Page 1

geoTHERM

VWS/VWW

GB; ES

Page 2

Page 3

For the owner

Operating manual

geoTHERM

Heat pump

VWS/VWW

GB

Page 4

Contents

Contents

General information ..................................................... 3

Data badge .............................................................................. 3

1 Information on this manual ............................. 3

1.1 Other applicable documents .................................. 3

1.2 Storage of the documents ...................................... 3

1.3 Symbols used ............................................................. 4

1.4 Applicability of the manual ..................................... 4

2 Safety instructions .......................................... 4

2.1 Coolants ....................................................................... 4

2.2 Prohibition on alterations ....................................... 5

3 Equipment and functional description ........... 5

3.1 Functional principle .................................................. 5

3.2 Operation mode of the coolant circuit ................ 6

3.3 Automatic auxiliary functions ................................ 6

3.4 Design of the heat pump ......................................... 7

4 Notes on the installation and operation ........ 8

4.1 Intended use ............................................................... 8

4.2 Requirements of the installation site .................. 9

4.3 Accumulation of condensate

(condensation water) ............................................... 9

4.4 Energy saving tips .................................................... 9

4.4.1 General energy saving tips ..................................... 9

4.4.2 Economising by using the control

system correctly ........................................................ 10

5.12.4 Warning messages .................................................... 25

5.12.5 Temporary malfunctions ......................................... 26

5.12.6 Blocking error ............................................................ 26

6 Warranty and customer service ..................... 27

6.1 Vaillant warranty....................................................... 27

6.3 Vaillant Service .......................................................... 27

7 Appendix ............................................................ 28

7.1 Technical Data VWS ................................................. 28

7.2 Technical Data VWW ................................................ 29

7.3 Data badge .................................................................. 31

5 Operation ........................................................... 11

5.1 Familiarising yourself with and operating

the controller ............................................................. 11

5.2 Setting menus and parameters ............................. 12

5.3 Description of the controller .................................. 12

5.3.1 Possible system circuits .......................................... 12

5.3.2 Energy balance controller ...................................... 13

5.3.3 Charging principle buffer cylinder ........................ 13

5.3.4 Resetting to factory settings ................................. 13

5.3.4 Controller structure ................................................. 13

5.3.5 Adjusting the energy saving functions ................ 13

5.4 Flow diagram .............................................................. 14

5.5 Displays at user level ............................................... 15

5.6 Installer Menu ............................................................ 21

5.7 Starting up the heat pump ..................................... 23

5.8 Shutting down the heat pump ............................... 23

5.9 Inspection by a specialist engineer ...................... 23

5.10 Inspection by the operator ..................................... 23

5.10.1 Checking the filling pressure of the

heating system .......................................................... 23

5.10.2 Checking the filling level and filling pressure

of the brine circuit .................................................... 24

5.11 Cleaning and care .................................................... 24

5.12 Troubleshooting and diagnosis ............................. 25

5.12.1 Error messages on the controller ......................... 25

5.12.2 Activating emergency mode .................................. 25

5.12.3 Errors/malfunctions that you can remedy ......... 25

Operating Manual geoTHERM VWS/VWW 0020051578_012

Page 5

N

General information

Information on this manual 1

General information

Vaillant geoTHERM heat pumps are generally referred

to in this manual as heat pumps. This operating manual

is valid for the following variants:

Type name Article number

Brine/Water Heat Pumps

VWS 220/2 0010002797

VWS 300/2 0010002798

VWS 380/2 0010002799

VWS 460/2 0010002800

Water/Water Heat Pumps

VWW 220/2 0010002801

VWW 300/2 0010002802

VWW 380/2 0010002803

VWW 460/2 0010002804

Table 0.1 Type designations and article numbers

The heat pumps state-of-the-art appliances

which have been constructed in accordance

with recognised safety regulations.

Conformity with the applicable standards has

been demonstrated.

VDE and tested safety

With the CE mark, we confirm as equipment manufacturers that the appliances in the geoTHERM range satisfy the requirements of the Directive on Electromagnetic

Compatibility (Council Directive 89/336/EWG).

The appliances meet the basic requirements of the

Low Voltage Directive (Council Directive 73/23/EEC).

Furthermore, the appliances satisfy the requirements of

EN 14511 (Heat pumps with electrically-driven compressors, heating, specifications for appliances for space

heating and for warming drinking water) as well as

EN 378 (safety and environmentally related specifications for refrigerating systems and heat pumps).

Data badge

The geoTHERM heat pump has an identification plate

which is mounted on the front face of the magnetic

steel sheet. The type designation is on the front cladding at the top of the unit (also see Fig. 3.3, Pos. 1).

In the appendix to Chap. 7.3 there is a picture of an

identification plate for customers who are interested

in the technical aspects of the system, and also a table

explaining the symbols shown on it.

1 Information on this manual

This manual contains important information on how

to operate your heat pump safely and professionally.

1.1 Other applicable documents

Other applicable documents are all manuals that describe the operation of the heat pump, and the manuals

supplied with the accessories used.

1.2 Storage of the documents

Store this operating manual and all related documents

in such a way that they are available whenever required.

You can store the documents inside the pillar cover.

If you move out or sell the appliance, pass on the documents to the buyer.

1

L

2

L

3

L

N

E

P

1

L

2

L

3

L

N

E

P

1

L

2

L

3

L

N

E

P

F

OTA

F

C

D

- +

AufZu

NL

HK2-P HK2 VF2 RF1 VF1 SP BUSDCF/AF EVU1xZPLP/UV 1

NL

SK2-P

NL

ZP

NNAufZuL N 121212121212

ZH

2 345SC

L LLL L1 LNNNN N 2N2121LN

1

B

678AS

H

0

-3

8

A

B

B

A

1

-0

0

-3

8

A

B

B

A

1

-0

0

-3

12

A

B

B

A

1

-0

0

-3

12

A

B

B

A

1

-0

0

-3

2

1

A

B

B

A

1

-0

0

-3

8

A

B

B

A

1

-0

Fig. 1.1 Removing the pillar cover

GB

3Operating Manual geoTHERM VWS/VWW 0020051578_01

Page 6

1 Information on this manual

2 Safety instructions

1.3 Symbols used

The following symbols are used in this operating manual

to denote levels of danger, information, activities and

energy-saving tips.

Danger!

Immediate risk of serious injury or

d

death!

Danger!

Danger of burning and scalding!

H

Caution!

Potentially dangerous situation for the

a

product and environment!

Note

Useful information and instructions.

h

This symbol points you to energy saving tips. You can

put this setting into effect by means of the heat pump

control system, among other things.

• Symbol for a necessary task

1.4 Applicability of the manual

This manual applies exclusively to heat pumps with the

type designations listed in Table 0.1.

2 Safety instructions

Observe the following safety instructions and regulations when operating the heat pump:

• Take advantage of the extensive instruction in the

operation of the heat pump provided by your

specialist technician.

• Carefully read through this operating manual.

• Only carry out activities that are described in this

operating manual.

2.1 Coolants

The heat pump is delivered with an operational filling of

R 407 C coolant. This is a chlorine-free coolant which

does not affect the Earth's ozone layer. R 407 C is neither a fire hazard nor an explosion risk.

Danger!

Environmental hazard!

a

d

h

This unit contains R 407 C coolant. The

coolant must not be allowed to escape

into the atmosphere. R 407 C is a fluorinated, chlorine-free greenhouse gas that

has been included in the Kyoto Protocol,

with a GWP of 1653 (GWP = Global

Warming Potential).

Before the appliance is disposed of, the

coolant it contains must be completely

drained into a suitable vessel so that it

can then be recycled or disposed of in

accordance with the regulations.

The relevant work in connection with the

coolant may only be carried out by officially certified specialists.

Danger!

Risk of injury from freezing as a result

of contact with the R 407 C coolant!

Escaping coolant can cause freezing if

the exit point is touched:

Do not inhale gases or vapours emanating from leaks in the coolant circuit.

Avoid contact with the skin and eyes.

Note

R 407 C coolant presents no danger

during normal use and under normal

conditions. With improper use, however,

it can cause injury and damage.

Danger!

Risk of burning as a result of contact

H

with heat pump components!

High temperatures can appear on heat

pump components.

Do not touch any uninsulated pipes on

the heat pump.

Do not remove any of the cladding

sections (apart from the pillar cover,

see Chap. 1.2).

Operating Manual geoTHERM VWS/VWW 0020051578_014

Page 7

Safety instructions 2

Equipment and functional description 3

If an external passive cooling system is installed in your

system:

Caution!

Danger of falling below the dew point and

a

a

2.2 Prohibition on alterations

d

condensate formation!

The heating flow temperature setting

must not be too low in cooling mode. The

cooling function is still effective with a

flow temperature of 20 °C.

Caution!

The cooling function is impaired if the

thermostatic radiator valves are closed!

The thermostatic radiator valves must

be switched to the "open" position in

cooling mode to ensure that the cooled

heating water circulates smoothly

through the underfloor circuit.

Danger!

Inappropriate alterations can cause

injuries!

Under no circumstances should you

attempt to make changes or alterations

to the heat pump or other parts of the

heating and hot water system yourself.

3 Equipment and functional

description

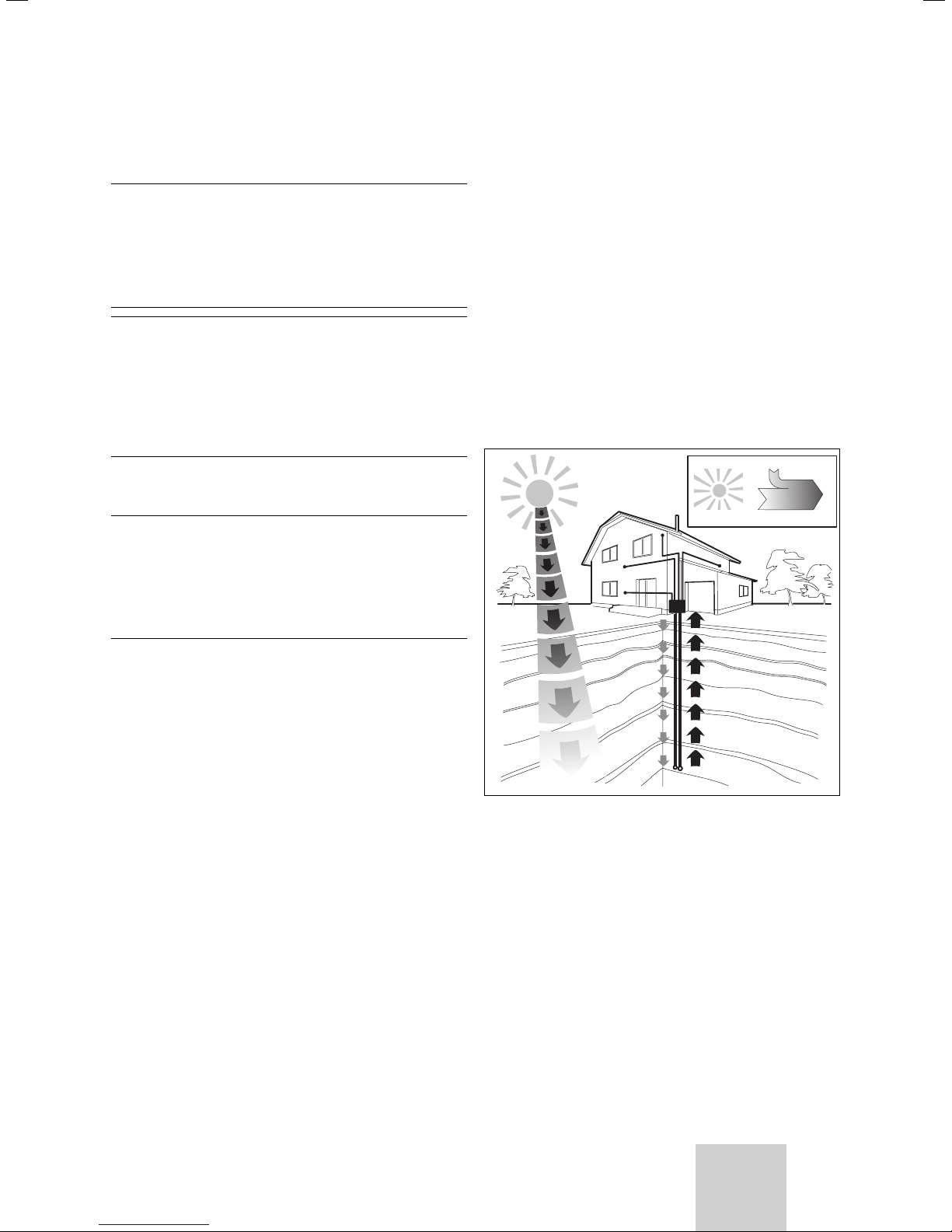

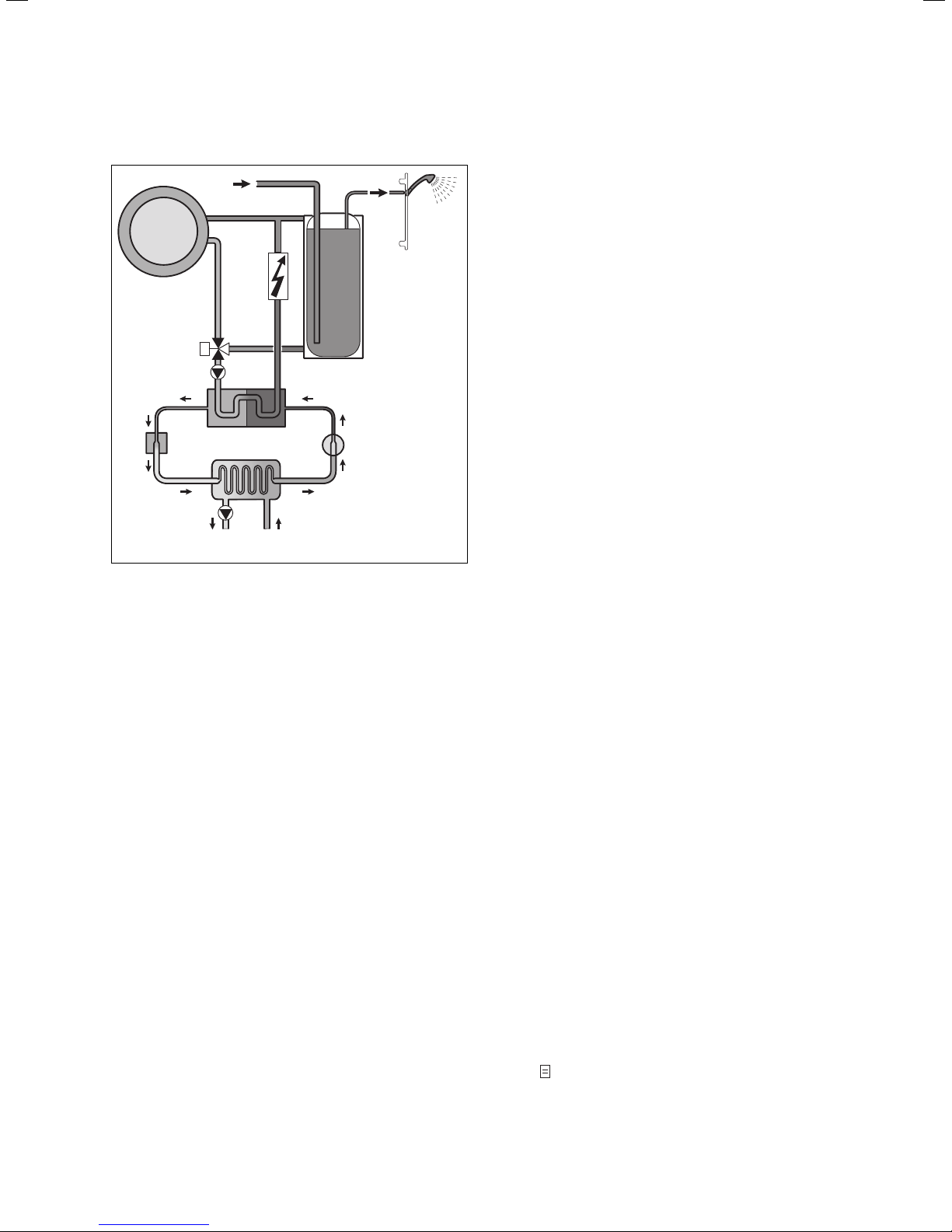

3.1 Functional principle

Heat pump systems consist of separate circuits in which

liquids or gases transport the heat from the heat source

to the heating system. As these circuits operate with

differing media (brine/water, coolant and heating

water), they are coupled to one another by means of

heat exchangers. In these heat exchangers the heat

passes from a medium at a high temperature to a

medium at a lower temperature.

The Vaillant geoTHERM heat pump uses geothermal

energy or ground water as its heat source.

1/4 Electrical energy

3/4 Environmental energy 4/4 Heating energy

The prohibition applies to:

— the heat pump,

— the vicinity of the heat pump,

— the supply lines for water and power.

For alterations to the heat pump or its peripherals, you

must call on a qualified engineer.

• Do not damage or remove seals or locking devices on

components. Only suitably qualified heating engineer

or our customer service may remove sealed components.

Fig. 3.1 Use of geothermal energy or ground water as the heat

source

The system consists of separate circuits which are coupled to one another by means of heat exchangers.

These circuits are:

- The heat source circuit, by means of which the energy

from the heat source is transported to the coolant

circuit.

- The coolant circuit, which releases its heat to the

heating water circuit by means of evaporation, compression, liquefaction and expansion.

- The heating water circuit, which supplies the heating

and the hot water generation for the domestic hot

water cylinder.

GB

5Operating Manual geoTHERM VWS/VWW 0020051578_01

Page 8

3 Equipment and functional description

3.2 Operation mode of the coolant circuit

Cold water

Hot water

Heating system

Additional

heating

Domestic

hot water cylinder

Switching valve

Heating water pump

3

Expansion valve

4

Brine pump

Fig. 3.2 Principle of operation of the heat pump

Condenser

Evaporator

Heat source

Compressor

1

Heating water circuit

2

Coolant circuit

Heat source circuit

The coolant circuit is connected by means of the evaporator (1) to the environmental heat source, from which it

extracts thermal energy. At the same time, the physical

state of the coolant changes; it evaporates. The coolant

circuit is connected by means of the condenser (3) to

the heating system, to which it releases the heat again.

In so doing, the coolant becomes liquid again; it condenses.

As thermal energy can only pass from a body at a higher temperature to a body at a lower temperature, the

coolant in the evaporator must have a lower temperature than the environmental heat source. On the other

hand, the temperature of the coolant in the condenser

must be higher than that of the heating water in order

to be able to release the heat to it.

These different temperatures are produced in the coolant circuit by means of a compressor (2) and an expansion valve (4) between the evaporator and condenser.

The coolant flows in vapour form from the evaporator

into the compressor, where it is compressed. This causes the pressure and temperature of the coolant vapour

to rise sharply. After this process it flows through the

condenser, where it releases its heat to the heating

water by condensation. It flows as a liquid to the expansion valve, where it expands significantly and in so doing

loses much of its pressure and temperature. This temperature is now lower than that of the brine flowing

through the evaporator. The coolant can thus take up

more heat in the evaporator, turning into vapour in the

process and flowing to the compressor. The cycle starts

again.

If required, the electric auxiliary heating can be

switched in by the integrated controller.

To prevent the formation of condensate in the interior

of the unit, the pipes of the heat source circuit and the

coolant circuit are insulated. In the unlikely event that

condensate forms, this collects in a condensate pan inside the unit and is discharged under the unit where a

suitable condensate drain should be installed.

3.3 Automatic auxiliary functions

Frost protection

The controller is equipped with a frost protection function. This function ensures that your heating installation

is protected from frost in all operating modes.

The set-back temperature is pre-set automatically for

each heating circuit if the outside temperature falls

below 3 °C.

Cylinder frost protection

This function starts automatically when the actual temperature of the cylinder falls below 10 °C. The cylinder is

then heated to 15 °C. This function is also active in the

"Off" and "Auto" operating modes, regardless of the

timer programmes.

Checking the external sensors

The hydraulic basic circuit given by you during commissioning determines the required sensors. The heat pump

constantly checks automatically that all sensors are installed and functioning.

Protection from loss of heating water

An analogue pressure sensor monitors possible low

water pressure and switches the heat pump off if the

water pressure on the pressure gauge reads less than

0.5 bar and switches it back on when the water pressure

is over 0.7 bar on the pressure gauge.

Pump seizing and valve seizing protection

To prevent the heating, circulation or brine pumps, or

the hot water diverter valve UV1, from seizing, those

pumps and the valve that have not been in operation for

the last 24 hours are turned on in sequence for approximately 20 seconds every day.

Protection against loss of brine (VWS only)

An analogue pressure sensor monitors possible low

brine pressure and switches the heat pump off if the

brine pressure is ever less than 0.2 bar on the pressure

gauge and error 91 is displayed on the error memory.

The heat pump switches on again when the brine pressure rises above 0.4 bar gauge pressure.

If the brine pressure drops below 0.6 bar on the pressure gauge for more than one minute a warning appears

in menu

1.

Operating Manual geoTHERM VWS/VWW 0020051578_016

Page 9

Equipment and functional description 3

Floor protection circuit for all hydraulics without

buffer cylinder (e.g. in hydraulic plans 1 and 3)

If the measured flow temperature in the underfloor

heating circuit continuously exceeds a specific value for

more than 15 minutes, the heat pump switches off and

issues the error message 72. When the heating flow

temperature falls below this value again and the error

has been reset the heat pump switches back on.

Caution!

Danger of damage to the floor.

a

Set the value for the floor protection

circuit ensuring that it is not high

enough to damage the floor as a result

of excessively high temperatures.

Phase monitoring

The sequence and existence of phases (clockwise rotating field) on the 400 V voltage supply are continuously

monitored during commissioning and operation. If the

sequence is not correct or if a phase breaks down, the

heat pump is switched off due to the error to avoid

damage to the compressor.

Freezing protection function

The outlet temperature of the heat source is constantly

measured. If the heat source outlet temperature falls

below a specific value, the compressor temporarily

shuts off with the error message 20 or 21. If these errors occur three times in a row there is a fault-induced

shutdown.

For the geoTHERM VWS heat pumps you can set the

value (Default setting -10 °C) for the freezing protection

in the installation assistant A4.

For the geoTHERM VWW heat pumps a default value of

+4 °C is set. This value cannot be changed.

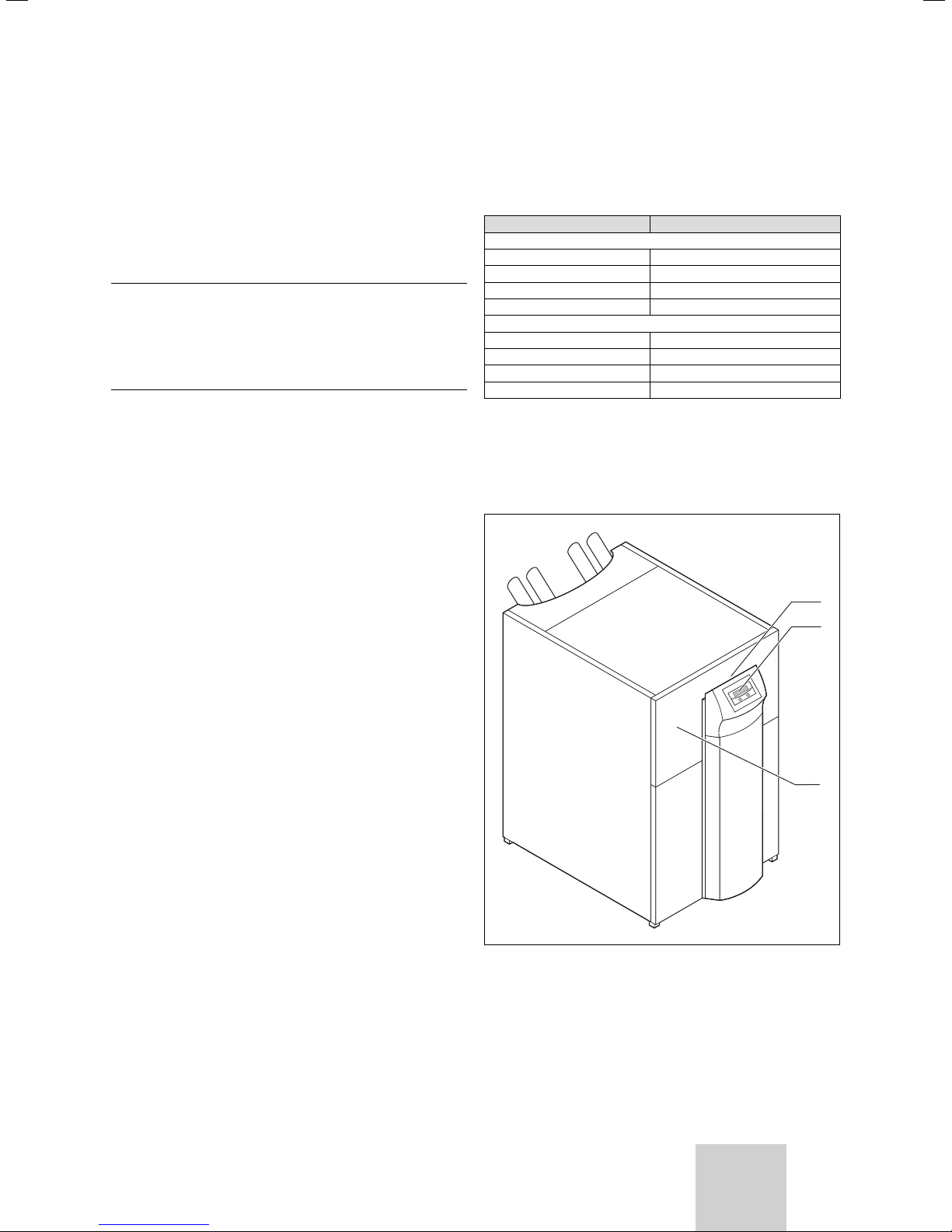

3.4 Design of the heat pump

The types of heat pump available are listed below. The

heat pumps are, above all, different from each other in

their output.

Type name Heating output (kW)

Brine-to-water heat pumps (B0/W35)

VWS 220/2 21.6

VWS 300/2 29.9

VWS 380/2 38.3

VWS 460/2 45.9

Water-water heat pumps (W10/W35)

VWW 220/2 29.9

VWW 300/2 41.6

VWW 380/2 52.6

VWW 460/2 63.6

Table 3.1 Type summary

1)

Thermal heating output with a brine temperature of 0 °C and

heating flow temperature of 35 °C

2)

Thermal heating output with a water temperature of 10 °C and

heating flow temperature of 35 °C

1)

2)

1

2

Fig. 3.3 Front view VWS/VWW

Key to Fig. 3.3

1 Label with heat pump type designation

2 Operating panel

3 Serial number

GB

3

7Operating Manual geoTHERM VWS/VWW 0020051578_01

Page 10

3 Equipment and functional description

4 Notes on the installation and operation

4 Notes on the installation and

operation

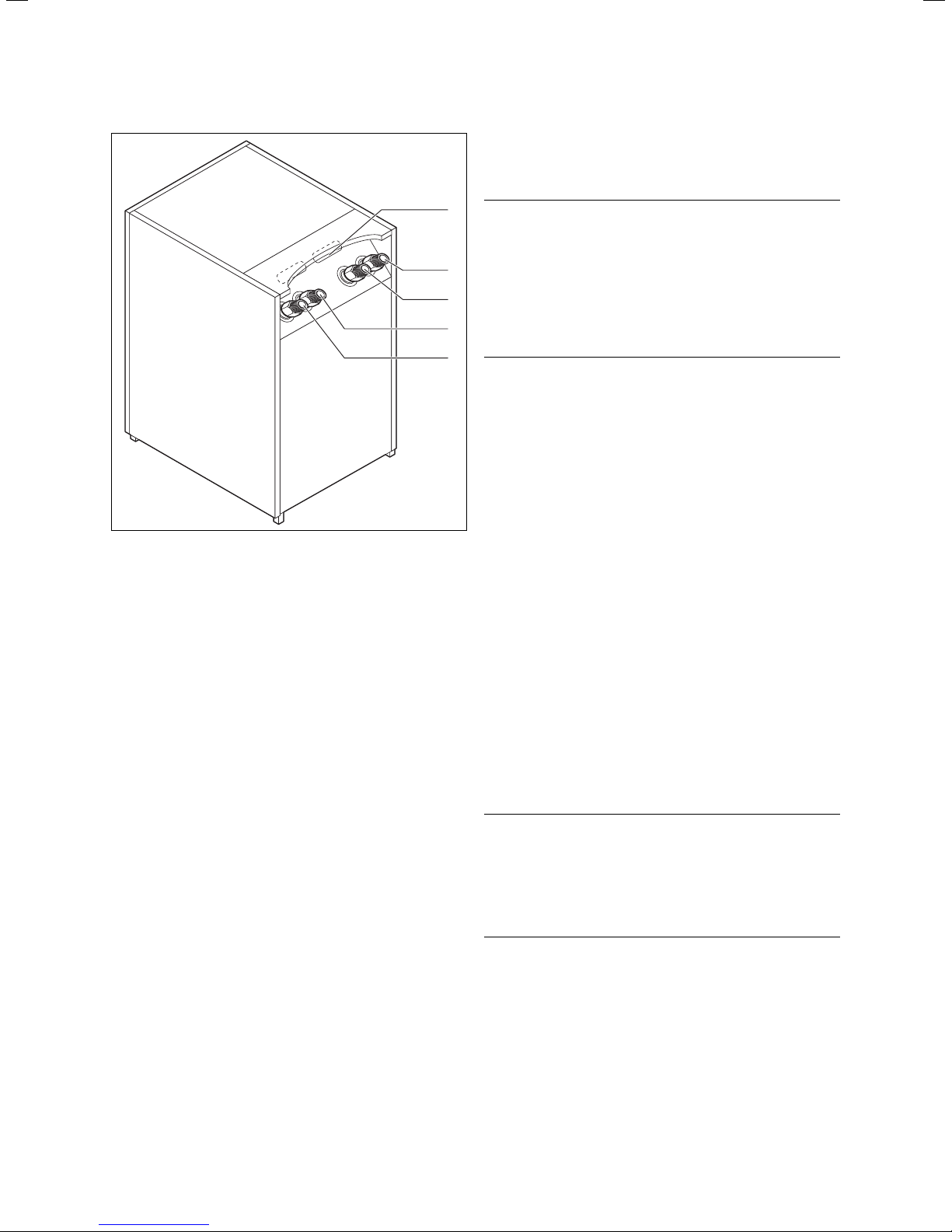

Fig. 3.4 Rear view VWS/VWW

Key to Fig. 3.4

1 Cable feedthrough for electrical connections

2 Heat source from the heat pump

3 Heat source to the heat pump

4 Heating return

5 Heating feed

1

d

2

3

4

5

4.1 Intended use

The Valliant geoTHERM heat pump has been built using

state-of-the-art technology in accordance with recognised safety regulations. Nevertheless, there is still a

risk of injury or death to the user or others or of damage to the device and other property in the event of improper use or use for which it is not intended.

This unit is not intended for use by persons (including

children) having limited physical, sensory or mental capacities or who have inadequate experience and/or

knowledge, unless supervised by a person responsible

for their safety or who has been given instructions from

them as to how to operate the unit.

Children must be supervised to ensure that they do not

play with the unit.

The heat pump is designed to generate heat for closed

hot water central heating installations and for hot water

generation. Any other use or extended use is considered

to be improper. The manufacturer or supplier is not liable for any resulting damage. The user alone bears the

risk.

Intended use also includes:

— observance of the operating and installation manual.

— observance of all other applicable documents.

— compliance with the inspection and care conditions.

Danger!

Risk to life as a consequence of using

unqualified personnel!

Installation, inspection and repair may

only be carried out by a qualified engineer. In particular, working on the electrical components and on the coolant

circuit requires an appropriate qualification.

d

Danger!

Danger of death due to improper use of

the system.

There is a risk of death or serious injury

to the user or others or of damage to the

unit and other property in the unit is improperly used or not used as intended.

Operating Manual geoTHERM VWS/VWW 0020051578_018

Page 11

Notes on the installation and operation 4

4.2 Requirements of the installation site

The installation site must be dimensioned such that the

heat pump can be properly installed and maintained.

• Ask your heating engineer which currently applicable

national building regulations must be observed.

The installation site must be dry and generally frostproof.

4.3 Accumulation of condensate

(condensation water)

The evaporator, the brine pumps and the pipes in the

heat source circuit, as well as some components in the

coolant circuit, are insulated in the interior of the heat

pump, so that no condensate can accumulate. If in the

unlikely event of a small amount of condensate forming,

this falls into an internal condensate pan in the bottom

section of the heat pump. As a result of the heat generated inside the heat pump, the condensate in the condensate pan evaporates. Small amounts of the accumulating condensate can be drained off under the heat

pump. In small amounts, accumulating condensate

should not be seen as a fault in the heat pump.

If an external passive cooling system is installed in your

system:

Caution!

Danger of falling below the dew point and

a

condensate formation!

The heating flow temperature setting

must not be too low in cooling mode. The

cooling function is still effective with a

flow temperature of 20 °C.

4.4 Energy saving tips

Below you will find important tips to help you operate

your heat pump system in an energy and cost-saving

manner.

4.4.1 General energy saving tips

You can even save energy through your general actions:

—Ventilate correctly:

Do not leave windows or French doors tilted open.

Instead, open these wide 3 to 4 times a day for

15 minutes and turn down the thermostatic valves

or room thermostats while ventilating.

— Do not block the radiators:

this will allow the heated air in the room to circulate

more effectively.

— Use a ventilation system with heat recovery:

The optimum exchange of air in the building is always

guaranteed by using a ventilation system with heat

recovery (windows no longer need to be opened for

ventilation purposes). If necessary, the air flow can be

matched to your individual requirements with the ventilation unit's remote control.

— Check that windows and doors are airtight:

Keep shutters and blinds closed at night, so that as

little heat as possible is lost.

— Do not cover controllers:

If a VR 90 remote control unit is installed as an accessory, do not obstruct it with furniture, etc. as otherwise it will not be able to record the circulating room

air as effectively.

— Awareness of water usage:

shower instead of bath, replace seals in dripping water

taps immediately, for example.

GB

9Operating Manual geoTHERM VWS/VWW 0020051578_01

Page 12

4 Information on the installation and operation

—Use thermostatic radiator valves:

You can adjust the room temperature to suit your in-

4.4.2 Economising by using the control system cor-

rectly

Further economies can be made by the correct use of

the control system on your heat pump.

A number of tips on how to make save energy by adjusting your heat pump's control system are provided

below:

— Set the correct heating flow temperature:

Your heat pump not only controls the heating flow

temperature with reference to the outside temperature, it also controls the heating flow temperature

with reference to the room temperature you have set.

Therefore select a room temperature that is just sufficient for your comfort, for example 20 °C. Every degree over and above that means an increase in energy

consumption of around 6 % per annum.

— Select the appropriate heating curve:

If your heat pump is used to operate underfloor heating, you should specify a heating curve that is less

than 0.4. We recommend that radiator heating systems are configured in such a way that they can still

function effectively at extremely low outside temperatures with a maximum flow temperature of 50 °C; this

corresponds to heating curves of less than 0.7.

— Choose an appropriate hot water temperature set-

ting:

The hot water set target temperature you specify

should be just enough to satisfy your consumption

requirements and no higher. Any further heating

results in unnecessary power consumption, and hot

water temperatures of more than 60 °C also lead to

increased lime scale production. We recommend that

hot water generation be achieved without the electric

auxiliary heating; by this method, the maximum hot

water temperature is determined by the high pressure

cut-out in the heat pump cooling circuit. This cut-out

corresponds to a maximum hot water temperature of

approx. 58 °C.

— Setting of heating times that take individual re-

quirements into account:

Use the timer programs for heating and hot water. Set

the times on the basis of your typical daily routine and

corresponding heat demand.

— Select the correct operating mode:

For the times that you are asleep or away, we recom-

mend that you switch the heating to set-back mode.

—Heat uniformly:

Through appropriate structuring of a heating pro-

gramme, you can arrange for all the rooms in your

house to be uniformly heated in accordance with your

pattern of use.

dividual requirements and ensure effective operation

of your heating installation using the thermostatic

valves in combination with a room temperature regulator (weather compensator).

— Optimise use of the circulation pump:

Adapt the operating times of the circulation pump to

actual requirements.

— Consult your expert technician:

He can adjust your heat pump installation to suit your

personal requirements.

You will find these and other energy saving tips in

Chap. 5.5. The controller settings that can potentially

save energy are described there.

Operating Manual geoTHERM VWS/VWW 0020051578_0110

Page 13

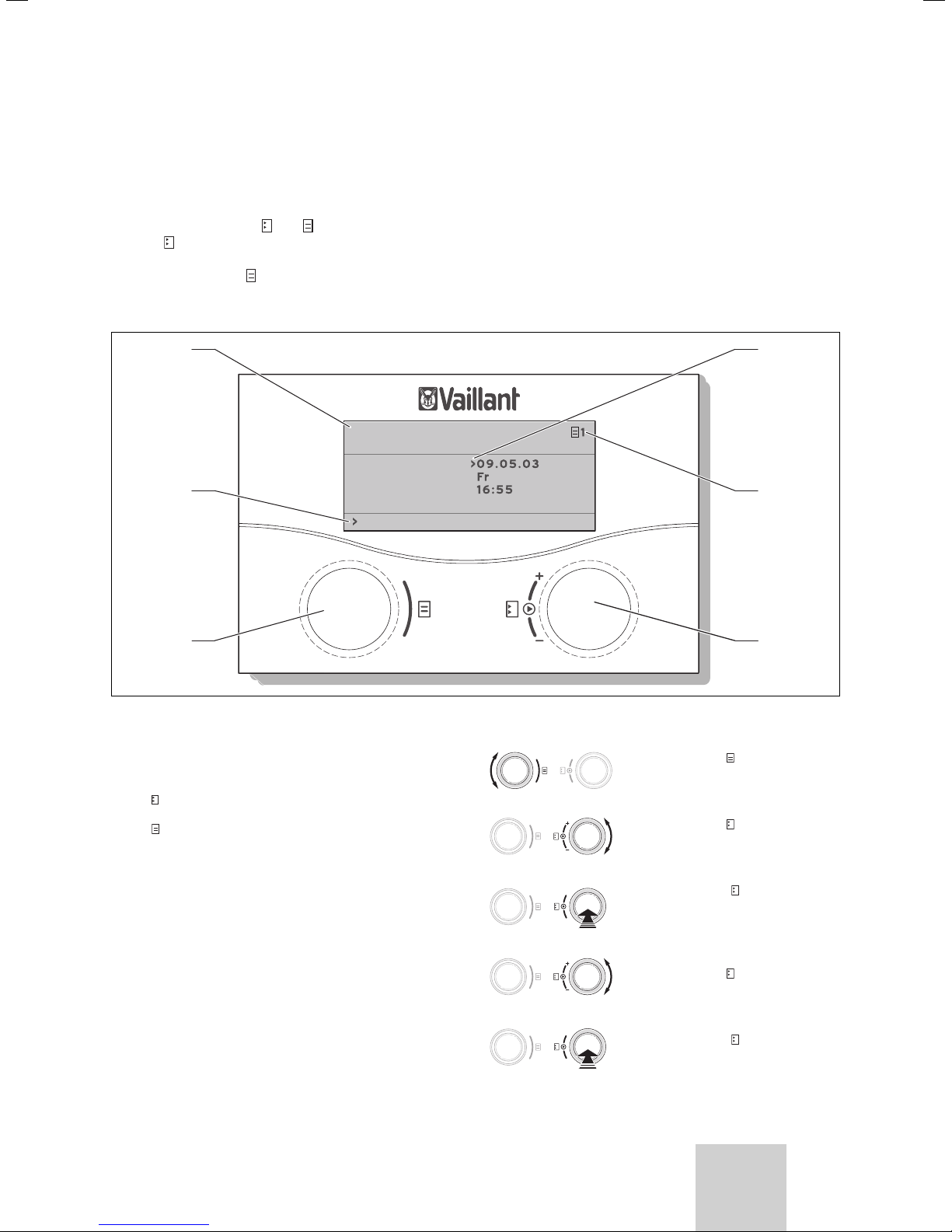

5 Operation

5.1 Familiarising yourself with and operating the

controller

All programming of the heat pump is carried out by

means of the two dials (

The dial

is used to select the parameter (by pressing)

and to alter the parameter

(by turning). The dial

(by turning) and to activate special functions (by pressing).

and ) on the controller.

is used to select the menu

Operation 5

1

Basic data

Date

Day of week

6

5

Fig. 5.1 Operating overview

Key

1 Menu name

2 Cursor indicates the selected parameter

3 menu number

4 Dial

5 Dial ,

6 Information line (in the example a handling request)

,

position parameter (turn), select parameter (press)

select menu (turn), activate special operation (press)

Time

Set day

2

3

4

Typical operating process (operator level)

• Turn the dial

to select the required menu.

• Turn the dial

to select the parameter to be

modified.

• Press the dial to mark the

parameter to be modified. The

parameter background is

darkened.

• Turn the dial to modify the

parameter setting value.

• Press the dial to mark the

setting value to be accepted.

GB

11Operating Manual geoTHERM VWS/VWW 0020051578_01

Page 14

5 Operation

5.2 Setting menus and parameters

setting to date modified setting

select menu:

Holiday programming

for cpl. System

Period of

time

1 >06.01.08 08.01.08

2 14.01.08 30.01.08

Room Temp. setpoint 12°C

>Set start day

Basic data

6

– Turn the dial: Select

menu e.g. from menu 6

to 7.

Select parameter:

7

Basic data

Date >21.04.08

Day of

week Mo

Time 09:35

>Set day

Basic data

7

7

Date >21.04.08

Day of

week Mo

Time 09:35

>Set day

Basic data

Date 21.04.08

Day of

week >Mon

Time 09:35

>Set weekday

• Turn the dial: select the

parameter to be modified,

e.g. from line 1 Day to line

2 Weekday (turn dial

through 3 further index

steps in this case).

Modify parameter weekday

7

from Monday to Tuesday:

– Push the dial:

Select parameter.

– Turn the dial:

Modify parameter.

– Push the dial:

Accept modification.

5.3 Description of the controller

The heating engineer will have set all the operating parameters to preset values during commissioning, so that

the heat pump can function optimally. However, you can

individually set and adapt the operating modes and

functions afterwards.

Date 21.04.08

Day of

week >Mon

Time 09:35

>Set weekday

Basic data

Date 21.04.08

Day of

week >Tues

Time 09:35

>Set weekday

7

5.3.1 Possible system circuits

The controller can control the following system circuits:

– a heating circuit.

– an indirectly heated hot water storage tank.

– a hot water circulation pump.

– a buffer circuit.

In order to extend the system a buffer circuit can be

used to connect up to six additional mixer circuit modules VR 60 (accessories) each with two mixer circuits.

The controller on the operating panel of the heat pump

is used to programme the mixer circuits.

In order to operate under comfortable conditions you

can connect the remote control units VR 90 for the first

eight heating circuits.

Operating Manual geoTHERM VWS/VWW 0020051578_0112

Page 15

Operation 5

5.3.2 Energy balance controller

The energy balance controller is only applicable to hydraulics without buffer cylinder.

For economical and fault-free operation of a heat pump,

it is important to regiment the starting of the compressor. The start-up of the compressor is the point at which

the highest loading occurs. With the help of the energy

balance controller it is possible to minimise starts of the

heat pump without compromising the comfort of a

pleasant room atmosphere.

As with other weather-controlled heating controllers the

controller determines a supply set target temperature

by capturing the outside temperature through a heating

curve. The energy balance calculation is carried out

based on this supply set target temperature and the

supply real temperature the difference of which is

measured per minute and added up:

1 degree minute [°min] = 1 K temperature difference in

the supply from 1 Minute (K = Kelvin)

The heat pump starts up at a defined heat deficit and

only switches off again when the supplied heat is equal

to the heat deficit.

The larger the preset negative numerical value is, the

longer the periods for which the compressor is kept

running or at standstill.

5.3.3 Charging principle buffer cylinder

The buffer cylinder is controlled depending on the setpoint flow temperature. The heat pump heats when the

temperature of the buffer cylinder head temperature

sensor VF1 is smaller than the set target temperature. It

heats until the temperature measured by the sensor at

the base of the buffer cylinder, RF1, has reached the setpoint temperature plus 2 K.

In the connection to a hot water cylinder charging the

buffer cylinder is also charged when the temperature of

the head temperature sensor VF1 is less than 2 K higher

than the set target temperature (premature reheating):

VF1 < T VL set + 2 K.

5.3.4 Resetting to factory settings

Caution!

Inadvertent deletion of specific settings!

a

When you reset the control system to

the default settings, specific system

settings can be deleted and the system

can shut down. The system does not

suffer damage.

After that you can select whether to reset only the

timer programme or all values to the default settings.

5.3.4 Controller structure

The top level display is a graphics display. It is the

starting point for all the available displays. This display

reappears automatically if you do not actuate any of the

dials for a long time when setting values.

Controller operation is subdivided into four levels:

The operator level is specified for the operator.

In Sect. 5.4 all of the controller's displays are shown as

a flow diagram. A detailed description of the displays is

contained in Sect. 5.5.

The code level (menu C1 - C9, D1 - D5, I1 - I5 and A1 - A9)

is reserved for the engineer and protected by a code to

protect it from unintentional modification.

As the operator you can scroll through the menus of the

code level and view the system-specific setting parameters however without changing the values.

In the menus C1 to C9 the engineer sets system-specific

parameters.

The menus D1 to D5 enable the engineer to operate and

test the heat pump in the diagnosis mode.

In Menus I1 to I5 you can obtain general information regarding the settings for the heat pump.

Menus A1 to A9 take the engineer through the installation menu to put the heat pump into operation.

The display and selection of special function

(e.g. the energy-saving function) is also possible for the

operator. Instructions on how to activate the special

functions are given in Chap. 5.6.

The fourth level contains functions for the optimisation

of the system and can only be set by the engineer using

vrDIALOG 810/2.

5.3.5 Adjusting the energy saving functions

Also described in Chap. 5.5 are heat pump settings that

will enable a reduction in your energy costs. This can be

achieved by finding the optimum setting of the heat

pump's weather-controlled energy balance controller.

This symbol points you to these energy saving tips.

• Press both dials simultaneously for at least 5 seconds

in the top-level display of the graphics display.

GB

13Operating Manual geoTHERM VWS/VWW 0020051578_01

Page 16

5 Operation

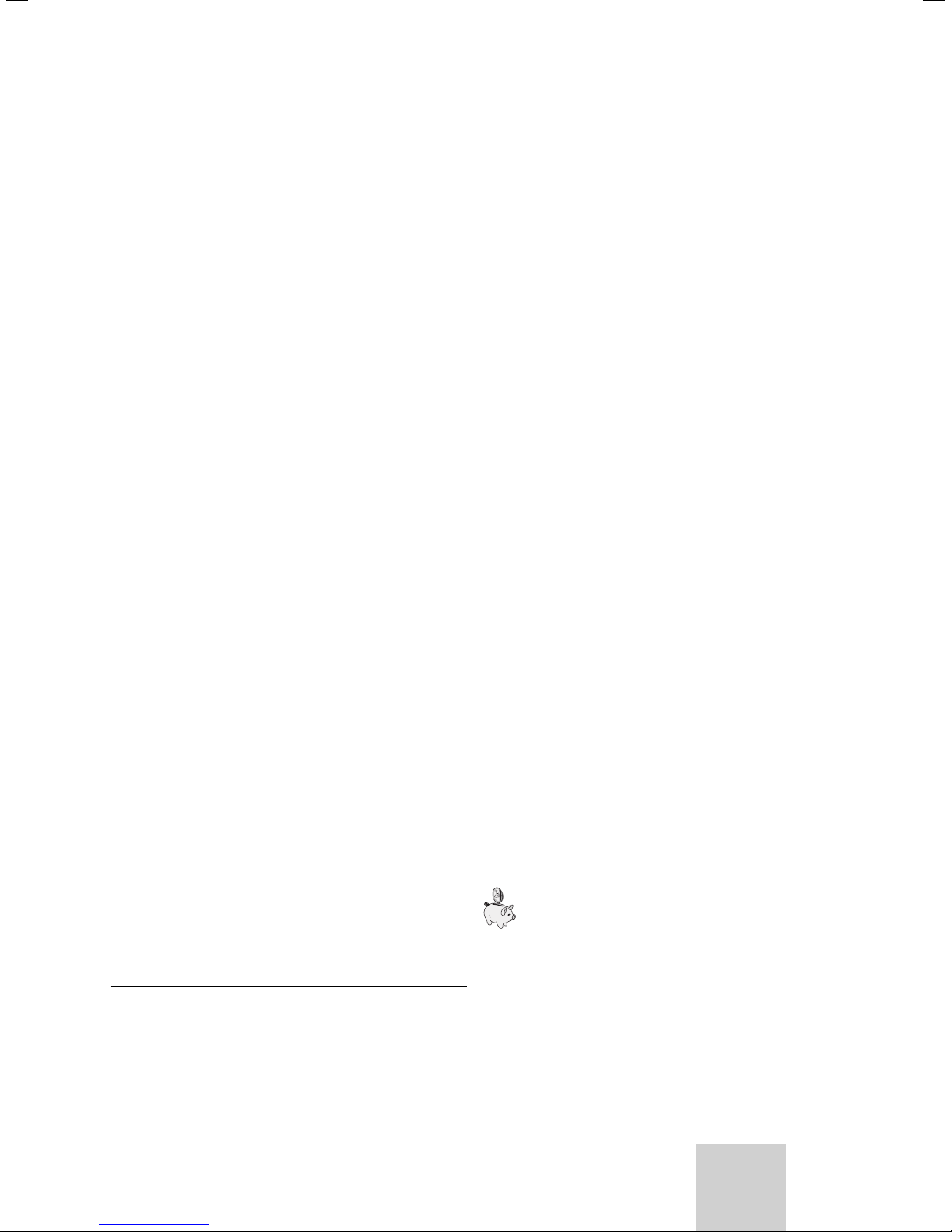

5.4 Flow diagram

Graphics display

Graphics display cooling*

Energy input display

Mo 21.04.08

Flow Temp. CH

System pressure 1,2bar

Brine pressure

CH : Comp only

Warning message

Warning message

16:49

28ºC

1,4bar

Reset to default

settings

We 16.02.08 9:35

> 5 sec.

Factory setting

Cancel

Time programme

Everything

> Select

NO/YES

NO/YES

NO/YES

Installer Menu

We 16.02.08 9:35

Sparen aktiviert for > 12:00

> Select stop time

We 16.02.08 9:35

Party function enabled

We 16.02.08 9:35

One-time

DHW tank loading enabled

1

Cooling settings *

We 16.02.08 9:35

Cooling function active for >3days

HK2

Parameters

HK2

Heating mode

Parameter

>Auto

Betriebsart Heizen

Set value day

>Auto

Night set back temp.

Raumsolltemp.

>Select operation mode

Night set back temp.

Domestic hot water

Parameters

Operation mode DHW > Auto

Max. DHW temp.

Min. DHW temp.

Current DHW temp.

>Select operation mode

HK2

Time programme

HK2

Time programme

>Mo

HK2

1 00:00 24:00

Time programme

>Mo

2 : :

1 00:00 24:00

>Mo

3 : :

2 : :

1 00:00 24:00

3 : :

>Select day of the week

2 : :

3 : :

>Select day of the week

>Select day of the week

20 ºC

15 ºC

60 ºC

44 ºC

51 ºC

2

20 ºC

15 ºC

4

5

2

5

5

Domestic hot water

Time programme

>Mo

1 06:00 22:00

2 : :

3 : :

>Select day of the week

Circulation pump

Time programme

>Mo

1 06:00 22:00

2 : :

3 : :

>Select day of the week

Holiday programming

for cpl. System

Periods

1 >06.01.08 08.01.08

2 14.01.08 31.01.08

Room Temp. setpoint

>Set starting day

Fig. 5.2 Displays at the user level

*) displays in grey may vary depending on the hydraulic plan set

> Set duration

5

5

6

12 ºC

Basic data 7

Date 21.04.08

Day of week > Mo

Time 09:35

> Set day of the week

Code layer 8

Code-Nummer:

> 0 0 0 0

Standard code:

1 0 0 0

>Adjust numeric character

Code level only for

expert technicians

Operating Manual geoTHERM VWS/VWW 0020051578_0114

Page 17

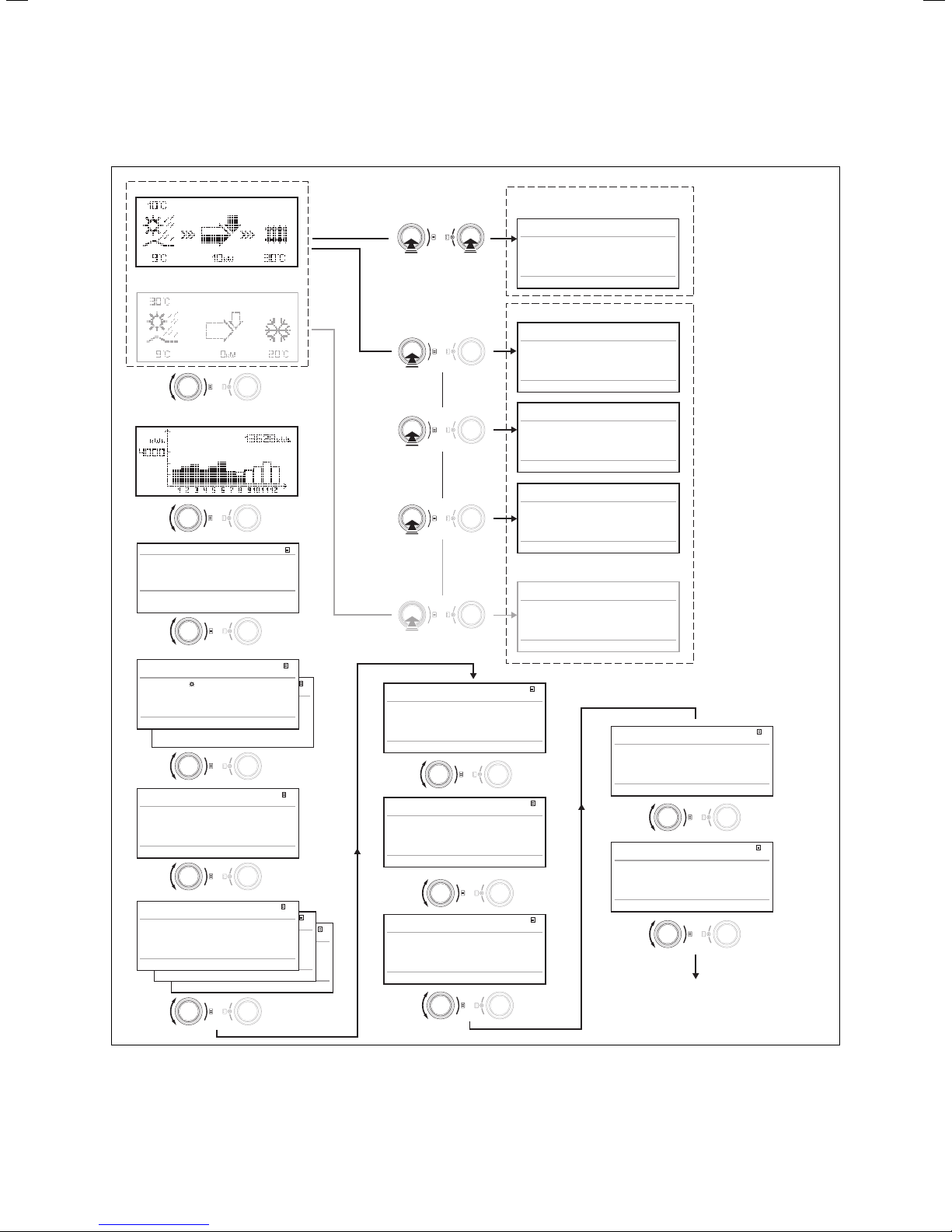

5.5 Displays at user level

The individual displays on the operator control panel are

described and explained below.

Display shown Description

Graphics display (Top-level display)

You can read off the instantaneous state of the system from this display. This is always shown if you have not actuated either of the dials

for a long time while another display is showing.

Operation 5

Outside temperature (here 10 °C)

Source inlet temperature: Temperature sensor;

in the example 9 °C

Under the arrow the output of the heat source

(in the example 10 KW) is displayed.

The extent of darkening of the arrow graphically

shows the energy efficiency of the heat pump

under the given operating conditions.

The output of the heat source must not be

equated with the heating output.

The heating output corresponds to approx. the

output of the heat source + compressor output.

When the compressor or the electric auxiliary

heating is switched on, the arrow is shown filled.

>>> Left and right flash when the compressor is

switched on and energy is consequently being

taken from the environment and fed to the heating system.

>>> Right flashes when energy is being fed to the

heating system (e.g. only from the electric auxiliary heating).

The heat pump is in the CH mode. The heating

flow temperature is also displayed (30 °C shown

in example).

The symbol indicates that the domestic hot

water cylinder is being heated or that the heat

pump is in the ready state. The temperature in

the domestic hot water cylinder is also displayed.

Only if cooling is installed and the corresponding

settings have been made by the expert technician at the heat pump controller:

The symbol indicates that the heat pump is in

cooling operation. Under the symbol the actual

heating flow temperature is displayed

(in the example 20 °C).

Table 5.1 Settable parameters in the operator level

GB

15Operating Manual geoTHERM VWS/VWW 0020051578_01

Page 18

5 Operation

Display shown Description

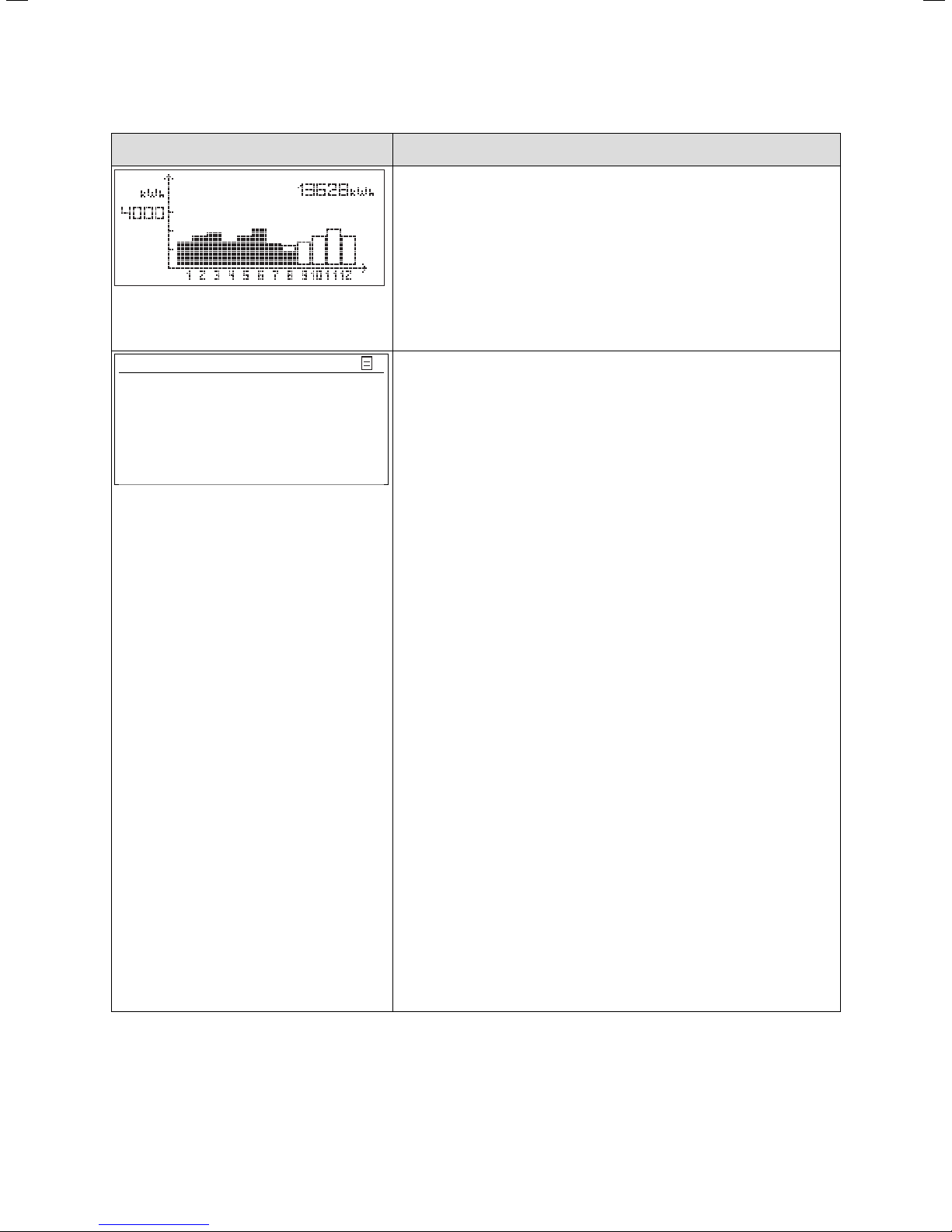

Energy input display

Shows the energy extracted from the environment for each of the

12 months of the current year (black bar). White-filled bars represent

the future months of the year; the height of the bar corresponds to

the yield for the month in the previous year (comparison possible).

On commissioning, the height of the bars is zero for all months, as no

information is available yet.

The scaling (in the example, 4000 kWh) adapts automatically to the

month's highest value.

Top right the total of the environmental yield since commissioning is

displayed (in the example: 13628 kWh).

Mon. 21.04.08 16:49 1

Current flow temp. 28 °C

CH pressure 1.2 bar

Brine pressure 1.4 bar

Heating only comp.

Warning message

Warning message

Day, date, time as well as flow temperature, heating system pressure

and heat source pressure are displayed.

Current flow temp: Current flow temperature in the unit.

Heating system pressure: Pressure sensor heating circuit.

Pressure heat source: Heat source pressure (Pressure sensor for

heat source circuit; brine pressure)

Heating only comp.: this status message provides information on the

current operating status. The following are possible:

Heating only comp.

Heating comp & ZH

CH: ZH only

CH:Comp&aux off

WW:Comp&aux off

WW: Comp only

WW: ZH only

Peak Rate: WW

Peak Rate: Stand-by

Acceleration mode

Frost prot. Heating

Frost prot. Cylind.

Legionella protect.

Automatic pump spin

Floor drying

Venting mode

Fault shutdown: heating

Error shutdown: heating

Fault shutdown: DHW

Error shutdown: DHW

Malfunction

Blocking error

Operation interlock

CH Comp overrun

WW Comp overrun

Cooling & WW

CH return too high

Table 5.1 Settable parameters in the operator level (contd.)

Under critical operating conditions a warning message is displayed in

both lower display lines. These lines are empty when the operating

conditions are normal.

Operating Manual geoTHERM VWS/VWW 0020051578_0116

Page 19

Operation 5

Display shown Description Factory setting

<HK2>

Parameters

Operating mode heating

>Auto

Set value day 22 °C

Night set back temp. 15 °C

>Select operating mode

The room set target temperature is the tempera-

2

ture to which the heating should be regulated in the

operating mode "Heat" or during the time slots.

Note: Select a room temperature that is just high

enough to ensure your personal well-being

(e.g. 20 °C). Each degree over and above the set

value means an increase in energy consumption of

around 6 % per annum.

The set-back temperature is the temperature to

which the heating is regulated during the set-back

period. An individual set-back temperature can be

set for each heating circuit.

The set operating mode determines under which

conditions the assigned heating circuit or hot water

circuit should be regulated.

Room set target

temp.: 20 °C

Set-back temp.:

15 °C

The following operating modes are available for

heating circuits:

Auto: The operation of the heating circuits alternates between the Heating and Energy Saving

operating modes in accordance with a settable timer

programme.

Eco: The operation of the heating circuits alternates

between the Heating and Off operating modes in

accordance with a settable timer programme. The

heating circuit is switched off during the set-back

period provided the frost protection function

(which depends on the outside

temperature) is not activated.

Heating: The heating circuit operates at the room

set target temperature regardless of any settable

timer programme.

Energy sav: The heating circuit operates at the setback temperature regardless of any settable timer

programme.

Off: The heating circuit is off, provided that the frost

protection function (depending on the external temperature) is not activated.

Note:

Additional heating circuits are displayed, depending

on the system configuration.

Table 5.1 Settable parameters in the operator level (contd.)

GB

17Operating Manual geoTHERM VWS/VWW 0020051578_01

Page 20

5 Operation

Display shown Description Factory setting

DHW loading

Parameters

Operating mode WW Auto

Max. DHW temp. 60 °C

Min. DHW temp. 44 °C

Cylinder temp. REAL

>Select set target temperature

51 °C

For connected domestic hot water cylinders and the

4

circulation circuit the operating modes Auto, On and

Off are possible.

The maximum WW temperature determines the

temperature to which the domestic hot water cylinder should be heated.

The minimum WW temperature determines the

limit below which the domestic hot water cylinder is

heated.

Note: The maximum WW temperature is only displayed when the auxiliary hot water heating is enabled.

Without electric auxiliary heating, the WW temperature is limited by the pressure sensor control shutoff in the cooling circuit and cannot be adjusted!

Cylinder temp. REAL: Current temperature in the

domestic hot water cylinder.

We recommend that hot water generation be

achieved without the electric auxiliary heating. by

this method, the maximum WW temperature is determined by the high pressure cut-out in the heat

pump cooling circuit. This cut-out corresponds to a

maximum hot water temperature of 58 °C. In order

to keep the heat pump starts to an absolute minimum as low a min. hot water temperature as possible should be selected.

Min. hot water

temp. 44 °C

You can set the heating times for each heating cir-

<HK2>

Time programme

>Mon

1 00:00 24:00

2: :

3: :

>Select weekday/block

5

cuit in the "HK2-Timer programme"

menu.

Up to three heating times can be programmed per

day or block. The control system operates according

to the heating curve and the room setpoint temperature.

The set back times can be dispensed with, depending

on the tariff agreement with power company (VNB)

or the construction of the house.

Power companies offer their own discounted tariffs

for heat pumps. It can make sense on economic

grounds to make use of the more favourable offpeak power.

In low-energy houses (in Germany standard as from

1st February 2002 energy conservation regulation)

the room temperature reduction can be dispensed

with owing to low heat losses.

The desired set-back temperature must be set in

menu 2.

Table 5.1 Settable parameters in the operator level (contd.)

Mon – Sun

0:00 – 24:00

Operating Manual geoTHERM VWS/VWW 0020051578_0118

Page 21

Operation 5

Display shown Description Factory setting

DHW loading

Time programme

>Mon

1 06:00 22:00

2: :

3: :

>Select weekday/block

You can set the times at which the domestic hot

5

water cylinder is heated in the "WW Timer Programme" menu.

Up to three times can be programmed per day or

block.

The hot water generation should only be active at

times when really hot water is to be run. Please set

this timer programme to your minimum requirements.

As an example, for working people a window from

6.00 – 8.00 hrs. and a second window from 17.00 –

23.00 hrs.can minimise the energy consumption due

to hot water generation.

Mon – Fri

6:00 – 22:00 hrs.

Sat

7:30 – 23:30

Su.

7:30 – 22:00

You can set the times at which the circulation pump

Circulation pump

Time programme

>Mon

1 06:00 22:00

2: :

3: :

>Select weekday/block

5

is to be operational in the "Circulation Pump Timer

Programme" menu.

Up to three times can be programmed per day or

block.

If the hot water operating mode (see menu

set to "ON", the circulation pump runs continuously.

The timer programme circulation pump should correspond to the

timer programme hot water, if necessary the time

slots could be selected even more restrictively.

If the desired hot water temperature is obtained

quickly enough without switching on the circulation

pump, the circulation pump can likewise be deactivated.

In addition, you can briefly activate the circulation

pump by means of electronic pushbutton switches

mounted in the immediate vicinity of the taps and

connected to the heat pump (the same idea as stairwell lighting). The operating times of the circulation

pump can thus be optimally matched to the actual

need.

Consult your expert technician about doing this.

Table 5.1 Settable parameters in the operator level (contd.)

3) is

Mon – Fri

6:00 – 22:00 hrs.

Sat

7:30 – 23:30

Su.

7:30 – 22:00

GB

19Operating Manual geoTHERM VWS/VWW 0020051578_01

Page 22

5 Operation

Display shown Description Factory setting

Holiday programming

for cpl. System

Period of

time

1 >06.01.08 08.01.08

2 14.01.08 30.01.08

Room Temp. setpoint 12 °C

>Set start day

For the controller and its connected system compo-

6

nents it is possible to programme two holiday periods with the introduction of the date. Moreover, the

desired target room temperature can be set for holidays, i.e. regardless of the preset timer programme.

After the holiday time has elapsed, the controller

automatically goes back to the previously selected

operating mode. The holiday program can be activated only in auto and eco operating mode.

Connected cylinder charging circuits or circulation

pump circuits are automatically switched to OFF

operating mode during the holiday time program.

Connected cylinder charging circuits or circulation

pump circuits are automatically switched to OFF

operating mode during the holiday time program.

Prolonged periods of absence can be set in the display "Programme holidays". The target temperature

during this period should be selected to be as low as

possible.

During this period hot water generation is not in

operation.

Period 1:

01.01.2003 –

01.01.2003

Period 2:

01.01.2003 –

01.01.2003

Room Temp. setpoint 15 °C

You can set the current date, the day of the week

Basic data

Date 21.04.08

Day of

week

Time 09:35

>Settable values

Code layer

Code number:

Mo

>0 0 0 0

7

and the current time, if DCF radio clock reception is

not possible, in the "Basic Data" menu.

These settings apply to all connected system components.

To access the Code level (Installer level), the appro-

8

priate code must be entered.

To view setting parameters without entering the

code, you must press the dial

view all parameters of the code level by turning

the dial

entering the code, you can view all menus in the

>Set figures

code level however not modify them.

Caution! Do not try to access the code level by

making arbitrary entries in the code level. Unintentional modification of the system-specific parameters can cause malfunctions or damage to the heat

pump.

Table 5.1 Settable parameters in the operator level (contd.)

once. You can then

but not change them. As operator, without

Operating Manual geoTHERM VWS/VWW 0020051578_0120

Page 23

5.6 Installer Menu

Special functions can be selected only from the basic

display. To do so press the left-hand dial

To change the parameter, you must turn the

.

dial. The

following special functions can be selected:

Operation 5

• Energy saving function: Press

• Party function: Press

dial twice.

• One-time charging: Press

• Cooling operation: Press

dial once.

dial 3 x.

dial 4 x

To activate one of the functions, you merely have to select it. In the energy saving function it is additionally

necessary to enter the time until which the energy saving function (regulation to set-back temperature) is to

apply.

The basic display appears either after the function has

elapsed (reaching the time) or by pressing the dial

again.

Display shown Description

We 16.02.08 9:35

Saving function:

With the saving function you can set back the heating times for a

Energy saving enabled

settable period.

Enter the time for the end of the saving function in the format hh:mm

(hour:minute).

>Select end time

We 16.02.08 9:35

Party function enabled

Party function:

With the party function you can set the heating and hot water times

beyond the next switch off time on to the next start of heating. The

party function can only be used for the heating circuits or hot water

circuits for which the operating mode "Auto" or "ECO" is set.

We 16.02.08 9:35

one-time

DHW tank loading enabled

Table 5.2 Special functions

One-time charging:

This function allows you to charge the hot water cylinder once,

regardless of the current time program.

GB

21Operating Manual geoTHERM VWS/VWW 0020051578_01

Page 24

5 Operation

Display shown Description

We 16.02.08 9:35

Only if cooling is installed and the corresponding settings have been

made by the expert technician at the heat pump controller:

Cooling function active for > 3 days

Cooling duration: OFF/1 to 99 days.

If the cooling operation is active,

– the symbol of an ice crystal appears in the graphic display.

Table 5.2 Special functions (contd.)

• Reset to default setting: Keep dial and dial

pressed for longer than 5 seconds. After that you can

select whether to reset only the timer programme or

all values to the default settings.

Display shown Description

We 21.04.08 9:35

Factory setting

cancel NO/YES

Time programme NO/YES

Everything NO/YES

>Settable values

The default settings will be reinstated.

Caution! Ensure that a qualified technician performs the default setting reset. The system-specific settings are reset. The system can be

shut down. The system does not suffer damage.

Press the two dials for at least 5 seconds to call up the default settings menu.

Table 5.3 Reinstating default settings

Operating Manual geoTHERM VWS/VWW 0020051578_0122

Page 25

Operation 5

5.7 Starting up the heat pump

The start-up of your heat pump was carried out after

installation by your expert technician company.

Your heat pump does not need to be started up again if

it disconnects from the mains unexpectedly, for example

as a result of a voltage drop (power cut, circuit breaker

defective, circuit breaker deactivated). Your geoTHERM

heat pump has an automatic reset function, i.e. the heat

pump reverts automatically to its starting condition,

provided no fault is present in the heat pump itself. Find

out what to do in the event of a fault in Chap. 5.12.

5.8 Shutting down the heat pump

The heat pump can only be switched off via the operator control panel by deactivating the heating and hot

water generation (operating mode "Off").

<HK2>

Parameters

Operating mode heating

>Off

Set value day 22 °C

Night set back temp. 15 °C

>Select operating mode

Fig. 5.3 Switching off the heating mode

DHW loading

Parameters

Operating mode WW >Off

Max. DHW temp. 60 °C 60 °C

Min. DHW temp. 44 °C 44 °C

Cylinder temp. REAL

>Select set target temperature

Fig. 5.4 Switching off the hot water generation

Deactivate the fuse on your heating sys-

tem if you need to de-energise the heat

h

pump installation completely.

51 °C 51 °C

2

4

5.9 Inspection by a specialist engineer

In contrast to heaters based on fossil fuels, no expensive maintenance work is necessary for the Vaillant geoTHERM heat pump. However an annual inspection of the

system by a specialist is a prerequisite for continued

operational safety, reliability and a long working life.

Danger!

If inspections are not carried out, this

d

h

5.10 Inspection by the operator

In addition to the annual inspection by an expert, a

small amount of inspection work needs to be carried out

by the operator.

5.10.1 Checking the filling pressure of the heating

The filling pressure of the heating installation should be

checked at regular intervals.

Mon. 21.04.08 16:49 1

Current flow temp. 28 °C

CH pressure 1.2 bar

Brine pressure 1.4 bar

Heating only comp.

Warning message

Warning message

Fig. 5.5 Check filling pressure

• Read off the filling pressure of your heating installation at the heat pump controller (see Fig. 5.5).

The pressure in the heating installation should be between 1 and 2 bar. If it falls below 0.5 bar, the heat pump

will be shut down automatically and an error message

will be displayed.

can result in damage to property and

personal injury.

Only have inspections and repairs carried out by an approved heating installation company.

Note Have your system checked regular-

ly by an expert technician company to

ensure efficient operation of your heat

pump.

system

GB

23Operating Manual geoTHERM VWS/VWW 0020051578_01

Page 26

5 Operation

Caution!

Risk of damage from water escaping due

a

h

5.10.2 Checking the filling level and filling pressure

Check the brine level or pressure in the brine circuit at

regular intervals.

• Read off the filling pressure of the brine circuit ("pressure, heat source") at the heat pump controller (see

Fig. 5.5).

The brine filling pressure should be between 1 and 2 bar.

If it falls below 0.6 bar for 2 minutes, or falls below

0.2 bar once, the heat pump is automatically switched

off and an error message is displayed

(see Chap. 3.3 "Low brine pressure protection").

to leaks in the system.

Close the cold water stop valve in the

event of leaks in the hot water pipework.

De-energise the heat pump if the heating

installation is leaking (fuse off).

Have the leaks repaired by an expert

technician.

Note

The cold water stop valve is not included

in the scope of delivery for the heat

pump. It is fitted on site by your heating

engineer. He will explain the location and

handling of the component to you.

of the brine circuit

If the filling level of the brine has fallen so far that it is

no longer visible in the expansion tank, you must have

the brine replenished.

12

Fig. 5.6 Filling level of the brine expansion tank

Key to Fig. 5.5

1 Filling level too low

2 Filling level correct

It is normal for the filling level of the brine to fall a little

in the first month after the start-up of the system. The

filling level can also vary depending on the temperature

of the heat source. However it should never sink so far

that it is no longer visible in the expansion tank.

a

a

Caution!

Risk of damage due to brine escaping

from leaks in the system.

De-energise the heat pump if the brine

circuit is leaking (fuse off).

Have the leaks repaired by an expert

technician.

Caution!

Risk of damage.

The brine circuit must be filled with

the correct quantity of fluid; otherwise

the system can be damaged. Check the

filling level of the brine circuit at regular

intervals and inform your expert technician company if the filling level in the

brine expansion tank is too low. The

filling of the brine circuit in your heat

pump installation may only be undertaken by authorised specialists.

5.11 Cleaning and care

Do not use any scouring or cleaning agents that could

damage the cladding.

Note

Clean the exterior of your heat pump

h

with a damp cloth and a little soap.

Operating Manual geoTHERM VWS/VWW 0020051578_0124

Page 27

Operation 5

5.12 Troubleshooting and diagnosis

5.12.1 Error messages on the controller

Error messages appear roughly 20 seconds after the

error has occurred in the display and are written in the

error memory of the controller if the error persists for

roughly 3 minutes. The engineer can then call up the

error message from the memory at a later date.

Error History

Fault number >1

Fault code 41

16.02.08 07:18

Error CH circuit

Sensor T3 heat source

Fig. 5.7 Error message in the error memory Menu I1

The geoTHERM control system has various malfunction

types:

– Malfunction of components which are connected via

eBUS.

– Temporary shutdown

The heat pump remains in operation. The error is displayed and disappears independently when the cause

of the fault is removed.

– Fault-induced shutdown

The heat pump is shut down. It can only be restarted

after the cause of the fault has been removed by the

expert technician and the error reset.

– Moreover, other errors/malfunctions can occur on

the unit or system.

I1

5.12.2 Activating emergency mode

Depending on the type of malfunction the expert technician can set the heat pump to continue operation in

emergency mode (via an integrated electric auxiliary

heating) until the cause of the error is remedied, and either for heating operation (display "heating priority"),

for hot water operation (display "hot water priority") or

for both (display "heating priority/hot water priority"),

see the following tables, column "emergency operation".

5.12.3 Errors/malfunctions that you can remedy

Malfunction sign Possible cause Solution

Noise in the heating

circuit.

Table 5.4 Other malfunctions

5.12.4 Warning messages

The following warning messages do not cause a malfunction in the operation of the heat pump. The heat

pump is not shut down.

Take note of the error code and text and discuss this

during the next inspection with the expert technician.

Fault code Error text/description

26 Overheating on compressor pressure side

36 Low brine pressure

Table 5.5 Warning messages, no shutdown

Dirt in the heating

circuit.

Faulty pump.

Air in the heating

circuit.

Bleeding heating

circuit.

a

h

Caution!

Heat pump malfunction!

Immediately notify your expert technician if error messages appear on the display on the operating panel which are

not listed in tables 5.4 to 5.7.

Do not attempt to remove the source of

the malfunction yourself.

Note!

Not all of the following listed malfunctions have to be dealt with by an expert

technician.

If you are unsure whether you can remedy the fault yourself or not or if the

error occurs repeatedly contact your

expert technician or Vaillant customer

service.

GB

25Operating Manual geoTHERM VWS/VWW 0020051578_01

Page 28

5 Operation

5.12.5 Temporary malfunctions

The heat pump is shut down temporarily and starts

up again independently when the cause of the fault is

removed.

Depending on the error the heat pump switches back on

automatically after 5 or 60 minutes.

Take note of the error code and text and discuss this

during the next inspection with the expert technician.

Fault code Error text/description

20 Frost protection heat source monitoring source

21

(only VWW)

22

(only VWS)

23

(only VWW)

27 Coolant pressure too high

28 Coolant pressure too low

29 Coolant pressure outside the range

outlet

Temperature difference of the heat source > set

value "permitted temp. difference"

This error message is deactivated as standard and

can only be activated via vrDIALOG parameter

"permitted temp. difference" (20 K difference

means deactivated).

Frost protection heat source over. source outlet

Source outlet temperature too low (<4 ºC)

Frost protection heat source over. source outlet

Source outlet temperature too low

(<parameter freezing protection in menu A4)

No ground water flow

Integrated flow switch does not detect any volume

flow

The integrated high pressure switch tripped at

30 bar (g).

The heat pump cannot be restarted until after

60 min. at the earliest.

The integrated low pressure switch tripped at

1.25 bar (g).

If the error occurs twice in a row the heat pump

cannot be started until after 60 min. at the earliest.

5.12.6 Blocking error

Errors could occur which result in the shutdown of the

heat pump.

Fault code Error text/description

32 Error heat source sensor T8

Short-circuit in the sensor

33 Error heat circuit pressure sensor

short-circuit in the pressure sensor

34 Error brine pressure sensor

short-circuit in the pressure sensor

40 Error comp outlet sensor T1

Short-circuit in the sensor

41 Error heat source sensor T3

Short-circuit in the sensor

42 Error HP return sensor T5

Short-circuit in the sensor

43 Error HP flow sensor T6

Short-circuit in the sensor

44 Error external sensor AF

Short-circuit in the sensor

45 Error DHW tank sensor SP

Short-circuit in the sensor

46 Error HB flow sensor VF1

Short-circuit in the sensor

47 Error HB return sensor RF1

Short-circuit in the sensor

48 Error flow sensor VF2

Short-circuit in the sensor

Emergency

mode

possible

possible

possible

possible

possible

possible

possible

possible

possible

possible

WW operation

possible

Table 5.6 Temporary malfunctions

52 Sensors are not suited to the hydrau-

60 Frost protection heat source moni-

61

only VWW

62

only VWS

Table 5.7 Error shutdown

lic plan

toring source outlet

Error 20 has occurred three times

in a row

Frost protection heat source monitoring source outlet

Error 21 has occurred three times in

a row

Frost protection heat source monitoring source outlet

Error 22 has occurred three times in

a row

Operating Manual geoTHERM VWS/VWW 0020051578_0126

_

possible

possible

possible

Page 29

Operation 5

Warranty and customer service 6

Fault

code

63

only

VWW

72 Flow temperature too high for under-

81 Coolant pressure too high

83 Coolant pressure too low. Check heat

84 Coolant pressure outside the range

90 Heating system pressure too low

Table 5.7 Fault-induced shutdown (contd.)

Error text/description

No ground water flow

Error 23 has occurred three times in a

row

floor heating

Flow temperature is for 15 min. higher

than a set value (max. HK temp. +

compr. hysteresis + 2 K).

Error 27 has occurred three times in a

row

source

Error 28 has occurred three times in a

row

Error 29 has occurred three times in a

row

Pressure <0.5 bar

Heat pump shuts down and goes into

operation automatically when the pressure rises above 0.7 bar

Emergency

mode

possible

_

possible

possible

possible

_

date the warranty (this does not affect the customer’s

statutory rights).

6.3 Vaillant Service

To ensure regular servicing, it is strongly recommended

that arrangements are made for a Maintenance

Agreement. Please contact Vaillant Service Solutions

(0870 6060 777) for further details.

• Consult your expert technician about doing this.

Note!

Only an expert technician can remedy

h

the fault and reset the error code.

Once the expert technician has remedied the error and

reset the error he can restart the heat pump.

6 Warranty and customer service

6.1 Vaillant warranty

Vaillant provide a full parts and labour warranty for this

appliance.

The appliance must be installed by a suitably competent

person in accordance with the Gas Safety

(Installation and Use) Regulations 1998, and the manufacturer’s instructions. In the UK ‘CORGI’ registered installers undertake the work in compliance with safe and

satisfactory standards.

All unvented domestic hot water cylinders must be installed by a competent person to the prevailing building

regulations at the time of installation (G3).

Terms and conditions apply to the warranty, details of

which can be found on the warranty registration card included with this appliance.

Failure to install and commission this appliance in compliance with the manufacturer’s instructions may invali-

GB

27Operating Manual geoTHERM VWS/VWW 0020051578_01

Page 30

7 Appendix

7 Appendix

7.1 Technical Data VWS

Description Unit VWS 220/2 VWS 300/2 VWS 380/2 VWS 460/2

Article number - 0010002797 0010002798 0010002799 0010002800

Height without connections

Width

Depth without pillars

Depth with pillars

Weight

- with packaging

- without packaging

- ready for operation

Rated voltage

- Compressor

- Brine pump

- Heating circuit pump

- Control circuit

- External auxiliary heating

Fuse, slow-blow A 20 25 32 40

Start-up current

- without start-up current limiter

- with start-up current limiter

Electrical power consumption/rated output

- min. for B-5W35

- max. for B20W60

- phase angle, cos phi

- external auxiliary heating

EN 60529 level of protection - IP 20

Hydraulic connections

- Heating circuit flow and return

- Heat source flow and return

Heat source circuit (brine circuit)

- Brine type

- max. operating pressure

- min. inlet temperature

- max. inlet temperature

- Nominal flow rate dT 3 K

- Residual head dT 3 K

- Nominal flow rate dT 4 K

- Residual head dT 4 K

- Electrical power consumption - pump

CH circuit

- max. operating pressure

- min. flow temperature

- max. flow temperature

- Nominal flow rate dT 5 K

- Pressure loss dT 5 K

- Nominal flow rate dT 10 K

- Pressure loss dT 10 K

- Electrical power consumption - pump

refrigerant circuit

- Coolant type

- Quantity kg 4.1 5.99 6.7 8.6

- Permissible operating overpressure

- Compressor type

- Oil

- Oil filling capacity

Table 7.1 Technical Data VWS

mm

mm

mm

mm

kg

kg

kg

-

A

A

kW

kW

kW

mm

mm

MPa (bar)

°C

°C

l/h

mbar

l/h

mbar

W

MPa (bar)

°C

°C

l/h

mbar

l/h

mbar

W

- R 407 C

MPa (bar)

-

l

356

326

341

1/N/PE 230 V 50 Hz 3/N/PE 400 V 50 Hz

99

44

4.9

10.0

0.7-0.84

4858

324

3644

468

390

3726

72

1902

23

4 4 4.14 4.14

370

340

359

1/N/PE 230 V 50 Hz (max. 1 x 2 A)

3/N/PE 400 V 50 Hz (max. 3 x 13 A)

127

65

6.6

12.0

0.72-0.83

6660

275

4995

439

390

5160

87

2580

25

1200

760

900

1100

394

364

386

3/N/PE 400 V 50 Hz

1/N/PE 230 V 50 Hz

167

85

8.5

16.0

0.76-0.86

3 x 3 (3 x 13 A)

G 1 1/2"

G 1 1/2"

Ethylene glycol 30 %

0.3 (3)

-10

20

8640

431

6480

655

585

0.3 (3)

25

62

6600

132

3336

40

2.9 (29)

Scroll

Ester

417

387

414

198

110

10.2

18.0

0.75-0.86

9840

379

7380

626

585

7680

173

3900

53

Operating Manual geoTHERM VWS/VWW 0020051578_0128

Page 31

Appendix 7

Description Unit VWS 220/2 VWS 300/2 VWS 380/2 VWS 460/2

Heat pump performance data

B0W35 dT5

- Heating output

- Power consumption

- Performance figure/COP

B0W35 dT10

- Heating output

- Power consumption

- Performance figure/COP

Performance data, heat pump (contd.)

B5W55

- Heating output

- Power consumption