Page 1

For the operator

Operating instructions

ecoTEC plus

VU, VUW

GB, IE

Operating instructions

Publisher/manufacturer

Vaillant GmbH

Berghauser Str. 40 D-42859 Remscheid

Tel. +49 21 91 18‑0 Fax +49 21 91 18‑28 10

info@vaillant.de www.vaillant.de

Page 2

Contents

2 Operating instructions ecoTEC plus 0020220342_01

Contents

1 Safety .................................................................... 3

1.1 Action-related warnings ......................................... 3

1.2 Intended use.......................................................... 3

1.3 General safety information .................................... 3

2 Notes on the documentation .............................. 5

2.1 Observing other applicable documents ................. 5

2.2 Storing documents................................................. 5

2.3 Applicability of the instructions .............................. 5

3 Product description............................................. 5

3.1 Product design....................................................... 5

3.2 Control elements.................................................... 5

3.3 Displayed symbols................................................. 6

3.4 Information on the identification plate.................... 6

3.5 Serial number ........................................................ 7

3.6 CE label ................................................................. 7

3.7 Energy Saving Trust Endorsed Products .............. 7

4 Operation.............................................................. 7

4.1 Operating concept ................................................. 7

4.2 Basic display.......................................................... 7

4.3 Menu display.......................................................... 7

4.4 Operating levels..................................................... 8

4.5 Cabinet-type casing............................................... 8

4.6 Opening the isolator devices ................................. 8

4.7 Starting up the product .......................................... 8

4.8 Switching on the product ....................................... 8

4.9 Setting the heating flow temperature..................... 8

4.10 Setting the hot water temperature ......................... 8

4.11 Switching Comfort mode on and off ...................... 8

4.12 Activating the shift-load cylinder ............................ 9

4.13 Switching off the product's functions ..................... 9

4.14 Guaranteeing the correct filling pressure of the

heating system....................................................... 9

4.15 Protecting the heating installation against

frost...................................................................... 10

5 Troubleshooting ................................................ 10

5.1 Detecting and rectifying faults ............................. 10

5.2 Calling up (Live monitor) status codes ................ 10

6 Care and maintenance ...................................... 10

6.1 Maintenance ........................................................ 10

6.2 Caring for the product .......................................... 10

6.3 Reading maintenance messages ........................ 10

6.4 Checking the condensate drain pipework and

tundish ................................................................. 11

7 Decommissioning.............................................. 11

7.1 Temporarily decommissioning the product.......... 11

7.2 Permanently decommissioning the product......... 11

8 Recycling and disposal..................................... 11

9 Guarantee and customer service..................... 11

9.1 Guarantee............................................................ 11

9.2 Customer service................................................. 11

Appendix ............................................................................ 12

A Operator level – overview ................................. 12

B Status codes – Overview .................................. 12

C Troubleshooting ................................................ 13

Page 3

Safety 1

0020220342_01 ecoTEC plus Operating instructions 3

1 Safety

1.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in

accordance with the severity of the possible

danger using the following warning signs and

signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of

severe personal injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental

damage

1.2 Intended use

There is a risk of injury or death to the user or

others, or of damage to the product and other

property in the event of improper use or use

for which it is not intended.

The product is intended as a heat generator

for closed heating installations and for hot

water generation.

Intended use includes the following:

– observance of the operating instructions

included for the product and any other

system components

– compliance with all inspection and main-

tenance conditions listed in the instructions.

This product can be used by children aged

from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge if

they have been given supervision or instruction concerning use of the product in a safe

way and understand the hazards involved.

Children must not play with the product.

Cleaning and user maintenance work must

not be carried out by children unless they are

supervised.

Any other use that is not specified in these

instructions, or use beyond that specified in

this document shall be considered improper

use. Any direct commercial or industrial use

is also deemed to be improper.

Caution.

Improper use of any kind is prohibited.

1.3 General safety information

1.3.1 Installation by competent persons

only

The installation, inspection, maintenance

and repair of the product, as well as the gas

ratio settings, must only be carried out by a

competent person.

1.3.2 Danger caused by improper

operation

Improper operation may present a danger to

you and others, and cause material damage.

▶ Carefully read the enclosed instructions

and all other applicable documents, particularly the "Safety" section and the warnings.

1.3.3 Risk of death from escaping gas

What to do if you smell gas in the building:

▶ Avoid rooms that smell of gas.

▶ If possible, open doors and windows fully

and ensure adequate ventilation.

▶ Do not use naked flames (e.g. lighters,

matches).

▶ Do not smoke.

▶ Do not use any electrical switches, mains

plugs, doorbells, telephones or other communication systems in the building.

▶ If it is safe to do so, close the emergency

control valve or the main isolator.

▶ If possible, close the gas isolator cock on

the product.

▶ Warn other occupants in the building by

yelling or banging on doors or walls.

▶ Leave the building immediately and ensure

that others do not enter the building.

▶ Notify the gas supply company or National

Grid Transco +44 (0) 800 111999 by telephone from outside of the building.

Page 4

1 Safety

4 Operating instructions ecoTEC plus 0020220342_01

1.3.4 Risk of death due to a blocked or

leaking flue gas pipe

What to do if you smell flue gas in the property:

▶ Open all accessible doors and windows

fully to provide ventilation.

▶ Switch off the product.

▶ Inform a competent person.

1.3.5 Risk of death from escaping flue

gas

If you operate the product with an empty condensate siphon, flue gas may escape into the

room air.

▶ In order to operate the product, ensure that

the condensate siphon is always full.

1.3.6 Risk of death due to explosive and

flammable materials

▶ Do not use or store explosive or flammable

materials (e.g. petrol, paper, paint) in the

installation room of the product.

1.3.7 Risk of death due to changes to the

product or the product environment

▶ Never remove, bridge or block the safety

devices.

▶ Do not alter the safety devices in any way.

▶ Do not damage or remove any seals on

components.

▶ Do not make any changes:

– The product itself

– to the gas, air, water and electricity sup-

plies

– to the entire flue gas installation

– to the entire condensate drain system

– to the expansion relief valve

– to the drain lines

– to constructional conditions that may

affect the operational reliability of the

product

1.3.8 Risk of poisoning caused by

insufficient supply of combustion

air

Conditions: Open-flued operation

▶ Ensure that there is a sufficient supply of

combustion air.

1.3.9 Risk of corrosion damage due to

unsuitable combustion and room air

Sprays, solvents, chlorinated cleaning

agents, paint, adhesives, ammonia compounds, dust or similar substances may lead

to corrosion on the product and in the air/flue

pipe.

▶ Ensure that the supply of combustion air is

always free of fluorine, chlorine, sulphur,

dust, etc.

▶ Ensure that no chemical substances are

stored at the installation site.

1.3.10 Risk of material damage caused by

frost

▶ Ensure that the heating installation always

remains in operation during freezing conditions and that all rooms are sufficiently

heated.

▶ If you cannot ensure the operation, have a

competent person drain the heating installation.

1.3.11 Risk of injury and material damage

due to maintenance and repairs

carried out incorrectly or not

carried out at all

▶ Never attempt to carry out maintenance

work or repairs on your product yourself.

▶ Faults and damage should be immediately

rectified by a competent person.

▶ Adhere to the maintenance intervals spe-

cified.

Page 5

Notes on the documentation 2

0020220342_01 ecoTEC plus Operating instructions 5

2 Notes on the documentation

2.1 Observing other applicable documents

▶ You must observe all operating instructions enclosed with

the system components.

2.2 Storing documents

▶ Keep this manual and all other applicable documents

safe for future use.

2.3 Applicability of the instructions

These instructions apply only to:

Product article number

Article number

Gas Council

Number

612 (VU GB 126/5‑5 A)

ecoTEC plus

0010018531 41-044-78

615 (VU GB 156/5‑5 A)

ecoTEC plus

0010018532 41-044-79

618 (VU GB 186/5‑5 A)

ecoTEC plus

0010018533 41-044-80

618 (VU GB 186/5‑5 A

LPG) ecoTEC plus

0010018534 41-044-81

624 (VU GB 246/5‑5 A)

ecoTEC plus

0010018535 41-044-82

630 (VU GB 306/5‑5 A)

ecoTEC plus

0010018536 41-044-83

630 (VU GB 306/5‑5 A

LPG) ecoTEC plus

0010018537 41-044-84

637 (VU GB 376/5‑5 A)

ecoTEC plus

0010018538 41-044-85

825 (VUW GB 256/5‑5)

ecoTEC plus

0010018353 47-044-57

832 (VUW GB 326/5‑5)

ecoTEC plus

0010018354 47-044-58

832 (VUW GB 326/5‑5

LPG) ecoTEC plus

0010018355 47-044-59

835 (VUW GB 356/5‑5)

ecoTEC plus

0010016540 47-044-53

838 (VUW GB 386/5‑5)

ecoTEC plus

0010018356 47-044-60

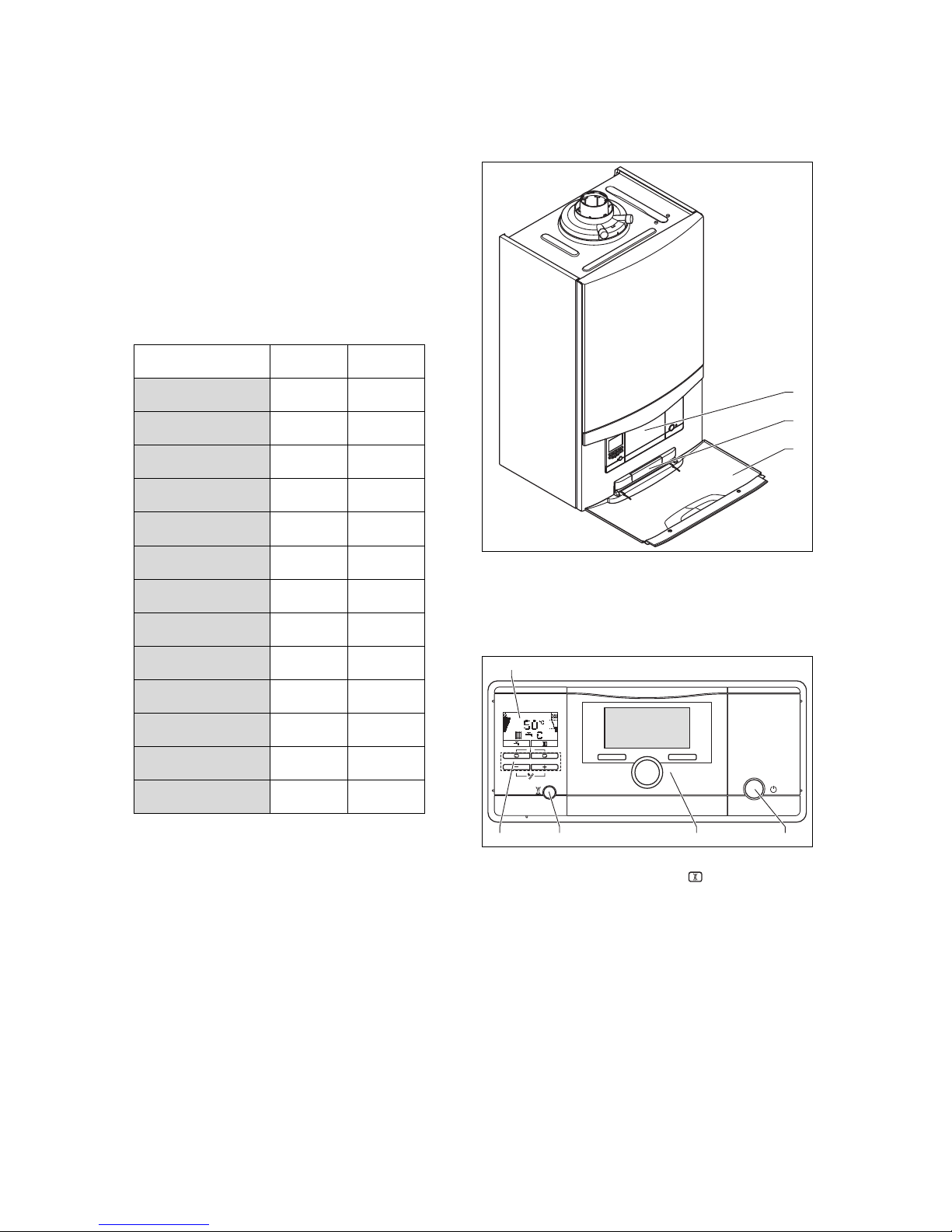

3 Product description

3.1 Product design

1

2

3

1 Control elements

2 Plate with serial number

on the rear

3 Front flap

3.2 Control elements

1234

5

1 On/off button

2 Built-in controller (ac-

cessory)

3 Fault clearance button

4 Operating buttons

5 Display

Page 6

3 Product description

6 Operating instructions ecoTEC plus 0020220342_01

3.2.1 Operator control panel

50

F. 0 1

1

2

3

4

8

7

5

6

1 Current heating flow

temperature, filling

pressure of the heating

installation, operating

mode, fault code or

additional information

2 Current assignment of

the right-hand selection

button

3 Left- and right-hand

selection buttons

4

and button

5 Maximum output op-

eration (for chimney

sweeps only)

6 Access to the menu for

additional information

7 Current assignment of

the left-hand selection

button

8 Active operating status

3.3 Displayed symbols

Symbol Meaning Explanation

Burner operating correctly

Burner on

bar

Current filling pressure of

the heating system

The dashed lines show

the permitted range

– Permanently on:

Filling pressure in

the permitted range

– Flashing: Filling

pressure outside

the permitted range

Hot water generation

active

– Permanently on:

Draw-off mode before burner is on

– Flashing: Burner on

in draw-off mode

Heating mode active – Permanently on:

Heating mode heat

requirement

– Flashing: Burner on

in heating mode

Symbol Meaning Explanation

Comfort mode active – Permanently on:

Comfort mode active

– Flashing: Comfort

mode active, burner

on

Maintenance required Information on the main-

tenance message in the

"Live Monitor"

Summer mode active

Heating mode is

switched off

Burner anti-cycling time

is active

To avoid the need for

frequent switching on

and off (increases the

product's working life).

F.X X

Fault in the product Appears instead of the

basic display, may be

an explanatory plain text

display.

3.4 Information on the identification plate

The identification plate is mounted on the underside of the

product in the factory.

Information on the

identification plate

Meaning

→ "CE label" section

Read the instructions.

VU… Vaillant gas-fired wall-hung boiler for

heating

VUW… Vaillant gas-fired wall-hung boiler for

heating and hot water generation

..6/5-5 Calorific value power/product generation

equipment

ecoTEC plus Product description

2H, G20 – 20 mbar

(2.0 kPa)

Gas group and gas connection pressure

as set at the factory

ww/yyyy Date of manufacture: Week/year

Cat. Permissible gas categories

Types Approved gas-fired units

PMS Permissible total overpressure in heating

mode

PMW Permissible total overpressure during hot

water generation

T

max.

Max. flow temperature

ED 92/42 Current efficiency directive fulfilled with

4* rating

V Hz Mains voltage and mains frequency

W Max. electrical power consumption

IP Level of protection

Heating mode

Hot water generation

P Nominal heat output range

Page 7

Operation 4

0020220342_01 ecoTEC plus Operating instructions 7

Information on the

identification plate

Meaning

Q Heat input range

D Nominal hot water draw-off rate

Proper disposal of the product

Bar code with serial number,

7th to 16th digit = product article number

3.5 Serial number

The serial number is located on a plastic plate behind the

front flap.

3.6 CE label

The CE label shows that the products comply with the basic

requirements of the applicable directives as stated on the

identification plate.

The declaration of conformity can be viewed at the manufacturer's site.

3.7 Energy Saving Trust Endorsed Products

Only the most energy efficient products can carry the

‘Energy Saving Trust Endorsed Product’ brandmark making

it easy for consumers to choose products that have met strict

energy performance criteria.

Available for: Boilers, Heating controls and chemical inhibitors, the Energy Saving Trust endorsed product brandmark

gives consumers confidence that a product will cost less to

run, help lower energy bills and reduce carbon emissions.

About the Energy Saving Trust

Energy Saving Trust is an independent and impartial organisation that provides trusted energy saving advice to empower millions of people to lead affordable, low energy lifestyles. For more information visit energysavingtrust.org.uk

4 Operation

4.1 Operating concept

Operator

control

element

Function

– Setting the hot water temperature

– Cancelling the activation of an operating

mode

– Cancelling a change to a set value

– Going one selection level higher

Operator

control

element

Function

– Setting the heating flow temperature

– Reading the system pressure

– Activating the comfort mode

– Activating the operating mode

– Confirm setting

– Going one selection level lower

+ at

the same

time

– Calling up the menu

or

– Reducing or increasing the set value

– Scrolling through menu entries

The current function of the and buttons is shown on

the display.

Adjustable values are always displayed as flashing.

You must always confirm a change to a value. Only then

is the new setting saved. You can press to cancel an

operation at any time.

4.2 Basic display

50

The basic display shows the current condition of the product.

If you press a selection button, the activated function is displayed in the display.

The functions that are available depend on whether a controller is connected to the product.

You can switch back to the basic display by:

–

Pressing to exit the selection levels

– Not pressing any button for longer than 15 minutes.

If there is an error message present, the basic displays

switches to the error message.

4.3 Menu display

Xxxx

Xxxxxxxxxxx

Xxxx Xxxxxxx

Xxxxxxxxxx

xxxxxx Xxxxxxx

1

4

3

2

1 Scroll bar

2 Current assignment of

the and buttons.

3 Selection level list

entries

4 Name of the selection

level

Page 8

4 Operation

8 Operating instructions ecoTEC plus 0020220342_01

You can find an overview of the menu structure in the appendix.

Operator level – overview (→ Page 12)

4.4 Operating levels

The product has two operating levels.

The operating level for the operator shows the information

and offers set-up options that do not require any special prior

knowledge.

The operating level for the competent person is protected by

a code.

4.5 Cabinet-type casing

Enclosing the product in cabinet-type casing requires compliance with the applicable design instructions.

If you require cabinet-type casing for your product, consult

a heating specialist company. Never, under any circumstances, enclose the product yourself.

4.6 Opening the isolator devices

1. Ask the competent person who installed the product to

explain to you where these isolator devices are located

and how to handle them.

2. Open the gas isolator cock fully.

3. Open the service valves in the heating installation's flow

and return.

Conditions: Product with integrated hot water generation or connected

domestic hot water cylinder

▶ Open the cold water stop valve.

4.7 Starting up the product

▶ Only start up the product once the casing has been com-

pletely closed.

4.8 Switching on the product

50

1

2

▶ Press the on/off button (1).

◁ The "Basic display" (→ Page 7) (2) appears on the

display.

4.9 Setting the heating flow temperature

1.

Press ( ).

◁ The target value of the heating flow temperature

appears on the display.

Note

The competent person may have adjusted

the maximum possible temperature.

Conditions: No controller connected

▶

Use or to set the required heating flow temperature.

▶

Confirm by pressing .

Conditions: Controller connected

▶ Set the maximum possible heating flow temperature on

the product.

▶

Confirm by pressing .

▶ Set the required heating flow temperature on the control-

ler (→ Controller operating instructions).

4.10 Setting the hot water temperature

1.

Press ( ).

◁ The set hot water temperature flashes in the display.

Conditions: No controller connected

▶

Change the hot water temperature by pressing or

.

▶

Confirm by pressing .

Conditions: Controller connected

▶

Use to set the maximum possible hot water temperature on the product.

▶

Confirm by pressing .

▶ Set the required hot water temperature on the controller

(→ Controller operating instructions).

4.11 Switching Comfort mode on and off

Note

Comfort mode immediately supplies hot water at

the required temperature, without you having to

wait for the water to heat up.

1.

Press ( ).

2.

Press ( ).

◁ Comfort on or Comfort off are shown flashing in

the display.

3.

Activate or deactivate Comfort mode by pressing or

respectively.

4.

Press to confirm this change.

◁

When you have activated Comfort mode, the " "

symbol appears on the basic display. When you

have deactivated Comfort mode, the " " symbol

goes out on the basic display.

Page 9

Operation 4

0020220342_01 ecoTEC plus Operating instructions 9

4.12 Activating the shift-load cylinder

Applicability: Product with integrated hot water generation and shift-load

cylinder

To activate an actoSTOR shift-load cylinder which is also

connected, you must switch on cylinder charging on your

product.

▶ To do this, activate Comfort mode (Comfort mode

(→ Page 8)).

◁

The symbol " " appears in the display.

▶ Set the hot water temperature.

Conditions: Cylinder charging switched on

– Hot water temperature: 50 … 65 ℃

Danger!

Risk of scalding!

The products are equipped with an automatic

anti-legionella function: If the temperature in

the shift-load cylinder falls below 50 °C for

24 hours, the cylinder is heated up to 70 °C

once.

▶ Please note when drawing water that it

can be very hot.

▶ If you want to switch off the "Anti-legionella function", you

should ask a competent person.

▶ If you want to switch off cylinder charging, deactivate

Comfort mode "Switching Comfort mode on and off

(→ Page 8)".

Conditions: Cylinder charging switched off

– Hot water temperature: 35 … 65 ℃

◁ The cylinder is not maintained at a specific temperat-

ure. If you draw off the water, the product switches on

and, in this case, only operates as an instantaneous

water heater.

4.13 Switching off the product's functions

4.13.1 Switching off heating mode (Summer

mode)

1. To switch off heating mode without switching off hot

water generation, press ( ).

◁ The value of the heating flow temperature appears

in the display.

2.

Use the button to set the heating flow temperature to

Heating off.

3.

Confirm by pressing .

◁ Heating mode is switched off.

◁

The symbol appears on the display.

4.13.2 Switching off hot water generation

Applicability: Product with hot water generation through external domestic

hot water cylinder

1. To switch off cylinder charging without switching off

heating mode, press ( ).

◁ The set hot water temperature flashes in the display.

2.

Use the button to set the hot water temperature to

Heating off.

3.

Confirm by pressing .

◁ Cylinder charging is switched off.

◁ Only the frost protection function for the cylinder

remains active.

4.14 Guaranteeing the correct filling pressure of

the heating system

4.14.1 Checking the filling pressure of the heating

installation

Note

To ensure that the heating installation operates

smoothly, the filling pressure when the heating

installation is cold must be between 0.1 MPa and

0.2 MPa (1.0 bar and 2.0 bar) or lie between the

two dashed lines in the bar graph display.

If the heating installation extends over several

storeys, a higher filling pressure may be required

for the heating installation. Ask a competent person for details.

In addition, the symbol appears after approx.

one minute.

If the filling pressure in the heating installation

falls below 0.05 MPa (0.5 bar), then the product

switches off. The display alternates between the

fault message F.22 and the current filling pressure.

1.

Press twice.

◁ The values for the current filling pressure and for the

minimum and maximum filling pressures appear in

the display.

2. Check the filling pressure in the display.

1 / 2

System pressure: 0.1 … 0.2 MPa (1.0 … 2.0 bar)

The filling pressure is in the intended pressure range.

2 / 2

Filling pressure: < 0.08 MPa (< 0.80 bar)

▶ Fill the heating installation. (→ Page 10)

◁ If you have topped up the installation with suf-

ficient heating water, the display automatically

disappears after 20 seconds.

Page 10

5 Troubleshooting

10 Operating instructions ecoTEC plus 0020220342_01

4.14.2 Filling the heating installation

Caution.

Risk of material damage due to heating

water that is extremely calciferous or corrosive or contaminated by chemicals.

Unsuitable tap water damages the seals

and diaphragms, blocks components in the

product and heating installation through

which the water flows and causes noise.

▶ Only fill the heating installation with suit-

able heating water.

▶ In case of doubt, ask a competent person

for details.

1. Ask a competent person where the filling cock is located.

2. Connect the filling cock to a hot water supply in the way

you were told by the competent person.

3. Open all radiator valves (thermostatic radiator valves) of

the heating installation.

4. Open the hot water supply.

5. Turn the filling cock on slowly and allow water to flow in

until the required filling pressure has been reached.

6. Close the hot water supply.

7. Purge all radiators.

8. Check the filling pressure in the display.

9. Top up with more water if necessary.

10. Close the filling cock.

11. Return to the basic display. (→ Page 7)

4.15 Protecting the heating installation against

frost

4.15.1 Frost protection function

Caution.

Risk of material damage due to frost.

The frost protection function cannot guarantee flow through the entire heating installation, which means that parts of the heating

installation may freeze and therefore become

damaged.

▶ During a period of frost, ensure that the

heating installation remains in operation

and that all rooms are sufficiently heated,

even when you are away.

Note

To keep the frost protection devices active, you

should switch your product on and off using the

controller, if one is provided.

If the heating flow temperature falls below 5 °C when the

on/off button is on, the product comes into operation and

heats the circulating water to approx. 30 °C on both the heating side and the hot water side (if available).

4.15.2 Draining the heating installation

When the unit is switched off for an extended period, frost

protection can be guaranteed by completely draining the

heating installation and the product.

▶ Consult a competent person about this.

5 Troubleshooting

5.1 Detecting and rectifying faults

▶ If faults occur, proceed in accordance with the table in

the appendix.

Troubleshooting (→ Page 13)

▶ If the fault cannot be eliminated using the specified

measures or if fault messages (F.xx) occur, contact a

competent person.

5.2 Calling up (Live monitor) status codes

▶

Press and at the same time.

Status codes – Overview (→ Page 12)

◁ The current operating status (status code) is shown

on the display.

6 Care and maintenance

6.1 Maintenance

An annual inspection of the product carried out by a competent person is a prerequisite for ensuring that the product is

permanently ready and safe for operation, reliable, and has a

long working life.

6.2 Caring for the product

Caution.

Risk of material damage caused by un-

suitable cleaning agents.

▶ Do not use sprays, scouring agents, de-

tergents, solvents or cleaning agents that

contain chlorine.

▶ Clean the casing with a damp cloth and a little solvent-

free soap.

6.3 Reading maintenance messages

If the symbol is shown on the display, the product requires

maintenance work.

The product is not in fault mode but continues to operate.

▶ Consult a competent person about this.

▶ If the water pressure is flashing at the same time, simply

add more heating water.

Page 11

Decommissioning 7

0020220342_01 ecoTEC plus Operating instructions 11

6.4 Checking the condensate drain pipework

and tundish

The condensate drain pipework and tundish must always be

penetrable.

▶ Regularly check the condensate drain pipework and tun-

dish for faults and, particularly, for blockages.

You must not be able to see or feel any obstructions in the

condensate drain pipework and tundish.

▶ If you notice a fault, have it rectified by a competent per-

son.

7 Decommissioning

7.1 Temporarily decommissioning the product

Caution.

Risk of material damage due to frost.

The frost protection and monitoring devices

are only active while the unit is connected

to the power mains and switched on via the

on/off button, and when the gas isolator cock

is open.

▶ Temporarily decommission the product

only if no frost is expected.

▶ Temporarily decommission the product only if no frost is

expected.

▶ Press the on/off button.

◁ The display goes out.

▶ When decommissioning the product for a prolonged

period (e.g. holiday), close the gas isolator cock and also,

for combination products, the cold water stop valve.

7.2 Permanently decommissioning the product

▶ Have a competent person permanently decommission

the product.

8 Recycling and disposal

▶ The competent person who installed your product is re-

sponsible for the disposal of the packaging.

If the product is identified with this symbol:

▶ In this case, do not dispose of the product with the

household waste.

▶ Instead, hand in the product to a collection centre for old

electrical or electronic appliances.

If the product contains batteries that are marked with

this symbol, these batteries may contain substances that are

hazardous to human health and the environment.

▶ In this case, dispose of the batteries at a collection point

for batteries.

9 Guarantee and customer service

9.1 Guarantee

– Two year guarantee for ecoTEC plus appliances

Vaillant provides this appliance with a parts and labour

guarantee against defects that may occur within twentyfour months of the installation date. For the 2nd year of the

guarantee to be valid an annual service must be carried out

by a competent person approved at the time by the Health

and Safety Executive one year after installation. The cost of

this annual service is not included in the guarantee.

– Registering with us

Registration is simple. Just complete the Guarantee Registration Card and return to Vaillant within 30 days of installation. Your details will then be automatically registered within

the Vaillant scheme.

– Immediate help

If your Vaillant boiler develops a fault your first action should

be to contact your installer, as his professional assessment

is needed under the terms of our Guarantee. If you are unable to contact your installer, phone Vaillant Service Solutions: 0870 6060 777

9.2 Customer service

To ensure regular servicing, it is strongly recommended

that arrangements are made for a Maintenance Agreement.

Please contact Vaillant Service Solutions for further details.

Vaillant Service Solutions: 0330 100 3461

Page 12

Appendix

12 Operating instructions ecoTEC plus 0020220342_01

Appendix

A Operator level – overview

Setting level Values Unit Increment, select Default

setting

Min. Max.

Water pressure →

Water pressure Current value bar

Live monitor →

Status Current value

Information →

Contact details Phone number

Serial number Permanent value

Display contrast Current value 1 25

15 40

Basic settings →

Language Current language Deutsch, English, French, Italian, Danish,

Dutch, Spanish, Turkish, Hungarian, Russian,

Ukrainian, Swedish, Norwegian, Czech, Polish,

Slovakian, Romanian, Slovenian, Portugese,

Serbian, Srpski, Greek

English

Resets →

Reset anti-cycl. time Current value min

B Status codes – Overview

Status codes that are not listed here can be viewed in the installation instructions.

Status code Meaning

Displays in heating mode

S.00 Heating: No heat demand

S.02 Heating mode: Pump pre-run

S.03 Heating mode: Ignition

S.04 Heating mode: Burner on

S.06 Heating mode: Fan overrun

S.07 Heating mode: Pump overrun

S.08 Heating, remaining anti-cycling time xx mins

Displays in hot water handling mode

S.10 Domestic hot water requirement via impeller sensor

S.14 DHW mode: Burner on

Displays in Comfort mode (product with integrated hot water generation) or in cylinder charging mode (product with hot water generation

via an external domestic hot water cylinder)

S.20 Hot water requirement

S.22 DHW mode: Pump pre-run

S.24 DHW mode: Burner on

Other displays

S.31 No heat demand: Summer mode

S.34 Heating mode: Frost protection

S.46 Comfort protection mode, flame loss at minimum load

Page 13

Appendix

0020220342_01 ecoTEC plus Operating instructions 13

C Troubleshooting

Fault Cause Measure

Product does not start

up:

– No hot water

– Heating remains cold

The gas isolator cock installed on-site and/or the gas

isolator cock on the product is closed.

Open both gas isolator cocks.

The power supply in the building is disconnected. Check the fuse in the building. The product

switches on automatically when the power is

restored.

The product is switched off. Switch on the product (→ "Switching on the

product" section).

The heating flow temperature is set too low or to the

Heating off position, and/or the hot water temperature

is set too low.

Set the heating flow temperature and hot water

temperature (→ "Setting the heating flow temperature" section/→ "Setting the hot water temperature" section).

The system pressure is insufficient.

Low water pressure in the heating installation (fault message: F.22).

Fill the heating installation (→ "Filling the heating

installation" section).

There is air in the heating installation. Have your competent person purge the heating

installation.

After three unsuccessful attempts to ignite the flame, the

product switches to fault mode (fault message: F.28).

Press the fault clearance key for one second.

The product makes another attempt to ignite the

flame.

If you have been unable to eliminate the ignition

fault after three fault clearance attempts, consult

a competent person.

Hot water generation

functioning correctly;

heating does not start

up.

The external controller is not set correctly. Set the external controller correctly (→ Controller

operating instructions).

Page 14

Page 15

Page 16

0020220342_01 23.10.2015

Vaillant Ltd.

Nottingham Road Belper Derbyshire DE56 1JT

Telephone 0330 100 3461 Telephone (renewables) 0207 022 0928

Vaillant Service Solutions 0330 100 3461 Spares Technical Enquiries 01773 596615

info@vaillant.co.uk technicalspares@groupservice.co.uk

www.vaillant.co.uk

© These instructions, or parts thereof, are protected by copyright and may be reproduced or distributed only with

the manufacturer's written consent.

Loading...

Loading...