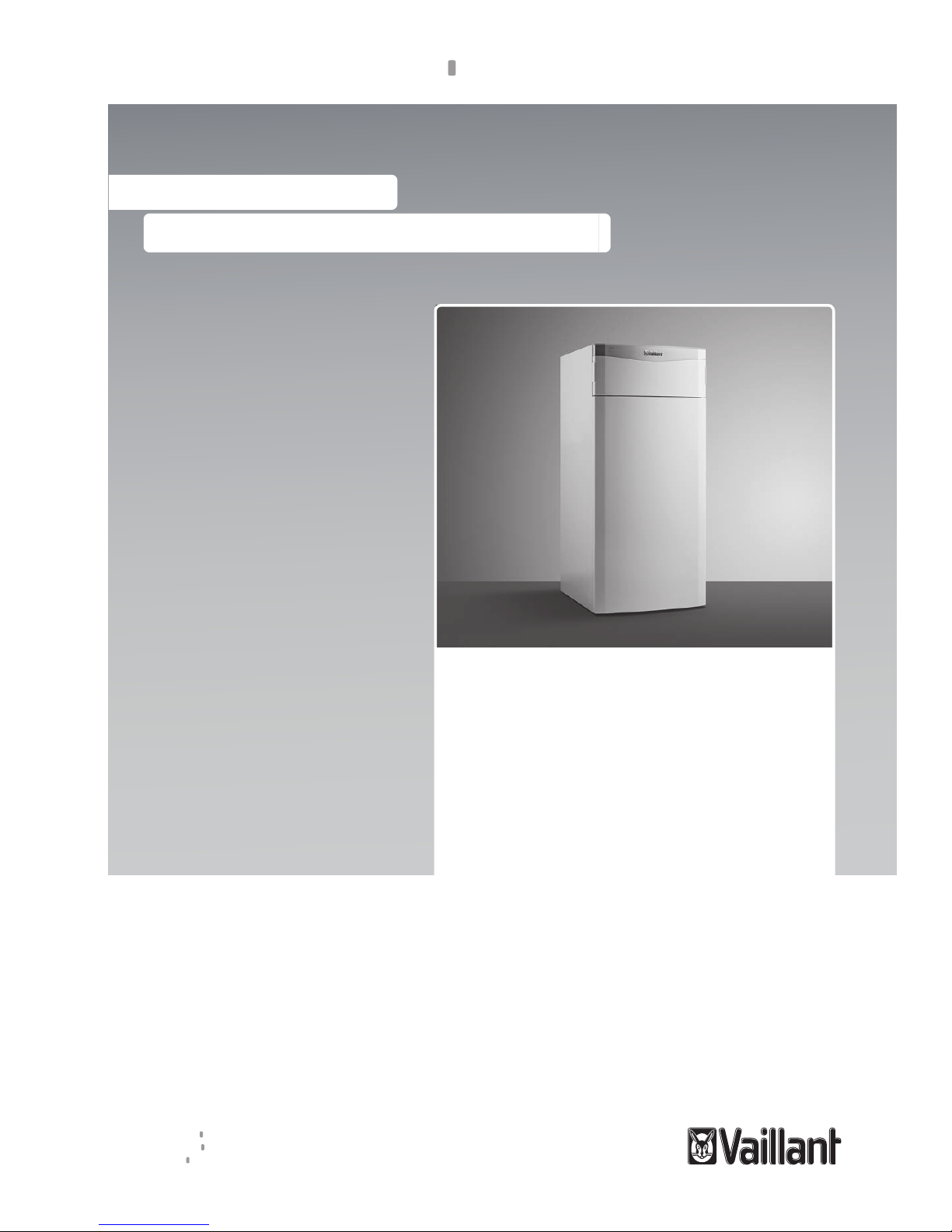

Vaillant flexoTHERM exclusive VWF 57/4, flexoTHERM exclusive VWF 87/4, flexoTHERM exclusive VWF 117/4 Installation And Maintenance Instructions Manual

Page 1

For the competent person

Installation and maintenance instructions

flexoTHERM exclusive

VWF 57/4 230 V

VWF 87/4 230 V

VWF 117/4 230 V

GB

Installation and maintenance instructions

Publisher/manufacturer

Vaillant GmbH

Berghauser Str. 40 D-42859 Remscheid

Tel. +49 21 91 18‑0 Fax +49 21 91 18‑28 10

info@vaillant.de www.vaillant.de

Page 2

Contents

2 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

Contents

1 Safety .................................................................... 4

1.1 Action-related warnings ......................................... 4

1.2 Intended use.......................................................... 4

1.3 General safety information .................................... 4

1.4 Regulations (directives, laws, standards) .............. 6

2 Notes on the documentation .............................. 7

2.1 Observing other applicable documents ................. 7

2.2 Storing documents................................................. 7

2.3 Applicability of the instructions .............................. 7

3 System overview.................................................. 7

3.1 Heat pump system design ..................................... 7

3.2 Functionality........................................................... 8

3.3 Safety devices ....................................................... 9

4 Product description........................................... 10

4.1 Product design..................................................... 10

4.2 Information on the identification plate.................. 10

4.3 Explanation of product stickers............................ 11

4.4 Type designation and serial number ................... 11

4.5 CE label ............................................................... 11

4.6 Benchmark........................................................... 11

5 Installation.......................................................... 12

5.1 Checking the scope of delivery............................ 12

5.2 Selecting the installation site ............................... 12

5.3 Dimensions.......................................................... 13

5.4 Minimum clearances............................................ 14

5.5 Transporting the heat pump ................................ 14

5.6 Installing the product............................................ 15

5.7 Removing carrying handles ................................. 15

5.8 Removing the front casing................................... 15

5.9 Removing the casing top and side casings ......... 16

5.10 Removing the refrigeration circuit cover .............. 16

6 Carrying out the hydraulics installation.......... 17

6.1 Requirements for the heating circuit.................... 17

6.2 Connecting the heat pump to the heating

circuit ................................................................... 17

6.3 Connecting the heat pump to the brine circuit ..... 17

6.4 Hydraulic wiring in the system ............................. 18

7 Filling and purging the system......................... 18

7.1 Filling and purging the heating circuit .................. 18

7.2 Filling and purging the brine circuit ...................... 19

8 Electrical installation......................................... 21

8.1 Routing eBUS lines.............................................. 21

8.2 Opening the electronics box ............................... 21

8.3 Switch box ........................................................... 22

8.4 Establishing the power supply ............................. 22

8.5 Mains connection PCB ........................................ 24

8.6 Controller PCB..................................................... 26

8.7 Connecting the system controller and

accessories to the electronics system ................. 28

8.8 Carrying out the wiring......................................... 28

8.9 Installing the VRC DCF........................................ 28

8.10 Installing optional accessories ............................. 28

8.11 Checking the electrical installation ...................... 28

8.12 Completing installation......................................... 28

9 Start-up ............................................................... 29

9.1 Operating concept ............................................... 29

9.2 Starting up the heat pump ................................... 29

9.3 Running the installation assistants ...................... 29

9.4 Calling up the installer level ................................. 30

9.5 Heating mode flow temperature regulation.......... 30

9.6 Calling up statistics .............................................. 30

9.7 Checking that the product works correctly........... 30

10 Adapting the unit to the heating

installation.......................................................... 30

10.1 Setting parameters .............................................. 30

10.2 Setting the high-efficiency pumps........................ 30

10.3 Setting the flow temperature in heating mode

(with no controller connected) ............................. 32

10.4 Setting the flow temperature in cooling mode

(with no controller connected) ............................. 32

10.5 Handing the product over to the operator ............ 32

11 Troubleshooting ................................................ 32

11.1 Displaying the Live Monitor (current product

status) .................................................................. 32

11.2 Checking fault codes ........................................... 33

11.3 Querying the fault memory .................................. 33

11.4 Resetting the fault memory.................................. 33

11.5 Restarting the installation assistant ..................... 33

11.6 Using check programmes .................................... 33

11.7 Carrying out the actuator test .............................. 33

11.8 Auxiliary electric heater circuit breaker ................ 33

12 Inspection and maintenance ............................ 33

12.1 Inspection and maintenance information............. 33

12.2 Procuring spare parts .......................................... 33

12.3 Inspection and maintenance check-list................ 34

12.4 Checking and correcting the filling pressure of

the heating installation......................................... 34

12.5 Checking and correcting the filling pressure in

the brine circuit .................................................... 34

12.6 Carrying out a restart and test operation ............. 34

13 Decommissioning.............................................. 34

13.1 Temporarily decommissioning the product.......... 34

13.2 Decommissioning the product ............................. 34

14 Recycling and disposal..................................... 34

14.1 Disposing of the brine fluid .................................. 35

14.2 Arranging disposal of coolant .............................. 35

15 Customer service............................................... 35

Appendix ............................................................................ 36

A Power supply 1~/N/PE 230 V (connection

diagram 1 = ).................................................. 36

B Power supply 3~/PE 230 V (connection

diagram 2 = ).................................................. 36

C Installer level overview...................................... 37

D Status codes – Overview .................................. 41

E Fault codes ......................................................... 43

Page 3

Contents

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 3

F Characteristic values for the VR 10 external

temperature sensor ........................................... 48

G Characteristic values for internal

temperature sensors ......................................... 49

H Characteristic values for the VRC DCF

outdoor temperature sensor............................. 50

I Heat pump schematic........................................ 51

J Commissioning Checklist ................................. 53

K Commissioning Checklist ................................. 56

L Technical data.................................................... 59

L.1 General................................................................ 59

L.2 Brine heat source................................................. 61

L.3 Groundwater heat source .................................... 63

M Measuring currents = In..................................... 65

Page 4

1 Safety

4 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

1 Safety

1.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in

accordance with the severity of the possible

danger using the following warning signs and

signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of

severe personal injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental

damage

1.2 Intended use

There is a risk of injury or death to the user or

others, or of damage to the product and other

property in the event of improper use or use

for which it is not intended.

The system is intended exclusively for domestic use.

The system is intended as a heat generator

with cooling function for closed heating installations and for hot water generation. Operation of the pump outside the application

limits results in the heat pump being switched

off by the internal control and safety devices.

Cooling mode with radiator heating systems

is not permitted since radiators do not have

an adequate heat transfer surface area.

Intended use includes the following:

– observance of accompanying operating,

installation and servicing instructions for

the product and any other system components

– installing and fitting the product in accord-

ance with the product and system approval

– compliance with all inspection and main-

tenance conditions listed in the instructions.

Intended use also covers installation in accordance with the IP class.

Any other use that is not specified in these

instructions, or use beyond that specified in

this document shall be considered improper

use. Any direct commercial or industrial use

is also deemed to be improper.

Caution.

Improper use of any kind is prohibited.

1.3 General safety information

1.3.1 Risk caused by inadequate

qualifications

The following work must only be carried out

by competent persons who are sufficiently

qualified to do so:

– Installation

– Disassembly

– Installation

– Start-up

– Maintenance

– Repair

– Decommissioning

▶ Observe all instructions that are included

with the product.

▶ Proceed in accordance with the current

state of technology.

▶ Observe all applicable directives, stand-

ards, laws and other regulations.

1.3.2 Risk of injury during transport due

to a high product weight.

▶ Make sure that the product is transported

by at least two people.

1.3.3 Risk of death due to lack of safety

devices

The schematic drawings included in this document do not show all safety devices required for correct installation.

▶ Install the necessary safety devices in the

system.

▶ Observe the applicable national and inter-

national laws, standards and guidelines.

Page 5

Safety 1

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 5

1.3.4 Risk of material damage caused by

frost

▶ Do not install the product in rooms prone

to frost.

1.3.5 Risk of death from electric shock

There is a risk of death from electric shock if

you touch live components.

Before commencing work on the product:

▶ Disconnect the product from the power

supply by switching off all power supplies

(electrical partition with a contact opening

of at least 3 mm, e.g. fuse or line protection switch).

▶ Secure against being switched back on

again.

▶ Wait for at least 3 minutes until the capa-

citors have discharged.

▶ Check that there is no voltage.

1.3.6 Risk of injury due to chemical burns

caused by brine fluid

The brine fluid ethylene glycol is harmful to

health.

▶ Avoid contact with the skin and eyes.

▶ Always wear gloves and protective

goggles.

▶ Do not inhale or swallow.

▶ Observe the safety data sheet that accom-

panies the brine fluid.

1.3.7 Risk of burns due to hot and cold

components

There is a risk of burns from any uninsulated

pipelines and from the auxiliary electric heating.

▶ Only carry out work on the components

once they have reached ambient temperature.

1.3.8 Material damage due to unsuitable

installation surface

The installation surface must be even and

have sufficient load-bearing capacity to support the operating weight of the product. An

uneven installation surface may cause leaks

in the product.

If the installation surface does not have sufficient load-bearing capacity, the product may

topple.

There is a risk of death if the connections are

subject to leaks.

▶ Make sure that the product is positioned

flush against the installation surface.

▶ Ensure that the installation surface has

sufficient load-bearing capacity to bear the

operating weight of the product.

1.3.9 Danger due to malfunctions

Ensure that the heating installation is in a

technically perfect condition.

▶ Ensure that no safety or monitoring

devices have been removed, bridged or

disabled.

▶ Immediately rectify any faults and damage

that may affect safety.

▶ Install the controller in a location where it is

not covered by furniture, curtains, or other

objects.

▶ If thermostatic control is activated, ad-

vise the operator that, in the room where

the controller is mounted, all the radiator

valves must be fully open.

▶ Do not use the units' free terminals as sup-

porting terminals for other wiring.

▶ At lengths of over 10 m, 230 V supply lines

must be laid separately from sensor or bus

lines.

1.3.10 Preventing the risk of injury from

freezing as a result of touching

coolant

The product is supplied with an operational

filling of R 410 A refrigerant. Escaping

coolant may cause freezing if the exit point is

touched.

▶ If coolant escapes, do not touch any com-

ponents of the product.

▶ Do not inhale any vapours or gases that

escape from the refrigerant circuit as a

result of leaks.

▶ Avoid skin or eye contact with the coolant.

▶ In the event of skin or eye contact with the

coolant, seek medical advice.

Page 6

1 Safety

6 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

1.3.11 Risk of material damage caused by

using an unsuitable tool

▶ Use the correct tool to tighten or loosen

screw connections.

1.3.12 Risk of material damage caused by

condensate inside the house

In heating mode, the lines between the heat

pump and the heat source (environment circuit) are cold, which means that condensate

may form on the lines in the house. In cooling mode, the building circuit lines are cold,

which means that condensate may also form

if the temperature falls below the dew point.

Condensate may lead to material damage,

for example due to corrosion.

▶ Ensure that you do not damage the heat

insulation on the lines.

1.3.13 Avoid environmental damage

caused by escaping coolant

The product contains R 410 A refrigerant.

The coolant must not be allowed to escape

into the atmosphere. R410A is a fluorinated

greenhouse gas covered by the Kyoto Protocol, with a GWP of 2088 (GWP = global

warming potential). If this gas escapes into

the atmosphere, its impact is 2088 times

greater than the natural greenhouse gas CO2.

Before the product is disposed of, the coolant

that is contained in it must be completely

drained into a suitable vessel so that it can

then be recycled or disposed of in accordance with regulations.

▶ Ensure that only officially certified com-

petent persons with appropriate protective

equipment carry out maintenance work on

the refrigerant circuit or access it.

▶ Arrange for the refrigerant that is contained

in the product to be recycled or disposed

of by a certified competent person in accordance with the regulations.

1.4 Regulations (directives, laws,

standards)

▶ Observe the national regulations, stand-

ards, guidelines and laws.

Page 7

Notes on the documentation 2

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 7

2 Notes on the documentation

2.1 Observing other applicable documents

▶ You must observe all the operating and installation in-

structions included with the system components.

2.2 Storing documents

▶ Pass these instructions and all other applicable docu-

ments on to the system operator.

2.3 Applicability of the instructions

These instructions apply only to:

Product

VWF 57/4 230V

VWF 87/4 230V

VWF 117/4 230V

3 System overview

3.1 Heat pump system design

A

B

A

B

The heat pump system consists of the following components:

– Heat pump

– System controller (from VRC 700)

– Outside temperature sensor with DCF receiver

– System sensor, if required

– With ground heat source: Ground sensor

– With well water heat source: Groundwater module

The heat pump system generates heat for heating installations and in hot water generation by extracting the thermal

energy from a heat source circuit and releasing this into

the heating circuit via the internal refrigeration circuit. At the

same time, there is an opportunity for active cooling to take

place via circulation reversal. The heat pump can be connected to two different types of heat source. This includes geothermal energy and groundwater, whereby the heat source is

connected to the heat pump via a transfer station connected

between the two.

3.1.1 Heat pump

– Fulfils the heating demand of the system controller down

to a minimum outside temperature and up to a maximum

target flow temperature.

– Fulfils the cooling requirements of the system controller

up to a maximum source temperature.

– Hot water generation with external domestic hot water

cylinder

3.1.2 Groundwater module

– Heat transfer from the groundwater to the brine heat

transfer medium in the heat pump.

3.1.3 Passive cooling module (optional)

– When using ground or groundwater as a heat source,

the heat of the heating water is transferred to the heat

source medium purely using circulation pumps and valve

switching.

Page 8

3 System overview

8 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

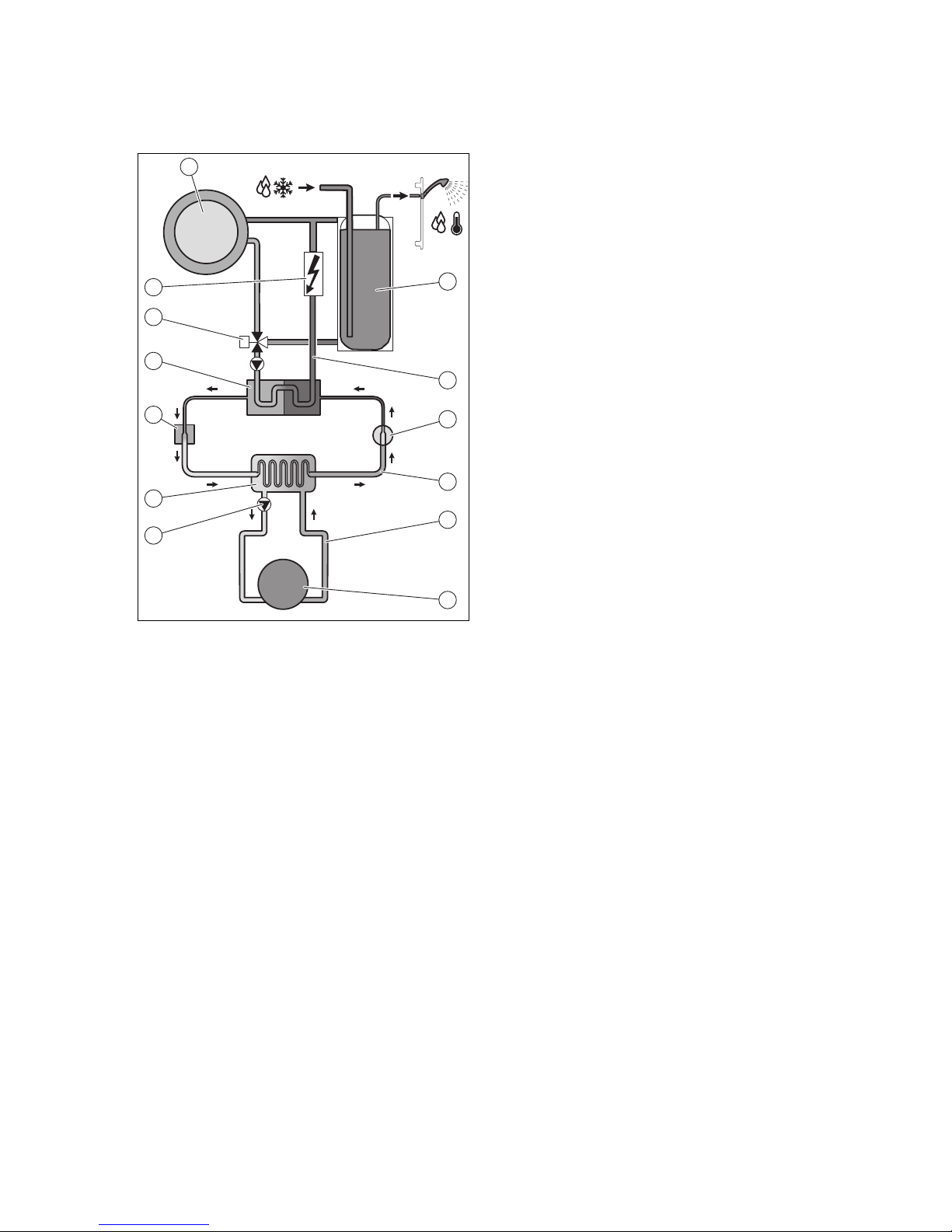

3.2 Functionality

3.2.1 Heat pump

2

3

1

4

5

6

7

8

9

10

11

12

13

1 Heating installation

2 Domestic hot water

cylinder (optional)

3 Heating circuit

4 Compressor

5 Refrigeration circuit

6 Brine circuit

7 Heat source

8 Brine pump

9 Evaporator

10 Electronic expansion

valve

11 Condenser

12 Heating/cylinder char-

ging diverter valve

13 Auxiliary electric heating

The heat pump system uses geothermal energy or groundwater as the heat source.

The heat pump consists of the following separate circuits

which are coupled with one another by means of heat exchangers. These circuits are:

– The brine circuit, which extracts the thermal energy from

the ground or the groundwater and transfers it to the refrigeration circuit

– The refrigerant circuit, which is used to bring the thermal

energy from the heat source to a usable, higher temperature level and deliver it to the heating circuit

– The heating circuit, which is used to heat up the living

rooms

The coolant circuit is connected via the evaporator to the

heat source, from which it extracts thermal energy. At the

same time, the physical state of the coolant changes; it

evaporates. The refrigerant circuit is connected via the

condenser to the heating installation, to which it releases the

thermal energy again. In so doing, the coolant becomes

liquid again; it condenses.

As thermal energy can only pass from a body at a higher

temperature to a body at a lower temperature, the coolant in

the evaporator must have a lower temperature than the heat

source. On the other hand, the temperature of the coolant in

the condenser must be higher than that of the heating water

in order to be able to release the thermal energy to it.

These different temperatures are produced in the coolant

circuit by means of a compressor and an expansion valve,

which are located between the evaporator and condenser.

The coolant flows in vapour form from the evaporator into the

compressor, where it is compressed. This causes the pressure and temperature of the coolant vapour to rise sharply.

After this process, it flows through the condenser, where it

releases its thermal energy to the heating water by condensation. It flows as a liquid into the expansion valve, where

it expands significantly and, in so doing, loses much of its

pressure and temperature. This temperature is now lower

than that of the brine that flows through the evaporator. The

coolant can thus absorb more thermal energy in the evaporator, turning into vapour in the process and flowing to the

compressor. The cycle starts again.

The evaporator and parts of the refrigerant circuit inside the

heat pump are cold-insulated, meaning that no condensate

can accumulate. Any small amounts of condensate which

may form evaporate as a result of the heat generated inside

the heat pump.

The product is equipped with an active cooling function

that you can use to maintain the temperature of your living

rooms when the outside temperature is high during summer.

Ground and groundwater are particularly good heat sources

for this use. For this purpose, a 4-way diverter valve is

integrated into the heat pump's refrigerant circuit. This uses

the principle of active cooling, in which the refrigerant circuit

is used to extract thermal energy from the heat recovery

system (e.g. the underfloor heating) in order to deliver this to

the heat source. For this, the 4-way diverter valve is used

to hydraulically swap the heat exchange processes in the

evaporator and condenser in the refrigerant circuit.

The heating water, which, when supplied, is colder in the

flow than the room temperature, absorbs thermal energy

from the rooms and is pumped by the heating pump to the

condenser (which works as an evaporator when in cooling

mode). This thermal energy is absorbed by the coolant and

heated to a higher temperature level using the compressor.

The thermal energy is then delivered to the brine in the evaporator (which works as a condenser when in cooling mode).

The cooled coolant is guided to the expansion valve to enable thermal energy to be absorbed from the condenser

again. The brine pump transports the hot brine into the earth,

where the thermal energy is dissipated.

During the installation, it may be useful to exclude some

rooms (e.g. the bathroom) from the cooling function and to

actuate stop valves especially for this. The heat pump electronics system emits a signal that can be used for actuating

these.

A passive cooling module is also available as an alternative,

whereby thermal energy is transported via underfloor heating, for example, from the rooms to the ground without the

compressor operating and therefore without the refrigerant

circuit operating.

If required, the integrated auxiliary electric heating can be

activated at different output levels via the heat pump display.

The auxiliary electric heating is then actuated by the system

controller.

Page 9

System overview 3

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 9

3.2.2 Weather-controlled system controller

The heat pump system is equipped with a weather-controlled

system controller that provides heating, cooling and hot water handling depending on the control type and controls this

in automatic mode.

The controller changes the target flow temperature based on

the outside temperature. The outside temperature is measured by a separate sensor which is mounted in the open air,

and the results are transmitted to the controller. The room

temperature depends only on the preset values. The system

compensates for the effect of the outside temperature. Hot

water generation is not affected by the weather compensation. The instructions for the system controller describe how

to install and operate the product.

3.3 Safety devices

3.3.1 Frost protection function

The frost protection function for the system is controlled via

the system controller. If the system controller fails, the heat

pump guarantees limited frost protection for the heating circuit.

3.3.2 Protection against low heating water

pressure

This function continuously monitors the pressure of the heating water in order to prevent a possible loss of heating water.

If the water pressure falls below the minimum pressure, an

analogue pressure sensor switches off the heat pump and

switches the other modules, where these exist, to standby

mode. It switches the heat pump on again if the water pressure reaches the operating pressure.

– Min. heating circuit pressure: ≥ 0.05 MPa (≥ 0.50 bar)

– Min. heating circuit operating pressure: ≥ 0.07 MPa

(≥ 0.70 bar)

3.3.3 Brine loss protection system

The brine loss protection system continuously monitors the

fluid pressure in the environment circuit in order to prevent a

possible shortage of fluid. If the fluid pressure falls below the

minimum pressure, an analogue pressure sensor switches

off the heat pump and switches the other modules, where

these exist, to standby mode. It switches the heat pump on

again if the fluid pressure reaches the operating pressure.

– Minimum brine fluid pressure: ≥ 0.05 MPa (≥ 0.50 bar)

– Min. brine fluid operating pressure: ≥ 0.07 MPa

(≥ 0.70 bar)

3.3.4 Freeze protection

This function prevents the evaporator from freezing when the

heat source temperature drops below a certain value.

The outlet temperature of the heat source is constantly

measured. If the outlet temperature of the heat source falls

below a certain value, the compressor temporarily switches

off and displays a status message. If this fault occurs three

times in a row, it is switched off and a fault message is

displayed.

3.3.5 Pump- and valve-blocking protection

system

This function prevents the pumps for heating water and

brine and all diverter valves from sticking. The pumps and

the valves, which were out of operation for 23 hours, are

switched on for 10 - 20 seconds, one after the other.

3.3.6 High-pressure pressure switch in the

refrigeration circuit

The high-pressure pressure switch shuts down the heat

pump if the pressure in the coolant circuit is too high. If the

pressure in the heat pump's refrigeration circuit exceeds

the maximum pressure, the high-pressure pressure switch

temporarily shuts down the heat pump. Following a waiting

period, another attempt is made to start the heat pump. After

three failed start attempts in succession, a fault message is

displayed.

– Refrigeration circuit pressure max.: 4.60 MPa (g) (46.00

bar (g))

– Waiting period: 5 minutes (after the first occurrence)

– Waiting period: 30 minutes

(after the second and every further occurrence)

The fault counter is reset if both of the following conditions

are met:

– Heat requirement without switching off prematurely

– 60 minutes of uninterrupted operation

3.3.7 Hot gas thermostat in the refrigeration

circuit

The hot gas thermostat shuts down the heat pump if the temperature in the refrigeration circuit is too high. If the temperature in the heat pump's refrigeration circuit exceeds the

maximum temperature, the hot gas thermostat temporarily shuts down the heat pump. Following a waiting period,

another attempt is made to start the heat pump. After three

failed start attempts in succession, a fault message is displayed.

– Max. refrigeration circuit temperature: 135 ℃

– Waiting period: 5 minutes (after the first occurrence)

– Waiting period: 30 minutes

(after the second and every further occurrence)

The fault counter is reset if both of the following conditions

are met:

– Heat requirement without switching off prematurely

– 60 minutes of uninterrupted operation

3.3.8 Safety cut-out (SCO) in the heating circuit

If the temperature in the heating circuit of the internal auxiliary electric heating exceeds the maximum temperature, the

SCO shuts down the auxiliary electric heating as a securing measure. Following a waiting period, another attempt is

made to start the auxiliary electric heating. A fault message

is displayed that can only be reset by pressing the Reset button or by switching the heat pump off and on again.

– Max. heating circuit temperature: 85 ℃

Page 10

4 Product description

10 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

4 Product description

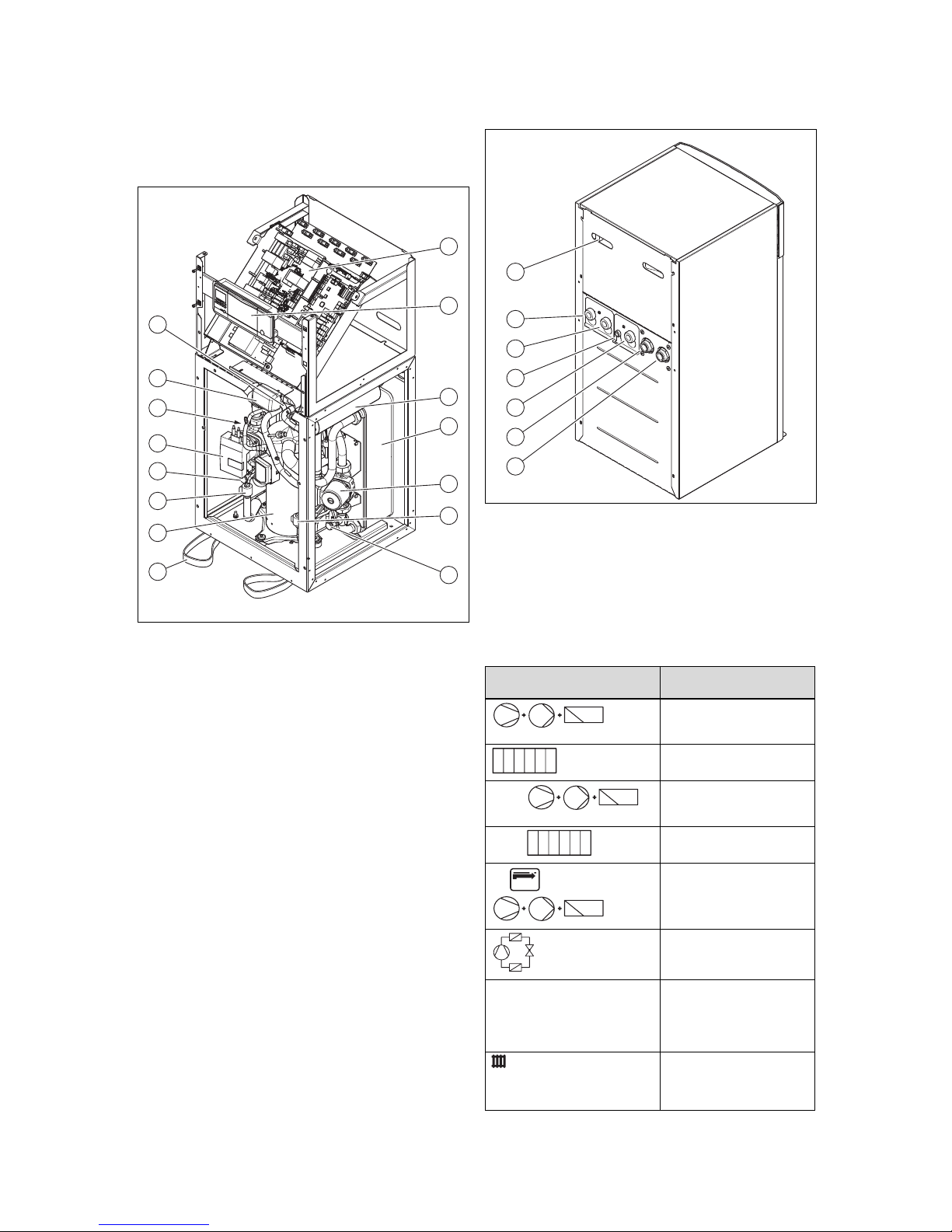

4.1 Product design

4.1.1 Front view, open

1

2

3

4

5

6

7

12

13

14

15

10

11

9

8

1 Switch box

2 Operator control panel

3 Auxiliary electric heating

4 Condenser

5 Heating pump

6 Electronic expansion

valve EVI (intermediate

circuit injection)

7 Heating circuit filling

and drainage tap

8 Carrying handles for

transport

9 Compressor

10 Electronic expansion

valve

11 Brine circuit filling and

drainage tap

12 Brine circuit pump

13 Evaporator (not visible)

14 Heating/cylinder char-

ging diverter valve

15 4-way valve

4.1.2 Rear view

1

2

4

3

5

6

7

1 Connection: From the

heat pump to the heat

source (cold brine, B)

2 Connection: From the

heat source to the heat

pump (hot brine, A)

3 Hot water return

4 Heating circuit dia-

phragm expansion tank

connection

5 Heating return

6 Heating flow

7 Recessed handles and

cable duct

4.2 Information on the identification plate

Information on the identification plate

Meaning

Rated voltage of the compressor, pumps and controller

Auxiliary heater rated voltage

P Max

Max. rated power of the

compressor, pumps and

controller

P Max

Max. rated power of the

auxiliary heater

I +

30 A

+

Start-up current

Coolant type, fill quantity,

permissible rated overpressure

COP B0/W35 /W45 /W55 Output figure (coefficient

of performance) at a brine

temperature of 0 °C and

heating flow temperature of

35/45/55 °C

B0/W35 /W45 /W55

Heating output at a brine

temperature of 0 °C and

heating flow temperature of

35/45/55 °C

Page 11

Product description 4

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 11

Information on the identification plate

Meaning

COP W10/W35 /W45 /W55 Output figure (coefficient of

performance) at a groundwater temperature of 10 °C and

a heating flow temperature

of 35/45/55 °C

W10/W35 /W45 /W55

Heating output at a groundwater temperature of 10 °C

and a heating flow temperature of 35/45/55 °C

V Mains voltage

Hz Power frequency

W Power consumption

IP Protection class

Information on disposal

Barcode with serial number,

7th to 16th digits = product

article number

Read the instructions

4.3 Explanation of product stickers

Symbol on the sticker Meaning

Heating flow connection

Heating return connection

Heating diaphragm expansion tank connection

A

Connection from the heat

source to the heat pump (hot

brine)

B

Connection from the heat

pump to the heat source

(cold brine)

Brine heat source

Energy supply company anticycling time

4.4 Type designation and serial number

The type designation and serial number can be found on

a plate behind the front flap and on the main identification

plate. The 7th to 16th digits of the serial number form the

article number.

4.5 CE label

The CE label shows that the products comply with the basic

requirements of the applicable directives as stated on the

identification plate.

The declaration of conformity can be viewed at the manufacturer's site.

4.6 Benchmark

Applicability: Great Britain

Vaillant is a licensed member of the Benchmark Scheme.

Benchmark places responsibilities on both manufacturers

and installers. The purpose is to ensure that customers are

provided with the correct equipment for their needs, that it is

installed, commissioned and serviced in accordance with the

manufacturer’s instructions by a competent person approved

at the time by the Health and Safety Executive and that it

meets the requirements of the appropriate Building Regulations. The Benchmark Checklist can be used to demonstrate compliance with Building Regulations and should be

provided to the customer for future reference.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark

Code of Practice which is available from the Heating and

Hotwater Industry Council who manage and promote the

Scheme.

Benchmark is managed and promoted by the Heating and

Hotwater Industry Council.

For more information visit www.centralheating.co.uk

Page 12

5 Installation

12 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

5 Installation

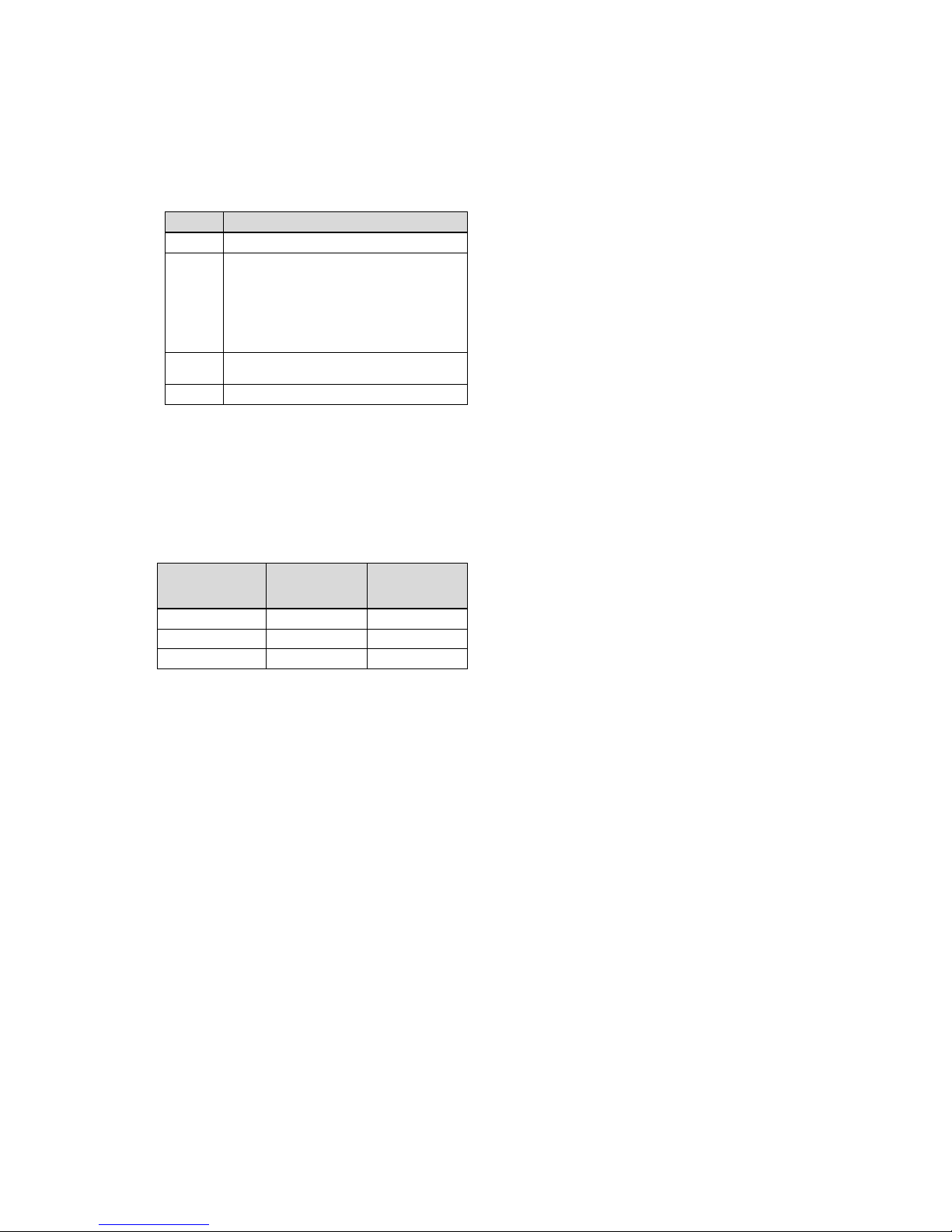

5.1 Checking the scope of delivery

1. Carefully remove the packaging and padding without

damaging the parts of the product.

2. Check that the scope of delivery is complete.

Quantity Description

1 Heat pump

1 Installation set comprising

– 3 x flat seal (yellow/green) for heating

circuit

– 1 x 3/4" flat seal for the heating expansion

vessel connection

– 2 x O-ring seals for brine circuit

1 Expansion relief valve for brine circuit, 1/2",

3 bar

1 Enclosed documentation

5.2 Selecting the installation site

▶ Select a dry room that is frost-proof throughout and in

which the permissible ambient temperature is neither

above nor below the permitted range.

– Permissible ambient temperature: 7 … 25 ℃

– Permissible relative air humidity: 40 … 75 %

▶ Ensure that the installation room has the required min-

imum volume.

Heat pump R 410 A refri-

gerant filling

volume

Minimum installation room

volume

VWF 57/4 230V 1.50 kg 3.41 m³

VWF 87/4 230V 2.40 kg 5.45 m³

VWF 117/4 230V 2.50 kg 5.68 m³

▶ Ensure that the required minimum clearances can be

maintained.

▶ When selecting the installation site, you must take into

consideration that when the heat pump is in operation, it

will transfer vibrations to the floor and the nearby walls.

▶ Ensure that the floor is level and has sufficient load-bear-

ing capacity to bear the weight of the heat pump and a

domestic hot water cylinder.

▶ Ensure that cables can be easily routed (for brine, hot

water and heating).

Page 13

Installation 5

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 13

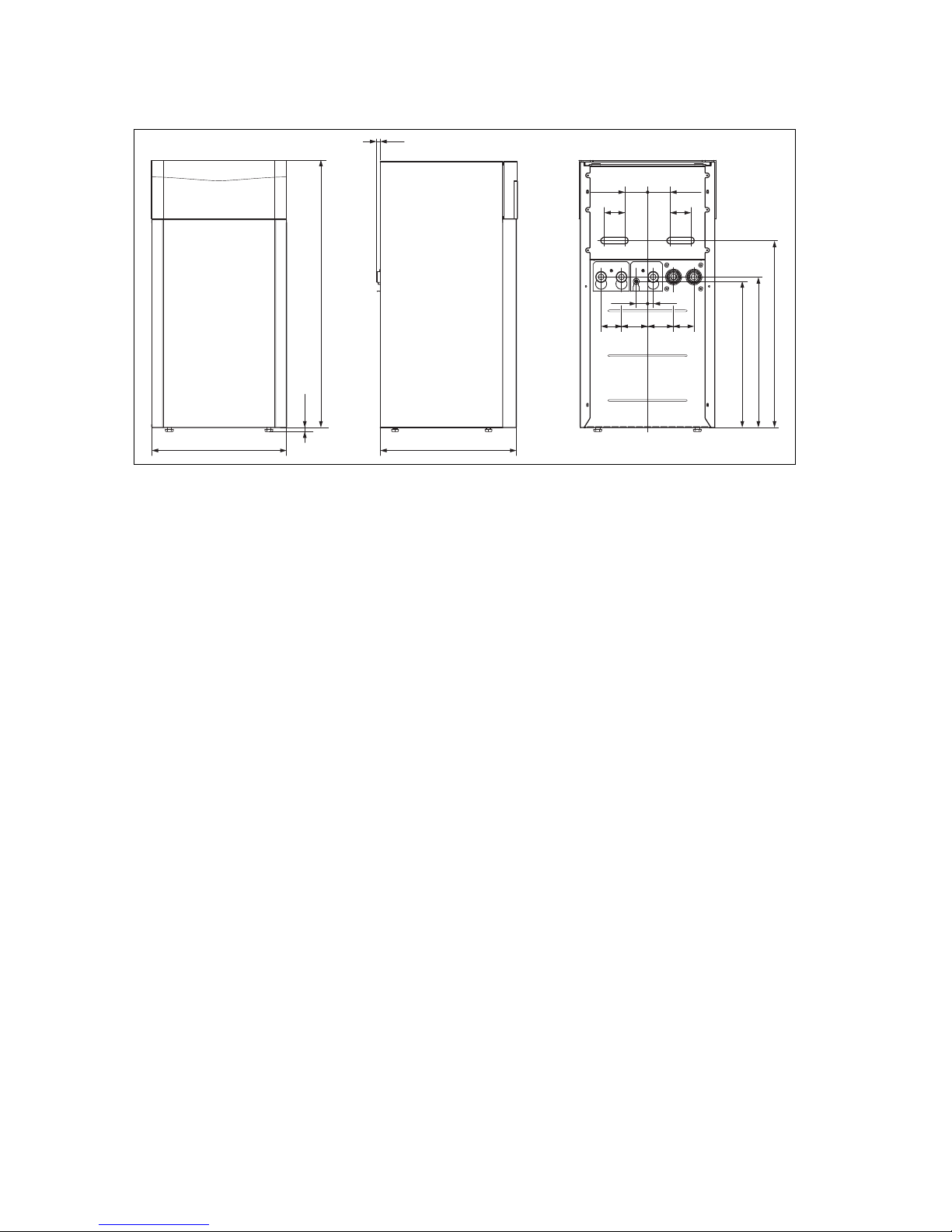

5.3 Dimensions

671

651

595 600

20

833

1183

18,2

91

100 100

91

2550

90 115 115 90

Page 14

5 Installation

14 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

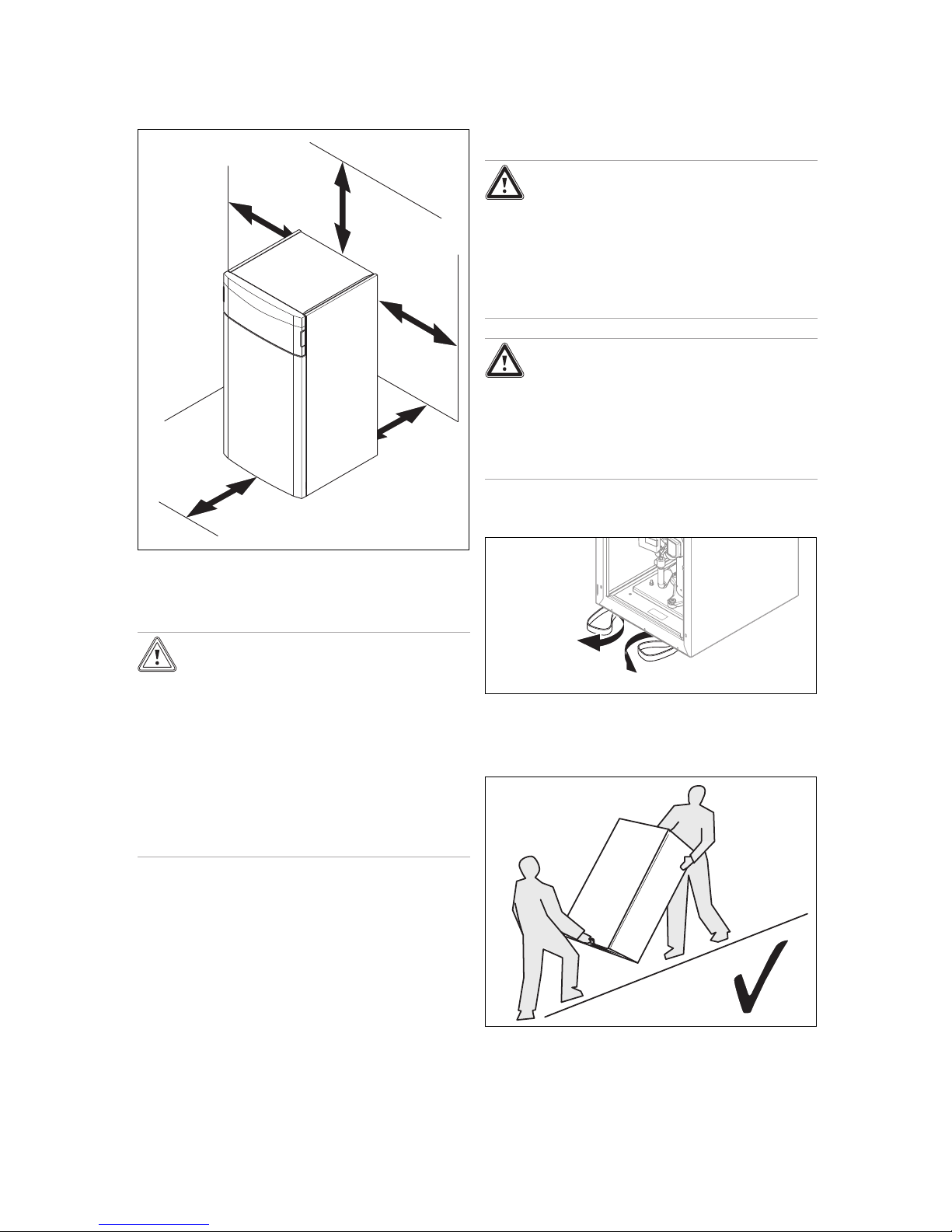

5.4 Minimum clearances

200 mm

250 mm

300 mm

300 mm

300 mm

▶ Comply with the minimum clearances specified above in

order to facilitate maintenance work.

5.5 Transporting the heat pump

Caution.

Risk of damage due to improper trans-

portation.

Regardless of the mode of transport, the heat

pump must never be tilted by more than 45°.

Otherwise, this may lead to malfunctions in

the coolant circuit during subsequent operation. In the worst case scenario, this may lead

to a fault in the whole system.

▶ During transport, do not tilt the heat pump

by any more than the maximum angle of

45°.

▶ Transport the product to the installation site. Use the

recessed handles on the rear and the retractable straps

at the front on the underside of the product as an aid.

▶ Transport the product using a suitable sack truck. Only

position the sack truck at the rear so that the weight distribution is as even as possible. Secure the product using

a retaining strap.

▶ Use a ramp to move the product from the pallet using

the sack truck, e.g. a piece of square timber and a sturdy

board.

5.5.1 Using carrying handles

1. Remove the front casing. (→ Page 15)

Danger!

Risk of injury due to repeated use of the

carrying handles.

Due to material ageing, the carrying handles

are not designed to be reused during any

subsequent transportation.

▶ Once the product has been started up, cut

off the carrying handles.

Danger!

Risk of injury when transporting due to

the carrying handles breaking away.

The carrying handles may break away during

transport if the front casing is fitted.

▶ Remove the front casing before you use

the carrying handles.

2. To transport the unit safely, use the two carrying

handles on the two front feet of the product.

3. Turn the carrying handles under the product so that

they face forwards.

4. Ensure that the feet are screwed in fully so that the carrying handles are held properly.

5. Always transport the product as illustrated above.

Page 15

Installation 5

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 15

6. Never transport the product as illustrated above.

5.6 Installing the product

0-10 mm

▶ Orientate the product horizontally by adjusting the ad-

justable feet.

5.7 Removing carrying handles

▶ Cut off the carrying handles and throw them away.

5.8 Removing the front casing

1

1. Remove the front flap on the operator control panel by

taking hold of the recessed handles with both hands

and lifting off the front flap towards you.

4x

2. Turn the four screws by a quarter turn and lift off the

cover on the operator control panel towards you.

Page 16

5 Installation

16 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

A

B

3. Pull each part of the front casing forwards slightly and

remove it by lifting it upwards.

5.9 Removing the casing top and side casings

1. Pull the casing top forwards slightly and remove it by

lifting it upwards.

A

A

B

B

2. To remove a side casing, remove the four screws at the

front and the three screws at the back.

3. Remove the side casing.

5.10 Removing the refrigeration circuit cover

A

B

1. Remove the four screws.

2. Pull the top of the refrigeration circuit cover forwards

and lift it out of the guide.

Page 17

Carrying out the hydraulics installation 6

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 17

6 Carrying out the hydraulics

installation

1. If you want to carry out active cooling using ground as

the heat source, make sure that the borehole/ground

sensor is suitable for this purpose and observe the national directives and laws. The use of ground collectors

for active cooling is prohibited.

2. Flush the heating installation through thoroughly before connecting the heat pump in order to remove any

residue which could be deposited in the heat pump and

lead to damage.

3. Install the supply lines (disconnected from the power

supply) in accordance with the dimension and connection drawings.

– Position the pipe brackets for securing the heating

circuit and brine circuit piping so that they are not

too close to the heat pump in order to prevent noise

transmission.

– If required, instead of pipe brackets, use cold insu-

lation clamps with additional rubber insulation and,

in some cases, reinforced hoses (armoured rubber

hoses).

– To prevent excessive pressure losses, do not use

stainless steel corrugated pipes.

– If required, use horizontal or right-angled connection

adaptors from the accessories.

Note

The heat pump's compressor has two-fold

vibration insulation. This eliminates vibrations in the coolant circuit that are inherent in

the system. However, under certain circumstances, residual vibrations may occur.

4. Attach automatic purging valves to the heating installation.

6.1 Requirements for the heating circuit

In heating installations that are equipped primarily with thermostatic or electrically controlled valves, a constant and sufficient flow through the heat pump must be ensured. Irrespective of which heating installation is selected, the minimum volume of circulating heating water (35% of the nominal flow; see the Technical data table) must be guaranteed.

6.2 Connecting the heat pump to the heating

circuit

Caution.

Risk of damage from magnetite deposits.

In heating installations with steel pipes,

static heating surfaces and/or buffer cylinder

systems, magnetite may form where large

volumes of water are involved.

▶ Insert a magnetite filter to protect the

pump inside the product.

▶ You must position the filter in direct prox-

imity to the return line to the heat pump.

1. Install a diaphragm expansion tank at the heat pump

connection provided.

2. Install an expansion relief valve (at least DN 20, opening pressure of 3 bar) with pressure gauge.

3. Install the expansion relief valve hose in a frost-free

environment and ensure that its routing ends in an open

tundish where it is then visible.

4. Install an air/dust separator in the return of the heating

circuit.

5. Connect the heating flow to the heating flow connection

of the heat pump.

6. Connect the heating return to the heating return connection of the heat pump.

7. Insulate all of the pipes in the heating circuit and the

connections for the heat pump so that they are vapourdiffusion-tight in order to prevent them from falling below the dew point in cooling mode.

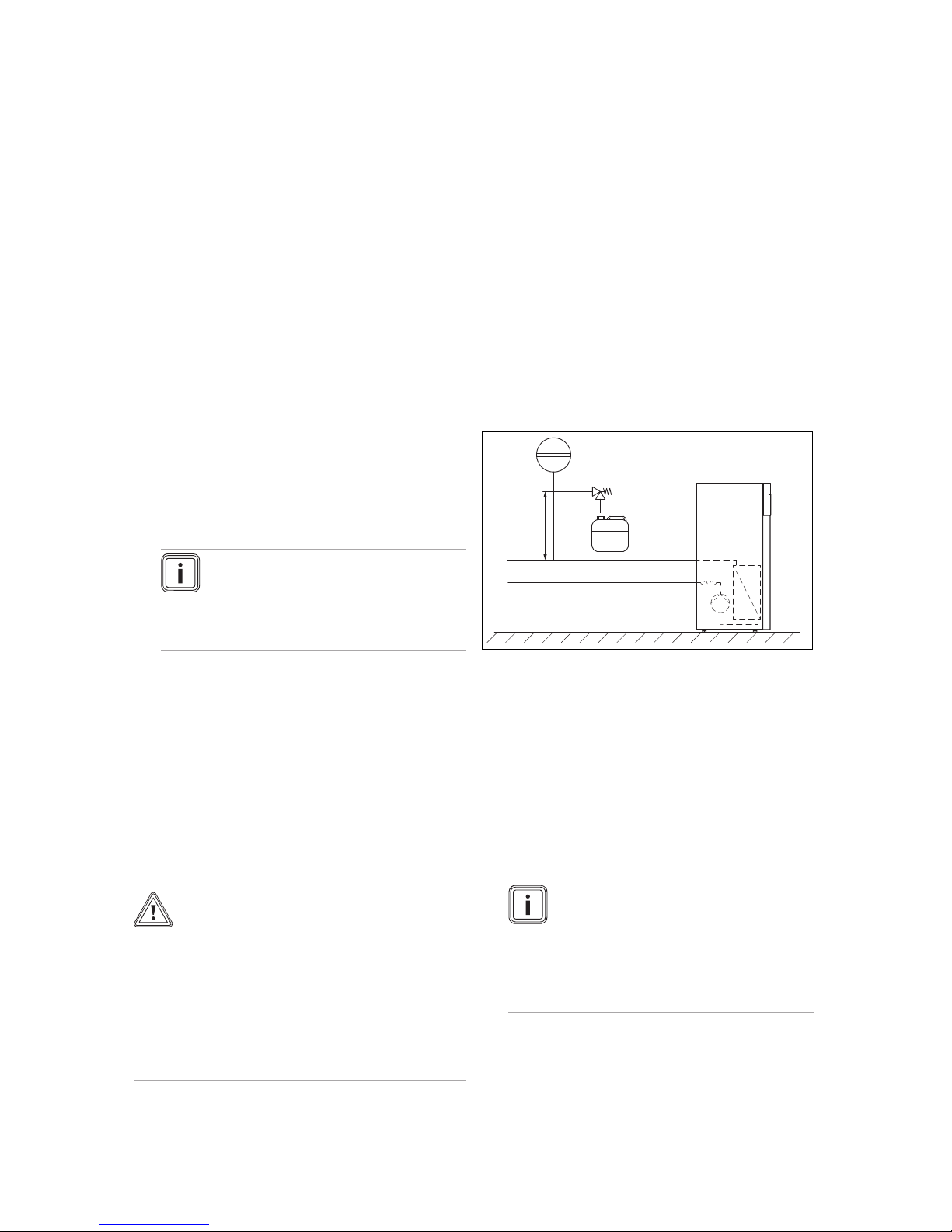

6.3 Connecting the heat pump to the brine

circuit

29

71

≥100 mm

42a

65

A

B

29 Brine pump

42a Brine expansion relief

valve

65 Brine collecting con-

tainer

71 Brine diaphragm expan-

sion tank

A From the heat source

to the heat pump (hot

brine)

B From the heat pump to

the heat source (cold

brine)

1. Remove the blind caps from the brine connections.

These are no longer required and can be properly disposed of.

2. Connect the brine lines to the heat pump.

3. Insulate all of the brine lines and the connections of the

heat pump so that they are vapour-diffusion-tight.

Note

Vaillant recommends that you install the

Vaillant heat pump brine filling unit (not

required when installing the groundwater

module). By doing this, it is then possible to

carry out a preparatory partial bleed of the

brine circuit, e. g. the flow and return lines of

the brine circuit to the product.

Page 18

7 Filling and purging the system

18 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

6.4 Hydraulic wiring in the system

6.4.1 Installing heating circuits with direct

connection

1. Install the hydraulic components in accordance with

the local requirements as shown in the system diagram

example, → Installation instructions for the system.

2. Connect the underfloor heating circuits or heating circuit

distributors directly to the heat pump.

3. Connect a limit thermostat to ensure that the heat

pump's underfloor protection works correctly.

(→ Page 22)

4. Ensure that a minimum volume of circulating water is

guaranteed.

– Minimum volume of circulating water: 35% of the

nominal flow

6.4.2 Installing heating circuits with direct

connection and domestic hot water cylinder

1. Install the heating circuits for direct operation.

(→ Page 18)

2. Secure the temperature sensor (VR10), available from

the range of accessories, in the domestic hot water

cylinder and connect it to the heat pump.

7 Filling and purging the system

7.1 Filling and purging the heating circuit

7.1.1 Checking and treating the heating

water/filling and supplementary water

Caution.

Risk of material damage due to poor-qual-

ity heating water

▶ Ensure that the heating water is of suffi-

cient quality.

▶ Before filling or topping up the system, check the quality

of the heating water.

Checking the quality of the heating water

▶ Remove a little water from the heating circuit.

▶ Check the appearance of the heating water.

▶ If you ascertain that it contains sedimentary materials,

you must desludge the system.

▶ Use a magnetic rod to check whether it contains mag-

netite (iron oxide).

▶ If you ascertain that it contains magnetite, clean the sys-

tem and apply suitable corrosion-protection measures, or

fit a magnet filter.

▶ Check the pH value of the removed water at 25 °C.

▶ If the value is below 8.2 or above 10.0, clean the system

and treat the heating water.

▶ Ensure that oxygen cannot get into the heating water.

Checking the filling and supplementary water

▶ Before filling the system, measure the hardness of the

filling and supplementary water.

Treating the filling and supplementary water

▶ Observe all applicable national regulations and technical

standards when treating the filling and supplementary

water.

Provided the national regulations and technical standards

do not stipulate more stringent requirements, the following

applies:

You must treat the heating water in the following cases:

– If the entire filling and supplementary water quantity dur-

ing the operating life of the system exceeds three times

the nominal volume of the heating installation, or

– If the guideline values listed in the following table are not

met, or

– If the pH value of the heating water is less than 8.2 or

more than 10.0.

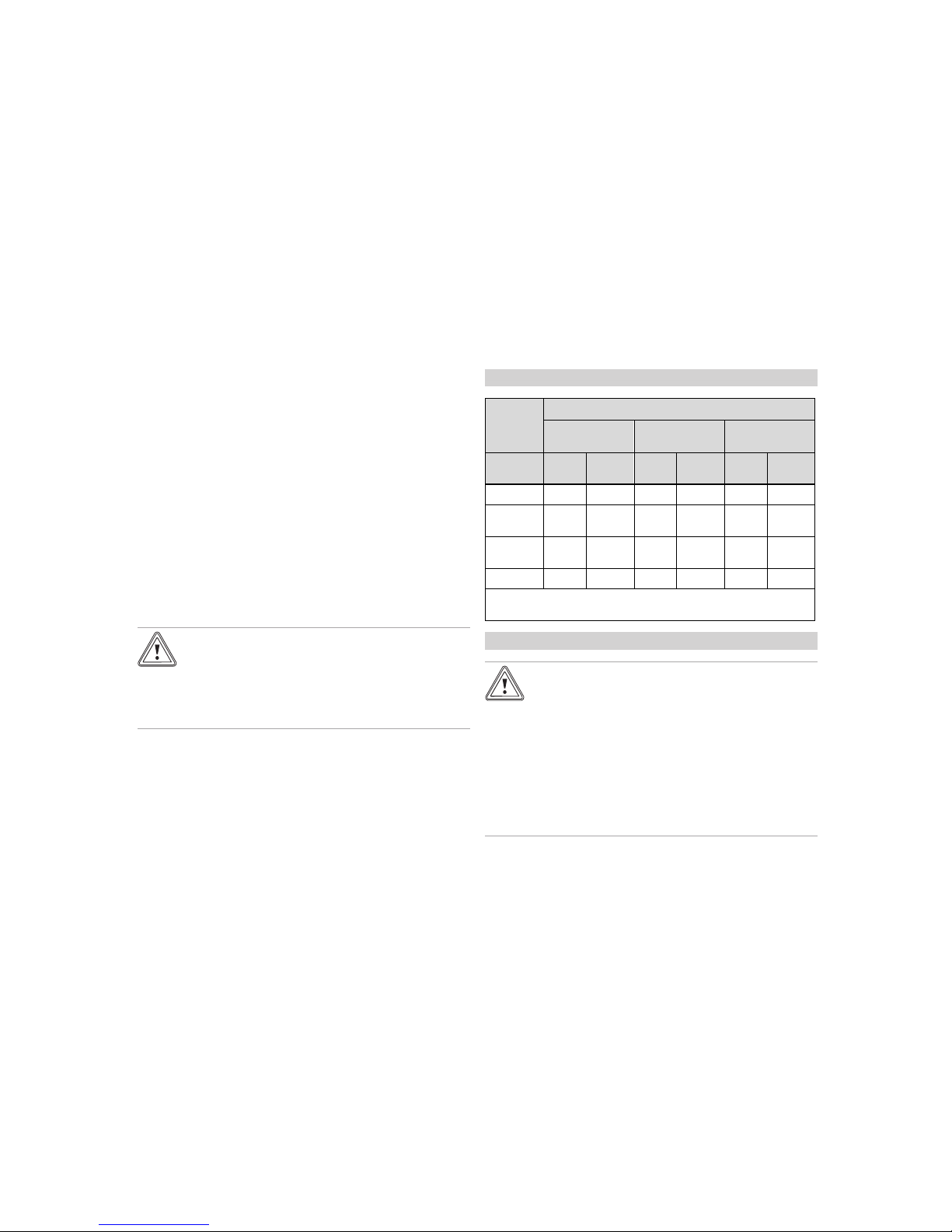

Applicability: Great Britain

Total

heating

output

Water hardness at specific system volume

1)

≤ 20 l/kW

> 20 l/kW

≤ 50 l/kW

> 50 l/kW

kW

ppm

CaCO₃

mol/m³ppm

CaCO₃

mol/m³ppm

CaCO₃

mol/

m³

< 50 < 300 < 3 200 2 2 0.02

> 50

to ≤ 200

200 2 150 1.5 2 0.02

> 200

to ≤ 600

150 1.5 2 0.02 2 0.02

> 600 2 0.02 2 0.02 2 0.02

1) Nominal capacity in litres/heating output; in the case of multiboiler systems, the smallest single heating output is to be used.

Applicability: Great Britain

Caution.

Risk of material damage if the heating

water is treated with unsuitable additives.

Unsuitable additives may cause changes in

the components, noises in heating mode and

possibly subsequent damage.

▶ Do not use any unsuitable frost and cor-

rosion protection agents, biocides or sealants.

No incompatibility with our products has been detected to

date with proper use of the following additives.

▶ When using additives, follow the manufacturer's instruc-

tions without exception.

We accept no liability for the compatibility of any additive or

its effectiveness in the rest of the heating system.

Additives for cleaning measures (subsequent

flushing required)

– Fernox F3

– Sentinel X 300

– Sentinel X 400

Additives intended to remain permanently in the

system

– Fernox F1

Page 19

Filling and purging the system 7

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 19

– Fernox F2

– Sentinel X 100

– Sentinel X 200

Additives for frost protection intended to remain

permanently in the system

– Fernox Antifreeze Alphi 11

– Sentinel X 500

▶ If you have used the above-mentioned additives, inform

the operator about the measures that are required.

▶ Inform the operator about the measures required for frost

protection.

7.1.2 Filling and purging the heating installation

1. Open all of the thermostatic radiator valves on the heating installation and, if required, all other stop valves.

2. Check all of the connections and the entire heating installation for leaks.

1

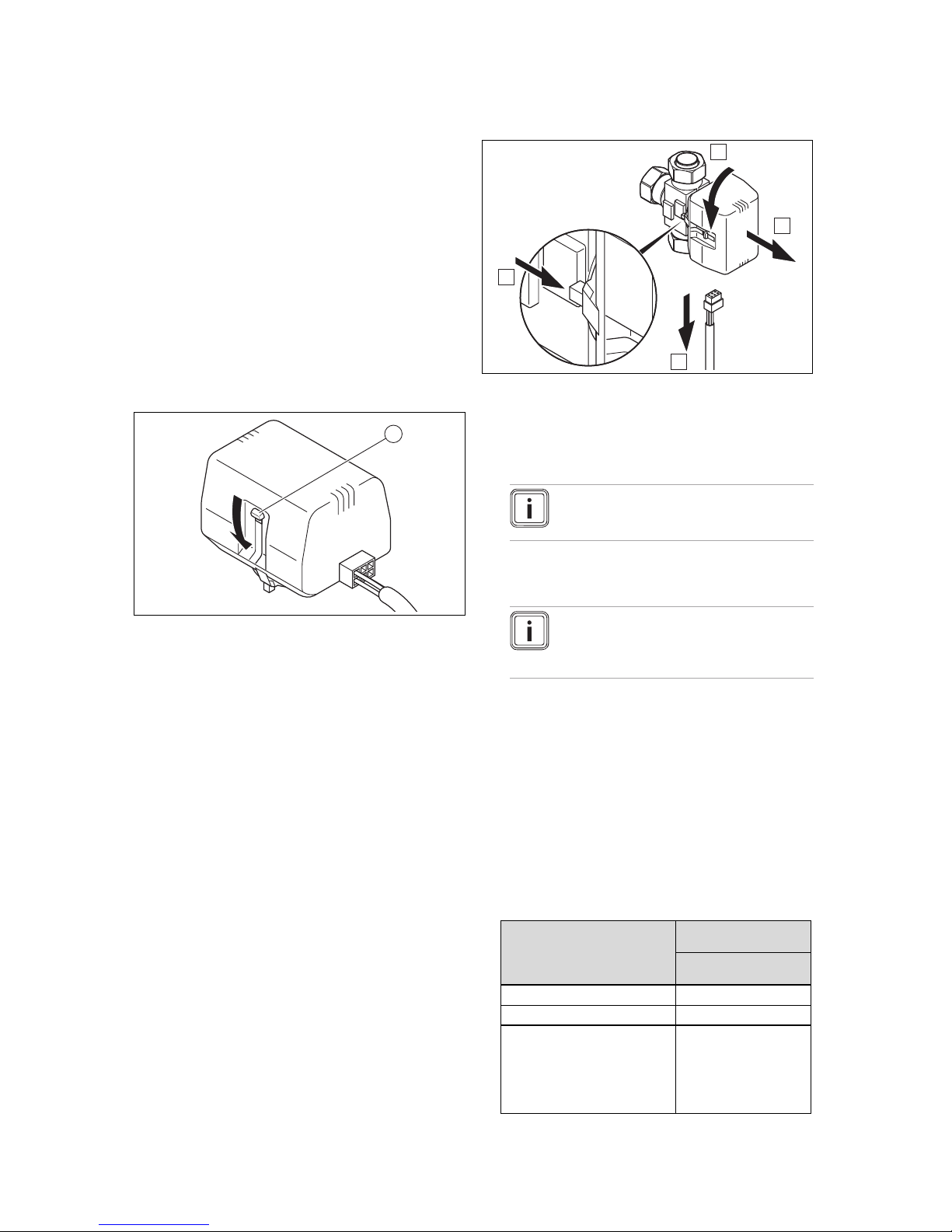

3. Push the white switching lever (1) on the motor head

of the diverter valve until it engages in its mid-position

in order to move the heating/cylinder charging diverter

valve into the mid-position.

◁ Both valves are open and the filling procedure is

improved since the air in the system can escape.

4. Connect a filling loop to the hot water supply.

5. Unscrew the screw cap from the heating circuit's filling

and drain valve and secure the free end of the filling

hose to here.

6. Open the filling and drain valve for the heating circuit.

7. Open the heating water supply slowly.

8. Fill with water until the pressure gauge (on-site) shows

that the heating installation has reached a pressure of

approx. 1.5 bar.

9. Close the filling and drain valve for the heating circuit.

10. Purge the heating circuit at the locations provided for

this.

11. Purge the heating pump using the heating pump's drain

screw.

12. Check the heating installation pressure again (if re-

quired, repeat the filling procedure).

13. Remove the filling loop from the filling and drain valve

and screw the screw cap back on.

Moving the heating/cylinder charging diverter

valve into the starting position

45°

A

B

C

D

14. Remove the power supply cable from the motor head of

the diverter valve.

15. Push the locking lever.

16. Turn the motor head by 45°.

17. Remove the motor head.

Note

This moves the spring in the valve body back

into the starting position.

18. Turn the motor head back towards the valve body and

reconnect the power supply cable.

Note

The white switch lever on the motor head

of the diverter valve should now be in the

starting position.

7.2 Filling and purging the brine circuit

7.2.1 Mixing the brine fluid

The brine fluid consists of water mixed with a concentrated

frost protection agent. The brine fluids that may be used differ greatly from region to region. For more information, contact the responsible authorities.

Only the brine fluids named here are authorised by Vaillant

for operating the heat pump.

Alternatively, suitable ready-mixed fluids for heat pumps can

be ordered from Vaillant.

▶ Use a sufficiently large mixing container.

▶ Carefully mix ethylene glycol with water.

Approved environment

source

Ground/groundwater

module

Brine content 30% vol.

Water content 70% vol.

* Cloud point

** Cold protection

Above this temperature,

the first ice crystals start

to form in the brine fluid.

At this temperature, half

of the fluid volume has

frozen; there is slush ice.

Page 20

7 Filling and purging the system

20 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

Approved environment

source

Ground/groundwater

module

Cloud point* of the aqueous

ethylene glycol mixture

-16 °C

Cold protection** of the aqueous

ethylene glycol mixture

-18 °C

* Cloud point

** Cold protection

Above this temperature,

the first ice crystals start

to form in the brine fluid.

At this temperature, half

of the fluid volume has

frozen; there is slush ice.

▶ Check the mixture ratio of the brine fluid.

– Working materials: Refractometer

In the event of special requirements, the following heat transfer media are also authorised by Vaillant for the ground and

groundwater heat sources:

– Aqueous solution with 33% ± 1% vol. propylene glycol

7.2.2 Filling the brine circuit

66

48

62

71

37

A

B

42a

63

61

33

67

65

33 Dirt filter

37 Automatic air separator

42a Brine expansion relief

valve

48 Pressure gauge (op-

tional)

61 Stop valve

62 Stop valve

63 Stop valve

65 Brine collecting con-

tainer

66 Brine container

67 Filling pump

71 Brine diaphragm expan-

sion tank

A From the heat source

to the heat pump (hot

brine)

B From the heat pump to

the heat source (cold

brine)

1. Install a dirt filter (33) in the pressure line.

2. Connect the filling pump's pressure line to the stop

valve (62).

3. Close the stop valve (63).

4. Open the stop valve (62).

5. Connect a hose, which leads to the brine fluid, to the

stop valve (61).

6. Open the stop valve (61).

Caution.

Risk of material damage caused by an

incorrect filling direction.

If you fill the brine pump against the direction

of flow, this may lead to a turbine effect which

can damage the pump's electronics.

▶ Ensure that the brine pump is filled in the

direction of flow.

7. Use the filling pump (67) to pour the brine fluid from the

brine container (66) into the brine circuit.

7.2.3 Purging the brine circuit

1. Start up the filling pump (67) in order to fill and rinse the

brine circuit.

2. Allow the filling pump (67) to run for at least 10 minutes

in order to fill and rinse the circuit sufficiently.

3. Then close the stop valves (61) and (62) and switch off

the filling pump (67).

4. If required, repeat this rinsing process.

5. Open the stop valve (63).

7.2.4 Building up pressure in the brine circuit

1. Use the filling pump (67) to pressurise the brine circuit.

Note

To operate the brine circuit without any problems, a filling pressure of 0.17 MPa (1.7 bar)

is required. The expansion relief valve opens

at 0.3 MPa (3 bar).

2. Read off the pressure on a pressure gauge (on-site).

– Brine fluid operating pressure range: 0.07

… 0.20 MPa (0.70 … 2.00 bar)

3. Build up the pressure in the brine circuit by opening the

stop valve (62) and using the filling pump to top up the

brine fluid.

4. If required, reduce the pressure in the brine circuit by

opening the stop valve (61) to drain brine fluid.

5. Check the brine circuit's filling pressure in the heat

pump's display.

6. If required, repeat the process.

7. Remove the two hoses from the valves (61) and (62).

8. Purge the system once more after starting up the heat

pump.

9. Label the container that holds the remaining brine fluid

with information about the type of brine fluid and the set

concentration.

10. Pass the vessel with the remaining brine fluid on to

the operator to be stored. Point out to the operator that

there is a risk of injury when handling brine fluid.

Page 21

Electrical installation 8

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 21

8 Electrical installation

Danger!

Risk of death from electric shock caused

by a residual-current circuit breaker not

working.

In certain cases, residual-current circuit

breakers may not work.

▶ If residual-current circuit breakers are re-

quired to ensure that people are protected and fire is prevented in line with the

applicable standards, use type A pulsecurrent-sensitive residual-current circuit

breakers or type B universal-current-sensitive residual-current circuit breakers.

▶ Observe the technical connection conditions for connect-

ing to the power supply network operator's low-voltage

network.

▶ Use the values for the maximum rated power that are

specified in the technical data to determine the required

line cross-sections.

▶ In each case, take into consideration the (on-site) install-

ation conditions.

▶ Connect the product using a fixed connection and an

electrical partition with a contact opening of at least 3 mm

(e.g. fuses or power switches).

▶ Install the electrical partition right next to the heat pump.

▶ Connect the product to the power supply according to the

identification plate.

▶ Fuse this connection using the exact values that are spe-

cified in the technical data.

▶ If the local power supply network operator requires that

the heat pump is controlled using a blocking signal, fit a

corresponding contact switch as prescribed by the power

supply network operator.

▶ Ensure that the sensor lines, e. g. for the VRC DCF re-

ceiver, do not exceed the maximum line length of 50 m.

▶ At lengths of 10 m or more, mains voltage supply lines

must be laid separately from sensor or bus lines. Minimum clearance for the extra-low voltage and mains

voltage line at a line length of > 10 m: 25 cm. If this is not

possible, use shielded lines. Lay the shielding on one

side of the sheet for the product's electronics box.

▶ Do not use free terminals on the heat pump as base ter-

minals for further wiring.

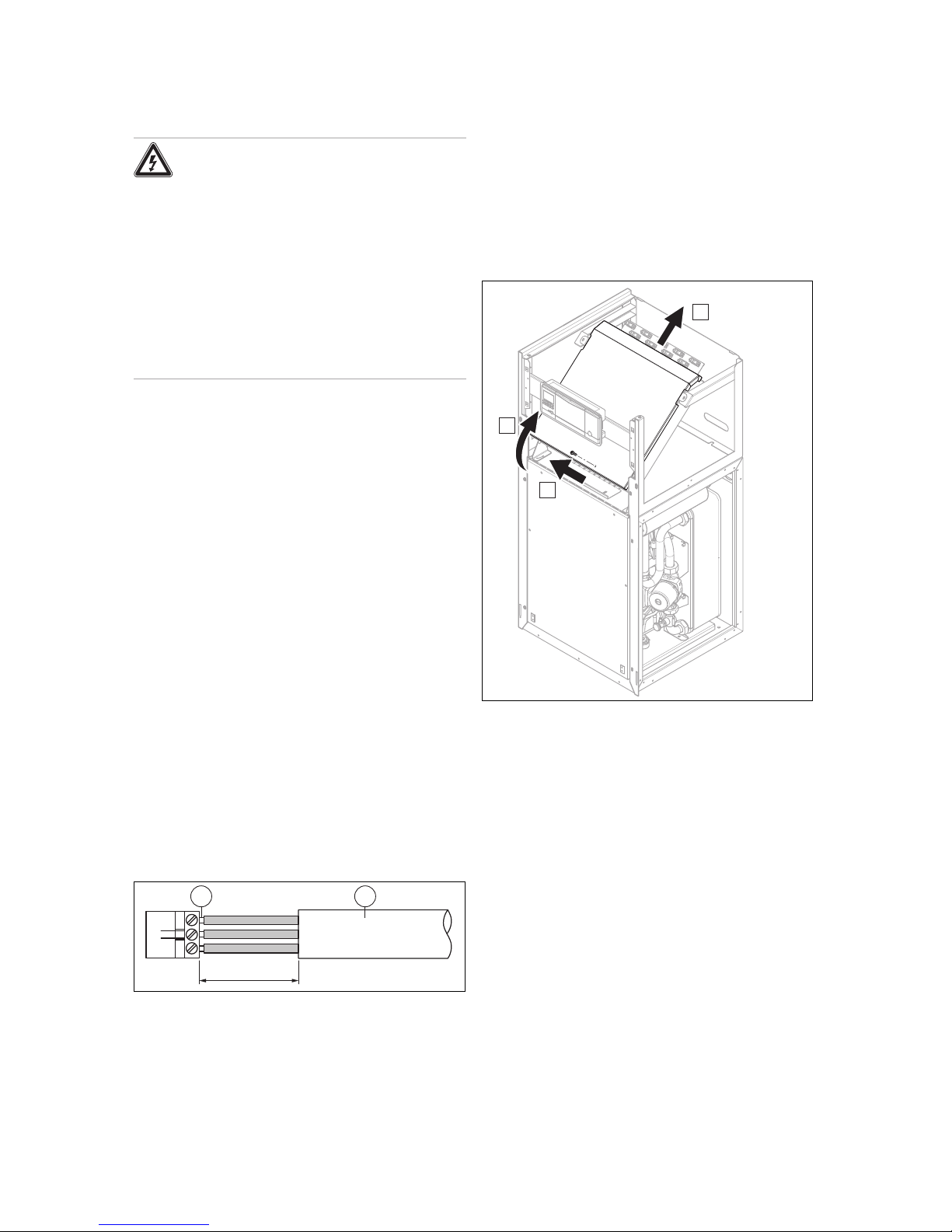

30 mm max.

1

2

1 Connecting wires 2 Insulation

▶ Only strip a maximum of 3 cm from the outer sheathing of

the flexible lines.

▶ Secure the conductors in the connection terminals.

– Max. torque of the connection terminals: 1.2 Nm

8.1 Routing eBUS lines

1. Route the eBUS lines in a star formation from a junction

box to the individual products.

2. Ensure that you do not route the eBUS lines parallel to

the mains connection lines.

– Piping diameter: ≥ 0.75 mm²

8.2 Opening the electronics box

A

C

B

1. Remove the screw.

2. Pull the bottom of the cover forwards and lift it upwards.

Page 22

8 Electrical installation

22 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

8.3 Switch box

1

8

7

3

6 45

2

9

1 VR 32 modulating bus

coupler (optional)*

* If the system diagram

selected on the system

controller makes provision for this accessory,

it can be connected

here.

2 Controller PCB

3 VR 40 multi-functional

module (2 in 7) (optional)**

** Relay 1 is used as

a fault contact connection/alarm output for the

heat pump. The function of relay 2 can be

set in the system controller.

4 Run capacitors

5 Start capacitor

6 In-rush current limiter

PCB

7 Line protection switch

8 Mains connection PCB

9 Mains connection ter-

minal for the auxiliary

electric heater

8.4 Establishing the power supply

1. Route the power supply line(s) through the holes in the

back wall of the product.

2. Guide the lines through the product, through the appropriate strain reliefs and to the terminals of the mains

connection and controller PCB.

3. Wire the connections as illustrated in the connection

diagrams below.

Note

There is no provision for using a connection diagram on the controller or on the heat

pump operator control panel.

4. Tighten the strain reliefs.

8.4.1 Connecting the continuous power supply

for the compressor and control system

▶ Connect the continuous power supply to the mains con-

nection (X101). (→ Page 36)

8.4.2 Connecting the blockable power supply for

the auxiliary heater

▶ Connect the power supply to the X102 mains connection.

(→ Page 36)

8.4.3 Connecting an external brine pressure

switch

In some cases (for example, in drinking water protection

areas), local authorities require the installation of an external

brine pressure switch that switches off the refrigerant circuit

if the pressure in the brine circuit falls below a certain level. If

the circuit is switched off by the brine pressure switch, a fault

message is shown on the display.

▶ Pull out the X131 plug for the bypass line (source monit-

oring) on the mains connection PCB.

▶ Connect an external brine pressure switch to the two

X131 terminals (Source Monitoring) on the mains connection PCB.

– Rated voltage of external brine pressure switch:

230 V 50 Hz

– Power range for external brine pressure switch (rms):

1 … 5 mA

8.4.4 Connecting a limit thermostat

In some cases where the underfloor heating has a direct

power supply, a limit thermostat (on-site) is essential.

▶ Pull out the S20 plug for the bypass line at terminal X100

on the controller PCB.

▶ Connect the limit thermostat at this terminal.

8.4.5 Connecting an external well pump

2

1

NLaLb

A changeover contact connection X143 (1) with the assignment Lb, La, N, PE is provided for connecting an external

well pump.

Lb is the opening contact. If the cut-off relay contact to the

well pump is closed, there is no voltage at Lb.

Page 23

Electrical installation 8

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 23

La is the closing contact. If the cut-off relay contact to the

well pump is closed, there is no voltage at La.

The X200 (2) connection for the optional temperature

sensors available as accessories is labelled RR for return

connections and VV for flow connections.

▶ Connect an external well pump to the X143 connection.

– Max. switching capacity at plug output: 1 A

▶ Connect the temperature sensors to the VV (suction well)

and RR (injection well) terminals.

Note

No functions are coupled to these temperature

sensors for monitoring the heat source. They

are simply shown on the display.

8.4.6 Connecting the temperature sensor for

an external domestic hot water cylinder

(optional)

1

2

▶ Connect the cable on the VR 10 temperature sensor

supplied as an accessory to bush (1) on plug (2). Use

a strain relief which does not have a mains voltage line

running through it.

Page 24

8 Electrical installation

24 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

8.5 Mains connection PCB

Note

The total current consumption of all connected external consumers (including X141, X143, X144, X145) must not

exceed 2.4 A.

1 3 52 6 74

8

9

23

22

25

24

12

11

14

15

16

17

1920 1821

10

1 [X102] Mains connection for internal auxiliary electric

heating

2 [X143] Well pump

3 [X120] Optional 230 V supply for protection anode

4 [X145] External auxiliary heating

5 [F1] F1 T 4A/250 V fuse (protects 230 V loads on

mains connection PCB)

6 Protective earth connection for the electronics box

7 [X101] Mains connection for compressor and 230

V electronics system – mains connection PCB (TB)

and controller PCB (HMU)

8 [X1A] 230 V supply for controller PCB

9 [X144] External 3-way valve

10 [X105] Connection for compressor with in-rush cur-

rent limiter

11 LED safety switch for compressor

Page 25

Electrical installation 8

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 25

12 [X20A] Connection for controller PCB communica-

tion line

14 [X201] (not used)

15 [X200] Optional temperature sensors for groundwa-

ter module

16 [X203] Optional flow temperature sensor for heating

circuit with passive cooling module

17 [X202] (not used)

18 [X90] (not used)

19 [X140] Connection for 3-way diverter valve for pass-

ive cooling module

20 [X142] 3-way mixer valve for passive cooling module

21 [X104] Internal auxiliary electric heating connection

22 [X131] Optional external brine pressure switch con-

nection

23 [X750] Safety cut-out for internal auxiliary electric

heating

24 LED safety switch for auxiliary electric heating

25 [X141] Signal output for active cooling mode

Page 26

8 Electrical installation

26 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

8.6 Controller PCB

1 2 3 4 5 6 7

8

9

24

23

22

11

10

14

15

16

17

18

19

2021

13

12

1 [X23] EEV connection (electrical expansion valve)

2 [X40] VR40 edge connector (electrical lines)

3 [X51] Edge connector for display connection

4 [X30] eBUS connection/diagnostics interface

5 [X25] Modbus plug for controlling the in-rush current

limiter

6 [X31] (not used)

7 [X24] (not used)

8 [X41] Edge connector for external sensors (outside

temperature sensor, DCF, system sensor, multifunction input (can be adjusted in the system controller))

9 [X26] Sensor cable harness

10 [X100/S20] Limit thermostat

11 [X100/S21] EVU contact

Page 27

Electrical installation 8

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 27

12 [X100/BUS] Bus connection (VR 900)

13 [X20] Data connection to mains connection PCB and

power supply for the in-rush current limiter

14 [X14] Circulation pump connection

15 [X15] Connection for internal 3-way valve for hot

water (DHW)

16 [X13] Internal brine pump connection

17 [X16] Internal heating pump connection

18 [X11] Connection for internal 4-way valve

19 [X1] 230 V supply for controller PCB

20 [F1] F1 T 4A/250 V fuse

21 [X12] Edge connector for 230 V supply for optional

VR 40

22 [X22] Connection for sensor cable harness (includ-

ing connection for internal VR 10 cylinder temperature sensor and EVI valve)

23 [X21] Connection for sensor cable harness

24 [X90] (not used)

Page 28

8 Electrical installation

28 Installation and maintenance instructions flexoTHERM exclusive 0020213395_00

8.7 Connecting the system controller and

accessories to the electronics system

1. Install the system controller in accordance with the in-

stallation instructions supplied.

2. Open the electronics box. (→ Page 21)

3. Carry out the wiring. (→ Page 28)

4. Connect controllers and accessories in accordance with

the relevant system diagrams and installation instructions.

5. Install the VRC DCF receiver.

6. Close the electronics box.

8.8 Carrying out the wiring

Caution.

Risk of material damage caused by incor-

rect installation.

Mains voltage at incorrect terminals and plug

terminals may destroy the electronics.

▶ Do not connect any mains voltage to the

eBUS terminals (+/-).

▶ Only connect the mains connection cable

to the terminals marked for the purpose.

1. Route the supply lines of the components to be connec-

ted through the cable duct provided on the rear of the

product on the left.

2. Use the cable channel on the top of the product.

3. Use strain reliefs.

4. Shorten the supply lines as necessary.

30 mm max.

5. To prevent short circuits if a strand accidentally comes

loose, only strip the outer sheathing of flexible lines to a

maximum of 30 mm.

6. Ensure the inner conductor insulation is not damaged

when stripping the outer sheathing.

7. Only strip inner conductors just enough to establish

good, sound connections.

8. To avoid short circuits resulting from loose individual

wires, fit conductor end sleeves on the stripped ends of

the conductors.

9. Screw the respective plug to the supply line.

10. Check whether all conductors are sitting mechanically

securely in the terminals of the plug. Remedy this if

necessary.

11. Plug the plug into the associated PCB slot.

8.9 Installing the VRC DCF

▶ Install the VRC DCF receiver in accordance with the in-

stallation instructions for the system controller.

8.10 Installing optional accessories

1. Route the lines through the ducts in the back wall of the

product.

2. Open the electronics box. (→ Page 21)

3. Connect the connection cable to the corresponding

plugs or slots on the mains connection PCB or controller PCB.

4. Use the strain reliefs to secure the lines in the product.

8.11 Checking the electrical installation

1. After the installation is complete, check the electrical installation to ensure that the connections that have been

established are secured properly and are sufficiently insulated.

2. Install the cover of the electronics box. (→ Page 21)

8.12 Completing installation

8.12.1 Fitting the casing

1. Fit the side casings and screw in the screws.

2. Place the casing top on the side casings and slide it

back into the recesses provided for this in the back wall.

3. Hook the upper part of the front casing, using the retaining brackets, into the recesses in the side casings and

lower it down.

4. Hook the lower part of the front casing, using the retaining brackets, into the recesses in the side casings and

fold it up.

5. Install the panel on the operator control panel.

6. Attach the operator control panel cover and check that

the cover can move easily when it is opened from either

side.

8.12.2 Checking the system pressure and leak-

tightness

1. After completing the installation, carry out a check of

the system.

2. Start up the product in accordance with the relevant

operating instructions.

3. Check the filling pressure of the heating installation and

check for leaks.

Page 29

Start-up 9

0020213395_00 flexoTHERM exclusive Installation and maintenance instructions 29

9 Start-up

9.1 Operating concept

→ Operating instructions

9.2 Starting up the heat pump

▶ Switch on the power supply.

◁ The basic display appears on the display.

Note

In the case of a restart following a loss of

voltage or a shutdown of the power supply,

the current date and time are automatically

reset by the DCF receiver or, if there is no

DCF reception, you must reset these values

yourself.

9.3 Running the installation assistants

The installation assistant is launched when the heat pump is

switched on for the first time.

Menu → Installer level Configuration

▶

Press to confirm that you wish to start the installation

assistant.

◁ All heating, cooling and hot water requests are

blocked whilst the installation assistant is active.

Note

You cannot exit the installation assistant until

the environment circuit type has been set.

▶

To access the next point, confirm by pressing in each

case.

9.3.1 Setting the language

1. To confirm the set language and to avoid unintentionally

changing it, press twice.

Conditions: Unknown language set

▶

Press and hold and at the same time.

▶

Also briefly press

reset

.

▶

Press and hold and until the display shows the

language setting option.

▶ Select the required language.

▶

Press twice to confirm this change.

9.3.2 Setting the environment circuit type

The following environment circuit types can be set:

– Ground/brine

– Air/brine

– Groundwater/brine

9.3.3 Setting the cooling technology

You must set the installed cooling technology.

When using ground/brine as the heat source, active cooling

is limited to a brine output temperature of 40 °C in order to

protect the source/probe borehole. If this temperature is ex-

ceeded (> 40 °C), active cooling mode is switched off. This

limit can only be changed by Vaillant Customer service.

9.3.4 Enabling auxiliary electric heating

On the system controller, you can select whether the auxiliary electric heating is to be used for heating mode, hot water

handling mode or both modes. Set the maximum output for

the auxiliary electric heater at the heat pump's operator control panel here.

▶ Activate the internal auxiliary electric heating with one of

the following output levels.

▶ Make sure that the maximum output of the auxiliary elec-

tric heating does not exceed the power of the fuse protection installed in the domestic electrical system (see

technical data for measuring currents).

Note

Otherwise the domestic circuit breaker may be

triggered later if the output of the heat source

is insufficient and the auxiliary electric heating

(which has a higher output) is switched off.

Output levels for the 230 V auxiliary electric heating (when

connecting one phase; see Appendix A):

– External

– 2.0 kW

– 3.5 kW

– 5.5 kW

Output levels for the 230 V auxiliary electric heating (when

connecting three separate phases; see Appendix B):

– 7 kW

– 9 kW

9.3.5 Purging the building circuit

▶ Start the check programme P.05 in order to purge the

building circuit. (→ Page 33)

9.3.6 Purging the environment circuit

▶ Start the check programme P.06 in order to purge the

environment circuit. (→ Page 33)

Conditions: Air/brine heat source

– Programme duration of approx. 1 hour. In addi-