Vaillant turboMAX pro 24/2 E, turboMAX pro 28/2 E Instructions For Installation And Servicing

For the installer

Instructions for Installation and Servicing

turboMAX pro

Wall hung room sealed fan assisted

combination and system boilers

24/2 E

28/2 E

GB

Table of Contents

1 List of Contents . . . . . . . . . . . . . . . . . . . . . 3

1.1 Contents included with boiler (turboMAX pro)3

2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 General Information . . . . . . . . . . . . . . . . . . . . . 4

2.2 EC designation . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Boiler Specification . . . . . . . . . . . . . . . . . . . 5

3.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Boiler connections . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Functional diagram . . . . . . . . . . . . . . . . . . . . . . 6

4 General Requirements . . . . . . . . . . . . . . . . . 7

4.1 Related documents . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Boiler location . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Gas supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.4 Flue system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.4.1 Top outlet flue system . . . . . . . . . . . . . . . . . . . . 8

4.4.2 Rear outlet flue system . . . . . . . . . . . . . . . . . . . 8

4.4.3 Extended top outlet flue system . . . . . . . . . . . 8

4.4.4 Flue termination . . . . . . . . . . . . . . . . . . . . . . . . 9

4.5 Air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.6 Cupboard or compartment ventilation . . . . . . 9

4.7 Electrical supply . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.8 Guide to system requirements . . . . . . . . . . . . . 10

4.8.1 Water circulation system . . . . . . . . . . . . . . . . . . 10

4.8.2 Filling and make up . . . . . . . . . . . . . . . . . . . . . . 10

4.8.3 Pressure relief valve . . . . . . . . . . . . . . . . . . . . . 10

4.8.4 Pressure gauge . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.8.5 Expansion vessel . . . . . . . . . . . . . . . . . . . . . . . . 10

4.8.6 Circulating pump . . . . . . . . . . . . . . . . . . . . . . . . 11

4.8.7 System by-pass . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.8.8 Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 Gas supply adjustments (Commissioning Part II) 21

7.1 Gas inlet working pressure . . . . . . . . . . . . . . . . 21

7.2 Main burner pressure . . . . . . . . . . . . . . . . . . . . 21

7.3 Adjusting the central heating output

(range rating) . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.4 Burner pressure and gas rate . . . . . . . . . . . . . . 23

7.5 Fit combustion chamber cover . . . . . . . . . . . . . 24

7.6 Fit boiler casing . . . . . . . . . . . . . . . . . . . . . . . . . 24

8 Functional checks (Commissioning Part III) . 25

8.1 Functional checks . . . . . . . . . . . . . . . . . . . . . . . 25

8.2 Functional check of operation . . . . . . . . . . . . . 25

8.3 Adjusting pump speed . . . . . . . . . . . . . . . . . . . . 26

8.4 Handing over to the user . . . . . . . . . . . . . . . . . 26

9 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.1 Initial inspection . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.2 Cleaning the burner and primary heat

exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10 Fault Finding . . . . . . . . . . . . . . . . . . . . . . . . 29

10.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.2 Logical fault finding procedure . . . . . . . . . . . . 29

11 Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11.1 Functional flow diagram . . . . . . . . . . . . . . . 37

11.2 Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Benchmark gas boiler commissioning

checklist..................................... 39

5 Boiler Installation Sequence . . . . . . . . . . . . 12

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Using boiler template . . . . . . . . . . . . . . . . . . . . 13

5.3 Fitting the boiler hanging bracket . . . . . . . . . . 13

5.4 Install the flue system . . . . . . . . . . . . . . . . . . . . 14

5.5 Fitting the boiler . . . . . . . . . . . . . . . . . . . . . . . . 14

5.6 Removing boiler casing . . . . . . . . . . . . . . . . . . . 14

5.7 Gas supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.8 Cold water mains inlet and hot water outlet . . 15

5.9 Central heating flow and return pipework . . . 15

5.10 Connect the flue system to the boiler . . . . . . . 16

5.11 Electrical installation . . . . . . . . . . . . . . . . . . . . . 16

5.12 Connection to the main supply . . . . . . . . . . . . 16

5.13 Electronic board layout . . . . . . . . . . . . . . . . . . . 17

5.14 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 Commissioning Part I . . . . . . . . . . . . . . . . . 20

6.1 Preliminary electrical checks . . . . . . . . . . . . . . 20

6.2 Gas supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3 Cold water supply . . . . . . . . . . . . . . . . . . . . . . . 20

6.4 Filling the heating system . . . . . . . . . . . . . . . . . 20

6.5 Initial system flush („cold“) . . . . . . . . . . . . . . . 20

Instructions for Installation and Servicing turboMAX pro R32

1 List of contents

8

7

6

1

2

5

4

I

0

3

9

10

1.1 Contents included with boiler

Ensure that all contents are included before commencing installation.

Note!

DO NOT remove the boiler from the polystrene

base at this stage.

List of contents 1

Fig. 1.1: Items supplied with unit (turboMAX pro)

Item Quantity Description

1 1 Boiler

2 1 Flue restriction ring

3 1 Cold water inlet valve

4 3 Flow and return service value, gas service

valve

5 5 Copper tails for water outlet connection

6 1 Template

7 1 Guarantee Card

8 1 Installation and connection accessories and

PRV packages incl. DHW outlet union nut

9 3 Installation and Servicing, Users and Flue

Installation Instructions

10 1 Hanging bracket

Instructions for Installation and Servicing turboMAX pro R3 3

2 Introduction

2 Introduction

2.1 General Information

Note!

This boiler must be installed and serviced by a

competent person in accordance with the Gas

Safety (Installation and Use) Regulations 1998.

In the UK „CORGI“ registered installers undertake the work to a safe and satisfactory

standard.

The turboMAX pro is a fully automatic, wall mounted,

room sealed combination boiler for central heating and

domestic hot water. Domestic hot water is supplied

directly from the boiler, without requiring a copper

cylinder, cold water tank, feed and expansion tank and

associated pipework. Domestic hot water has priority

over central heating. The boiler has been designed for

use with a sealed central heating system, and comes

fully tested and assembled with a built in circulating

pump, expansion vessel and diverter valve.

The turboMAX pro has an output for domestic hot water

of 24 or 28 kW. The boiler is easily sited on any internal

wall and can be installed with either a horizontal or

vertical RSF (room sealed fan assisted) flue. Two types

of flue system are available, rear flue outlet, top outlet

(with turret) concentric flue system (100 mm outside

diameter) and an extended concentric flue system

(125 mm outside diameter). Flue extensions and additional bends and elbows are available for both flue systems

to increase the siting flexibility. The boiler is not suitable

for external installation. This boiler is available in Natural

Gas. An optional LPG conversion kit is available. If desired, an inhibitor may be used in the system. Guidance on

the use of inhibitors is contained in these instructions.

The boiler contains a domestic hot water heat exchanger. The temperature in the heat exchanger is limited by

the boiler control system and it is not necessary to

install a scale reducer on the cold mains to the boiler.

However, in exceptionally hard water areas to prevent

scale formation in the property hot water system pipework, a scale reducer may be fitted.

turboMAX pro combination boilers have a built in diagnostic system which indicates the operational status of

the boiler. This feature provides key information to aid

commissioning and fault finding.

The data badge is fitted on the rear of the control panel.

See text of General Requirements for installation requirements or notes.

Vaillant ltd. support the Benchmark initiative.

In this installation manual you will find the Benchmark

gas boiler commissioning checklist. It is very important

that this is completed correctly at the time of installation and commissioning..

Important!

When tightening or slackening screwed connections always use suitable open-ended spanners

(not pipe wrench, or extensions, etc.).

Incorrect use and/or unsuitable tools can lead to

damage being caused (e.g. gas or water leakage)!

2.2 EC designation

turboMAX pro (24/28) a carry the "CE" Mark. This

demonstrates that the boilers fulfil the essential requirements of the Gas Appliance Directive(90/396/EEC) and

the Gas Appliance (Safety) Regulations 1992.

The "CE" Mark also demonstrates that the boilers comply with the requirements of the Electromagnetic

Compatibility Directive (89/336/EEC), the Low Voltage

Directive (72/23/EEC), the Boiler Efficiency Directive

(92/42/EEC) and the Boiler (Efficiency) Regulations 1993.

Instructions for Installation and Servicing turboMAX pro R34

Boiler Specification 3

3 Boiler Specification

3.1 Technical Data

turboMAX pro 24/2 E turboMAX pro 28/2 E Units

(VUW GB 242/2-3) (VUW GB 282/2-3)

Maximum CH heat input (net) 29.7 (101.000) 31.1 (106.200) kW (Btu/h)

CH heat output range (80/60 °C) 8.9 - 24 10.4 - 28

(30.400 - 81.900) (35.500 - 95.500) kW (Btu/h)

Maximum DHW heat input (net) 26.7 (91.200) 31.1 (106.200) kW (Btu/h)

SEDBUK Band D D

SAP Seasonal Efficiency 79.6 79.7 %

DHW heat output 24 28 kW

DHW flow rate ∆T = 35 °C rise 9.8 11.5 l/min

DHW flow rate at factory set

temperature rise (∆T 42 °C) 8.2 9.5 l/min

Mains water pressure required

for max. flow rate 0.5 0.5 bar

Minimum water flow rate 1.5 1.5 l/min

Mains water pressure required

for min. flow rate 0.15 0.15 bar

Maximum inlet water pressure 10 10 bar

Inlet gas working pressure

required (natural gas) 20 20 mbar

Gas supply (G20) Gross CV (s.t.) 37.8 37.8 MJ/m

Gas burner pressure max. rate (natural gas) G 20 9.8 10.8 mbar

(LPG 3+) G 30/31 28 - 30/37 28 - 30/37 mbar

Gas burner pressure ignition rate G 20 1.9 1.8 mbar

G 30/31 3.9/5.4 3.8/5.3 mbar

Gas rate max. (DHW) - 2.8 3.3 m3/h

CH temperature flow range 35 - 82 35 - 82 °C

Minimum CH water flow

(for 20 °C rise) 1032 1203 l/h

Pump pressure available 0.25 (25) 0.25 (25) bar (KPa)

Expansion vessel

pre-charge pressure 0.75 0.75 bar

Maximum CH system pressure 3 3 bar

Weight 42 45 kg

Primary water content 2.0 2.0 l

Electrical supply 230/50 230/50 V~/Hz

External fuse 3 3 A

Power input 150 150 W

Case height 800 800 mm

Case width 440 440 mm

Case depth 338 338 mm

3

Instructions for Installation and Servicing turboMAX pro R3 5

3 Boiler Specification

C

C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

17

16

18

19

21

22

23

24

25

26

27

28

29

30

31

0

7

6

264638

145

6

5

100

100

35 35

432

130

180

1

148

8

543 2 1

902

3.2 Boiler connections

3.3 Functional Diagram

Fig. 3.1: Connection diameters turboMAX pro

Key:

1 Heating system return (22 mm tail)

2 Cold water connection with shut off valve

(15 mm tail)

3 Gas connection (15 mm tail)

4 Hot water connection (15 mm tail)

5 Heating system flow (22 mm tail)

Fig. 3.2: Functional Diagram

6 Flue outlet (100 mm flue with turret)

7 Hanging bracket

8 Rear flue outlet

1 Air duct

2Fan

3 Main heat exchanger

4 Temperature sensor (NTC I)

5 Flame sensing electrodes

6 Modulating burner

7 Fully modulating automatic gas value

8 Maximum hot water temperature control

9 Maximum radiator temperature control

10 Diverter valve

11 DHW heat exchanger

12 Automatic bypass valve

13 CH flow service valve

14 Hot water outlet

15 Gas service valve

16 Cold water service valve

17 CH return service valve

18 Pressure relief valve

19 Aqua sensor (DHW flow switch)

21 Main on/off control

22 Pressure gauge

23 Indicator lights

24 Expansion vessel

25 Expansion vessel charging valve

26 Circulating pump

27 Automatic air vent

28 Ignition electrode

29 Temperature sensor (NTC II)

30 Air pressure switch

31 Flue gas duct

Instructions for Installation and Servicing turboMAX pro R36

General Requirements 4

4 General Requirements

4.1 Related Documents

The installation of the boiler must be in accordance with

the relevant requirements of Gas Safety (Installation

and Use) Regulations 1998, Health and Safety Document

No. 635 (The Electricity at Work Regulations 1989),

BS7671 (IEE Wiring Regulations) and the Water Supply

(WaterFittings) Regulations. It should also be in accordance with the relevant requirements of the Local

Authority, Building Regulations, Building Standards

(Scotland) Regulations and the relevant recommendations of the following British Standard; Including current

amendments to Approved Documents Part L and J.:

BBSS 55444400::

exceeding 70 kW net:

- Part 1: Flues

- Part 2: Ventilation

BBSS 55444499::

for domestic premises.

BBSS 55554466::

domestic premises.

BBSS 66770000::

within buildings and their curtilages.

BBSS 66779988::

boilers not exceeding 70 kW input net.

BBSS 66889911::

gas pipework up to 28 mm (R1) in domestic premises

nd

family gas).

(2

BBSS 77559933::

central heating systems.Institute of Gas Engineers

Publication IGE/UP/7/1998: Guide for Installation in

Timber Framed Housing. Benchmark Code of Practice.

Building Regulations Approved Documents Part L 2002

Part J 2002.

Flues and ventilation of gas fired boilers not

Specification for forced circulation hot water

Specification for gas hot water supplies for

Services supplying water for domestic use

Specification for installation of gas fired

Specification for installation of low pressure

Treatment of water in domestic hot water

Important!

The appliance must be installed and serviced by

a competent person as stated in the Gas Safety

(Installation and Use) Regulations 1998.

Standards (Scotland) Regulations, in respect of the

installation of a boiler in a room containing a bath or

shower.

Note!

Where a room sealed boiler is installed in a

room containing a bath or shower, any electrical

switch or boiler control utilising mains electricity should be so situated that it cannot be touched by a person using the bath or shower.

Where the installation of the boiler will be in an unusual

location, special procedures may be necessary and BS

5546 and BS 6798 give detailed guidance on this

aspect. The boiler must be mounted on a flat, vertical

wall, which must be sufficiently robust to take the

weight of the boiler. The boiler may be installed on a

combustible wall, subject to the requirements of the

Local Authorities and Building Regulations.

A compartment used to enclose the boiler must be designed and constructed specifically for this purpose. (An

existing cupboard or compartment may be used provided that it is modified for the purpose). Details of essential features of cupboard/compartment design including

airing cupboard installations are given in BS 6798.

If the boiler is to be fitted in a timber framed building, it

should be fitted in accordance with Institute of Gas

Engineers Publication IGE/UP/7/1998 „Guide for Gas

Installation in Timber Framed Housing“.

4.3 Gas Supply

The gas supplier should ensure the availability of an

adequate supply of gas.

A gas meter may only be connected to the service pipe

by the supplier of gas or their contractor.

An existing meter should be checked to ensure that it is

capable of passing the rate of gas supply required.

Installation pipes should be fitted in accordance with BS

6891.

Pipework from the meter to the boiler must be of an

adequate size. Do not use pipes of a smaller size than

the boiler gas connection (15 mm).

The complete installation must be tested for soundness

and purged as described in BS 6891.

Preliminary remarks

This appliance should only be installed in conjunction

with a Vaillant flue system.

Install the flue system as detailed in the separate flue

installation instructions supplied with this boiler.

4.2 Boiler location

The location chosen for the boiler must permit the

provision of a satisfactory flue termination. The location

must also provide adequate space for servicing and air

circulation around the boiler. The boiler may be installed

in any room, although particular attention is drawn to

the requirements of BS7671 (IEE Regulations) and, in

Scotland, the electrical provisions of the Building

Instructions for Installation and Servicing turboMAX pro R3 7

4.4 Flue system

Note!

The boilers are delivered ready for installation

utilising a top outlet flue assembly. For installation with a rear outlet flue assembly refer to

the boiler flue outlet adaptation instructions

supplied with the rear flue accessory.

4 General Requirements

70

1103

70

15

48

1285

603

4.4.1 Top outlet flue system

(100 mm outside diameter)

The top outlet horizontal flue system (Art. No. 303 807)

is suitable for installations up to 720mm measured from

the centre of the boiler flue outlet to the outside face of

the wall. Flue extensions are available to extend this

length up to 4.5 m for 24 kW and 3.2 m for 28 kW.

Both 90° bends and 45° elbows are also available to

increase siting flexibility.

A vertical flue system is also available

(Art. No. 303 800).Refer to flue system installation

instructions for full details.

800

48

4

48

Fig. 4.1: Art.-No. 303 807

A vertical flue system is also available

(Art. No. 303 800).

Refer to flue system installation instructions for full

details.

4.4.2 Rear outlet flue system

(100 mm outside diameter)

The rear outlet horizontal flue system (Art. No. 303 817)

is suitable for installations up to 600 mm wall thickness.

800

Fig. 4.3: Art.-No. 303 817

4.4.3 Extended top outlet flue system

(125 mm outside diameter)

A top outlet horizontal flue system of 125 mm outside

diameter is also available (Art. No. 303 609) and can be

used to achieve flue lengths of up to 12.9 m for 24 kW;

10 m for 28 kW.

Both 45° and 90° bends and elbows are also available to

increase siting flexibility.

A vertical 125 mm concentric flue system is also available (Art. No. 303 600).

Refer to flue system installation instructions for full

details.

Fig. 4.2: Art.-No. 303 800

Fig. 4.4: Art.-No. 303 609

Instructions for Installation and Servicing turboMAX pro R38

General Requirements 4

A

BCD

A

G

H, I

F

J

B

F

M

L

L

K

K

G

G

F

F

E

A

A

4.4.4 Flue termination

The following details refer to both flue systems.

a. The terminal must be positioned such that the pro-

ducts of combustion can disperse freely at all times.

b. In certain weather conditions a plume of water

vapour may be visible from the flue terminal.

Positions where this could be a nuisance should be

avoided.

c. If the terminal is fitted less than 2 m above a bal-

cony, above ground or above a flat roof to which

people have access then a suitable terminal guard;

280 mm x 280 mm x 270 mm deep, must be provided and fitted (made by Tower Flue Components,

Tonbridge, TN9 1TB).

Note!

Vertical flues must not terminate within

600 mm of an openable window, air vent or any

other ventilation opening.

The flue assembly shall be so placed or shielded as to

prevent ignition or damage to any part of the building.

Terminal position for fan-assisted flue

(minimum distance) mm

A1)Directly below an openable, above an opening

or horizontal to an opening i.e. air brick, opening

window or other, etc 300

B Below gutters, soil pipes or drain pipes 25

C Below eaves 25

D Below balconies (below car port roof) 25

E From vertical drain pipes and soil pipes 25

F From internal or external corners 25

G Above ground or balcony level 300

H From a surface or boundary facing a terminal 600*

H From a terminal facing a terminal 1200

J From an opening in a car port (e.g. door, window)

into a dweling 1200

K Vertically from a terminal on the same wall 1500

L Horizontally from a terminal on the same wall 300

M Distance from adjacent wall for vertical Flue 500

1) In addition, the terminal should not be nearer than 150mm to an

opening in the building fabric formed for the purpose of

accommodating a built-in element such as a window.

* BS 5440-1 It is recommended that a fanned flue terminal should

be positioned as follows: a) at least 2m from an opening in a building directly opposite, and b) so that the products of combustion

are not directly directed to discharge across a boundary.

4.5 Air supply

Detailed recommendations for air supply are given in BS

5440: Part 2. It is not necessary to have an air vent in

the room or internal space in which the boiler is installed.

Fig. 4.5: Flue termination

4.6 Cupboard or compartment ventilation

The boilers are very high efficiency appliances. As a consequence the heat loss from the appliance casing during

operation is very low. For cupboard or compartment installations it is therefore not necessary to provide any high

or low level permanent air vents for cooling purposes.

4.7 Electrical supply

A 230 V, ~ 50 Hz single phase electricity supply fused to

3 Amp. must be provided in accordance with the latest

edition of BS7671 (IEE Wiring Regulations) and any other

local regulations that may apply.

The method of connection to the mains electricity supply must provide a means of completely isolating the boiler and its ancillary controls. Isolation is preferably by

the use of a fused three pin plug and unswitched shuttered socket outlet, both complying with the requirements

of BS 1363. Alternatively, a 3 Amp. fused doublepole

Instructions for Installation and Servicing turboMAX pro R3 9

switch with a 3 mm contact separation on both poles

may be used.

4 General Requirements

Important!

This appliance must be earthed.

4.8 Guide to system requirements

4.8.1 Water circulation system

Detailed recommendations for the water circulation

system are given in BS 6798 and BS 5449: Part 1 (for

small bore and micro bore central heating systems).

Pipework not forming part of the useful heating surface

should be insulated to help prevent heat loss and

possible freezing, particularly where pipes are run

through roof spaces and ventilated underfloor spaces.

Draining taps must be located in accessible positions

which permit the draining of the whole system including

the boiler and the hot water system. Draining taps

should be at least 1/2 in. BSP nominal size and be in

accordance with BS 2879.

The boiler is suitable for use with minibore or microbore

systems. Copper tubing to BS 2871: Part 1 should be

used for water carrying pipework. All capillary joints in

all DHW pipework must be made with lead free solder.

Particularly where a new boiler is to be fitted to an

existing system, it is good practice that the system is

thoroughly cleansed.

Important:

To prevent the formation of deposits and prevent serious damage to the appliance and

system , cleansers must be used carefully and

must be completely removed by thoroughly

flushing the system. Cleansers should only be

left in systems for a maximum of 24 hours.

This cleansing must take place prior to the fitting of the

new boiler and be in accordance with BS 7593.

For advice on the application of system cleansers

contact either Sentinel, GE Betz. Widnes, Cheshire,

WA8 8UD. Tel: 0151 420 9595

4.8.2 Filling and make up

The system can be filled using the built in filling loop.

The connection must be removed when filling is

completed. Where local Water Authority regulation does

not allow temporary connection, a sealed system filler

pump with break tank must be used. The heating system

will not be filled automatically from the domestic hot

water side.

(Alternative methods of filling sealed systems are given

in BS 5449).

4.8.3 Pressure relief valve

A pressure relief valve is provided with the boiler. This

safety device is required on all sealed C.H. systems and

is preset at 3 bar and provided with a 15 mm

compression connection for a discharge pipe, which

must be of no less than 15 mm in diameter. The

Pressure Relief Valve must not be used for draining

purposes.

4.8.4 Pressure gauge

This is factory fitted to the boiler and indicates the

primary circuit pressure to facilitate filling and

testing.

4.8.5 Expansion vessel

The 24 kW boiler incorporate a 6 litre expansion vessel

which is suitable for a sealed heating system with a

maximum water content of 60 litres. A 10 litre

expansion vessel kit is available as an optional

accessory.

The 28 kW boilers incorporate a 10 litre expansion

vessel which is suitable for a sealed heating system with

a maximum water content of 100 litres. If the nominal

capacity of the built in expansion vessel is not sufficient

for the heating system (for instance in case of modernization of old open systems) an additional expansion

vessel can be installed external to the boiler. It should

be fitted in the return pipe as close as possible to the

boiler in accordance with BS 5449: Part 1. Guidance on

the sizing of an additional expansion vessel is given in

Table.

Vessel Volume [L]

Initial system pressure (bar) 1.0 1.5

Pressure relief valve setting (bar) 3.0

Total water content of system ltres

25 2.7 3.9

50 5.4 7.8

100 10.9 15.6

125 13.6 19.5

150 16.3 23.4

175 19.1 27.3

200 21.8 31.2

225 24.5 35.1

250 27.2 39.0

275 30.0 42.9

300 32.7 46.8

325 35.7 50.7

350 38.1 54.6

375 40.9 58.5

400 43.6 62.4

425 46.3 62.4

450 49.0 58.5

475 51.8 74.1

500 54.5 78.0

For system volumes other than those given

above, multiply the system volume by the

factor across 0.109 0.156

Instructions for Installation and Servicing turboMAX pro R310

4.8.6 Circulating pump

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400

50

100

150

200

250

300

350

400

450

500

550

600

650

700

Volume flow [l/h]

Lift [mbar]

setting III

setting II

The circulating pump is included in the boiler. The pump

head available for the heating system is shown in

fig. 4.6.

General Requirements 4

Fig. 4.6: Pump specifications

4.8.7 System by-pass

An automatic system by-pass is included within the boiler. The boiler is suitable for use in systems with thermostatic radiator valves and no additional by-pass is

required.

4.8.8 Venting

The boiler is fitted with an automatic air vent. Additional

provision should be made to enable the heating system

to be vented during filling and commissioning either by

automatic air vents or manually.

Instructions for Installation and Servicing turboMAX pro R3 11

150

5

200

500

5

I

0

0120

60

9030

°C

bar

4

3

2

1

0

5 Boiler Installation Sequence

440

800

338

I

0

0120

60

9030

°C

bar

4

3

2

1

0

5 Boiler Installation Sequence

5.1 General

Preparation of boiler location

Clearances required

Mount the boiler on a flat and vertical area of wall of

sufficient area for the boiler plus the required clearances for installation and servicing.

The clearances are as detailed below and are shown on

the installation template supplied with the boiler:

- 150 mm below the boiler

- 5 mm on either side of the boiler

- 210 mm on top of the boiler

- 500 mm in front of the boiler*

* Clearance is only required to enable easier access to

the boiler for servicing and may be provided by an

openable door, etc.

Note!

If the boiler is to be fitted in a timber framed

building, it should be fitted in accordance with

Institute of Gas Engineers Publication

IGE/UP/7/1998 „Guide for Gas Installations in

Timber Framed Dwellings“.

Fig. 5.2: Free space required for installation

Selecting position of boiler

Refer to „Boiler location“ for information regarding siting the appliance. In general the boiler must be positioned such that.

• There is adequate space around the boiler for service

and maintenance.

• The boiler can be correctly flued, i.e. the flue terminal

position is sited in accordance with the flue termination section and the air/flue duct can be installed in

accordance with the flue installation instructions supplied.

• All necessary pipework can be connected, including

the pressure relief valve.

Note!

Should it be necessary to run system pipework

to above the boiler within the width of the

casing, use the optional top connection accessory (Art.No. 306 251).

Fig. 5.1: Dimensions of boiler

Instructions for Installation and Servicing turboMAX pro R312

Boiler Installation Sequence 5

55

210

124163 21200/202/240/242/280/282/824/828 Pro/Plus

60/100

07/2002

2

3

1

turboMAX only

3

402

171

174,5

12,5

1

1

2

5.2 Using boiler template

Fix the paper template to the wall ensuring that the correct flue exit point has been identified, ensure that the

template is vertical.

The template shows

- The position of the fixing holes for the boiler mounting bracket (1).

- The position of the connections.

- The position of the flue exit hole.

- Upper hole (2) indicates top outlet flue with flue turret facing rearward.

- Lower hole (3) indicates rear outlet flue exiting

directly through wall.

• Mark the position of the hanging bracket fixing holes (1).

• Drill 2 holes Ø 8 mm for the hanging bracket.

Note!

Use alternative fixing holes where necessary.

Identify correct flue exit

Mark the centre of the selected air/flue duct and its circumference, e.g. by drilling through the template. For

installation of a rear exit outlet please refer to the

installation instructions of the rear exit outlet kit

(Art. No. 303 817).

Other flue options

Flue instructions for other flue systems such as vertical

RSF flues, flues run to the side of the boiler and the use

of additional bends etc. are detailed in the flue installation instructions provided with the boiler.

Remove the template from the wall and plug the drilled

holes using the wallplugs supplied.

5.3 Fitting the boiler hanging bracket

Fix the hanging bracket (2) to the wall using the screws

supplied. (it may be necessary to use additional or

alternative fixings to ensure adequate support).

Fig. 5.3: Using Boiler template

Fig. 5.4: Free space required for installation

Note!

If the boiler is to be fitted in a timber framed

building ensure that the bracket is secured to a

substantial part of the timber frame capable of

taking the weight of the boiler.

Instructions for Installation and Servicing turboMAX pro R3 13

I

0

1

2

5 Boiler Installation Sequence

3

I

0

2

I

0

90°90°

1

5.4 Install the flue system

Install the flue system (refer to separate air/flue duct

installation instructions).

5.5 Fitting the boiler

• Lift the boiler (3) up to the wall so that it is slightly

above the hanging bracket (1).

Note!

Lift the boiler from either side at the bottom

edge.

• Lower the boiler slowly onto the hanging bracket so

that the cross member at the rear of the boiler fully

engages onto the hanging bracket.

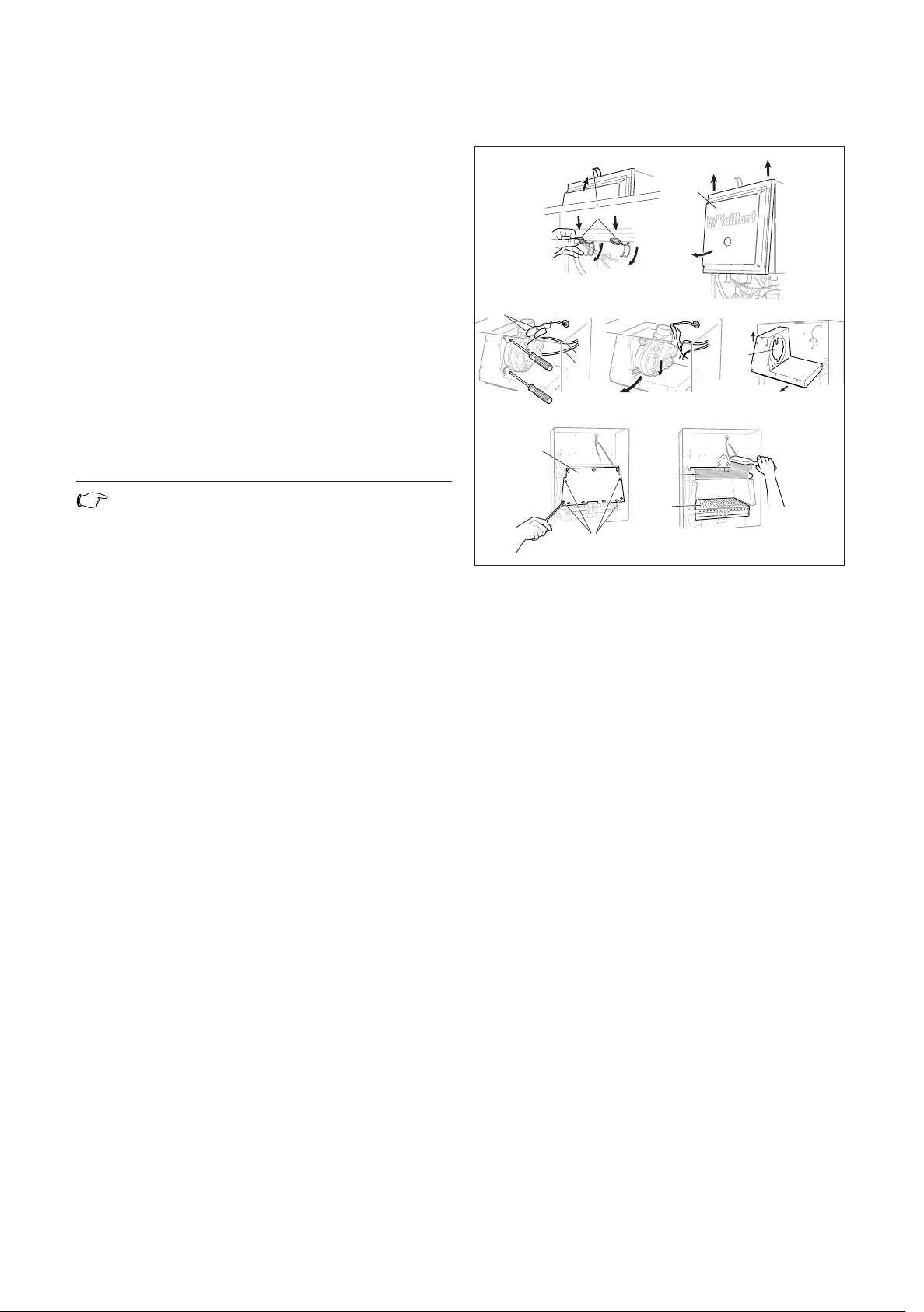

5.6 Removing boiler casing

• Turn both securing fasteners (1) anti-clockwise by 90°

to release control panel (2).

• Pull the case (3) forward at the bottom to disengage

from the securing clips.

• Lift the case slightly to clear the top locations and pull

forward to remove.

5.7 Gas supply

• Connect the 15 mm compression gas service cock (1)

supplied with the appliance (2) and tighten.

• Connect a gas supply pipe of not less than 15 mm

diameter to the gas service cock.

• Tighten all connections.

(Ensure the gas supply pipework is adequately sized

such that a 20 mbar gas pressure is available at the

boiler inlet at full flow rate).

Fig. 5.5: Remove of boiler casing

Fig. 5.6: Fitting the gas connection

Instructions for Installation and Servicing turboMAX pro R314

Boiler Installation Sequence 5

1

2

3

4

6

I

0

I

0

4

1

2

3

5

6

5.8 Cold water mains inlet and hot water outlet

Flush all foreign matter from the mains supply before

connecting to the boiler.

• Connect the cold water service valve (1) to the cold

inlet water connection (3) of the appliance with the

washer (2) provided and tighten.

• Connect the cold water inlet pipe copper tail to the

cold water service valve and tighten.

• Connect the 15 mm hot water outlet copper tail (4) to

the hot water outlet connection of the appliance (6)

with the washer provided (5) and tighten.

Note!

The hot water outlet union nut is packed in with

the PRV fitting pack.

5.9 Central heating flow and return pipework

Before connecting the heating circuit to the boiler appliance, all pipework and radiators must be thoroughly

flushed to remove any installation debris.

• Connect the central heating flow (4) and return (1) service valves to the appliance (6 and 3) with the washers

provided (2 and 5) and tighten the nuts. Ensure that

the valve spindles face downwards and the drain

points face to either side of the boiler.

• Connect the central heating pipework to the flow (4)

and return (1) tails.

Pressure Relief Valve

Connect a discharge pipe not less than 15 mm diameter

to the outlet of this valve.

The discharge pipework should be as short as possible

and installed with a continuous fall away from the boiler.

The pipe should terminate in a position which ensures

that any discharge of water or steam from the valve

cannot create a hazard to persons in or about the premises, or cause damage to any electrical components or

external wiring, and the point of discharge should be

clearly visible (see diagram in plastic bag).

Fig. 5.7: Fitting the hot and cold water connections

Fig. 5.8: Central heating flow and return pipework

Instructions for Installation and Servicing turboMAX pro R3 15

5 Boiler Installation Sequence

2

1

5.10 Connect the flue system to the boiler

• Refer to separate air/flue duct installation instructions

included with the boiler.

5.11 Electrical installation

General requirements

Important!

All electrical work shall be carried out by a

competent person and shall comply with

BS7671 (IEE Regulations).

The boiler is supplied for connection to 230 V, ~ 50 Hz

supply fused at 3 A rating.

Connection to the mains supply shall be made via a

fused 3 pin plug to an unswitched shuttered socket,

both complying to the requirements of BS1363.

(Alternatively, connection may be made via a 3 A fused

double pole isolator having a contact separation of at

least 3 mm in all poles and supplying the boiler and controls only).

The point of connection to the mains supply must allow

complete electrical isolation of the boiler and its ancillary controls. It should be readily accessible and adjacent to the boiler. A 3 core flexible cord according to

BS6500 tables 6, 8 or 16 (3 x 0.75 to 3 x 1.5 mm2)

should be used.

3

NL987543

RT 24V 230V RT 230V

Fig. 5.9: Wiring system

Warning!

This appliance must be earthed.

Important!

Ensure that all cords pass through the cable

clamps in the rear of the control box and are

securely fixed. Ensure that the power supply is

connected such that the current carrying conductors become taut before the earth conductor

should the supply cord slip from the cable

clamp.

Warning!

Mains connection terminals L and N remain live

even when the boiler on/off control is switched

off.

5.12 Connection to the main supply

• Lower the control panel.

• Unclip the terminal box cover (1) from the control

panel (2).

• Feed the power supply cord in to the appliance as

shown (fig 5.9).

• Use cable clamps.

Fig. 5.10: Exposed rear view of switchgear cabinet

• Connect the power supply cord as follows (Fig. 5.11).

Green/yellow (earth) wire: boiler terminal Earth sign

Blue (neutral) wire: boiler terminal N

Brown (live) wire: boiler terminal L

Note!

DO NOT use boiler terminal connections 7-8-9.

• Refit the terminal box cover by pushing into place

until it clips back into position.

• Raise the control panel and secure in place.

Instructions for Installation and Servicing turboMAX pro R316

NL987

F3

543

24V

230V

F1

5.13 Electronic board layout

Boiler Installation Sequence 5

Socket X2 for internal unit components

Socket X4 for minority reversing

Socket X7 for accessory box connection

Do not

use!

Socket X8 for VRC-VC connection

Mains power supply: connections L, N and earth

Room thermostat, 230 V: connections 3, 4 and 5

Socket X12: pump connection

Socket X14: gas valve connection

Abb. 0.0 Bildunterschrift

Fig. 5.11 Connection wiring

Instructions for Installation and Servicing turboMAX pro R3 17

Socket X13: fan unit connection

5 Boiler Installation Sequence

LN

234

LN 3

4

1

ACL Drayton

Tempus 1, Tempus 2

Lyfestyle LP111, LP711

ACL Drayton

Switchmaster

SM300

ACL Drayton

Switchmaster 980

Danfoss Randall

103 Series

Danfoss Randall

Set 1E, TS975

Danfoss Randall

TS715

Grässlin Towerchron

QE1, QM1

Honeywell

ST610A, ST6100C

Horstmann

Channel Plus

H11, H17, 425 Coronet

Horstmann

Centaur Plus

C11, C17

LN

234

LN 4

3

1

Potterton Myson

EP 4002, EP 5002

Smiths Timeguard

SupplyMASTER

FST11, FST17

Sunvic

Select 107

N1

AB C

N4

2

L

L

3

34

12

65E

4L3

N

3

E

NE

234

NE

1

L

L

3

56

4

LN

234

LN 3

4

1

LN

234

LN 3

4

1

LN

234

LN 3

4

1

NE

234

NE

1

L

L

3

56

4

NE

234

NE

1

L

L

3

4

LN

234

LN 3

4

1

LN

234

LN 3

4

1

AB

DLN

LN

C

N

E

3

12

4

345E

12

4

432/L

1/N

3

65

mains supply

LN E

E

Landis & Staefa

RWB7, RWB30

LN

234

LN 3

4

1

ACL Drayton

Lyfestyle PT271, PT371

ACL Drayton

Digistat 2, 3, 4

ACL Drayton

Digistat RF - SCR Receiver

Danfoss Randall

TP4, TP5, TP5E

Danfoss Randall

TP5E RF with receiver RX1

Danfoss Randall

TP75

Grässlin Towerchron

RTC7

Honeywell

CM61, CM67, CM31, CM37

Horstmann

Centaurstat 1, 7

Landis & Staefa

REV 11, REV 15, REV 22

12

34

3

Sunvic

TLX 6501

Sunvic

TLX RFP, TLX RFD

Vaillant

VRT 230, 220

N1

3

N3

2

L

L

4

32

43

1

LN

234

LN 3

4

1

BC

2341

A

3

56

4

12

34

3

AB

34

C

12

4

34

3

LL1

34

Smiths Timeguard

ProgramaSTAT PRT11, PRT17

LN

4

LN

3

34

12

34

3

LN

234

LN 3

4

1

3

45

5.14 Controls

External electrical controls

The boiler terminals 3, 4 and 5 are for connecting

external electrical controls such as a time switch and/or

room thermostat. Terminals 3 and 4 are linked together

when the boiler is supplied. If external controls are used,

this link must be removed, and the controls connected

across terminals 3 and 4.

Terminal 5 is an additional neutral connection for external neutrals such as from the anticipator of a room

thermostat.

Connection of external controls

Connection details for programmable room

thermostats.

Fig. I.12 shows the connection details where a programmable room thermostat (time switch with built in

room thermostat) is used to control the boiler.

Attention!

The arrowed numbers indicate connection into

the relevant terminal in the boiler terminal strip.

Connection details for external time switches and

boiler terminal strip.

Fig. 5.13 shows the connection details where a time

switch is used without a room thermostat to control the

boiler.

Attention!

The arrowed numbers indicate connection into

the relevant terminal in the boiler terminal strip.

If a room thermostat is to be connected in addition to a

time switch the wire between the time switch „ON“ terminal and boiler terminal 4 should be broken by the

contacts of the room thermostat (see schematic layout,

Fig. 5.14).

Vaillant optional plug in timer accessories

Refer to the instructions supplied with the optional

accessories for connection details.

Upon completion of all electrical connections refit the

terminal box cover by pushing into place. The cover is

secured by two locking clips.

Fig. 5.12 Connection details for programmable thermostats

Fig. 5.13 Connection details for time switch

Instructions for Installation and Servicing turboMAX pro R318

Fig. 5.14

3

987

MAINS

SUPPLY

230 V

50 Hz

L

L

LN

N

N

N

20 VDCDO NOT USE IN UK!

3 A FUSE

SWITCH

CONTACTS

ROOM

THERMOSTAT

CLOCK

4

5

Thermostatic radiator valves

The boiler has a built in automatic bypass valve making

it ideal for use in systems with thermostatic radiator valves (no separate system bypass is required).

For optimum fuel economy it is recommended that

where TRV’s are used they are used in conjunction with

a programmable room thermostat or separate timer and

room thermostat to ensure complete boiler shut down

when the heating demand is satisfied. (The radiator in

the room containing the room thermostat should not be

fitted with a TRV).

Boiler Installation Sequence 5

Automatic pump spin control (APS)

The boiler incorporates a built in control which will spin

the built in circulating pump and operate the diverter

valve (turboMAX only) once in a 24 hour period. This

control helps to prevent seizure when the boiler is not

operated for a period of time. This control is not active

when the power supply to the appliance is turned off.

Frost protection

The boiler has an integral frost thermostat which is designed for protection of the boiler.To protect remote or

exposed parts of the heating system or property additional frost protection measures must be taken such as the

installation of an external frost thermostat. This frost

thermostat should be connected across the boiler terminals 3 and 4, in parallel with any external heating controls. External frost protection cannot be used when

plug in timers have been fitted.

Circulating pump

The boiler incorporates a built in circulating pump that

is fully prewired (no additional wiring is necessary). The

pump incorporates an automatic overrun period after

the boiler switches off.

Anti-cycling ‘economiser’ control

The boiler incorporates a built in anti-cycling control to

ensure that energy wasteful short cycling of the boiler

cannot occur. This control prevents the boiler from reigniting for a preset period of 5 minutes after central

heating operation (the hot water operation is unaffected

by this control and hot water can be drawn at any time).

Note!

To temporarily override the anti-cycling control

turn the main boiler on/off switch to the off

position „0“ and then back to the on position

„I“ after a few seconds.

Instructions for Installation and Servicing turboMAX pro R3 19

6 Commissioning Part I

2

5

3

4

1

6 Commissioning Part I

6.1 Preliminary electrical checks

Check the electrical installation by carrying out short

circuit, earth continuity and resistance to earth tests

and a check for correct polarity.

6.2 Gas supply

The complete gas installation including the gas meter

must be inspected, tested for soundness and purged in

accordance with BS 6891.

The gas supply to the boiler can be purged by slackening the gas service valve beneath the boiler. Ensure

that there is adequate ventilation, extinguish all naked

flames and do not smoke whilst purging.

After purging, the gas service valve connection must be

retightened and tested for soundness. (The boiler itself

does not require purging as this will be done by the

automatic burner sequence control).

6.3 Cold water supply

Open all domestic hot water taps supplied by the boiler,

turn on the mains water supply to the boiler and open

the mains water isolating valve below the boiler.

Water will now flow through the boiler to the hot taps.

Starting with the lowest tap supplied, turn the hot taps

off one at a time until the hot water pipework is purged

of air. Check all hot and cold water pipework for leaks.

6.4 Filling the heating system

Proceed as follows to fill the system:

• Open all radiator valves on the system.

• Fill the system via the seperate filling point.

• Open the valve slowly and fill the unit with water until

the required pressure has been acheived (2).

• Bleed the air from the radiators.

• The boiler is equipped with an automatic air release

valve. To allow this to vent the boiler, the cap top must

be slackened by 1 - 2 turns. (This cap must be left

slackened during operation to ensure any residual air

or system gases are released).

• Close the filling valve (1) and disconnect the temporary

connection.

• Now check the water pressure in the unit again (and

add more water if necessary).

6.5 Initial system flush (“cold“)

The whole of the heating system must be flushed out at

least twice: once cold, and once hot as instructed later.

Open all radiator and heating valves and the boiler CH

service valves and drain the heating system and boiler

completely from the lowest points of the system via 1/2”

BSP drain taps (opened full bore to remove any installation debris prior to lighting the boiler).

Refill the heating system. Check the operation of the

pressure relief valve by rotating the knob on the valve.

Now check the water pressure in the unit again (and add

more water if necessary).

Fig. 6.1: Filling / draining the heating system

Close the filling valve (1) and disconnect the temporary

connection.

Instructions for Installation and Servicing turboMAX pro R320

Gas supply adjustments (Commissioning Part II) 7

1

1

2

1

1a

2

2a

7 Gas supply adjustments

7.1 Gas inlet working pressure

To check the gas inlet working pressure:

• Lower the front panel of the boiler.

• Lower the control panel.

• Slacken the sealing screw (1) located at measuring

point ”P.IN”.

• Attach U-gauge to the inlet test point on the gas valve

(2).

• Ensure that the gas service valve is open.

• Set the DHW temperature control to maximum and

fire the boiler at full rate by opening a hot water tap.

• Ensure that the hot water outlet temperature

adjustment control is set to maximum.

• Check that the U-gauge is reading in the range of 18 to

20 mbar. (If the pressure is not within this range this

should be investigated before continuing with the

commissioning preocedure.

(Lower pressures than this range are indicative of an

incorrectly sized or partially blocked gas supply.)

• Turn off the hot tap.

• Remove U-gauge, tighten test point sealing screw (1).

• Test for soundness.

• Record appliance working gas inlet pressure (mbar) in

the Benchmark gas boiler commissioning checklist.

7.2 Main burner pressure

The burner pressure on this appliance has been factory

set and does not require adjustment. To check the main

burner pressure connect the U-Gauge as follows depending on the gas type.

• Remove front case and combustion chamber cover.

Note!

All measurements and adjustments to the gas

valve must be done with the combustion chamber cover removed.

For natural gas appliances:

• Slacken the sealing screw (1) at test point on the gas

valve and attach one arm of a U-gauge (2) to the test

point.

For LPG appliances:

• Slacken the sealing screw (1a) at test point on the burner inlet gas pipe and attach one arm of a U-gauge

(2a) to the test point.

Connection for Natural gas

Fig. 7.1: Gas inlet working pressure

Connection for LPG

Fig. 7.2

Instructions for Installation and Servicing turboMAX pro R3 21

7 Gas supply adjustments (Commissioning Part II)

1

+

-

2

Set the DHW temperature control to maximum and fire

the boiler at full rate by fully opening a hot water tap.

Check that the burner pressure is as the maximum

shown in table 7.1.

Measure the domestic hot water mode burner operating

pressure (mbar), the heat input (kW), the inlet and outlet

domestic hot water temperatures (°C) and flow rate

(l/min) and record details in the boiler logbook.

After completion of all tests tighten sealing screw,

replace the sealing plug and check all test points for

soundness (1/1a).

7.3 Adjusting the central heating output (range

rating)

The boilers are fully modulating for central heating, and

it is therefore not necessary to range rate the boiler.

However, if desired, it is possible to range rate the boiler,

as follows:

• Connect the U-gauge to check burner pressure.

• Use Table 7.1 on to determine the central heating

output required.

• Identify required range rating setting and note main

burner pressure in mbar for that output.

• Turn on the central heating.

• Turn the central heating maximum radiator tempera-

ture control to its highest setting.

• Ensure that any thermostatic radiator valves are open

and set to high.

• Wait for approx. 2 minutes until the burner pressure

switches to full load.

• The central heating output can now be altered by ins-

erting an electricans screwdriver into the

potentiometer (2).

• Turn the potentiometer fully anticlockwise.

• Slowly turn the potentiometer clockwise, whilst

observing the U-gauge.

• Stop turning the potentiometer when the burner pres-

sure is at the correct setting for the output required.

• Turn off the hot tap.

• Remove U-gauge, tighten test point sealing screw (1).

• Reassemble the boiler.

• Refit plastic plug in chamber sensing tube.

• Carry out all safety checks as detailed in these

instructions.

• Record central heating operating pressure in the

Benchmark gas boiler commissioning checklist along

with the heat input (kW) and temperature difference

between flow and return.

Fig. 7.3: Adjusting the central heating output

Note!

This illustration shows the U-tube pressure

gauge connected to a system configured to run

on natural gas. When connecting the U-tube

pressure gauge to a system running on LPG,

please refer to Fig. 7.2 on page 21.

Attention!

DO NOT open any hot water tap while carrying

out this procedure (turboMAX plus only).

Instructions for Installation and Servicing turboMAX pro R322

Gas supply adjustments (Commissioning Part II) 7

7.4 Burner Pressure and gas rate

Burner Pressure turboMAX pro 24/2 E

Delivered gas Output[kW] Ignition rate 8.9 10.0 12.0 14.0 16.0 18.0 20.0 22.0 24.0

Natural gas 2H Burner pressure1)[mbar]

Main burner jet mark

2)

for G20

7 / 120

LPG 3+

Main burner jet mark

2)

Burner pressure1)[mbar]

for G30 3.9 3.9 4.9 6.9 9.2 11.8 14.7 17.8 21.1 24.7

7 / 072 for G31 5.4 5.4 6.7 9.4 12.5 16.0 19.8 24.0 28.5 33.3

Burner Pressure turboMAX pro 28/2 E

Delivered gas Output[kW] Ignition rate 10.4 12.0 14.0 16.0 18.0 20.0 22.0 24.0 26.0 28.0

Natural gas 2H Burner pressure1)[mbar]

Main burner jet mark

7 / 120

LPG 3+

Main burner jet mark

7 / 072 for G31 5.3 5.3 6.9 9.3 11.9 14.8 18.0 21.4 25.1 29.0 33.1

2)

for G20

Burner pressure1)[mbar]

2)

for G30 3.8 3.8 5.0 6.7 8.7 10.8 13.1 15.6 18.3 21.2 24.2

1.9 1.9 2.1 2 .9 3.7 4.7 5.8 6.7 8.4 9.8

1.8 1.8 2.3 3.0 3.9 4.8 5.8 6.8 8.0 9.2 10.5

Table 7.1 Burner pressure

1) 15 °C, 1013mbar, dry

2) The nozzles are stamped with the mark shown in this table.

The marking corresponds to the nozzle hole diameter multiplied by 100

Gas Rate turboMAX pro 24/2 E

Delivered gas Output[kW] 8.9 10.0 12.0 14.0 16.0 18.0 20.0 22.0 24.0

Natural gas 2H Gas Rate1)[m3/h]

Main burner jet mark

2)

for G20

1.1 1.2 1.4 1.7 1.9 2.1 2.4 2.6 2.8

7 / 120

Gas Rate turboMAX pro 28/2 E

Delivered gas Output[kW] 10.4 12.0 14.0 16.0 18.0 20.0 22.0 24.0 26.0 28.0

Natural gas 2H Gas Rate1)[m3/h]

Main burner jet mark

7 / 120

2)

per G20

1.3 1.5 1.7 1.9 2.1 2.4 2.6 2.8 3.1 3.3

Table 7.2 Gas flow rate

1) 15 °C, 1013mbar, dry

2) The nozzles are stamped with the mark shown in this table.

The marking corresponds to the nozzle hole diameter multiplied by 100

Instructions for Installation and Servicing turboMAX pro R3 23

7 Gas supply adjustments (Commissioning Part II)

1

I

0

I

0

90°

90°

3

2

7.5 Fit combustion chamber cover

Carefully re-fit the combustion chamber cover to the

boiler ensuring it is correctly sealed. Secure cover with

retaining clamps.

7.6 Fit boiler casing

• Carefully push case (1) onto the boiler such that the

locating points either side at the top of the boiler

engage. Push the casing onto the securing clips at the

bottom of the boiler.

• Close control panel (2).

• Secure control panel by turning both securing fasten-

ers (3) clockwise by 90°.

Fig. 7.4: Fit boiler casing

Instructions for Installation and Servicing turboMAX pro R324

Functional Checks (Commissioning Part III) 8

I

0

I

0

1

2

3

4

5

67

8 Functional Checks

8.1 Functional checks

Procedure

Once the unit has been installed and the gas supply has

been checked, operate the system to ensure that it is

working correctly.

• Operate the system, following the operating instruc-

tions supplied with the boiler.

• Check the system for water leaks and escaping gas.

• Check that the flue has been correctly installed,

according to the fitting instructions supplied with the

flue assembly.

• Check the burner for correct ignition and flame

picture.

• Check the hot water system for correct operation.

• Check the heating system for correct operation.

• By illuminating in this sequence the indicator lights

have demonstrated correct operation of the boiler for

DHW.

Note!

Should the boiler fail to light it will attempt 2

re-ignition sequences, if the boiler still fails to

light the burner lock out indicator will

illuminate (7). This usually means that the gas

supply is turned off or has not been purged of

air. Check the gas supply, push the reset button

and repeat the lightning procedure.

Fig. 8.2 Functional check

Heating system

• Ensure that the power on indicator is illuminated (1).

Fig. 8.1 Test for correct functioning

• Ensure that the maximum radiator temperature

control is turned to the high position.

8.2 Functional check of operation

The Vaillant turboMAX pro is equipped with a set of diagnostic indicator lights to show the operational

status of the boiler.

A functional check of DHW and CH operation can be

made using these indicator lights.

• Ensure external controls are calling for heat.

• The central heating demand indicator will illuminate

(3).

• Providing the boiler has not achieved its set

temperature, and the anti-cycling control is not

activated, the boiler will start its lighting sequence.

Once the fan and flue system have proved their satis-

Hot water system

• Ensure that the power on indicator (1) is illuminated.

• Turn on a hot top and draw water at a high rate.

• The hot water demand indicator (2) will illuminate.

• The appliance will start its lighting sequence. Once

the fan and flue system has proved itself, the fan operation indicator (4) will light.

• The gas valve will open and sparking will commence

at the burner. The ignition indicator (5) will illuminate.

• As soon as the burner has ignited and the flame has

factory operation the fan operation indicator (4) will

light.

• The gas valve will open and sparking will commence

at the burner. The ignition indicator (5) will illuminate.

• As soon as the burner has ignited and the flame has

been sensed the flame indicator (6) will illuminate.

• By illuminating in this sequence the indicator lights

have demonstrated correct operation of the boiler for

CH.

been sensed the flame indicator (6) will illuminate.

Instructions for Installation and Servicing turboMAX pro R3 25

8 Functional Checks (Commissioning Part III)

1

Further information can be obtained from Sentinel,

8.3 Adjusting pump speed

The unit is fitted with a two-speed pump. The pump is

delivered with the switch (1) set to position III.

Attention!

Important note:

The boiler should only be operated at pump setting III because the heating capacity for hot

water is reduced when operated at pump

setting II!

It is possible, however, to change the pump setting from

Level III to Level II manually when there is noise coming

from the heating system.

GE Betz. Widnes, Cheshire, WA8 8UD.

Tel: 0151 420 9595

• Disconnect the temporary filling connection.

• Refit the boiler casing.

• Attach the bottom cover to the boiler by securing with

the four screws provided. It may be necessary to

apapt the bottom cover by removing the easy break

sections.

8.4 Handing over to the user

• Set the maximum radiator temperature control to the

desired setting.

• Set the maximum hot water temperature control to

the desired setting.

• Instruct the user in the safe and efficient operation of

the boiler, in particular the function of:

- The boiler on/off control

- The maximum radiator temperature control

- The maximum hot water temperature control

- The pressure gauge

Fig. 8.3: Pump speed

Final system flush („HOT“)

• Turn on the boiler for central heating and allow the

boiler and system to reach operating temperature.

• Check that the heating system is watertight.

• Turn the boiler off and rapidly drain both boiler and

system while still hot.

• Refill the system and release all air. Release water

from the system until the system design pressure of

1.0 bar is attained.

(The actual reading on the pressure gauge should ideally be 0.5 bar plus an additional pressure corresponding

to the highest point of the system above the base of the

boiler - 10 m head equals an additional 1 bar reading on

the pressure gauge. The minimum pressure should not

be less than 1 bar in any installation.)

If the system is to be treated with an inhibitor it should

be applied at this stage in accordance with the manufacturers instructions.

• Show the user how to operate any external controls.

• Explain to the user the importance of having the boiler regularly serviced by a competent servicing company. To ensure regular servicing, it is strongly recommended that arrangements are made for a

Maintenance Agreement. Please contact Vaillant

Service Solutions (0870 6060 777) for further details.

• Ensure the Benchmark gas boiler commissioning

checklist is fully completed.

Failure to install and commission this appliance to the

manufacturers instructions may invaludate the warranty (Note: This does not affect your statutory

rights).

• Leave the user instructions in the clips provided in the

front panel of the boiler.

• Leave the installation and servicing instructions with

the user.

Note!

When you have finished the installation, attach

the sticker supplied (835593) to the appliance

in the user’s language.

Attention!

The device may only be used

• for initial operation

• for testing

• for continuous operation

with the chamber cover closed and with the flue

system fully mounted and sealed.

Instructions for Installation and Servicing turboMAX pro R326

9 Servicing

9.1 Initial Inspection

To ensure the continued safe and efficient operation of

the boiler it is recommended that it is checked and serviced as necessary at regular intervals. The frequency of

servicing will depend upon the particular installation

conditions and usage, but in general once per year

should be adequate. It is the law that all servicing work

is carried out by a competent person (Corgi registered).

Important!

Before starting any maintenance work:

• Isolate the mains electricity supply by disconnecting

the plug at the socket outlet (if there is only an isolating switch remove the fuse from the switch).

• Turn OFF the gas supply at the gas service valve fitted

to the boiler.

• Always test for gas soundness and always carry out

functional checks after any service work and after

exchanging any gas carrying component.

• Always check earth continuity, polarity and resistance

to earth with a multimeter after any service work and

after exchanging any electrical component.

Servicing 9

Note!

The boiler is fitted with a combustion analysis

test point. A suitable combustion analyser can

be connected to this point to establish the combustion performance of the boiler.

Before commencing any servicing or maintenance work,

carry out an initial inspection of the system as follows:

• Inspect the flue, pipework and electrical connections

for indications of damage or deterioration.

• Inspect the air supply and ventilation arrangements of

the installation.

• Check the heating and water system, in particular the

condition of radiator valves, evidence of leakage from

the heating system and dripping hot water taps.

Functional check of boiler operation

• Carry out a functional check of the boiler operation as

prevoiusly detailed.

• Remove the appliance casing as detailed and operate

the boiler by fully opening a hot water tap. Inspect the

burner operation through the viewing window. Check

that the flames are evenly covering the surface of the

burner. Inspect for signs of excessive flame lift or sooting.

Instructions for Installation and Servicing turboMAX pro R3 27

9 Servicing

6a

6b

7

9

10

8

2

1

5

5

4

6c

9.2 Cleaning the burner and primary heat exchanger

• Turn off the boiler.

• Isolate the electrical supply to the boiler.

• Remove the boiler case as described.

• Turn off the gas service valve.

• Turn off the boiler CH service valves.

• Turn off the cold water inlet service valve.

• Release the three clamps (1), remove the combustion

chamber cover (2).

• Pull the three cables (4) and two tubes (5) from the

fan assembly.

• Remove the fan assembly (6a, 6b, 6c).

• Remove the four screws (7) and detach the front

cover panel from the combustion chamber (8).

• Check the burner (9) and heat exchanger fins (10) and

remove any loose deposits with a soft brush.

• Reassemble in reverse order.

• Check central heating expansion vessel.

Note!

It is not necessary to carry out this check

every year – a check every three years should

be sufficient.

• Release the system water pressure from the boiler.

• Remove valve cap from expansion vessel charge point.

• Check that the internal charge pressure of expansion

vessel is between 0.7 - 0.9 bar. If pressure is lower

than this the vessel should be re-pressurised using an

air pump.

• Refit valve cap.

• Open central heating service valves and re-pressurise

the boiler and heating system if necessary.

• Open the gas service valve.

• Turn on the mains power supply.

• Operate the boiler and carry out soundness, safety

and function checks.

• Complete the service interval record section in the

Benchmark gas boiler commissioning checklist.

Fig. 9.1 Cleaning the burner and primary heat exchanger

Instructions for Installation and Servicing turboMAX pro R328

Fault Finding 10

10 Fault Finding

10.1 Introduction

The turboMAX pro has built in diagnostic indicator lights

to assist you with fault finding in the unlikely event of a

boiler malfunction. The lights will illuminate in sequence,

indicating the operational status of the boiler. Should a

fault develop in the boiler the indicators may flash highlighting the possible fault e.g.

Power on indicator (green)

Illuminates when the electricity supply to the boiler is

on, the main on/off control is set to position (I) and the

internal boiler fuses are o.k.

(A flashing indicator shows that the overheat thermostat has cut out.)

Hot water demand indicator (yellow)

Illuminates whenever there is a demand for hot water

i.e. a hot water tap is opened.

Central heating demand indicator (yellow)

Illuminates whenever there is a demand for central heating i.e. the radiator temperature control is turned on

and the external heating controls are calling for heat.

Note!

If the external controls are not calling for heat

(i.e. the room thermostat has reached

temperature) this indicator will go out. This is

perfectly normal.

To reset the appliance after a lockout (either burner

lockout illuminated or any other indicator light flashing), turn the central heating control to the reset position and release.

10.2 Logical fault finding procedure

Preliminary Checks

These checks must be carried out before attempting to

use the fault finding guide:

1) Carry out electrical safety checks.

2)Check that the external electricity supply to the boiler

is on, and a supply of 230 V~ is present

between boiler terminals „L“ and „N“.

3)Check that gas supply to the boiler is on and that it

has been correctly purged.

4)Ensure the heating system is full of water and charged

to approx. 1 bar. If not refill the system and vent

system. Ensure boiler flow and return service valves

are open.

5)Check that boiler main on/off control is set to position

(I)

6)Ensure that the Maximum Radiator Temperature and

Maximum Hot Water Temperature controls are set to

high position.

7)Check that all the external controls are on and calling

for heat (if no external controls are fitted, boiler terminals 3 and 4 must be linked). Check that boiler anticycling „economiser“ control is not engaged.

Procedure

Fan operation indicator (yellow)

Illuminates to indicate that the fan is operating and has

been checked by the fan pressure switch.

(A flashing indicator shows that the air pressure switch

has not made.)

Ignition indicator (yellow)

Illuminates when gas valve, operator and ignition transformer are energised. This indicator remains on during

burner operation.

(A flashing indicator shows lack of water or poor water

circulation in central heating system.)

Flame indicator (yellow)

Illuminates when flame is recognised by the flame monitoring system.

(A flashing indicator shows that an NTC sensor is broken, not connected or shorted to earth.)

Burner lockout indicator (red)

Illuminates if the burner fails to light within 10 seconds

of illumination of the ignition indicator after the 3rd ignition cycle.

(A flashing indicator shows a failure in the electronic

boards.)

Note!

Always check the operation of the boiler for

central heating first before checking hot water

operation. Do not open a hot tap unless

instructed to by the fault finding guide.

Instructions for Installation and Servicing turboMAX pro R3 29

10 Fault Finding

Ensure boiler main

ON/OFF control is set

to position "1"

Ye s Go to sheet C

Check electrical supply, appliance fuses and on/off control

No

Is 230VAC present across

terminals L and N?

Ye s

Is 230VAC present across

terminals 3 and 5?

Ye s

Is voltage between

16-26 VDC present across

terminals 8 and 9?

Ye s

Is 5 VDC present between

5V and GND test points

on electronic board?

Replace LCD display

Ye s

NoRepair external fault

Is the continuity

across fuse F1?

Go to sheet B

Does ON/OFF knob

operate switch on

electronic board

Boiler ON/OFF control

defective,

change electronic

board

Replace switch

mechanism

No

No

No

Ye s

Ye s

Note 1:

For test purposes, disconnect

external controls from terminal

3 - 4 and replace with a bridge

between these terminals.

It appliance then operates, the

fault is with the external controls.

Sheet A

Is there continuity

across fuse F3?

No

No

Replace electronic

board

No

Check transformer

Replace if

necessary

Ye s

Does green power on

indicator glow?

Instructions for Installation and Servicing turboMAX pro R330

Instructions for Installation and Servicing turboMAX pro R3 31

Sheet BCheck operation of pump and fan

Turn off the main ON/OFF control to the

"0" position

Diconnect the power supply to the boiler

Go to sheet A

Check transformer 230 VAC primary

(black/red) and approx. 17 VDC secondary

(blue/brown)

Check/replace pump

Replace fuse F1

If fan commences operation, exchange

gas valve

After approx. 20 secs.

Does fuse F1 blow?

Produce central heating demand.

Does fuse blow immediately?

Turn the main ON/OFF control to the "1"

position

Does green power on indicator glow?

Ye s

No

No

No

Ye s

Check/replace fan Replace electronic board

No

Ye s

Ye s

Does green power on indicator glow?

Fault Finding 10

10 Fault Finding

Check central heating and controls

Ensure that radiator temperature control knob

is set to vertical position and that any internal

timer (if fitted) is calling for heat

No

Is 230 VAC present across terminals 4 and 5

No

External fault: Check all external controls are

calling for heat, replace or repair as necessary

(see also note 1 sheet A)

Ye s

Ye s Disconnect built in timer (if fitted)

No Go to sheet D

Does ignition

commence?

No

Ye s

Replace defective

timer

Sheet C

Does yellow central heating demand

indicator glow?

Does yellow flame indicator flash?

Instructions for Installation and Servicing turboMAX pro R332

Instructions for Installation and Servicing turboMAX pro R3 33

Does fan run after approx. 30 secs.?

Check flue and ignition system

No

Check pitot tube (in fan outlet) and air

hoses are not obstructed and correctly

aligned.

Check or replace air pressure switch.