Vaillant recoVAIR VAR 260/4 E, recoVAIR VAR 360/4 E, recoVAIR VAR 260/4, recoVAIR VAR 360/4 Operating Instructions Manual

Page 1

Operating instructions

recoVAIR

VAR 260/4 (E), VAR 360/4 (E)

AT, CH (de), DE

Publisher/manufacturer

Vaillant GmbH

Berghauser Str. 40 D-42859 Remscheid

Tel. +49 21 91 18‑0 Fax +49 21 91 18‑2810

info@vaillant.de www.vaillant.de

Page 2

Contents

2 Operating instructions recoVAIR 0020159950_07

Contents

1 Safety.................................................................... 3

1.1 Action-related warnings......................................... 3

1.2 Intended use.......................................................... 3

1.3 General safety information .................................... 3

2 Notes on the documentation .............................. 5

2.1 Observing other applicable documents ................. 5

2.2 Storing documents................................................. 5

2.3 Validity of the instructions...................................... 5

3 Product description............................................. 5

3.1 Role and function................................................... 5

3.2 Symbols on the product......................................... 6

3.3 Product design....................................................... 6

3.4 Digital Information and Analysis System (DIA)...... 6

3.5 Information on the identification plate.................... 6

3.6 CE label ................................................................. 7

4 Operation.............................................................. 7

4.1 Operating concept ................................................. 7

4.2 Basic display.......................................................... 7

4.3 Operating levels..................................................... 7

4.4 Operator level – overview...................................... 8

4.5 Switching the product on/off .................................. 8

4.6 Setting the ventilation ............................................ 8

4.7 Setting the desired temperature ............................ 9

5 Troubleshooting .................................................. 9

5.1 Detecting and rectifying faults ............................... 9

6 Maintenance and care......................................... 9

6.1 Spare parts .......................................................... 10

6.2 Carrying out maintenance work........................... 10

7 Decommissioning.............................................. 11

7.1 Permanently decommissioning the product......... 11

8 Recycling and disposal..................................... 11

9 Guarantee and customer service ..................... 12

9.1 Guarantee............................................................ 12

9.2 Customer service................................................. 12

Appendix ............................................................................13

A Operator level – overview................................. 13

B Ventilation levels – Overview ........................... 14

C Status messages – Overview ........................... 14

D Maintenance messages – Overview................. 15

E Limp home mode messages – Overview......... 15

F Troubleshooting and fault elimination ............ 15

F.1 Troubleshooting................................................... 15

F.2 Remedy ............................................................... 15

Page 3

Safety 1

0020159950_07 recoVAIR Operating instructions 3

1 Safety

1.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in

accordance with the severity of the possible

danger using the following warning signs and

signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of

severe personal injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental

damage

1.2 Intended use

There is a risk of injury or death to the user or

others, or of damage to the product and other

property in the event of improper use or use

for which it is not intended.

The product is only intended for aerating and

ventilating living areas. If the product is operated with a heat production source, the heat

production source must be room-sealed. The

remote control must only be used to control

the product. The product must only be operated when the filters are inserted.

The product is not suitable for aerating and

ventilating swimming pool systems. Due to

the high level of exposure to dust, the product

must not be operated during the construction

phase.

Intended use includes the following:

– observance of the operating instructions

included for the product and any other

system components

– compliance with all inspection and main-

tenance conditions listed in the instructions.

This product can be used by children aged

from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge if

they have been given supervision or instruction concerning use of the product in a safe

way and understand the hazards involved.

Children must not play with the product.

Cleaning and user maintenance work must

not be carried out by children unless they are

supervised.

Any other use that is not specified in these

instructions, or use beyond that specified in

this document shall be considered improper

use. Any direct commercial or industrial use

is also deemed to be improper.

Caution.

Improper use of any kind is prohibited.

1.3 General safety information

1.3.1 Danger caused by improper

operation

Improper operation may present a danger to

you and others, and cause material damage.

▶ Carefully read the enclosed instructions

and all other applicable documents, particularly the "Safety" section and the warnings.

▶ Only carry out the activities for which in-

structions are provided in these operating

instructions.

1.3.2 The product must only be installed

and started up by the competent

person

The product must only be properly installed

and started up by a competent person.

1.3.3 Risk of poisoning caused by

simultaneous operation with a heat

production source

If the product is operated at the same time as

a heat production source, life-threatening flue

gas may escape into the rooms from the heat

production source.

▶ Ensure that the competent person has

installed a safety device that monitors the

pressure difference between the living

room and flue system.

Page 4

1 Safety

4 Operating instructions recoVAIR 0020159950_07

1.3.4 Risk of injury and material damage

due to incorrect maintenance and

repairs

▶ Only carry out permitted maintenance work

on the product.

▶ Employ a competent person to carry out all

other maintenance and repair work.

▶ Never carry out repair work on the product

yourself.

▶ Adhere to the maintenance intervals spe-

cified.

1.3.5 Danger due to changes to the

product environment

There is a risk of injury or death to the operator or others, or of damage to the product

and other property, in the event of changes to

the product environment.

▶ Never shut down the safety devices.

▶ Do not tamper with any of the safety

devices.

▶ Do not damage or remove any seals on

components. Only qualified competent

persons and customer service personnel

are authorised to make modifications to

sealed components.

▶ Do not make any changes:

– The product itself

– to the product bypass

– to the pipelines and connections for exit

air, supply air, exhaust air and outside air

– to the condensate discharge

– to the mains connection

▶ Ensure that the mains plug/circuit breaker

(depending on the country) is always accessible after the installation by the competent person and during the entire time

the product is operating.

▶ Do not seal off any air inlets and outlets in

doors, ceilings, windows and walls.

▶ When installing floor coverings, do not

close off or reduce in size the ventilation

openings on the undersides of doors.

▶ If loudspeaker announcements from the

fire brigade/police or radio announcements request that you close windows and

doors, you must switch off the product.

(→ Page 8)

Page 5

Notes on the documentation 2

0020159950_07 recoVAIR Operating instructions 5

2 Notes on the documentation

2.1 Observing other applicable documents

▶ You must observe all operating instructions enclosed with

the system components.

2.2 Storing documents

▶ Keep this manual and all other applicable documents

safe for future use.

2.3 Validity of the instructions

These instructions apply only to:

Product article number

Applicability: Switzerland

Switzerland

VAR 260/4

0010016042

VAR 260/4 E

0010016350

VAR 360/4

0010016041

VAR 360/4 E

0010016351

Product article number

Applicability: Germany

Germany

VAR 260/4

0010016040

VAR 260/4 E

0010016348

VAR 360/4

0010015166

VAR 360/4 E

0010016349

Product article number

Applicability: Austria

Austria

VAR 260/4

0010016040

VAR 260/4 E

0010016348

VAR 360/4

0010015166

VAR 360/4 E

0010016349

3 Product description

This product is a domestic ventilation unit.

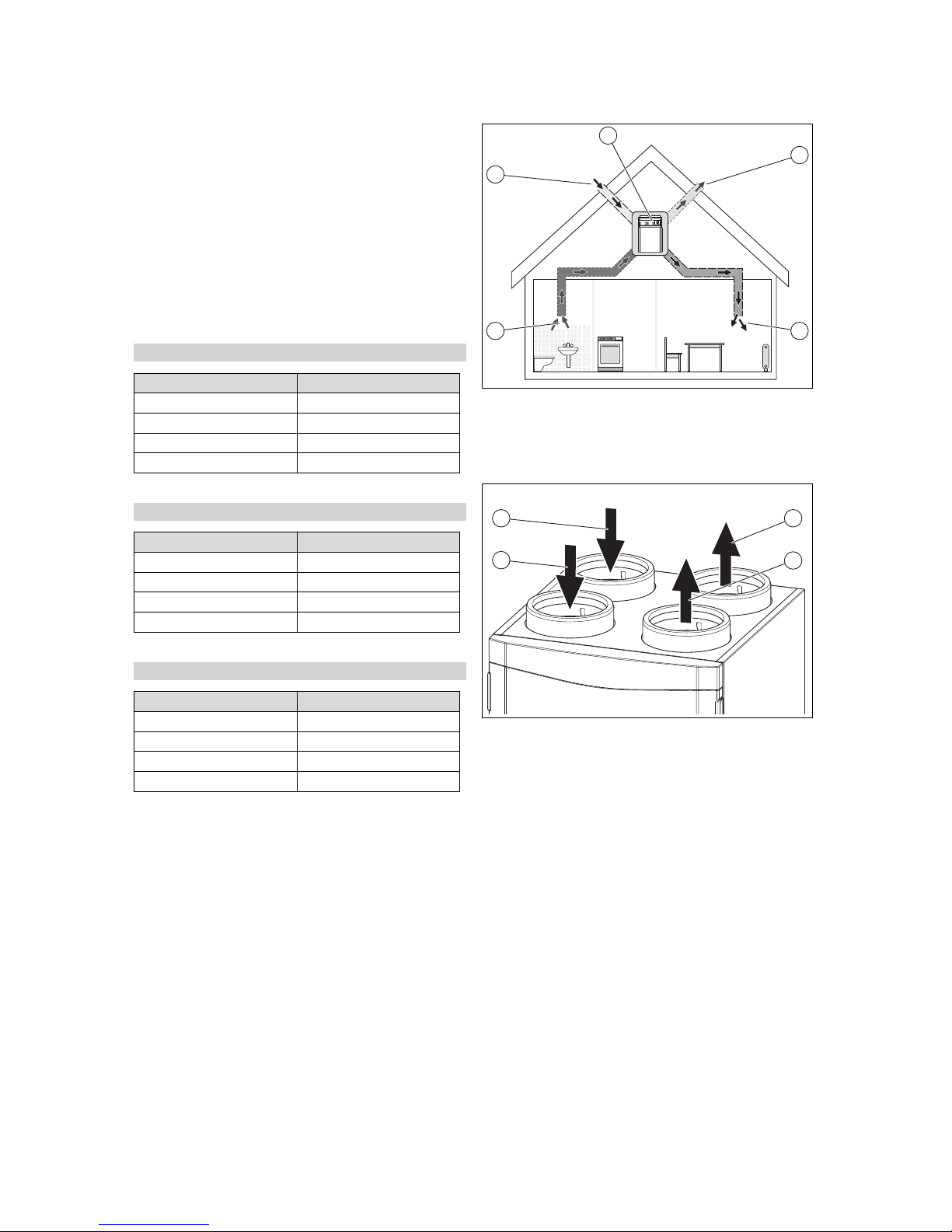

3.1 Role and function

Task

The product aerates and ventilates living spaces and ensures a constant exchange of air with heat recovery in the

building.

Furthermore, the product guarantees the hygienically necessary minimum air exchange and prevents damage to the

building caused by moisture and mould.

Functionality

1

23

4

5

The product (5) is the central component in controlled room

ventilation. Fresh outside air (4) is guided to the living rooms

and bedrooms via air intake openings (2). The used air from

the kitchen, bathroom and WC is guided outside (1) via the

exhaust air openings (3).

4

3

2

1

The exhaust air (2) from the dwelling is guided to the

product. The filter for the exhaust air cleans the exhaust

air and guides the exhaust air to the heat exchanger. The

heat exchanger extracts the heat from the exhaust air (heat

recovery). The cooled air is guided outside as exit air (4).

The outside air (1) is guided to the product from the outside.

The filter for the outside air cleans the outside air and guides

the outside air to the heat exchanger. The heat exchanger

transfers the heat from the exhaust air to the outside air. The

heated air is guided to the dwelling as supply air (3).

On summer nights, the outside temperature is often lower

than the room temperature. Through the automatic bypass,

the cooler outside air is no longer preheated by the heat exchanger. The bypass guides the warmer exhaust air past the

heat exchanger directly outside. The frost protection function

reduces the supply air volume flow according to demand,

which leads to an increase in the exit air temperature. This

prevents the heat exchanger from freezing. If the reduction in

the supply air volume flow is no longer sufficient, the product

switches off.

The humidity sensor records the current moisture in the

exhaust air. If you operate the product in auto mode, the

current air volume flow is regulated according to demand

(aguaCARE.

Page 6

3 Product description

6 Operating instructions recoVAIR 0020159950_07

In the winter, the room air humidity can be perceived as

dry. The optional enthalpy heat exchanger (heat exchanger

with moisture recovery) has the opposite effect (aguaCARE

plus).

3.2 Symbols on the product

Symbol Meaning

Opening for the outdoor-air filter

Opening for the exhaust air filter

3.3 Product design

1

2

3

5

6

7

8

9

4

1 Exit air connection

2 Supply air connection

3 Front casing

4 Front flap

5 Operator control panel

6 Exhaust air filter

7 Outdoor air filter

8 Exhaust air connection

9 Outside air connection

3.3.1 Overview of the operator control elements

278

3

12

1 Fault clearance key

2 Operating buttons

3 Display

3.4 Digital Information and Analysis System

(DIA)

The product is equipped with a Digital Information and Analysis System (DIA system). This system provides information

on the operating status and helps you deal with faults.

278

1

2

3

7

6

5

4

1 Display of the current

air volume flow

2 Display of the current

configuration of the

right-hand selection

button

3 Left- and right-hand

selection buttons

4 "+" button/"-" button

5 Access to the menu for

additional information

6 Display of the current

configuration of the lefthand selection button

7 Display of the symbols

for the active operating

status of the ventilators

Symbol Meaning

Air volume flow:

– Symbol is filled: Air volume flow is greater

– Symbol is empty: Air volume flow is smaller

Heat recovery:

– Permanently on: Heat recovery is switched off

– Permanently off: Heat recovery is active

– Shown in the display: Ventilation active

– Display in the current configuration of the left-

hand selection button: Adjustment range for the

air volume flow

Adjustment range for the desired temperature

F.XXX

Fault in the product: Appears instead of the basic

display, may be an explanatory plain text display

3.5 Information on the identification plate

The identification plate is mounted on the underside of the

product.

Information on the identification plate

Meaning

Read the installation and

maintenance instructions.

VAR 260/4 (E)

VAR 360/4 (E)

Type designation

VAR

Vaillant ventilation unit with

heat recovery

260

360

Max. air volume flow in m3/h

/4 Unit generation

E Enthalpy

P

MAX

Max. power consumption

Page 7

Operation 4

0020159950_07 recoVAIR Operating instructions 7

Information on the identification plate

Meaning

V

MAX

Max. air volume flow

dP

MAX

Delivery pressure at max. air

volume flow

T

MAX

Max. operating temperature

Bar code with serial number,

The 7th to 16th digits of the

serial number form the article

number

3.6 CE label

The CE label shows that the products comply with the basic

requirements of the applicable directives as stated on the

identification plate.

The declaration of conformity can be viewed at the manufacturer's site.

4 Operation

4.1 Operating concept

Operator

control

element

Meaning

(Left-hand

selection

button)

– Setting the air volume flow

– Cancelling the activation of an operating

mode

– Cancelling a change to a set value

– Going one selection level higher

(Right-hand

selection

button)

– Setting the desired temperature

– Activating the operating mode

– Confirm setting

– Going one selection level lower

Press

+

at the same

time

Calling up the menu

/

– Switching back and forth between the menu

items for the entry list

– Decreasing/increasing the set value

Both selection buttons have a soft key function. This means

that their function can be changed.

If the display has been dimmed, the light is switched on by

the first press of the button. In this case, to trigger the button

function, you must press a button again.

The display shows a highlighted selection level, a setting

level or a highlighted value with white font on a black background. A flashing, highlighted value means that you can

change the value.

You always have the option to cancel the change to a setting

and the reading of a value or to exit the selection level by

pressing the left-hand selection button.

If you do not press any buttons for more than 15 minutes,

the display returns to the basic display. Changes that are not

confirmed will not be applied.

4.1.1 Selection level display fields

Menu

Energy yield

Live Monitor

Information

Back Select

1

2

3

4

1 Scrollbar (if more than

three list entries are

available)

2 Current functions of

the right and left-hand

selection buttons (soft

key functions)

3 Selection level list

entries

4 Current function or

selection level

You can use the selection levels to navigate to the display

and setting levels in which you can read or change settings.

The selection levels have four display fields.

In the following, a path name is specified which shows you

how to access a function, e.g. Menu → Information → Con-

tact data.

4.2 Basic display

278

The basic display shows the current condition of the product.

From the basic display, you can directly call up and change

the air volume flow (ventilation) and the desired temperature.

You can access all other functions via the menu.

If there is a fault message, the basic display switches to a

plain text display of the fault message.

From the basic display, you can directly change and read

the most important settings and information by pressing the

selection buttons.

The functions that are available depend on whether a controller is connected to the product.

4.3 Operating levels

The product has two operating levels:

– The operator level shows the most important information

and offers set-up options which do not require any special prior knowledge.

– The installer level must only be operated by persons with

expertise and is therefore protected by a code.

Page 8

4 Operation

8 Operating instructions recoVAIR 0020159950_07

4.4 Operator level – overview

The appendix contains the complete overview of the end

user level. The most important menu points are explained

below.

Operator level – overview (→ Page 13)

4.4.1 Reading the energy yield

Menu → Energy yield →

You can use this function to read the energy yield for the

entire operation.

If a controller is connected, you can also read the energy

yield for the previous day, month and year.

The output figure represents the relationship between recovered and used energy.

4.4.2 Reading the Live Monitor (current status)

Menu → Live Monitor →

You can use the Live Monitor function to read the current

status of the product, the connected components, and the

temperature and parameter values. The display is automatically updated.

4.4.3 Reading contact details

Menu → Information → Contact data

If your competent person has entered their telephone number during the installation, you can read the telephone number under Contact details.

4.4.4 Reading serial and article numbers

Menu → Information → Serial number

You can use this function to read the serial and article number. The article number is found in the second line of the

serial number.

4.4.5 Reading the filter change

Menu → Information → Days until filter chg.

You can use this function to read when the filters have to be

replaced.

4.4.6 Filter change overdue

Menu → Information → Filter chg. overdue

You can use this function to read by how long the filter

change is overdue.

4.4.7 Reading the maintenance interval

Menu → Information → Days until maint.

You can use this function to read when you should have your

product serviced.

4.4.8 Maintenance interval overdue

Menu → Information → Maintenance overdue

You can use this function to read by how long the maintenance for your product is overdue.

4.4.9 Setting the language

Menu → Basic settings → Language

You can use this function to change the language settings

for your product.

4.4.10 Set display contrast

Menu → Basic settings → Display contrast

You can use this function to set the display contrast.

4.4.11 Setting the heat recovery

Menu → Basic settings → Heat recovery

You can use this function to set the heat recovery.

– Auto heat recovery (recommended): The bypass is auto-

matically closed/opened depending on the outside temperature.

– Heat recovery on: The bypass is closed.

– Heat recovery off: The bypass is open.

4.5 Switching the product on/off

The mains plug/circuit breaker (depending on the country)

must remain accessible after the installation by the competent person and during the entire time the product is operating.

4.5.1 Switching on the product

▶ Plug the product's mains plug into the earthed plug

socket (230 V) or use the circuit breaker (depending on

the country) to switch on the product.

◁ The product's electronics start up.

◁ The basic display appears on the display.

4.5.2 Switching off the product

▶ Pull the product's mains plug out of the earthed plug

socket (230 V) or use the circuit breaker (depending on

the country) to switch off the product.

4.6 Setting the ventilation

4.6.1 Setting the ventilation on the product

1.

Alternatives 1 / 2

▶

Press in the basic display.

▶

Use and to select the desired ventilation level.

– Adjustment range: Nominal ventilation, In-

creased ventil., Reduced ventilation, Auto

Ventilation levels – Overview (→ Page 14)

▶

Confirm by pressing .

1.

Alternatives 2 / 2

▶

Press in the basic display.

▶

Press .

▶

Use and to select the desired ventilation level.

Page 9

Troubleshooting 5

0020159950_07 recoVAIR Operating instructions 9

– Adjustment range: Intens. ventilation On, In-

tens. ventilation Off

Ventilation levels – Overview (→ Page 14)

▶

Confirm by pressing .

4.6.2 Setting the ventilation at the step switch

Conditions: Step switch connected

6

5

4

3

1

2

1 Maintenance indicator

2 Rotary switch

3 Increased ventilation

4 Nominal ventilation

5 Automatic ventilation

6 Reduced ventilation

▶ Use the step switch to set the ventilation level (optional

accessory).

Ventilation levels – Overview (→ Page 14)

Note

The maintenance display (1) lights up if the

product requires a filter change or general

maintenance, or if a fault is present.

4.6.3 Setting the ventilation at the control

Conditions: Controller connected

▶ Navigate to the corresponding menu in the control and

set the ventilation level (→ Control operating instructions).

Ventilation level

Proportion of the nominal ventilation

1)

0 40 %

1 70 %

2 80 %

3 90 %

4 100 %

5 110 %

6 120 %

7 130 %

1)

The nominal ventilation is the normal operating mode with

normal loading of the room air and a normal number of

people.

4.7 Setting the desired temperature

Conditions: Controller connected, No boiler connected

OR: No controller connected, No other units connected (only recoVAIR is

available)

▶

Press in the basic display.

▶

Use and to select the desired

temperature.

– Adjustment range: 16 … 28 ℃

▶

Confirm by pressing .

5 Troubleshooting

5.1 Detecting and rectifying faults

Danger!

Risk of death from electric shock!

Risk of death from electric shock when working on live connections (230 V).

▶ Before carrying out any work on the

product, pull the product's mains plug

out of the earthed plug socket or use the

circuit breaker (depending on the country)

to switch off the product's power supply.

▶ Secure the power supply against being

switched on again.

▶ Check that there is no voltage in the con-

nections.

▶ If faults or fault messages (F.XXX) or limp home mode

messages (Lhm.XXX) occur, proceed in accordance with

the tables in the appendix.

▶ If the product is not functioning correctly, contact a com-

petent person.

6 Maintenance and care

Danger!

Risk of death from electric shock!

Risk of death from electric shock when working on live connections (230 V).

▶ Before carrying out any work on the

product, pull the product's mains plug

out of the earthed plug socket or use the

circuit breaker (depending on the country)

to switch off the product's power supply.

▶ Secure the power supply against being

switched on again.

▶ Check that there is no voltage in the con-

nections.

An annual inspection and biennial maintenance of the

product carried out by a competent person is a prerequisite

for ensuring that the product is permanently ready and

safe for operation, reliable, and has a long service life. The

Page 10

6 Maintenance and care

10 Operating instructions recoVAIR 0020159950_07

inspection may require maintenance to be carried out earlier,

depending on the results.

6.1 Spare parts

All spare parts that are used must be Original Vaillant spare

parts.

Original Vaillant spare parts are available from your heating

specialist company.

6.2 Carrying out maintenance work

▶ Only carry out the maintenance work that is listed in the

operating instructions.

▶ Observe the displayed maintenance messages and

measures in accordance with the table in the appendix.

▶ Switch off the product before carrying out any mainten-

ance work. (→ Page 8)

▶ Switch on the product after carrying out any maintenance

work. (→ Page 8)

▶ Ensure that all other maintenance work that is not listed

here is carried out by a competent person.

6.2.1 Caring for the product

Caution.

Risk of material damage caused by un-

suitable cleaning agents.

▶ Do not use sprays, scouring agents, de-

tergents, solvents or cleaning agents that

contain chlorine.

▶ Clean the casing with a damp cloth and a little solvent-

free soap.

6.2.2 Cleaning the supply and exhaust air valves

▶ Clean the supply and exhaust air valves in the living

areas (→ Instructions for valves).

6.2.3 Maintaining the filters

Removing the filters

3

2

1

4

1. Remove the front flap (4) by pushing the recessed

handle.

2. Pull out both of the filter plugs (3).

3. Pull the outdoor air filter (1) and the exhaust-air filter (2)

out of the product.

4. Check the filters for dirt.

– Recommended check: Every three months

1 / 2

Degree of contamination: Filter is lightly soiled

Caution.

Risk of material damage caused by

incorrect cleaning of the filter.

Water and other liquids may damage the

filters and the product.

▶ Only clean the filters with a vacuum

cleaner.

▶ Clean the filters.

– Vacuum cleaner at a low setting

2 / 2

Degree of contamination: Filter is heavily soiled

Operating days: ≥ 182 d

Replacement interval reached: At least twice annually

▶ Replace the filters in the system.

– Exhaust-air filter class: G4 (in accordance

with EN 779)/ISO Coarse (in accordance with

ISO 16890)

– Outdoor-air filter class: F7 or F9 (in ac-

cordance with EN 779)/ISO ePM2,5 65%

or ISO ePM1,0 85% (in accordance with

ISO 16890)

– Exhaust air valve filter

Installing the filters

5. Install the filters in the product and ensure that they are

correctly aligned as you do so.

– Labelling on the filters and slot positions

6. Place the filter plugs on the filters.

Resetting the filter days

7. Switch on the product. (→ Page 8)

8.

Press the + buttons simultaneously to access the menu.

9. Navigate to the Resets → Res. days until fil. ch. menu.

10. Reset the filter days.

11.

Press the button to exit the menu.

12. Secure the front flap.

6.2.4 Cleaning the condensate siphon

Note

Wear gloves and avoid contact with the skin and

eyes.

1. Check the condensate siphon for dirt each time you

change the filter.

Condensate siphon contaminated

▶ Remove the condensate siphon from the product.

▶ Clean the condensate siphon.

Page 11

Decommissioning 7

0020159950_07 recoVAIR Operating instructions 11

Connecting the condensate siphon/dry siphon and

condensate drain pipework

2. Connect the condensate siphon/dry siphon to the

product (→ Installation instructions for the condensate

siphon/dry siphon, accessories).

– Condensate discharge pipe downward gradient

(descending from the product): > 5°

min. 20

1

A

B

Danger!

Risk of damage to health caused by incor-

rectly connected condensate drain pipework!

In the interests of hygiene, the condensate

drain pipework must not be directly connected to the waste-water piping.

▶ Connect the condensate discharge to the

second siphon.

Caution.

Risk of material damage caused by con-

densate.

If a condensate discharge pipe has been connected incorrectly, a build-up of condensate

and uncontrolled condensate drainage may

damage the product. Furthermore, the condensate may leak out of the product and onto

the floor.

▶ Install a drip distance of min. 20 mm

between the outlet for the condensate

drain pipework and the second siphon.

▶ Note the downward gradient for the con-

densate discharge pipe (> 5°).

3. Connect the condensate drain pipework to the second

siphon while taking into consideration the drip distance

(1).

– Drip distance: ≥ 20 mm

4. Fill the condensate siphon/dry siphon with water.

6.2.5 Establish system efficiency

1. Clean the supply and exhaust air valves and their corresponding filters. (→ Page 10)

2. Check whether any obstructions are impeding the air

flows.

3. Clean the outside air's intake tract and the exit air's

outlet openings.

4. Carry out maintenance on the product filter.

(→ Page 10)

5. Remove the front flap if this has not yet been done.

6. Switch the product on if this has not already been done.

(→ Page 8)

7. Press the reset button.

◁ Maintenance message M.802 is no longer shown in

the display. No other measures are required.

▽ Maintenance message M.802 is still being shown in

the display.

▶ Inform a competent person.

8. Secure the front flap.

7 Decommissioning

7.1 Permanently decommissioning the product

▶ Have a competent person permanently decommission

the product.

8 Recycling and disposal

Disposing of the packaging

▶ The competent person who installed your product is re-

sponsible for the disposal of the packaging.

Disposing of the product and accessories

▶ Do not dispose of the product or the accessories (apart

from the filters) with household waste.

▶ Ensure that the product and all accessories are disposed

of properly.

▶ Dispose of used filters with household waste.

▶ Observe all relevant regulations.

Page 12

9 Guarantee and customer service

12 Operating instructions recoVAIR 0020159950_07

9 Guarantee and customer service

9.1 Guarantee

Applicability: Switzerland

Werksgarantie gewähren wir nur bei Installation durch einen

anerkannten Fachhandwerksbetrieb. Dem Eigentümer des

Geräts räumen wir eine Werksgarantie entsprechend den

landesspezifischen Vaillant Geschäftsbedingungen und den

entsprechend abgeschlossenen Wartungsverträgen ein.

Garantiearbeiten werden grundsätzlich nur von unserem

Werkskundendienst ausgeführt.

Applicability: Germany

OR Austria

Herstellergarantie gewähren wir nur bei Installation durch

einen anerkannten Fachhandwerksbetrieb.

Dem Eigentümer des Geräts räumen wir diese Herstellergarantie entsprechend den Vaillant Garantiebedingungen

ein. Garantiearbeiten werden grundsätzlich nur von unserem

Kundendienst ausgeführt. Wir können Ihnen daher etwaige

Kosten, die Ihnen bei der Durchführung von Arbeiten an

dem Gerät während der Garantiezeit entstehen, nur dann

erstatten, falls wir Ihnen einen entsprechenden Auftrag erteilt

haben und es sich um einen Garantiefall handelt.

9.2 Customer service

Applicability: Austria

Vaillant Group Austria GmbH

Clemens-Holzmeister-Straße 6

1100 Wien

Österreich

E-Mail Kundendienst: termin@vaillant.at

Internet Kundendienst: http://www.vaillant.at/werkskundendienst/

Telefon: 05 7050‑2100 (zum Regionaltarif österreichweit, bei

Anrufen aus dem Mobilfunknetz ggf. abweichende Tarife nähere Information erhalten Sie bei Ihrem Mobilnetzbetreiber)

Der flächendeckende Kundendienst für ganz Österreich ist

täglich von 0 bis 24 Uhr erreichbar. Vaillant Kundendiensttechniker sind 365 Tage für Sie unterwegs, sonn- und feiertags, österreichweit.

Applicability: Switzerland

Vaillant GmbH (Schweiz, Suisse, Svizzera)

Riedstrasse 12

CH-8953 Dietikon

Schweiz, Svizzera, Suisse

Kundendienst: 044 74429‑29

Techn. Vertriebssupport: 044 74429‑19

Applicability: Germany

Auftragsannahme Vaillant Kundendienst: 021 91 5767901

Page 13

Appendix

0020159950_07 recoVAIR Operating instructions 13

Appendix

A Operator level – overview

Setting level Values Unit Increment, select Default

setting

Min. Max.

Menu → Energy yield →

Energy yield: Today Current value kWh

En. yield: Prev. day Current value kWh

Energy yield: Month Current value kWh

Energy yield: Year Current value kWh

Energy yield: Total Current value kWh

Output figure Current value

Menu → Live Monitor →

Status Current value

Frost prot. element Current value

Heat recovery Current value

Power efficiency Current value

Wh/m

3

Exhaust air temp. Current value ℃

Exhaust air humidity Current value % rel.

Supply air temp. Current value ℃

Outside air temp. Current value ℃

Supply air targ. val. Current value m³/h

Menu → Information →

Contact data Phone number

Serial number Permanent

value

Days until filter chg. Current value d

Filter chg. overdue Current value d

Days until maint. Current value d

Maintenance overdue Current value d

Menu → Basic settings →

Language Current lan-

guage

Languages available for selection English

Display contrast Current value 1 25

15 40

Heat recovery Current value OFF, ON, Auto Auto

Menu → Resets →

Res. days until fil. ch. Yes, No No

Page 14

Appendix

14 Operating instructions recoVAIR 0020159950_07

B Ventilation levels – Overview

Ventilation

level

Meaning

Automatic

ventilation

(recommended)

The relative humidity in the extract air is continuously measured and the volume flow is

adapted to the current requirement. This setting can be used throughout the entire year.

Nominal ventilation

The nominal ventilation is the normal operating mode at normal loading of the room air

and a normal number of people.

Reduced ventilation

Reduced ventilation should be selected if you

will be absent for an extended period of time

in order to reduce the energy consumption.

Increased

ventilation

Increased ventilation should be selected

for increased loading of the room air. For

example, if there is an increased number of

people or for activities such as cooking, etc.

Ventilation

boost (can only

be set using

the control

elements on

the product or

the control)

Ventilation boost should be selected if there is

temporarily increased load. Ventilation boost

is activated for 30 minutes, after which the

product automatically switches back to the

operating mode that was previously set.

C Status messages – Overview

Statuscode Meaning

S.800 Frost prot. element active

The frost protection element is activated at outside temperatures below −3 °C in order to prevent the

product from freezing.

S.802 Heat recovery active The bypass is closed. Heat is recovered via the heat exchanger.

S.803 Heat recovery not active

The bypass is open. The rooms are passively cooled.

S.804 Heat recovery 50% The bypass is half-open. The rooms are also passively cooled. However, part of the volume flow is

guided through the heat exchanger in order to prevent supply air being too cool.

S.805 Automatic mode The ventilation of the rooms depends on the moisture in the rooms. The more moisture there is, the

more intensive the ventilation. If the optional CO2sensors (carbon dioxide) are installed, the CO2content is taken into consideration.

S.806 Manual mode The product is operated at the selected ventilation level. This is set using the control elements on the

product, the step switch or an optional control.

S.807 Intens. ventilation Intensive ventilation has been activated.

S.808 Calibration Calibration mode has been activated.

S.809 Check programme or

sensor/actuator test active

A check programme or sensor/actuator test has been activated.

S.810 Days away from home

active

Days away from home mode has been activated.

S.811 Moisture protection

active

The moisture protection function has been activated. This is sometimes activated by functions of the

limp home mode.

S.812 Standard frost prot.

active

The standard frost protection function has been activated. The supply air ventilator is down-regulated,

depending on the outside temperature, in order to prevent the product from freezing.

S.813 Cut-off protection bypass active

The automatic bypass cut-off protection has been activated.

S.814 Intensive ventilation

overrun

A phase with nominal ventilation always follows an intensive ventilation phase.

S.815 System off Frost protection active

The product is switched off at low temperatures in order to prevent the product from freezing.

Page 15

Appendix

0020159950_07 recoVAIR Operating instructions 15

D Maintenance messages – Overview

# Message Description Maintenance work Interval

1 M.800 Filter

change

The maintenance interval for

the filters was exceeded.

Maintaining the filters At least twice annually

10

2 M.801 Mainten-

ance

The maintenance interval for

the product was exceeded.

Have the maintenance work

carried out on the product by a

competent person

At least annually

3 M.802 System ef-

ficiency impaired

The system efficiency is adversely affected.

Establish system efficiency As required

11

E Limp home mode messages – Overview

Message Possible cause Measure

Lhm.806 Supply air temp. too

low

Frost protection active ▶ Wait until the supply-air temperature increases again. The

product then starts normal operation.

Supply air temp.: > 10 ℃

F Troubleshooting and fault elimination

F.1 Troubleshooting

Symptom Possible cause Measure

Product not operating The mains voltage has been

interrupted/power cut

▶ Wait until the mains voltage has been re-established and the

product automatically switches on (all settings are retained).

Frost protection active (mains

voltage present)

1. Check whether S.815 is displayed in the Live Monitor.

2. Wait until the outside temperature increases (the product

automatically switches on no later than 60 minutes after the

temperature increases.).

– Outside temperature: > −3 ℃

Product has a reduced air flow Filter slightly dirty ▶ Clean the filters.

Filter heavily dirty ▶ Replace the filter.

Supply-air temperature too low ▶ Wait until the supply-air temperature increases again. The

product then starts normal operation.

Supply air temp.: > 10 ℃

Outside temperature too low 1. Check whether S.812 is displayed in the Live Monitor.

2. Wait until the outside temperature increases again. The

product then starts normal operation.

– Outside temperature: > −3 ℃

Product with increased noise

level

Filter slightly dirty ▶ Clean the filters.

Filter heavily dirty ▶ Replace the filter.

Product with bad/unpleasant air Filter heavily dirty ▶ Replace the filter.

F.2 Remedy

Message Possible cause Measure

F.801 Frost protection not

guaranteed

Heat exchanger protection is

active

▶ Wait until the outside temperature increases (the product auto-

matically switches on no later than 60 minutes after the temperature increases.).

Outside temperature: > −3 ℃

F.804 Supply air temp. too

low

Bypass does not work/is defective

1. Press the fault clearance key.

– Fault clearance attempts: ≤ 3

2. If the fault cannot be eliminated with the fault clearance attempt, inform a competent person.

Heat exchanger does not

work/is defective

1. Press the fault clearance key.

– Fault clearance attempts: ≤ 3

2. If the fault cannot be eliminated with the fault clearance attempt, inform a competent person.

Page 16

0020159950_07 12.07.2017

Supplier

Vaillant Deutschland GmbH & Co.KG

Berghauser Str. 40 D-42859 Remscheid

Telefon 021 91 18‑0 Telefax 021 91 18‑2810

Auftragsannahme Vaillant Kundendienst 021 91 5767901

info@vaillant.de www.vaillant.de

Vaillant Group Austria GmbH

Clemens-Holzmeister-Straße 6 1100 Wien

Telefon 05 7050 Telefax 05 7050‑1199

Telefon 05 7050‑2100 (zum Regionaltarif österreichweit, bei Anrufen aus dem Mobilfunknetz ggf. abweichende

Tarife - nähere Information erhalten Sie bei Ihrem Mobilnetzbetreiber)

info@vaillant.at termin@vaillant.at

www.vaillant.at www.vaillant.at/werkskundendienst/

Vaillant GmbH (Schweiz, Suisse, Svizzera)

Riedstrasse 12 CH-8953 Dietikon

Tel. 044 74429‑29 Fax 044 74429‑28

Kundendienst 044 74429‑29 Techn. Vertriebssupport 044 74429‑19

info@vaillant.ch www.vaillant.ch

© These instructions, or parts thereof, are protected by copyright and may be reproduced or distributed only with

the manufacturer's written consent.

We reserve the right to make technical changes.

0020159950_07

Loading...

Loading...