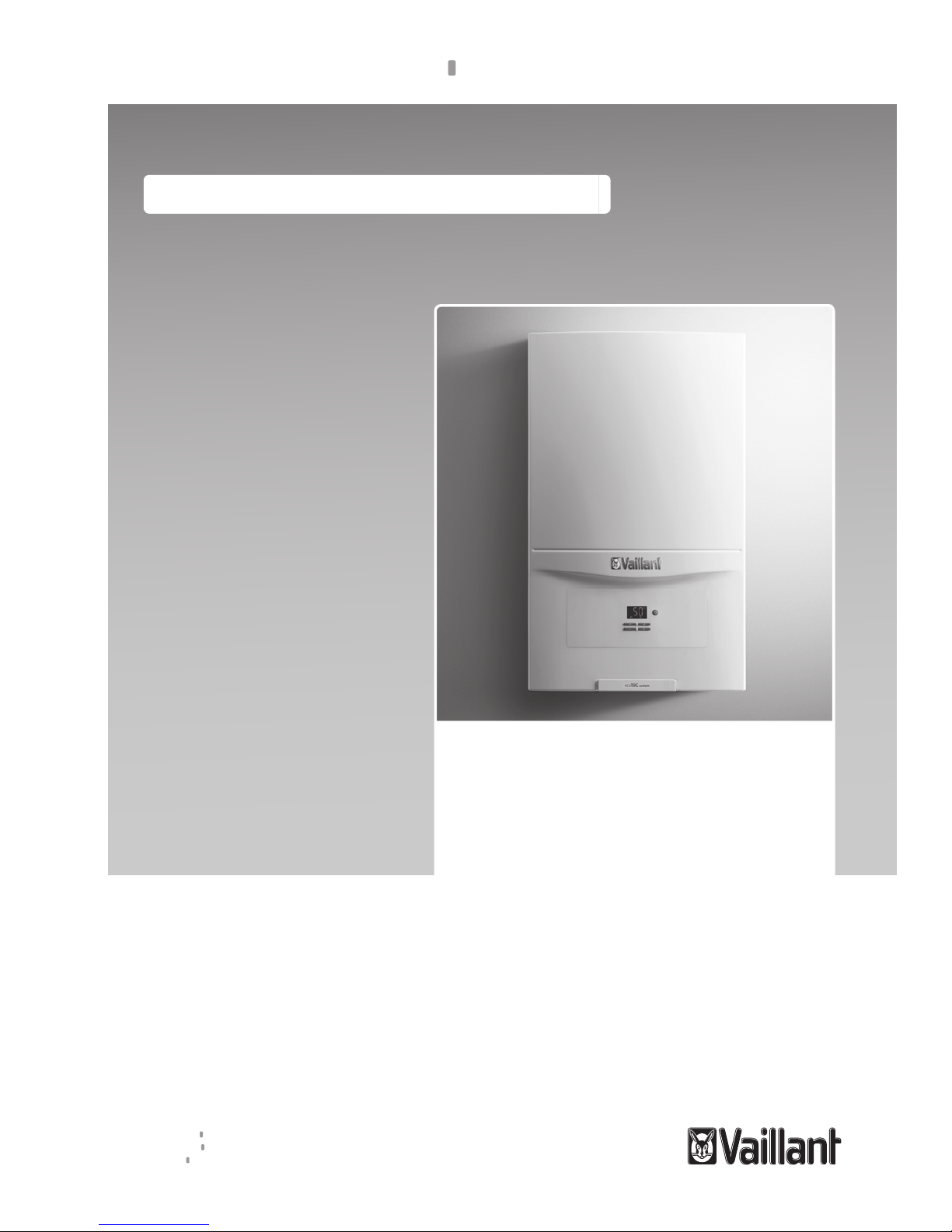

Vaillant ecoTEC sustain 24, ecoTEC sustain 28, ecoTEC sustain 34 Installation And Maintenance Instructions Manual

Page 1

Installation and maintenance instructions

ecoTEC sustain

24, 28, 34

GB

Installation and maintenance instructions

Publisher/manufacturer

Vaillant GmbH

Berghauser Str. 40 D-42859 Remscheid

Tel. +49 21 91 18‑0 Fax +49 21 91 18‑2810

info@vaillant.de www.vaillant.de

Page 2

Contents

2 Installation and maintenance instructions ecoTEC sustain 0020253094_01

Contents

1 Safety .................................................................... 4

1.1 Action-related warnings ......................................... 4

1.2 Intended use.......................................................... 4

1.3 General safety information .................................... 4

1.4 Regulations (directives, laws, standards).............. 6

2 Notes on the documentation .............................. 7

2.1 Observing other applicable documents ................. 7

2.2 Storing documents................................................. 7

2.3 Validity of the instructions ...................................... 7

2.4 Benchmark............................................................. 7

3 Product description............................................. 7

3.1 Product design....................................................... 7

3.2 Information on the identification plate.................... 8

3.3 Serial number ........................................................ 8

3.4 CE label ................................................................. 8

3.5 Energy Saving Trust Endorsed Products .............. 8

4 Set-up.................................................................... 8

4.1 Transporting the unit.............................................. 8

4.2 Unpacking the product........................................... 9

4.3 Checking the scope of delivery.............................. 9

4.4 Dimensions............................................................ 9

4.5 Minimum clearances............................................ 10

4.6 Clearance from combustible components ........... 10

4.7 Using the installation template............................. 10

4.8 Wall-mounting the product................................... 10

4.9 Removing the front casing................................... 11

4.10 Removing the side section .................................. 11

5 Installation.......................................................... 11

5.1 Installation requirements ..................................... 12

5.2 Gas and water connections ................................. 13

5.3 Connecting the condensate drain pipework ........ 13

5.4 Installing the discharge pipe on the expansion

relief valve............................................................ 13

5.5 Flue installation.................................................... 13

5.6 Electrical installation ............................................ 14

6 Operation............................................................ 16

6.1 Operating concept ............................................... 16

6.2 Installer level overview......................................... 17

6.3 Calling up the installer level ................................. 17

6.4 Using diagnostics codes...................................... 17

6.5 Displaying the status codes................................. 17

6.6 Using check programmes.................................... 17

7 Start-up ............................................................... 18

7.1 Carrying out the initial start-up............................. 18

7.2 Gas type check .................................................... 18

7.3 Checking the factory setting ................................ 18

7.4 Checking and treating the heating water/filling

and supplementary water .................................... 18

7.5 Preventing low water pressure ............................ 19

7.6 Filling the condensate siphon .............................. 19

7.7 Filling and purging the heating installation .......... 19

7.8 Filling the hot water circuit ................................... 20

7.9 Switching the product on and off ......................... 20

7.10 Checking the gas settings ................................... 20

7.11 Checking leak-tightness ...................................... 22

8 Adapting the unit to the installation ................ 22

8.1 Activating diagnostics codes ............................... 22

8.2 Burner anti-cycling time ....................................... 22

8.3 Setting the maximum heating output ................... 23

8.4 Setting the maintenance interval ......................... 23

8.5 Setting the pump output....................................... 23

8.6 Setting the bypass ............................................... 24

8.7 Setting the hot water temperature ....................... 24

8.8 Handing the product over to the operator............ 24

9 Troubleshooting ................................................ 24

9.1 Checking service messages................................ 24

9.2 Rectifying faults ................................................... 25

9.3 Calling up the fault memory ................................. 25

9.4 Deleting the fault memory.................................... 25

9.5 Resetting parameters to factory settings ............. 25

9.6 Preparing the repair work .................................... 25

9.7 Replacing defective components......................... 25

9.8 Completing repair work........................................ 28

10 Inspection and maintenance ............................ 28

10.1 Observing inspection and maintenance

intervals ............................................................... 28

10.2 Checking and adjusting the gas ratio setting ....... 28

10.3 Checking the CO₂ content ................................... 29

10.4 Setting the CO₂ content ....................................... 29

10.5 Preparing the maintenance work ......................... 30

10.6 Draining the product ............................................ 30

10.7 Removing the compact thermal module .............. 30

10.8 Cleaning the heat exchanger............................... 31

10.9 Checking the burner ............................................ 31

10.10 Checking the ignition electrode ........................... 31

10.11 Cleaning the condensate siphon ......................... 32

10.12 Cleaning the filter in the cold water inlet .............. 32

10.13 Cleaning the heating filter.................................... 32

10.14 Installing the compact thermal module ................ 32

10.15 Checking the product for leak-tightness .............. 33

10.16 Checking the admission pressure of the

expansion vessel ................................................. 33

10.17 Completing inspection and maintenance work .... 33

11 Decommissioning.............................................. 33

11.1 Permanently decommissioning the product......... 33

12 Recycling and disposal..................................... 33

13 Customer service............................................... 33

Appendix ............................................................................ 34

A Check programmes – Overview ....................... 34

B Overview of diagnostics codes........................ 34

C Status codes – Overview .................................. 38

D Overview of fault codes .................................... 39

Page 3

Contents

0020253094_01 ecoTEC sustain Installation and maintenance instructions 3

E Wiring diagrams................................................. 41

E.1 Wiring diagram..................................................... 41

E.2 Wiring diagram..................................................... 42

F Inspection and maintenance work –

Overview............................................................. 43

G Opening in the flue pipe .................................... 44

G.1 Positioning of the opening of a fan-supported

flue gas pipe ........................................................ 44

G.2 Horizontal terminal positioning ............................ 45

H Commissioning Checklist ................................. 46

I Technical data.................................................... 50

Index ................................................................................... 53

Page 4

1 Safety

4 Installation and maintenance instructions ecoTEC sustain 0020253094_01

1 Safety

1.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in

accordance with the severity of the possible

danger using the following warning signs and

signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of

severe personal injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental

damage

1.2 Intended use

There is a risk of injury or death to the user or

others, or of damage to the product and other

property in the event of improper use or use

for which it is not intended.

The product is intended as a heat generator

for closed heating installations and for hot

water generation.

Depending on the gas-fired boiler type, the

products referred to in these instructions

must only be installed and operated in conjunction with the air/flue pipe accessories listed in the other applicable documents.

Intended use includes the following:

– observance of accompanying operating,

installation and servicing instructions for

the product and any other system components

– installing and fitting the product in accord-

ance with the product and system approval

– compliance with all inspection and main-

tenance conditions listed in the instructions.

Intended use also covers installation in accordance with the IP class.

Any other use that is not specified in these

instructions, or use beyond that specified in

this document shall be considered improper

use. Any direct commercial or industrial use

is also deemed to be improper.

Caution.

Improper use of any kind is prohibited.

1.3 General safety information

1.3.1 Risk caused by inadequate

qualifications

– Set-up

– Disassembly

– Installation

– Start-up

– Maintenance

– Repair

– Decommissioning

▶ Observe all instructions that are included

with the product.

▶ Proceed in accordance with the current

state of technology.

▶ Observe all applicable directives, stand-

ards, laws and other regulations.

1.3.2 Risk of injury due to the heavy

weight of the product

▶ Make sure that the product is transported

by at least two people.

1.3.3 Risk of death from escaping gas

What to do if you smell gas in the building:

▶ Avoid rooms that smell of gas.

▶ If possible, open doors and windows fully

and ensure adequate ventilation.

▶ Do not use naked flames (e.g. lighters,

matches).

▶ Do not smoke.

▶ Do not use any electrical switches, mains

plugs, doorbells, telephones or other communication systems in the building.

▶ If it is safe to do so, close the emergency

control valve or the main isolator.

▶ If possible, close the gas isolator cock on

the product.

▶ Warn other occupants in the building by

yelling or banging on doors or walls.

▶ Leave the building immediately and ensure

that others do not enter the building.

Page 5

Safety 1

0020253094_01 ecoTEC sustain Installation and maintenance instructions 5

▶ Notify the gas supply company or the Na-

tional Grid +44 (0) 800 111999 by telephone once you are outside of the building.

1.3.4 Risk of death from escaping flue

gas

If you operate the product with an empty condensate siphon, flue gas may escape into the

room air.

▶ In order to operate the product, ensure that

the condensate siphon is always full.

1.3.5 Risk of death from leaks if the

product is installed below ground

level

Liquid gas accumulates at floor level. If the

product is installed below ground level, liquid

gas may accumulate at floor level if there

are any leaks. In this case, there is a risk of

explosion.

▶ Make sure that liquid gas cannot escape

from the product or the gas line under any

circumstance.

1.3.6 Risk of death due to blocked or

leaking flue gas routes

Installation errors, damage, tampering, unauthorised installation sites or similar can cause

flue gas to escape and result in a risk of poisoning.

What to do if you smell flue gas in the property:

▶ Open all accessible doors and windows

fully to provide ventilation.

▶ Switch off the product.

▶ Check the flue gas routes in the product

and the flue gas diversions.

1.3.7 Risk of poisoning and burns caused

by escaping hot flue gases

▶ Only operate the product if the air/flue pipe

has been completely installed.

▶ With the exception of short periods for

testing purposes, only operate the product

when the front casing is installed and

closed.

1.3.8 Risk of death due to explosive and

flammable materials

▶ Do not use or store explosive or flammable

materials (e.g. petrol, paper, paint) in the

installation room of the product.

1.3.9 Risk of death due to cabinet-type

casing

Cabinet-type casing can give rise to dangerous situations when used on a product which

is operated with an open flue.

▶ Ensure that the product is supplied with

sufficient combustion air.

1.3.10 Risk of poisoning caused by

insufficient supply of combustion

air

Conditions: Open-flued operation

▶ Ensure that the air supply to the product's

installation room is permanently unobstructed and sufficient in accordance with the

relevant ventilation requirements.

1.3.11 Risk of death due to lack of safety

devices

The schematic drawings included in this document do not show all safety devices required for correct installation.

▶ Install the necessary safety devices in the

system.

▶ Observe the applicable national and inter-

national laws, standards and guidelines.

1.3.12 Risk of death from electric shock

There is a risk of death from electric shock if

you touch live components.

Before commencing work on the product:

▶ Unplug the mains plug.

▶ Or disconnect the product from the power

supply by switching off all power supplies

(electrical partition with a contact opening

of at least 3 mm, e.g. fuse or line protection switch).

▶ Secure against being switched back on

again.

▶ Wait for at least 3 minutes until the con-

densers have discharged.

Page 6

1 Safety

6 Installation and maintenance instructions ecoTEC sustain 0020253094_01

1.3.13 Risk of being burned or scalded by

hot components

▶ Only carry out work on these components

once they have cooled down.

1.3.14 Risk of material damage caused by

using an unsuitable tool

▶ Use the correct tool to tighten or loosen

screw connections.

1.3.15 Risk of material damage caused by

frost

▶ Do not install the product in rooms prone

to frost.

1.3.16 Risk of corrosion damage due to

unsuitable combustion and room

air

Sprays, solvents, chlorinated cleaning

agents, paint, adhesives, ammonia compounds, dust or similar substances may lead

to corrosion on the product and in the flue

gas guiding.

▶ Ensure that the supply of combustion air is

always free of fluorine, chlorine, sulphur,

dust, etc.

▶ Ensure that no chemical substances are

stored at the installation site.

▶ If you are installing the product in

hairdressing salons, painter's or joiner's

workshops, cleaning businesses or similar

locations, choose a separate installation

room in which the room air is technically

free of chemical substances.

1.4 Regulations (directives, laws,

standards)

▶ Observe the national regulations, stand-

ards, guidelines and laws.

Page 7

Notes on the documentation 2

0020253094_01 ecoTEC sustain Installation and maintenance instructions 7

2 Notes on the documentation

2.1 Observing other applicable documents

▶ You must observe all the operating and installation in-

structions included with the system components.

2.2 Storing documents

▶ Pass these instructions and all other applicable docu-

ments on to the system operator.

2.3 Validity of the instructions

These instructions apply only to:

Product article number

ecoTEC sustain 24 VUW 246/7-2 (H-

GB)

0010019980

ecoTEC sustain 28 VUW 286/7-2 (H-

GB)

0010019981

ecoTEC sustain 34 VUW 346/7-2 (H-

GB)

0010019982

Gas Council Numbers

ecoTEC sustain 24 VUW 246/7-2 (H-

GB)

47-044-79

ecoTEC sustain 28 VUW 286/7-2 (H-

GB)

47-044-80

ecoTEC sustain 34 VUW 346/7-2 (H-

GB)

47-044-81

2.4 Benchmark

Vaillant is a licensed member of the Benchmark Scheme.

Benchmark places responsibilities on both manufacturers

and installers. The purpose is to ensure that customers are

provided with the correct equipment for their needs, that it is

installed, commissioned and serviced in accordance with the

manufacturer’s instructions by a competent person approved

at the time by the Health and Safety Executive and that it

meets the requirements of the appropriate Building Regulations. The Benchmark Checklist can be used to demonstrate compliance with Building Regulations and should be

provided to the customer for future reference.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark

Code of Practice which is available from the Heating and

Hotwater Industry Council who manage and promote the

Scheme.

Benchmark is managed and promoted by the Heating and

Hotwater Industry Council.

For more information visit www.centralheating.co.uk

3 Product description

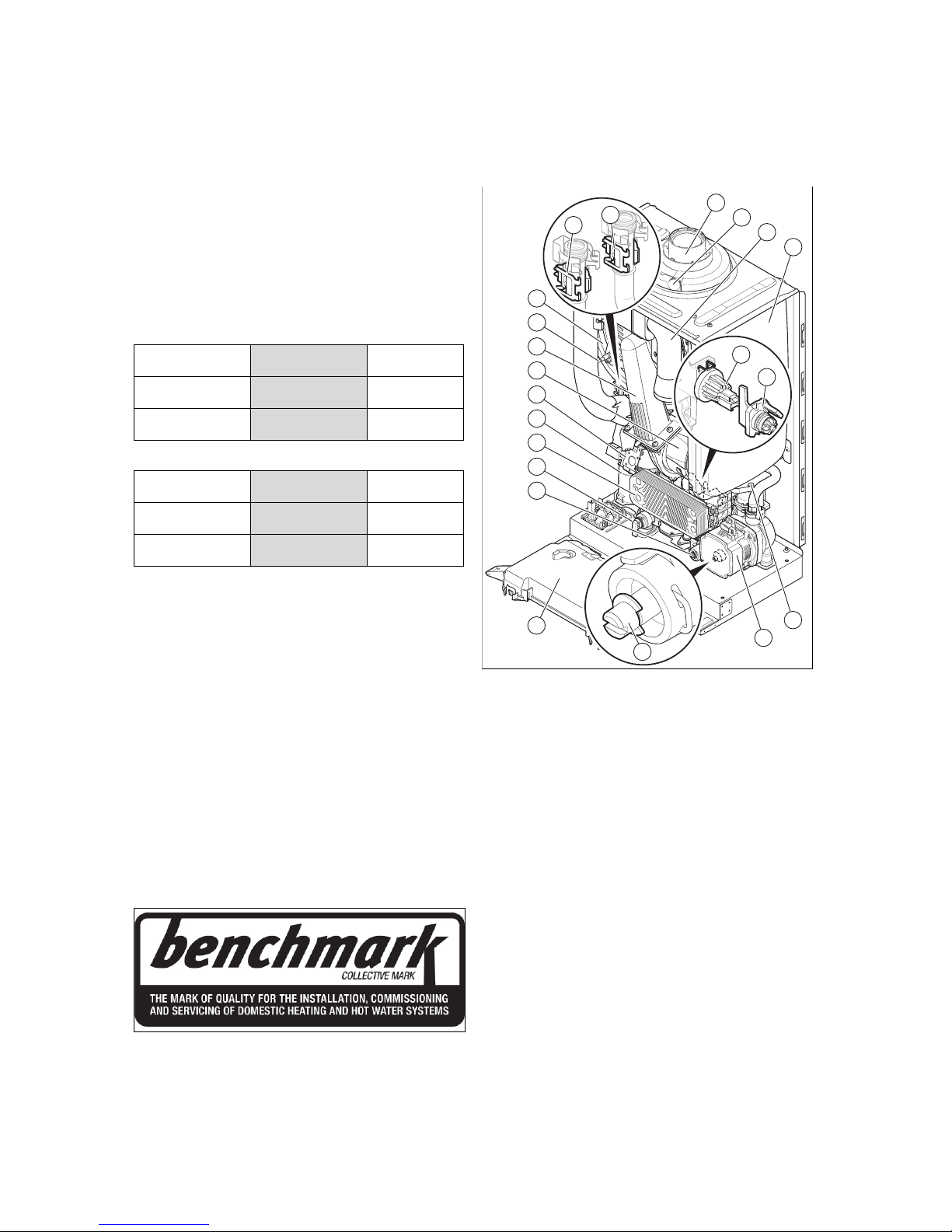

3.1 Product design

3.1.1 Functional elements

20

19

14

13

15

16

18

17

11

12

21

1

3

2

6

4

5

7

9

10

8

1 Electronics box

2 Diverter valve

3 Expansion relief valve

4 Plate heat exchanger

5 Condensate siphon

6 Gas valve

7 Fan

8 Compact thermal

module

9 Ionisation and ignition

electrode

10 Primary heat exchanger

11 Temperature sensor in

the heating flow

12 Temperature sensor in

the heating return

13 Connection for the flue

pipe

14 Flue gas measuring

stub pipe

15 Air intake pipe

16 Expansion vessel

17 Pressure sensor

18 Impeller sensor (hot

water)

19 Automatic air vent

20 Heating pump

21 Bypass

Page 8

4 Set-up

8 Installation and maintenance instructions ecoTEC sustain 0020253094_01

3.2 Information on the identification plate

The identification plate is mounted on the underside of the

product in the factory.

The identification plate keeps record of the country in which

the product is to be installed.

Information on the

identification plate

Meaning

Condensing technology

Efficiency class of the boiler in accordance with EC Directive 92/42/EEC

Serial number For quality control purposes; 3rd and 4th

digits = year of production

For quality control purposes; 5th and 6th

digits = week of production

For identification purposes; 7th to 16th

digits = product article number

For quality control purposes; 17th to 20th

digits = place of manufacture

... ecoTEC ... Product designation

Cat. Approved gas category

Type: Xx3(x) Permissible flue gas connections

2H / 2E / 3P / 2K... Gas group and gas connection pressure

as set at the factory

Tmax Max. flow temperature

PMS Maximum water pressure in heating

mode

NOx NOx class for the product

V

Hz

Electric connection

W Max. electrical power consumption

IP Protection class

Code (DSN) Specific product code

Heating mode

Qn Nominal heating load range in heating

mode

Pn Nominal heat output range in heating

mode

Pnc Nominal heat output range in heating

mode (condensing technology)

Hot water generation

Qnw Nominal heating load range in hot water

handling mode

Pnw Nominal heat output range in hot water

handling mode

D Specific flow rate

PMW Maximum water pressure in hot water

handling mode

Barcode with serial number

GC No. Gas council number

Note

Make absolutely sure that the product is compatible with the gas group at the installation site.

3.3 Serial number

The serial number can be found on a plastic label at the bottom of the front casing and on the identification plate.

3.4 CE label

The CE label shows that the products comply with the basic

requirements of the applicable directives as stated on the

identification plate.

The declaration of conformity can be viewed at the manufacturer's site.

3.5 Energy Saving Trust Endorsed Products

Only the most energy efficient products can carry the

‘Energy Saving Trust Endorsed Product’ brandmark making

it easy for consumers to choose products that have met strict

energy performance criteria.

Available for: Boilers, Heating controls and chemical inhibitors, the Energy Saving Trust endorsed product brandmark

gives consumers confidence that a product will cost less to

run, help lower energy bills and reduce carbon emissions.

About the Energy Saving Trust

Energy Saving Trust is an independent and impartial organisation that provides trusted energy saving advice to empower millions of people to lead affordable, low energy lifestyles. For more information visit energysavingtrust.org.uk

4 Set-up

4.1 Transporting the unit

Important: With regard to the regulations of 1992 concerning

the manual handling of loads, the unit exceeds the weight

that can be lifted by a single person.

4.1.1 General

▶ Hold the load as close as possible to your body. Do not

twist your body – instead, reposition your feet.

▶ If the unit is being lifted by two persons, ensure your

movements are coordinated during lifting.

▶ Avoid bending your upper body – do not lean forwards or

to the side.

▶ Wear appropriate cut-resistant and non-slip gloves to

protect yourself against sharp edges and maintain a safe

and secure grip.

▶ If required, get somebody to assist you in this.

4.1.2 Unloading the box from the delivery van

▶ It is recommended that two people lift the unit together.

▶ Lift the box using the straps provided.

▶ Use safe lifting techniques – keep your back straight and

bend your legs at the knee.

▶ Hold the load as close as possible to your body.

Page 9

Set-up 4

0020253094_01 ecoTEC sustain Installation and maintenance instructions 9

▶ If the unit is being lifted by two persons, ensure your

movements are coordinated during lifting.

▶ If required, get somebody to assist you in this.

4.2 Unpacking the product

1. Remove the product from its box.

2. Remove the protective film from all parts of the product.

4.3 Checking the scope of delivery

▶ Check that the scope of delivery is complete and intact.

4.3.1 Scope of delivery

Quantity

Description

1

Heat generator

1

Bag with accessories:

– Hanging bracket

– Bag with seals

– Bag with bolts and rawl plugs

– Installation template

– Flexible condensate drain pipework

– Bag containing the hydraulic connections

1

Enclosed documentation

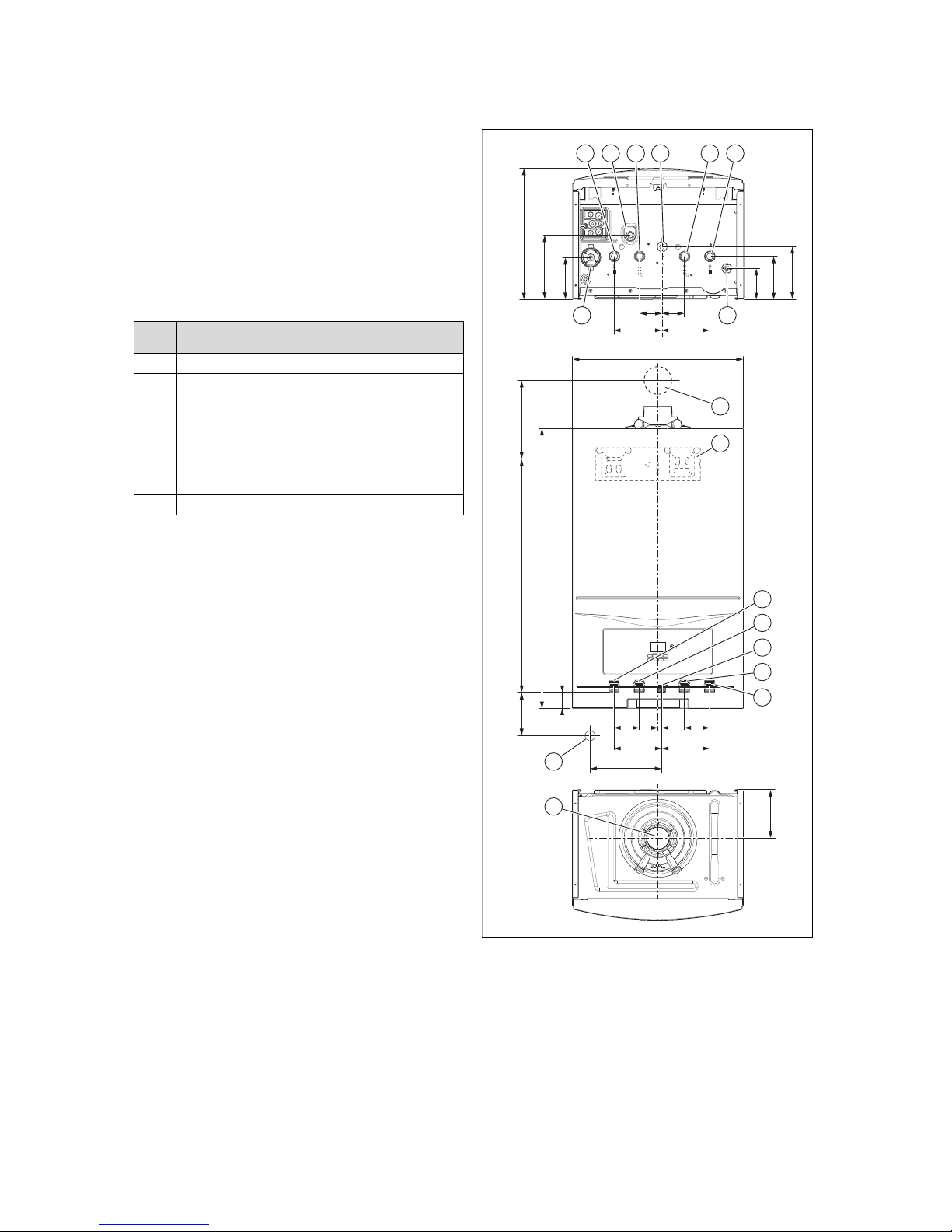

4.4 Dimensions

99

164

75

110

135

338

58 58

123123

440

125

180

40

123 123

183

65 65

600

720

A

10

1 8

9

10

11

12

2

4

5

6

7

2 43 5 6 7

1 Condensate siphon

(condensate discharge

connection, 21.5 mm

diameter)

2 Heating flow connec-

tion, G3/4

3 Heating expansion relief

valve drain pipework

connection, 15 mm

diameter

4 Hot water connection,

G3/4

5 Gas connection, G1/2

6 Cold water connection,

G3/4

7 Heating return connec-

tion, G3/4

8 Drain cock

Page 10

4 Set-up

10 Installation and maintenance instructions ecoTEC sustain 0020253094_01

9 Flue pipe wall duct

A = see installation

template (60/100 mm

diameter air/flue pipe)

A = 235 mm

(80/125 mm diameter

air/flue pipe)

10 Product holder

11 R1 tundish/condensate

siphon connection

12 Flue pipe connection

Consult the installation template that is supplied to find the

dimension A.

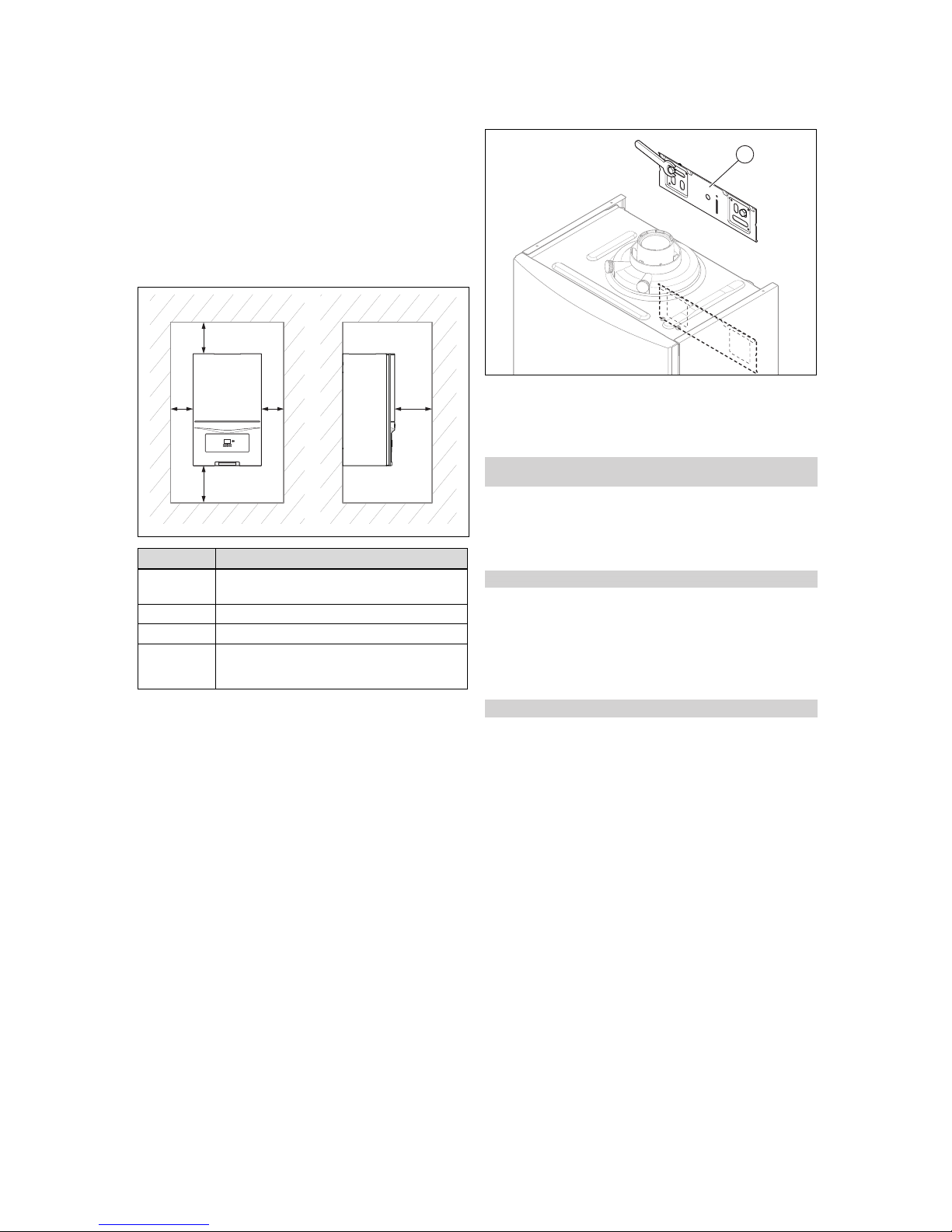

4.5 Minimum clearances

C C

AB

D

Minimum clearance

A 165 mm: Flue pipe, 60/100 mm diameter

275 mm: Flue pipe, 80/125 mm diameter

B 180 mm; optimum approx. 250 mm

C 5 mm; optimum approx. 50 mm

D 500 mm clearance in front of the heat generator

to enable easy access for maintenance work (the

same as a door opening).

4.6 Clearance from combustible components

It is not necessary to maintain a clearance between the

product and components made of combustible materials that

go beyond the minimum clearances (see page).

4.7 Using the installation template

▶ Use the installation template to ascertain the locations at

which you need to drill holes and make breakthroughs.

4.8 Wall-mounting the product

1

1. Check whether the wall has sufficient load-bearing capacity to bear the operational weight of the product.

2. Check if the supplied fixing material may be used for

the wall.

Conditions: The load-bearing capacity of the wall is sufficient, The fixing

material may be used for the wall

▶ Wall-mount the product as described.

▶ Install the hanging bracket (1) on the wall.

▶ Hang the product on the product bracket from above

using the suspension bracket.

Conditions: The load-bearing capacity of the wall is not sufficient

▶ Ensure that wall-mounting apparatus on-site has a suf-

ficient load-bearing capacity. Use individual stands or

primary walling, for example.

▶ Do not wall-mount the product if you cannot provide

wall-mounting apparatus with a sufficient load-bearing

capacity.

Conditions: The fixing material may not be used for the wall

▶ Wall-mount the product as described using the adapted

fixing material provided on-site.

Page 11

Installation 5

0020253094_01 ecoTEC sustain Installation and maintenance instructions 11

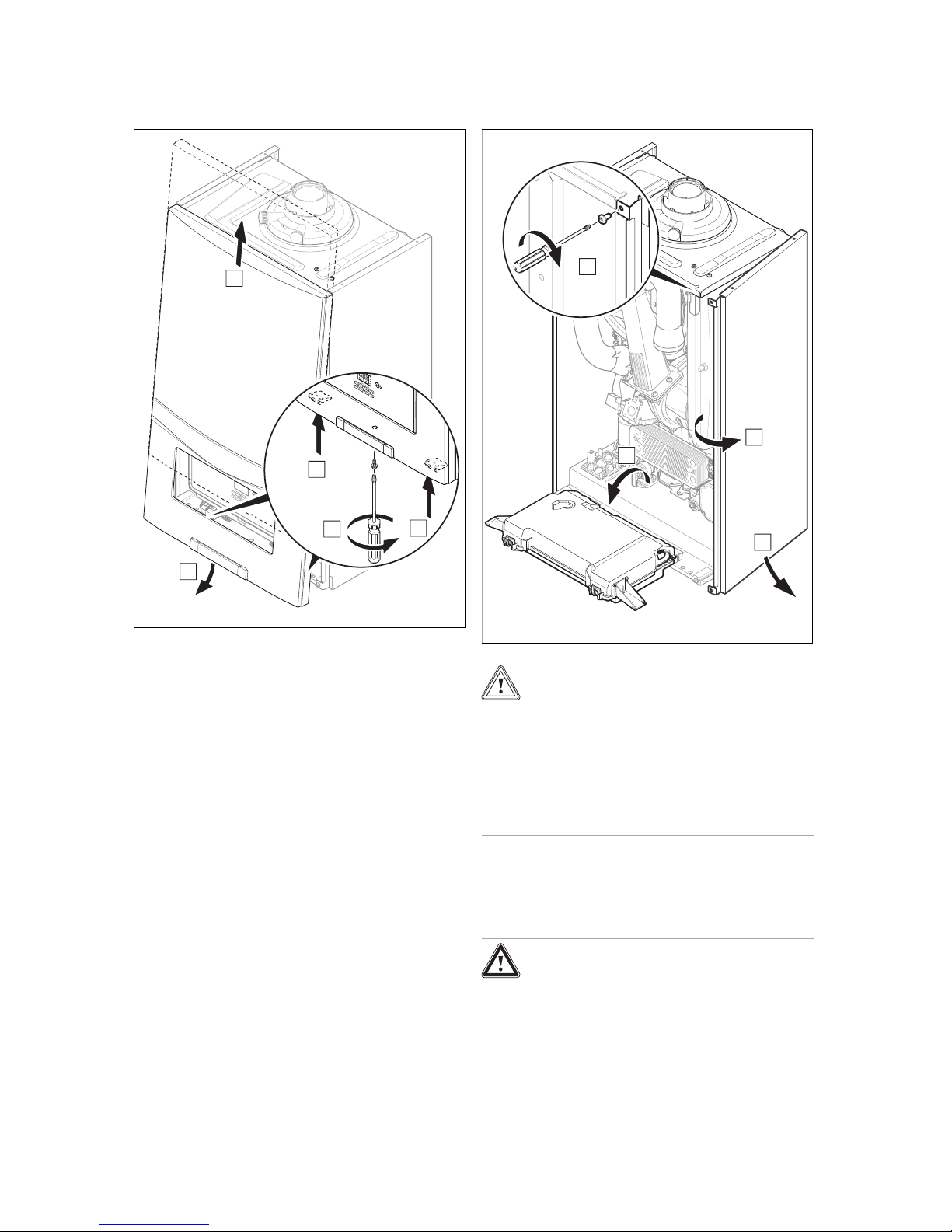

4.9 Removing the front casing

A

B

B

C

D

▶ Remove the front casing as shown in the illustration.

4.10 Removing the side section

2X

A

B

C

D

Caution.

Risk of material damage caused by mech-

anical deformation.

Removing both side sections may cause

mechanical distortion in the product, which

may cause damage to the piping, for example, and potentially result in leaks.

▶ Always only remove one side section –

never both side sections at the same time.

▶ Remove the side section as shown in the illustration.

5 Installation

Danger!

Risk of explosion or scalding caused by

incorrect installation.

Stresses in the connection cable can cause

leaks.

▶ Make sure there is no stress in the con-

nection cables when they are installed.

Page 12

5 Installation

12 Installation and maintenance instructions ecoTEC sustain 0020253094_01

Caution.

Risk of material damage due to the gas

leak-tightness test.

At a test pressure of >11 kPa (110 mbar), gas

leak-tightness tests may cause damage to

the gas valve.

▶ If, during gas leak-tightness tests, you

also place the gas lines and the gas valve

in the product under pressure, use a max.

test pressure of 11 kPa (110 mbar).

▶ If you cannot limit the test pressure to

11 kPa (110 mbar), close any gas isolator

cocks that are installed upstream from the

product before you carry out the gas leaktightness test.

▶ If, during gas leak-tightness tests, you

have closed the gas isolator cock that is

installed upstream of the product, relieve

the gas line pressure before you open this

gas isolator cock.

Caution.

Risk of material damage caused by corro-

sion

Due to non-diffusion-tight plastic pipes in the

heating installation, air gets into the heating

water. Air in the heating water causes corrosion in the heat generator circuit and in the

product.

▶ If you use non-diffusion-tight plastic pipes

in the heating installation, ensure that no

air gets into the heat generator circuit.

Caution.

Risk of material damage due to heat trans-

fer during soldering.

▶ Only solder connection pieces if the con-

nection pieces are not yet screwed to the

service valves.

Caution.

Risk of material damage caused by

changes to the connected pipes.

▶ Only bend connection pipes if they have

not yet been connected to the product.

5.1 Installation requirements

5.1.1 Information on liquid gas operation

In the as-delivered condition, the product is preset for operation with the gas group indicated on the identification plate.

If you have a product that has been preset for operation with

natural gas, you must convert it to run on liquid gas. You will

need a conversion kit for this. The conversion procedure is

described in the manual supplied with the conversion kit.

5.1.2 Purging the liquid gas tank

If the liquid gas tank is not purged properly, this may result in

ignition problems.

▶ Ensure that the liquid gas tank has been purged properly

before installing the product.

▶ If required, contact the filler or the liquid gas supplier.

5.1.3 Using the correct type of gas

Using the incorrect type of gas may cause fault shutdowns in

the product. Ignition and combustion noise may occur in the

product.

▶ Only use the gas type listed on the identification plate.

5.1.4 Required preliminary work

1. Make sure that the existing gas meter is capable of

passing the rate of gas supply required.

2. Install a system separator (to be provided on-site) directly on the cold water connection for the combination

unit.

3. Check that the volumetric capacity of the expansion

vessel is sufficient for the system volume.

▽ If the volume of the expansion vessel is insufficient

for the system.

▶ Install an additional expansion vessel in the

heating return, as close to the product as possible.

▶ Install a non-return flap at the product's outlet

(heating flow).

4. Ensure that the system has the following components:

– A cold water stop cock for the unit

– A gas stopcock for the unit

– A filling and draining device in the heating installa-

tion

Page 13

Installation 5

0020253094_01 ecoTEC sustain Installation and maintenance instructions 13

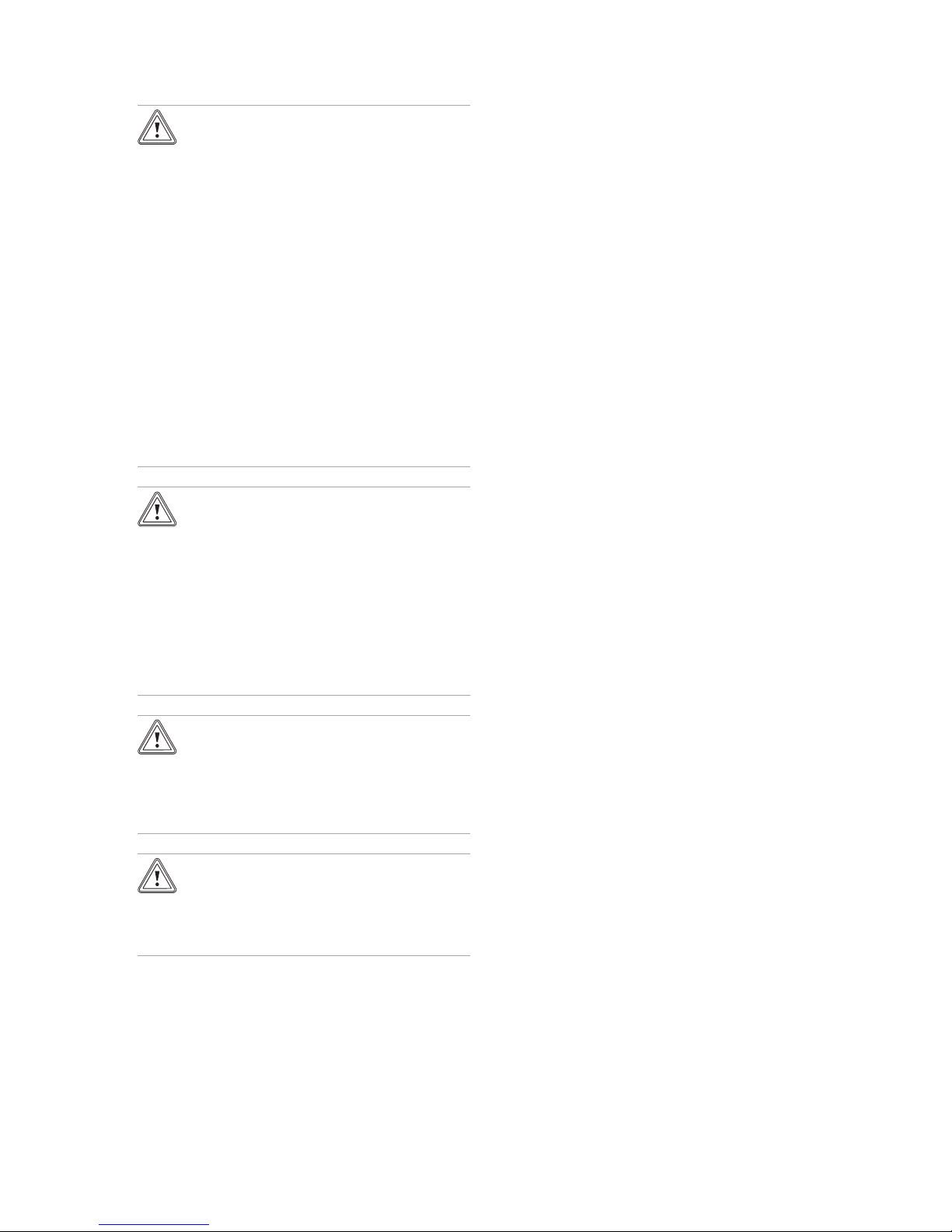

5.2 Gas and water connections

1

2

3

4

5

1 Heating flow connec-

tion, G3/4

2 Hot water connection,

G3/4

3 Gas connection, G1/2

4 Connection for the cold

water supply line, G3/4

5 Heating return connec-

tion, G3/4

1. Connect the water and gas connections in accordance

with the applicable standards.

2. Purge the gas line before start-up.

3. Check whether the connections (→ Page 22) are leaktight.

4. Check the entire gas line properly for leak-tightness.

5.3 Connecting the condensate drain pipework

min.

180

1

2

▶ Follow the instructions listed here and observe directives

and local regulations on condensed water discharge.

▶ Use PVC or another material that is suitable for draining

the non-neutralised condensed water.

▶ If you cannot guarantee that the materials from which the

condensate discharge pipe is made are suitable, install a

system to neutralise the condensate.

Note

The condensate drain pipework must have a

continuous fall (45 mm per metre) and should

whenever possible terminate at a suitable

drain point within the heated envelope of the

building that will remain frost free under long

periods of low external temperatures.

▶ Connect the condensate siphon (1). Use the supplied

condensate drain hose (2) to do this.

▶ Connect a condensate discharge pipe (21.5 mm, not in-

cluded in the scope of delivery) to the condensate discharge hose (2).

▶ During installation remove all burs from inside of cut pipe

work and avoid excessive adhesive which may trap small

pockets of water close to the pipe wall which can freeze

and build into a larger ice plug.

▶ As with other pipe work insulate the condensate dis-

charge pipe to minimise any risk of freezing and beware

when crossing cavities that the fall is maintained and the

pipe sleeved.

You can find further information in the "BS 6798" specification for installing and maintaining gas-fired boilers with a

nominal heat load of less than 70 kW.

5.4 Installing the discharge pipe on the

expansion relief valve

1

1. Ensure that the pipeline is visible.

2. Connect the expansion relief valve (1).

3. The pipe must have a continuous fall and be routed

to a position so that any discharge of water, possibly

boiling, or steam cannot create any danger to persons,

damage to property or external electrical components

and wiring.

◁ The components must be set up in such a way that

you can see the water flowing out.

5.5 Flue installation

5.5.1 Installing and connecting the flue pipe

1. You can find out which flue pipes may be used by con-

sulting the enclosed flue pipe installation manual.

Conditions: Installation in damp rooms

▶ You must connect the product to a room-sealed air/flue

gas installation. The combustion air must not be taken

from the installation site.

Caution.

Risk of poisoning due to escaping flue

gas.

Mineral-oil-based greases can damage the

seals.

▶ Instead of grease, use only water or com-

mercially available soft soap to aid installation.

2. Install the flue pipe using the installation manual.

Page 14

5 Installation

14 Installation and maintenance instructions ecoTEC sustain 0020253094_01

5.5.2 Replacing the connection piece for the

air/flue pipe as required

1. Replace the connection piece for the air/flue pipe as

required. The product-specific standard equipment is

listed under Technical data.

2. Remove the connection piece for the air/flue pipe – this

is installed at the factory. (→ Page 14)

3.

Alternatives 1 / 2

▶ If required, install the connection piece for the

air/flue pipe, 80/125 mm diameter. (→ Page 14)

3.

Alternatives 2 / 2

▶ If required, install the connection piece with

offset for the air/flue pipe, 60/100 mm diameter.

(→ Page 14)

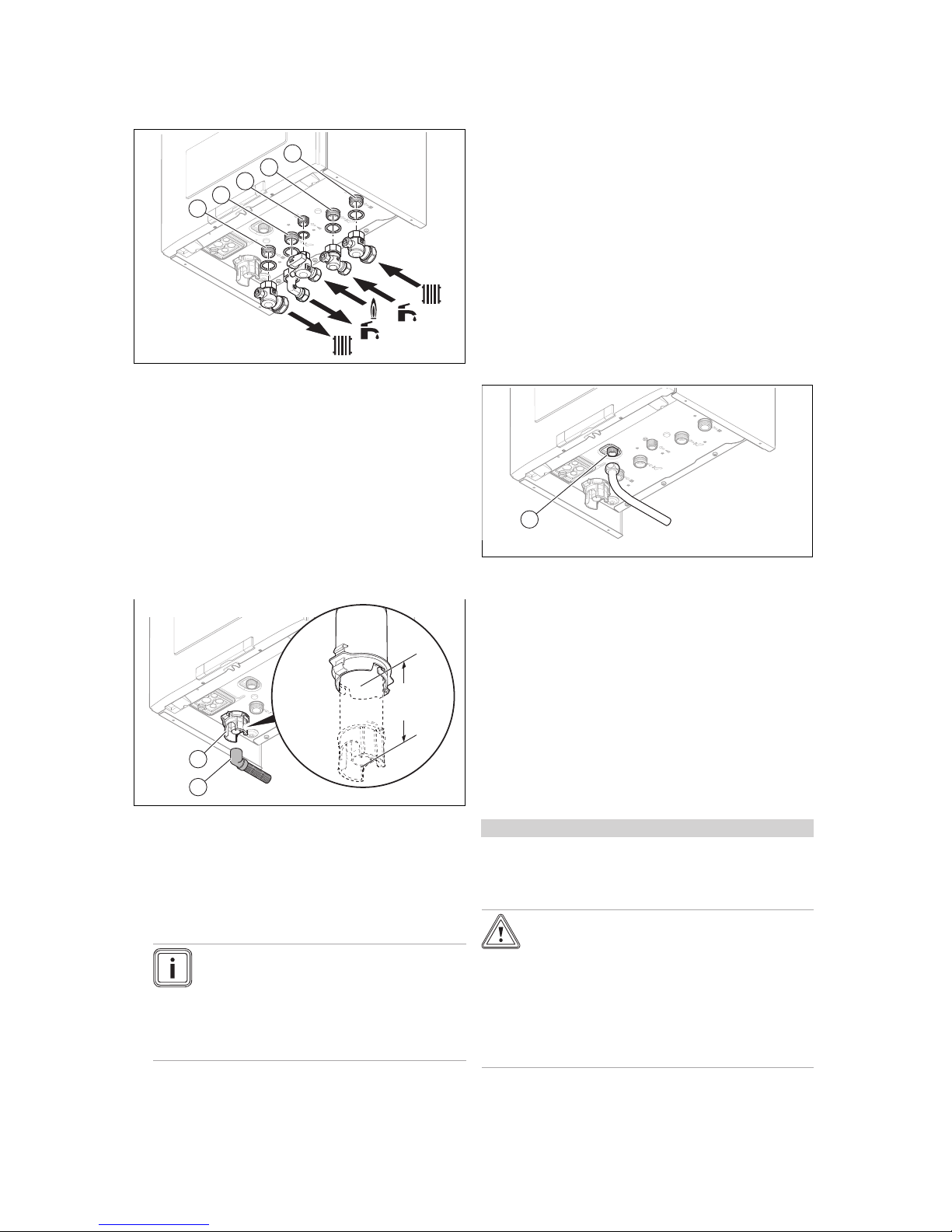

5.5.2.1 Removing the connection piece for the

air/flue pipe

A

B

C

1. Insert a screwdriver into the gap between the measur-

ing points.

2. Press the screwdriver carefully down.

3. Turn the connection piece anticlockwise as far as it will

go and then remove it by pulling it upwards.

5.5.2.2 Installing the connection piece for the

air/flue pipe, 80/125 mm diameter

1. Remove the connection piece for the air/flue pipe – this

is installed at the factory. (→ Page 14)

2. Insert the alternative connection piece. Pay attention to

the lugs.

3. Turn the connection piece clockwise until it clicks into

position.

5.5.2.3 Installing the connection piece with offset

for the air/flue pipe, 60/100 mm diameter

1. Remove the connection piece for the air/flue pipe – this

is installed at the factory. (→ Page 14)

65

1

2. Insert the alternative connection piece with offset towards the front.

3. Use two screws (1) to secure the connection piece to

the product.

5.6 Electrical installation

The electrical installation must only be carried out by a qualified electrician.

Danger!

Risk of death from electric shock!

Since mains connection terminals L and N remain live even if the on/off button is switched

off:

▶ Switch off the power supply.

▶ Secure the power supply against being

switched on again.

5.6.1 Opening the electronics box

B

B

A

▶ Open the electronics box as shown in the illustration.

Page 15

Installation 5

0020253094_01 ecoTEC sustain Installation and maintenance instructions 15

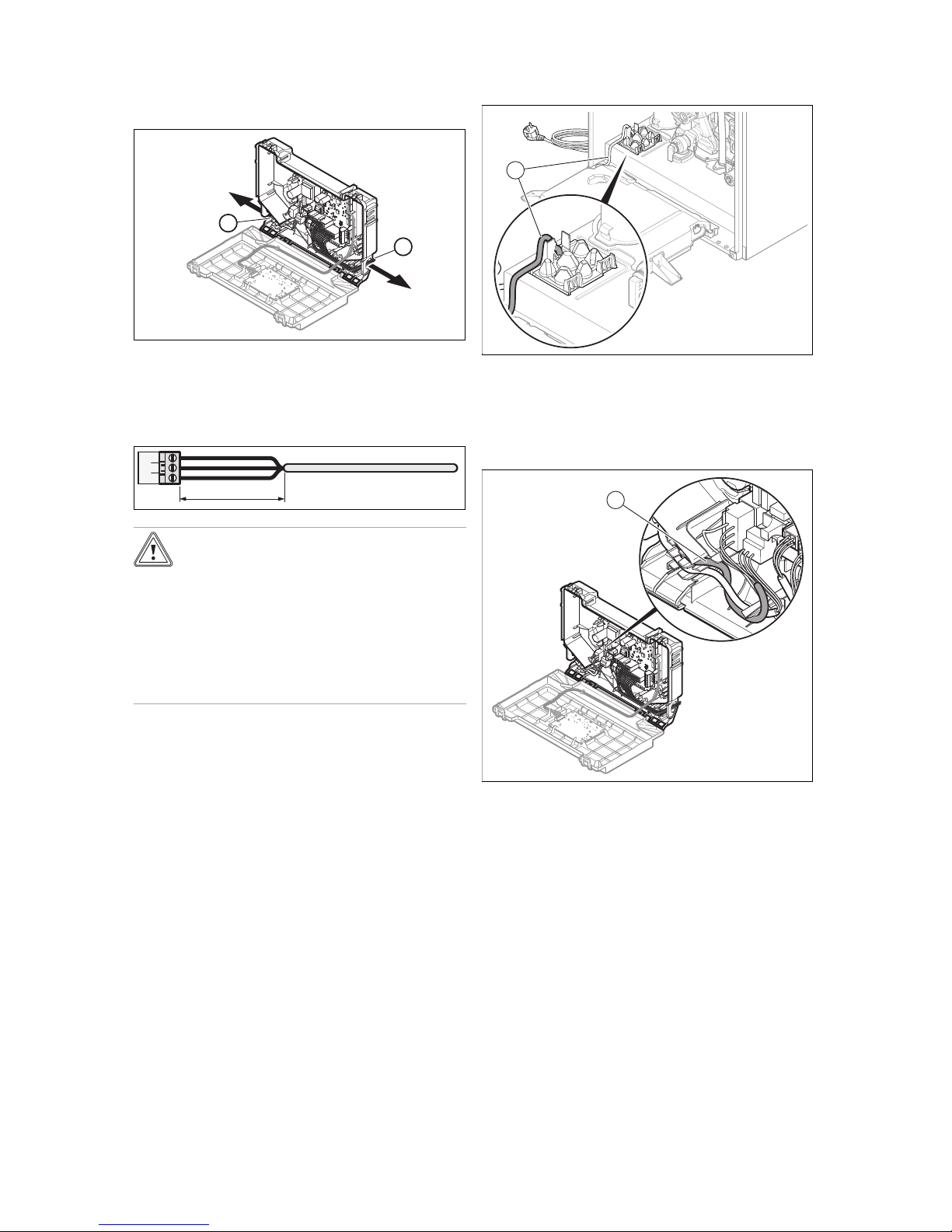

5.6.2 Cable route

1

2

1 24-V eBUS cable route

2 230-V eBUS cable route

5.6.3 Wiring

30 mm max.

Caution.

Risk of material damage caused by incor-

rect installation.

Mains voltage at incorrect terminals and plug

terminals may destroy the electronics.

▶ Do not connect any mains voltage to the

eBUS terminals (+/-).

▶ Only connect the mains connection cable

to the terminals marked for the purpose.

1. Shorten the connection cables to the appropriate

lengths to prevent them from causing damage inside

the electronics box.

2. Screw the plug to the connection cable.

3. Plug the plug into the slot provided on the PCB.

5.6.4 Establishing the power supply

1. Observe all valid regulations.

– The applicable regulations state that the connection

must be made via an electrical partition with a contact opening of at least 3 mm at each pole.

– Power supply cable: Flexible line

2. Make sure that the rated voltage of the mains is 230 V.

1

3. Route a three-core power supply cable that complies

with the relevant standards through the grommet and

into the product.

4. Observe the routing of the power supply cable (1) in the

grommet in order to guarantee that there is no strain.

5. Open the electronics box. (→ Page 14)

1

6. Observe the flow of the power supply cable (1) in the

electronics box in order to guarantee that there is no

strain.

7. Provide one common electricity supply for the boiler

and for the corresponding controller:

– Power supply: Single-phase, 230 V, 50 Hz

– Fuse: ≤ 3 A

Page 16

6 Operation

16 Installation and maintenance instructions ecoTEC sustain 0020253094_01

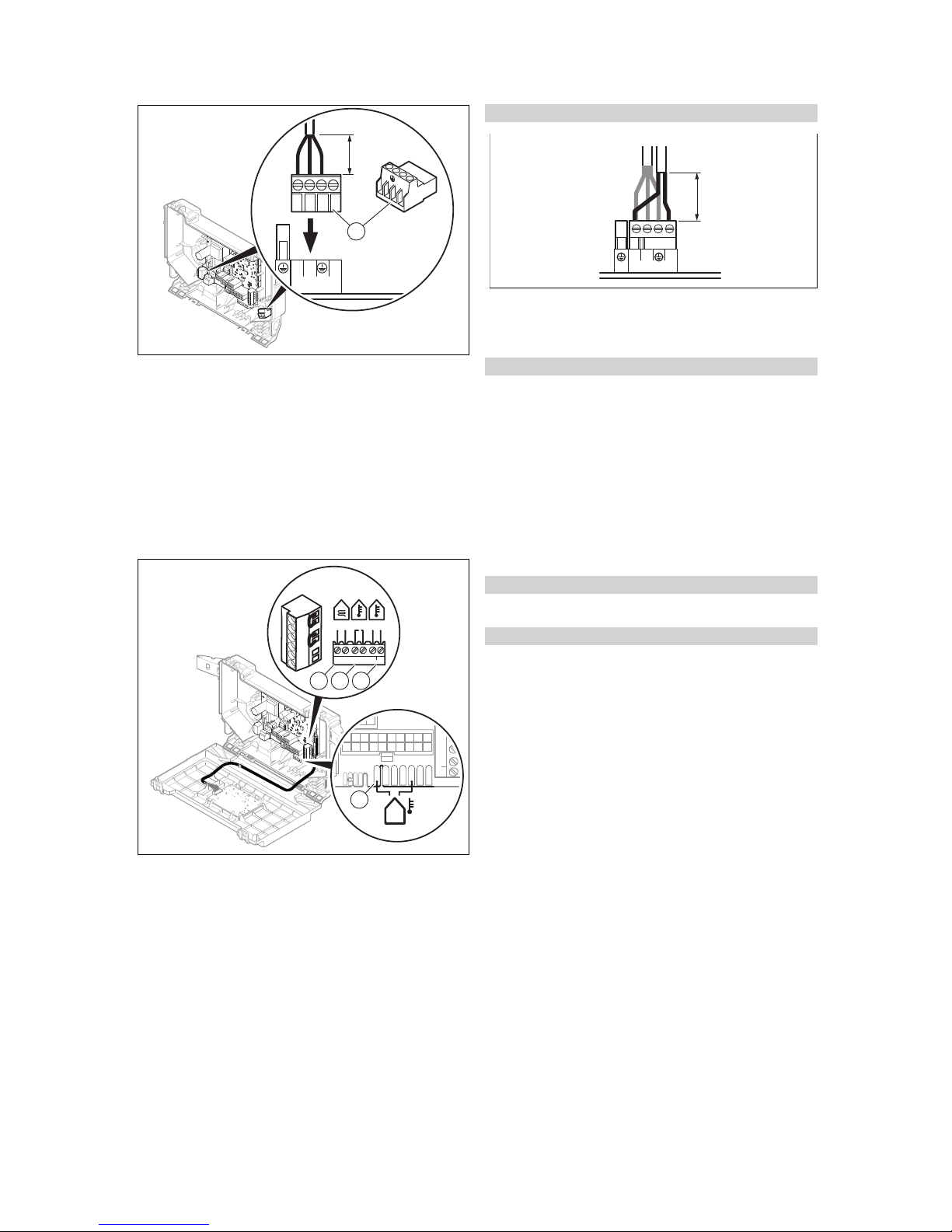

≤ 30 mm

N

RT

230V~

X1

L

N

RT

L

1

8. Wire the unit. (→ Page 15)

9. Screw the supplied plug (1) to a three-core power supply cable that complies with the relevant standards.

10. Plug the plug for the power supply cable into a suitable

plug socket.

11. Make sure that access to the power supply is always

available and is not covered or blocked.

12. Close the electronics box.

5.6.5 Connecting controllers to the electronic

system

–

+

24V=

RT BUS

Burner

off

X106

BUS24 V

BUSRTB.off

Burn

er

o

f

f

R

T

24V =

-

+

BUS

X2

X41

X22

–

+

24V=

RT BUS

Burner

off

X106

1

2 3

4

1 Safety thermostat for

underfloor heating

2 24 V (ON/OFF) control

3 eBUS controller or radio

receiver unit

4 Outside temperature

sensor, wired

1. Open the electronics box (→ Page 14).

2. Wire the unit. (→ Page 15)

3. Connect the individual components depending on the

type of installation.

Conditions: If you are connecting a controller (230 V).

≤ 30 mm

NL

X1

230V~

RT

▶ Connect the controller to the main plug.

▶ Remove the bridge from the plug 24V=RT.

4. Close the electronics box.

Conditions: Connecting a limit thermostat for underfloor heating

▶ Remove the bridge and connect the limit thermostat to

the Burner off connection.

▶ Close the electronics box.

▶ For multi-circuit controllers (→ Page 17), change the

parameter d.18 from Eco (intermittently operating pump)

to Confort (continuously operating pump).

5.6.6 Connecting additional components via

VR 40 ("2 in 7" multi-functional module)

1. Install the components in accordance with the respect-

ive instructions.

Conditions: Components connected to relay 1

▶ Activate (→ Page 17) D.27.

Conditions: Components connected to relay 2

▶ Activate (→ Page 17) D.28.

6 Operation

6.1 Operating concept

The operating concept and the display and setting facilities

of the operator level are described in the operating instructions.

An overview of the display and setting options in the installer

level can be found in the section "Overview of the installer

level". (→ Page 17)

Page 17

Operation 6

0020253094_01 ecoTEC sustain Installation and maintenance instructions 17

6.2 Installer level overview

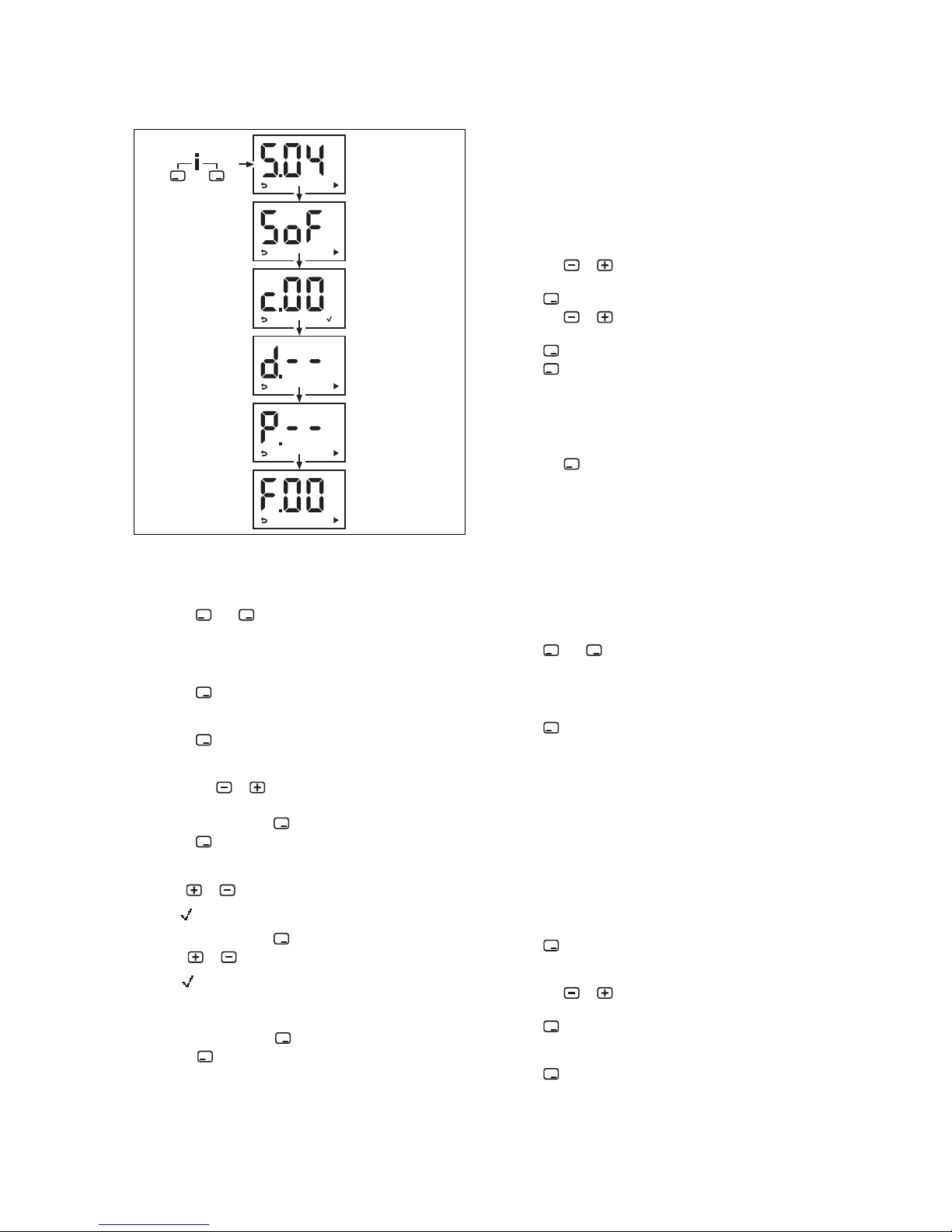

6.3 Calling up the installer level

1. Only call up the installer level if you are a competent

person.

2.

Press and ("i") at the same time.

◁ S.xx (current unit status) appears in the display,

followed by the heating flow temperature and the

heating installation pressure.

3.

Press to access the installer level.

◁ SoF and the software version appear in the display.

4.

Press .

◁ c.00 appears in the display.

5.

Press the or button to change the installer code.

– Installer code: 17

6.

Confirm by pressing .

7.

Press to access the diagnostics codes (d.), the

check programmes (P.) and the fault codes (F.) and to

return to the diagnostics codes (d.).

8.

Use or to set the required value .

◁

appears in the display.

9.

Confirm by pressing .

10.

Use or to set the required value .

◁

appears in the display if the value can be set.

◁ "no" appears in the display if the value cannot be

set.

11.

Confirm by pressing .

12.

Press to cancel a setting or exit the installer level.

6.4 Using diagnostics codes

You can use the parameters marked as adjustable in the

table of diagnostics codes to adapt the product to the system

and customer requirements.

6.4.1 Setting a diagnostics code

1. Call up the installer level. (→ Page 17)

◁ d.-- is shown in the display.

2.

Press the or button to select the diagnostics

code.

3.

Press to confirm.

4.

Press the or button to set the value of the diagnostic code.

5.

Press to confirm.

6.

Press to return to the sequence.

◁ The diagnostics codes are shown in the display

once again.

7. Proceed accordingly for all parameters that need to be

changed.

8.

Press the button 2 times to exit the diagnostics code

configuration.

◁ The display switches to the basic display.

6.5 Displaying the status codes

The status codes display the product's current operating

status.

Status codes – Overview (→ Page 38)

6.5.1 Live Monitor (status codes)

1.

Press and ("i") at the same time.

◁ The S.xx message appears in the display, followed

by information about the installation (→ Activating

access for the competent person).

2.

Press .

◁ The display switches to the basic display.

6.6 Using check programmes

By activating various check programmes, you can trigger

various special functions on the product.

Check programmes – Overview (→ Page 34)

6.6.1 Calling up the check programmes

1. Call up the installer level. (→ Page 17)

◁ d.-- is shown in the display.

2.

Press .

◁ P.-- is shown in the display.

3.

Press the or button to select the check

programme.

4.

Press to confirm.

◁ The check programme starts.

5.

Press .

Page 18

7 Start-up

18 Installation and maintenance instructions ecoTEC sustain 0020253094_01

◁ The heating water temperature and the filling pres-

sure for the heating installation are shown alternately in the display.

6.

Press to return to the check programme.

◁ The display shows the check programme.

7.

Press to exit the check programme.

◁ OFF is shown in the display.

◁ The display changes to show the check pro-

grammes.

8.

Press the button 2 times to exit the check

programme.

◁ The End message appears in the display.

◁ The display switches to the basic display.

7 Start-up

7.1 Carrying out the initial start-up

Initial start-up must be carried out by a customer service

technician or an authorised competent person using the firstcommissioning-checklist. The first-commissioning-checklist

in the appendix (→ Page 46) of the installation instructions

must be filled in and stored carefully along with the unit's

documentation.

▶ Carry out the initial start-up using the first-commission-

ing-checklist in the appendix.

▶ Fill out and sign the first-commissioning-checklist.

7.2 Gas type check

Make sure that the product is set up correctly by checking

the type of gas. This ensures optimum combustion quality.

▶ Check the type of gas as part of routine product mainten-

ance work when replacing components, carrying out work

on the gas route and carrying out a gas conversion.

7.3 Checking the factory setting

The product combustion is checked on-site and pre-set to

the type of gas specified on the identification plate.

▶ Check the information about the type of gas indicated on

the identification plate and compare this with the type of

gas available at the installation location.

Conditions: The product design is not compatible with the local type of

gas

You will require the conversion kit for the gas conversion;

this kit also contains the required conversion instructions.

▶ Follow the instructions in the manual for the conversion

kit to carry out the gas conversion on the product.

Conditions: The product design is compatible with the local type of gas

▶ Proceed in accordance with the description in these in-

structions.

7.4 Checking and treating the heating

water/filling and supplementary water

Caution.

Risk of material damage due to poor-qual-

ity heating water

▶ Ensure that the heating water is of suffi-

cient quality.

▶ Before filling or topping up the system, check the quality

of the heating water.

Checking the quality of the heating water

▶ Remove a little water from the heating circuit.

▶ Check the appearance of the heating water.

▶ If you ascertain that it contains sedimentary materials,

you must desludge the system.

▶ Use a magnetic rod to check whether it contains mag-

netite (iron oxide).

▶ If you ascertain that it contains magnetite, clean the sys-

tem and apply suitable corrosion-protection measures, or

fit a magnet filter.

▶ Check the pH value of the removed water at 25 °C.

▶ If the value is below 8.2 or above 10.0, clean the system

and treat the heating water.

▶ Ensure that oxygen cannot get into the heating water.

Checking the filling and supplementary water

▶ Before filling the system, measure the hardness of the

filling and supplementary water.

Treating the filling and supplementary water

▶ Observe all applicable national regulations and technical

standards when treating the filling and supplementary

water.

Provided the national regulations and technical standards

do not stipulate more stringent requirements, the following

applies:

You must treat the heating water in the following cases:

– If the entire filling and supplementary water quantity dur-

ing the operating life of the system exceeds three times

the nominal volume of the heating installation, or

– If the guideline values listed in the following table are not

met, or

– If the pH value of the heating water is less than 8.2 or

more than 10.0.

Total

heating

output

Water hardness at specific system volume

1)

≤ 20 l/kW

> 20 l/kW

≤ 50 l/kW

> 50 l/kW

kW

ppm

CaCO₃

mol/m³ppm

CaCO₃

mol/m³ppm

CaCO₃

mol/

m³

< 50 < 300 < 3 200 2 2 0.02

> 50

to ≤ 200

200 2 150 1.5 2 0.02

> 200

to ≤ 600

150 1.5 2 0.02 2 0.02

> 600 2 0.02 2 0.02 2 0.02

1) Nominal capacity in litres/heating output; in the case of multiboiler systems, the smallest single heating output is to be used.

Page 19

Start-up 7

0020253094_01 ecoTEC sustain Installation and maintenance instructions 19

Caution.

Risk of material damage if the heating

water is treated with unsuitable additives.

Unsuitable additives may cause changes in

the components, noises in heating mode and

possibly subsequent damage.

▶ Do not use any unsuitable frost and cor-

rosion protection agents, biocides or sealants.

No incompatibility with our products has been detected to

date with proper use of the following additives.

▶ When using additives, follow the manufacturer's instruc-

tions without exception.

We accept no liability for the compatibility of any additive or

its effectiveness in the rest of the heating system.

Additives for cleaning measures (subsequent

flushing required)

– Adey MC3+

– Adey MC5

– Fernox F3

– Sentinel X 300

– Sentinel X 400

Additives intended to remain permanently in the

system

– Adey MC1+

– Fernox F1

– Fernox F2

– Sentinel X 100

– Sentinel X 200

Additives for frost protection intended to remain

permanently in the system

– Adey MC ZERO

– Fernox Antifreeze Alphi 11

– Sentinel X 500

▶ If you have used the above-mentioned additives, inform

the operator about the measures that are required.

▶ Inform the operator about the measures required for frost

protection.

7.5 Preventing low water pressure

The required filling pressure is between 0.08 and 0.2 MPa

(0.8 and 2 bar).

If the water pressure falls below 0.05 MPa (0.5 bar), the

value flashes in the display.

If the water pressure falls below 0.03 MPa (0.3 bar), the

product switches off. The display shows 0.0 bar (0.0 MPa).

Fault F22 is stored in the fault list.

▶ Top up the water in the heating installation to start up the

product again.

◁ The pressure value flashes in the display until a

pressure of 0.05 MPa (0.5 bar) or higher has been

reached.

7.6 Filling the condensate siphon

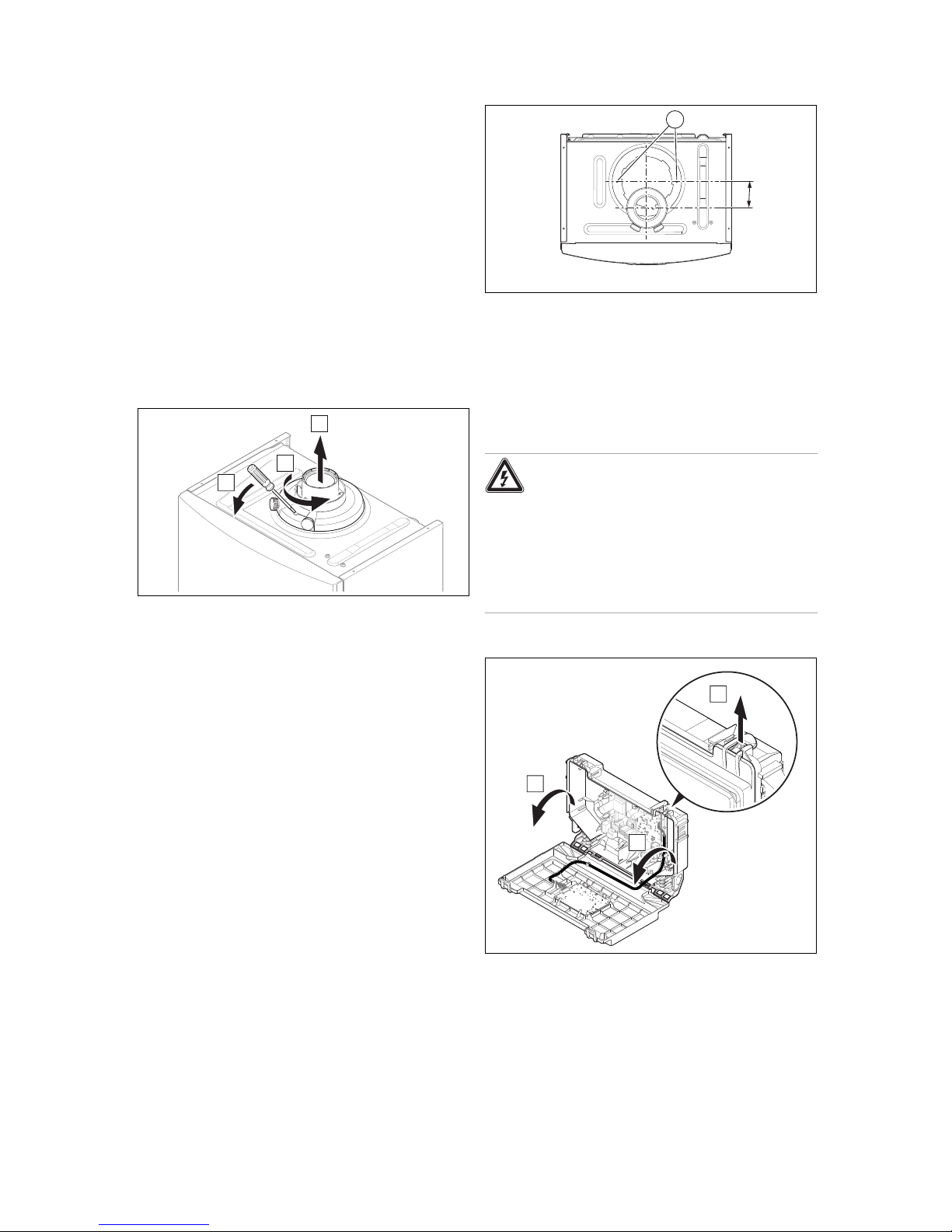

A B

C

1

2

3

1. Unclip the lower section of the siphon (1) from the upper section of the siphon (2) without removing the product's front casing.

2. Remove the float (3).

3. Fill the lower section of the siphon with water up to 10

mm below the upper edge of the condensate discharge

pipe.

4. Reinsert the float (3).

Note

Check that the float is present in the condensate siphon.

5. Clip the lower section of the siphon (1) into the upper

section of the siphon (2).

7.7 Filling and purging the heating installation

Preliminary work

1. Flush the heating installation through.

2. Observe the information on the topic of treating

(→ Page 18) heating water.

1

1. Loosen the cap on the automatic air vent (1) by one or

two rotations.

2. Open all thermostatic radiator valves.

3. Supply the heating circuit with water.

4. Check whether the stop cocks for the heating flow and

return are open.

5. Start filling programme P.06.

Page 20

7 Start-up

20 Installation and maintenance instructions ecoTEC sustain 0020253094_01

Check programmes – Overview (→ Page 34)

◁ The diverter valve is moved to the mid-position.

6. Fill with water until the required filling pressure is

reached.

– Recommended filling pressure: 0.8 … 2 bar

◁ The heating and hot water function cannot be activ-

ated.

◁ The pressure value flashes in the display until a

pressure of 0.05 MPa (0.5 bar) or higher has been

reached.

◁ An automatic air vent function is activated if the

pressure exceeds 0.07 MPa (0.7 bar) for longer than

15 seconds.

7. Purge each radiator until the water escapes normally,

and then close the system's purging valves.

Note

Leave the cap on the pump's air vent valve

unscrewed.

8. Check whether all connections are leak-tight.

Conditions: If the noise persists in the boiler

▶ Purge the product again by activating check programme

P.00.

Check programmes – Overview (→ Page 34)

7.8 Filling the hot water circuit

1. Open the taps to fill the hot water circuit.

2. Close the taps once the required volume of water has

flowed into the circuit.

◁ The hot water circuit is filled.

3. Check all connections and the entire system for leaktightness.

7.9 Switching the product on and off

▶ Press the on/off button on the product.

◁ The basic display appears on the display.

7.10 Checking the gas settings

Only a qualified competent person is authorised to implement the CO2 setting on the gas valve assembly.

Never modify the factory setting of the gas pressure regulator of the gas valve.

7.10.1 Checking the gas flow rate

The gas flow rate has been set during production and does

not require adjustment. With the front casing fitted check the

gas flow rate of the boiler as follows:

▶ Start up the product with the check programme P.01.

▶ In addition, ensure that maximum heat can be dissipated

into the heating system by turning up the room thermostat.

▶ Wait at least 5 minutes until the boiler has reached its

operating temperature.

▶ Ensure that all other gas appliances in the property are

turned off.

▶ Measure the gas flow rate at the gas meter.

▶ Compare the measured values with the corresponding

values in the table.

Qnw from

the data

plate

H gas in m³/h P gas in m³/h

Nom.

+5%

−10% Nom.

+5%

−10%

24,4 2,58 2,71 2,32 1,90 2,00 1,71

28,5 3,02 3,17 2,72 2,21 2,32 1,99

34,6 3,66 3,84 3,29 2,69 2,82 2,42

Conditions: Gas flow rate not in the permissible range

▶ Check all of the piping and ensure that the gas flow rates

are correct.

▶ Only put the product into operation once the gas flow

rates have been corrected.

Conditions: Gas flow rate in the permissible range

▶ End the check programme P.01.

▶ Allow the boiler to cool down by allowing pump overrun to

operate for a minimum of 2 minutes.

▶ Record the boiler maximum gas flow rate onto the

Benchmark gas boiler commissioning checklist.

7.10.2 Checking the gas connection pressure (gas

flow pressure)

2

1

1. Ensure that the gas inlet working pressure can be

obtained with all other gas appliances in the property

working.

2. Close the gas isolator cock (1).

3. Undo the sealing screw on the measuring nipple (2).

4. Connect a pressure gauge to the measuring nipple (2).

5. Open the gas isolator cock (1).

6. Start up the product with check programme P.01.

7. In addition, ensure that maximum heat can be dissip-

ated into the heating system by turning up the room

thermostat.

8. With the boiler operating at full load check that the gas

inlet working pressure at the reference test point (2)

complies with the requirements.

Permissible connection pressure

Great Britain

Natural gas G20

1.7

… 2.0 kPa

(17.0

… 20.0 mbar)

Liquid gas G31

2.5

… 4.5 kPa

(25.0

… 45.0 mbar)

9. Should the pressure recorded at the reference test point

in the boiler be lower than indicated check if there is

Page 21

Start-up 7

0020253094_01 ecoTEC sustain Installation and maintenance instructions 21

any blockage in the pipework or if the pipework is undersized.

Conditions: Gas flow pressure not in the permissible range

Caution.

Risk of material damage and operating

faults caused by incorrect gas connection pressure.

If the gas connection pressure lies outside

the permissible range, this can cause operating faults in and damage to the product.

▶ Do not make any adjustments to the

product.

▶ Do not start up the product.

▶ If you cannot correct the failure, notify the gas supply

company and proceed as follows:

▶ End the check programme P.01 or P.04.

▶ Allow the boiler to cool down by allowing pump overrun

to operate for a minimum of two minutes.

▶ Close the gas isolator cock.

▶ Remove the pressure gauge and retighten the sealing

screw (2) for the measuring nipple.

▶ Open the gas isolator cock (1).

▶ Check the measuring nipple for gas tightness.

▶ Close the gas isolator cock (1).

▶ Disconnect the product from the power mains.

▶ You must not start up the boiler.

Conditions: Gas flow pressure in the permissible range

▶ End the check programme P.01 or P.04.

▶ Allow the boiler to cool down allowing pump overrun to

operate for a minimum of two minutes.

▶ Close the gas isolator cock (1).

▶ Remove the pressure gauge and retighten the sealing

screw (2) for the measuring nipple.

▶ Open the gas isolator cock (1).

▶ Check the measuring nipple for gas tightness.

▶ Reset boiler controls for normal operation.

▶ Record the appliance gas inlet working pressure (kPa

resp. mbar) in the Benchmark gas boiler commissioning

checklist.

7.10.3 Checking the leak-tightness of the flue gas

installation and flue gas recirculation

1. Check the flue gas installation is intact in accordance

with the latest gas safe technical bulletin and information supplied in the installation instructions.

2. For extended flue gas installations check for flue gas

recirculation using the air analysis point.

3. Use a flue gas analyser.

4. If you discover CO or CO2in the supply air, search for

the leak in the flue gas installation or for signs of flue

gas recirculation.

5. Eliminate the damage properly.

6. Check again whether the supply air contains any CO or

CO2.

7. If you cannot eliminate the damage, do not start up the

product.

7.10.4 Thoroughly flushing the heating installation

("hot")

1. Operate the appliance until the boiler and the heating

system are up to temperature.

2. Check the heating system for leaks.

3. Connect a hose to the drain valve located at the lowest

position of the heating system.

4. Shut off the boiler, open the drain valve and all purge

valves on the radiators and allow the water to flow out

of the heating system and the boiler quickly and fully.

5. Close the drain valve.

6. Re-fill the system until the system design pressure of

0,1 MPa (1,0 bar) is attained.

Note

The actual reading on the digital pressure

gauge should ideally be 0,05 MPa (0,5 bar)

plus an additional pressure corresponding

to the highest point of the system above the

base of the boiler – 10 m head equals an additional 1 bar reading on the pressure gauge.

The minimum pressure should not be less

than 0,1 MPa (1 bar) in any installation. If

the system is to be treated with an inhibitor it

should be applied at this stage in accordance

with the manufacturer’s instructions. Further

information can be obtained from Sentinel,

Betz Dearborn Ltd., Tel: 0151 420 9595, or

Fernox, Alpha– Fry technologies. Tel: 0870

8700362.

7. Fit the front panel.

7.10.5 Checking the CO₂ content

1. Start up the product with the check programme and set

the value.

– Setting value for the programme P.01: 100

Check programmes – Overview (→ Page 34)

2. Wait until the value that is read is stable.

– Waiting period for reading a stable value: 5 min

1

3. Unscrew the cover from the flue gas analysis point (1).

4. Measure the CO₂ content at the flue gas analysis point.

5. Compare the measured value with the corresponding

value in the table.

Page 22

8 Adapting the unit to the installation

22 Installation and maintenance instructions ecoTEC sustain 0020253094_01

Checking the CO₂ content

Great Britain

Fitted front casing

Natural

gas

Liquid

gas

G20 G31

9.2 ±1 % 10.4

±0.5 %

◁ The value is OK.

▽ The value is not OK; you cannot start up the

product.

▶ Contact customer service.

7.10.6 Performing gas conversion:

Note

You will need a conversion kit, which is available

separately.

The conversion procedure is described in the

manual supplied with the conversion kit.

▶ Follow the instructions in the manual for the conversion

kit to carry out the gas conversion on the product.

7.11 Checking leak-tightness

▶ Check the gas pipe, the heating circuit and the hot water

circuit for leak-tightness.

▶ Check that the air/flue pipe has been installed correctly.

Conditions: Room-sealed operation

▶ Check whether the vacuum chamber has been sealed so

that it is leak-tight.

7.11.1 Checking the hot water generation

1. Activate the hot water handling mode on the user

interface.

2. Open a hot water valve completely.

3. Call up the status codes. (→ Page 17)

Status codes – Overview (→ Page 38)

◁ If the product is working correctly, the display shows

S.14.

7.11.2 Checking the heating mode

1. Activate the heating mode on the user interface.

2. Turn all thermostatic radiator valves on the radiators

until they are fully open.

3. Allow the product to operate for at least 15 minutes.

4. Fill and purge the heating installation. (→ Page 19)

5. Call up the status codes. (→ Page 17)

Status codes – Overview (→ Page 38)

◁ If the product is working correctly, the display shows

S.04.

8 Adapting the unit to the installation

8.1 Activating diagnostics codes

You can find the setting options in the diagnostics codes in

the installer level.

▶ Set a diagnostics code. (→ Page 17)

8.2 Burner anti-cycling time

To prevent frequent switching on and off of the burner and

thus prevent energy losses, an electronic restart lockout

is activated for a specific period each time the burner is

switched off. The burner anti-cycling time is only active for

the heating mode. Switching on domestic hot water mode

during the burner anti-cycling time has no effect.

8.2.1 Setting the maximum burner anti-cycling

time

1. Set a diagnostics code. (→ Page 17)

T

Flow

(target)

[°C]

Set maximum burner anti-cycling time [min]

1 5 10 15 20 25 30

30 2.0 4.0 8.5 12.5 16.5 20.5 25.0

35 2.0 4.0 7.5 11.0 15.0 18.5 22.0

40 2.0 3.5 6.5 10.0 13.0 16.5 19.5

45 2.0 3.0 6.0 8.5 11.5 14.0 17.0

50 2.0 3.0 5.0 7.5 9.5 12.0 14.0

55 2.0 2.5 4.5 6.0 8.0 10.0 11.5

60 2.0 2.0 3.5 5.0 6.0 7.5 9.0

65 2.0 1.5 2.5 3.5 4.5 5.5 6.5

70 2.0 1.5 2.0 2.5 2.5 3.0 3.5

75 2.0 1.0 1.0 1.0 1.0 1.0 1.0

T

Flow

(target)

[°C]

Set maximum burner anti-cycling time

[min]

35 40 45 50 55 60

30 29.0 33.0 37.0 41.0 45.0 49.5

35 25.5 29.5 33.0 36.5 40.5 44.0

40 22.5 26.0 29.0 32.0 35.5 38.5

45 19.5 22.5 25.0 27.5 30.5 33.0

50 16.5 18.5 21.0 23.5 25.5 28.0

55 13.5 15.0 17.0 19.0 20.5 22.5

60 10.5 11.5 13.0 14.5 15.5 17.0

65 7.0 8.0 9.0 10.0 11.0 11.5

70 4.0 4.5 5.0 5.5 6.0 6.5

75 1.0 1.0 1.0 1.0 1.0 1.0

2. If required, adjust the maximum burner anti-cycling time

using diagnostics code d.02.

Page 23

Adapting the unit to the installation 8

0020253094_01 ecoTEC sustain Installation and maintenance instructions 23

8.2.2 Resetting the remaining burner anti-cycling

time

▶

Press and hold the button for more than three

seconds.

◁ All symbols are shown in the display.

8.3 Setting the maximum heating output

The product's maximum heating output is set to automatic

mode at the factory. If you want to set your own fixed maximum heating output, however, you can specify a value under d.00 which equates to the product output in kW.

8.4 Setting the maintenance interval

If you set the maintenance interval, after a configurable number of burner operating hours, the message that the product

must be serviced appears in the display, together with the

maintenance symbol .

▶ Use diagnostics code d.84 to set the number of operating

hours until the next maintenance is due (number of operating hours = display value x 10). Guideline values can

be found in the following table.

Heat demand

Number

of persons

Guideline value for burner

operating hours until the

next inspection/maintenance

work is due for an average

operating time of one year

(dependent upon the system

type)

5.0 kW

1 ‑ 2 1050 h

2 ‑ 3 1150 h

10.0 kW

1 ‑ 2 1500 h

2 ‑ 3 1600 h

15.0 kW

2 ‑ 3 1800 h

3 ‑ 4 1900 h

20.0 kW

3 ‑ 4 2600 h

4 ‑ 5 2700 h

25.0 kW

3 ‑ 4 2800 h

4 ‑ 6 2900 h

> 27.0 kW

3 ‑ 4 3000 h

4 ‑ 6 3000 h

The values stated correspond to an average operating time

of one year.

If you do not set a numerical value but do set the symbol

"– – –", the function is not active.

Note

On completion of the set operating hours, you

must set the maintenance interval again.

8.5 Setting the pump output

Applicability: VUW 246/7-2 (H-GB)

OR VUW 286/7-2 (H-GB)

OR VUW 346/7-2 (H-GB)

Conditions: Modulating pump

The product is equipped with a speed-regulated high-efficiency pump, which adjusts independently to the hydraulic

conditions of the heating installation.

If you have installed a low loss header in the heating installation, we recommend switching off the speed regulation and

setting the pump output to a fixed value.

▶ If required, use diagnostics code d.14 to adjust the set-

ting for the operating-mode-dependent pump speed.

▶ Set a diagnostics code. (→ Page 17)

Remaining feed head of the pump

Pump curve

Applicability: VUW 246/7-2 (H-GB)

OR VUW 286/7-2 (H-GB)

6

0 500 1000 1300

A

B

0

5

10

15

20

25

30

35

40

5

321 4

7

1 PWM 65%

2 PWM 73%

3 PWM 80%

4 PWM 88%

5 PWM 95 to 100%

6 Saturation 25 kPa

7 Saturation 17 kPa

A Throughput in circuit

(l/h)

B Available pressure

(kPa)

Pump characteristic line

Applicability: VUW 346/7-2 (H-GB)

6

0 500 1000 1400

A

B

0

5

10

15

20

25

30

35

40

5

321 4

7

1 PWM 65%

2 PWM 73%

3 PWM 80%

4 PWM 88%

5 PWM 95 to 100%

6 Saturation 25 kPa

Page 24

9 Troubleshooting

24 Installation and maintenance instructions ecoTEC sustain 0020253094_01

7 Saturation 17 kPa

A Throughput in circuit

(l/h)

B Available pressure

(kPa)

8.6 Setting the bypass

Conditions: D.14 is set to 0 = auto

Caution.

Risk of material damage caused by incor-

rect setting of the high-efficiency pump

When the pressure at the bypass is increased (turning clockwise), malfunctions

may occur if the pump output is set below

95%.

▶ In this case, set the pump output to 5 = 95

to 100% using diagnostics parameter

D.14.

▶ Do not change the factory settings.

Conditions: D.14 is set to 1–5

▶ Remove the front casing. (→ Page 11)

1

▶ Regulate the pressure using the adjusting screw (1).

Position of the

adjusting screw

Pressure

in MPa

(mbar)

Notes/application

Right-hand stop

(turned all the

way down)

0.035

(350)

If the radiators do not heat

up sufficiently at the default

setting. In this case, you

must set the pump to the

maximum speed.

Mid-position (six

anti-clockwise

rotations)

0.025

(250)

Default setting

Five further anticlockwise rotations starting from

the mid-position

0.017

(170)

If noises are produced in

the radiators or radiator

valves

▶ Fit the front panel.

8.7 Setting the hot water temperature

Danger!

Risk of death from Legionella.

Legionella multiply at temperatures below

60 °C.

▶ Ensure that the operator is familiar with all

of the Anti-legionella measures in order

to comply with the applicable regulations

regarding legionella prevention.

▶ Set the hot water temperature.

Conditions: Water hardness: > 3.57 mol/m³

– Hot water temperature: ≤ 50 ℃

8.8 Handing the product over to the operator

▶ When you have finished the installation, affix the en-

closed sticker (which requests that the user reads the

instructions) to the front of the product in the operator's

language.

▶ Explain to the operator how the safety devices work and

where they are located.

▶ Inform the operator how to handle the product.

▶ In particular, draw attention to the safety information

which the operator must follow.

▶ Inform the operator of the necessity to have the product

maintained according to the specified intervals.

▶ Pass all of the instructions and documentation for the

product to the operator for safe-keeping.

▶ Instruct the operator about measures taken to ensure the

supply of combustion air and flue gas pipe. Point out, in

particular, that the operator must not make any changes,

however minor.

▶ Inform the operator that they must not store or use ex-

plosive or highly flammable substances (such as petrol,

paper or paint) in the installation room of the product.

9 Troubleshooting

9.1 Checking service messages

appears, for example, if you have set a maintenance interval and this has passed or if a service message has been

issued. The product is not in fault mode.

▶ Call up the Live Monitor. (→ Page 17)

Conditions: S.46 is displayed.

The product is in Comfort protection mode. The product continues to run with restricted comfort after it has detected a

fault.

▶ To establish whether or not a component is defective,

read the fault memory. (→ Page 25)

Note

If no fault message is present, the product will

automatically switch back to normal operating

mode after a certain time.

Page 25

Troubleshooting 9

0020253094_01 ecoTEC sustain Installation and maintenance instructions 25

9.2 Rectifying faults

▶ If fault codes (F.XX) are present, refer to the table in the

appendix for advice or use the check programme(s).

Overview of fault codes (→ Page 39)

Check programmes – Overview (→ Page 34)

If several faults occur at the same time, the fault codes are

shown alternately on the display.

Resetting the product:

▶

Press and hold the button for more than three

seconds.

◁ The product restarts.

▶ If you are unable to clear the fault code and it reappears

despite several fault clearance attempts, contact customer service.

9.3 Calling up the fault memory

The last ten fault codes are stored in the fault memory.

▶ Call up the installer level. (→ Page 17)

◁ d.-- is shown in the display.

▶

Press the button 2 times.

◁ F.XX is shown in the display.

▶

Press the and buttons to call up the fault codes.

Overview of fault codes (→ Page 39)

◁ The fault code and the time of occurrence are shown

alternately on the display.

▶

Press .

◁ The display switches to the basic display.

9.4 Deleting the fault memory

1. Clear the fault memory using diagnostics code d.94.

2. Set a diagnostics code. (→ Page 17)

9.5 Resetting parameters to factory settings

1. Reset all parameters to the factory settings using diagnostics code d.96.

2. Set a diagnostics code. (→ Page 17)

9.6 Preparing the repair work

1. Decommission the product.

2. Disconnect the product from the power mains.

3. Remove the front casing. (→ Page 11)

4. Close the gas isolator cock.

5. Close the service valves in the heating flow and in the

heating return.

6. Close the service valve in the cold water pipe.

7. Drain the product to replace hydraulic components

(→ Page 30).

8. Ensure that water does not drip on live components

(e.g. the electronics box).

9. Use only new seals and o'ring. Do not use additional

compounds.

9.6.1 Procuring spare parts

The original components of the product were also certified

by the manufacturer as part of the declaration of conformity.

If you use other, non-certified or unauthorised parts during

maintenance or repair work, this may void the conformity of

the product and it will therefore no longer comply with the

applicable standards.

We strongly recommend that you use original spare parts

from the manufacturer as this guarantees fault-free and safe

operation of the product. To receive information about the

available original spare parts, contact the contact address

provided on the reverse of these instructions.

▶ If you require spare parts for maintenance or repair

work, use only the spare parts that are permitted for the

product.

9.7 Replacing defective components

9.7.1 Replacing the burner

1

2

1. Undo the four screws (1) on the burner.

2. Remove the burner.

3. Install a new seal (2) on the new burner.

Page 26

9 Troubleshooting

26 Installation and maintenance instructions ecoTEC sustain 0020253094_01

9.7.2 Replacing the fan or gas valve

7

4

3

2

1

6

9