Page 1

Quick Reference Guide

Field Check Adapter

26150GM

FIELD CHECK OF AMMONIA DETECTORS

The performance of the Vaisala AMMONICAP® Ammonia

Detector Series AMT100 can be checked on site with ammonia

gas. A field check ensures the detector is functioning and the

sensor responds to ammonia gas.

During the field check, the sensor is purged using a reference gas

with a known ammonia concentration. The ammonia gas causes

alarm signals (in the case of AMT100 Series, led lights) to turn

on, thus indicating that the detector is functioning.

Note that a field comparison can only check the performance of

the detector. For accurate calibration and adjustment, the probe

or the detector should be returned to Vaisala Service (see table

on the reverse side).

Field Check Equipment

To perform a field check, certified calibration gas, a pressure

regulator, a field check adapter, and flexible tubes (preferably

teflon) with inner diameters of 4 mm and 6 mm are required.

Reference gas, pressure regulators and the field check adapter

can be ordered from Vaisala with the following order codes:

• Ammonia reference gas 100ppm 210374

• Ammonia reference gas 300ppm 210375

• Pressure regulator 210376

• Field check adapter 26150GM

gas outlet pipe is 6 mm, and the diameter of the field check

adapter’s inlet is 4 mm.

4. Open the bottle valve and let the reference gas flow through

the adapter. The regulator’s preset flow rate is 0.5 l/min.

5. Let the gas flow for 2...5 minutes. (If you want to check the

exact reading or if the reference concentration is very close to

the alarm level, let the gas flow for at least 5 minutes to establish

a stabilized environment.)

6. The low level and high level leds are lit as the ammonia

concentration on the sensor exceeds the two alarm setpoint

levels. This indicates that the detector reacts to ammonia and that

the alarms are functioning.

7. On completion, close the bottle valve and detach the adapter

from the probe.

8. When the readout has dropped below the alarm levels, turn the

detector back to normal operation mode by pressing the

SERVICE MODE button.

– Tool for easy field checking

– Compatible with Vaisala AMMONICAP

Ammonia Detector Series AMT100 and

Vaisala CARBOCAP

®

Carbon Dioxide Probes

Series GM220

100 ppm reference gas is recommended for probes with a 0...100

ppm measuring range. For probes with a 0...1000 ppm measuring

range, the 300 ppm reference gas is recommended.

The gas bottles contain 34 liters of ammonia compressed into a

small and light (1 lb/0.44kg) container. The bottles are not

®

refillable. The pressure regulator, however, can be used again.

Field Check Instructions

1. Turn the detector to SERVICE MODE either by pressing the

button or via the serial line connection. When the detector is in

service mode, the operation light is blinking.

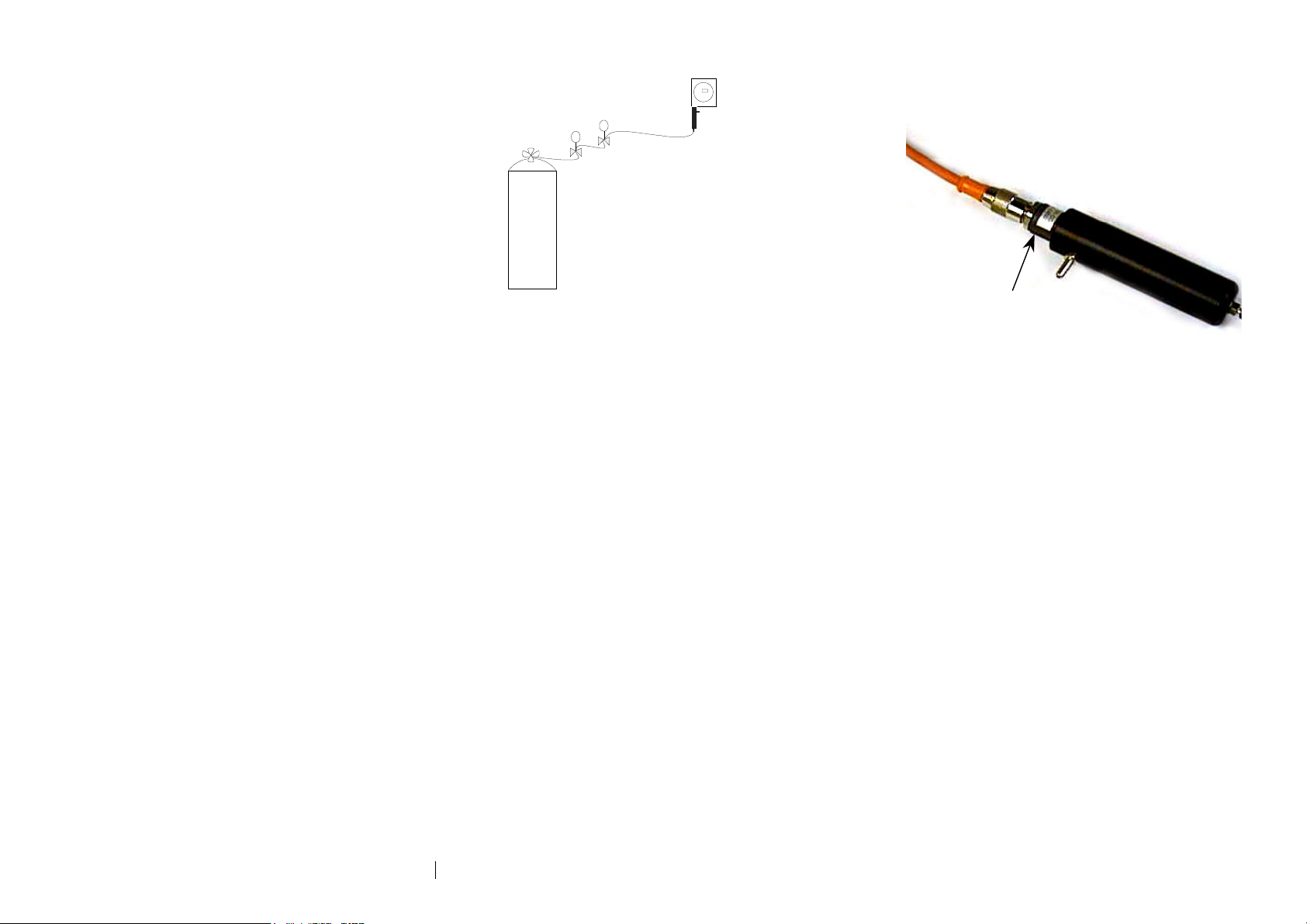

2. Place the field check adapter onto the probe.

3. Connect the reference gas bottle to the adapter inlet (at the

bottom of the adapter) with flexible tubing. The diameter of the

Field checking ammonia detector.

M210450en-A

Page 2

FIELD CHECK OF CARBON DIOXIDE

TRANSMITTERS

The field check adapter for Vaisala CARBOCAP¨ Carbon

Dioxide Probes Series GMP220 can be used as

- a chamber for feeding in reference gas in a field checking

of the probes

- a chamber for pump aspirated sampling system.

Note that a field comparison can only check the performance of

the transmitter. For accurate calibration and adjustment, the

probe or transmitter should be returned to Vaisala Service

Centre.

Field Check Equipment

• Accurate reference gas (Basically any concentration within

the measurement range will do. If available, a good choice

is one close to the normal measurement concentration.)

• A pressure regulator for reducing the pressure of the

calibration gas

• A flow meter to adjust the gas flow

• Tubing with 3mm (1/8") inner diameter (for example

neoprene tubing, part no. 18229. (Teflon tube NOT

recommended).

• The field check adapter (part no. 26150 GM)

Field Check Instructions for the GMT220-series

1. Attach the adapter to the probe of your GMT220 series

transmitter. The adapter fits both the probe sizes available

(GMP221 and GMP222) and can be attached to a probe on a

transmitter as well as one attached to a cable. Push the adapter

up the probe. Connect tubing to the bottom port of the adapter.

2. Connect the adapter with the tubing to the flow meter, the

pressure regulator, and further to the reference gas bottle. The

other port of the adapter is left open for gas outflow.

GMT220/ GMM220 series

transmitter

flow meter

pressure regulator

CO

2

3. Let the reference gas flow through the pressure regulator and

the flow meter to the adapter. The recommended flow rate is 0.6

l/min. Let the transmitter stabilize for 5 minutes.

4. Check the reading on the display, or if the transmitter has no

display, from the analog output. If the difference between the

reading and the reference gas concentration after pressure and

temperature correction is more than the accuracy and long-term

stability specifications allow, detach the probe and send it to

Vaisala for adjustment.

Note when installing the probe

- The probe should be pushed into the adapter deep enough, so

that none of the diffusion holes will be outside the adapter

chamber.

- Also the excess space inside the chamber should be

minimized by pushing the probe well inside the chamber

(this is especially important if using the field check adapter

with inadequate gas flows of below 0.4 l/min)

Important note for the GMP221 !

When using the shorter probe (GMP221) with the Field

Check Adapter, the adapter must be inserted on the probe

so that the o-ring inside the adapter is not on the sticker of

the probe (see Figure). If the adapter is placed on the

sticker, the seam between the probe and the adapter will

let the gas leak from the chamber.

O-ring inside the adapter shall

not be on the sticker of the

probe !

The Field Check Adapter and a GMP220 Series probe.

VAISALA SERVICE CENTERS

NORTH AMERICAN SERVICE CENTER

Vaisala Inc., 100 Commerce Way, Woburn,

MA 01801-1068, USA.

Phone: +1 781 933 4500, Fax +1 781 933 8029

Email: us-customersupport@vaisala.com

EUROPEAN SERVICE CENTER

Vaisala Instruments Service, Vanha Nurmijärventie 21

FIN-01670 Vantaa, FINLAND.

Phone: +358 9 8949 2758, Fax +358 9 8949 2295

E-mail: instruments.service@vaisala.com

ASIAN SERVICE CENTER

Vaisala KK, 42 Kagurazaka 6-Chome, Shinjuku-Ku,

Tokyo 162-0825, JAPAN.

Phone: +81 3 3266 9611, Fax +81 3 3266 9610

E-mail: aftersales.asia@vaisala.com

www.vaisala.com

www.vaisala.com

Loading...

Loading...