Page 1

Instructions

for Installation

and Servicing

Vaillant

Combined appliances

for

heating

and

This aooliance shall

Codes of

CORGI

These

the installation

Practice by British Gas or by an

member)

instructions should be left near the

be installed in

is completed.

accordance

authorized

gas

domestic

VCW-sine 18 T3 W

with the relevant

installer

meter when

hot water

VCW 2Ol1 T3 W

GC-No. 47 04403

VCW 2511 T3

GC-No. 47

GC-No.

Domestic hot water

04405

47

O44 01

Central

W

heating

Page 2

Contents

lntroduction

1.

2.

Construction

J.

General

4.

lnstallation

Water

Commissioning

Assembling

7.

Servicing

8.

q

Foult

10.

Short

11.

Technical

2 Construction

of aPPliance

reouirements

boiler

of

circulation

combi

of

finding

ports

list of

data

system

and

heater

testing

of

P4e The

2 natural draught

2

4

^l

;\

;;

,;

46

61

64 system

ApPliance

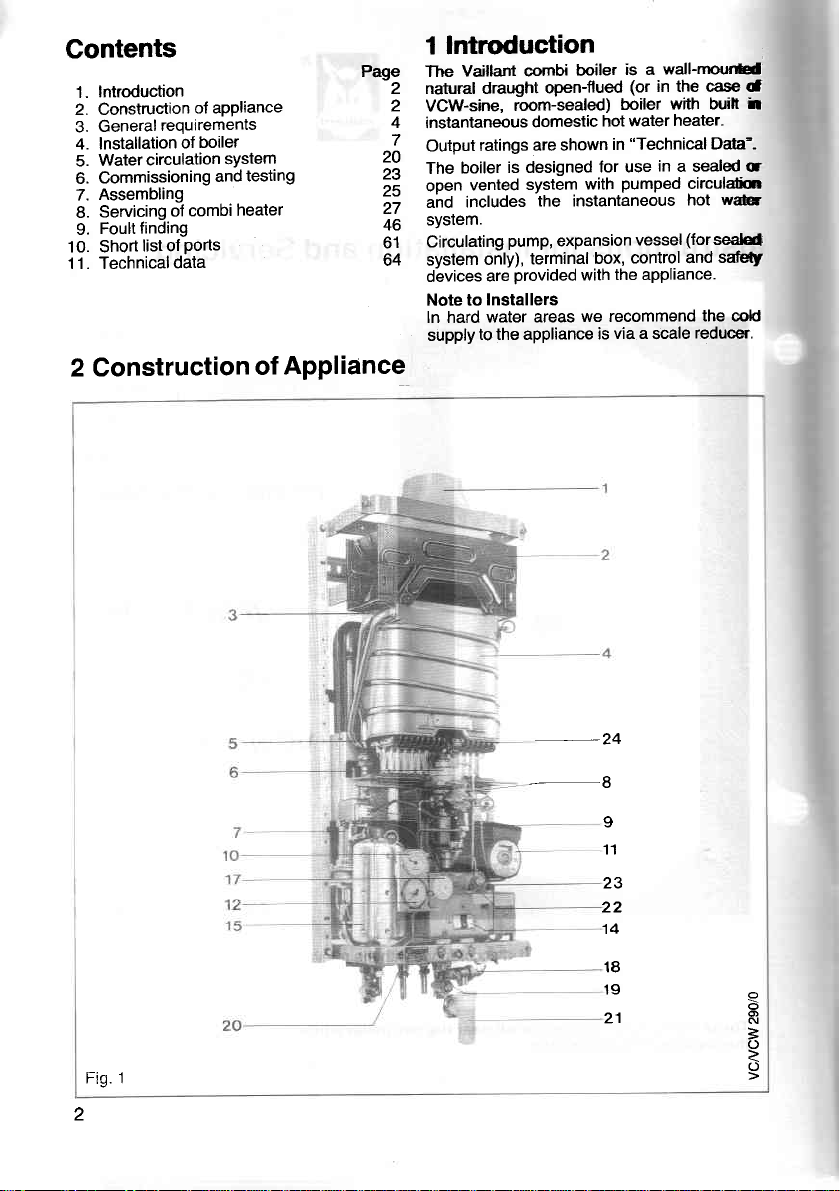

1 lntrcduction

Vaillant csnbi

VCW-sine,

instantaneous

Output

The

open

ahd

sYSIem.

Circulating

devices

Note to

ln hard

supply

room-sealed)

ratings are shown

is designed

boiler

vented

includes

pump,

only),

provided

are

Installers

water areas

to the appliance

boiler

open-flued

domestic

system

the instantaneous

expansion

terminal

wall-rnqrrH

is a

(or

in the case d

with buifr

boiler

hot water

in

for use

with

box,

with

we recommend

via a

is

heater,

"Technical

in

a sealed c

pumped

(forseald

vessel

control and

the appliance.

scale

Dda-.

circuldin

w&

hot

sdetf

the d

reducer.

it

2

trin I

-24

9

11

23

22

14

18

19

21

o

N

3

o

Page 3

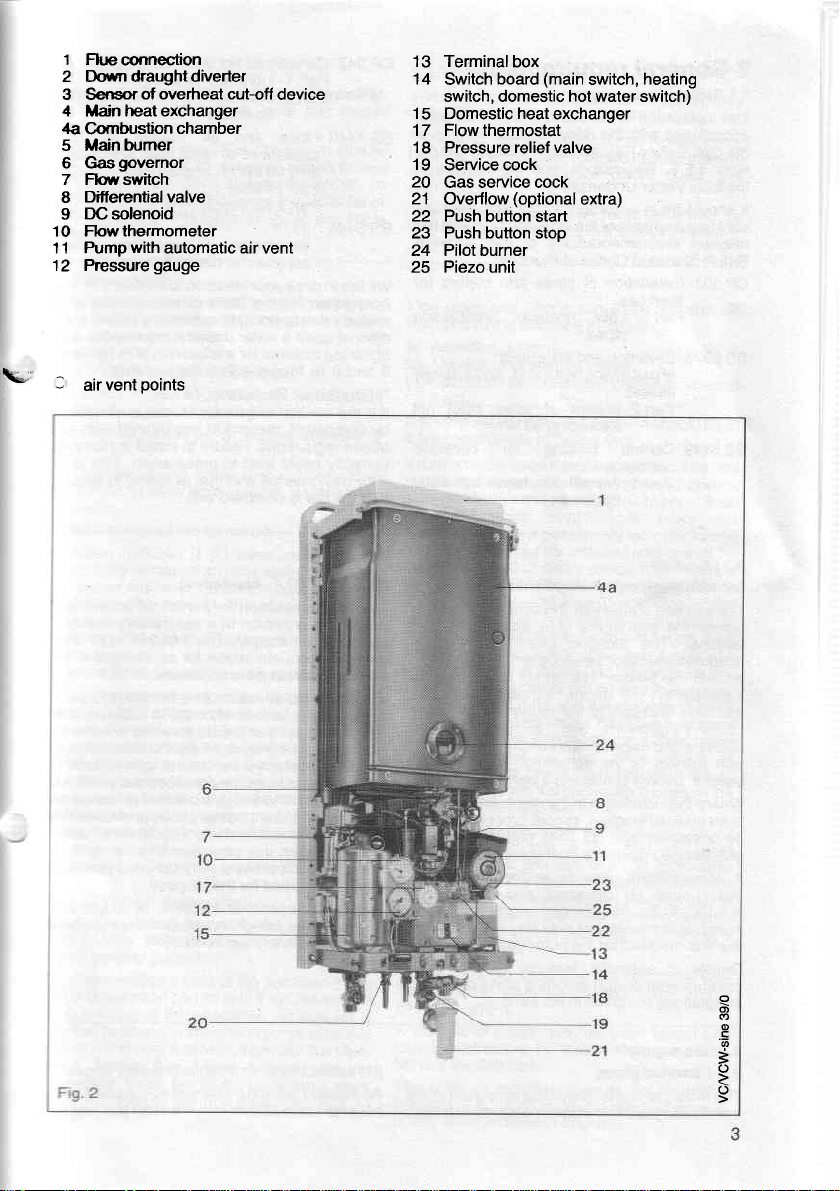

l Fkrcorinection

2 Down draught diverter

3 Sensorof

4 Mainheatexchanger

4a

Combustion

Main hrmer

5

6 Gasgovernor

7 Flowswitch

Differential valve

8

DC

9

10 Fbwthermometer

11 Pump

12 Pressuregauge

\a-

l

vent

air

overheat cut-off

solenoid

with

automatic air vent

points

chamber

device

Terminal

13

14

Switch

switch, domestic hot water switch)

Domestic heat

15

Flowthermostat

17

'18

Pressure relief valve

19

Service cock

20

Gas service cock

Overflow

21

Push

22

Push button stop

23

Pilot burner

24

Piezo unit

25

box

(main

board

exchanger

(optional

button start

switch,

extra)

heating

o

o

'6

=

o

Page 4

General

3

Related

3.1

installation

The

accordance

the Gas

tions,

the

It

vant

relevani

British

CP 331

BS 5376

BS

3.2

3.2.1

The

oermit

ierminal.

adequate

around

electrical

with

boiler

Where

be

give

A

Safety

l.E.E.

Water Undertaking.

local

be

should

requirements

recommendations

Standard

Installation

lown

Part

Selection

of

gases).

Part

Central

5449

oremrses.

Part

Location

Vcwqjle

location

the

The

space

the

installed

attention

l.E.E.

in an

boiler

specifically

board

that

Details

compartment

instdllations

in any

is cjrawn

Regulations

provisions

respect

in a room

installation

the

unusual

necessary

detailed

compartment

must

iompartment

or

modified

it is

of

requirements

documents

the combi

of

with the

Begulations.),

Regulations,

in accordance

the

of

Codes

of

gas,

Low

3:

pipes.

and

gas

space

2 Boilers

exceeding

heating

1 Forced

syslems.

(8.F. APP|iance)

dhosen

provisions

location

for servicing

The combi

heater.

room,

to

of

the

to

containing

location,

BS

and

guidance on

used

be designed

purpose. An existing

this

for

the

for

essential

design

given

are

boiler

relevant

for

installation

including

requirements

and

also

local authority

of

Practice:

of

pipes

Pressure

installation

heating

rated

of

60

circulation

the combi

satisfactory

of a

must also

and air

although

the requirements

in Scotland,

and,

the building

bath or

a

combi boilerwill

of the

special

5546 and

this aspect.

to enclose

and constructed

may be

purpose.

features

in BS 5376

must be

regula-

building

the byelaws

with any

the

and

(1

. and

kW.

for domestic

boiler

of the combi

procedures

used

of

airing

rele-

the

and

following

meters

installation

2. family

not

inPut

hot water

must

boiler

flue

provide

circulation

may be

particular

of

regulations,

shower.

may

BS 5376

the combi

cup-

provided

cupboardi

cupboard

: 2.

cP

in

of

BS 5440

ot

BS 5446:

for

We

connection

sealed

ditional

obtaining

3

.)

It is

by competent

above

correctly

your

ihat the

3.2.2

The

permit

bdequate

provide

circulation

The combi

the

containing

the

recommended

be

the combi

special

be

5'326

this

: 2

combi

specifically

bbard

that

Details

compartment

installations

342 Centralized

Part

Part 2

hot water

1 Individual

Buildings

dwellings.

Flues

appliances

60

ding

Part 1

kW

Flues

of

(1.

rated

and

air suPPlY

and

Part 2 Air suPPlY.

1979

Installation

supplies

like to drawyourattention

primary

and

8

Safety

Gas

the law

regulations.

own

VCW

location

fitted

:2 and

aspect.

boiler

or iompartment

it is modified

the

for

circuit

water undertaking

upon a

consentfora

(1)

from

Regulation,

that all

persons

lead

bould

interest

law is complied

(O.F.

chosen

provision

the

air supply.

adequate

around

boiler

bath or

a

that

in a bedroom.

boiler

procedures

BS 5546

A compartment

must

this

for

of essential

design

are

of

for domestic

filling or

from

relaxation

the Secretary

gas

appliances

in accordance

Failure

prosecution. This

to

that of safety

and

with.

APPliance)

for the combi

of a satisfactory

The location

space

the appliance.

not be installed

must

shower.

the combi

Where

in

be

will

may be

give

be designed

purpose. An existing op-

may be used

purpose.

for the

features

including

given

in BS

suPPlY

dwellings,

than

other

for

input not

familY

2.

gas

hot

PurPoses

tothefactthd

replenishing ol

a supply

1972:

to

for servicing

an

detailed

pipe

seeking aa

otits

of State.

are

install appliar a

to erisG

boiler

must fu

In addition,

should

boiler

installationd

the

unusual

necessary

guidanceot

to enclosete

used

and construec

of cupboard

cupboad

airing

: 2.

5376

is

can

Byeh

ins{d

with t:

b L

nrrsl

flue ad

ard *

rqq

in a

it

rd

posilb\

and BS

provided

a

,

b

supply

Gas

3.3

3.3.1 Service

The

installation

planning

gas

local

4

pipes

region should

in order

stage

be consulted

at the

to establish

availability

the

An existing

prior

out

consultation

an adequate

of

service

pipe

with the

must

gas.

of

supply

not be used

gas

local

regiorl

wit>

Page 5

Meters

3.3.2

gas

A

meter is

connected

gas

local

the

contractor.

An

existing

that it is capable of

2.95 ms/h

(or

3.38

2.47 melh

installed.

Flue

3.4

Detailed

in BS

5440

give general

to

VCW-sine

3.4.1

\=i=

The

boiler

terminal is

Termination should be on a clear expanse

wall;

the terminal being

600 mm

projecilon.

Do not install the terminal:

Within

a)

from the

vent,

b) Within

ground

Within

c)

the terminal.

lmmediately

d)

Where the lowest

than 2 m

balcony, flat roof

access,

guard

of durable

guard

is available as an optional extra with

combi boiler. The air inleVproducts

and the terminal of the boiler must not

than 50

Detailed recommendations

combustible

VCW

3.4.2

Detailed recommendations for fluing

in BS 5440 : 1 . The following notes

give general guidance.

to

The

cross sectional

combi boiler must be not less

the flue outlet of the appliance. An

supplied to allow the fitting of 125 mm

pipe

or 125 mm light

When fitting flue

connector

disconnection of

16).

fig.

region

meter should be checked to

(106

(122

mslh

(89

CFH)

system

recommendations for fluing

: 1. Thefollowing notes

guidance.

(B.F.

must be installed so that the flue

exposed

(2

ft.) awayfrom acorner, a recessora

mm

300

bottom of an openable window,

or any other

mm

300

level.

600 mm

beneath eaves or a balcony.

(6,6

ft.) above the level

mm

material

(O.F.

must

or

material.

(2

in.)

Appliance)

the terminal must

to the

a local

or

passing

CFH) before the VCW

CFH) before

the VCW-sine 18)

before

Appliance)

to the external

preferably

(1

ft.) measured

ventilation

(1

ft.)

above adjacent

(2

ft.) of any

part

the termlnal

of

place

to which

protected

by

A terminal

to combustible material.

on

given

are

area of

asbestos cement

pipes

fitted

be

the flue

in BS 5440 : 1.

the flue

than the

a split

to ensure

pipe (see page

pipe

service

gas

region

ensure

an additional

the VCW

not less

opening.

surface facing

of any

Drotection

are

intended

are

air.

vertically

is less

ground,

people

protective

outlet duct

be closer

are

intended

are

fitted to

area of

adapter is

steel flue

flue

socket

25

given

than

have

by

the

given

the

pipe.

easy

13

lnstallation

3.3.3

by

Installation

with CP

must

a smaller

20

connection.

or

The

is

soundness

Flue

from

a) Asbestos cement,

b) Aluminium

c) Cast-iron

lf double-walled flue

of

a type acceptable to British

lf

that is

acid-resistant

with

acceptable if the

540

materials in

air

connection

chimney

or lined with a non-porous

material it should be lined with

flexible flue liner or any

type acceptable to British

meter

in the technical

mustbe kepttoaminimum. lf

to be connected

a

draught diveder a flue

constructed from

above should

draught diverter and

Before

inserting a liner into,

of

previously

swept clean of any soot

register

fitted

connecting the

liner into, the flue.

The

the relevant

5440:1, table 4.

A terminal

found

fitted

The

600

or any other ventilation

331

Pipework

be of a adequate

complete installation

pipes

one of the following materials:

lined.

a chimney

composed of or lined with a nonporous

salt-glazed earthenware

: 1 .) A flue

is to

of the liner must

connecting the combi

plate,

in the flue, it must

flue should terminate

satisfactory by British

the flue

at

point

(2

mm

pipes

pipes

should

:3.

from the meter

than

size

as described in the

fittings

and

or stainless steel,

acid-resistant

is

used it

material.

pipes

pipe

a) to c) above

to lined

be used which is not composed

data and the number

directly to the combi boiler

one of the materials in

form

the connection

used, the flue must

restrictor

combi boiler to, or inserting

recommendations

of a type

outlet.

of termination must

ft.)

of an openable window,

fitted

be

in accordance

to the

size. Do not

the

should be constructed

pipe

is

preferably

comply with BS 65 and

constructed from

should

chimneys. Where

other

Gas.

not be less than

flue

liner.

a flue that has been

and

plate,

that has

opening.

combi

use

combi boiler

must

be tested

above

vitreous

used it should be of

Gas.

should be one

(Chimneys

pipes

one of the

form the initial

acid-resistant

a stainless steel

liner

that is of a

The internal

thefluelinerisnot

pipe

which is

between

boiler

be thoroughly

loose material. lf

damper etc.

be removed before

in

accordance with

given

been tested and

Gas

should be

not be within

boiler

pipes

gas

Code.

enamel

lined

dia-

shown

joints

of

to

a)

the

to,

in BS

air vent

of

for

are

a

of

c)

or

a

is

a

c

Page 6

Air supPlY

3.5

Detailed

given in

intended

3.5.1

The

located

vent

an adiacent

itself

i-n" same

3.5.2

Where

cuoboard

are

case

combustion

compaftment

recommendations

BS 5440

give general

to

Room

or

room

must

be

must

'have

sizd

Cupboard

combi

the

or

required

open

6f

of

Pos.

vents

air

High

Level

LOW

Level

The

2.

:

guidance.

internal

or

space

have

either

room

permanent

a

compartment,

(for

and

at

space

in which

permanent air

a

to the

direct

internal

or

to

direct

compartment

or

is to be

boiler

cooling

appliances

flued

flue dilution)

high and

vcw20/1

vcw25/1

VCW-sine

vcw20/1

vcw25i1

VCW-sine

supply

for air

following

air

the

permanent air

purposes and

low level'

air supply

the

outside

space

vent of

outside

installed

in the

notes

boiler

vent'

which

air supply

also

cupboard

These air

This

or

air

must

least

at

The

air.

vents

in

Airfrom

internal

cmz

280

320

235

560

640

,235

minimum

vent(s)

are

maximum

are

is

to

The balanced

does

have a oermanent

vents

internal

or

in a

the

for

or

minimum

The

vents

air

compartment

are ielated

the unit.

room

space

,

{42)

(50)

(36,5)

(84)

(1

(36,5)

effective

is specified

rated

Appliance

vcw20/1

vcw25/1

require

not

either

must

space

etfective

required

are specified

to the

vent areas

Air

or

(inr)

00)

area

below

input

heat

combi

flued

room

the

vent.

air

communicate

direct

or be

areas

in the

niaximum

Airdirectfrom

cm2

140

160

120

280

320

120

permanent

of

is

and

the unit.

of

cmz

108

130

boiler,

internal

or

to outside

the

of

below

rated

outside

I

to

related

in.2

16

20

VCW-sine,

space

the

with

air.

permanent

cupboard

(Tab. 1)

input

heat

(inr)

(21)

(25)

(18,5)

(42)

(50)

(18,5)

air

the

to

room

or

and

of

Tab.1

Both

Note:

the

both

be

air.

Effect

3.5.3

is anv

lf there

oremises

iir

ipittag"

3.6

Detailed

circulation

5449

heatinq

notes

not forming

should

and

6

there

area

inlet

of

Water

(Jor

:1

svstems)

ire

belnsulated

possible

air

same

on

an

of

tvpe

i6

from

products from

the

circulation

recommendations

system

small

particular importance.

of

pbrt

freezing,

room

the

extract

of

possibility

the

are

bore

and

the

ot

internal

or

wall

same

fan

extract

outside

system

given in BS

and

342-

CP

useful

help

to

particularly

communicate

must

vents

or

space

the outside

to

fitted

fan

if adequate

that

provided

is not

open

the

the

for

5376

bore

micro

prevent heat

following

the

Pipework

heating

where

surface

with

must

the

in

flued

water

BS

:2'

central

loss

pipes

cupboard

Where

communichte

room

the

permanent air

combi

is

fan

occur

must

taken.

are

underfloor

Draininq

oosition-s

svstem

water

1/2 in.

2879.

BS

internal

or

boilers

in operation.

a spiilage

be carried

through

run

sPaces.

taps

which

including

system.

nominal

or

the

with

vent(s)

could

flue

test

out

roof

must

permit

the combi

Dlaining

size

compartment

or

room

must

space

specified

as

when

occur

such

Where

detailed

as

and

be

and

necessary

any

spaces

located

draining

the

heater

should

taps

in accordance

be

vents

air

internal

and

space

have

itself

in 3.5.1.

extract

the

installations

BS 5440.:

in

actlon

ventilated

in accessible

whole

the

of

the

and

least

at

be

with

a

1

hot

Page 7

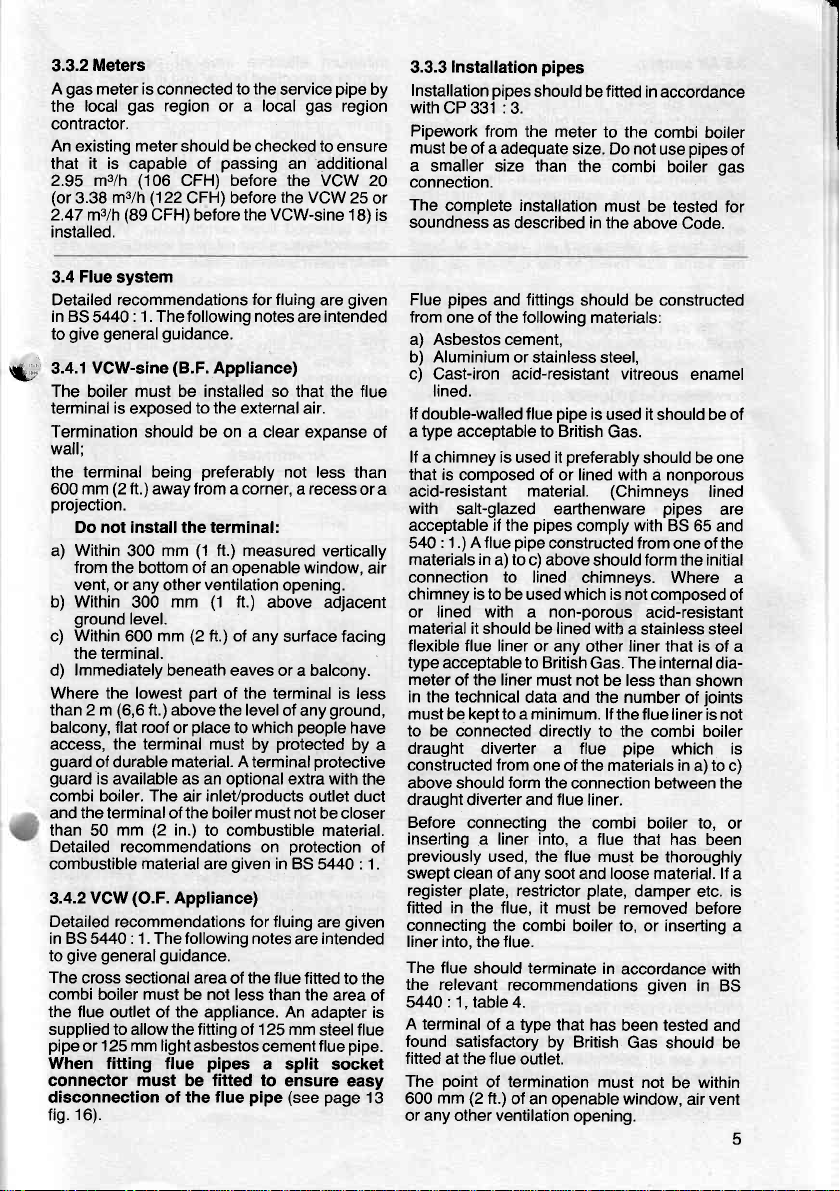

Electrical supply

3.7

Wiring

The combi boiler

external

installed in accordance

be

Regulations

apply.

4 lnstallation

4.1 General

The combi

flat area of

vertical

measure as shown

This

area does

installation and servicing.

fitted on a

be

should

material.

\-

In addition. a minimum clearance of

to the combi boiler

and any

local regulations which

is

supplied

of

is to be wall-mounted and a

boiler

wall is required which must

on template-

not include

wall

of combustible

protected

by a sheet of fireproof

with the l.E.E.

for 22O/24O V,

boiler

clearance

lf the

appliance

material,

must

the wall

400

50 Hz. Fuse rating is

The

combi boiler has to

the mains

terminal

For wiring

(16

appliance to enable the

servrceo.

Service clearance of 150 mm

side

For the

for

and

is

the flue. The

2

cartons, one containing

the

carton containing the terminal/duct

delivered with the balanced flued appliance.

mm

electricity supply

box.

instructions

in.) must

is reouired.

open

25/1

an additional clearance is required for

installation

o

o

c

o6

>o-

FO.

(U

3 A.

be connected

paragraph

see

be available at the front of the

flue

combi boiler is supplied in

accessories. An additional

combi boiler to be

type appliances VCW 2011

the

vcw20/1 vcw25/1

using the internal

direct to

4.7.

(6

inches)

either

boiler, the other

assembly

is

F

,l

E-

Fig.3

All

dimensions

in mm

A 1095 mm 1161 mm

B

D

r

1014mm 1080 mm

K

weight 59 kg 60 kg

Minimum distance

)

remove expansion vessel.

130mm

125

mm with adaoter

15mm 22mm

'l00mm

Electrical

connection

107mm

mains

required to

Installation may require

another distance.

7

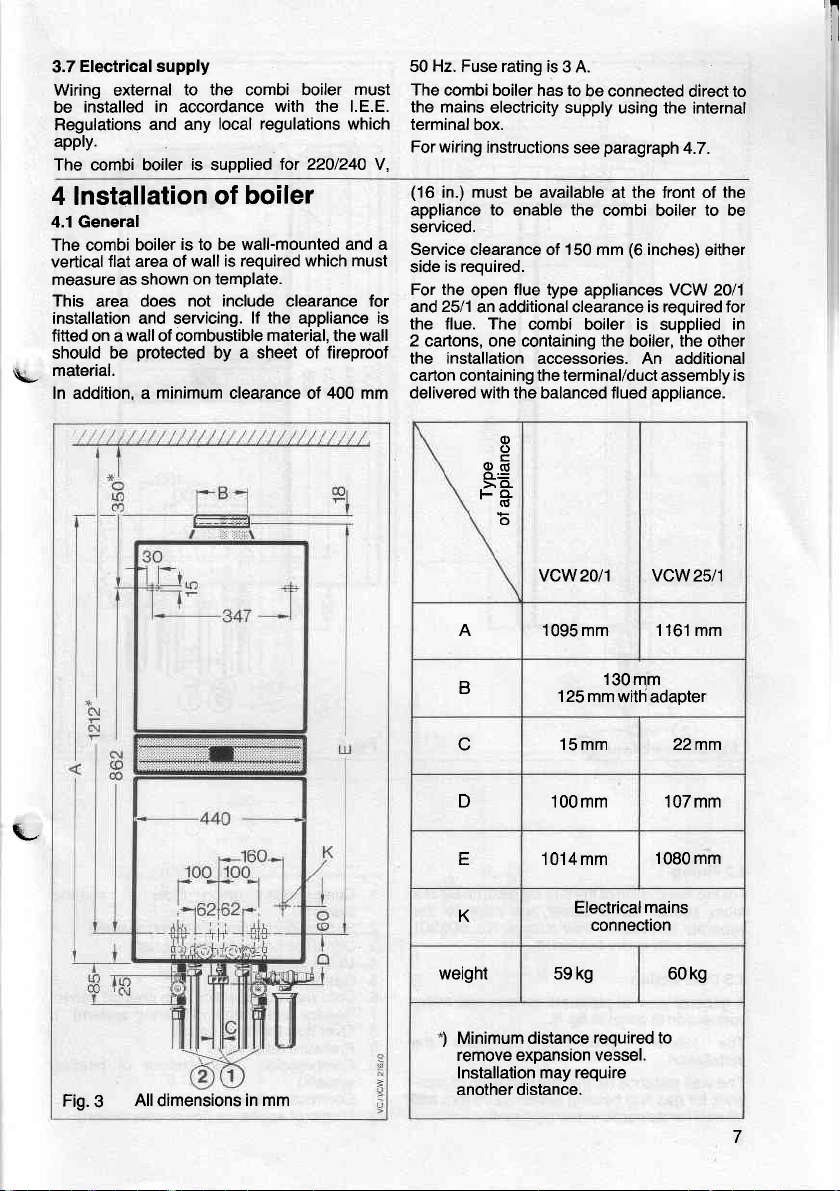

Page 8

Fluing

4.2

installation

the

For

room

.!-o"t"i"

iniluded

-in.t"llation

sealed

with

4.3 Connection

A oeneral

coinection

The

view

is

following

installation.

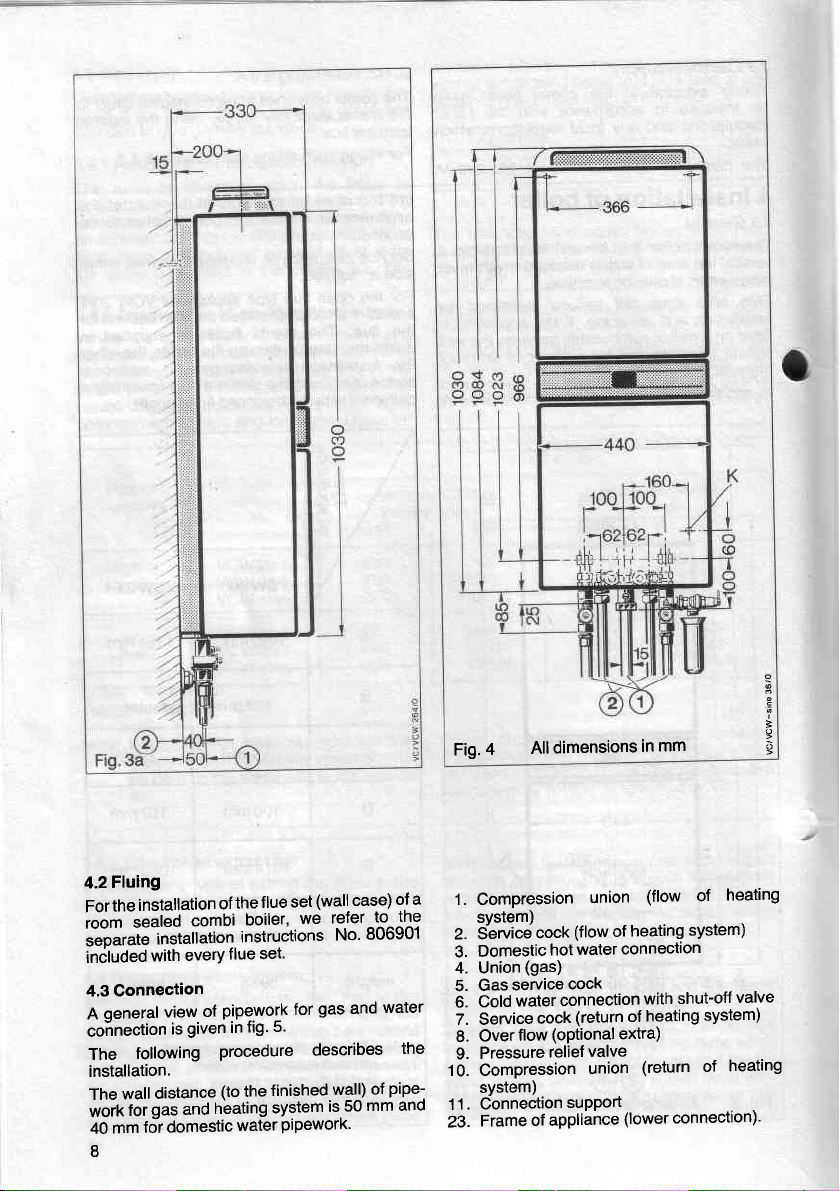

The

woit<

40

gas

toi

for domestic

mm

and

distance

wall

8

of

combi

every

pipework

of

given

procedure

(to

hbating

flue

the

boiler,

nstructions

i

flue set.

5.

fig.

in

finished

the

system

water

PiPework'

(wall

set

reter-to

we

gas

for

describes

wall)

is.50

case)

No'

and

ot a

rne

806901

water

the

pipe-

of

mm and

Fig.4

All dimensions

1. Compression

svstem)

z. S-ervice

3.

4. Union

5.

6.

7. Service

8.

9.

cock

Domestic

(gas)

service

Gas

water

Cold

cock

flow

Over

Pressure

hot

cock

connection

(optional

relief

10. Compression

system)

Connection

11.

Frame

23.

support

of appliance

union

(flow

of

water

(return

valve

union

mm

in

(flow

system)

heating

connection

shut-off

with

heating

of

extra)

(return of

(lower

connection)'

heating

of

valve

system)

heating

!

;

t

Page 9

,,4

I

Page 10

lnstallation

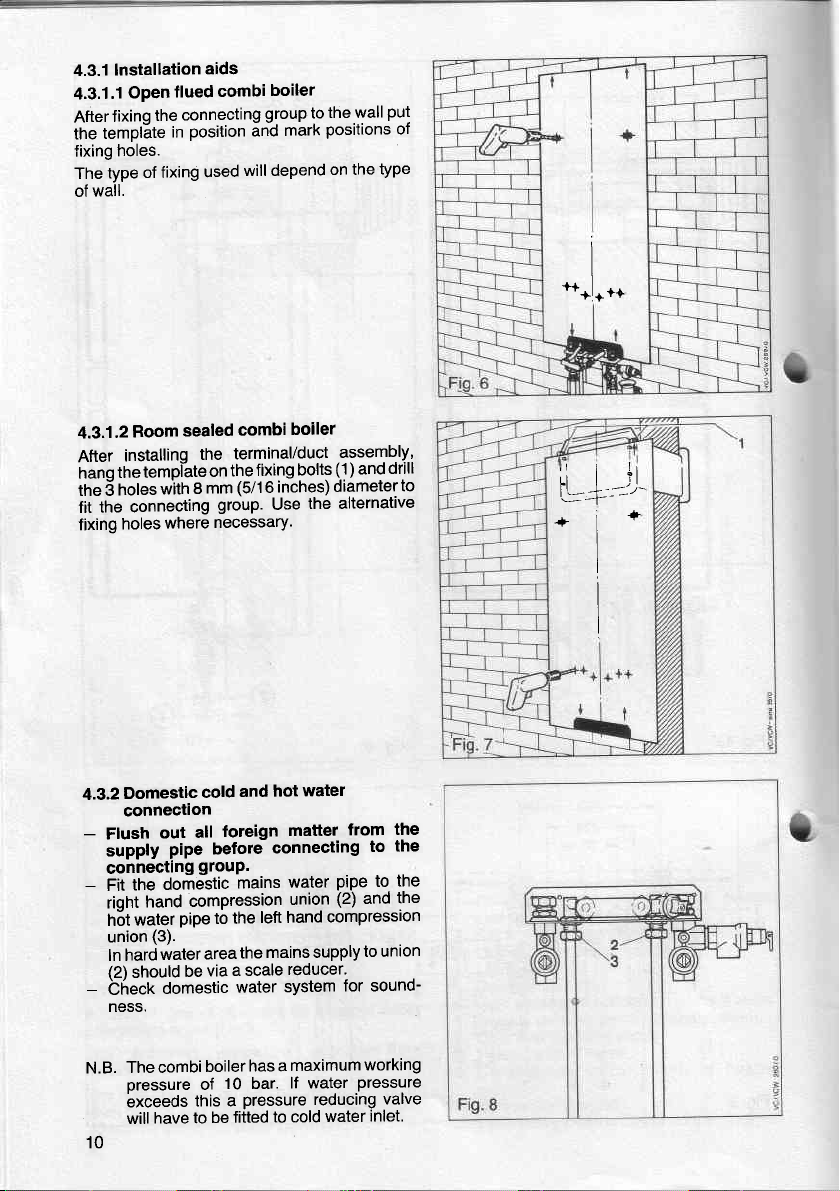

4.3.1

4.3.1.1

fixing

After

template

the

holes.

fixing

type

The

wall.

of

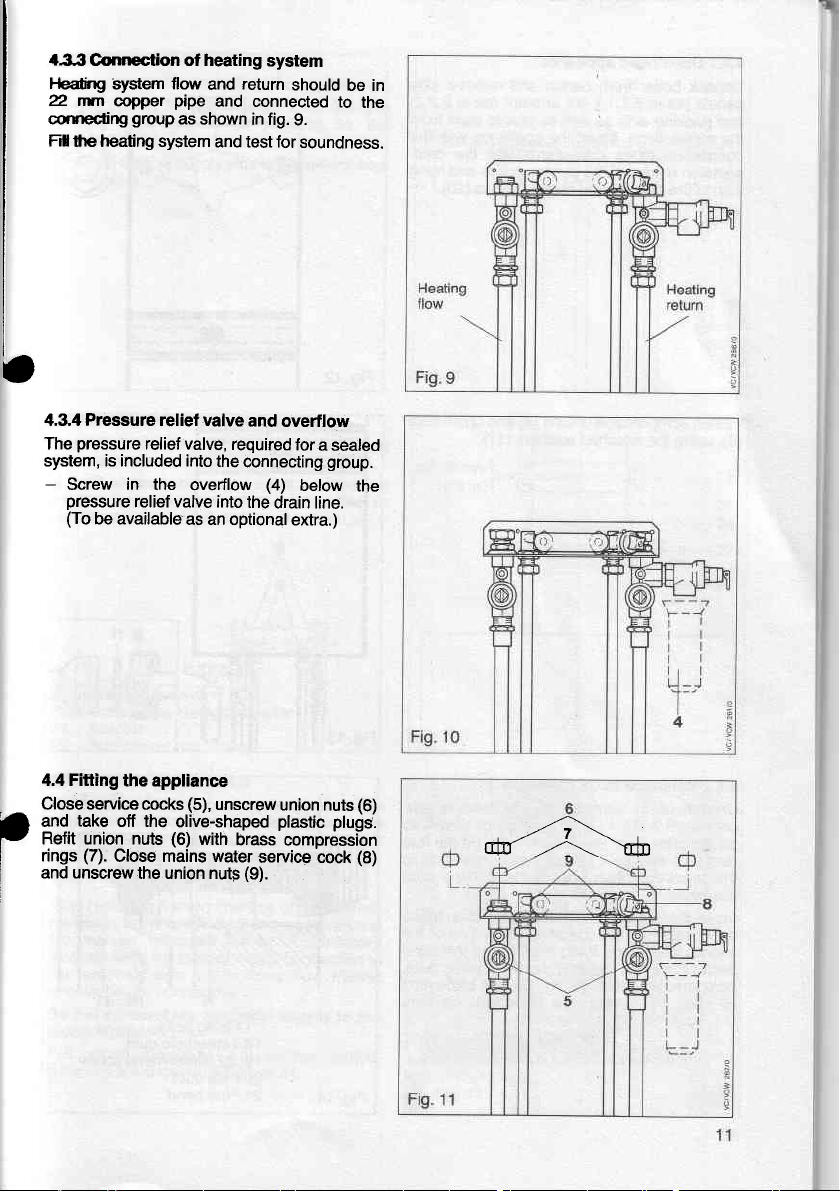

4.3.1.2

After

the

hano

holes

the 5

fit the

holes

fixing

flued

Open

connecting

the

position

in

used

of fixing

sealed

Room

installinq

connecting

the

tempi-ate

8

with

where

aids

boiler

combi

group to

ancl

will depend

combi

terminal/duct

fixing

the

on

(5/16

group.

inches)

Use

mm

necessary.

thewall

posltlons

mark

on the

boiler

assembly,

(1

bolts

and

)

diameterto

the alternative

put

oI

type

drill

I

I

**!**o

rl

I ll

fl | )l

+1-

I

Domestic

4.3.2

connection

-

Flush

supply

connecting

-

the

Fit

riqht

water

h5t

union

ln hard

(2)

should

-

bhect

ness.

Thecombi

N.B.

oressure

bxceeds

will

10

cold

all

out

pipe

grouP.

domestic

compression

hand

pipe

(3).

area

water

be

domestic

of

this a

have to

watel

hot

and

loreign

before

to

via

boilerhas

10 bar.

be

matter

connecting

water

mains

union

left hand

the

mains supply

the

reducer'

a scale

system

water

amaximumworking

lf water

pressure reducing

to cold

fitted

the

from

the

to

pipe

(2)

compression

water

the

to

the

and

to union

for sound-

pressure

valve

inlet.

Page 11

I

I

I

I

I

t

{33

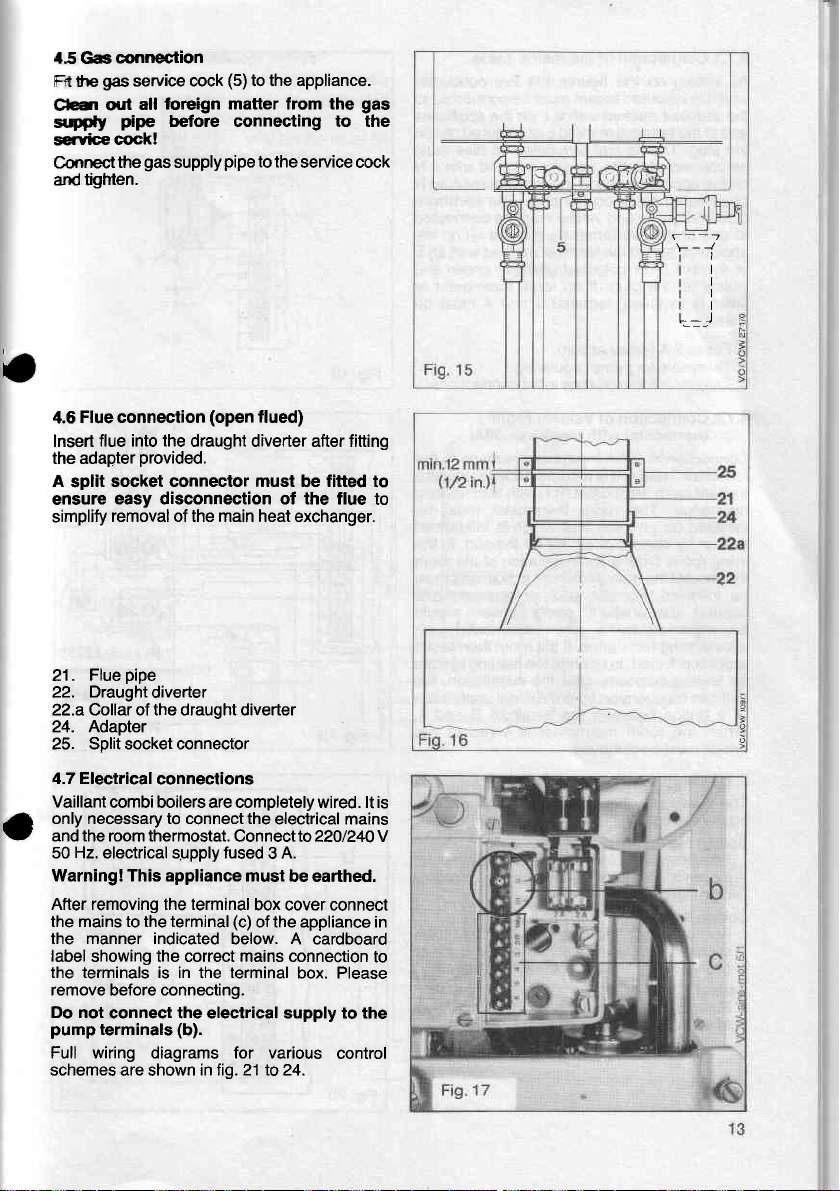

Gonnection of heating

Fledirtg

2. rrtn

cqrtecting

Ftl

syslem flow

copper

group

lhe heating system

return

and

pipe

and connected

as

shown in fig.

and test for

system

should

9.

soundness.

be in

to

the

4.3.4 Pressure relief valve

pressure

The

system, is included into

-

Screw

pressure

(To

4.4 Fitting

Close service cocks

take

and

Refit union nuts

(7).

rings

I

and unscrew

relief

in

relief valve into

be availableas

the appliance

off the

Close mains water

the union nutF

valve, required

the

the

overflow

an optional

(5),

unscrew

olive-shaped

(6)

with

and overflow

for

a sealed

connecting

(4)

the

brass'compr6ssi-on

service

(9).

group.

below

drain line.

extra.)

union nuts

plastic

plugS.

cock

the

(6)

(8)

*-A-6

Page 12

flued

Open

4.4.1

from

pait

boiler

ing

unions

bolts(1)

the

8.1'1.),

in

aids

tubes

Unpack

oarieis las

inO

the ionneciions.

connection

oiession

it on to

aPPliance

carton

lint

well

as

the

Insert

downwards

service

the

of

fasten

and

remove

and

arrestor

(as in 8'2'2)

plastic caps.from

as

appliance

into

cocks

screws

the

and

wltn

(10)'

side

tne

comhang

compression

Fasten

ig),

4.4.2

Unoack

Janels

blastic

buct

the t;le6copic

assemblY.

Insert

downward

service

bolts

compression

is,

(11,fig.13).

using

Balanced

(as

baps

(20)

the

cocks

the

of

iig.

thb

boiler

in 8.1.1

irtitn

appliance

iirio

13)

unions

attached

lued

f

carton

from

.) and

the

from

2 sheet

tne

(16)

duct

with

compression

the

hang

and

case

wall

unions

using

(6,

(6)

and

(1

washers

aPPliance

packing

connections.

(1),

fig.

the

1)'

remove

and

aids

metal screws

terminal/duct

the

of

connection

the

unions

to the

on

it

14.

fig.

13) and

attached

union

wellas

as

Fit the

(22) to

threaded

Fasten

union

washers

nuts

side

flue

tubes

the

of

nuts,

nuts

Fig.

14

1 Fixing

Telescopic

16

22 Sheet

1 9,

Flue

20

Flue

2'l

bolts

duct

bend

20

duct

metal

21

screw

12

Page 13

45 Gcconnection

Frt the

Cleil

s.Dpty

service

Connect

and tighten.

a

Flue connection

4.6

Insert flue

the adapter

A

split

ensure

simplify

gas

service cock

foreign matter from the

all

out

pipe

cock!

gas

the

into the

provided.

socket connector must be fitted

easy disconnection of the flue

removal of the main heat exchanger.

(5)

to the appliance.

before connecting to the

pipe

(open

to the

flued)

service cock

supply

draught diverter after fitting

gas

to

F--i

tl

tl

tl

ri

to

22.

22.aCollar otthe draught diverter

24. Adapter

25. Splitsocketconnector

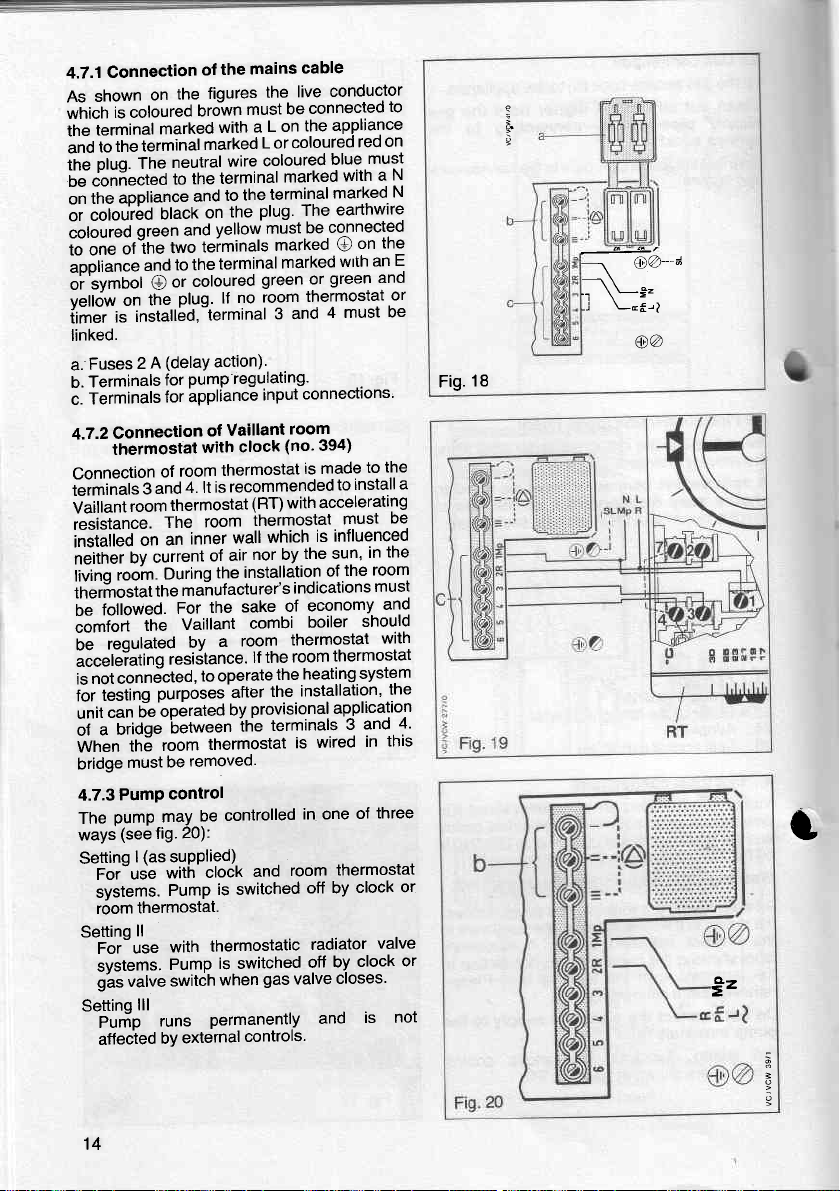

4.7 Electrical

Vaillant

only necessary to connect the

a

and the room thermostat.

50 Hz. electrical sgpply fused 3 A.

Warning!This appliance must

After removing the terminal

the mains to the terminal

the manner indicated

label

showing the correct mains connection

the terminals is in

remove before connecting.

Do not

pump

Full wiring diagrams for various

schemes are shown

diverter

connections

combi boilers are completelywired. lt is

the

connect the electrical supply to the

terminals

(b).

intig.21 Io 24.

pipe

. Flue

21

Draught

electrical mains

Connectto220/240v

be earthed.

box cover connect

(c)

of the appliance in

below. A cardboard

terminal

box. Please

to

control

Page 14

Connection

4.7.1

shown

As

is coloured

*nicn

terminal

the

inO

the Dluq.

6e

on tne

oi

coloured

i" rn"

"opiiin""

oi svmbol O

vellow

iimer

linked.

a.

b.

i-

4.7.2

--

Connection

terminiri

Vaillant

resistance.

inJiiiteo

neiiner

livinq

therftostat

be

iotfurt

be

icceleiating

is

ior

,nit "an

oi

Wfren

bridge

4.7.3

The

ways

Settinq

Setting

tetminal

tne

to

The

ioni"ct"O

aoptiance

coioureO

qreen

otine

and

on

installbd,-terminal

is

2

Fuses

Terminals

Terminals

Connection

thermostat

g

room

on

Ov

rooin.

followed.

the

requlated

not connected,

i"iting

bi

OriOge

a

tfrE

must

PumP

pump

(see

(as

I

For-use

systems.

thermostat.

room

ll

For"use

svstems.

valve

o'as

ttl

seltting

Purip

affected

the

of

figures

the

on

brown

marked

the

A

anO

current

the

purposes'after

fig.

runs

with

marked

wire

neutral

terminal

the

to

black

two

to the

or

plug.

(delay

for

for hppliance

room

of

thermostat

The

an

During

For

Vaillant

resiitance.

op6rated

between

room

be

control

may

suPPlied)

with

Pump

with

Pump

switih

bY

the

to

and

the

on

yellow

and

teiminals

terminal

coloured

no

lf

action).

pump regulating'

Vaillant

of

clock

with

thermostat

recommended

is

4. lt

room

wall

inner

air

of

the

manufacturer's

sake

the

room

a

by

to operate

by

ihe

thermostat

removed.

controlled

be

20):

clock

is switched

thermostatic

is switched

when

Permanently

external

cable

mains

conductor

live

the

connected

be

must

the

L on

a

L or coloured

coloured

marked

terminal

plug' The

be

must

marked

marked

green or

thermostat

room

input

(RT) with

thermostat

which

nor by

installation

combi

lf the

provisional application

and

gas

controls.

4 must

and

3

connections'

room

(no'

394)

is made

accelerating

is

the sun,

of

indications

economy

of

boiler

thermostat

room

heating

the

installation,

the

terminals

wired

is

in one

room

off by

radiator

off

valve

and

to

appliance

on

red

must

blue

a

with

marked

earthwire

connected

the

on

O

an

wrth

green ano

or

be

the

to

install

to

De

must

influenced

the

in

room

the

must

and

should

with

thermostat

system

the

and

3

this

in

three

of

thermostat

clock

valve

clock

by

closes'

is

N

N

E

a

4'

not

or

or

Fig.18

1

..'\L*=

LEf,-l

-j

@@_a

@a

t

Sz

14

i

Page 15

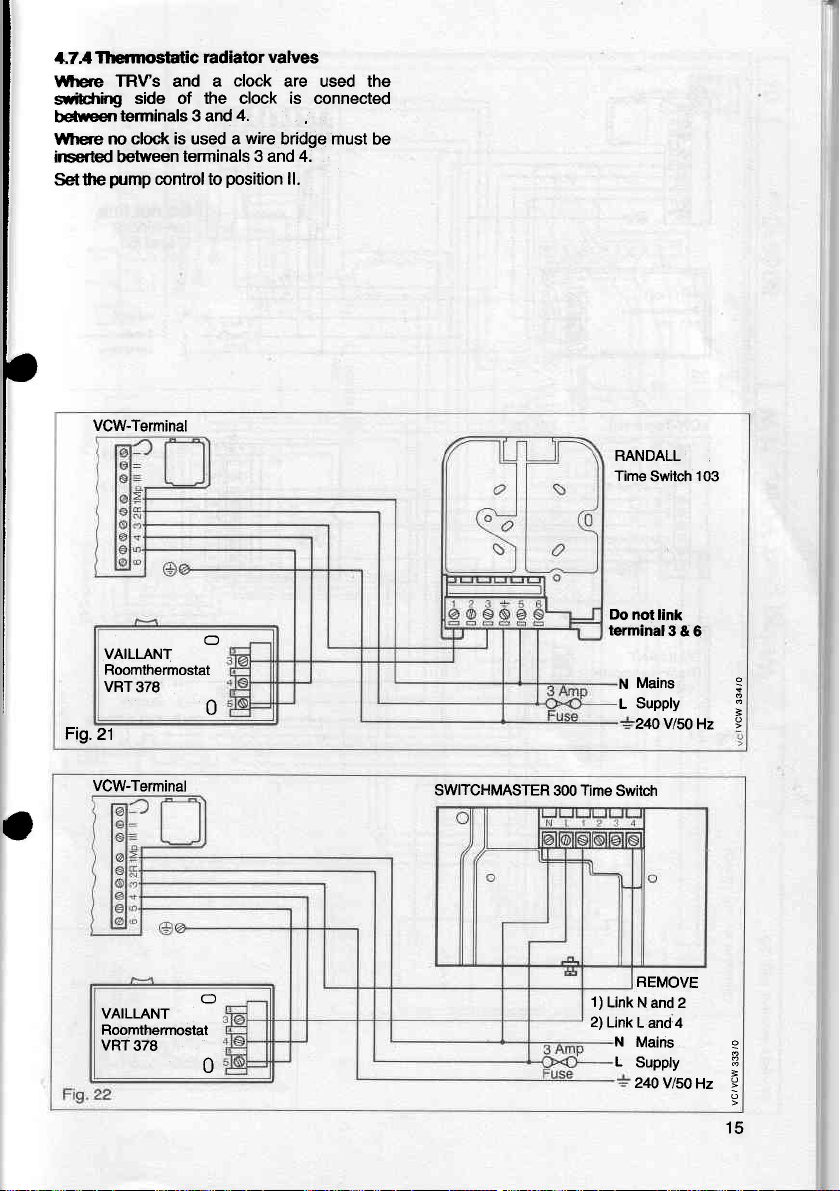

Thcrmostatic

1,7,

TRVs and a

l$rere

ilibfrirg

betreen

lYhere

side of the clock is connected

teminals 3 and

no clock is used a

inserted between

pump

Setthe

VCW-Terminal

Fig.21

control to

VAILLANT

Roomthermostat

VBT378

radiator valves

clock

are used the

4.

wire

bridge

lerminals 3 and 4.

position

ll.

0

must be

RANDALL

TimeSwitch 103

Do

not link

terminal3

N

L

& 6

Mains

Supply

24OV/5OHz

I

a

VCW-Terminal

VAILLANT

Roomthermostat

VRT378

SWITCHMASTER

O

0

300

Time

1)

2)

Switch

REMOVE

Link N

and 2

Link

L and:4

N

Mains

L

Supply

24OVlsOHz

3

15

Page 16

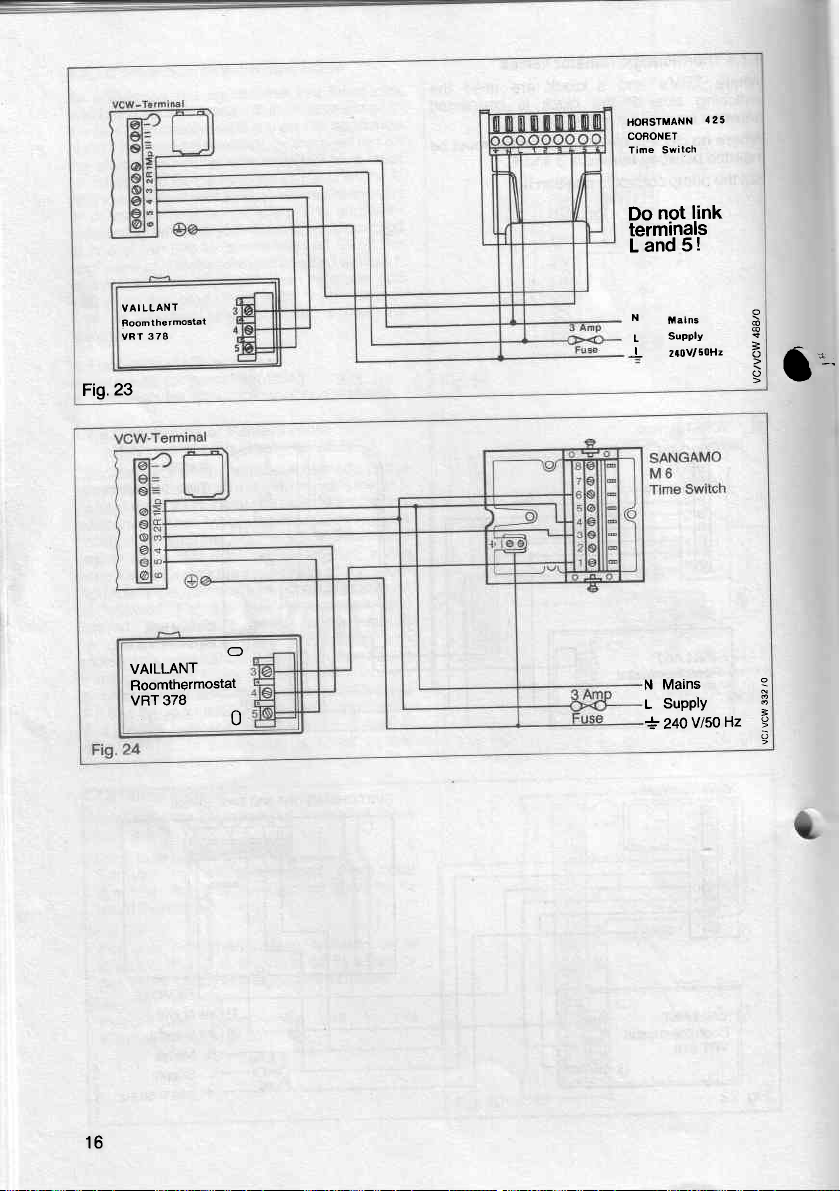

Fig.23

LLANT

VAI

Foomlhetmostat

3 78

vRT

HORSTMANN

COFONET

Time Switch

link

not

Do

terminals

Land5!

N

t.in"

SuPPIY

L

2r0v/50H2

J

125

3

o

l':-'

VAILLANT

Roomthermostat

VRT 378

16

O

N Mains

SUPPIY

0

L

24ovl5oHz

+

B

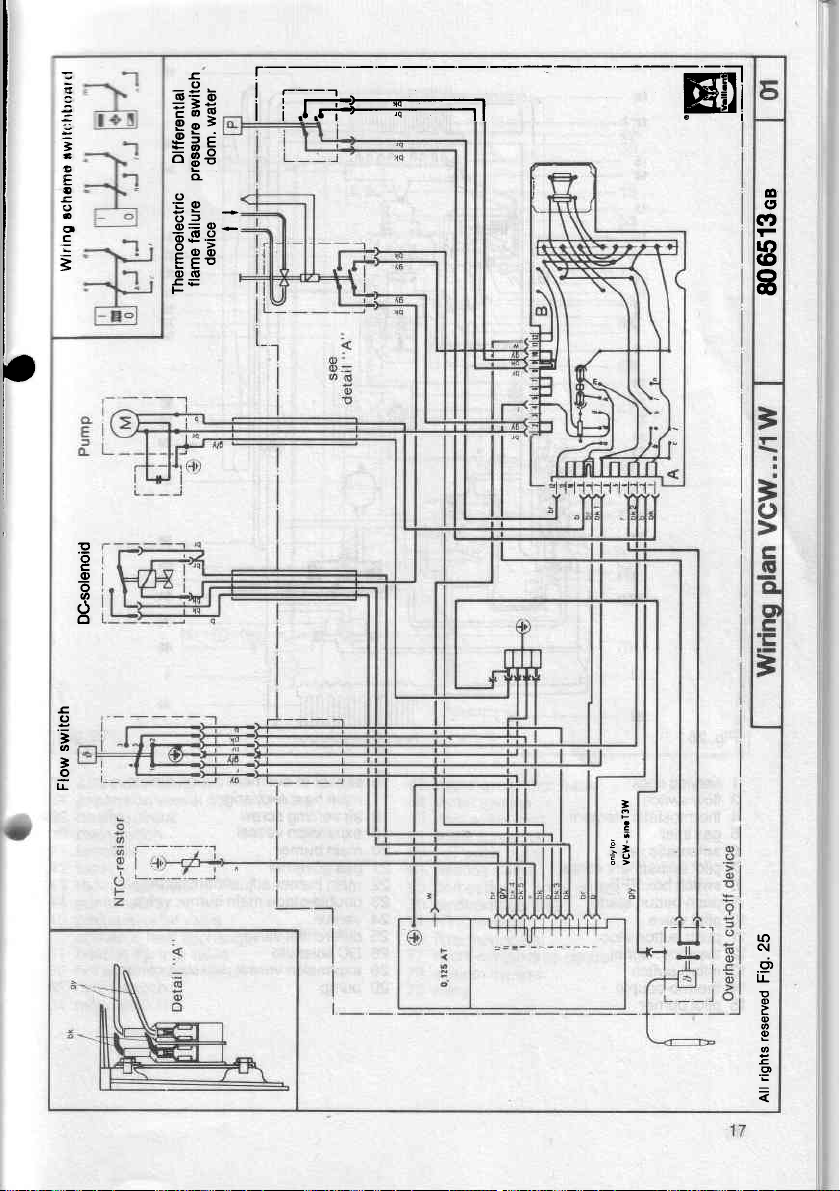

Page 17

l

I

I

I

b

i

i

E

-9-

6=O

E;E

9p5

;

a

E

o

a

cl

c

3

p

o

c

o

o

a?

o

o

"9=i

E$s

a

lt^

ol

988-

x*'t

:oo

o(g

F

.o

(,

CD

lo

(o

I

3

o

'

o

=

;

",

1

EY

r()

AI

.st,

tt

E

o

o

o

c

'=

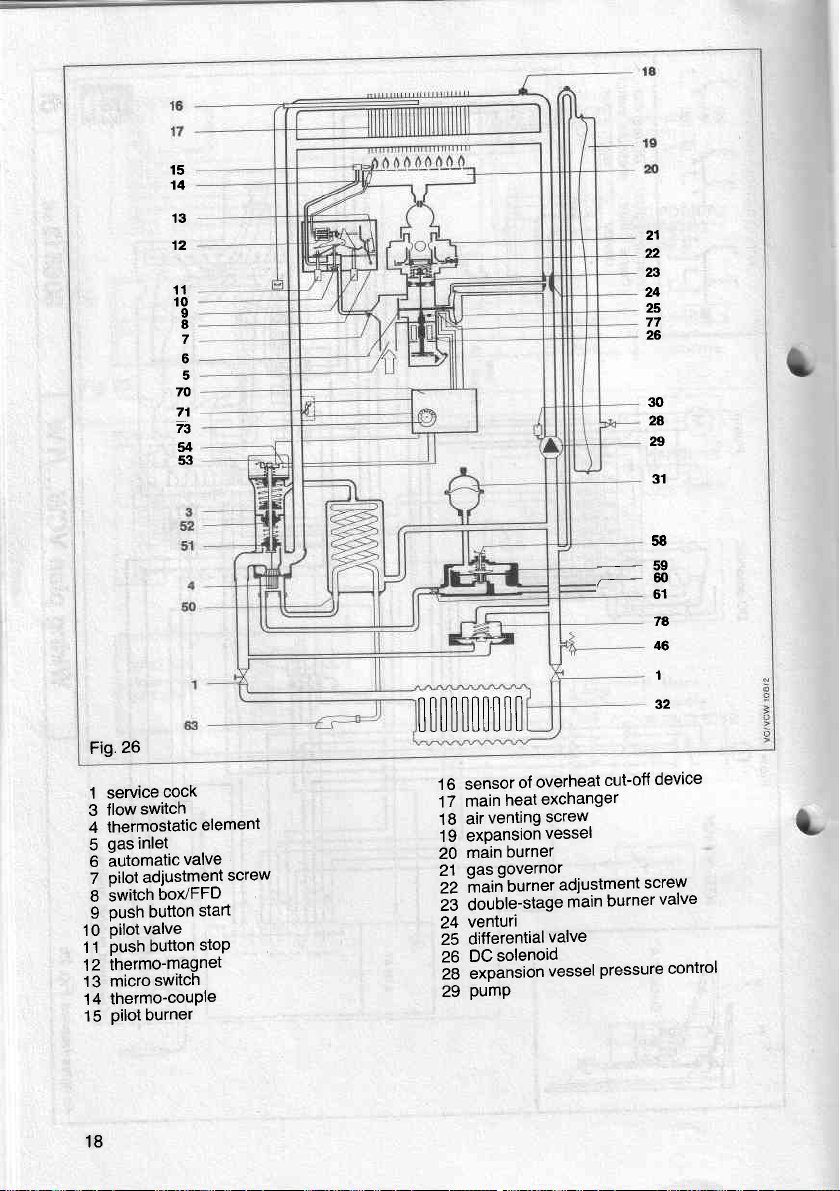

Page 18

15

14

13

'12

11

10

9

I

7

6

5

70

71

73

54

5:l

Fig.26

flow

cock

switch

1 service

3

4 thermostatic

gas inlet

5

6 automatic

pilot

7

switch

I

9 oush

pilot

10

push button

1 1

thermo-magnet

12

micro

13

thermo-couple

14

pilot

15

valve

adiustment

box/FFD

button

valve

switch

burner

element

screw

start

stop

0t[|il[[|ll

overheat

1 6 sensor

17 main

18

19

20

21

22 main

i3

24

25

26

i8

29

of

excnanger

heat

screw

venting

air

expansionvesset

burner

main

governor

gas

burner

double-stage

venturi

differential

DC

expansion

pump

solenoid

valve

vessel

/-ffi

cut-off

..

adjustment

burner

main

pressure

21

n

23

24

25

77

26

30

2A

n

31

58

61

7A

46

1

32

device

screw

valve

control

18

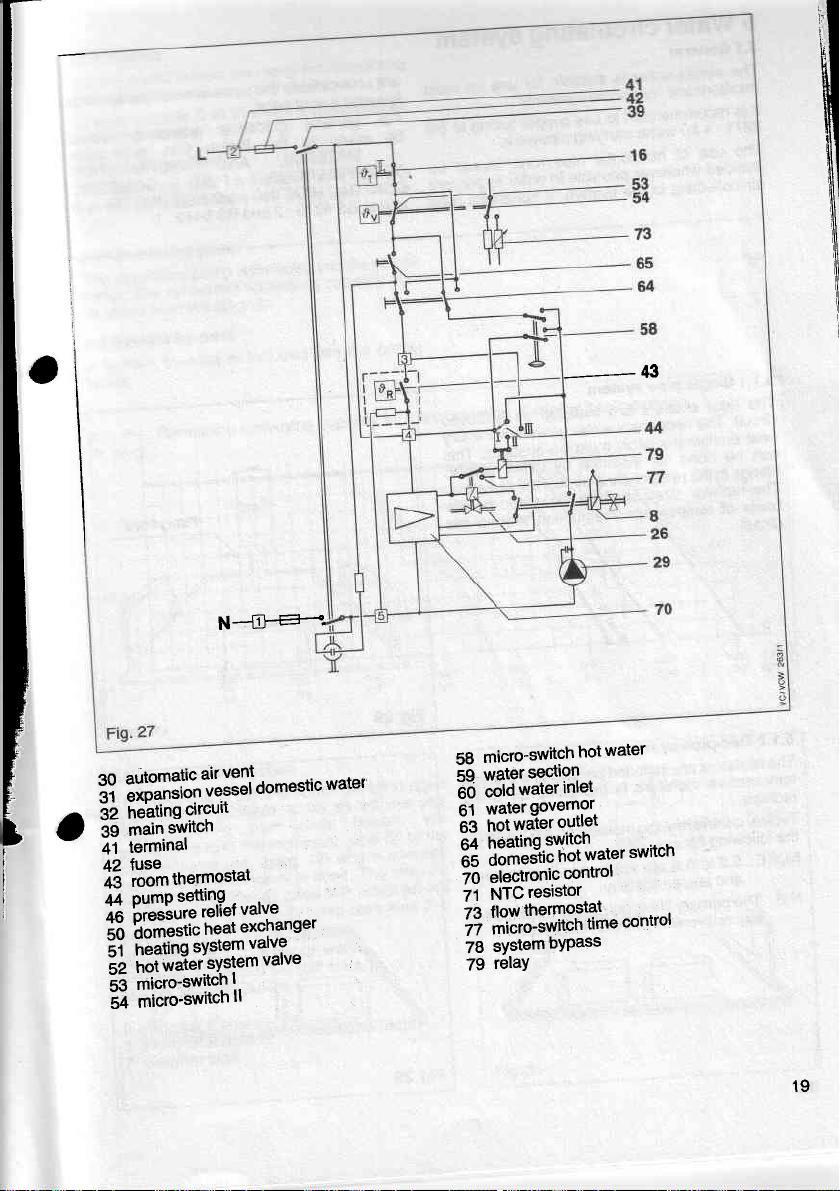

Page 19

-'_-43

N--.a.-:.*.

water

sedlon

inlel

water

governor.

outlel

control

resistor

hot

.

switch

*"*"'

micro-switch

58

water

:li"#3[?t!l3ll

3?

32

39

i

i

41

X3

$i[#s$:rrtt:"'

53

54

circutr

heating

switch

main

terminal

tlo"o"*

rn"rto""'

micro-switcn

micro'switcn

o"'"""'ic

t.

ll

water

59

cold

60

water

61

water

hot

63

!3il'J3-:Y':ilvarcr

3e

electronic

70

NTC

71

"1.1H,$3#3f;'ftL

1?

systembypass

78

relaY

79

19

Page 20

Water

5

General

5.1

The combi

minibore

It is

2871

The use

avoided

air

and

recommended

:1for

wherever

collecting

circulating

is

boiler

water

of

suitable

microbore

to use

carrying

horizontal

possible

the system.

in

systems.

pipe

system

use on

for

tubing

copper

PiPework.

runs

in order

lf horizontal

most

to

should

prevent

to

unavoidable

are

towards

For

BS

be

runs

mide

be

-

SPECIFICATIONS

CENTRAL

to

and

point.

a vent

qeneral

MATERIAL

BS 5376:2

quidance

ihe

to

HEATING

the

pipes

British

AND

AND

and

should

reference

Gas

INSTALLATION

FOR

HOTWATER

BS 5449

rise upwards

should

publication

DOMESTIC

-,

:1.

B

Single

5.1.1

The

circuit.

heat

can

fittinos

PiPe

emitters

heat

necessary

The

(radiator) must be

emitter

done

be

the return

in

The-radiator

temperature

of

basis

circuit.

Two-pipe

5.1.2

radiators

The

temperature

radiator.

central

Typical

following

the

to 5.5

5.2

NOTE:

and sealed

primary

The

N.B.

convenient

any

sYstem

installed

are

water

for instance

connection

shall

sizes

distribution

system

installed

are

therefore

heating

figures.

is the same

installation

are applicable

systems.

point

filling

point

on a closed

quantity

for every

ensured.

by using

of

be calculated

suction

the radiators.

on

around

parallel

may

the circuit.

on

the

and

for every

are shown

to both open

placed

be

This

the

the

Fig.28

flow

in

Filling Point

at

20

Fig.29

Page 21

S2Gontols

Vdilt

cofiti bcilers

oleebcLft:d mains.

conhds

W$Gn

h figures 21

sfwn

lrolating valves

53

The

+dianoe

(service

dws

4-3_3.

5.'tGirculating

The

cirolating

boiler. The remaining

betaken from

SssYstem by-pass

A

system

bdler.

(24OV)

shall

cocks)

pump

pump

the

diagram.

by-pass is

to 24.

ready

are

may

installed

be

as described

is included

conveying

included

for

connecting

be

connected

with isolatinq

into

the

capacity

into

the

as

unde-r

combi

can

combi

5.6 Open

lf it is required

systems

modification

recommend

isofation

the

British

a:

should

Min static head:

Max

see BS

2

3 expansion

7

vented

to

possible

it is

to

to fit

pressure

relief

(no.

valve

Standards

otl.gr requirements

be

strictly

0.15

static head:2.0

5449 clause 24.1

expansion

overflow

pipe

cistern

pipe

system

use the

combi

to

the

combi

the

expansion

7,tig.

valve is

and

Codes

involved

observed.

(5'water)

bar

(67'water)

bar

heater

in

heater.

(2)

normallv

The

relevani

as

also

ooen

W6

at the

well

3.1)

do so without'anv

pipe

12)

where

fitted.

of Practice

(see

800

176

1000

Fig.31

220

1200

264

14c,0

308 352 cPH

1600

L/h

21

Page 22

systems

Sealed

5.7

Sealed

exDansion

ouitiW

Jsed

systems

cisterns,

raOiator

in order

to

topping-uP.

Pressure

5.7.1

is required

This

connected'as

5.7.2

is

This

pressure

shown

Pressure

factory

the

in

do

open

valve's

prevent

lelief

all

on

gauge

to

fitted

Primary

require

not

vents

fittings

and

excessive

valve

sealed

4'3.4'

in

boiler

the

circuit.

leed

only

etc'

should

detrlmenlal

systems

shows

and

and

gooo

be

and

the

is

3

Expansion

5.7.3

expansion

litres

1 5

A

ihe combi

iuit".

260

lf the

vessel

itor-instance

iioen

cin Oe

ieturn

pressure relief

5.7.4

The

seoar6te

on'

Authority

connection

connection

b6iler

with

(57.2

litres

nominal

is not

Jvstems)

instatt6d

service

Filling

svstem

lilling

neati-nb

the

Regulation

to-the

must

completed.

Reqirlation

corinection,

break

witt

domestic

ln

waier

shown

Methods

appendix

must

tank

be

not

side.

principle,

mat<e-up

some

that

filling

of

of

A

vessel

vessel

suitable

maximum

a

galls')

lmP.

capacity

sufficient

in

of

case

additional

an

the

to

in connection

cock

valve.

make

and

be

should

point

fitted

circuit.

mains

be

Where

does

a sealed

used.

be

automatically

filled

sealed

faciliti6s,

make-up

sealed

BS 5376:2.

is incorporated

a sealed

of

for

for

the

water

built-in

heating

the

contents

expansion

modernization

expansion

connection

side

uP

water

with

filled

a convenientpoint

at

local

Where

allows,

removecl

local

not

system

systems

a

b,e

may

when

Water

allow

filler

heating

The

do

experience

but

may be

systems

not

necessary'

are

into

heating-

of

sys,tem.

old

of

ve-ssel

the

of

the

with

a

via

Water

temporary

The

used'

lllllng

ls

Authority

temporary

pump

with

system

the

from

require

has

given in

Fig.32

Pipework

5.7.5

All oioework

run'n'eatly

and

be securely

shall

concealed

be

supported,

possible'

where

shall

22

Page 23

6 Cornmissioning

testing

6, 1

El€ctrical

r-e,'rinary

+€sflcal

:r,mpetent

r

tne INSTRUCTIONS

IiIULTIMETER.

6.2 Gas installation

Tne

reter.

soundness

iecommendations

t

6.3 Water

The

whole

wtrn

Dotn

are

open.

With

the

be

fiiled

through

Loosen

-z

oy 1

for.water

until

the

PSI).

(The

system

from

a

or

La_lK.

5376

: 2,

Check

Trom

rne

oL.-t,z

otnerence.

gauge

emtner

whole

sealed

operation

oat

and

ts

installation

electrical

safety

person.

of the

should

be inspected

purged

and

circulation

oJ the

cotd

and

combi

boiler

and

air

the

the

turns.

pressure

by

system

locks

4

vent

black

Vent

soundness.

should

system

a

method

appendix

of

until

ts

atatned,

in

height

rhe point

connected_

sysiem

shall

Those

gas

installation,

of

Cp

system

system

hot

water.

fitted,

cteared.

points

cap

on the

all

heat

On

gauge

be filled

filler pump

of filling

A.)

safety

the

initial

taking

between

at

which

and

checks

be

carried

checks

FOR

BR|T|SH

and

in

accordance

331 :

3.

should

be flushed

Ensure

the

system

V6nt

shown

ln

automaiic

emitters

a

sealed

registers

with

given

valve.

Release

system

into

the

the

higtiest

to

out

are

outliired

includinq

testej

with

all valves

should

tnJOoifei

tiq.

iand'2.

air

and

check

svstem

t.s

iraiizr.S

water

either

with

a

break

in

water

pressure

account

pressur6

ensure

by

GAS

the

for

the

out

vent

fiti

BS

anv

heat

a

Fig.33

t

components

detection

6.4.2

Pull

matn

pressure

6.4

Lighting

The

first

lighting

quatttied

oy

a

verbat

instructions

operate

the

generally.

separately

6.4,1

Gas

Test

gas

for

fluid.

Main

off the plug

Durner

test

the

combi

of the

fitteronly.

combi

boiler,

Light

the

"lnstructions

in

the

soundness

soundness

using

burner

pressure

of the

pressure

point.

boiter

appliance

He

shall

to

the

user

controls

combi

boiler

for

around

sense

of

smell

NTC-resistor

at

the

shall

be

also give

on

how

and

systemi

as

described

use,,.

boiler

and

and

test

main

burnei

done

clear

to

qas

l6ak

the

23

Page 24

Nominal

6.4.2.1

pressure

The

intetbressure:20

burner

main

2011

vcw

2511

vcw

VCW-sine

The apoliance

.b'ti"5i

n"lJ""urv

g"d gouernor

"itne

pilot

adiustment

1

pilot gas

2

solenoid

DC

3

burner

+ main

gasgovenor

5

blocking

6

inLipti.irte

7

Flue

6.4.3

that

Check

JomOustion

carryinq

i

il6'

aooliances.)

lii,irl"-"iihrtish

LturitLn,

ii'tn"l"li

Flame

6.4.4

the

Check

donoiuoiler

"'"'ini

"tt

"iir,li

seconos.

heating

must

mbar

pressure

18

is

neating

to a[6r

filter

Pressure

Plate

test

there

from

spillage

a

r.

thppiicaote

Check

check

tvpe

lriv

tailure

operation

to

sit

regulated

influt.

thb

is

the

thatihere

inPut

follows:

as

be

(8.08

in'

(cold

and

mbar

9.0

mbar

9.0

mbar

10.6

at

Therefore

of

setting

installation'

during

screw

test

Point

(near rear

point

spillage

no

draught

down

as

test

only

appearance

is

outlined

as

also

of

extract

fan

device

flame

the

of

that

ensure

to

main

the

WG)

hot):

(3.61

(3.61

(4.26

factory

it

or

.input

plate)

products,of

of

diverter

detalleo

open{lued

to

llames

ol

adequate

under

fitted'

failure

device

the

within

burner

WG)

in.

WG)

in.

wG)

in.

to

is

output

In

air

3'5'3

devic.e

the

not

by

t:D

In

for

will

60

Flow

6.4.5

the

Check

Jontiofs

controls

6.5

Allow

woif<inq

iornon""...

off

iu.t".

idcis.

the

are

to appropriate

Water

the

temperatuie

rapidly

ind

should

Sealed

initial

Examine

for

thermostat

thermostat

flow

operating

soundness

system

water

ihe system

drained

again

sistems

design

system

water

soundness.

and

satisfactorily'

settings.

reach

to

examine

and

while

be

should

still

and

filled

should

then

hot'

be

pressure

automatic

all

Readjust

maximum

for

turned

be

The

cleared

adjusted

1,2bar'

of

B

water

water

air

of

to

instructions

User's

6.6

instructions

the

Hand

l"T"niio"

ii. aooriince.

oi"cauiibns

ihe svstem

JoLJ'not

instruct

unO

necessary

and

remain

ditions.

Leave

Note:

instructions

continued

For

"iirt-viiiii"ni

liLaiion"e

ippliance

a'vear

company'

important

is

It

ariangements

that

cA-sr6ereLtwith

ilt

ififfiv

to ensure

24

use

for

the

in

the

the

prevent

to

building

Advise

to

operative

installation

efficient

at

and

meter'

the

and

should

qualified

a

bv

strongly

made

are

qualified

a

regular

safe

during

and

user

if

safe

be

of

damage

system

th-e

con-

frost

servicing

operation,

serviced

user

the

to

operation.of

servicing

re-comm.ended

a

for

-!44!!!!9

servicing

servicing'

for

the

to

Please

Vo-u-r

region,

contact

nearestVaillint

Fig.35

your

senticing

oryour

office

company'

gas

local

o

o

N

=

o

o

Page 25

7 Assembling

ieotace

:ernperature

:ssembling.

the

plug

to the

Coefficient)

NTC

resistor

(Negative

before

0

=

()

a

7.1 Lint arrestor

To fit the lint

arrestor hang

the lower retaining

appilance.

Side

the 2

and

two

panels

screw

pairs

7.6.

panels

side

to the

of captive

to

7.2

Push

boiler

with

door isre^quired

section

(open

flued

frame

from

upper

slotted

open from

appliance)

it into

and

clip it

the front

and lower

the front

against the

onto

frames

screws.

the

right

side of

the

lf

the

see

Fig.

38

o

+-

=

o

25

Page 26

7.3 Screen

Position

unOer

eJoe

the-slots

otit"

ileolace

the

tne side

tne

ot

in

*itn

the

Front

7.4

the

Press

enameled

engage

bolts

Plate

hand

left

panel. Press

hand

riqht

screen

the

screws

3

thermostat

Panel

front

sbction

centre

in the

the

of

edge

side

plate. Secure

as

panel

spring-bolted

the

panel

indicated

knob'

including

onto

slide

the

screen

under

align

and

the screen

fig

in

the

boiler'

supports'

plate

the

with

39'

grey

the

4

Door

7.5

door

The

hand side

the

from

door

the

with

support

26

supports

panel

The

left).

the

into

the

attached

are

the appliance

of

is fitted

door

support

upper

screw.

hinge

the

at

(door opening

follows:place

as

fix to

and

right

lower

I

Page 27

-

Changing

6

-r€

-i:--.

-rc,er.

-,ar'.

:E€}

7.7 Stickers

Stick

-

-

to

fio.

can also

roor

as described

and

to the

an@.

on

instructions

-

-

diagram

wiring

inner side

the

43.

attachment

door

be

the following:

in

lower door

the

serial

test

date

hand side

left

sheet

no.,

point pressure

of commissioning

of

to

fitted

after

the door as

open

support

filling

and

from the

Changethe

from the

panel

of

in

shown on

right

the

8.

$ The

-

once

with

INSTALLER.

8.1

To service

-

Switch

-

Turn off

isolating

shut-off

Servicing

should

boiler

combi

year.

A service

a

BRITISH

Turning off

GAS

combi

the

the combi

off electrical

gas

service

(4,

valves

(5,

valve

of combi

be serviced

contract

boiler

supply

tig. 44).

may be agreecl

or

Your

boiler

(1

tig.44).

,

(3,

cock

fig.

tig. 44) and

boiler

least

at

CORGI

44),

boiler

water

cold

e

@

@__

a-]r*Lrz

I \,{\

ta,

Page 28

Removing

8.1.1

Remove

oullinq

banei

jlanel

'screw

screws

door

door

Oy

bir

over

(c)

left.

Remove

buttom

then

case

side

screws

pulling

of

VCW-sine

(A)

remove

to

fig.45.

in

shown

Draining

8.1.2

(fig.44

necessary,

When

follows.

as

-

Open

-

Drain

46).

fig.

-

D-rain

screw

relief

the

of

case

outer

by unscrewing

down.

and

out

pulling

outwards.

rockei

sliding

boiler

switches

right

iemoving

and

panels by unscrewing

(d)

to clear

panels

outwards

the balanced

remove

flued

the 4 screws

combustion

aPPliance

the

46)

and

appliance

the

46)

(18, fig.

vent

air

appliance

domestic

(C,

vdlve

water

through

heat

46)

fig.

(D,

fig.

section.

exchanger

as

46) at

(fig.44)

Remove

Remove

gauge

(b)

pin

hinge

thermostat

loosening

and

panel

hand

top and

clips

internal

and off'

combi

and washers

may

.

draln

as

the

case

be drained

nlpple

via drain

pressure

lower

chamber

well

and

upper

knob'

to the

and

In the

boiler

as

(tr,

part

{eir

'ry

t

Cleaning

8.2

Cleaning

8.2.1

8.2.1.1

Remove

nut

union

lose

to

couple

ten6ion

28

of

of

Balanced

the burner

(E),

the

pilot

the

pulling

by

from

lead

burner

burner

llued

unscrewing

by

pilot

airfilter

inlector.

down

ignition

the

lint arrestor

and

appliances

(F),

Remove

taking

and

electrode.

the retaining

take care

the

the high

off

not

thermo

L

Page 29

l,lrcrer the retaining

trcs.

il

CEE'.

Cilean bumers,

certbly

with

screws

a light

Fbsenble in reverse

bumer

gasket

if necessary.

m-r

(T)

and

injectors

brush

remove

nozzles

or a vacuum

order, replacing

and

the

Fig.48

82.1.2 Open

Remove bumers

a screwdriver. Remove

pulling

by

probe

that

pilot

assembly.

Remove

Clean burners

vacuum

replacing main

llued

appliance

by levering

downwards

disengaged

by unscrewing

burner bar

by unscrewing

injectors

and

cleaner. Reassemble

gasket

burner

off burner

thermo-couple probe

pilot

from

from

circlip.

screw

with

in reverse

if necessary.

assembly

Remove

(F).

nut

a light

brush or

bar with

(E).

order,

so

29

Page 30

Cleaning

8.2.2

(open

flued

lint arrestor

part

the

which

Remove

the

appliance.

with the

Clean

Reassemble

8.3 Cleaning

8.3.1

Remove

screws

far as

as

Remove

device

exchanger.

exchanger

above

Clean

with hot

necessary

aqent.

st-raighten

8.3.2

Remove

Slacken

Slacken

diverter

possible.

but-off

the heat

of

heat exchanger

the

nuts

clean

with

necessary,

aoent.

st"raighten

in reverse order.

Balanced

burner

holding

possible.

sensor

pocket

from

Undo

unions

Remove

them.

heating

waier,

descale

not bend

Do

carefully

flued aPPliance

Open

burner

split

the

slide

and

Remove

device

exchanger.

(H)

above

heating

water, detergent

hot

descale

not bend

Do

caref

lint arrestor

of

aPPliances)

pulling

by

near the connections

is

vacuum cleaner.

light brush

main

of

flued aPPliances

as under

the

body

collar.

2 screws

from

them.

body

ully

or a

heat exchanger

.1 . Slacken

8.2.1

flue hood

(3)

on

union

and

detergents

with screwdriver.

assembly

draught

sensor

the

unions

and

with screwdriver.

and slide

of overheat

hand side of

left

nuts

locking

slacken

heat exchanger.

especially

with

the

Remove

with

and

propriety

fins.

as

holding

diverter

(3)

of

pocket

on

union

Undo

slacking

and

heat exchanger'

especially

and

proprietary

fins, if

the

downward

of the

the

hood up

cut-off

(G)

fins carefully

lf necessary,

under

left hand side

heat

heat

on

(H)

nuts

brush.

descaling

82.1

the draught

far as

up as

the overheat

(G)

nuts

locking

fins

carefully

brush.

descaling

necessary

2

lf

.2.

L

on

lf

30

Page 31

-:_Tove

-a-c

:,:.e

-

=;lp9emble

A:shers

-

:

8.4

111:l]r_etcessarytodescatethedomestic-heat

excnanger

.1"_.-:y'q

-nscrewing

:o

the

=i:"^

.1?I--qy9

-o_

rarn

:11e_:

arerwards

3ea:semble

/yashers.

the

connection

and

o-ring,

-gcessary.

.are

rlue

J

duct

Descaling

remove

saus"

the

connections.

p^y

.unscrewing

the

lng_

?y

3

screws

ptoryetary

with

in

venturi

tube

of

the

clean

bore

reverse

..in

fitted

in

engaged

of

2

clean

heat

in

domestic

the

"nd

t-n"',i:",ru

tubing

nuts.

reriove

tne

u.nion

nuts

(

l).

Descale

descating

water.

reverse

situated

heating

and-repla6"

oroer,

"".n",ig"i'r;;;X

spigot

in

heat

exchanger

tl

For

6et-tei;;;";i

the

b;;;;e;;fi;;

S

retatning

(K)

b,jr".ti"

agents

oroer

using

in

the

riqht_

O"Ov.b'nZci

;_*;;

ensurino

flr;

6rrn*;;;i

i:Ji:?"T;

;;;ily

"io-ir,"'"2

rlt"?

anO

rinl-e

new

:

8.5

Cleaning

I?_-l"Toy.q.

'nrernat..

connections

i:^,,!:tl

:ne

tower

(N)

":tess

retaining

of

the

and

and

water

water

the

loosen

to

the

frame.

section

section

the

connections

unscrew

external-

screw

(M)";"i;;

(L).

unscrew

the

Page 32

water

the

Open

(O)

replace,

or

water

anO

tpj

necessary.

Reassemble

washers.

stuffing

Where

water

to

too

box.

section.

necessary'

if

governor

reverse

in

gland needs

section,

the

Clean

Check

(61),

order

incorporating

replacing

filter

water

diaphragm

replace,

new

using

new

fit

new stuffing

if

Maintenance

8.6

Mark and

unscrew

Ooen

dihohraom

eaiv

the

differential

ruininq

casebi

In

box.

recommendable

it is

Lubricate

disc.

disconnect

and

Mark

by blowing

clean

Reassemble

of differential

disconnect

retaining

three

valve

replace,

and

pin

diaphragm

of

replacement

to

pin

with

the

through.

in reverse

the two

screws

and

necessary.

if

of

replace

suitable

control

two

order.

valve

unions

(Q).

clean.

disc

stuffing

the

also

grease.

and

Check

Check

in stuffing

box'

diaphragm

lines and

.

Jt-

32

Fig.58

Page 33

s

Eryansion

E-7

system

lnec*

should

*nir*r

srstem

build-in

of

:'al

pump, if necessary.

ar

Final

8.8

Final

8.8.1

all drain

Close

service

svstem

a-ccording

qas

and

;ticker

flame

Check

adluster

rate

seoarate

larqe,

seiarate

Replace

Check

Check

reassemble

7.

under

Final test

8.8.2

Check

vessel

onlY)

internal

pressure of expansion

be 0,7

appliance

of

pressure gauge

tests

heating

test

screws

to

cocks

ensure

to 6.3. Switch

the appliance

start

inner side

the

at

device

failure

pilot

the

flame

(7)

flames.

flame,

loose

flames develop,

jet

pilot

appliance

the

all controls

outer

electrical

-

earth

polarity

resistance

INSTRUCTIONS

according

GAS

to

MULTIMETER.

(sealed

to 0,9

is without

i{:.--

ti f5f

system

nipples and

and

the

appliance.

pressure

refill the

on electricity,

as outlined

the f ront door.

of

for correct

and adjust

that there

so

flame

lf the

increase

as shown

if necessary.

for soundness.

for correct

casing

system

continuity

to earth

heating

if heating

bar'

pressure

Refill

at 0).

open

lf

a sealed

1.2 bar

is

functioning.

the

with

are

profile

gas

rate until

fig. 60a'

in

functioning'

appliance

of

FOR BBITISH

vessel

(black

with

the

turn on

the

on

Check

pilot

three

is

one

as

I

l_

(

i

I

I

o

tf

o

3

O

3

Change

8.9

Disconnect

jet

pilot

and

ordbr.

of

In case

pilot

assembly

Changb

bcrew.

order.

reverse

connections

Check

of

iet

Pilot

pilot

tube

the

and

washer

an open-flued

unscrewing

by

pilot

the

for

gas

pilot'

the

from

reassemble

appliance

jet

remove

the

reassemble

and

soundness.

Change

reverse

in

retaining

the

in

Page 34

Change

8.10

Disconnect

thermocouple

Insert

support.

thermolead

plate

retaining