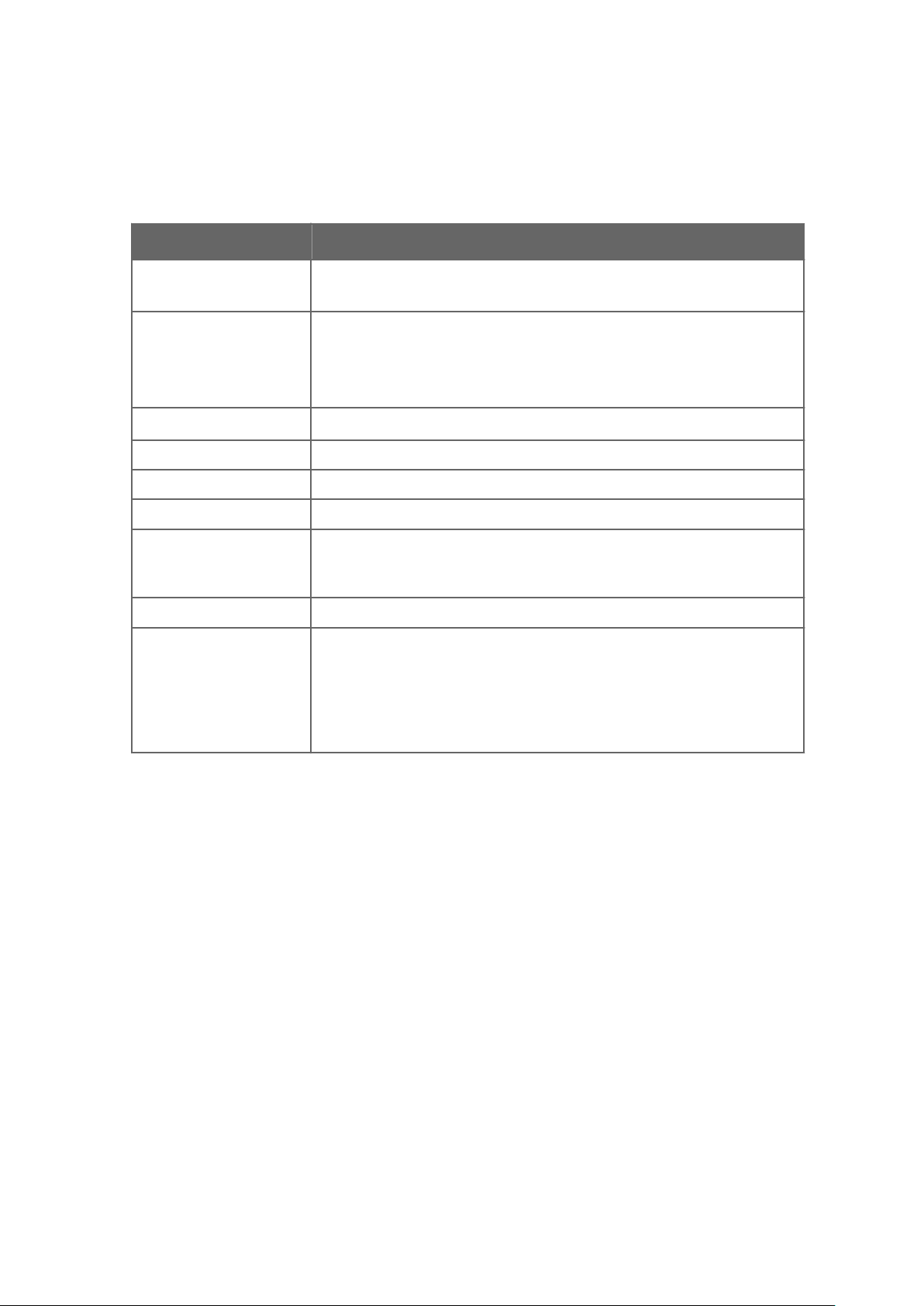

Table 3 CAB100 c

Property Description/Value

Cabinet size

(H × W × L

Powering Power supply:

Dierential pr

Analog input channels 4 ... 32 channels, 4 ... 20 mA

Safety barrier 1 ... 16 pcs, 1 barrier per channel

Galvanic isolator 1 ... 12 pcs, 1 isolator per channel

Ethernet communication CAB100A: Vaisala vNet Power over Ethernet Data Logger Interface, with PoE

Ethernet Ethernet switch, +4 PoE IEEE 802.3af/at

Standards

)

onfiguration options

CAB100A: 200 × 300 × 400 mm (7.87 × 11.81 × 15.75 in)

CAB100B: 200 × 500 × 600 mm (7.87 × 19.69 × 23.62 in)

•

Within cabinet: 24 VDC / 2.5 A

• To cabinet: 110 ... 240 VAC

Power over Ethernet (with loop power, without fan)

essure 1 ... 12 pcs, ±60 Pa or ±0.25 in H2O

option via R

CAB100B: Up to 2 serial-to-Ethernet devices via RJ45 (DIGI PortServer TS4)

EN/IEC61326-1 (Basic electromagnetic environment)

EN5

5032 Class B

IEC/UL/EN 61010-1

IP66/NEMA 4 (CAB100B) / IP54 (CAB100A)

Safety listed in USA and Canada

J45 connector

3)

1)

2)

4)

1) PoE is available for CAB100A PDT101 model only.

Excluding CAB100 analog input channels, which are not surge protected.

2)

3) UL listing pending.

4) Safety listing pending.

More information

‣

C

AB100 specifications (page 116)

‣

Component specifications (page 119)

‣

Spare parts and accessories (page 126)

9

Page 12

CAB100 Installation Guide M212242EN-C

2.2.1 CAB100A models

CAB100A is available in 4 pr

e-configured models. There are 2 communication interface

options for CAB100A: serial port server (for all models) or the Vaisala vNet PoE data logger

interface (option for PDT101 model only).

CAB100A model Maximum number of measurement devices per model

PDT101 model 4 PDT101 transmitters

Analog channel model 4 analog input channels

Safety barrier model 4 safety barriers

Galvanic isolator model 4 galvanic isolators

More information

‣

C

AB100A layout diagrams (page 138)

2.2.2 CAB100B models

CAB100B is available in 4 pr

CAB100B models is a multiport serial port server.

CAB100B model Maximum number of measurement devices per model

e-configured models. The communication interface in all

PDT101 model 16 PDT101 transmitters

Analog channel model 32 analog input channels

Safety barrier model 16 safety barriers

Galvanic isolator model 12 galvanic isolators

In addition to the above, mixed CAB100B models are available, with limitations. Contact

your Vaisala sales representative for details. For an example configuration, see Figure 4

(page 13).

More information

‣

CAB100B layout diagrams (page 143)

10

Page 13

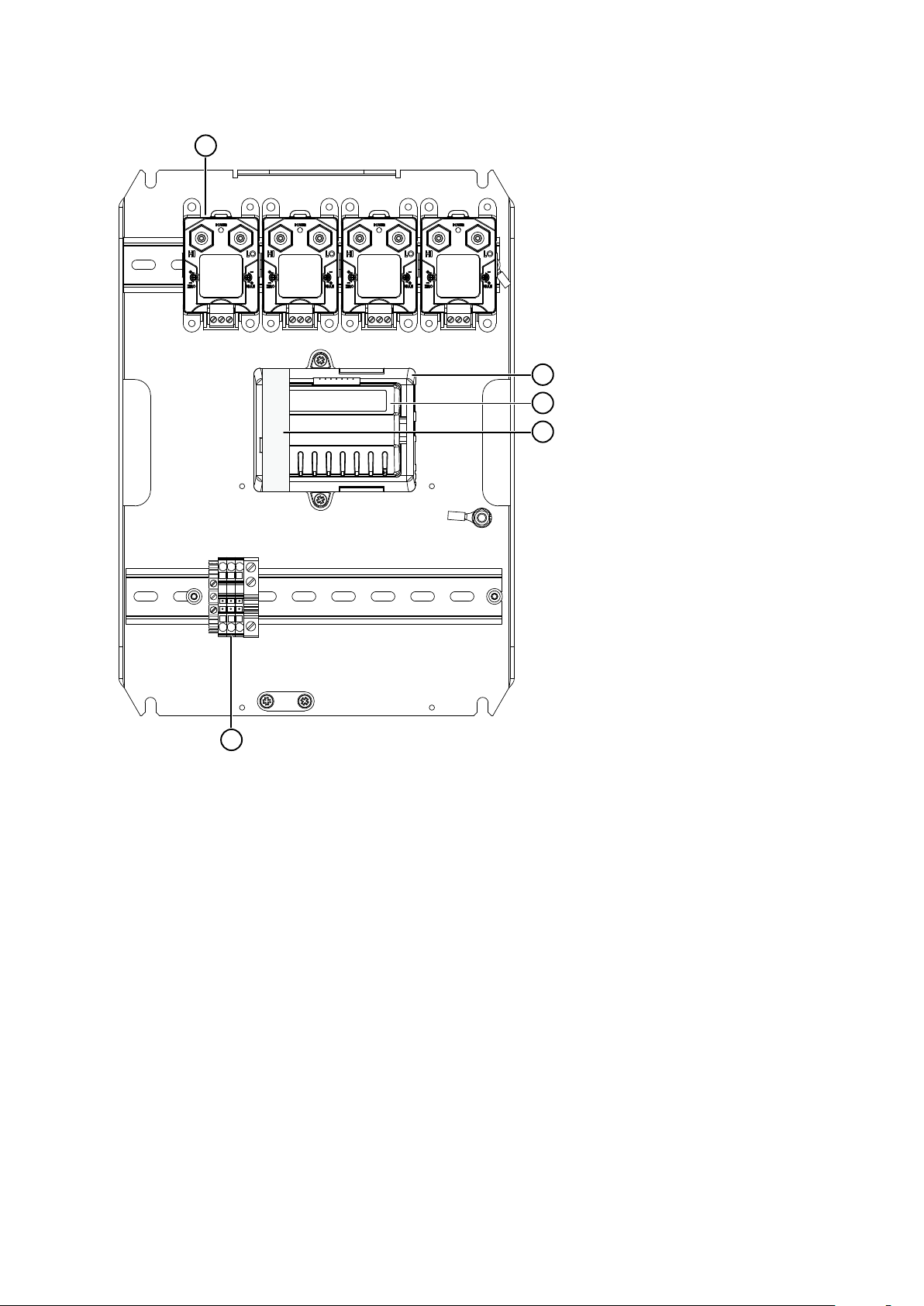

1

5

6

4

7

8

3

910

2

Chapter 2 – Product overview

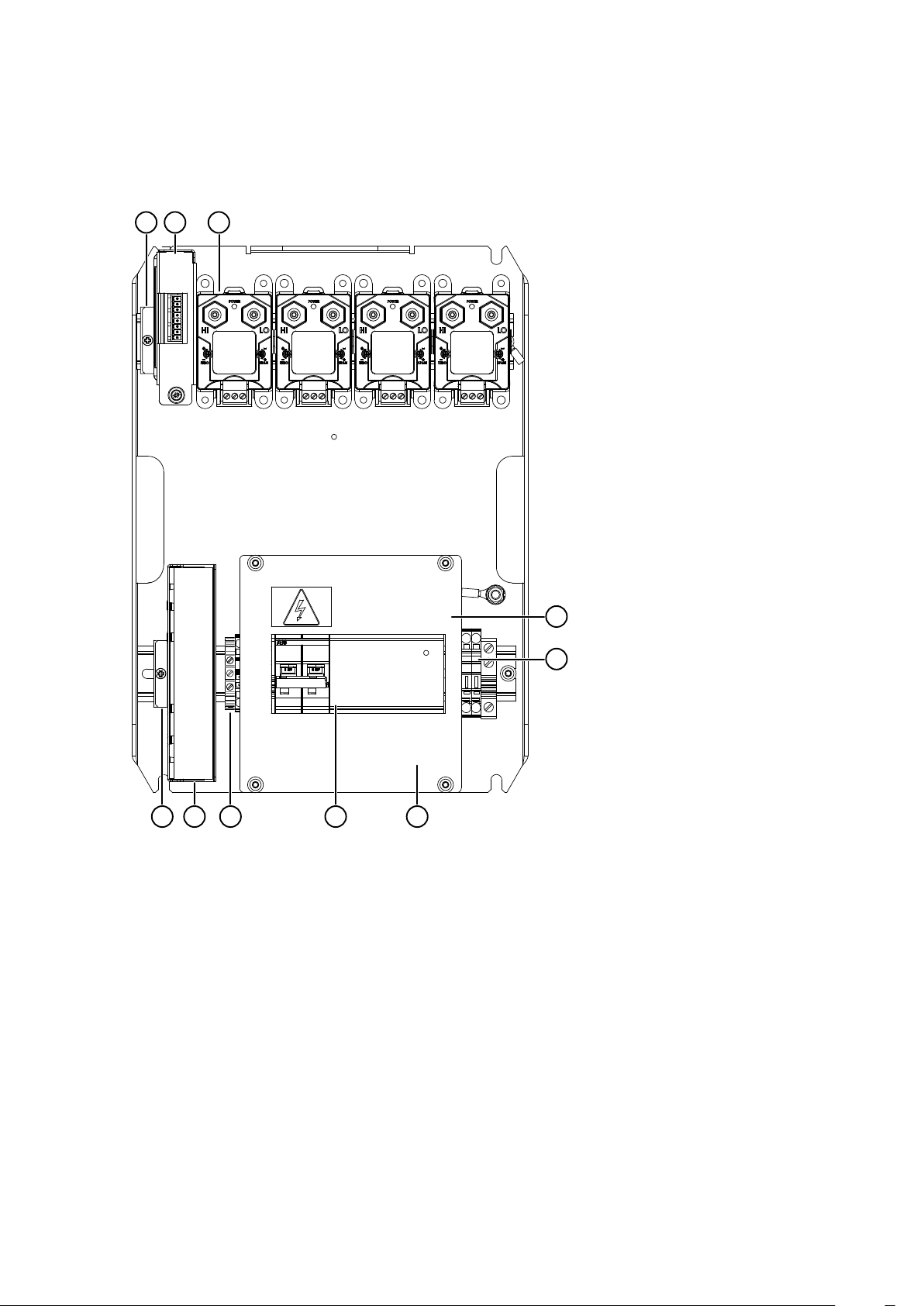

2.3 Physical structure and components

Figure 2 Main components inside CAB100A, PDT101 model with serial port server and 24 VDC

wer supply

po

1 Mounting clamp for DL4000 data logger

2 DL4000 data logger

3 PDT101 transmitters (4 pcs)

4 Cover plate

5 24 VDC fuses T2.5A, 5 × 20 mm (2 pcs)

6 110 … 240 VAC mains input and grounding point (under cover plate)

7 Circuit breaker and power supply module

8 Grounding terminal block

9 Serial port server

10 Mounting clamp for serial port server

11

Page 14

1

3

2

5

4

CAB100 Installation Guide M212242EN-C

Figure 3 Main components inside CAB100A, PDT101 model with vNet PoE

1 PDT101 transmitters (4 pcs)

2 vNet PoE data logger interface

3 DL4000 data logger

4 Protective label. R

emove before installation.

5 Grounding terminal block

12

Page 15

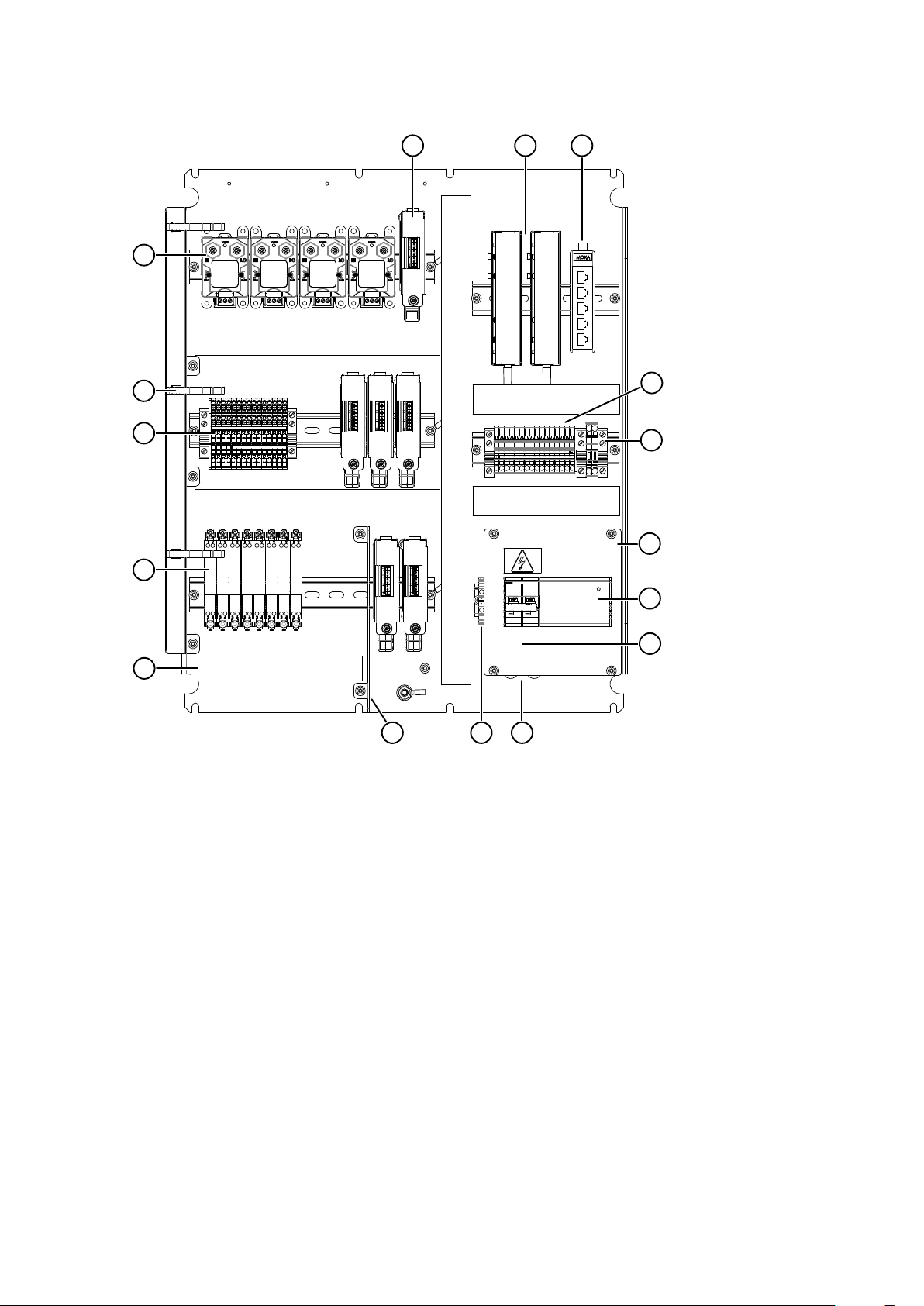

5

6

1

7

9

10

12

16

4

8

2

3

14

11

13

15

Chapter 2 – Product overview

Figure 4 Main components inside CAB100B, mixed model with PDT101s, analog input channels,

and saf

1 Cable duct for intrinsically safe connections

ety barriers

2 Safety barriers (8 pcs)

3 Terminal block for analog input channels

4 Holders for tubing (3 pcs)

5 PDT101 transmitters (4 pcs)

6 DL4000 data loggers (6 pcs)

7 Serial port servers (2 pcs)

8 Ethernet switch

9 24 VDC power block

10 24 VDC fuses T2.5A, 5 × 20 mm (2 pcs)

11 Cover plate

12 Circuit breaker and power supply module

13 110 … 240 VAC mains input (under cover plate)

14 Cable strain relief

15 Grounding terminal block

16 Partition plate separating intrinsically safe and non-intrinsically safe connections

13

Page 16

400 [15.74]

207.6 [8.17]

202.1 [7.96]

300 [11.81]

418 [16.5]

mm

[in]

600 [23.62]

500 [19.69]

206 [8.11]

618 [24.33]

mm

[in]

CAB100 Installation Guide M212242EN-C

For more layout diagrams of CAB100 c

diagrams (page 138) and CAB100B layout diagrams (page 143).

2.3.1 Enclosures

Figure 5 CAB100A enclosure dimensions

onfiguration options, see CAB100A layout

Figure 6 CAB100B enclosure dimensions

The CAB100A enclosure is made of aluminium, and has IP54 rating. The CAB100B enclosure

is made of stainless steel, and has IP66/NEMA 4 rating.

1) The IP ratings apply only when using the factory-installed top and bottom flanges in the enclosures.

14

1)

Page 17

800226

Chapter 2 – Product overview

There are flanges f

or cable lead-through on the top and bottom of the enclosures. The top

flange of both small and large cabinet is made of rubber. Stainless steel and rubber flange

models are available to order for the bottom of the cabinet.

The enclosures come with a mounting frame for easy installation.

More information

‣

Installing CAB100A with mounting frame (page 16)

‣

Installing CAB100B with mounting frame (page 19)

‣

Enclosure flanges (page 23)

‣

CAB100 specifications (page 116)

2.4 Regulatory compliances

This product complies with the following electromagnetic compatibility and safety

s

tandards:

• EN/IEC 61326‑1: Basic electromagnetic environment.2) EN 55032 Class B.

• EN/UL/IEC 61010‑1: Safety requirements for electrical equipment for measurement,

control, and laboratory Use – Part 1: General requirements.

2) Excluding CAB100 analog input channels, which are not surge protected.

15

Page 18

CAB100 Installation Guide M212242EN-C

3. Installing the enclosure

Installing CAB100A with mounting

3.1

frame

• 4‑mm Allen k

• 10-mm wrench

• Drill and 8-mm drill bits for making the installation holes

• Spirit level

CAUTION!

requires at least 2 people.

CAUTION!

f

ollowing:

• The analog input channel wiring must not exceed 30 meters.

• The wiring must not come from outside the building where CAB100 is installed.

If CAB100 cannot be installed in an environment that meets the above criteria, use a

suitable surge protection device that has been installed following local regulations.

CAUTION!

damage the equipmen

ey

For safety reasons, do not carry out installations alone. Safe installation

CAB100 analog input channels are not surge protected. Therefore, note the

Do not drill holes in the backplate or the enclosure. Drill shavings may

t inside the cabinet.

CAB100 is shipped with a mounting frame and installation accessories for indoor wall

ins

tallation. If the screws delivered with the mounting frame are not suitable for the wall

material in the installation location, use any appropriate screws to attach the frame.

16

Page 19

4

1

3

2

200 [7.9]

300 [12]

Ø

8 [0.31]

mm

[in]

Chapter 3 – Installing the enclosure

Figure 7 CAB100A wall installation accessories

1 Hole for wall plug (4 pcs)

2 Mounting slot (2 pcs)

3 Wall plug (4 pcs)

4 Hex wood screw M6×40 DIN571 A2 (4 pcs)

1. Drill holes into the wall. Use the mounting frame as a guide.

Place the wall plugs into the drilled holes.

2.

17

Page 20

CAB100 Installation Guide M212242EN-C

3. Attach the mounting frame to the wall with screws.

4. Lift the enclosure into place.

Hang the enclosur

e onto the frame by sliding the mounting studs on the back of the

enclosure into the mounting slots of the frame.

18

Page 21

5. Attach the bottom of the enclosure to the mounting frame.

1

2

Chapter 3 – Installing the enclosure

1 Washer with EPDM gasket 6.8/16×1.5/A2/EPDM (2 pcs)

2 Hex screw M6×16 ISO7380 A4 (2 pcs)

3.2 Installing CAB100B with mounting

ame

fr

• 4‑mm Allen k

• 10-mm wrench

• Drill and 8-mm drill bits for making the installation holes

• Spirit level

CAUTION!

r

equires at least 2 people.

ey

For safety reasons, do not carry out installations alone. Safe installation

19

Page 22

CAB100 Installation Guide M212242EN-C

CAUTION!

ollowing:

f

• The analog input channel wiring must not exceed 30 meters.

• The wiring must not come from outside the building where CAB100 is installed.

If CAB100 cannot be installed in an environment that meets the above criteria, use a

suitable surge protection device that has been installed following local regulations.

CAUTION!

damage the equipmen

CAB100 analog input channels are not surge protected. Therefore, note the

Do not drill holes in the backplate or the enclosure. Drill shavings may

t inside the cabinet.

CAB100 is shipped with a mounting frame and installation accessories for indoor wall

tallation. If the screws delivered with the mounting frame are not suitable for the wall

ins

material in the installation location, use any appropriate screws to attach the frame.

20

Page 23

175 [6.9]

175 [6.9]

440 [17.3]

Ø

8 [0.31]

4

1

3

2

mm

[in]

Chapter 3 – Installing the enclosure

Figure 8 CAB100B wall installation accessories

1 Hole for wall plug (4 pcs)

2 Wall plug (4 pcs)

3 Mounting slot (2 pcs)

4 Hex wood screw M6×40 DIN571 A2 (4 pcs)

1. Drill holes into the wall. Use the mounting frame as a guide.

Place the wall plugs into the drilled holes.

2.

21

Page 24

CAB100 Installation Guide M212242EN-C

3. Attach the mounting frame to the wall with screws.

4. Lift the enclosure into place.

Hang the enclosur

e onto the frame by sliding the mounting studs on the back of the

enclosure into the mounting slots of the frame.

22

Page 25

5. Attach the bottom of the enclosure to the mounting frame.

1

2

Chapter 3 – Installing the enclosure

1 Washer with EPDM gasket 6.8/16×1.5/A2/EPDM (2 pcs)

2 Hex screw M6×16 ISO7380 A4 (2 pcs)

3.3 Enclosure flanges

Vaisala recommends that you lead cables, wires, and tubes into the CAB100 enclosure

thr

ough the top and bottom flanges as explained in Table 4 (page 23).

Table 4 Enclosure flanges and r

Number and type of flanges per

c

abinet model

CAB100A:

•

1 flange on the top and

1 on the bottom of the

enclosure

• Top flange is made of rubber.

Rubber or stainless steel flange

is available to order for the

bottom.

ecommended use

Type of connection Recommended flange to

use

AC (mains) cable Top flange

Tubes for PDT101 transmitters

E

thernet PoE cable

Wires for safety barriers, galvanic isolators,

and external measurement devices

Bottom flange

23

Page 26

2

1

CAB100 Installation Guide M212242EN-C

Number and type of flanges per

abinet model

c

CAB100B:

•

2 flanges on the top and

2 on the bottom of the

enclosure

• Top flanges are made of

rubber. Rubber or stainless

steel flanges are available to

order for the bottom.

Type of connection Recommended flange to

Tubes for PDT101 transmitters

Wires for external measurement devices

AC (mains) cable Bottom right-hand flange

Wires for safety barriers and galvanic

isola

tors

3.3.1 Leading cables through rubber flange

CAUTION!

through the flanges as instructed.

• Pipette

•

Wire cutters

• Wire-stripping pliers

To preserve the IP rating of the enclosure, make sure that you lead cables

use

Top flange

Bottom left-hand flange

only

1. Lead the cables into the enclosure using the pipette provided.

1 Cable

2 Pipette for leading the cable through the flange

2. Insert the pipette through one of the feed-through rondels in the flange

.

3. Insert a cable and pull it through to the inside.

4. Inside the enclosure, connect the cables and wires according to the wiring diagram.

24

Page 27

1 2 3 4 5

Chapter 3 – Installing the enclosure

CAUTION!

es properly. Too much strain may cause the cable or wire to fall o or damage the

wir

cable, wire, or connector.

To avoid strain on the connector, make sure that you connect cables and

More information

‣

Ins

tallation safety (page 27)

‣

Connecting AC (mains) power (page 28)

‣

Wiring diagrams (page 128)

‣

Layout diagrams (page 138)

3.3.2 Leading cables through stainless steel flange

CAUTION!

thr

ough the flanges as instructed.

• Wire cutters

•

Wire-stripping pliers

To preserve the IP rating of the enclosure, make sure that you lead cables

Figure 9 Stainless steel flange

1 Flange

2 Cable gland, cable diameter 7.5 … 14 mm (0.30 … 0.55 in)

3 Dummy plug M16 × 1.5

4 Cable gland, cable diameter 5 … 10 mm (0.20 … 0.39 in)

5 Cable gland, cable diameter 3 … 6.5 mm (0.12 … 0.26 in)

1. Lead the cables through the cable glands in the flange.

25

Page 28

CAB100 Installation Guide M212242EN-C

2. RJ45 connectors do not fit thr

ough the cable glands. Cut o the existing connector,

lead the Ethernet cable through a cable gland, and attach a new cable connector to the

cable. For instructions, see the connector documentation.

3. Inside the enclosure, connect the cables and wires according to the wiring diagram.

CAUTION!

es properly. Too much strain may cause the cable or wire to fall o or damage the

wir

cable, wire, or connector.

To avoid strain on the connector, make sure that you connect cables and

More information

‣

Ins

tallation safety (page 27)

‣

Connecting AC (mains) power (page 28)

‣

Wiring diagrams (page 128)

‣

Layout diagrams (page 138)

26

Page 29

Chapter 4 – Electrical installation

4.

Electrical installation

4.1 Installation safety

WARNING!

adher

e to local and state legislation and regulations.

WARNING!

servic

eable parts inside the module. If the power supply module is faulty, replace it.

WARNING!

egulations at all times.

r

Only licensed experts may install electrical components. They must

Do not open the AC/DC power supply module. There are no user-

Keep away from live circuits. Operating personnel must observe safety

WARNING!

minimiz

WARNING!

some time

them.

CAUTION!

ollowing:

f

• The analog input channel wiring must not exceed 30 meters.

• The wiring must not come from outside the building where CAB100 is installed.

If CAB100 cannot be installed in an environment that meets the above criteria, use a

suitable surge protection device that has been installed following local regulations.

CAUTION!

cannot be loop-powered.

Ground the product and verify installation grounding periodically to

e shock hazard.

After disconnecting the power cable, dangerous voltages can exist for

. To avoid injury, disconnect the power and discharge circuits before touching

CAB100 analog input channels are not surge protected. Therefore, note the

Do not use the power block in CAB100 to power measurement devices that

27

Page 30

CAB100 Installation Guide M212242EN-C

CAUTION!

ety barriers or galvanic isolators, ensure that you comply with the safe work

saf

procedure outlined in IEC/EN 60079-14 and possible applicable local safety standards.

CAUTION!

oper modification may lead to safety hazards, equipment damage, failure to

Impr

perform according to specification, decreased equipment lifetime, or the warranty

becoming void.

CAUTION!

requires at least 2 people.

More information

‣

W

iring diagrams (page 128)

‣

Layout diagrams (page 138)

When working in explosion hazardous areas with installations involving

Do not modify the unit or use it in ways not described in the documentation.

For safety reasons, do not carry out installations alone. Safe installation

4.1.1 ESD protection

Electrostatic discharge (ESD) can cause immediate or latent damage to electronic circuits.

V

aisala products are adequately protected against ESD for their intended use. However, it is

possible to damage the product by delivering an electrostatic discharge when touching,

removing or inserting any objects inside the equipment housing.

Avoid touching component contacts or connectors when working with the device.

4.2 Connecting AC (mains) power

WARNING!

the main power source.

CAUTION!

Ins

tallation safety (page 27)

Before connecting the AC (mains) power cable, switch o the po

Before connecting power to the device, read carefully the safety notes in

wer from

28

Page 31

Chapter 4 – Electrical installation

• Screwdriver

Wire cutters

•

• Wire-stripping pliers

For the AC (mains) power connection, you need an external disconnection device (for

e

xample, a power cable or a mains power switch).

Note the following:

• The disconnection device must be rated 16 A or 20 A at 250 VAC, and must conform to

any additional local regulations.

• The disconnection device must be visible from the cabinet, or lockable with a key to

prevent accidental switching on during installation and maintenance.

• The cabinet must not block access to the disconnection device after it has been

installed. The disconnection device must remain easy to operate.

The AC (mains) cable is not included in the delivery. Use an AC (mains) cable with a

minimum cross-section of 3 × 0.75 mm2 (18 AWG).

Refer to La

yout diagrams (page 138) for the locations of components inside the cabinet.

1. Unscrew and remove the transparent cover plate protecting the circuit breaker and the

wer supply module.

po

2. Lead the AC (mains) cable into the enclosure.

Lead the cable through a flange in the cabinet enclosure, following relevant safety

regulations. Take note of safe areas around safety barriers or galvanic isolators inside

the enclosure.

29

Page 32

100 [3.94]

50 [1.97]

mm

[in]

1

2

3

CAB100 Installation Guide M212242EN-C

3. Strip approximately 100 mm (4 in) of the cable, and cut the phase and neutral wires to

the length of appr

oximately 50 mm (2 in). If you are using a stranded wire, add cable

ferrules to the ends.

CAUTION!

es. Under mechanical stress, the grounding wire must be the last to disconnect

wir

Make sure that the grounding wire is longer than the phase and neutral

from the protective ground terminal.

Number Wire Wire color

(in

ternational)

1 Phase L Brown Black Solid wire: 4 mm2 (12 A

2 Neutral N Blue White Solid wire: 4 mm2 (12 AWG)

Wire color (North

America)

Maximum wire cross-section

WG)

Stranded wire: 2.5 mm2 (14 A

WG)

3 Grounding

PE/

GND

Stranded wire: 2.5 mm2 (14 A

Yellow/Green Green Solid wire: 4 mm2 (12 AWG)

Stranded wire: 2.5 mm2 (14 A

WG)

WG)

30

Page 33

2

1

3

L N

Chapter 4 – Electrical installation

4. Connect the phase, neutral, and grounding wires of the AC (mains) cable as indicated in

the figur

e below.

1 Connect the (green or yellow-green) grounding wire to the grounding terminal

block.

2 Connect the phase (L) and neutral (N) wires to the circuit breaker: the phase in the

left

-hand screw terminal and the neutral in the right-hand screw terminal.

3 Mount the AC (mains) cable to the strain relief fixture located under the circuit

breaker.

5. Reattach the transparent cover plate.

6.

Switch on the circuit breaker.

7. Switch on mains power.

More information

‣

Wiring diagrams (page 128)

‣

Layout diagrams (page 138)

31

Page 34

CAB100 Installation Guide M212242EN-C

4.3

Connecting power over Ethernet to

CAB100A

CAUTION!

tallation safety (page 27).

Ins

1. In CAB100A PDT101 model with vNet PoE, power the cabinet by connecting your

thernet PoE cable to the vNet device.

E

Before connecting power to the device, read carefully the safety notes in

2. Switch on mains power.

User documentation for Vaisala vNet Power over Ethernet Data Logger Interface is

available in www.vaisala.com.

More information

‣

W

iring diagrams (page 128)

‣

Layout diagrams (page 138)

4.4 Supplying power to external

measur

Small screwdriver

ement device from CAB100B

CAUTION!

wiring instructions in the device-specific user documentation.

32

Before connecting any external measurement device to CAB100, refer to the

Page 35

Chapter 4 – Electrical installation

CAUTION!

wer block and the CAB100 analog terminal block.

po

Do not power an external measurement device both via the CAB100 24 VDC

You can use the 24 VDC power block in CAB100 for powering measurement devices that

equire external powering.

r

For instructions on powering loop-powered devices via the CAB100 analog terminal block,

see Wiring and powering loop-powered measurement devices (page 62).

To power an externally powered device from the CAB100B power block:

1. De-energize the cabinet: switch o mains power and the circuit breaker located inside

the cabinet.

1 Circuit breaker

2. Use the available connectors on the bottom row of the CAB100B power block for

c

onnecting the power wires of the external measurement device.

The power block is located on the right-hand side of the cabinet.

33

Page 36

2

1

CAB100 Installation Guide M212242EN-C

3. Connect the wires of the device in the same order as shown below: negative (black) on

the righ

t, with positive (red) on its left.

Do not disconnect the existing power wires on the bottom row.

1 Row available for power wires of external measurement devices

2 Power wires from the CAB100B power supply module. Do not disconnect.

CAUTION!

sensor pur

devices momentarily. When powering external devices, please make sure that the

additional power requirements do not exceed the capacity of the CAB100B power

supply. If in doubt, contact Vaisala for more information.

Some functionalities of external measurement devices (for example,

ge in Vaisala probes) may increase the power consumption of the

4. After connecting the power wires, reconnect power in the cabinet.

Switch on the circuit breaker.

a.

b. Switch on mains power.

More information

‣

Wiring diagrams (page 128)

‣

Layout diagrams (page 138)

34

Page 37

Chapter 5 – Adding devices to CAB100A

5. Adding devices to CAB100A

5.1 Expanding PDT101 transmitter

tallation in CAB100A

ins

• Small fla

Check the type of your PDT101 transmitters (voltage model / current model) before

dering new devices, as you cannot mix dierent types of PDT101 models in a cabinet

or

installation. For more information, see Spare parts and accessories (page 126).

Follow the steps below to add new PDT101 transmitters to an existing set of transmitters in

C

AB100A. Note the dierent steps for 24 VDC and PoE powered models.

Refer to CAB100A layout diagrams (page 138) when planning the installation.

1. Switch o mains power.

2. De-energize the existing PDT101 transmitters as shown below.

3. De-energizing 24 VDC powered CAB100A model:

Disconnect the PDT101 power wires from the fuse terminal blocks located at the righthand end of the power block.

t head screwdriver

35

Page 38

CAB100 Installation Guide M212242EN-C

4. De-energizing vNe

t PoE powered CAB100A model:

Disconnect the Ethernet PoE cable from the vNet device.

5. Mount the new PDT101 transmitter on the DIN rail.

est the upper part of the locking mechanism on the DIN rail and push down firmly.

R

This will click the device into place.

6. Use the existing wires in the PDT101 wire set to connect the new PDT101.

Discard the black wire end caps before connecting the wires.

7. Fasten the wires to the screw terminal connector in the PDT101 with a small fla

screwdriver.

• Connect the black wire in the wire set to the

C

OM terminal and the red wire to the Vin terminal of

PDT101

• When connecting the third wire in the wire set to the

Vout terminal, please observe the color of the wire

coming from the DL4000 data logger connector. The

PDT101 transmitters installed at the factory are

connected so that the rightmost PDT101 on the DIN rail is

connected to data logger channel 4. See the location of

the data logger connector and channel markings next to

it in step 6 above.

36

t head

Page 39

Chapter 5 – Adding devices to CAB100A

8. Reconnect power in 2

4 VDC powered CAB100A model:

a. Reconnect the power wires in the fuse terminal blocks.

b. Switch on mains power.

. Reconnect power in vNet PoE powered CAB100A model:

9

a. Reconnect the Ethernet PoE cable to the vNet device.

b. Switch on mains power.

e information

Mor

‣

PDT101 calibration (page 114)

‣

CAB100A wiring diagrams (page 128)

‣

CAB100A layout diagrams (page 138)

37

Page 40

CAB100 Installation Guide M212242EN-C

5.2 Expanding safety barrier installation

in C

Follow the steps below to add new safety barriers to an existing set of devices in CAB100A.

A ma

ximum of 4 barriers can be housed inside CAB100A.

Refer to CAB100A layout diagrams (page 138) when planning the installation.

AB100A

• Small fla

Vaisala recommends that you use the cable lead-throughs on top of the cabinet to lead

the e

The cable set for safety contains wiring for 4 safety barriers. If the number of barriers

inside CAB100A totals less than 4 after installation, leave the extra wires unconnected and

the wire end caps in place.

t head screwdriver

xternal wiring for the safety barriers into the cabinet.

1. Switch o mains power.

2. De-energize the existing safety barriers.

Disconnect the barrier power wires from the fuse terminal blocks located at the righthand end of the power block.

3. Take note of the wiring instructions printed on the side of the barrier. The information

will be r

barrier in step 6.

elevant when connecting wires in the intrinsically safe screw terminals of the

38

Page 41

4. Mount the barrier on the DIN rail.

Min. 100 mm [3.94 in]

Chapter 5 – Adding devices to CAB100A

CAUTION!

the DL4000 da

A safety distance of minimum 100 mm (3.94 in) must remain between

ta logger and the leftmost barrier.

a. Make sure the blue end of the device, with the intrinsically safe screw terminals,

aces up towards the top of the cabinet.

f

b. Rest the locking mechanism at the back of the barrier on the DIN rail and push down

firmly. This will click the device into place.

39

Page 42

1

CAB100 Installation Guide M212242EN-C

5. To connect the new barrier, use the existing barrier wires in the cable set.

Discard the black wire end caps.

a.

b. Observing polarity, connect the wires to the connectors at the bottom of the barrier.

1 Safety barrier wires connected

6. For wiring of the intrinsically safe screw terminals at the blue end of the barrier, refer to

the wiring ins

tructions printed on the side of the barrier and the Operating Instructions

leaflet provided in the barrier packaging.

7. Reconnect power in CAB100A.

a. Reconnect the power wires in the fuse terminal blocks.

b. Switch on mains power.

More information

‣

CAB100A wiring diagrams (page 128)

‣

CAB100A layout diagrams (page 138)

40

Page 43

Chapter 5 – Adding devices to CAB100A

5.3

Expanding galvanic isolator

installation in CAB100A

• Small fla

Vaisala recommends that you use the cable lead-throughs on top of the cabinet to lead

the e

The galvanic isolator cable contains wiring for 4 isolators. If the number of isolators inside

CAB100A totals less than 4 after installation, leave the extra wires unconnected and the

wire end caps in place.

Follow the steps below to add new galvanic isolators to an existing set of devices in

C

AB100A. A maximum of 4 isolators can be housed inside CAB100A.

t head screwdriver

xternal wiring for the galvanic isolators into the cabinet.

Refer to CAB100A layout diagrams (page 138) when planning the installation.

1. Switch o mains power.

2. De-energize the existing isolators.

Disconnect the isolator power wires from the fuse terminal blocks located at the righthand end of the power block.

3. Take note of the wiring instructions printed on the side of the isolator. The information

will be r

isolator in step 6.

elevant when connecting wires in the intrinsically safe screw terminals of the

41

Page 44

Min. 100 mm [3.94 in]

CAB100 Installation Guide M212242EN-C

4. Mount the isolator on the DIN rail.

CAUTION!

the DL4000 da

A safety distance of minimum 100 mm (3.94 in) must remain between

ta logger and the leftmost isolator.

a. Make sure that the intrinsically safe blue screw terminals face up towards the top of

the cabine

t.

b. Rest the locking mechanism at the back of the isolator on the DIN rail and push

down firmly. This will click the device into place.

42

Page 45

1

Chapter 5 – Adding devices to CAB100A

5. To connect the new isolator, use the existing wires in the isolator cable.

Discard the black wire end caps.

a.

b. Observing polarity, connect the isolator wires to push-in terminals 1 and 2, and the

power wires to terminals 7 and 9 at the bottom of the isolator.

1 Galvanic isolator wires connected

6. For wiring of the intrinsically safe screw terminals in the galvanic isolators, refer to the

wiring ins

tructions printed on the side of the isolator and the Safety Manual leaflet

provided in the isolator packaging.

7. Reconnect power in CAB100A.

a. Reconnect the power wires in the fuse terminal blocks.

b. Switch on mains power.

More information

‣

CAB100A wiring diagrams (page 128)

‣

CAB100A layout diagrams (page 138)

43

Page 46

CAB100 Installation Guide M212242EN-C

6. Adding devices to CAB100B

6.1 Adding PDT101 transmitters as new

modules t

• Empty DIN rail in the cabinet

PDT Wiring Set, 1 set per 4 PDT101 transmitters. The set contains the following:

•

• Cable set for PDT or safety

• Data logger data cable

• Data logger holder

• DL4000 data logger(s), 1 logger per 4 PDT101 transmitters

• Small flat head screwdriver

For item codes, see Spare parts and accessories (page 126).

You can install only one type of device or measurement point (PDT101 transmitters, analog

input channels, safety barriers, or galvanic isolators) per row in the cabinet.

In cabinet models with 5 to 8 data loggers, you need 2 serial port servers.

One serial port serv

o CAB100B

er controls the trac of maximum 4 data loggers.

Make sure to number the data loggers as well as the cable sets and wires in the PDT

W

iring Set before you install and connect them.

DL4000 data loggers are delivered with default factory settings. For instructions on

c

onfiguring measurement units and scaling in DL4000 data loggers, see the Vaisala

viewLinc Enterprise Server User Guide for your viewLinc version, available at

www.vaisala.com/viewlinc.

Follow the steps below to install PDT101 transmitters as new devices to an empty DIN rail in

C

AB100B. Refer to CAB100B layout diagrams (page 143) when planning the installation.

For instructions on expanding the number of PDT101 transmitters installed in the cabinet,

see Expanding PDT101 transmitter installation in CAB100B (page 50).

44

Page 47

Chapter 6 – Adding devices to CAB100B

1. De-energize the cabinet: switch o mains po

wer and the circuit breaker located inside

the cabinet.

1 Circuit breaker

2. Remove the cable duct cover below the PDT101 mounting location.

Remove the long vertical cable duct cover in the middle of the cabinet.

3.

4. Mount the new PDT101 transmitters on the DIN rail, preferably at the left end of the rail.

Rest the upper part of the PDT101 locking mechanism on the DIN rail and push down

firmly. This will click the device into place.

5. Assemble the data logger holder.

a. Place the data logger in the logger holder.

b. Fit the cover into place.

c. Tighten the screw by hand.

45

Page 48

CAB100 Installation Guide M212242EN-C

6. Connect the logger data cable to the RS-232 serial port in the data logger.

Use a small fla

t head screwdriver to tighten the screw attached to the connector.

7. Mount the data logger on the DIN rail, preferably at the right-hand end of the rail.

est the logger holder locking mechanism on the DIN rail and push down firmly. This

R

will click the device into place.

8. Connect the logger data cable to a free port in the serial port server.

46

Page 49

Chapter 6 – Adding devices to CAB100B

9. Connect the PDT101 transmitters to the data logger and the power block as shown in

tep 10 to step 15.

s

Use the cable set for PDT, which is included in PDT Wiring Set (Vaisala item code:

ASM213079SP).

1 Power wires and connector

2 PDT101 wires

3 Data logger connector

The cable set for PDT contains wiring for 4 PDT101 transmitters. If you install only

o 3 PDT transmitters, leave the extra wires unconnected and the wire end caps in

1 t

place.

10. Remove the end caps from the wires in the cable set for PDT.

11.

Disconnect the screw terminal connector from the PDT101 by pulling it out.

12. Observing polarity, connect the PDT101 wires to the screw terminal connector with a

small fla

t head screwdriver.

47

Page 50

CAB100 Installation Guide M212242EN-C

13. Follow the terminal block label markings on the PDT101 and plug the connector back in.

14. Connect the data logger connector to the DL4000 data logger.

48

Page 51

Chapter 6 – Adding devices to CAB100B

15. Connect the power wire connector to the power block on the right-hand side of the

cabine

t.

16. The new PDT101 transmitters are now mounted and connected.

1 Wires connected to PDT101 screw terminal connector

2 Data logger wires connected to data logger

3 Power wires connected to power block

17. Route the wires along the cable ducts.

Insert any extra length of wire into the cable ducts and replace the cable duct covers.

18.

19. Reconnect power in the cabinet.

a. Switch on the circuit breaker.

b. Switch on mains power.

49

Page 52

CAB100 Installation Guide M212242EN-C

More information

‣

PD

T101 calibration (page 114)

‣

CAB100B wiring diagrams (page 133)

‣

CAB100B layout diagrams (page 143)

6.2

Expanding PDT101 transmitter

installation in CAB100B

• PDT Wiring Set (Vaisala item code: ASM213079SP), 1 set per 4 PDT101 transmitters.

he set contains the following:

T

• Cable set for PDT or safety

• Data logger data cable

• Data logger holder

• DL4000 data logger(s), 1 logger per 4 PDT101 transmitters

• Small flat head screwdriver

Check the type of your PDT101 transmitters (voltage model / current model) before

or

dering new devices, as you cannot mix dierent types of PDT101 models in a cabinet

installation. For more information, see Spare parts and accessories (page 126).

You can install only one type of device or measurement point (PDT101 transmitters, analog

input channels, saf

ety barriers, or galvanic isolators) per row in the cabinet.

In cabinet models with 5 to 8 data loggers, you need 2 serial port servers.

One serial port serv

Make sure to number the data loggers as well as the cable sets and wires in the PDT

W

iring Set before you install and connect them.

er controls the trac of maximum 4 data loggers.

Follow the steps below to add new PDT101 transmitters to an existing set of transmitters in

AB100B. Refer to CAB100B layout diagrams (page 143) when planning the installation.

C

For instructions on introducing PDT101 transmitters as new devices to an empty DIN rail in

the cabinet, see Adding PDT101 transmitters as new modules to CAB100B (page 44).

50

Page 53

Chapter 6 – Adding devices to CAB100B

The PDT Wiring Set consists of wiring for 4 devices. Any unused wires in the Wiring Set have

been plac

ed in the cable duct at the factory. If you have, for example, 3 PDT101 transmitters

installed on a DIN rail, and want to complete the set by installing a fourth one, use the

existing PDT101 wires present in the cable duct.

1. De-energize the cabinet: switch o mains power and the circuit breaker located inside

the cabinet.

1 Circuit breaker

2. Disconnect the PDT101 power wire connector from the power block located on the

righ

t-hand side of the cabinet.

3. Remove the cable duct cover below the PDT101 mounting location.

. Mount the DL4000 data logger (or loggers), as shown in the following steps.

4

Each set of 4 PDT101 transmitters requires a data logger of its own. If you are

talling the second, third, or fourth transmitter to complete a set of 4,

ins

step 5 to step 8 are not relevant, as you can connect the new transmitter(s) to the

existing data logger with the factory-installed cable set for PDT.

51

Page 54

CAB100 Installation Guide M212242EN-C

5. Assemble the data logger holder.

Place the data logger in the logger holder.

a.

b. Fit the cover into place.

c. Tighten the screw by hand.

6. Connect the logger data cable to the RS-232 serial port in the data logger.

Use a small fla

t head screwdriver to tighten the screw attached to the connector.

7. Mount the data logger on the DIN rail, preferably at the right-hand end of the rail.

Rest the logger holder locking mechanism on the DIN rail and push down firmly. This

will click the device into place.

52

Page 55

Chapter 6 – Adding devices to CAB100B

8. Connect the logger data cable to a free port in the serial port server.

9. Mount the new PDT101 transmitter(s) on the DIN rail.

est the upper part of the locking mechanism on the DIN rail and push down firmly.

R

This will click the device into place.

10. Connect the PDT101 transmitters to the data logger and the power block, as shown in

step 11 to step 16.

Use the cable set for PDT, which is included in PDT Wiring Set (Vaisala item code:

ASM213079SP).

When mounting the second, third, or fourth PDT101 transmitter on the DIN rail, use the

existing wires in the cable duct below the PDT101 mounting location.

1 24 VDC power wires and connector

2 PDT101 wires

3 Data logger connector

The cable set for PDT contains wiring for 4 PDT101 transmitters. If you install only

1 t

o 3 PDT transmitters, leave the extra wires unconnected and the wire end caps in

place.

53

Page 56

CAB100 Installation Guide M212242EN-C

11. Disconnect the screw terminal connector from the PDT101 by pulling it out.

12. Observing polarity, connect the PDT101 wires to the screw terminal connector with a

small fla

t head screwdriver.

13. Follow the terminal block label markings on the PDT101 and plug the connector back in.

54

Page 57

Chapter 6 – Adding devices to CAB100B

14. Connect the data logger connector to the DL4000 data logger.

15. Remove the cable duct cover above the power block.

Connect the 24 VDC power connector to the power block, or reconnect any existing

16.

power wires (disconnected in step 2).

17. Route the wires along the cable ducts.

Insert any extra length of wire into the cable ducts and replace the cable duct covers.

18.

19. Reconnect power in the cabinet.

a. Switch on the circuit breaker.

b. Switch on mains power.

More information

‣

PDT101 calibration (page 114)

‣

CAB100B wiring diagrams (page 133)

‣

CAB100B layout diagrams (page 143)

55

Page 58

CAB100 Installation Guide M212242EN-C

6.3 Adding analog input channels to

AB100B

C

• Empty DIN rail in the cabinet

•

Analog Wiring Set (Vaisala item code: ASM213078SP). 2) One set contains the

following:

• Cable set, 24 VDC power block to analog terminal block

• Cable set, data logger to analog terminal block

• Data logger data cable

• Data logger holder

• Terminal block accessories for 4 analog input channels

• Document Vaisala CAB100 Assembling Analog Channel Terminal Block Technical

Note (M212262EN)

• DL4000 data logger(s), 1 logger per 4 analog input channels

• Small flat head screwdriver

For item codes, see Spare parts and accessories (page 126).

You can install only one type of device or measurement point (PDT101 transmitters, analog

input channels, saf

In cabinet models with 5 to 8 data loggers, you need 2 serial port servers.

One serial port serv

ety barriers, or galvanic isolators) per row in the cabinet.

er controls the trac of maximum 4 data loggers.

1)

Make sure to number the data loggers as well as the cable sets and wires in the Analog

iring Set before you install and connect them.

W

DL4000 data loggers are delivered with default factory settings. For instructions on

onfiguring measurement units and scaling in DL4000 data loggers, see the Vaisala

c

viewLinc Enterprise Server User Guide for your viewLinc version, available at

www.vaisala.com/viewlinc.

Follow the steps below to install terminal blocks for analog input channels as new devices to

an empt

y DIN rail in CAB100B.

You can apply this installation procedure also when expanding the number of analog input

channels in the cabinet. For example, to increase the number of analog input channels on a

DIN rail from 4 to 12, order 2 Analog Wiring Sets and 2 data loggers.

1) Required only when introducing analog input channels as new devices in CAB100B.

2) You need 3 Analog Wiring Sets (Vaisala item code: ASM213078SP) to assemble a 12-channel terminal block.

56

Page 59

Chapter 6 – Adding devices to CAB100B

Refer to C

AB100B layout diagrams (page 143) when planning the installation.

1. De-energize the cabinet:

a. Switch o mains power and the circuit breaker located inside the cabinet.

1 Circuit breaker

b. Only when e

xpanding the analog terminal block installation on a DIN rail:

Disconnect the analog channel 24 VDC power cable connector from the power

block, located on the right-hand side of the cabinet.

2. Remove the cable duct cover below the empty DIN rail reserved for the analog terminal

block.

emove also the long vertical cable duct cover in the middle of the cabinet.

R

3. Assemble the new analog channel terminal block.

See the instructions in Vaisala CAB100 Assembling Analog Channel Terminal Block

Technical Note (M212262EN), included in the Analog Wiring Set (ASM213078SP).

4. Mount the analog channel terminal block on the DIN rail.

57

Page 60

CAB100 Installation Guide M212242EN-C

5. Assemble the data logger holder.

Place the data logger in the logger holder.

a.

b. Fit the cover into place.

c. Tighten the screw by hand.

6. Connect the logger data cable to the RS-232 serial port in the data logger.

Use a small fla

t head screwdriver to tighten the screw attached to the connector.

7. Mount the data logger on the DIN rail, preferably at the right-hand end of the rail.

Rest the logger holder locking mechanism on the DIN rail and push down firmly. This

will click the device into place.

58

Page 61

1 2

Chapter 6 – Adding devices to CAB100B

8. Connect the logger data cable to a free port in the serial port server.

9. Connect the analog channel terminal block to the data logger and to the 24 VDC power

block, as sho

wn in step 10 to step 12 below.

Use the cables in the Analog Wiring Set (Vaisala item code: ASM213078SP).

1 Cable set for connecting data logger to analog terminal block

2 Cable set for connecting 24 VDC power block to analog terminal block

59

Page 62

1

2

CAB100 Installation Guide M212242EN-C

10. Connect the cable sets to the analog channel terminal block.

1 Logger to analog cable set

2 Power cable set

11. Connect the black terminal connector of the logger to analog cable set to the DL4000

da

ta logger.

60

Page 63

1

2

1

3

2

4

Chapter 6 – Adding devices to CAB100B

12. Connect the power cable set to the power block located on the right-hand side of the

cabine

t.

1 Vertical cable duct

2 Power cable set connected to power block

13. Route the wires along the cable ducts.

14

. The new analog channel terminal blocks are now mounted and connected.

1 Logger to analog cable set connected to analog channel terminal block

2 Power cable set connected to analog channel terminal block

3 Power cable set connected to power block

4 Logger to analog cable set connected to data logger

15. Insert any extra length of wire into the cable ducts and replace the cable duct covers.

61

Page 64

CAB100 Installation Guide M212242EN-C

16. Only when e

xpanding the analog terminal block installation on a DIN rail:

Reconnect the 24 VDC power cable connector (disconnected in step 1.b) in the power

block.

17. Reconnect power in the cabinet.

Switch on the circuit breaker.

a.

b. Switch on mains power.

More information

‣

CAB100B wiring diagrams (page 133)

‣

CAB100B layout diagrams (page 143)

6.3.1 Wiring and powering loop-powered measurement devices

• Small screwdriver

Wire cutters

•

• Wire-stripping pliers

CAUTION!

ollowing:

f

• The analog input channel wiring must not exceed 30 meters.

• The wiring must not come from outside the building where CAB100 is installed.

If CAB100 cannot be installed in an environment that meets the above criteria, use a

suitable surge protection device that has been installed following local regulations.

CAUTION!

wiring ins

CAB100 analog input channels are not surge protected. Therefore, note the

Before connecting any external measurement device to CAB100, refer to the

tructions in the device-specific user documentation.

62

Page 65

Chapter 6 – Adding devices to CAB100B

CAUTION!

onnected in the same analog channel terminal block.

c

Loop-powered and externally powered measurement devices cannot be

Follow the steps below to connect a loop-powered measurement device, for example

aisala Humidity and Temperature Transmitter Series HMT120 transmitter, to the CAB100

V

analog terminal block. Note that once connected, the loop-powered device is powered via

the CAB100 analog terminal block.

1. De-energize the cabinet: switch o mains power and the circuit breaker located inside

the cabinet.

1 Circuit breaker

2. Disconnect the analog channel 24 VDC power cable connector from the power block,

loca

ted on the right-hand side of the cabinet.

3. Strip approximately 10 mm (0.4 in) from the analog output wires of the external

measur

ement device.

63

Page 66

2

1

4

3

5

CAB100 Installation Guide M212242EN-C

4. Insert the wires in the push-in terminals of the CAB100 analog terminal block.

1 CH1+

2 CH1−

3 CH2+

4 CH2−

5 Numbering of the terminal block

onnectors runs 1 ... 4 left to right

c

5. Connect the wires to the corresponding screw terminals inside the external

measur

ement device (wiring inside HMT120 shown below).

See the wiring instructions in the device-specific user documentation of the external

measurement device.

6. Reconnect power in the cabinet.

a.

Switch on the circuit breaker.

b. Switch on mains power.

More information

‣

CAB100B wiring diagrams (page 133)

‣

CAB100B layout diagrams (page 143)

64

Page 67

Chapter 6 – Adding devices to CAB100B

6.3.2 Wiring externally powered measurement devices

• Red 5-pole plug-in bridges (3 pcs). The bridges are included in the CAB100B

cessory bag (included in the delivery)

ac

• Small screwdriver

• Wire cutters

• Wire-stripping pliers

CAUTION!

f

ollowing:

• The analog input channel wiring must not exceed 30 meters.

• The wiring must not come from outside the building where CAB100 is installed.

If CAB100 cannot be installed in an environment that meets the above criteria, use a

suitable surge protection device that has been installed following local regulations.

CAUTION!

wiring ins

CAUTION!

c

onnected in the same analog channel terminal block.

To avoid measurement errors, make sure that the analog outputs of the external

measur

CAB100 analog input channels are not surge protected. Therefore, note the

Before connecting any external measurement device to CAB100, refer to the

tructions in the device-specific user documentation.

Loop-powered and externally powered measurement devices cannot be

ement device are galvanically isolated.

Follow the steps below to connect an externally powered measurement device, for example

aisala Humidity and Temperature Transmitter Series HMT330 transmitter, to the CAB100B

V

analog terminal block.

For instructions on using the 24 VDC power block in CAB100B for powering measurement

devices, see Supplying power to external measurement device from CAB100B (page 32).

65

Page 68

CAB100 Installation Guide M212242EN-C

1. De-energize the cabinet: switch o mains po

wer and the circuit breaker located inside

the cabinet.

1 Circuit breaker

2. Disconnect the 24 VDC power cable connector of the analog terminal block from the

wer block.

po

3. Disconnect the other end of the 24 VDC power cable from the analog terminal block.

emove the 24 VDC power cable from the cabinet.

R

66

Page 69

1

2

3

1

2

Chapter 6 – Adding devices to CAB100B

4. Remove the red and blue plug-in bridges, as well as the yellow filler plugs fr

om the

CAB100B analog terminal block.

1 Filler plugs

2 Red bridge

3 Blue bridge

5. Move the data logger connector(s) to the top row of the analog terminal block.

Insert 3 pcs 5-pole plug-in bridges in the r

ow below the connector(s).

1 Data logger connectors

2 Red bridges

67

Page 70

1

2

CAB100 Installation Guide M212242EN-C

6. Remove the black wire (= common wire) from the push-in terminal of the data logger

onnector(s).

c

Reconnect the wire to the lower (negative) row of the analog terminal block.

Connectors #5, #10, and #15 are reserved for the common wires.

The 4 connectors to the left of each common wire are reserved for the analog output

es of your external measurement device.

wir

7. Strip approximately 10 mm (0.4 in) from the analog output wires of the external

measurement device.

8. Connect the positive wires in the upper row and the negative wires in the lower row of

the CAB100B analog terminal block.

The following figure shows CH1 … CH2 wires from 2 measurement devices connected.

1 CH1 … CH2 wires from device 1

2 CH1 … CH2 wires from device 2

68

Page 71

Chapter 6 – Adding devices to CAB100B

9. Connect the wires to the corresponding screw terminals inside the external

measur

See the wiring instructions in the device-specific user documentation of the external

measurement device.