Page 1

GA100CS Series

Combination Gas

Fired Cast Iron

Boiler and Indirect

Water Heater

Vaillant ......

Installation and

Service Manual

Table of Contents

Page

Number

2

1. Boiler Dimensions

& Specifications

2. Rules for Safe Installation 3

& Operation

3. Locating the Unit 3

4. Combustion Air Requirements 3

5. Vent Pipe Connections 4

6. System Piping Boiler 5

7. Gas Supply Piping 5

8. Electrical Wiring 7

9. Flame Roll-Out 7

10. Blocked Vent System 9

11, Checkout Procedures 9

12. Maintenance Requirements 10

®

PRICE $5.00

Vaillant

Vaillant Corp.

2607 River Road

Cinnaminson, NJ 08077

(609) 786-2000

Fax (609) 786-8465

All of our appliances should be installed

by qualified fitters only, who will be

responsible for the observance of all

existing national and/or local installation

inStructionsand code regulations.

On installation please hand this pamphlet

to your customer.

o)

T--

"T

o

z

Page 2

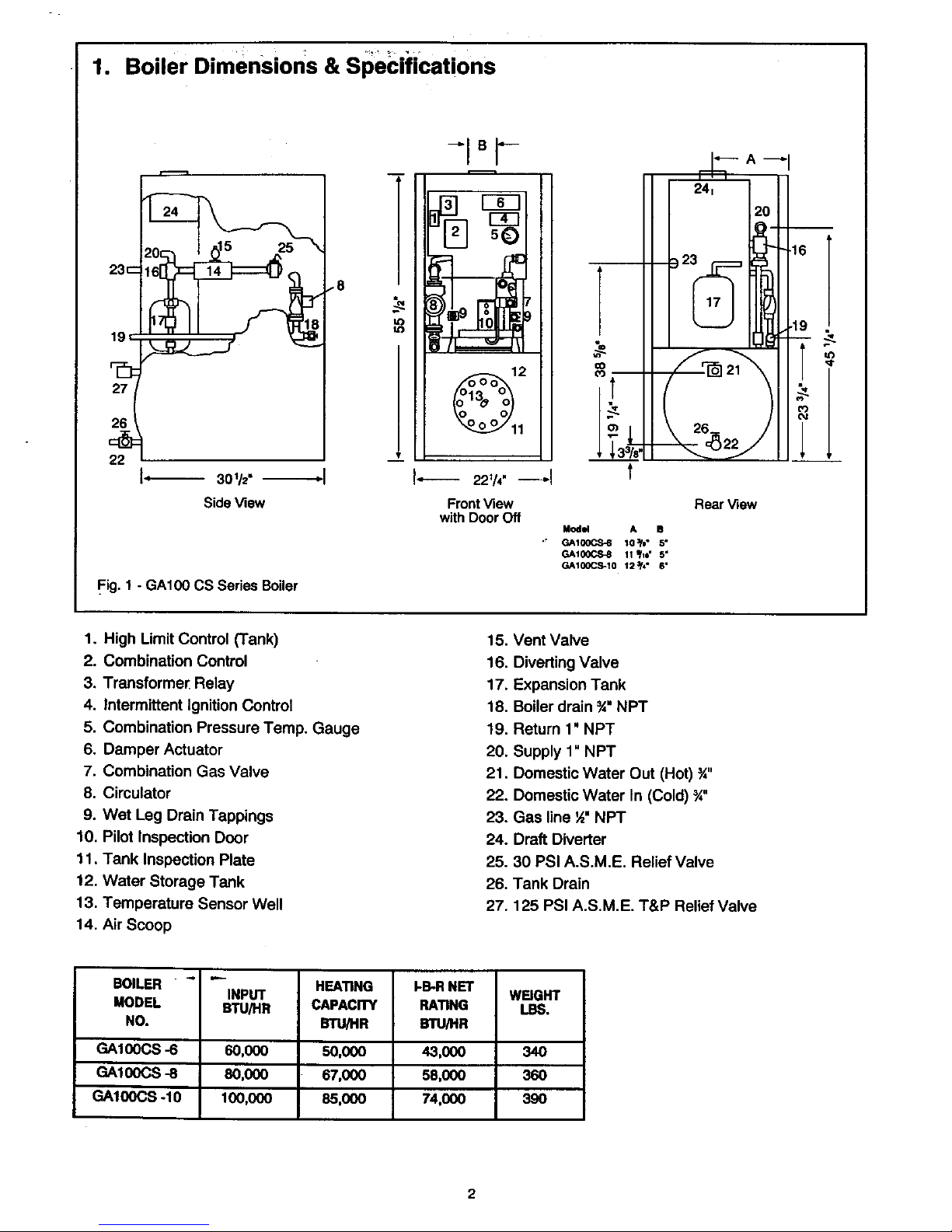

1. Boiler Dimensions & Specifications

I*-- 3o'/,"--÷1

SideView

Fig. 1 - GA100 CS Series Boiler

,-8

-IBI--

.=

t"------" 221/4" --'-*1

FrontView

with Door Off

[__._]A ---*

i°

16

t

RearView

ModM A B

" GAt00CS-6 10_/1" 5"

GAI00CS_ 11_11" 5"

GAI00CS-10 12_4" 6'

]

1. High Limit Control (Tank)

2. Combination Control

3. Transformer Relay

4. Intermittent Ignition Control

5. Combination Pressure Temp. Gauge

6. Damper Actuator

7. Combination Gas Valve

8. Circulator

9. Wet Leg Drain Tappings

10. Pilot Inspection Door

11. Tank Inspection Plate

12. Water Storage Tank

13. Temperature Sensor Well

14. Air Scoop

15. Vent Valve

16. DivertingValve

17. Expansion Tank

18. Boiler drain _' NPT

19. Return 1" NPT

20. Supply 1" NPT

21. Domestic Water Out (Hot) ¾"

22. Domestic Water In (Cold) ¾"

23. Gas line ½" NPT

24. Draft Diverter

25. 30 PSI A.S.M.E. Relief Valve

26. Tank Drain

27.125 PSI A.S.M.E. T&P Relief Valve

BOILER " " "- HEATING I-B-R NET

INPUT WBGHT

MODEL BTU/HR CAPACITY RATING I.BS.

NO. BTU/HR B'I'U/HR

GA100CS -6 60,000 ,50,000 43,000 340

GA100CS -8 80,000 67,000 58,000 360

GA100CS -10 100,000 85,000 74,000 390

Page 3

2. Rules for Safe

Installation &

Operation

1. Read this manual and the

Owner's Manual carefully.

Failure to follow the rules for

safe operation and the instruc-

tions could cause a malfunction

of the boiler and result in death,

serious injury, and/or property

damage.

2. Check your local codes and

utility requirements before

installation. The installation

must be in accordance with

their directives.

3. Before servicing, allow boiler to

cool and always shut off any

electricity and gas to boiler

when working on it. This will

prevent any electrical shocks or

burns.

4. Never test for leaks with open

flame. Use soap suds to check

all connections. This will avoid

any possibilityof fire or explo-

sion.

5. Be certain boiler isequipped for

type of gas (natural or propane)

to be used. Over-firing will result

in premature failure of the boiler

sections and cause dangerous

operation.

6. Never vent this boiler into an

enclosed space. Always con-

nect the boiler to the outside.

Never vent to another room or

inside a building.

7. Be sure there is adequate air

supply for complete combus-

tion.

8. Follow a regular service and

maintenance schedule for effi-

cient and safe operation.

WHEN YOUR BOILER ARRIVES

BE SURE TO SAVE AND REFER

TO INSTRUCTION .S_"-

First, inspect each item received for

visible damage or shortage. If any

parts are damaged, report this to

the freight company immediately,

and request them to cell and make

an inspection before you make any

installation. Have the Inspector

prepare a signed report. Send

Vaillant a copy of this report and we

will send replacements for the

damaged parts. But, we must have

the signed inspection report ofthe

freight company to prove their

liability.

Examine all packaging material

carefully for loose parts before

discarding.

Also, store all parts received where

they will not be lost or damaged.

If you have had to unpack the boiler

outside, you may also have to dis-

assemble itto carry itto the installa-

tion area. In this case, use the Parts

List drawings hereinto guide you.

NOTE: The GA1 O0CS Series of

boilers were evaluated by the

American Gas Association to certify

that they meet all of the safety crite-

ria of ANSI standard 7_21.13a-Latest

Edition "Gas Fired Low Pressure

Steam and Hot Water Boilers." Safe

lightingand other performance crite-

ria were met with the gas manifold

and control assembly provided on

the boiler when the boiler underwent

tests specified in this standard.

The following steps are all neces-

sary for proper installation and safe

operation of the boiler.

1. Locating the boiler.

2. Fresh air for combustion.

3. Chimney & vent pipe connection.

4. System piping.

5. Gas supply piping.

6. Electrical wiring.

7. Check out and adjust.

8. Maintenance.

3, Locating the Unit

If unit is to be part of an existing

system, it is usually best to put it

where the old one was. If you plan

to change location, you will need

additional material as well as an

adequate base. The following rules

apply not only to replacement boil-

ers, they also applyto new installa-

tions:

1. The unit must be level.

2. Use a raised base if floor can

become wet or damp.

3. The vent pipe connection should

be short. The center ofthe chim-

ney opening must be high

enough to allow a '/,"per ft.

upward slope in vent from unit

to chimney opening

4. Maintain clearances for fire safety

as well as servicing.

The room must have a total cubic

foot volume notless than 16

times that of the boiler.

5. Fresh air for combustionmust be

available at the front ofthe boiler.

6. While this boiler may be installed

on combustibleflooring, it must

not be installed on carpeting.

7. The installation mustconform to

the requirements of the authority

having jurisdictionor, in the

absence of such requirements, to

the national Fuel Gas Code.

ANSI Z223.1-Latest Edition.

8. Where required by the authority

having jurisdiction,the installation

must conform to American

Society of Mechanical Engineers

Safety Code for Controls and

Safety Devices for Automatically

Fired Boilers,No. CSD-I.

Clearance from Combustible

Materials

The following minimumclearances

are required between boiler and

combustible construction:

Top ............................... 12 inches

Right Side....................... 6 inches

Left Side ......................... 6 inches

Rear................................ 6 inches

Flue Connector ............... 6 inches

Hot Water Pipe ................... 1 inch

Flue and stackmust be at least 6"

from combustible surfaces.

If hotwater pipe passes through

combustible floors,walls, or ceil-

ings, clearance must be not less

than ½"capped with a non-com-

bustible plate (see NFPA bulletin

89M, heating equipment clearance).

Servicing requirements may require

larger clearances than those

required forfire safety.

As the electrical and piping connec-

tions are at the rear of the unit,

there should be space to permit

access to the rear of the unit for ser-

vice.

Page 4

4. Combustion Air

Requirements

WARNING

Be Sure to Provide Enough Fresh

Air for Combustion

You must providefor enough fresh

air to assure proper combustion.

The fire in the unit uses oxygen.

The air in a house contains only

enough oxygen to supply the bumer

for a short time. Outside air must

enter the house to replace that used

bythe burner. Study the following

examples to determine your fresh

air requirements.

EXAMPLE 1: UNIT LOCATION IN

UNCONFINED SPACE

Ifyour unit is in an open area in a

conventional house, the air that

leaks through the cracks around the

door and windows will usually be

adequate to provide air for combus-

tion. The doors should notfit tightly.

Do not caulk the cracks around the

windows.

EXAMPLE 2: UNIT LOCATED IN A

HOUSE HAVING TIGHT CON-

STRUCTION

If the house is of tight construction

with weathemtripped windows, not

enough outside air will enter for safe

combustion. Installa duct orpipe

from a point near the burner to a

ventilated attic or crawl space orthe

outside where fresh air is freely

available. Vertical ducts should

have a net free area of 1 square

inchfor each 4,000 BTU per hour

input of all gas appliances and for

each 2,000 BTUihr. if horizontal

ducts are used. Screen the open-

ings to keep animals and birdsfrom

entering. This is also required ifthe

boiler is installed near an exhaust

fan orclothes dryer.

Provisions for combustion and venti-

lation air in accordance with section

5.3, Air for CombustTon'_nd

Ventilation, of the National Fuel Gas

Cede, ANSI Z223.1-Latest Edition,

or applicable provisions of the local

building codes.

5. Vent Pipe

Connections

Check Your Chlmney

This is a very important part of your

heating system. It must be clean,

the dght size, propedy con_ed

and in good condition. No boiler can

function properly with a bad chim-

ney. If your chimney isjust big

enough for your new boiler, it will

not have extra capacity forother

gas appliances.

When two or more appliances are

vented into the same chimney, the

cress-section area inside the chim-

ney must be at least equal to the

area ofthe largest vent PLUS ½the

area of each additional vent.

For example, if your boiler vent has

a diameter of 5 inches (area 19.6

square inches), the water heater

vent, a diameter of 4 inches (12.6

square inches), the minimum chim-

ney area must be 19.6+ ½ of 12.6 or

25.9 square inches. They will

require a 6" diameter round chim-

ney.

When removing a boiler from a

common venting system the venting

system is likely to be too large:for

proper venting of the remaining

appliances connected to it.

At the time of removal of an existing

boiler, the following steps shall be

followed with each appliance

remaining connected to the com-

mon venting system placed in oper-

ation, while the other appliances

remaining connected to the com-

mon venting system are not in oper-

ation.

(a) Seal any unused openings in

the common venting system.

(b) Visually inspect the venting

system for proper size and hori-

zontal pitch and determine there

isno blockage or restriction, leak-

age, corrosion and other deficien-

cies which could cause an unsafe

condition.

(c) Insofar as is practical, close

all buildingdoors and windows

and all doors between the space

in which the appliances remaining

connected to the common venting

system are located and other

spaces of the building. Turn on

clothes dryer and any appliance

not connected to the common

venting system. Turn on any

exhaust fans, such as range

hoods and bathroom exhausts,

4

so they will operate at maximum

speed. Do not operate a summer

exhaust fan.

(d) Place in operationthe appli-

ance being inspected. Followthe

lighting instructions.Adjust ther-

mostat so appliance will operate

continuously.

(e) Test for spillage at the draft

hoed relief opening after 5 min-

utes of main burner operation.

Use the flame of a match or can-

dle, or smoke from a cigarette,

cigar or pipe.

(f) After it has been determined

that each appliance remaining

connected to the common vent-

ing system propedy vents when

tested as outlined above, return

doors, windows, exhaust fans,

fireplace dampers and any other

gas burning appliance to their

previous conditionsof use.

(g) Any improperoperation of the

common venting system should

be corrected so the installation

conforms with the National Fuel

Gas Code, ANSI Z223.1-Latest

Edition. When resizing any por-

tion of the common venting sys-

tem, the common venting system

should be resized to approach

the minimum size as determined

using the appropriate tables in

Appendix G in the National Fuel

Gas Code, ANSI Z223.1-Latest

Edition

Connect the Vent Pipe

WARNING

NEVERINSTALLA MANUALLY

OPERATED DAMPER IN THE

VENT PIPE OFANY GAS APPLI-

ANCE.

1. Do not modify draft diverter fur-

nished with the boiler.

2. Vent pipe must be same size as

outlet collar on draft diverter.

3. Slope pipe up from b_ler'to chim-

ney not less than ¼"per foot.

4. Run pipe as directly as possible

with as few elbows as possible.

5. Do notconnect to fireplace flue.

6. The sections ofvent pipeshould

be fastened with sheet metal screws

to make the piping rigid. Use

stovepipe wires to support the pipe

from above.

Page 5

MinimumVentPipeClearance

fftheventpipemustgothrougha

crawlspace,doublewallventpipe

shouldbeused.Whereventpipe

passesthroughacombustiblewail

orpartition,Useaventilatedmetal

thimble.Thethimble should be 4

inches larger in diameter than the

vent pipe. If boiler is installed with a

single wall galvanized type vent, it

must have 6" clearance between its

surface and any combustible materi-

al. If Underwriters Laboratories list-

ed type B (insulated vent pipe) is

used, clearance between it and

combustible material to be as listed.

In lieu of thimble protection, all com-

bustible material in the wall shall be

cut away from the vent pipe a suffi-

cient distance to provide the clear-

ance required from vent pipe to

combustible material. Any material

used to close up such opening shall

be non-combustible.

For boilers for connection to gas

vents or chimneys, vent installations

shall be in accordance with Part 7,

Venting of Equipment, of the

National Fuel Gas Cede, ANSI

Z223.1--Latest Edition, or applica-

ble provisions of the local building

codes.

Automatic Vent Damper

The GA100 Series of boilers are fit-

ted with an integral vent damper

which is operated by an actuator

mounted on the front panel (See

Fig. 1).

The stack damper should be

checked for alignment and freedom

of operation priorto installation and

during subsequent routine service.

6. System Piping

Boiler

Place the boiler in a selected loca-

tion (as near chimne_yyas possible).

Your boiler is shipped assembled.

You need onlyto install a ¾"relief

valve drain line. Run a pipe from the

relief valve outlet to an open drain,

tub or sink, or other suitable

drainage point not subject to freez-

ing. Failure to do so may cause

water damage or injuryshould the

relief valve open. Pipe must be

_'ame size as outlet and open end

must not be threaded.

Connect supply and returnlines to

boiler. The connections may require

certain additional fittings and parts

as shown on Fig. 2.

If you are replacing an old boiler

with this new one, possiblyallyou

will need to do is to connect the

existing pipingto your boiler.

Ifyou are installing an entire new

heating system, firstinstall all of

your radiation units (panels, radia-

tors, or cabinets) and the supply

and return mains--then make the

connection to the boiler.

When connecting the cold water

supply tothe water valve, make

sure that a clean water supplyis

available. When the water supplyis

from a well or a pump, a sand

strainer should be installed at the

pump.

When boiler is used in connection

with refrigeration systems, it shall be

installed so that the chilled water is

piped in parallel with the heating

boiler with appropriate valves to pre-

vent the chilledwater from entering

the heating system boiler.

The boiler piping system of a hot

water heating boiler connected to

heating coils located inair handling

unitswhere they may be exposed to

refrigerated air circulation must be

equipped with flow controlvalves or

other automatic means to prevent

gravity circulation of the boiler water

during the cooling cycle.

NOTE: A hotwater boiler installed

above radiation level must be pro-

vided with a low water cutoff device

at the time of boiler Installation.

It is recommended that the boiler be

installed with gate valves on the

supply and return lines so that it

may be removed for service without

draining the entire system. The gate

valve on the supply pipe must not

be located between the boiler and

the relief valve or expansion tank.

Water Heater

The relief valve and drain valve for

the flow and for the hot water tank

(Fig. 2) are packed in separate

boxes and mount directly to the flow

and return.

If the selected temperature at the

temperature control (Fig. 1, No. 1) is

in excess of 125°F a mixing valve

should be installed to minimize the

danger of scalding.

7. Gas Supply Piping

INSTALL GAS PIPING AS OUT-

LINED IN THE AMERICAN

NA't'IONAL STANDARD ANSI

Z223.1-1984-- NATIONAL GAS

FUEL CODE FOR U.S.A. INSTAL-

LATIONS

The gas pipe to your boiler should

run direct from the gas meter (or

propane regulator). It should supply

only the boiler. It must be the cor-

rect size for the length of the run

and the boiler rating. See Fig. 3 for

the proper size. Be sure your gas

line complies withlocal codes and

the gas company requirements.

Connecting the Gas Piping

Refer to Fig. 1 for the general layout

at the boiler. It shows the basic fit-

tings you will need. The gas line

enters the boilerfrom the back. The

following rules apply:

1. Use new, properlycleaned

black iron piping and fittings,

free from chips.

2. Apply good quality pipe dope to

pipe only, leaving 2 end threads

bare.

3. Install a sediment trap to trap

dirt and moisture before it can

enter the boiler.

4. Install a manual shut-off valve in

vertical pipe about 5 feet above,

floor (not supplied by Vaillant).

5. Tighten all joints securely.

6. Propane gas connections

should only be made by a

licensed propane installer.

7. The boiler and its individual

shut-off valve must be discon-

nected from the gas supply pip-

ing system during any.pressure

testing of that system at test

pressures in excess of ½psig.

8. The boiler must be isolated from

the gas supplypiping system by

closing its individual manual

shutoff valve during any pres-

sure testing of the gas supply

piping system at test pressure

equal to or tess than ½psig

(3.5KPa).

Page 6

ZONE VALVE

IIIIIII1

HEATING cl_curr GATE

DRAIN VALVES

CIRCUITS VALVES

* ZONE VALVE

© __

III1[1111

t

vE_, _

VALVE

EXPANSION

TANK

AIR SCOOP

ASME PRESS.

_-_ REUEF VALVE

I

BOILER

t

t

'._ to.,_._.

TO FAUCETS

&SHOWERS

ASMET&P

REUEFVALVE

DOMESTIC "-_

COLD WATER . - ..-

vALVE

DR/UN

VALVE

t

STORAGE TANK

* NOTE:- Zone valves

should be located in

the supply side of the

heating circuit as close

as is possible to the

three way valve. This

will minimize the chance

of waterhammePoocuring.

CAUTION: When storage tank is above 125°F a mixing valve should be installed

to minimize the chance ofscalding.

F,ig. 2 - Typical Piping Arrangements

Page 7

Checking the Gas Piping

Upon completion of piping, chock

right away for gas leaks. Open the

manual shut-off valve. Test for leaks

by applying soap suds (or a liquid

detergent) to each joint. Bubbles

foaming indicate a leak.

CORRECT EVEN THE SMALLEST

LEAK AT ONCE.

WARNING

NEVER USE A MATCH OR OPEN

FLAME TO CHECK FOR LEAKS.

LENGTH

OF PiPE

-FT.

NATURAL GAS

PiPE CAPACITY

CUBIC FEET/HOUR

_" ¾" 1" 1_"

20 74 150 280 580

40 50 100 195 400

60 40 84 155 320

80 34 72 135 275

Fig. 3 - Gas Pipe Capacities

MODEL GA100 CS -60 -80 -100

Elevation

Sea level to 2,000 ft. 38 42 38

2,000 to 5,000 ft. 40 43 41

5,000 to 7,000 ft. 41 44 42

7,000 to 9,000 ft. 42 46 43

9,000 to 10,000 ft. 43 47 44

Fig. 4 - Orifice Size for Natural Gas

MODEL GA100 CS -60 -80 -100

Elevation

Sea level to 2,000 ft. 52 53 52

2,000 to 5,000 ft. 53 55 53

5,000 to 7,000 ft. 53 55 53

7,000 to 9,000 ft. 55 56 54

9,000 to 10,000 ft. 55 56 54

Fig. 5 - Orifice Sizefor Propane (LPG)

Orifice Sizing

All Vaillant GA100 CS series units

are factory equipped with orifices

sized for installation at elevations

ranging from sea level up to 2,000

feet. For higher elevations, smaller

orifices are required to assure safe

operation. Order the proper orifices

e

from your supplier and install them

before turning boiler on. See Figs. 4

&5.

8. Electrical Wiring

Install Your Thermostat.

The thermostat location has an

important effect on the operation of

your boiler system. BE SURE TO

FOLLOW THE INSTRUCTIONS

INCLUDED WITH YOUR THERMO-

STAT.

Locate the thermostat about five

feet above the floor on an inside

wall. It may be mounted vertically on

the wall or on a vertically mounted

outlet box. It should sense average

room temperature, so avoid the fol-

lowing:

Dead Spots:

1. Behind doors

2. Corners and alcoves

Hot Spots:

1. Concealed pipes

2. Fireplaces

3. TV sets

4. Radios

5. Lamps

6. Direct sunlight

7. Kitchens

Cold Spots:

1. Concealed piping or ducts

2. Stairwell drafts

3. Door drafts

4. Unheated rooms on other side

of wall

Control Wiring Diagrams

Field Wiring and Wire Replacement

in the following wiring diagrams

dashed lines .... represent fac-

tory wiring 24V; dashed lines

• • • represent field wiring 24V;

solid lines -- represent factory

wiring 120V; solid lines _ rep-

resent field wiring 120V.

Field wiring, whether for a new

installation or to replace damaged

field or factory installed widng, must

be the type listed below, and must

be installed in accordance with the

National Electric Code and all other

codes and standards covering the

boiler installation.

120-Volt Wiring

All new and replacement wiring

must be U.L. listedand 14-gauge

size (minimum). Installwire in

approved conduit. All terminals and

splices must be in a listed covered

box.

If an external electrical source is uti-

lized, the boiler, when installed,

must be electrically ground in accor-

dance with the requirements ofthe

authority having jurisdiction or, in

the absence of such requirements,

with the National Electrical Code,

ANSI/NFPA No. 70-Latest Edition.

24-Volt (Low Voltage) Wiring

Use listed low-voltage cable. All

junctions must be clean, joined firm-

ly, and suitably covered with electri-

cal tape or approved wire connec-

tors.

9. Flame Roll Out

The GA100 CS Series is equipped

with a Flame Roll-Out Safety Shut-

Off System. The system is designed

to shut offthe boiler if a blockage

occurs in the heat exchanger that

causes flames to roll-outthe bottom

of the burner tray. Temperature acti-

vated switch is located on a bracket

next to the pilot or ignitoron the

underside of the burner tray.

When corrective action has been

taken to eliminate the restriction

the pre-set switch has to be

replaced with a Vaillant supplied

replacement.

10. Blocked Vent

System

The GA100 CS Series is equipped

with a =BlockedVent Shut-Off

System'. This system relies on a

temperature sensitive-6witch located

on the side ofthe draft hood. Ifthe

vent pipe or chimney should

become obstructed to the point of

not completely evacuating the flue

gases, the switch will break and

close down the unit.

When the vent or chimney restric-

tion has been removed, the switch

can be reset.

Page 8

I

I" I I

I !

i I

.......... °

fill

OUT I

llll

I I i LREO=_ I I I I

I L_ WHITE I I II

I GREEN I

GOLD

L8148E

©

®

BLUE

BLUE

$8_0

i_ 24v TH

MV PV PV GiNID GND 24V -W

!

!

I

I

I

L .... _

BLUE

WHITE

_E

IMPORTANT:

F,_Wy W_V_ -_V

S_d Lira Rm_er_ Fmo,y W_) -_20V

AAAAAAAA'*AAAAA ;'_'* *. FieklW_ng -120V

eI.ACK

WHITE

I

I ....... .e.._m__K. __

! I

t_ -. __R___. i • i L°

I • IE

I • IT

t c B

I • _-I

II YELLO_ 1 •r-e--- -_ I "-f- •

! -- I I --

', , [ , ' [

C°l Y I I v

! I • J I •

[

,-I i I=""='"_ • _ i •

;"_L _'- _'" '_' ' •

-_l f %1 " •, ' •

I f ,,,-,'r,'_l I • I l •

, R_ I \ ..... 11 • , , •

...... ..,, ..T_/ •, ', •

"n4REEWAYL _St.ACK __, I •

• I I •

I-r.. I,,'.._ •; ', "-

I_,;_ I--- "b- e •

Ik._,i_d,,_ _, , •

I I..... -_- .... •

I I • •

#

DAMP IGN

glv-1

• Fig. 6 - 24 Volt Intermittent Pilot System - Field Wiring Diagram

8

Page 9

11. Checkout

Procedures

Test for Any Gas Leaks

Inspect carefully all gas connections

for gas leaks before lighting bumer.

Do not check for leaks with an

open flame.

Test for leaks with a soap solution

made of 2 tablespoons of flake,

granular, orliquid soap mixed well

with _ cup ofwarm water and

spread generously on connection in

question, using a brush or cloth.

For Your Safety Read

Before Operating

WARNING

IF YOU DO NOT FOLLOW

THESE INSTRUCTIONS EXACT-

LY, A FIRE OR EXPLOSION MAY

RESULT CAUSING PROPERTY

DAMAGE, PERSONAL INJURY

OR LOSS OF LIFE.

A. This appliance is equipped with

an ignition device which automati-

cally lightsthe burners. Do not try

to light the pilot by hand.

B. Before operating smell all around

the appliance area forgas. Be

sure to smell next to the floor

because some gas is heavier

than air and will settle on the

floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch;

do not use any phone inyour

building.

• Immediately call your gas sup-

plier from a neighbor's phone,

follow the gas supplier's instruc-

tions.

• If you cannot.r.ea_,byour gas

supplier, call the Fire

Department.

C. Use only your hand to push in or

turn the gas control knob, never

use tools. If the knob will not push

in or turn by hand, don't try to

repair it, call a qualified service

technician. Force or attempted

repair may result in a fire or

explosion.

Operating Instructions

1. STOP! READ THE SAFETY

INFORMATION.

2. Set room thermostat to lowest

temperature.

3. Turn off electric power.

4. Turn gas cock knob clockwise

and turnto OFF. Wait five min-

utes, then turn knob to latch

position at ON.

5. Turn on electric switch. Burner

should turn on when thermostat is

set above room temperature.

Reset Ignition System

1. Turn the thermostat to the low

end of itstemperature range.

2. Turn the electric switch to the

OFF position.

3. Wait 5 minutes, then turn the

system switch to ON position set

the thermostat at least 4°F

(2.2°C) above room temperature.

The boiler should start. Ifthe

above steps do not start the pilot

and main burner, call your gas

appliance service technician, do

not attempt to light manually.

To Turn Off Gas To Appliance

1. Set the thermostat to lowest

setting.

2. To shutoff burner manually, turn

gas cock knob clockwise F'_

and turn to OFF position.

3. Turn off electric switch.

Adjustment of Gas Input--Natural

Gas

To check for proper flow of gas into

combustion chamber, determine the

BTU/hr. input from the instruction

plate on the jacket. Divide this input

by the BTU per cubic foot of avail-

able gas to get the required number

of cubic feet of gas per hour.

ELECTRONIC IGNITION

II_'T "_ OUTLET

GROUND

TERM_kt_L

B

VR8440

ELECTRONIC IGNmON

_CO_I ROUND

TERMINAL

INLET _

L g-J_B

VR8204A

HOT SURFACE IGNmON

GAS..>.

INLET

GAS CONTROL KNOB

36E03

- SIEP

FEATURE

Determine flow of gas through the

gas meter for 2 minutes and multiply

by 30 to get the hourly flow rate.

Turn off all other gas equipment

connected to meter when making

this test.

Manifold pressure should be set to

about 4" W.C. for natural gas. Small

variations in gas flow may be made

by means of the gas pressure regu-

lator adjustment. However, the final

manifold pressure setting should not

vary more than plus oTmlhus 0.3"

from the 4" valve. Any necessary

major changes in the flowshould be

made by changing the size of the

burner orifice.

Page 10

Safety Check of Controls

After boiler has been hooked upand

is ready foroperation, a few simple

checks should be made to be sure

all controls are functioning properly.

1. Thermostat--Turn thermostat to

highest setting. This shouldturn

on the main burner. Adjust heat

anticipator to proper current draw.

2. Thermocouple--The pilot lights

the main burner on demand and

provides a safety feature through

either a singlecouple thermocou-

pie or multiple couple thermocou-

pie which is placed in the pilot

flame. These thermocouples gen-

erate a small amount of electricity

which permits the valve to open

only when the pilot is burning. To

check the thermocouple for safe

operation, ignite the main burner,

then disconnect the thermocouple

lead. The main burner should

shut off.

3. Limit--The limitturns off the

burner when the boiler water tem-

perature reaches the temperature

setting of the limit. To check this,

set the limitat a lowest setting

and let the burner run untilthe

limitturns it off. Raise tempera-

ture setting of limit.This should

turn on burner.

Relief Valve

You have a safety relief valve on

your boiler. It will automatically open

at 30 psig pressure. This will relieve

the strain on the boiler and system.

Run apipe from the relief valve out-

let (pipe must be same size as out-

let and open end must not be

threaded) to an open drain, tub or

sink, or other suitable drainage point

not subject to freezing. Failure to do

so may cause water ci_mage or

injuryshould Relief Valve release.

Main Burner

The main burner flame can be

observed through the inspection

door (Fig. 7). The flame should be

translucent and blue in color. The

presence of any yellow streaking

would indicatethe presence of dust

or lack of primary air. A vacuum

cleaning of the burner tray and com-

bustion area is indicated.

DOOR _

Fkj.7

Checks for Electronic Ignition

The probe lead connections to

sensing probe and controlterminal

must be secure. Electrodes should

have a spark gap of '/a".If the pilot

burner does notignite, check to see

that all connections are proper.

Observe presence of spark. If spark

is not present, determine if power is

available to the control. The ignition

controlshould be replaced if, with

power applied and spark gap prop-

erly set at _", sparking does not

occur. If pilotgas does not light

even though a spark is present, gas

is not available at the pilot burner or

the gas pressure istoo low or high.

If pilotignites, but burner does not,

check probe lead connections to the

sensing probe and control.Do not

attempt to field repair the control.

Replace defective controls.

12. Maintenance

Requirements

CLEANING MUST INCLUDE PERI-

ODIC EXAMINATION OF VENTING

SYSTEMS. ALL FLUE GAS PAS-

SAGEWAYS FROM BOILER TO

CHIMNEY AND THE CHIMNEY

ITSELF SHOULD BE INSPECTED

AND CLEANED IF NECESSARY.

THIS SHOULD BE PERFORMED

AT LEAST ONCE A YEAR, PRIOR

TO THE STARTING OF THE

HEATING SEASON.

1. Brush entire surface of all flues

using a long handled wire brush.

Remove all soot, rust and scale

found. Inspect with a flashlight to

see that all flueways are com-

pletely open. Remove soot and

dirt from bottom of boiler.

2. Inspect the flue cover, draft

diverter, and smokepipe and

replace unserviceable parts,

clean all soot, rust or scale from

these parts and from chimney.

Clean the burners; use a soap

solution if necessary.

CAUTION: If it becomes necessary

to remove the draft diverter, it must

be rasealed to the casting using

new sealant to be sure no fumes

can escape.

3. Reassemble all parts and start

the boiler following the installation

instructions. Carefully inspect fire

above each burner for a stable

and blue flame. Carbon monoxide

poisoning can be caused by yel-

lowish unstable (wavy) flame.

10

Page 11

;urnerCleaning

urnersshouldbeinspectedafter

achboilercleaning.Slots(ports)

anbebrushedfreeofdirtandlint

,itha stiffbristle brush. Do not

amage metal at ports. The pilot

nd thermocouple or pilot generator

should be brushed free of dirt. Take

care notto damage pilot, bend it out

of position, or to plug pilotgas port.

Maintained Inspection

The homeowner and service per-

sonnel must, at all times, be alerted

for these items:

1. Gas odor.

a) Open the windows.

b) Do not touch any electrical

switch.

c) Extinguish any open flame,

ifpossible.

d) Shut off the main gas valve.

e) Call the gas supplier.

2. Excessive heat, odors, smoke,

unusual noise. Shut off gas to

all appliances and call gas sup-

plier or Fire Department and

service organization.

3. Keep area around the boiler

clean and free from combustible

materials, gasoline and other

flammable vapors and liquids.

4. Make allowances and maintain

free flow of combustion and

ventilating air.

Freeze Protection

If the boiler is taken out of service

during potentially freezing weather,

always DRAIN IT COMPLETELY

since any water left inthe boiler or

pipes can freeze and cause dam-

age. Be sure to open drain cocks on

the wet legs of the left and right

castings, see Fig. 1.

Pilot and Burner

Check for proper pilotflame as

explained in "Checkout Procedures'

on page 9.

BurnerPorts

and Slots 4- 3/..

-..-,/.. ±'/."

PilotBracketMounted

on BurnerPanel

ForUse withNatural

& PropaneGas

Pilot and Burner Assembly - GA100 -60 Thru GA100 -100 E.I.

Fig. 9 - Electronic Ignition

11

Page 12

Vaillant

Vaillant Corp.

2605-07 River Road

Cinnaminson, NJ 08077

(609) 786-2000

m

Booklet No.:2180-0113

Loading...

Loading...