Vaillant recoVAIR/3 SERIES, recoVAIR VAR 275/3, recoVAIR VAR 350/3 Operating And Installation Manual

Page 1

For the owner and expert technician

Operating and Installation Manual

recoVAIR/3

Domestic ventilation unit with heat recovery and remote control

recoVAIR VAR 275/3

recoVAIR VAR 350/3

GB

Page 2

Page 3

For the owner

Operating Manual

recoVAIR/3

Contents

General Information...................................................4

1 Notes on the documentation .........................4

1.1 Documents storage ................................................4

1.2 Used Symbols ...........................................................4

1.3 Manual Validity ........................................................4

1.4 CE Label .....................................................................4

1.5 Identification Plate .................................................5

2 Safety Instructions and Regulations ...........5

2.1 Safety Instructions .................................................5

2.1.1 Assembly and Installation .....................................5

2.1.2 Operation ..................................................................5

2.1.3 Changes in the Environment of the

Domestic Ventilation Unit .....................................5

2.2 Precaution Instructions .........................................6

3 Installation and Operation Instructions ......6

3.1 Intended Use ............................................................6

3.2 Installation Site Requirements ............................6

3.3 Servicing ....................................................................6

3.4 Recycling and Disposal ..........................................6

3.4.1 Device .........................................................................6

3.4.2 Packing ......................................................................6

3.5 Energy Saving Tips ................................................. 7

4 Handling ...........................................................7

4.1 Assembling of the Domestic Ventilation

Unit .............................................................................7

4.2 Bypass (optional) ....................................................7

4.3 Switching-on and -off of the device ................... 7

4.4 Functional Overview of the Digital Remote

Control ....................................................................... 7

4.5 Display Overview .....................................................8

4.5.1 Meaning of Symbols ...............................................8

4.6 Settings from the Basic Display ..........................8

4.7 Programming of the Clock Timer .......................9

4.8 Special functions ................................................... 10

4.9 Information Level ....................................................11

5 Troubleshooting ..............................................11

6 Maintenance .................................................. 12

6.1 Cleaning or Replacing the Filter in the

Domestic Ventilation Unit ....................................12

6.2 Cleaning or Replacing the Filters in the

Bypass Casing .........................................................13

6.3 Filter ..........................................................................13

7 Warranty and Customer Service .................13

7.1 Manufacturer’s Warranty and Liability.............13

7.2 Vaillant Service .......................................................13

Page 4

General Information

1 Notes on the documentation

General Information

The domestic ventilation unit consists of a central ventilation appliance for air exchange with heat recovery and

a remote control. For summer operation, you can obtain

a bypass as accessory. It can directly provide living

rooms with cool external air whenever it is necessary.

The external air flow bypasses the heat exchanger.

The unit is connected to an air ducting system, which is

equipped with silencers, pre-filters, fresh-air and exhaust-air grilles and louvres.

Fresh air grilles supply fresh air to the living areas and

stale moist air is extracted from the kitchen, bathroom

and WC.

With the digital remote control the user is able to automatically switch and adapt the domestic ventilation unit

power to their own requirements.

The unit ensures:

– A constant air exchange in the building

– The hygienic minimum air exchange in accordance

with UK building regulations Part F

– Energy savings thanks to high efficiency heat recov-

ery

– A high hygiene standard due to the prevention of hu-

midity and mould damages of the building

The exact model description of the unit is to be found

on the identification plate positioned below the unit.

1 Notes on the documentation

The following notes serve as a guide for the entire documentation.

Other documents are valid in connection with this operating manual.

We accept no liability for any damage caused by failure to observe these instructions.

1.1 Documents storage

Please store this operating manual and other applicable

documents where they are accessible at all times.

1.2 Used Symbols

When operating the unit, please observe the safety instructions in this operating manual!

Danger!

d

Immediate danger to life and limb!

Danger!

e

Risk of death from electric shock!

Caution!

a

Potentially dangerous situation for the product

and environment!

Note

h

Useful Information and Hints.

• Symbol for a required task.

1.3 Manual Validity

This operating manual applies exclusively to units with

the following article numbers:

0010006801

0010006802

For the article number of your unit, refer to the identification plate.

1.4 CE Label

The CE label shows that the recoVAIR ventilation unit

complies with the basic requirements of the following

directives and guidelines:

– Low-voltage Directive 73/23/EEC, modified with

Directive 93/68/EEC

– EMC-Directive 89/336/EEC, modified by the Directive

91/263/EEC, 92/31/EEC and 93/68/EEC

Operating Manual recoVAIR/3 0020062918_034

Page 5

Notes on the documentation 1

Safety instructions and regulations 2

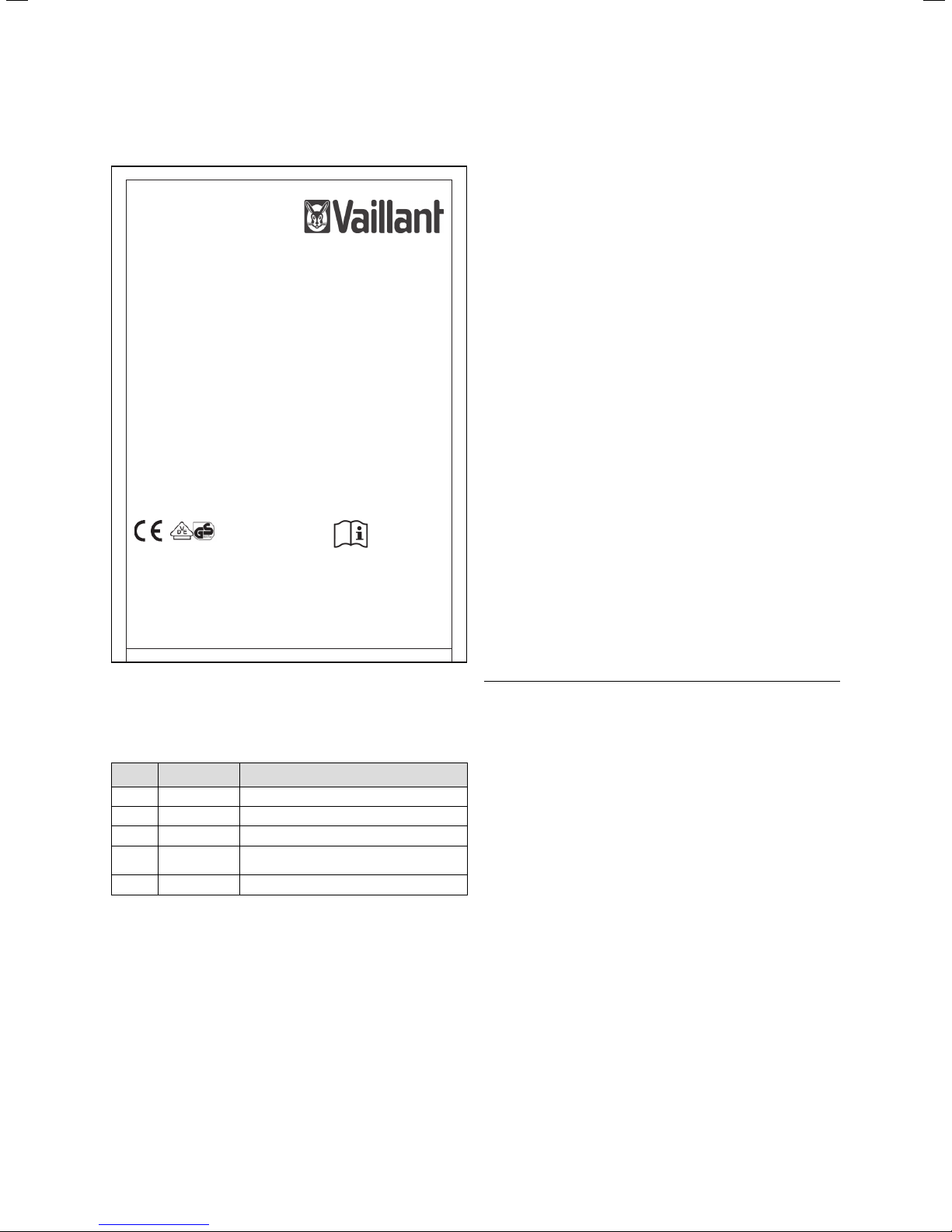

1.5 Identification Plate

Vaillant GmbH Remscheid / Germany

Serial-no. 1234567890xxxxxx

VAR 275 / 3

P

V

dP

T

Max

Max

Max.

210 W

275 m³ / h

170 Pa

Max

60 °C

IPX2

Bar – Code

230V~ 50 HZ

2.1.1 Assembly and Installation

The installation of the device can only be carried out by

a qualified expert technician. He/she will be responsible

for the correct installation and start-up.

He/she is also responsible for the inspection and the

corrective maintenance of the device as well as for the

changes in the air flow adjustment.

If the system is used for ventilation in locations with

room-dependent combustion equipment depending on

the room air, the corresponding flue gas extraction systems must be checked and maintained by a trained

technician. It is mandatory to prevent flue gas leakage

from the combustion equipment.

2.1.2 Operation

Note that the device can only be used if all ventilation

pipes of the device are connected and the entire device

is closed.

The unit must only be operated with the supplied filters

installed. Regularly check whether the filters are dirty

and damaged.

We recommend to visually check the filters every

6 months and to replace them every 12 months, or after

2000 operating hours at the latest. If the system is to

be used for ventilation purposes in locations with roomdependent combustion facilities, the corresponding flue

gas extraction systems must be checked and maintained

by suitably trained personnel.

Fig. 1.1 Identification Plate

The identification plate is positioned below the unit. The

indications given on the identification plate have the following meaning:

Units Value Description

230 V ~50 Hz Mains voltage

P

V

dP

T

Table 1.1 Explanation of identification plate

210 W Maximum electrical power consumption

max

275 m3/h Maximum air volume flow

max

170 Pa Allowable pressure loss of the device at

max

60 °C Maximum operating temperature

Max

V

Max

2 Safety Instructions and Regulations

2.1 Safety Instructions

Always observe the following safety instructions and

regulations.

2.1.3 Changes in the Environment of the Domestic

Ventilation Unit

Caution!

a

Do not make any changes to the unit or casing

which might impair the system functions!

Do not modify

- the unit,

– the outside air, fresh air, exhaust and discharge air

ducts, the pipes for condensation water and the unit

mains connection.

This also applies to alterations to structural elements in

the vicinity of the unit which might affect its operational

safety.

– do not obstruct the air inlets and outlets with doors,

ceilings, windows and walls even temporarily. Do not

cover the air inlets and outlets, e.g. with clothes or

similar. When laying floor materials, do not block or

reduce the vent apertures at the bottom of the doors.

To make alterations to the unit or to its environment,

you must refer to the suitably qualified expert technician who is qualified to do this work.

5Operating Manual recoVAIR/3 0020062918_03

Page 6

2 Safety instructions and regulations

3 Installation and Operation Instructions

Only expert technicians are authorised to execute repair

and maintenance work (with the exception of replacing

the filters). It is recommended that you carry out a visual inspection of the filters at least every 6 months and

replace the filters every 12 months, or at least after

2,000 hours of operation."

2.2 Precaution Instructions

Danger!

e

Risk of fatal electric shock from touching live

connections.

Before working on the unit always disconnect

from the mains supply and ensure that the unit

cannot be restarted.

In case of failures during operation, proceed in accordance with the fault finding table of chapter 5 of this

document. In case it is not possible to eliminate the

fault, please contact an expert technician.

3 Installation and Operation

Instructions

3.1 Intended Use

The Vaillant domestic ventilation units are built and designed according to accepted safety rules and regulations. Nevertheless, improper use can cause serious or

fatal injury to the user or others, and the appliance or

other property can be damaged.

This device is not designed to be used by persons (including children) with limited mental and sensory capabilities or by persons who have not enough experience

and/or knowledge, unless they are supervised by a person who is responsible for their safety or have been instructed by him/her about how to use the device.

Children must be supervised to ensure they do not play

with the unit.

The domestic ventilation unit must be installed by a

qualified technician, who is responsible for the observance of the existing regulations, rules and guidelines.

Due to high level of dust, operation during the construction phase is not allowed.

The domestic ventilation units are specifically designed

for the ventilation of residential spaces. The remote

control including the operating mode selector and the

timer must only be used for controlling the domestic

ventilation unit as described in these instructions; it is

not designed for any other purpose.

Any other or additional use is considered to be improper. The domestic ventilation unit is not suitable for ventilating swimming pools.

The manufacturer/supplier shall not be responsible for

any damages resulting from such improper use.

The user alone bears the risk.

Intended use includes observing the operating and installation manual and all other applicable documents, as

well as adhering to the maintenance and inspection conditions.

Caution!

a

Any improper use is forbidden.

3.2 Installation Site Requirements

– These ventilation units may be internally installed in

flats, cellar spaces, storage or multipurpose rooms as

well as in attic spaces.

– The unit must be mounted wall-hung and in the verti-

cal position. Please observe the permitted load carrying capacity of the wall.

– There must be enough space for mounting the air

duct connections, for a 230V mains voltage connection (usually a switched socket outlet) provided by the

customer as well as a drain outlet with a drain trap.

– The installation site should be frost-proof.

– The installation site must be equipped with a ventila-

tion system.

– The local mains power isolator must always be

easily accessible.

3.3 Servicing

• Clean the cladding of your unit with a damp cloth and

a little soap.

Note

h

Do not use abrasive cleansers or agents which

could damage the cladding of the coated steel

plate.

3.4 Recycling and Disposal

The ventilation unit as well as the packaging consist

mainly of recyclable raw materials.

3.4.1 Device

The filters used with the unit may be disposed of with

the normal household waste. Do not dispose the unit

and the other accessories with normal household waste.

Please ensure that the old unit and accessories are

properly disposed of.

Note

h

Please observe applicable national regulations.

3.4.2 Packing

Leave the disposal of the transport packaging to the

qualified servicing company which installed the appliance.

Operating Manual recoVAIR/3 0020062918_036

Page 7

Installation and Operation Instructions 3

Handling 4

3.5 Energy Saving Tips

Although this unit is used to increase comfort and energy savings, it is possible to maximise energy savings if

you observe the following.

Note

h

At low ambient temperatures below the room

temperature, you will reach the maximum energy saving if you keep the windows closed and

ensure the necessary air exchange by the operation of the domestic ventilation unit.

It goes without saying that venting the room is always

possible by opening the windows.

4 Handling

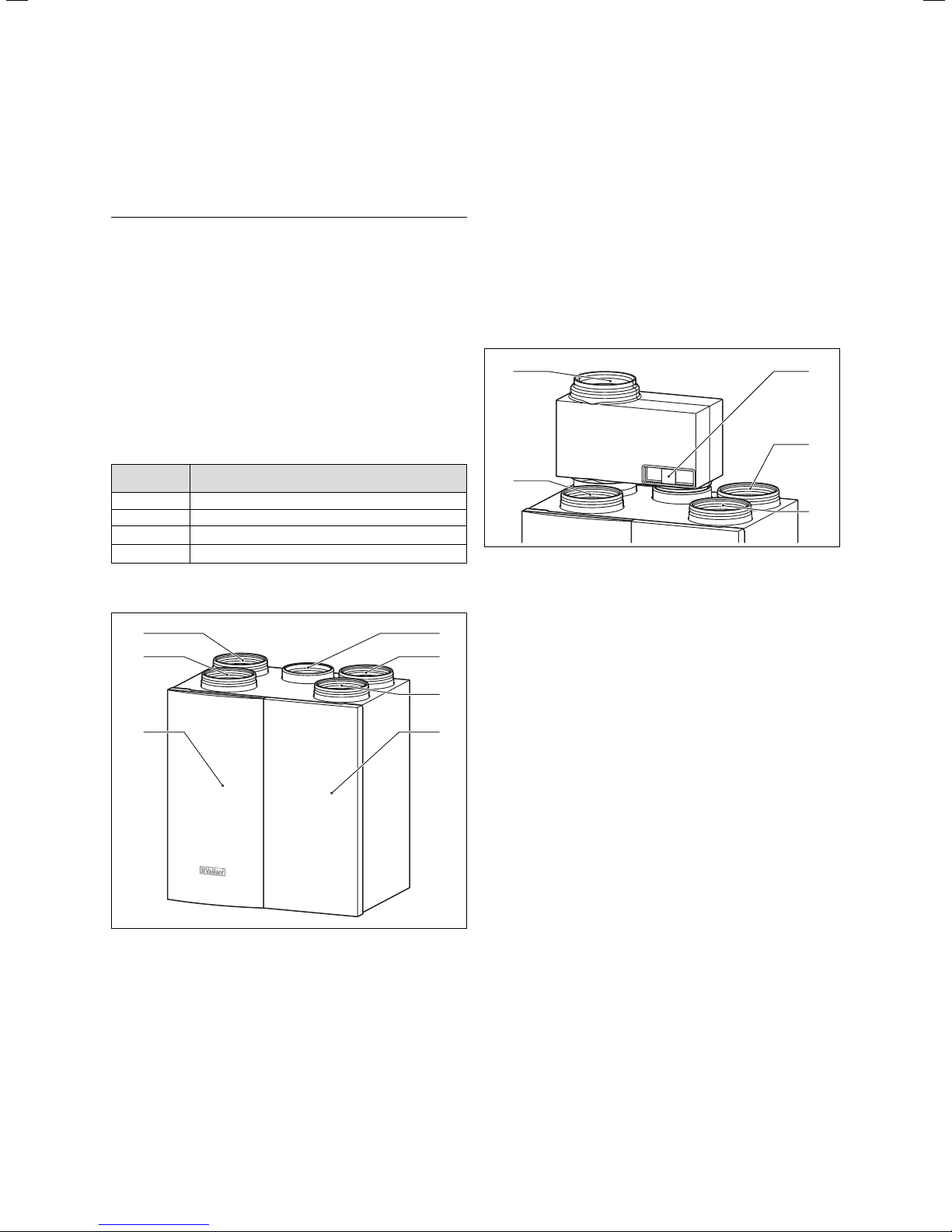

4.1 Assembling of the Domestic Ventilation Unit

Designation Explanation

Fresh air From the ventilation unit into the living space

Exhaust air From the living space into the ventilation unit

Outside air From outside to the domestic ventilation unit

Outgoing air From the domestic ventilation unit to outside

Table 4.1 Designation of the ventilation ducts

7

6

1

2

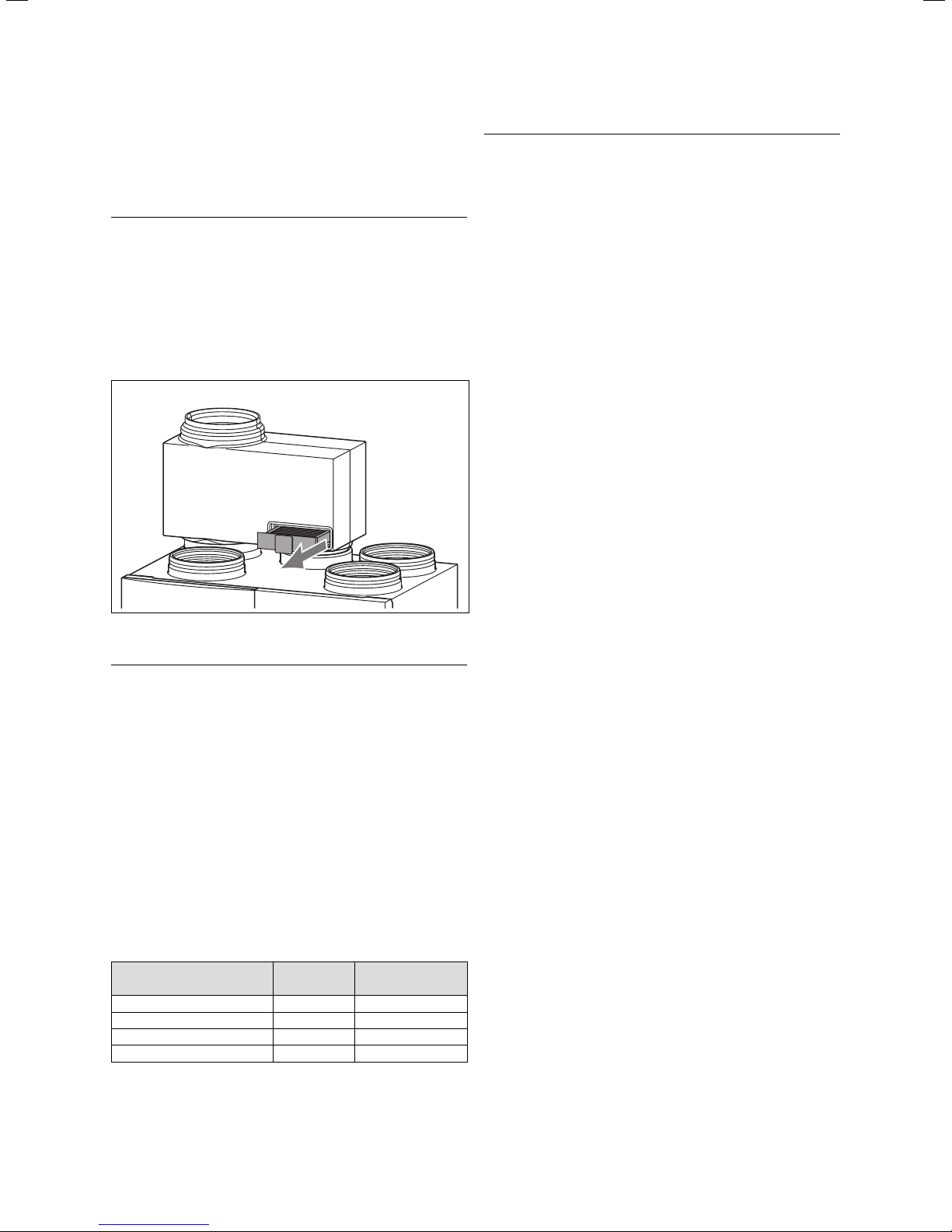

4.2 Bypass (optional)

The device can be equipped with a bypass, which is fitted on the top of the device, see fig. 4.2.

With a bypass installed the user may operate the socalled "free cooling mode" during the summer months

with the outside temperature falling below room temperature during the night. The cooler outside temperature will not be warmed by the device before it was

blown into the room. To protect the bypass valve from

dirt, we recommend an outside air filter of the filter

class at least G3. The filter is installed on site into the

outside air duct, possibly close to the air inlet.

5

4

Fig. 4.2 Bypass

Key

1 Filter

2 Outgoing air connection

3 Fresh air connection

4 Exhaust air connection

5 Aeration with the outside air

1

2

3

5

Fig. 4.1 recoVAIR VAR 275/3 and 350/3

Key

1 Bypass connection 5 Door in cladding

2 Discharge air duct connec-

tion

3 Fresh air duct connection 7 Outside air duct connec-

4 Front cladding

6 Exhaust air duct connec-

tion

tion

3

4.3 Switching-on and -off of the device

The domestic ventilation unit is supplied with electrical

4

power via a 230 V mains line.

• Insert the mains plug into the 230-V socket.

The electronics of the ventilation appliance is starting.

The display shows the unit type (display "RECO 275 or

350") and then, after about 3 seconds, the indication

switches to the basic display.

• To switch off the unit, pull the mains plug out of the

plug socket. Using the "off" menu point on the remote

control switches the unit to the lowest fan speed.

4.4 Functional Overview of the Digital Remote

Control

The domestic ventilation unit is equipped with a digital

remote control to operate the unit.

The remote control has three buttons as well as a dial

(Vaillant operating concept "turn and click") to set various operating programs. In addition, you can set special

functions as well as a time-controlled function of the

ventilation unit.

7Operating Manual recoVAIR/3 0020062918_03

Page 8

4 Handling

1

2

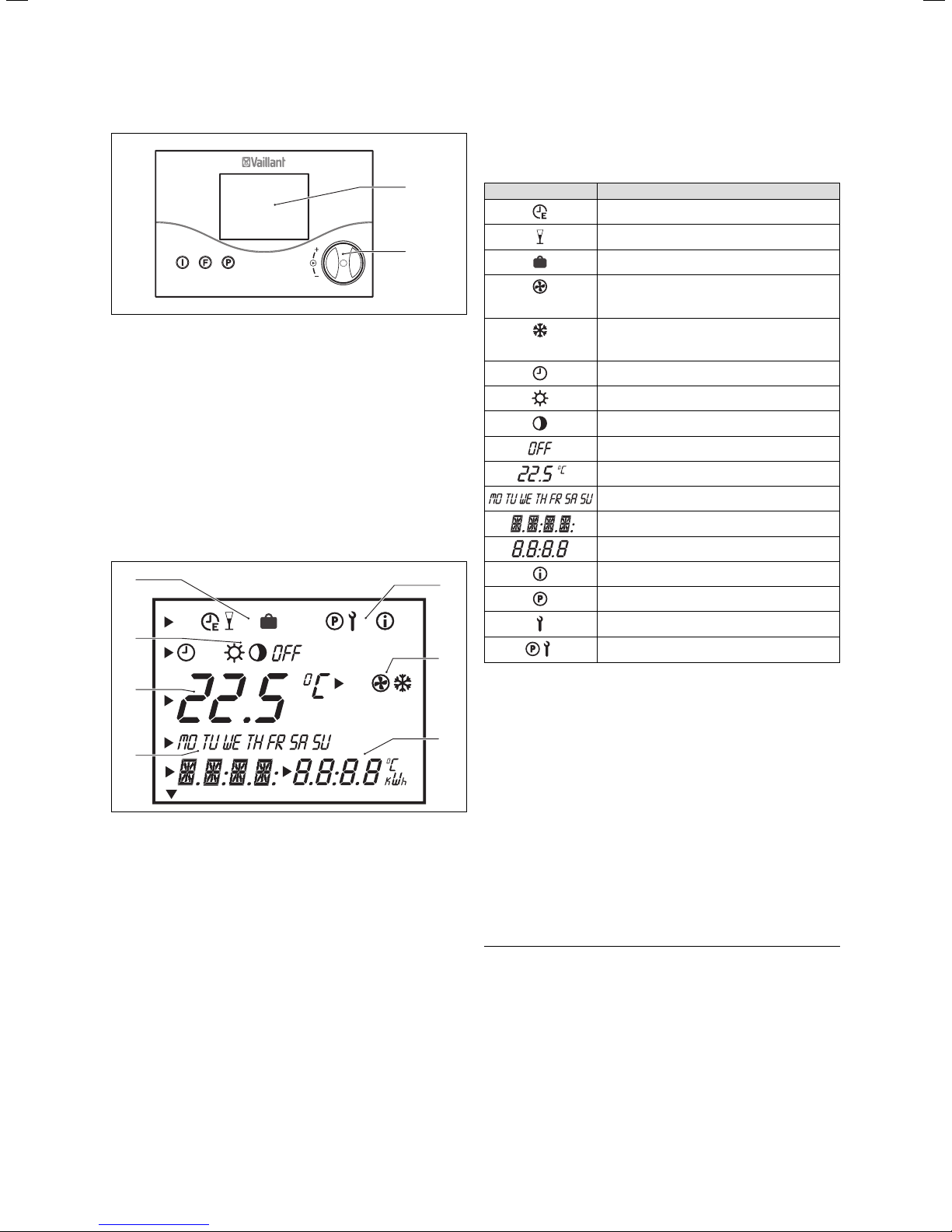

Fig. 4.3 Digital Remote Control recoVAIR

Key

1 Display

2 Dial ("Turn and Click")

i Information key

F Special functions key

P Programming key (expert technician level)

4.5 Display Overview

The display shows either the current operating mode in

the basic display or, if activated, the special function.

Furthermore, the current room temperature, current

weekday and current time is displayed.

7

1

6

2

5

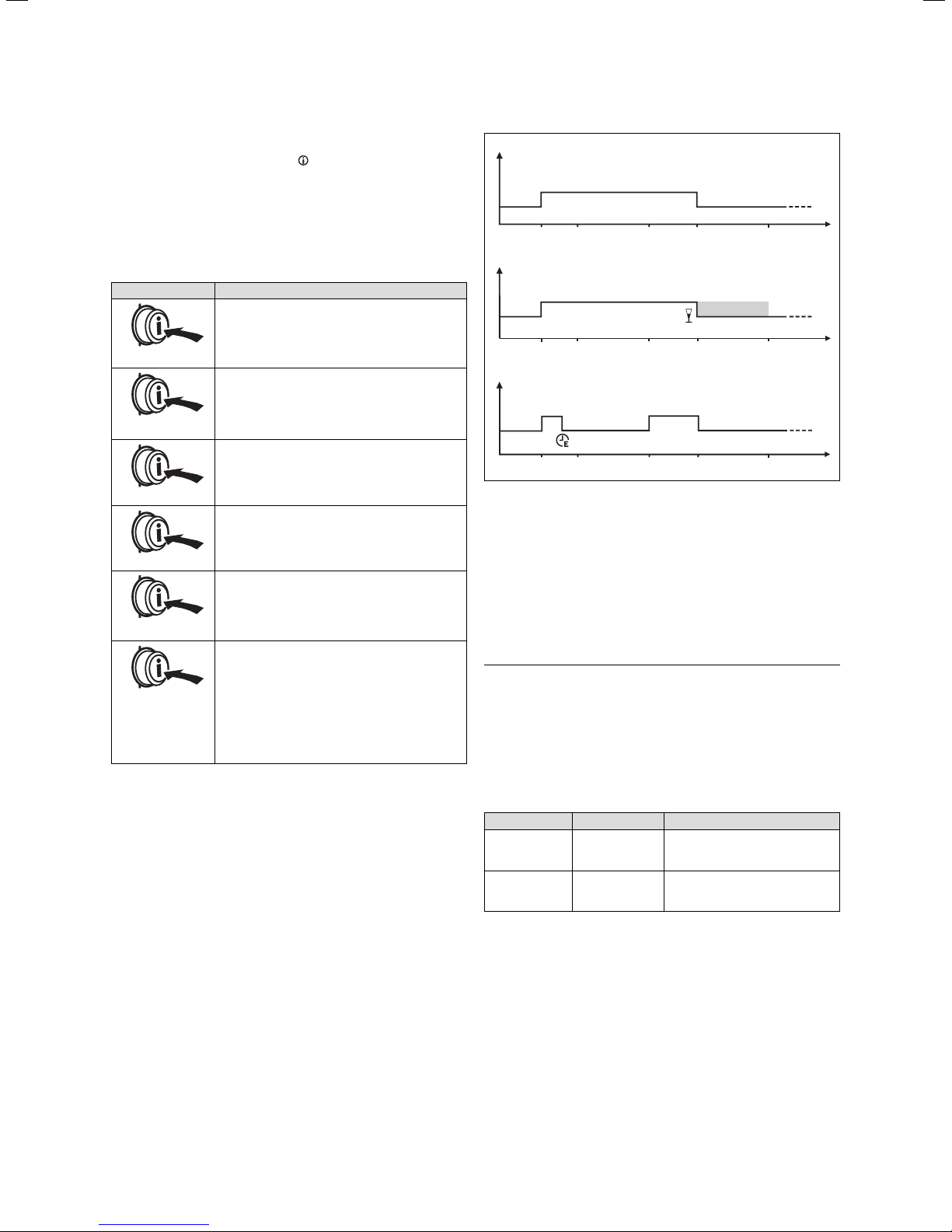

4.5.1 Meaning of Symbols

The following symbols may appear in the display:

Symbol Meaning

Special function Energy-saving

Special function Advance

Special function Holidays

Static: 2nd fan stage (day mode)

Flashing: 3rd fan stage (HIGH)

Off: 1. fan stage (night mode)

Static: Cooling required

Flashing: Bypass open (summer mode)

Off: Bypass not fitted or closed

Automatic mode

Day mode (2nd fan stage)

Night mode (1st fan stage)

Mode with fan stage holidays (minimum)

Actual room temperature

Day of week

Multi-function display left (time ...)

Multi-function display right (KWh)

Information level

Time programming level

Installer level

Service/diagnostic level

Table 4.2 Symbols

4

Fig. 4.4 Display Overview

Key

1 Operator levels

2 Ventilators/Bypass display

3 Multi-functional display

4 Week days

5 Actual values

6 Operation modes

7 Special functions

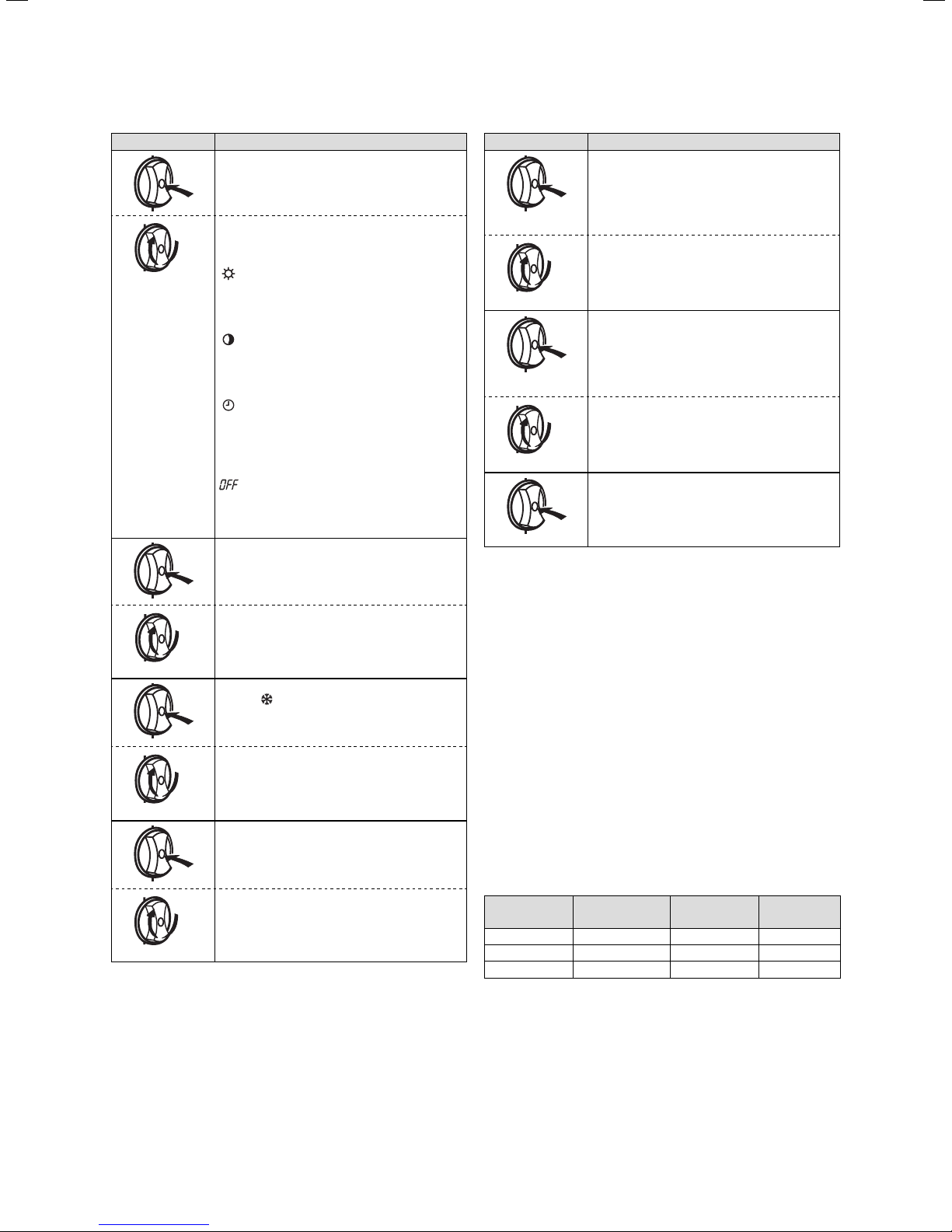

4.6 Settings from the Basic Display

3

From the basic display you can select and then change

the major functions with the "turn and click" dial:

With the "click" - you can move from one menu item to

the other. Press the dial from the

basic display several times in a row

until you have reached the desired

function.

The parameter to be changed is

blinking and an indication arrow appears.

With the "turn" - you can change the blinking value.

Note

h

After the necessary settings have been made,

no confirmation is required.

10 seconds after the last input the indicated

function is automatically activated and then

the display returns to the basic display.

Operating Manual recoVAIR/3 0020062918_038

Page 9

Handling 4

Action Setting of

Operating mode

Selected symbol is flashing

Click

Turn the dial in order to change the operat-

Turn

ing mode.

You can select the following settings:

Day mode:

Irrespective of the time programme the

remote control switches the fans into

2nd stage.

Night mode:

Irrespective of the time programme the

remote control switches the fans into

1st stage

Automatic operation:

The change between the day and night

operation occurs depending on time. Additionally, the current operating mode is

displayed.

Minimum operation

Irrespective of the time programme the

remote control switches the fans into the

lowest stage.

Fan stage 3

Display HIGH

Click

Turn the dial in order to set the period of

Turn

time. The 3rd fan stage is active at this time.

To deactivate this function, set the period

of time to "0.0".

Bypass in stand-by

Display

If no bypass unit is connected, this menu

Click

point will be left out!

Turn the dial to set the number

Turn

ing which the bypass shall be

mode. Under the correct temperature conditions the bypass engine switches to summer

mode.

Check and setting of the time

Press the dial several times in order to se-

lect days of the week, hours and minutes as

required.The selected category flashes in the

Click

display.

Turn the dial to change days of the week,

Turn

hours and minutes.

Table 4.3 Operation from the basic display

of days dur-

in stand-by

Action Setting of

Check and setting of the year clock

Press the dial several times in order to se-

lect the day, the month and the year.

If the clock is not activated, this point will

Click

be left out!

Turn the dial in order to change the day, the

Turn

month and the year.

Check and reset of the filter timer

Display FILT

The timer indicates the number of days after

Click

the last reset since the filter has been used.

Turn the dial to the left to reset the timer to

Turn

0. Turn the dial to the right to reset the previous value.

Return to basic display

If no new setting is executed for more than 10

seconds, the display will automatically return

Click

to the basic display.

Table 4.3 Operation from the Basic Display (continued)

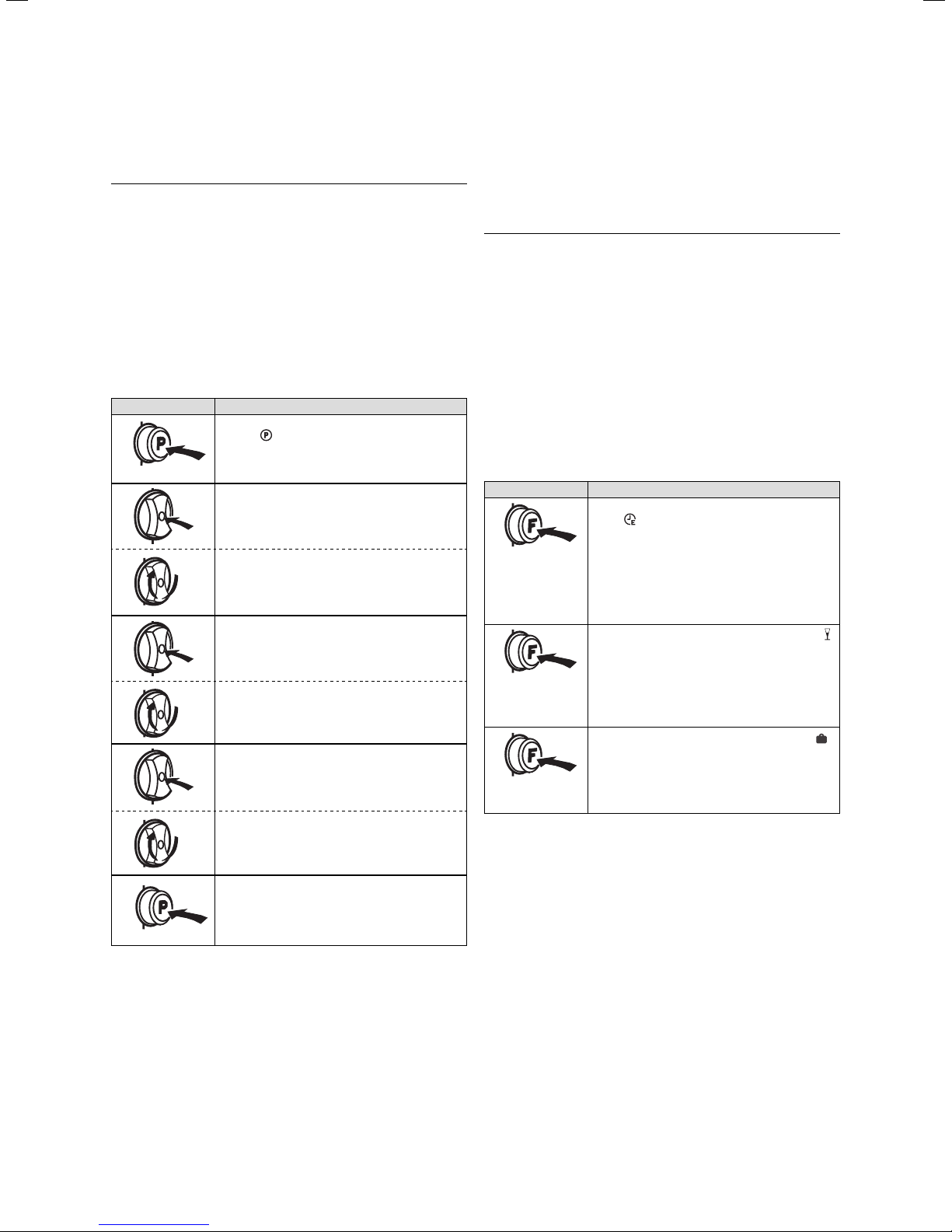

4.7 Programming of the Clock Timer

With the programming button you can change the times

for the timer mode. With activated timer, function recoVAIR will switch between the first and the second stage

(time-controlled)

• Outside the time window: Stage 1 = night operation

• Within the time window: Stage 2 = day operation

It is possible to set up to three different switching-on

and -off times (time windows) for each day of the week.

In the display of the remote control these time windows

are called H1, H2 and H3.

You can combine individual days in groups or a

week block. The following groups are possible:

MO - SU; MO - FR; SA - SU.

Factory-set operating times are:

Time window Day of the

week/Block

H1 MO-FR 6:00 22:00

H1 SA 7:30 22:30

H1 SU 7:30 22:00

Table 4.4 Factory-set operating times

Start time End time

The operating times are set as follows:

• Start with the P button to programme the times.

• Select the time window.

• Select a day or a week block.

• Determine the starting time.

• Determine the end time.

9Operating Manual recoVAIR/3 0020062918_03

Page 10

4 Handling

• Terminate programming of the operating time with

the P button.

Note

h

Within the programming level you can navigate

with the "turn and click technique".

With the "click" - you can change within one program-

ming level from one menu item to

the other. Push the dial several times

in order to reach the desired function. The parameter you want to

change is blinking and an indication

arrow appears.

With the "turn" - you can change the blinking value.

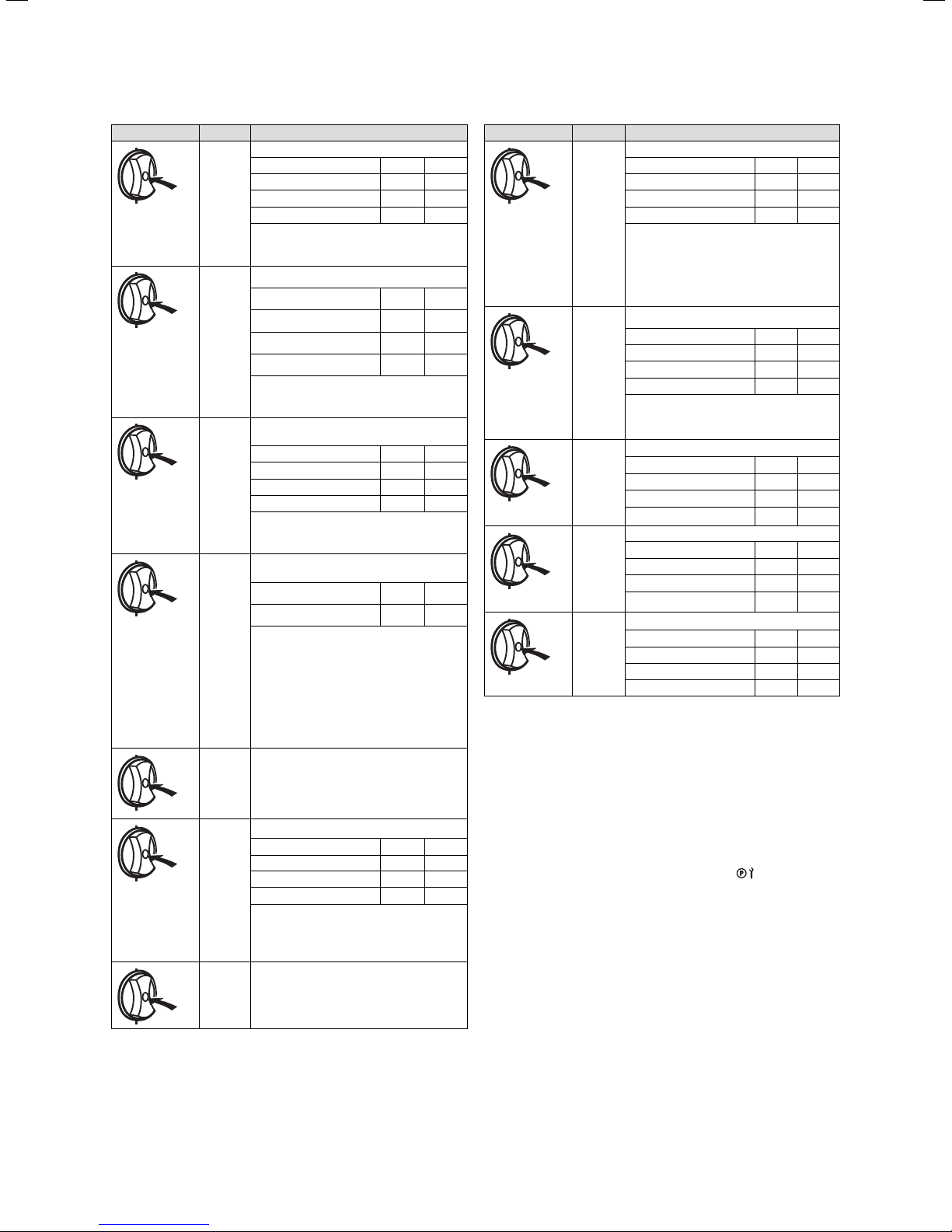

Action Setting of

Activation of the programming level

Display

Select the time window

Click

Turn the dial to select the time window H1 to

Turn

H3.

Select the days of the week or the blocks

for the week

Click

Turn the dial in order to select the individual

Turn

days or week blocks.

Select On and Off times

You select successively the hours and minutes for the switching time by pressing the

Click

dial several times.

Turn the dial in order to change the hours or

Turn

minutes of the switching times.

4.8 Special functions

With the F button (special functions) you can start the

individual special functions.

You select the function by pressing the F button several

times.

Note

h

After the necessary settings have been made,

no confirmation is required 10 seconds after the

last input the indicated function is automatically activated and then the display returns to the

basic display.

By once pressing the "F" button you can deactivate an

active special function.

The deactivation takes 2 seconds. By selecting another

special function the currently activated special function

is terminated.

It is only possible to operate one special function at a

time.

Action Special function

Table 4.6 Special functions

Energy-saving function symbol in the display:

With the energy-saving function the activated

fan stage is set to night mode (stage 1) for a

limited period of time. The user indicates the

period in hours and minutes (minimum

2:30 h). Then the remote control switches

back to the timer mode. Also see figure 4.5

Advance function symbol in the display:

The advance function is used to bridge the

set timer program and activate day mode

(stage 2). The function will remain activated

till the next programmed switch-over to day

mode starts. Also see figure 4.5

Holiday function symbol in the display:

In case the holiday function has been selected, the fan stage is set to a minimum value

for a period to be set (in days). At 0:00 hours,

a day is subtracted from the set period.

Return to basic display

If no new setting is executed for more than

5 minutes, the display will return as well to

the basic display.

Table 4.5 Programming of the time windows

Operating Manual recoVAIR/3 0020062918_0310

Page 11

Handling 4

Troubleshooting 5

4.9 Information Level

Press the information button

to reach the info level.

In addition to identifying the controller, the information

level is used to quickly and easily check the set operating times. Each time window may be individually opened.

If there is no setting action for more than 10 seconds,

the display will return to the basic display.

Action Special function

Table 4.7 Information level

RECO 275/350

Display of the unit type

FILT

Filter days

Indication of the days for which the filter has

been operated since the last filter reset.

AIR

Current air flow supply in m3/h

BYP

Display of the fresh air temperature in oC, if a

bypass has been installed.

DATE

The current date is displayed. Prerequisite is

to activate the calendar first.

Time programme

for the activated heating times

You can call the timer program by pressing

the information button repeatedly.

If the current day of the week is not indicated

in the display, the controller is in the daily

program.

Automatic mode

6:00 22:00

Advance function

6:00 22:0017:0010:00

Energy-saving function

Energy-saving 5h

6:00 22:0017:0010:00 2:00

Fig. 4.5 Comparison of automatic, advance and energy-saving

mode

17:0010:00

2:00

2:00

time

time

time

5 Troubleshooting

Do not try to remedy any other failure than those indicated in table 5.1. For all other failures contact an expert

technician.

Danger!

e

Risk of fatal electric shock from touching live

connections. Pull the mains plug before starting

to work on the device.

• For troubleshooting it is mandatory to pull the mains

plug in order to disconnect the unit from the power

supply.

Malfunction Cause Remedy

No function Mains voltage

Reduced air

flow

Table 5.1 Troubleshooting

interrupted

Filter is heavily

soiled

With the mains voltage re-established the unit will automatically switch on.

Clean or replace the soiled filters as described in chapter 6.

Never interfere or modify the domestic ventilation unit

or other parts of the system.

Only restart the domestic ventilation unit after all failures and malfunctions have been remedied by an expert

technician.

11Operating Manual recoVAIR/3 0020062918_03

Page 12

6 Maintenance

6 Maintenance

Continued efficient operation, reliability and a long service life as well as safety, require inspections and maintenance work to be regularly carried out by an expert

technician on an annual basis.

You must employ a qualified technician to complete

such work.

Caution! You must always ensure that units mounted

high up and units mounted in roof spaces can easily be

reached using suitable equipment.

Caution!

a

We recommend making a maintenance agreement. The operational reliability of the device

can be impaired, resulting in damage to property or personal injury, if maintenance work is

not carried out.

The following must be checked:

– Soiling of the filters (cleaning or replacing the filters)

– Condensate discharge

– Function of the installed bypass unit

You as the owner or user may execute the following

maintenance work yourself:

– Clean and replace the filters in the domestic ventila-

tion unit.

– Clean and replace the filter in the bypass casing

(if installed).

– Clean the fresh air or exhaust air valves in the living

space.

– Reset the time interval for filter replacement in ac-

cordance with section 4.6 "Settings from the basic

display" Caution: Always ensure suitable access equipment is used to gain access to eqipment installed at

high levels or in a loft space.

Caution!

a

Always ensure that the facilities installed higher or in the loft must be well accessible, if required, a suitable equipment must be used.

It depends on the contamination levels how often the filters must be cleaned or replaced. We recommend to

regularly check the filters during the initial operational

period and asses the need to clean them e.g. every

three months. If you then feel that the filters are only

slightly contaminated or dirty, you may extend the interval.

Note

h

Replace the filters at least once a year or after

maximum 2000 operating hours.

You can clean the filters with a vacuum cleaner. If this is

not enough, the filters must be replaced. Cleaning the

filters with water or other liquids is expressly prohibited.

Dispose the used filters with the domestic waste.

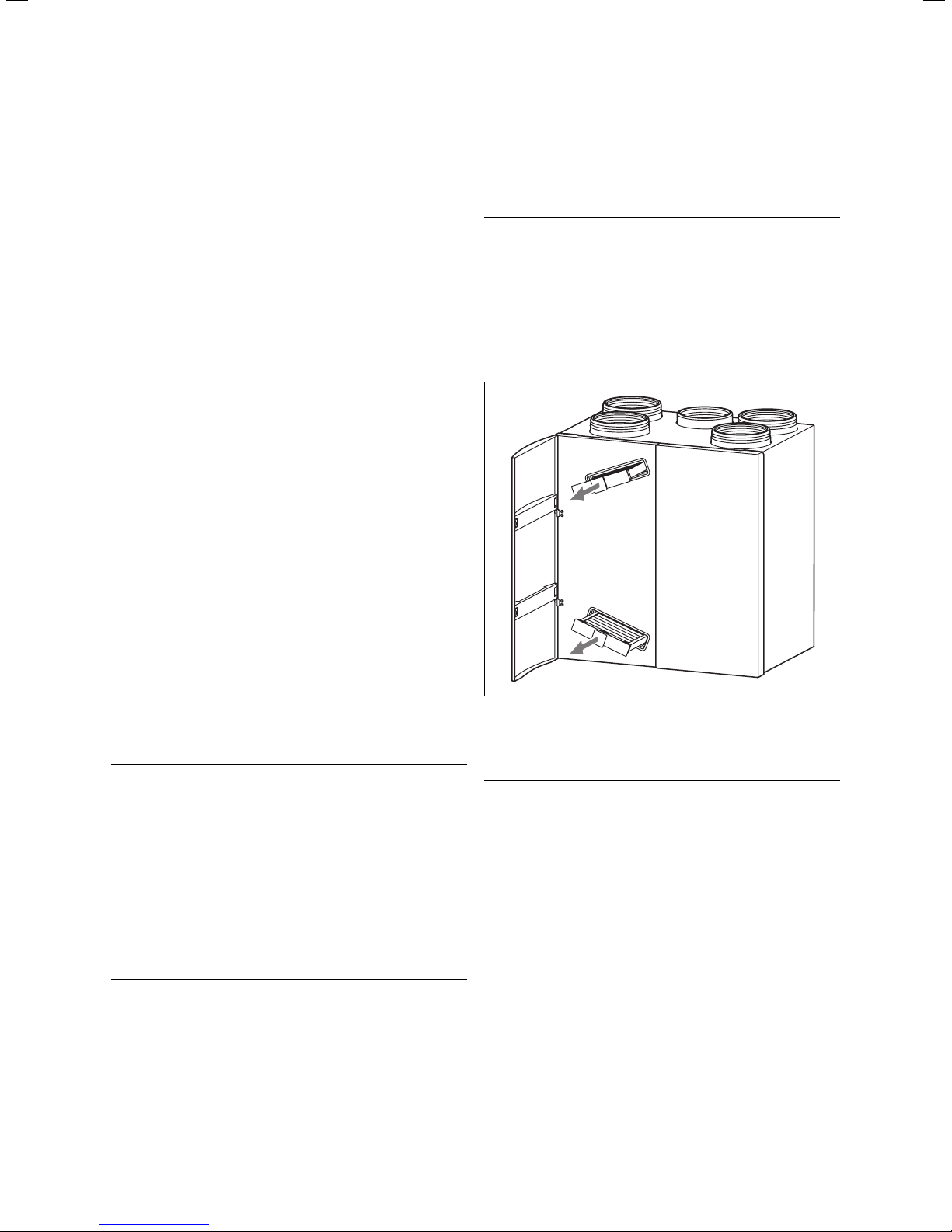

6.1 Cleaning or Replacing the Filter in the

Domestic Ventilation Unit

To check and clean the filters, please proceed as follows:

Danger!

e

Risk of fatal electric shock from touching live

connections. Pull the mains plug before starting

to work on the device.

• Open the left front flap.

• Pull the filter out of the unit.

• Remove the filter handles from the filters.

• Observe the descriptions in the inner side of the door.

Fig. 6.1 Filter replacement

• The filters are to be cleaned or replaced depending on

the degree of soiling.

Caution!

a

Before inserting the filters, please ensure the

correct positioning in order to avoid damaging

of the filters.

• Position the filter handles on the clean or new filters.

On the one side, the filter handles are fitted with guides

which must be pushed into the grooves in the unit.

– The upper filter is mounted with these guide pointing

to the bottom.

– The lower filter is mounted with the guide pointing to

the top.

• Push the filters back into the unit.

• Close the front flap.

• Plug in the mains plug into the plug socket.

The unit is now ready for operation.

Operating Manual recoVAIR/3 0020062918_0312

Page 13

Maintenance 6

Warranty and Customer Service 7

6.2 Cleaning or Replacing the Filters in the

Bypass Casing

To check and clean the bypass filter, please proceed as

follows:

Danger!

e

Risk of fatal electric shock from touching live

connections. Pull the mains plug before starting

to work on the device.

• Pull the filter out of the unit.

• Remove the filter handle from the filter.

• The filter is to be cleaned or replaced depending on

the degree of soiling.

Fig. 6.2 Removing the bypass filter

Caution!

a

When mounting the bypass filter please ensure

the correct positioning in order to avoid damaging the filter.

• Position the filter handle on the clean or new filter.

On one side of the filter handle there are guides, which

must be pushed into the corresponding grooves. The filter is mounted with the guides pointing to the bottom.

• Push the filter back into the unit.

• Plug in the mains plug into the plug socket.

6.3 Filter

Only use the original Vaillant filters.

In addition to the standard filters there are as well available special fine filters. If you intend to use such filters,

please contact an expert technician.

Description Filter class Ordering number

Filterset recoVAIR G3 0020023930

Filter recoVAIR Bypass G3 0020023931

Feinfilterset recoVAIR F6 0020026061

Feinfilter recoVAIR Bypass F6 0020026118

Table 6.1 Filter

Note

h

Replace the filters at least once a year or after

maximum 2000 operating hours.

7 Warranty and Customer Service

7.1 Manufacturer’s Warranty and Liability

Vaillant GmbH warrants that this product is free from

defects of manufacture.

It is covered by a manufacturer’s warranty of

24 months.

The aforesaid manufacturer’s warranty shall be applied

in addition to any legal warranty cover and shall not replace or restrict your legal claims under the Sale of

Goods Act. This warranty shall become effective from

the day of installation, or 2 years after the manufacture

of this system whichever is soonest. This warranty shall

be applicable only for such appliances which have been

installed in UK by a competent installer.

If on the rare occasion that material or fabrication defects arise during the warranty period, the Vaillant

Customer Service will repair these defects free of

charge. It shall be at the sole discretion of the manufacturer’s Customer Service if he is to repair a defective

appliance or to replace it. Work under warranty shall

never cause an extension of the warranty period.

This warranty shall only cover material or manufacturing defects. The warranty shall not be applicable to such

faults or defects caused due to improper installation,

commissioning, handling and use, insufficient maintenance or intervention by unauthorised persons. The

warranty shall become void if such work is executed to

the appliance by other persons than those belonging to

our customer service or an authorised installer. The

aforesaid shall apply as well if parts or components are

incorporated in the appliance or if the appliance is connected to parts or components which have not been approved and certified by Vaillant GmbH. Furthermore, the

aforesaid warranty shall not be applicable to such

claims exceeding the elimination of defects and faults

free of charge, e.g. claims for damages.

Please call our service number 0870-8503073 to report

any defects under warranty.

7.2 Vaillant Service

To ensure regular servicing, it is strongly recommended

that arrangements are made for a Maintenance Agreement. Please contact Vaillant Service Solutions

(0870-8503073) for further details.

13Operating Manual recoVAIR/3 0020062918_03

Page 14

Page 15

For the heating engineer

Installation Instructions

recoVAIR/3

Contents

1 Notes on the documentation ........................16

1.1 Documentation Storage ...................................... 16

1.2 Used Symbols ......................................................... 16

1.3 Manual Validity ...................................................... 16

1.4 CE label .................................................................... 16

2 Device description .........................................16

2.1 Identification Plate ............................................... 16

2.2 Intended Use .......................................................... 16

2.3 Connections .............................................................17

2.3.1 Domestic Ventilation Unit ....................................17

2.3.2 Digital Remote Control recoVAIR ......................17

2.3.3 Condensate Drain Trap .........................................17

2.4 Functionality ............................................................17

3 Safety Instructions and regulations ...........17

3.1 Safety Instructions ................................................17

3.2 General requirements ...........................................17

3.2.1 Preliminary remarks for heat recovery

ventilation products ..............................................17

3.2.2 Related documents ............................................... 18

3.3 Regulations ............................................................. 18

4 Assembly and Installation ........................... 18

4.1 Scope of Delivery .................................................. 18

4.2 Installation Site Requirements .......................... 18

4.2.1 Installation Site of the Domestic

Ventilation Unit...................................................... 18

4.2.2 Installation Site of the Remote Control ..........19

4.3 Assembling ............................................................. 19

4.3.1 Domestic Ventilation Unit ................................... 19

4.3.2 Remote control ..................................................... 20

4.3.3 Bypass ..................................................................... 20

4.4 Measurements ........................................................21

4.4.1 Measurements recoVAIR VAR 275/3

and 350/3 ................................................................21

4.5 Assembly and Installation of the Domestic

Ventilation Unit......................................................22

4.5.1 Mounting of the Fixing Bracket .........................22

4.5.2 Mounting of the Domestic Ventilation

Unit ...........................................................................22

4.5.3 Connection of the Condensed Water Drain ....22

4.5.4 Establishment of Pipe Connections ..................23

4.6 Opening and Closing the Domestic

Ventilation Unit......................................................23

4.7 Mounting and Electrical Connection of

the Bypass (optional) ......................................... 24

4.8 Assembly and Installation of the Remote

Control .................................................................... 25

4.8.1 Establishment of Electrical Connection

of the Remote Control ........................................ 26

4.9 Establishment of Electrical Connection

of the 3-stage Switch (optional) ....................... 28

4.10 Alarm Input (optional) ........................................ 28

4.11 Alarm Output (optional) ..................................... 28

4.12 Function check-out .............................................. 29

5 Start-Up ........................................................ 29

5.1 Adjustment of the Digital Remote Control .... 29

5.1.1 Expert Technician Level ..................................... 29

5.1.2 Service/Diagnostics Level ................................. 30

5.1.3 Testing of the bypass and other functions .....31

5.1.4 Reset to the Factory Setting ...............................31

5.1.5 Setting from the Week to the Day Mode .........31

5.2 Domestic Ventilation Unit Adjustment .............31

5.2.1 Adjustment procedure ..........................................31

5.2.2 Total Air Flow Adjustment ...................................31

5.3 Operator Delivery .................................................32

6 Inspection and maintenance .......................32

6.1 Removing and Cleaning the Filter of

the Domestic Ventilation Unit............................32

6.2 Removing and Cleaning the Heat

Exchanger ...............................................................32

6.3 Cleaning the Condensed Water Drain ..............33

6.4 Cleaning or Replacing the Bypass Filter ........ 34

6.5 Test Operation and Restart ............................... 34

6.6 Spare Parts and Accessories ............................ 34

7 Troubleshooting ............................................35

7.1 Error Messages in the Remote Control .......... 36

7.2 Resistance Values of the Temperature

Sensor ..................................................................... 36

8 Warranty and Customer Service ................37

8.1 Manufacturer’s Warranty and Liability............37

8.2 Vaillant Service ......................................................37

9 Technical Data ............................................. 38

9.1 Domestic Ventilation Unit .................................. 38

9.2 Remote Control .................................................... 38

9.3 Bypass .....................................................................38

9.4 Performance Diagrams ....................................... 39

10 Templates ..................................................... 40

10.1 Templates: Start-up measuring report ...........40

10.2 Template: Filter replacement report ................ 41

10.3 Template: Hygiene check report ...................... 42

Page 16

1 Notes on the documentation

2 Device description

1 Notes on the documentation

The following notes serve as a guide for the entire documentation.

Further documents apply in combination with this installation instructions. We accept no liability for any damage caused by non-observance of these instructions.

1.1 Documentation Storage

Give this installation manual, all accompanying documents and all auxiliary materials, if there are some, to

the operator who will store them so that they are available when required.

1.2 Used Symbols

When operating the unit, please observe the safety instructions in this operating manual!

Danger!

d

Immediate danger to life and limb!

Danger!

e

Risk of death from electric shock!

Caution!

a

Potentially dangerous situation for the product

and environment!

2 Device description

2.1 Identification Plate

Vaillant GmbH Remscheid / Germany

Serial-no. 1234567890xxxxxx

VAR 275 / 3

230V~ 50 HZ

P

V

dP

T

Max

Max

Max.

210 W

275 m³ / h

170 Pa

Max

60 °C

IPX2

Note

h

Useful Information and Hints.

• Symbol indicating the required action

1.3 Manual Validity

This installation manual is valid exceptionally for devices with the following item numbers:

0010006801

0010006802

For the article number of your unit, refer to the identification plate.

1.4 CE label

The CE label shows that this unit complies with the following directives:

– Low-voltage Directive 73/23/EEC, modified with

Directive 93/68/EEC

– EMC-Directive 89/336/EEC, modified by the Directive

91/263/EEC, 92/31/EEC and 93/68/EEC

Bar – Code

Fig. 2.1 Identification plate

The identification plate is positioned below the unit. The

indications given on the identification plate have the following meaning:

Units Value Description

230 V ~50 Hz Mains voltage

P

V

dP

T

Table 2.1 Identification plate

For further information please read section 9 "Technical data".

2.2 Intended Use

The Vaillant domestic ventilation units are built and designed according to accepted safety rules and regulations. Nevertheless, there is still a risk of injury or death

to the user or others or of damage to the device and

other property in the event of improper use or use for

which it is not intended.

210 W Maximum electrical power consumption

max

275 m3/h Maximum air volume flow

max

170 Pa allowable pressure loss of the device

max

60 °C Maximum operating temperature

Max

at V

Max

Installation Manual recoVAIR/3 0020062918_0316

Page 17

Device description 2

Safety instructions and regulations 3

The recoVAIR domestic ventilation unit must be installed by a qualified expert technician, who is responsible for the observance of the existing regulations, rules

and guidelines.

This device is not designed to be used by persons (including children) with limited mental and sensory capabilities or by persons who have not enough experience

and/or knowledge, unless they are supervised by a person who is responsible for their safety or have been instructed by him/her about how to use the device.

Children must be supervised to ensure they do not play

with the unit.

The domestic ventilation units are specifically designed

for the ventilation of residential spaces.

The remote control including the operating mode selector and the timer must only be used for controlling the

domestic ventilation unit as described in these instructions; it is not designed for any other purpose.

Due to high level of dust, operation during the construction phase is not allowed.

Any other or additional use is considered to be improper. The domestic ventilation unit is not suitable for ventilating swimming pools. The manufacturer/supplier

shall not be responsible for any damages resulting from

such improper use.

The user alone bears the risk.

Intended use includes the observance of the operating

and installation manual and all other applicable documents, as well as adherence to the maintenance and inspection conditions.

Caution!

a

Any improper use is forbidden.

2.3.3 Condensate Drain Trap

The attached condensate drain trap must be connected

to the threaded tube under the device. Additionally, an

odour trap is required in the waste water system. For

hygienic reasons, between the drain traps an air gap of

at least 20 mm must be provided.

2.4 Functionality

1

4

2

Fig. 2.2 Air flow diagram

Key

1 Outside air (from outside)

2 Exhaust air (from the living room)

3 Fresh air (to the living room)

4 Outgoing air (to the outside)

3

2.3 Connections

2.3.1 Domestic Ventilation Unit

Necessary connections:

– recoVAIR VAR 275/3: 4 x air duct connections

ø 150 mm, or alternative ø 160 mm and ø 180 mm

– recoVAIR VAR 350/3: 4 x air duct connections

ø 180 mm, or alternative ø 200 mm

– Condensed water drain G 3/4 connection for the con-

densate drain trap

– Electrical connection above mains voltage socket with

230 V 50 Hz mains voltage

2.3.2 Digital Remote Control recoVAIR

On the remote control installation site, the following additional connections are required:

– Control cable from the remote control to the domestic

ventilation unit is a 2-core cable, with cross-section

0,75 mm

The connection must comply with the valid local and national rules and regulations.

2

. Maximum cable length 300 m

3 Safety Instructions and regulations

3.1 Safety Instructions

Installation of the device can be only carried out by a

qualified technician. He/she will be responsible for the

correct installation and start-up.

He/she is also responsible for the inspection and the

corrective maintenance of the device as well as for the

changes in the air flow adjustment.

3.2 General requirements

3.2.1 Preliminary remarks for heat recovery

ventilation products

This appliance should only be used in conjunction with a

propriety ductwork system installed in accordance with

HVCA guide DW144 (steel ductwork) & DW154 (plastic

ductwork).

17Installation Manual recoVAIR/3 0020062918_03

Page 18

3 Safety instructions and regulations

4 Assembly and installation

3.2.2 Related documents

The installation of the heat recovery ventilation unit and

any associated ductwork and outlets must be in accordance with the relevant requirements of the Health and

Safety Document No. 635 (The Electricity at Work Regulations 1989), BS7671 (IEE Wiring Regulations). It should

also be in accordance with the relevant requirements of

the Local Authority, Building Regulations, The Building

Regulations (Scotland), The Building Regulations (Northern Ireland) and the relevant recommendations of the

following:

BS 5588 – Fire precautions in design construction and

use in buildings

BSEN 13141 - Ventilation for buildings. Performance testing of components/products for residential ventilation.

BS EN 1506 - Ventilation for buildings. Sheet metal air

ducts and fittings with circular cross-section.

BS EN 13142 - Ventilation for buildings. Components/

products for residential ventilation. Required and optional performance characteristics

BS EN 12236 - Ventilation for buildings. Ductwork hangers and supports. Requirements for strength

3.3 Regulations

If the system is to be operated with boilers or other gas

appliances which are dependent on the ambient air, the

ventilation must be balanced in accordance to the needs

of the appliance.

The following laws, rules, regulation standards and

guidelines in the valid version must be complied with for

the installation:

– Safety instructions and regulations for low-voltage in-

stallations EN 1010

– EST Good Practice guide 268 – Efficient ventilation of

buildings – A guide to specifiers

– Rules and regulations for air circulation in flats and

habitable areas and residential buildings EN 1087

– Rules and regulations for ventilation systems

DIN 1946

– Any pertaining rules and regulations of the local or

national building authorities

– The present instructions for installation

4 Assembly and Installation

4.1 Scope of Delivery

– Domestic ventilation unit

– Digital remote control recoVAIR

– Mounting set consisting of:

– Fixing brackets 405 x 60 mm

– Condensate drain trap

4.2 Installation Site Requirements

The installation site of the domestic ventilation unit

must be constantly frost-free and dry. The system installation must be planned in detail. Especially pay attention to the positioning of the fresh air and exhaust

air ducts and to include sufficient sound insulation.

Caution!

a

The temperature of the device can be considerably lower than the temperature of the room is

being installed. To avoid undesirable accumulation of condensate, the circulation of fresh and

exhaust air must be provided in the room (basic

ventilation).

4.2.1 Installation Site of the Domestic Ventilation

Unit

Please note the following instructions before choosing

where to install the ventilation unit:

Caution!

a

When mounting the system it is absolutely necessary to ensure the horizontal positioning of

the ventilation unit and an angle of > 0° and < 1°

in vertical position to ensure that the condensation water can easily flow out of the unit.

The domestic ventilation unit is wall-mounted, preferably close to a drain outlet for the condensation water

drain.

– The ventilation unit must be installed with due consid-

eration of the requirement for adequate and practical

air ducting and services (fresh air and exhaust air,

electrical power). Ensure enough space is provided on

top of the unit and at its sides to be able to mount the

required air ducts, additional silencers and bypass

unit.

– The installation site must be selected so that the duct-

work distances to and from the domestic ventilation

unit are as short as possible.

– The wall to which the domestic ventilation unit is to be

mounted must offer sufficient load-carrying capacity

for the weight of the commissioned ventilation unit.

– It is possible that the supplied fixing elements do not

meet the requirements of the installation wall. The required mounting elements must be provided by the

customer.

– The condensed water drain must be connected with

the attached condensate drain trap to the water outlet with the odour trap (siphon).

Accessories (optional)

– Bypass recoVAIR

– Filtersets

Installation Manual recoVAIR/3 0020062918_0318

Page 19

600

300

100

0-1˚

Assembly and installation 4

– When installing the fresh air input and discharge air

ducts you will have to ensure sufficient separation to

avoid that the discharged air being re-circulated into

the fresh air input.

According to VDI 6022 the minimum separation is

10 m.

4.2.2 Installation Site of the Remote Control

– The remote control must be mounted such that there

is enough space around it to complete the electric wiring as well as easy operation of the control.

– The remote control must be installed inside the living

space in an easily accessible place. For further details

see section 4.8.

4.3 Assembling

100 300

1000

Fig. 4.1 Required minimum distances/installation free spaces

– The attached condensed water drain trap is destined

to compensate pressure between the device and the

installation room, for that reason it must always be

filled with clear water.

– For hygienic reasons, it must not be directly connect-

ed to the odour trap of the waste water system. Ensure an air gap of at least 20 mm.

– For the installation, at least 10 cm of free space on the

side of the device must be provided.

– For installation, filter replacement and maintenance

works, about 1 m working space in front of the ventilation unit is needed. Over and beneath the device at

least 30 cm are required (see also fig. 4.1).

– If the domestic ventilation unit is mounted on an inter-

nal wall, do not select a location directly above bedrooms due to possible sound transfer. Always choose

a location above a non-occupied room such as a hall

or bathroom.

– With wood-joist ceilings or similar you can provide ad-

ditional sound insulation by adding insulation between

the joists.

– Always ensure that the condensation water drain is

free running.

– To avoid annoyance by excessive noise select a

sound-absorbing hose for final connections from the

unit to the air outlets.

– Install a silencer. This will help to neutralise possible

noise transmission between the unit and the air ducting and reduce annoyance by noise.

– Keep the air supply inlet at a sufficient distance from

discharge air, exhaust air and drain ventilation. Comply with the legal building rules and regulations.

4.3.1 Domestic Ventilation Unit

14

13

12

11

10

9

8

Fig. 4.2 Assembling recoVAIR VAR 275/3 and 350/3

Key

1 Air duct Outgoing air

2 Air duct Fresh air

3 Fresh air fan

4 Circuit board

5 Exhaust air fan

6 Condensate drain outlet

7 Electrical connection of

the 3-stage switch

8 Outside air filter

9 Heat exchanger

10 Exhaust air filter

11 Mounting point Front

cladding

12 Air duct Exhaust air

13 Air duct Outside air

14 Bypass connection

1

2

3

4

5

6

7

The unit is equipped with a frost protecting sensor.

This sensor measures the temperature of the discharge

air. The fresh air fan is switched off if the discharge air

temperature falls below 3 °C.

Once switched off, the fresh air fan is only switched on

again when the discharge air temperature has risen

above 8 °C.

19Installation Manual recoVAIR/3 0020062918_03

Page 20

4 Assembly and installation

If the protection circuit is activated against the low

pressure (STOV, see section 5.1.1), the frost protection

sensor switches both ventilators off.

The outside air flow may be much cooler than the temperature of the discharge air measured by the frost protection sensor before the anti-freeze monitoring device

is activated. Its operation is possible up to -7 °C outside

temperature.

4.3.2 Remote control

The control elements of the remote control are explained in the operating manual in section 4.4.

4.3.3 Bypass

Vaillant GmbH Remscheid / Germany

Serial-no. 1234567890xxxxxx

Bypass VAR 275 - VAR 350

12 V DC

P

3 W

Max

3

Fig. 4.3 Bypass Installation

Key

1 Filter

2 Ventilation flap

3 Air inlet from outside

IPX2

nur zu verwenden mit recoVAIR 275 / 350

12

only to use with recoVAIR 275 / 350

alleen te gebruiken met recoVAIR 275 / 350

utiliser seulement avec le recoVAIR 275 / 350

Kan kun bruges sammen med recoVAIR 275/350

Bar – Code

Fig. 4.4 Identification plate Bypass

You can find the identification plate on the top of the

device. The indications given on the identification plate

have the following meaning:

Units Value Description

12 V DC Voltage supply

P

3 W Maximum electrical power consumption

max

Table 4.1 Explanation of bypass identification plate

Installation Manual recoVAIR/3 0020062918_0320

Page 21

4.4 Measurements

4.4.1 Measurements recoVAIR VAR 275/3 and 350/3

182

182

Assembly and installation 4

441

53EF

ØC (4 x)

41 A

986

709

Y- Y

450

115

403

200

315

645

B

14 2 400

D

680

Fig. 4.5 Measurements recoVAIR VAR 275/3 and 350/3

recoVAIR VAR 275/3 recoVAIR VAR 350/3 Remarks

A 77 127

B 471 521

C ø 150/ø 160/ø 178 ø 180/ø 198 Pipe diameter to be selected for all 4 air connections

D ø 150/ø 160/ø 178/ø 198 ø 150/ø 160/ø 178/ø 198 Pipe diameter to be selected for the bypass connection

A 102 122

F 210 240

Table 4.2 Table of dimensions for recoVAIR VAR 275/3 and 350/3 (dimensions in mm)

21Installation Manual recoVAIR/3 0020062918_03

Page 22

4 Assembly and installation

4.5 Assembly and Installation of the Domestic

Ventilation Unit

• First mount the domestic ventilation unit and the re-

mote control, and then proceed to the electrical connections.

• Ensure there is enough space for assembly at the

sides of the domestic ventilation unit (at least 10 cm).

This domestic ventilation unit is solely intended for vertical wall mounting.

4.5.1 Mounting of the Fixing Bracket

A fixing bracket is supplied for the wall mounting of the

unit, the unit is hooked onto it.

Caution!

a

When mounting the system it is absolutely necessary to ensure the horizontal positioning of

the ventilation unit and an angle of > 0° and < 1°

in vertical position to ensure that the condensation water can easily flow out of the unit.

4.5.2 Mounting of the Domestic Ventilation Unit

Danger!

d

If not mounted correctly, the unit may fall off.

Ensure that the wall offers the appropriate load

carrying capacity and that the proper fixing

means are used for secure mounting. It is possible that the attached mounting set with the

fixing screws and wall plug is not suitable for

every wall.

Danger!

The ventilation unit weighs about 35 kg. When

hooking the unit onto the fixing bracket, never

lift the unit alone.

• Position the domestic ventilation unit above the

bracket and then hook it onto the clips.

• The unit must have fitted absolutely horizontal and

vertical.

4.5.3 Connection of the Condensed Water Drain

• Join the connecting piece for the condensate drain

trap to the connection outlet on the bottom of the domestic ventilation unit.

• Connect the attached condensate drain trap with the

connection piece (see fig. 4.7).

min 945

0-1˚

Fig. 4.6 Mounting of the fixing bracket

• Determine the installation site (see section 4.2 "Requirements of the installation site").

• Drill the holes for the fixing screws and position the

wall plugs.

• Screw the fixing bracket horizontally to the wall.

Fig. 4.7 Assembly of the condensate drain trap

Installation Manual recoVAIR/3 0020062918_0322

Page 23

Assembly and installation 4

Caution!

a

For the condensate discharge of the ventilation

appliance a second drain trap is required!

Caution!

For hygienic reasons, the condensate drain trap

must not be directly connected to the waste

water system.

An air gap of at least 20 mm must be provided.

A wrongly installed condensate outlet can lead

to condensate accumulation and to an uncontrollable escape of condensate. Use of the customer service and possible subsequent damages are not covered by the Vaillant warranty.

airVENT

> 2 cm

4.6 Opening and Closing the Domestic Ventilation

Unit

The domestic ventilation unit is equipped with a fixed

front cladding with a pivoting door to the left. Behind

this door there are the filters. For mounting and maintenance work on the unit it is necessary to remove the

front cladding. This is how to do it:

Danger!

e

Risk of fatal electric shock from touching live

connections. Pull the mains plug before starting

to work on the device.

Note

h

Remove filters from the device first because

they are fixed in the front cladding.

• Open the left door on the unit front.

• Pull both filters out of the unit and then close the

door (fig. 4.9, pos. a)

• Loosen and remove the screw on the left toggle-type

fastener below the unit (fig. 4.9, pos. b).

Then open both toggle-type fasteners (fig. 4.9, pos. c).

• Pull the lower part of the front cladding close to you

(fig. 4.9, pos. d).

• Now lift the front cladding above the top fixing points

(fig. 4.9, pos. e).

airVENT airVENT

Fig. 4.8 Correct installation of the condensate outlet

4.5.4 Establishment of Pipe Connections

• Before executing the final connection check the air

ducts are still clean. If necessary, clean the air ducts.

• Only then connect the air ducts to the domestic ventilation unit.

• Connect the air ducts individually as shown to the

connections on top of the unit.

Caution!

a

Air ducts must be tightly connected with the

ventilation unit - use suitable accessories or

sealing material. Insulation of the fresh air and

outgoing air ducts must be diffusion resistant.

To close the ventilation unit, carry out the steps in reverse order. Always ensure the screw is replaced into

the left hand toggle after re-assembly to avoid unauthorised access to the unit.

Note

h

Ensure that after the repeated assembly the

screw is inserted into the left lever again to

prevent access by unauthorised persons.

23Installation Manual recoVAIR/3 0020062918_03

Page 24

4 Assembly and installation

a

a

4.7 Mounting and Electrical Connection

of the Bypass (optional)

The bypass must be mounted in accordance with the installation scheme (see section 2.4 "Functioning") within

the outside air flow in order to bypass the domestic ventilation unit.

Danger!

e

Risk of fatal electric shock from touching live

connections. Pull the mains plug before starting

to work on the device.

Danger!

e

Risk of fatal electric shock from touching live

connections. Improper electric installation may

cause accidents. Therefore it is absolutely

mandatory to have a competent person complete the electric installation.

Note

h

The bypass must be first electrically connected

because the electric lines are not accessible

after the mounting.

• Open the domestic ventilation unit as described in

section 4.6.

• Remove the plug from the middle air connection by

pushing it upwards from the inside (see fig. 4.10).

b

c

e

d

Inside the bypass air connection in the domestic ventilation unit, there is a 10-pole connector to which the bypass plug is connected.

You will find a plug in the bag in the casing wall. Pull the

plug out of the bag of the casing wall.

• Release the cable with the 10-pin connector from the

casing wall and connect the bypass plug with the connector (fig. 4.10).

Fig. 4.9 Opening and closing of the domestic ventilation unit

Fig. 4.10 Electrical connection of the bypass

Installation Manual recoVAIR/3 0020062918_0324

Page 25

Assembly and installation 4

To install the temperature sensor, proceed as follows

(see fig. 4.10):

• Remove the plug from the sensor hole in the outside

air duct.

• Push the temperature sensor through the hole into

the exhaust air duct.

Caution!

a

To ensure the correct bypass function the temperature sensor must project at least 25 mm

into the exhaust air flow.

4.8 Assembly and Installation of the Remote

Control

Normally the best siting of the remote control is in the

main living space at an inside wall at a height of about

1.5 m. There the controller is able to detect the circulat-

ing ambient air clearly and unimpeded from furniture,

curtains or other external influences. The position

should be selected so that neither air drafts from the

door or the window nor heat sources such as radiators,

chimney wall, TV or solar irradiation may directly influence the controller.

A connection with the ventilation unit is established via

a 2-core connection cable.

1

4

2

5 mm

2

Fig. 4.11 Mounting position of the temperature sensor

After completing the electrical connection of the bypass, you can mount the bypass unit.

• Push the bypass into or over the both outside air connections of the device as shown in fig. 4.10.

Make sure that the filter unit is aligned towards you.

• Check that the bypass is completely inserted.

• Plug in the mains plug into the plug socket.

5

2

4

Fig. 4.12 Mounting of the remote control

3

Key

1 Casing

2 Mounting holes

3 Wall base

4 Cable bushings

5 Terminal strip

• Pull the casing (1) of the remote control from the wall

base (3).

• Make two mounting holes (2) with diameter 6 mm

(as shown in fig. 4.12) and insert the provided dowels.

• Pull the connection cable through one of the cable

openings (4).

• Fasten the wall base to the wall using the two supplied

screws.

• Connect the cable to the corresponding terminals

(eBUS "+" and "-") on the terminal connecting

strip (5).

• Place the casing (1) on to the wall base (2) such that

the pins at the back of the upper part locate into the

seats.

25Installation Manual recoVAIR/3 0020062918_03

Page 26

4 Assembly and installation

• Press the casing to the wall base till it locates, taking

care not to bend the controller connection pins. Make

sure that you do not bend the contacts.

4.8.1 Establishment of Electrical Connection of the

Remote Control

Danger!

e

Risk of fatal electric shock from touching live

connections. Pull the mains plug before starting

to work on the device.

Note

h

To prevent accidents, electric installation can

only be carried out by a qualified expert technician.

The remote control is connected to the domestic ventilation unit via a two-core cable. Communication is done

via a 2-pole eBUS. The eBUS connector is sized to accommodate wiring of 2 x 0.75 mm

2

(recommended). It is

possible to interchange the connections without affecting communication. This connection is at the bottom of

the unit.

• Connect the control cable as shown in Fig. 4.13 to the

eBUS-clamps "+" and "-".

BUS

Swi

t

ch

0

D

H

Fig. 4.13 Establishment of the electrical connection of the re-

mote control

Installation Manual recoVAIR/3 0020062918_0326

Page 27

Assembly and installation 4

Mains connection

BUS connection

Switch 2

Switch 1

0 - 10 V Control

signal (analog)

Alarm input

Alarm output

X 15

X 16

230 V~

F4

2AT

Bus

Switch 2

Switch 1

Analog

Error In Err. Out

PC

connection

N

L

-+ 12 12DO

H

DO

H

+

X 1X 9

white whitewhite

N

L

Freh air fan

Exhaust air fan

N

L

X 2

Control signal

X 3

X 4

X 5

0 - 10 V

Hz

Gnd

Control signal

0 - 10 V

Hz

Gnd

Temperature sensor EAO

ϑ

(Frost protection sensor)

Bypass Motor

M

ϑ

Temperature sensor EAI

ϑ

Temperature sensor SAO

ϑ

Temperature sensor SAI

red blue white

X 10

X 11

white white white

X 12

X 13

10

white

X 14

X 17

9

5

4

8

3

7

2

6

1

X 6

X 7

Fig. 4.14 Wiring diagram

X 8

27Installation Manual recoVAIR/3 0020062918_03

Page 28

4 Assembly and installation

4.9 Establishment of Electrical Connection of the

3-stage Switch (optional)

In addition to the standard control unit, you can also use

a universal 3-stage switch to control the domestic ventilation unit. This must be potential-free (no voltage).

• Connect three lines as shown in fig. 4.15 to the clamps

"0↓", "D↑" and "H↑".

The following switch positions are possible:

Position Function Electrical contact

1 ("0") Control system with remote

2 ("D") Day position (fans stage 2) 0↓ connected to D↑

3 ("H") HIGH position

Table 4.3 Switch positions of the 3-stage switch

0

Switch

0 D

H

control

(fans stage 3)

BUS

-

H

D

+

0↓ open

0↓ connected to H↑

0

D

H

4.10 Alarm Input (optional)

The alarm input (connection "X 14" on the board) is

bridged when the unit is delivered. If the connection is

undone with an external potential-free switching contact

(break contact), both fans will be switched off. On the

display of the remote control you will find the message

"LOCK".

Danger!

e

Risk of fatal electric shock from touching live

connections.

Pull the mains plug before starting to work on

the device.

• Remove the unit front cladding as described in

section 4.6.

• Now place the 2-core cable (minimum 0.35 mm

2

) in

the respective cable routing to the PCB.

• Connect the lines to the connection "X 14" (alarm

input) in accordance with figure 4.14 "Wiring scheme".

Note

h

When the contact is opened, the word "LOCK"

appears on the display of the remote control.

The fans on the domestic ventilation unit are

then switched off.

4.11 Alarm Output (optional)

The alarm output (connection "X 16" on the board) is

made of a potential-free switching contact with a resistive load (Ohm) of maximum 2 A.

1

Fig. 4.15 Electrical connection of the 3-stage switch

Key

1 Strain relief alarm outlet

40 mm

Ø 4,5 - 10 mm

Fig. 4.16 Removal of cable insulation

• Remove the cable insulation as shown in fig. 4.16.

• Lead the cable through the strain relief (see fig. 4.15)

and screw them together.

Installation Manual recoVAIR/3 0020062918_0328

Page 29

Assembly and installation 4

Start-up 5

An alarm will be triggered

– If the time set for the filter replacement has expired.

The duration is set under the installer level option on

the remote control.

– If one of the error messages described in section 7.1 is

indicated in the remote control display.

Danger!

e

Risk of fatal electric shock from touching live

connections. Pull the mains plug before starting

to work on the device.

• Remove the unit front cladding as described in

section 4.6.

• Now place the 2-core cable (minimum 0.35 mm

2

) in

the respective cable routing to the PCB.

• Connect the lines to the connection "X 16" (alarm output) in accordance with figure 4.14 "Wiring scheme".

4.12 Function check-out

Once all supply lines are correctly installed in accordance with the wiring scheme, check the functions of the

remote control, the domestic ventilation unit and the

bypass (see section 5.1.3). When doing so, note that the

unit must not be started until all ventilation ducts are

connected to the unit and the unit and all ductwork are

completely sealed.

In the sections 4.4 to 4.8 of the operating manual you

will find in detail all the settings for the individual operating modes and the special functions. For testing functions proceed as follows:

• Select the "night" operating mode and check that the

fans in the domestic ventilation unit are operating at

low output.

• Select the "day" operating mode and check that the

fans in the domestic ventilation unit are operating at

medium output (AIR2).

• Activate the special function "advance". Check that

the fans in the domestic ventilation unit are operating

at medium output (AIR2).

• If the output stages are not correctly switched, you

must check the wiring on the terminals of the remote

control and the domestic ventilation unit.

5 Start-Up

The start-up and the operation of the unit as well as instruction to the user must be done by a competent person.

Please note that the device can only be started up if all

ventilation pipes of the device are connected and the

entire device is closed.

As part of the start-up it is necessary to adjust the domestic ventilation unit.

The domestic ventilation units are delivered ex factory

with basic setting of both fans. As each fresh air and exhaust air installation is different and thus offers different external resistance in the air ducting you will have

to separately adjust the fresh air and the exhaust air fan

to suit.

You can adjust the domestic ventilation unit using the

remote control. Below are the necessary steps.

5.1 Adjustment of the Digital Remote Control

To optimally match the system parameters to the required conditions it is necessary to set these parameters with the remote control. The system parameters