Vaillant ECOTEC PLUS VU 80, ECOTEC PLUS VU 100, ECOTEC PLUS VU 120 Installation And Maintenance Instructions Manual

Page 1

Installation and maintenance instructions

For the competent person

Installation and maintenance instructions

ecoTEC plus

VU 80, 100, 120kW

GB, IE

Page 2

Table of contents

Table of contents

1 Notes on the documentation .....................................3

1.1 Storing documents ..........................................................3

1.2 Applicability of the instructions ...................................3

1.3 Identification plate ...........................................................3

1.4 CE label ...............................................................................3

1.5 Type overview ...................................................................4

2 Safety .................................................................................5

2.1 Safety and warning information ..................................5

2.2 Intended use ......................................................................5

2.3 Basic safety information ................................................ 6

2.4 General requirements .....................................................7

3 Unit and functional description ................................11

4 Installation ......................................................................12

4.1 Scope of delivery ............................................................12

4.2 Transporting the unit .....................................................12

4.3 Dimension drawing and connection dimensions .....15

4.4 Requirements for the installation site .......................15

4.5 Wall-mounting the boiler ...............................................16

4.6 Removing/fitting the front casing ..............................16

5 Gas installation ..............................................................17

5.1 Preparing for installation ..............................................17

5.2 Connecting the gas line .................................................17

6 Hydraulic installation ................................................. 18

6.1 Preparing for installation ............................................. 18

6.2 Connecting the heating flow and heating return....19

6.3 Connecting the condensate drain pipework ........... 20

6.4 Connecting the discharge pipe to the expansion

relief valve on the heating installation ......................21

7 Flue gas installation ...................................................22

7.1 Preparing for installation .............................................22

7.2 Installing the flue pipe ..................................................22

7.3 Flue gas guiding opening .............................................22

8 Electrical installation .................................................24

8.1 Preparing for installation .............................................24

8.2 Opening/closing the electronics box .........................24

8.3 Establishing the mains connection and

connecting the pump group ........................................24

8.4 Connecting the controller ............................................26

8.5 Connecting additional units ........................................27

8.6 Connection wiring diagram .........................................28

10 Operation ........................................................................33

10.1 Calling up the installer level ........................................33

10.2 Overview of the menu structure ............................... 34

11 Start-up ...........................................................................36

11.1 Switching on the boiler .................................................36

11.2 Installation assistant .....................................................36

11.3 Appliance configuration and diagnostics menu .....37

11.4 Using test programmes ................................................37

11.5 Checking the function of the boiler ......................... 38

12 Adapting the unit to the heating installation ....39

12.1 Overview of the parameters in the diagnostics

menu .................................................................................39

12.2 Handing the boiler over to the operator ................. 43

13 Inspection and maintenance ................................... 44

13.1 Inspection and maintenance intervals ..................... 44

13.2 Inspection and maintenance work ............................ 48

13.3 Using the function menu ............................................49

13.4 Removing/fitting the upper casing ........................... 50

13.5 Carrying out maintenance work ................................ 50

14 Troubleshooting ........................................................... 55

14.1 Contacting Vaillant customer service ...................... 55

14.2 Performing diagnostics ............................................... 55

14.3 Using the function menu ..............................................61

14.4 Running check programmes ........................................61

14.5 Resetting parameters to factory settings .................61

15 Replacing components ...............................................62

15.1 Preparing for and completing replacement work ..62

15.2 Removing/fitting the side section (ifrequired) .....62

15.3 Replacing the gas valve ................................................63

15.4 Replacing the burner ....................................................63

15.5 Replacing insulating mats ........................................... 64

15.6 Replacing the fan .......................................................... 64

15.7 Replacing the heat exchanger ................................... 64

15.8 Replacing the PCB and/or the display ..................... 65

15.9 Ending repairs ................................................................ 65

16 Decommissioning ........................................................ 66

16.1 Temporarily shutting down the boiler ..................... 66

16.2 Permanently decommissioning the boiler .............. 66

16.3 Disposing of the boiler ................................................66

17 Vaillant Commercial Service ................................... 66

9 Establishing operational readiness ........................29

9.1 Reading the temperature or pressure display ........29

9.2 Preparing the heating water .......................................29

9.3 Filling and purging the heating installation ............29

9.4 Preventing low water pressure .................................. 30

9.5 Filling the condensate siphon ......................................31

9.6 Checking the gas ratio setting .....................................31

2 ecoTEC plus installation and maintenance instructions 0020134823_01

18 Technical data

19 Glo

20 Appendix ........................................................................ 69

Index ...........................................................................................72

ssary ......................................................................... 68

...............................................................67

Page 3

Notes on the documentation

1

1 Notes on the documentation

The following information is intended to help you throughout the entire documentation. Other documents apply in

addition to these Installation instructions. We accept no liability for any damage caused by failure to observe these

instructions.

Other applicable documents

> During installation, you must observe all the installation

instructions for the assemblies and components of the

system.

These installation instructions are enclosed with the various

system parts and supplementary components.

> Furthermore, observe all operating instructions enclosed

with components of the system.

1.1 Storing documents

> Pass these installation instructions and all other applica-

ble documents and, if necessary, any required tools to

the system operator.

The system operator should retain these instructions and

tools so that they are available when required.

1.2 Applicability of the instructions

These instructions apply for the following products only:

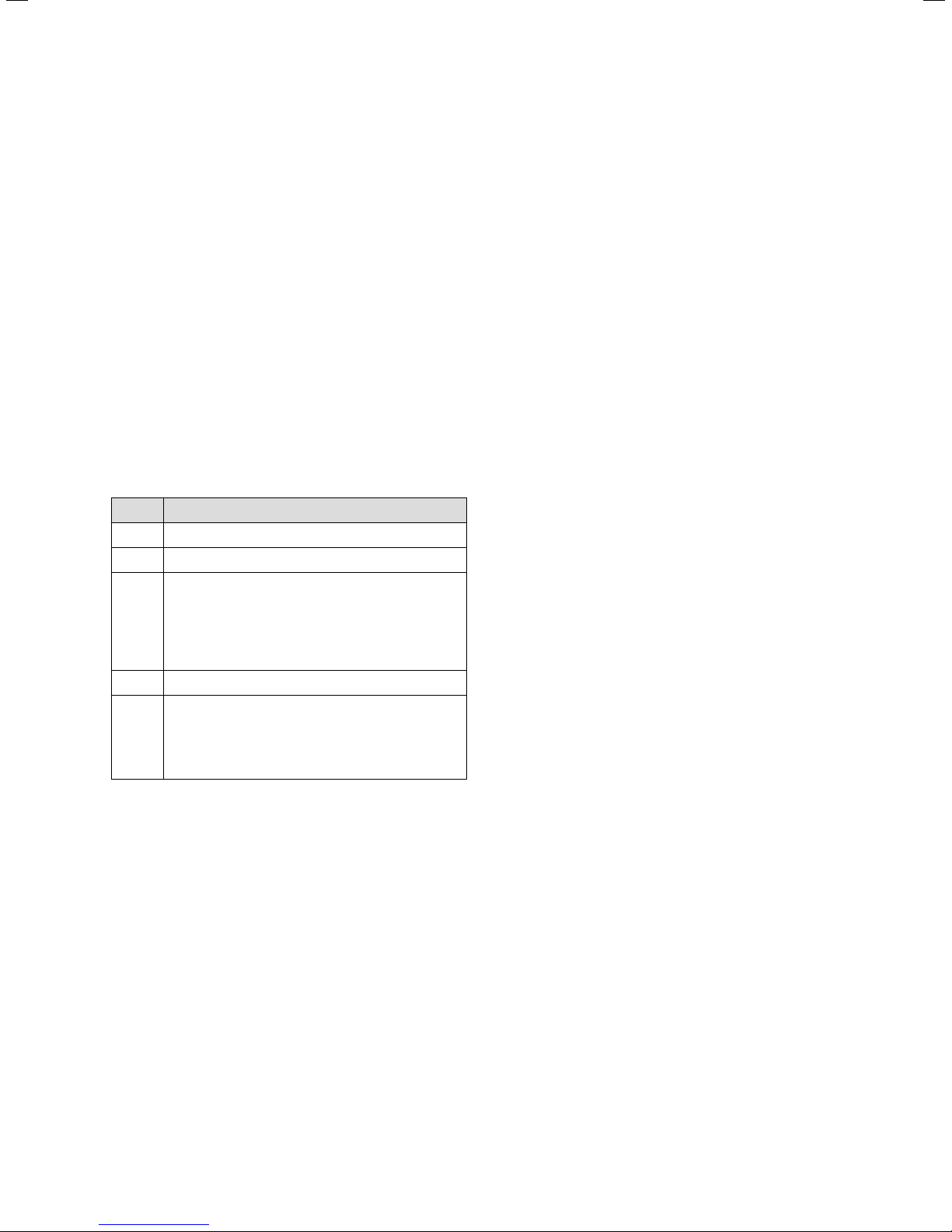

Unit Type designation

ecoTEC plus 806 (VU GB 806/5-5) 0010010767 41-044-68

ecoTEC plus 1006 (VU GB 1006/5-5) 0010010780 41-044-69

Article

number

Gas

Council

Number

1.4 CE label

CE labelling shows that, based on the type

overview, the units comply with the basic

requirements of the following directives:

– Directive 2009/142/EC of the Council with amendments

"Directive for Harmonisation of Legal Regulations of the

Member States for Gas Consumption Appliances"

(GasAppliances Directive)

– Directive 92/42/EC of the Council with amendments

"Directive Concerning the Efficiency of New Hot Water

Heating Boilers Fired by Liquid or Gaseous Fuels"

( Efficiency directive)

– Directive 2006/95/EC of the Council with amendments

"Directive Concerning Electrical Equipment for Use

Within Specific Voltage Limits" (Low voltage directive)

– Directive 2004/108/EC of the Council with amendments

"Directive Concerning Electromagnetic Compatibility"

The boilers comply with the type sample described in the

EC Type testing certificate

PIN no. CE-0085CM0415

The units comply with the following standards:

– EN 12828

– EN 15417

– EN 15420

– EN 50165

– EN 55014

– EN 60335-1

– EN 6100-3-2

– EN 6100-3-3

– prEN 15502-1

– prEN 15502-2

ecoTEC plus 1206 (VU GB 1206/5-5) 0010010791 41-044-70

1.1 Type overview

> The article number of the unit can be found on the iden-

tification plate.

1.3 Identification plate

The identification plate of the Vaillant ecoTEC plus is

attached to the bottom of the boiler at the factory.

The article number of the gas-fired wall-hung boiler can be

found in the serial number. The seventh to sixteenth numbers constitute the article number.

The serial number is also located on a plate, which is placed

in a plastic fish plate behind the front flap on the underside

of the boiler. The serial number can also be shown in the

display of the boiler (¬Operating instructions).

ecoTEC plus installation and maintenance instructions 0020134823_01 3

Page 4

Notes on the documentation

1

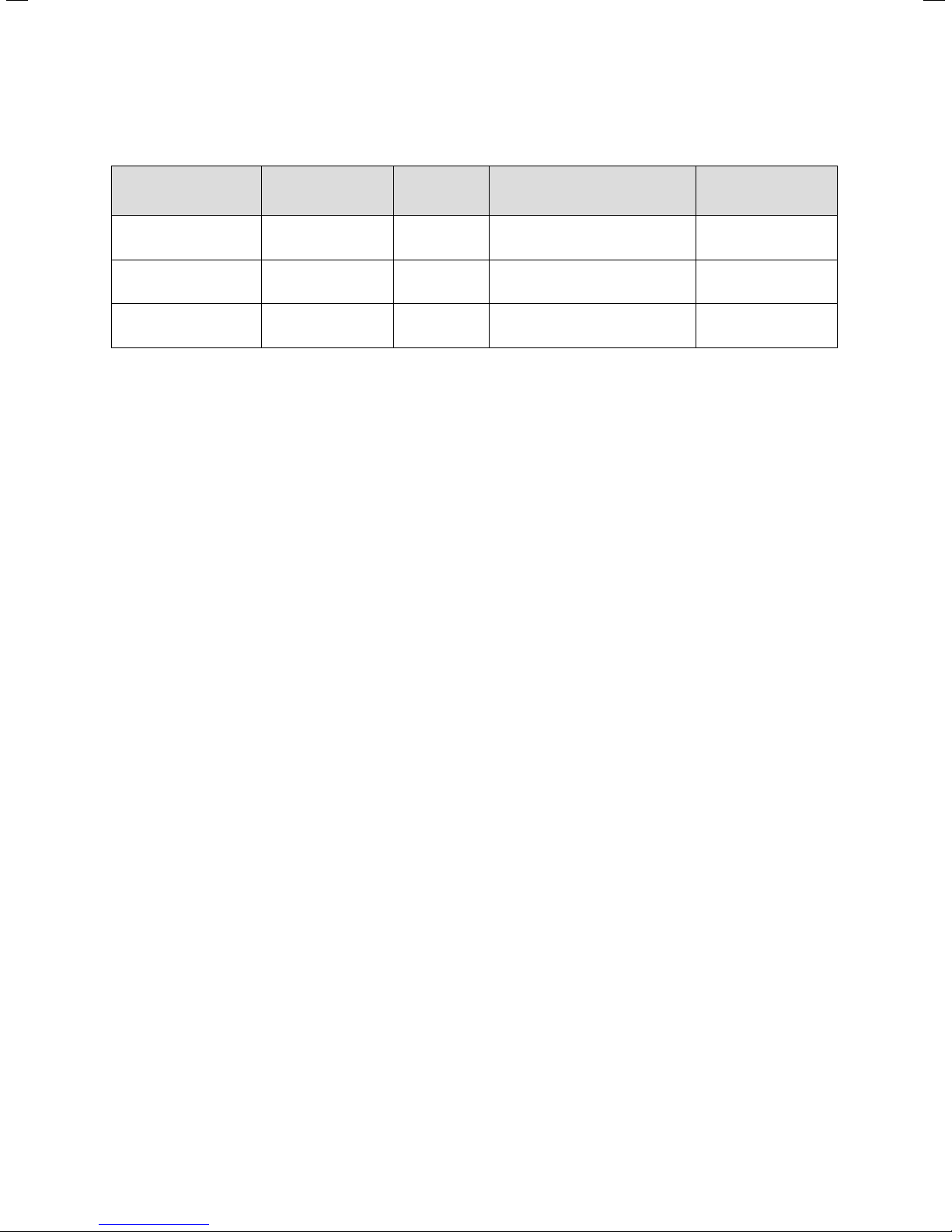

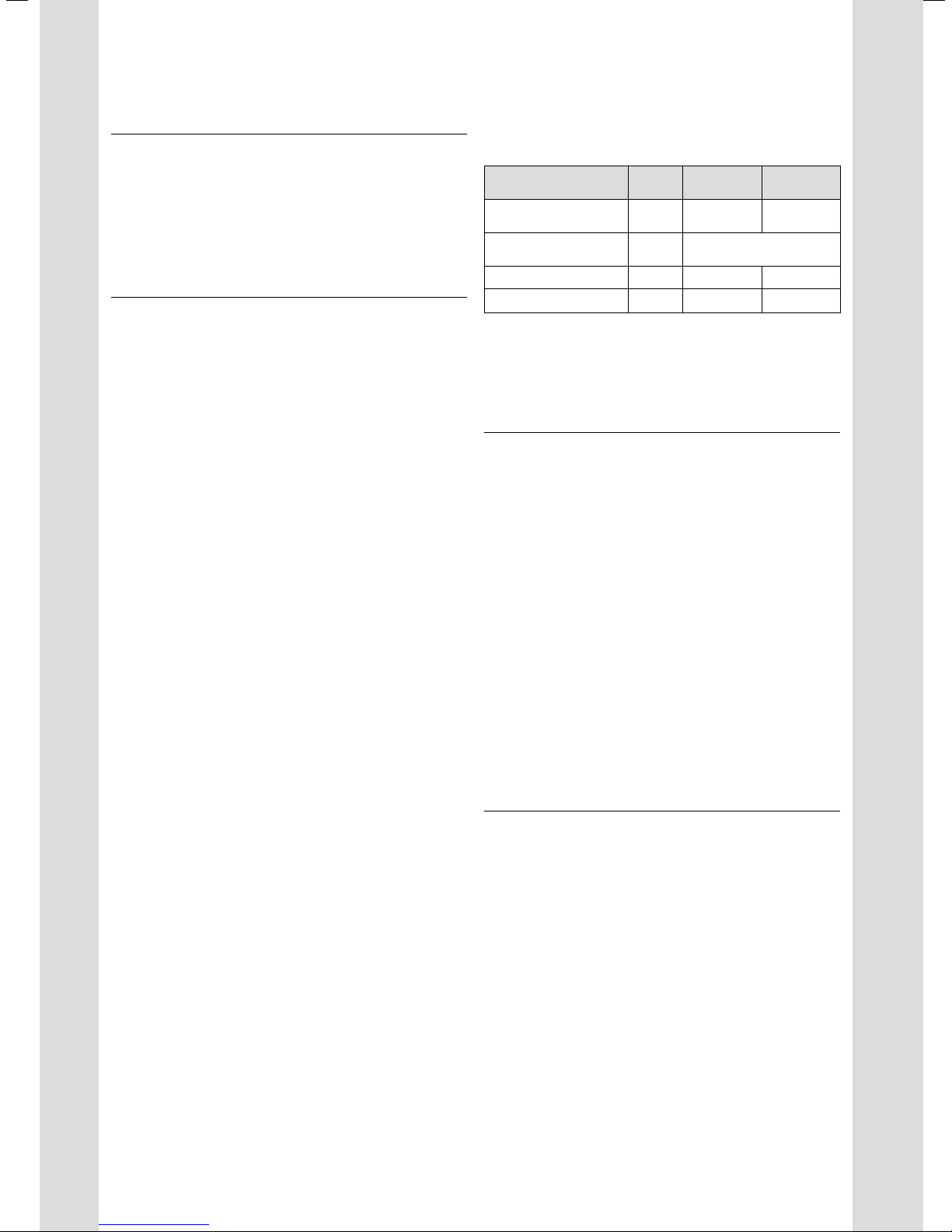

1.5 Type overview

Unit type

ecoTEC plus

806 (VU GB 806/5-5)

1006 (VU GB 1006/5-5)

1206 (VU GB 1206/5-5)

1.2 Type overview

Designated country

(designation in accordance with ISO 3166)

GB (Great Britain)

IE (Ireland)

GB (Great Britain)

IE (Ireland)

GB (Great Britain)

IE (Ireland)

Approval

category

II

2H3P

II

2H3P

II

2H3P

Gas group

Natural gas H - G20 - 2kPa (20mbar)

Propane - G31 - 3.7kPa (37mbar)

Propane - G31 - 5kPa (50mbar)

Natural gas H - G20 - 2kPa (20mbar)

Propane - G31 - 3.7kPa (37mbar)

Propane - G31 - 5kPa (50mbar)

Natural gas H - G20 - 2kPa (20mbar)

Propane - G31 - 3.7kPa (37mbar)

Propane - G31 - 5kPa (50mbar)

Nominal heat output

range [kW]

16 - 80

20 - 100

24 - 120

4 ecoTEC plus installation and maintenance instructions 0020134823_01

Page 5

a

Safety

2

a

2 Safety

2.1 Safety and warning information

> When installing the ecoTEC plus, you must observe all

the general safety information and the warning notes

that appear before all of the actions.

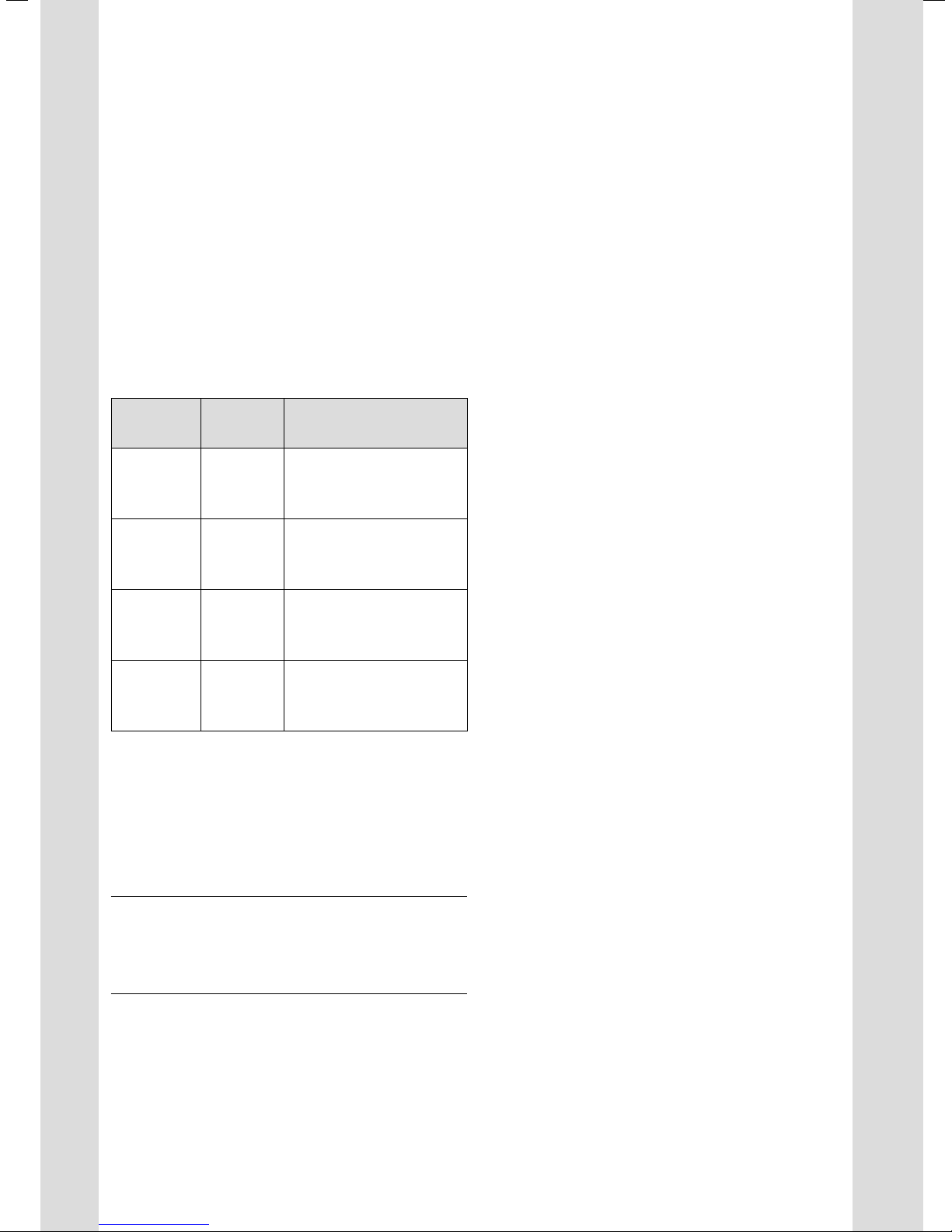

2.1.1 Classification of warnings

The warnings are classified in accordance with the severity

of the possible danger using the following warning signs

and signal words:

Warning

symbol

a

Signal

word

Danger!

Danger!

Explanation

Imminent danger to life or

risk of severe personal

injury

Risk of death from electric

shock

e

Warning. Risk of minor personal injury

a

Risk of material or environ-

Caution.

mental damage

b

2.2 Intended use

There is a risk of injury or death to the user or others, or of

damage to the product and other property, in the event of

improper use or use for which it is not intended.

The product is intended as a heat generator for closed hot

water/central heating installations and for hot water generation. The products referred to in this manual must only be

installed and operated in conjunction with the accessories

listed in the associated flue pipe installation manual.

Intended use includes the following:

– observance of accompanying operating, installation and

servicing instructions for the Vaillant product, as well as

all other components of the system

– installing and fitting the product in accordance with the

product and system approval

– compliance with all inspection and maintenance condi-

tions listed in the instructions.

The use of the product in vehicles, such as mobile homes

and caravans, is not classed as intended use. Units that are

not classed as vehicles are those that are installed in a

fixed and permanent location (known as "fixed installation").

Installing and using the product in locations where it will be

subject to possible moisture or spray water is considered to

be improper use.

Any other use that is not specified in these instructions, or

use beyond that specified in this document, shall be considered improper use. Any direct commercial or industrial use

is also deemed to be improper.

The manufacturer/supplier is not liable for any claims or

damage resulting from improper use. The user alone bears

the risk.

Caution.

Improper use of any kind is prohibited.

2.1 Classification of warnings

2.1.2 Structure of warnings

Warning signs are identified by an upper and lower separating line. and are laid out according to the following basic

principle:

Signal word!

Type and source of danger!

a

ecoTEC plus installation and maintenance instructions 0020134823_01 5

Explanation of the type and source of

danger

> Measures for averting the danger

Page 6

a

2

Safety

a

2.3 Basic safety information

> Observe the following safety information at all times.

European installation directive

Installation and maintenance of the boiler must only be performed by a competent person with valid accreditation from

the Health and Safety Executive in accordance with the

"Gas Safety (Installation and Use) Regulations 1998" (hereinafter abbreviated to "competent person" or "heating specialist company"). The existing regulations, rules and guidelines must be observed when doing so. The competent person is also responsible for inspection, maintenance and

repairs to the boiler, and alterations to the gas volume setting.

IE only: The installation must comply with the current Version of I.S.813 ‘Domestic Gas Installations’ and current

Building Regulations.

The current ETCI Regulations for installing electrical systems must also be observed.

Risk of poisoning and burns caused by escaping

hot flue gases!

Hot flue gas can escape and cause poisoning and burns if

the boiler is operated with an incompletely installed or flue

pipe or if the boiler is operated with internal leaks with the

front casing open.

> Operate the boiler for start-up and in continuous mode

only when the front casing is fitted and closed and the

flue pipe is completely fitted.

> For test purposes only (such as gas flow pressure test-

ing), the boiler may be operated with the front casing

removed for short durations ONLY but must have a completely installed flue pipe.

What to do in an emergency if you smell gas

Installation errors, damage, tampering, unauthorised installation sites or similar can cause gas to escape and result in

a risk of poisoning and explosion. If there is a smell of gas

in the building, proceed as follows:

> Avoid rooms that smell of gas.

> If possible, open doors and windows fully and ensure

adequate ventilation.

> Do not use naked flames (e.g. lighters, matches).

> Do not smoke.

> Do not use any electrical switches, mains plugs, door-

bells, telephones or other communication systems in the

building.

> Close the gas meter isolator device or the main isolator.

> If possible, close the gas isolator cock in the gas supply.

> Warn other occupants in the building by yelling or bang-

ing on doors or walls.

> Leave the building.

> If you can actually hear gas leaking, leave the building

immediately and ensure that others do not enter the

building.

> Alert the fire brigade and police when you are outside

the building.

> Notify the gas supply company or National Grid Transco

0800 111999 by telephone from outside the building!

What to do if you smell flue gas

Installation errors, damage, tampering with the unit, unauthorised installation sites or similar can cause flue gas to

escape and result in a risk of poisoning. If there is a smell of

flue gas in the building, proceed as follows:

> If possible, open doors and windows fully and ensure

adequate ventilation.

> Switch the boiler off.

> Check the flue gas routes in the boiler and the flue gas

pipes.

> In particular, check that the flue gas opening is not

blocked. If required, seek expert assistance for this.

Installation in rooms with ventilation

For open-flued operation, the unit must not be placed in

rooms from which the air is extracted using fans (for example, ventilation systems, extractor hoods, tumble dryer ventilation). These systems create negative pressure in the

room. As a result of the negative pressure, flue gas from

the opening is drawn through the annular gap between the

flue gas pipe and the shaft into the installation room.

The unit may only be operated dependent on the room air,

if simultaneous operation of the unit and fan is not possible.

> To interlock the fan and unit, install the Vaillant acces-

sory multi-functional module 2 from 7.

> Please inform the system operator of the possible risk

from running exhaust fans.

Material damage caused by corrosion

To prevent corrosion on the boiler and also in the flue pipe,

note the following:

> Do not use sprays, solvents, chlorinated cleaning agents,

paint, adhesives or similar substances in the vicinity of

the boiler.

Under unfavourable circumstances, these substances may

cause corrosion.

Material damage due to improper use and/or

unsuitable tools

The use of unsuitable tools or improper use thereof may

cause damage, such as gas or water leaks.

> To tighten or loosen threaded connections, only use a

suitable open-ended spanner (combination wrench) – do

not use pipe wrenches, extensions, etc.

Changes to the surroundings of the boiler

Changes may not be made to the following equipment:

– the boiler

– the gas, air and water pipes and power lines

– the flue pipe

– the drain line and expansion relief valve for the heating

water

– constructional conditions that could affect the opera-

tional safety of the boiler

6 ecoTEC plus installation and maintenance instructions 0020134823_01

Page 7

a

Safety

2

a

Using the correct gas type

Using the wrong gas type may cause a fault shutdown on

the boiler. Furthermore, ignition and combustion noise may

occur in the boiler.

> Observe the gas setting values in accordance with

¬section1.5.

Risk of death due to lack of safety devices

A lack of safety devices (e.g. expansion relief valve, expansion vessel) can lead to potentially fatal scalding and other

injuries, e.g. due to explosions.

The schematic drawings included in this document do not

show all safety devices required for correct installation.

> Install the necessary safety devices in the system.

> Inform the operator about the function and position of

the safety devices.

> Observe the applicable national and international laws,

standards and guidelines.

2.4 General requirements

2.4.1 Related documents

To ensure the safe installation and continued satisfactory

operation of your appliance, all works shall be carried out

by a competent installer fully conversant with the equired

current and up to date, acts standards, laws and regulations

relevant for this range of equipment at the time of installation. In addition any special requirements of Local Authorities, gas undertakings or insurers must be complied with.

Installers shall carryout a full site risk assessment and put

into place all necessary steps and procedures to comply

with Health and Safety at Work Act and ensure safety of

themselves and others with regard to manual handling and

working at height requirements.

Attention shall be paid to (but not restricted to) the following:

– Gas Safety (Installation and Use) regulations.

– Non Domestic Heating, Cooling and Ventilation Compli-

ance Guide.

– All Building Regulations 2000 for England and Wales,(as

amended).

– (Includes Approved Codes of Practice and Approved Doc-

uments for building regulations e.g. L1, L2A, L2B, L8.)

– The Building Standards, Scotland, and any requirements

determined by the local authorities within.

– BS 7671 Requirements for electrical installations. IEE Wir-

ing Regulations

– The Electricity at Work Regulations.

– The Clean Air Act 1993, 1968 and the 3rd Edition of the

1956 Clean Air Act. (installations exceeding 150kW)

– The Water supply (water fittings) regulations 1999.

– BS 5854 Code of practice for flues and flue structures in

buildings.

– BS EN 12828 Design of water-based heating systems.

– BS 6644 Specification for the installation of gas fired

hot water boilers with rated inputs between 70 kW (net)

and 1.8 MW (net) (2nd and 3rd family gases).

– I.S. 820 Non Domestic gas Installations (Ireland)

– BS 6700 Specification for the design, installation, testing

and maintenance of services supplying water for domes-

tic use within buildings and their curtilages.

– BS 6880 Code of practice for low temperature heating

systems with outputs greater than 45 kW.

Part 1 Fundamental and design considerations.

Part 2 Selection of equipment.

Part 3 Installation, commissioning and maintenance.

– BS 6981 Installation of low pressure gas pipework of up

to 35mm in domestic premises.

– BS 4814 Specification for: Expansion vessels using an

internal diaphragm, for sealed hot water and heating sys-

tems.

– BS 7074 Application, selection and installation of expan-

sion vessels and ancillary equipment for sealed water

systems.

Part 1 Code of practice for domestic heating and hot water.

Part 2 Code of practice for low and medium temperature

hot water systems.

– BS 7593 Code of practice for treatment of water in

domestic hot water central heating systems

– BS EN 13831 Closed expansion vessels with built in dia-

phragm

– BS EN 14336 Heating systems in buildings. Installation

and commissioning of water based heating systems.

Institute of Gas Engineers Publications:

– IGE/UP/1 (Edition 2) Strength testing, tightness testing

and direct purging of industrial and commercial gas

installations.

– IGE/UP/1A (Edition 2) Strength testing, tightness testing

and direct purging of small, low pressure industrial and

commercial natural gas installations.

– IGE/UP/1B (Edition 2) Tightness testing and direct purg-

ing of small natural gas installations.

– IGE/UP/ 7 (Edition 2) Gas in timber and light steel

framed buildings.

IGE/UP/10 Installation of gas appliances in industrial and

–

commercial premises.

Part 1 Flued appliances.

ecoTEC plus installation and maintenance instructions 0020134823_01 7

Page 8

a

2

Safety

a

2.4.2 Installation site

The installation site of the boiler should allow proper connection of the flue pipe to the boiler. In addition, there

should be adequate room for maintenance work and air circulation around the boiler.

The boiler must be set up in a separate installation room.

In case of installation of the boiler in an unusual location,

special procedures may be necessary and BS 5546 and

BS6798 give detailed instructions on this aspect. The boiler

must be installed on a flat, vertical wall, which must be sufficiently robust to take the weight of the boiler. The boiler

may be installed on a combustible wall, subject to the

requirements of the Local Authorities and Building Regulations.

If the boiler is to be installed in a timber frame

house, the installation must be performed in

i

b

> Observe the following when choosing the installation site

and operating the boiler:

> Operate the boiler independently of room air or in a sep-

arate installation room, otherwise this may cause corrosion in the boiler and in the flue gas installation, if

> Do not route the combustion air through an old oil fur-

nace hearth, as this can also cause corrosion.

> When installing the unit, please observe the local con-

densate regulations,

The condensate connection must not be modified or

blocked.

accordance with the Institute of Gas Engineers

Publication IG/UP/7 edition 2 "Guideline for gas

installations in wooden and light metal-clad residences".

Caution.

Risk of damage caused by aggressive

vapours and dust.

Aggressive vapours and dust in the installation room may cause corrosion damage to

the boiler and to the flue gas installation.

> Ensure that the boiler is room-sealed if

the air in the installation room contains

aggressive vapours or dust.

– Do not install the boiler in rooms prone to frost.

– Do not install the boiler in rooms in which the com-

bustion air contains chemical substances, e.g. fluoride,

chlorine, sulphur, dust, etc. (e.g. sprays, solvents,

cleaning agents, paint, adhesives).

– the combustion air supply contains the aforemen-

tioned substances,

– you install the boiler in hairdresser salons, painter's or

joiner's workshops, cleaning businesses or similar.

– avoid horizontal sections in the condensate and flue

gas route.

2.4.3 Gas supply

An existing gas meter should be checked to ensure that it is

capable of passing the rate of gas supply required.

The lines must be fitted in accordance with BS 6891. In IE in

accordance with the current issue of IS813. The lines

between the gas meter and boiler must be of an appropriate size.

Do not use any lines that are smaller than the connection

to the boiler (25mm). The complete system must be tested

for leaks and purged as described in BS 6891.

2.4.4 Electrical connection

Danger!

Risk of death from electric shock!

e

A common, single-phase 230V-, ~50Hz electricity supply

fused to a max. 3 A must be provided for the boiler and its

additional controllers in accordance with the latest edition

of the directive BS7671 (IEE Wiring Regulations) and any

other local regulations that may apply. In IE reference

should be made to the current edition of the ETCI rules. The

method of connection to the power mains must provide a

means of completely isolating the boiler and its ancillary

controllers from the power mains. It is preferable to isolate

the boiler using a two-pin switch with a 3-mm contact opening on both pins. The isolator should be attached and

marked accordingly so that it is easily accessible and adjacent to the boiler.

2.4.5 System of parts through which water flows

Lines which do not form part of the usable heating surface

should be insulated to prevent heat losses and possible

freezing up, especially where the lines run under roofs and

ventilated cellar spaces. The drain connections must be easily accessible, so that the entire system including the boiler

and hot water system can be drained. The drain connections should be at least 1/2" (BSP nominal size) and must be

in accordance with BS2879.

The water pipes must be thoroughly cleaned, especially

when connecting a new boiler to an existing system.

If the boiler is not earthed, it may be electrically live if a defect occurs.

> Earth the boiler and the metal pipes that

are connected to the boiler.

8 ecoTEC plus installation and maintenance instructions 0020134823_01

Page 9

a

Safety

2

a

Caution.

Risk of material damage if the heating

b

Mixing additives with the heating water may result in material damage. However, no incompatibility with Vaillant boilers has been detected with proper use of the following

products over a long period.

> When using additives, follow the manufacturer's instruc-

tions without exception.

Vaillant accepts no liability for the compatibility of any additive or its effectiveness in the rest of the heating installation.

Additives for cleaning measures (subsequent

flushing required)

– Fernox F3

– Sentinel X 300

– Sentinel X 400

Additives intended to remain permanently in the

system

– Fernox F1

– Fernox F2

– Sentinel X 100

– Sentinel X 200

Additives for frost protection intended to remain

permanently in the system

– Fernox Antifreeze Alphi 11

– Sentinel X 500

> Inform the operator about the measures required if you

have used these additives.

> Inform the operator about the measures required for

frost protection.

water is treated with unsuitable frost or

corrosion protection agents!

Frost and corrosion protection agents may

cause changes in the seals, noises during

heating and may lead to further damage.

> Do not use any unsuitable frost or corro-

sion protection agents.

Permissible salt content

Heating water

characteristics

Electrical conductivity at

25 °C

Appearance

pH value at 25 °C 8.2 - 10.0

Oxygen mg/l

1) For aluminium and aluminium alloys, the pH value range is

restricted from 6.5 to 8.5.

2.2 Guideline values for heating water: Salt content

Permissible water hardness

Caution.

Heating water that is extremely calcifer-

b

ous or corrosive or contaminated by

chemicals may cause damage to the

boiler.

Unsuitable heating water damages the

seals and diaphragms, blocks components

in the boiler and heating installation

through which the water flows, and causes

noise.

The heating water must fulfil the limit values based on the system volume in accordance with fig.2.1 and, if required, must be

treated.

In addition, the national regulations with

regard to water treatment shall apply.

To treat the water, we recommend treatment plants that work according to the

reverse osmosis process.

> Condition the water for the initial filling

as well as the water for any subsequent

fillings.

Unit Low-salt Saline

1)

100 - 1500

8.2 - 10.0

mS/cm < 100

Free of sedimentary

materials

< 0.1 < 0.02

1)

ecoTEC plus installation and maintenance instructions 0020134823_01 9

Page 10

a

2

Safety

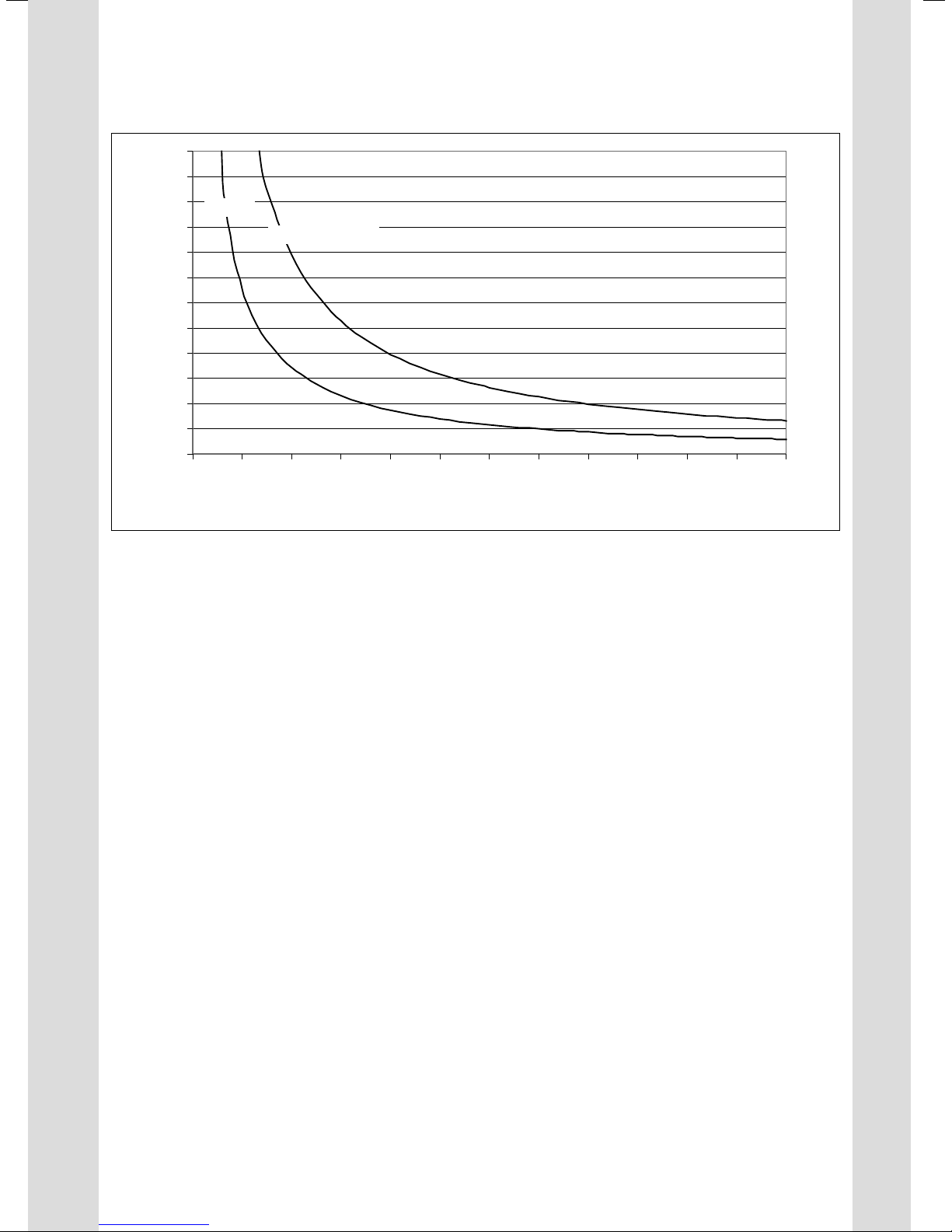

3,6

3,3

3

2,7

2,4

]

3

2,1

1,8

1,5

y [mol/m

1,2

0,9

0,6

0,3

0,0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

80 kW

100/120 kW

80 kW: A

B

a

A

100/120 kW: B

x [l]

2.1 Water preparation depending on water hardness and system

volume

Key:

x System volume [l]

y Water hardness [mol/m3]

(1 mol/m3 corresponds to 100 mg/l CaCO3)

A Water treatment required

B Water treatment not required

2.4.6 Expansion relief valve

The boiler is supplied with a 6bar presure relief valve,

which must be fitted to the boiler and drained to a safe but

visible location. The safety discharge pipe must be a minimum of 18mm diameter and must be solely used for this

purpose.

Ensure that all components that are fitted in the heating

installation are suitable for a max. operating pressure of

6bar.

2.4.7 Purging

The boiler is equipped with an automatic air vent. Other

measures need to be taken to allow the heating system to

be purged during filling and during commissioning either

manually or using an automatic air vent.

Risk of damage due to frost

Insufficient frost protection measures may cause frost damage to the heating installation

> Explain to the operator how to protect the heating instal-

lation against frost.

10 ecoTEC plus installation and maintenance instructions 0020134823_01

Page 11

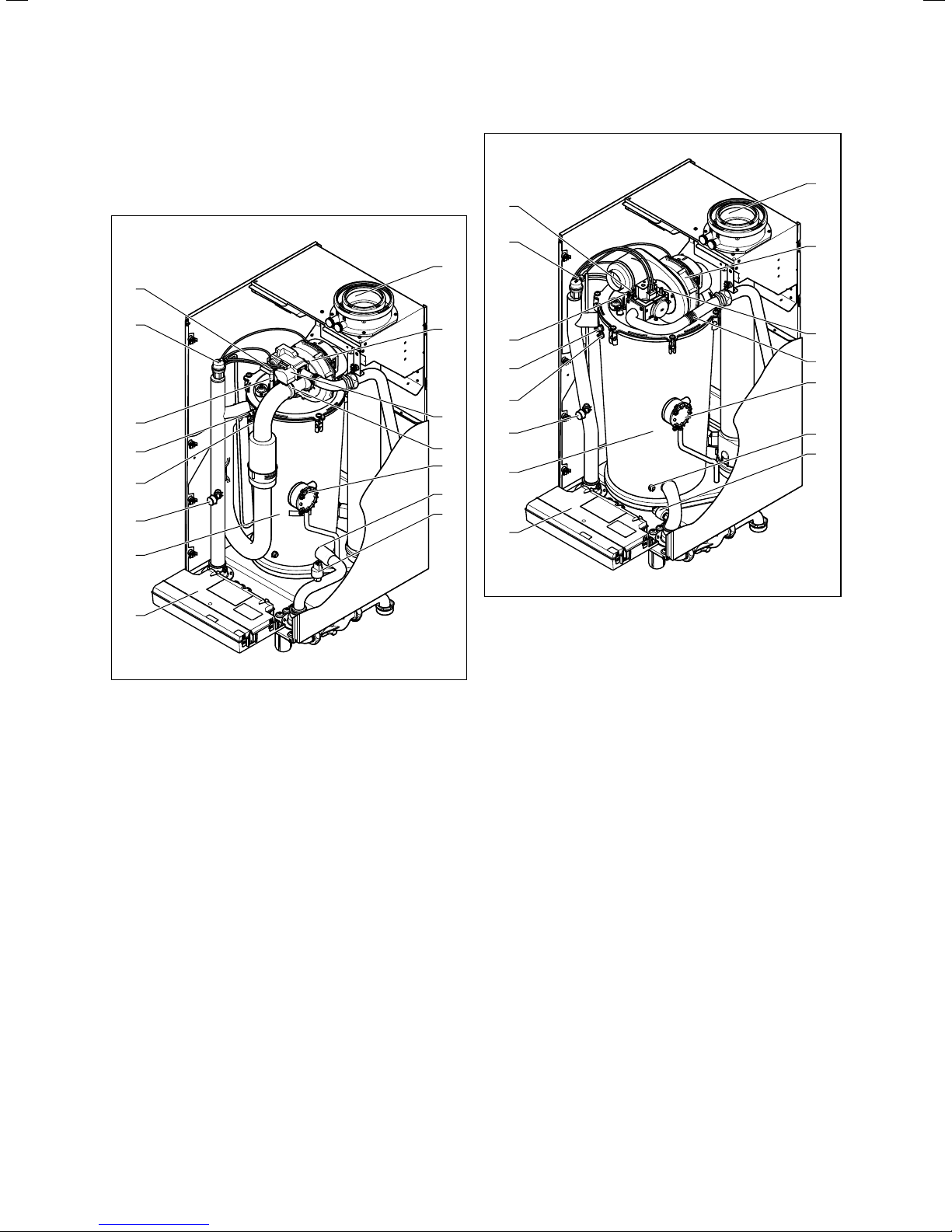

3 Unit and functional description

Unit and functional description

3

Construction and function

15

14

13

12

11

10

9

8

15

14

1

2

13

12

11

3

10

4

5

6

7

9

8

3.2 Functional elements (VUGB1006/5-5 and

VUGB1206/5-5)

1

2

3

4

5

6

7

3.1 Functional elements (VUGB806/5-5)

Key

1 Connection for the flue pipe

2 Fan

3 Gas valve

4 Connection for air intake pipe

5 Flue gas pressure cartridge

6 Return sensor

7 Water pressure sensor

8 Electronics box

9 Stainless steel heat exchanger

10 Pressure gauge

11 Flow sensor

12 Safety cut-out

13 Ignition electrode

14 Automatic air vent

15 Monitoring electrode

Key

1 Connection for the flue pipe

2 Fan

3 Gas valve

4 Supply air collector

5 Flue gas pressure cartridge

6 Return sensor

7 Water pressure sensor

8 Electronics box

9 Stainless steel heat exchanger

10 Feed sensor

11 Safety cut-out

12 Ignition electrode

13 Automatic air vent

14 Monitoring electrode

ecoTEC plus installation and maintenance instructions 0020134823_01 11

Page 12

Installation

4

4 Installation

4.1 Scope of delivery

The Vaillant ecoTEC plus is delivered pre-assembled in a

packaging unit.

4.1.1 Unpacking the boiler

> Open the box by pulling on the tear-off strings.

> Remove the boiler from its box.

> Remove the protective film from all parts of the boiler.

> Place the boiler so that it is vertical on the foot pad.

4.1.2 Checking the scope of delivery

> Check that the scope of delivery is complete and intact

(¬ table 4.1).

Number Description

1 Hanging bracket

1 Unit

Enclosed documentation

1

- Installation and maintenance instructions

- Operating instructions

- Flue pipe installation manual

- Installation template

- Guarantee card

- Various stickers

1 Condensate siphon

Bag containing small parts (assembly kit)

1

- 1 x expansion relief valve, 6bar

- 2 x service valves

- 6 x wood screws

- 6 x rawl plug, 10 x 60 mm

- 6 x washers

4.1 Scope of delivery

4.1.3 Disposing of the packaging

> Dispose of the cardboard packaging used on the ecoTEC

plus at a recovered paper collection point.

> Dispose of the plastic film and plastic filling at an appro-

priate plastic recycling site.

> Observe valid national regulations.

4.2 Transporting the unit

Important:

In regard to the regulations of 1992 concerning the manual

handling of loads, the unit exceeds the weight which can be

lifted by a single person.

General handling recommendations

> Clear your path before lifting the unit.

> Use safe lifting techniques – keep your back straight –

and bend your legs at the knee.

> Hold the load as close as possible to your body. Do not

twist your body – instead, reposition your feet.

> If the unit is being lifted by 2 persons, ensure your move-

ments are coordinated during lifting.

> Avoid bending your upper body - do not lean forwards or

to the side.

> Wear appropriate cut resistant and non-slip gloves to

protect yourself against sharp edges and maintain a safe

and secure grip.

> If required, get somebody to assist you in this.

Unloading the box from the delivery van

It is recommended that two people lift the unit together.

> Lift the box using the straps provided.

> Use safe lifting techniques – keep your back straight –

and bend your legs at the knee.

> Hold the load as close as possible to your body.

> If the unit is being lifted by 2 persons, ensure your move-

ments are coordinated during lifting.

> If required, get somebody to assist you in this.

Transporting the box from the delivery point to the

installation site – ground floor

It is recommended that two people lift the unit together.

> Use safe lifting techniques – keep your back straight –

and bend your legs at the knee.

> Hold the load as close as possible to your body.

> If the unit is being lifted by 2 persons, ensure your move-

ments are coordinated during lifting.

> Clear your path before lifting the unit.

> Use safe lifting techniques – keep your back straight –

and bend your legs at the knee.

> Do not twist your body – instead, reposition your feet.

> Avoid tripping hazards, slippery or wet surfaces as well

as steps and stairs.

> If required, get somebody to assist you in this.

12 ecoTEC plus installation and maintenance instructions 0020134823_01

Page 13

Installation

4

Transporting the box from the delivery point to the

installation site – first or higher floor, cellar

It is recommended that two people lift the unit together.

> Use safe lifting techniques – keep your back straight –

and bend your legs at the knee.

> Hold the load as close as possible to your body.

> If the unit is being lifted by 2 persons, ensure your move-

ments are coordinated during lifting.

> Avoid bending your upper body - do not lean forwards or

to the side.

> Clear your path before lifting the unit.

> Use safe lifting techniques – keep your back straight –

and bend your legs at the knee.

> Do not twist your body – instead, reposition your feet.

> Avoid tripping hazards, slippery or wet surfaces as well

as steps and stairs.

> If required, get somebody to assist you in this.

Transporting the box from the delivery point to the

installation site – roof

> The unit must be lifted by two persons.

> Coordinate your movements.

> Avoid bending your upper body - do not lean forwards or

to the side.

> Clear your path before lifting the unit.

> Avoid tripping hazards, slippery or wet surfaces as well

as steps and stairs.

> If the unit is being transported to an attic storey, one

person must guide the unit from above, while the other

supports the unit from below.

> Use safe lifting techniques – keep your back straight –

and bend your legs at the knee.

> Hold the load as close as possible to your body.

> If required, get somebody to assist you in this.

> The attic storey must be safely accessible and must have

a solid floor and suitable lighting.

> If the attic storey is accessed via a hatch, the hatch must

be secured against falling using a suitable guard rail.

> Before setting up the unit, it is recommended that you

perform a risk assessment of the attic storey, to clarify

access, floor rigidity, lighting and other factors, and any

measures to be undertaken in advance.

Unpacking the unit from the box

> It is recommended that two persons lift the unit out of

the box.

> Always keep the working area free from obstacles.

> Cut through the two straps.

> Open the box flaps.

> Remove the polystyrene parts from the box

> Separate the box in the centre at the pull-out strap.

> Lift the upper part of the box away.

> Lift the unit out of the box.

> Use safe lifting techniques – keep your back straight –

and bend your legs at the knee.

> Hold the load as close as possible to your body.

> If required, get somebody to assist you in this.

> Dispose of the packaging responsibly.

> Wear appropriate cut-resistant and non-slip gloves to

protect yourself against sharp edges and maintain a safe

and secure grip while handling the unpackaged unit.

Positioning the unit for final installation – no

obstacles

> If the unit weighs more than 25 kg, it should always be

transported by two persons, where possible.

> Fix the unit bracket securely to the wall before lifting the

unit and placing it in position.

> Ensure that you hold on to the front and side of the unit

securely, lift it, hold it in a balanced position and then lift

it further upwards and position it on the bracket.

> Use safe lifting techniques – keep your back straight –

and bend your legs at the knee –if you are lifting some-

thing from the floor.

> Do not twist your body – instead, reposition your feet.

> During the entire lifting process, hold the boiler as close

as possible to your body to minimise the strain on your

back.

> Ensure your movements are coordinated so that the

weight of the unit is evenly distributed.

> If required, get somebody to assist you in this.

> Wear appropriate cut-resistant and non-slip gloves to

protect yourself against sharp edges and maintain a safe

and secure grip while handling the unit.

Positioning the unit for final installation – above a

work surface, possible obstacles, etc.

If the unit weighs more than 25 kg, it should always be

transported by two persons, where possible.

> Fix the unit bracket securely to the wall before lifting the

unit and placing it in position.

> If required, provide the work surface with sufficient pro-

tection against damage.

> Ensure that you hold the unit securely at the front and

side and lift it - if available - onto the work surface.

> Hold the unit in a balanced position and then lift it fur-

ther upwards and position it on the bracket.

> If the unit is being positioned on the bracket by two per-

sons, ensure that you have a firm grip on the front and

side/bottom of the boiler.

> Ensure your movements are coordinated if the unit is

being lifted by 2 persons, so that its weight is evenly dis-

tributed.

Use safe lifting techniques – keep your back straight – and

bend your legs at the knee –if you are lifting something

from the floor.

> Do not twist your body – instead, reposition your feet.

> During the entire lifting process, hold the boiler as close

as possible to your body to minimise the strain on your

back.

> Avoid bending your upper body - do not lean forwards or

to the side.

> If required, get somebody to assist you in this.

> Wear appropriate cut-resistant and non-slip gloves to

protect yourself against sharp edges and maintain a safe

and secure grip while handling the unit.

ecoTEC plus installation and maintenance instructions 0020134823_01 13

Page 14

Installation

4

Positioning the unit for final installation –

restricted installation

> If the unit weighs more than 25 kg, it should always be

transported by two persons, where possible.

> Fix the unit bracket securely to the wall before lifting the

unit and placing it in position.

> If required, provide the work surface with sufficient pro-

tection against damage.

> Ensure that you hold the unit securely at the front and

side and lift it - if available - onto the work surface.

> Hold the unit in a balanced position and then lift it fur-

ther upwards and position it on the bracket.

> If the unit is being positioned on the bracket by two per-

sons, ensure that you have a firm grip on the front and

side/bottom of the boiler.

> Ensure your movements are coordinated if the unit is

being lifted by 2 persons, so that its weight is evenly distributed.

> Use safe lifting techniques – keep your back straight –

and bend your legs at the knee –if you are lifting some-

thing from the floor.

> Do not twist your body – instead, reposition your feet.

> During the entire lifting process, hold the boiler as close

as possible to your body to minimise the strain on your

back.

> If required, get somebody to assist you in this.

> Wear appropriate cut-resistant and non-slip gloves to

protect yourself against sharp edges and maintain a safe

and secure grip while handling the unit.

Positioning the unit for final installation – with

restricted installation position under the roof.

> If the unit weighs more than 25 kg, it should always be

transported by two persons, where possible.

> Ensure that you hold onto the front and side of the unit

securely, lift it, hold it in a balanced position and then lift

it further upwards and position it on the bracket.

> If the unit is being positioned on the bracket by two per-

sons, ensure that you have a firm grip on the front and

side/bottom of the boiler.

> Ensure your movements are coordinated if the unit is

being lifted by 2 persons, so that its weight is evenly distributed.

> If the unit is being positioned on the bracket by one per-

son, ensure that you have a firm grip and lift the boiler

from the bottom.

> Use safe lifting techniques – keep your back straight –

and bend your legs at the knee –if you are lifting some-

thing from the floor.

> Do not twist your body – instead, reposition your feet.

> During the entire lifting process, hold the boiler as close

as possible to your body to minimise the strain on your

back.

> If required, get somebody to assist you in this.

> Wear appropriate cut-resistant and non-slip gloves to

protect yourself against sharp edges and maintain a safe

and secure grip while handling the unit.

> Before setting up the unit, it is recommended that you

perform a risk assessment of the attic storey, in order to

check the access, floor rigidity, lighting, and railing, and

to take all required remedial actions before the unit is

installed.

14 ecoTEC plus installation and maintenance instructions 0020134823_01

Page 15

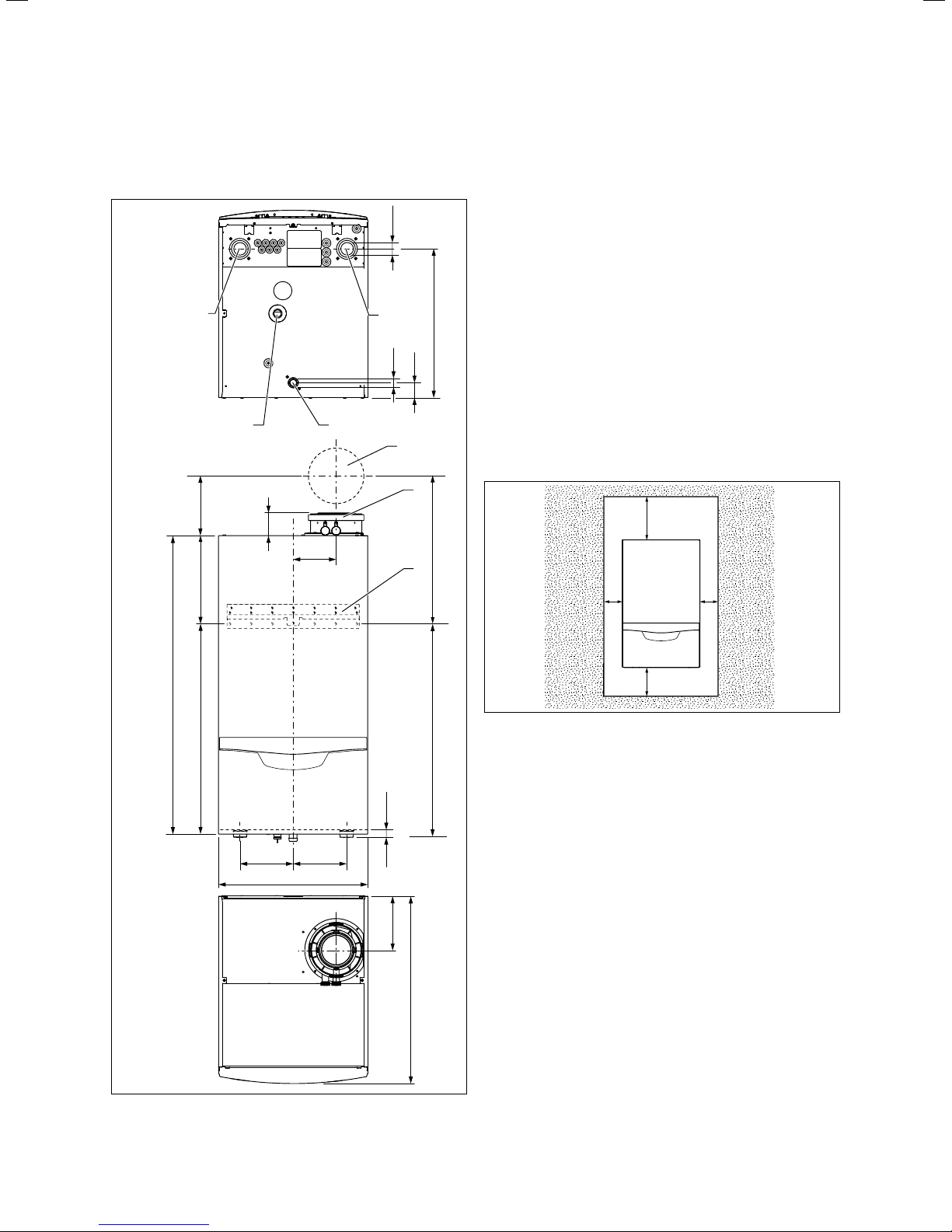

4.3 Dimension drawing and connection

dimensions

G 1 1/4

4

7

Ø25

49

482

Installation

Key

1 Wall breakthrough for flue pipe

2 Flue pipe connection

3 Hanging bracket

4 Heating flow

5 Condensate siphon connection

6 Gas connection

7 Heating return

4.4 Requirements for the installation site

4

960

190

287

673

5

70

172 172

480

138

6

1

2

3

22

4.4.1 Required minimum clearances/installation

clearances

AB

477

CC

4.2 Recommended minimum clearances/installation clearances

680,5

Key

A 350 mm (flue pipe diameter 110/160 mm)

450 mm (with cascade design)

B 400 mm

C optional approx. 200 mm

> When using the accessories, observe the minimum clear-

ances/installation clearances.

> Where units are installed in cascade, observe the gradi-

ent of the flue pipe (approx. 50mm/m).

4.1 Connection dimensions in mm

ecoTEC plus installation and maintenance instructions 0020134823_01 15

175

603

When installing the 110/160 mm flue pipe,

observe the minimum clearances in accordance

i

A side gap is not required, however you can remove the

side panels if there is sufficient space at the side

(approx.200 mm) for maintenance.

It is not necessary to ensure sufficient clearance between

the boiler and combustible materials or components as the

temperature of the boiler will always be less than the maximum permissible temperature of 85 °C due to its nominal

heat output.

with ¬fig. 4.1.

Page 16

Installation

4

4.5 Wall-mounting the boiler

Danger!

Risk of death if the load-bearing capacity

a

of the fixing elements used is insufficient!

If the fixing elements or wall do not have

sufficient load-bearing capacity, the boiler

can come loose and fall down. This may

also cause leaks in the gas line, which is

potentially fatal.

> When installing the boiler, make sure that

the fixing elements have a sufficient

load-bearing capacity.

> Check if the supplied fixing kit may be

used for the wall.

> Check the quality of the wall.

> If required, use individual stands from

the cascade programme which is availa-

ble as an accessory.

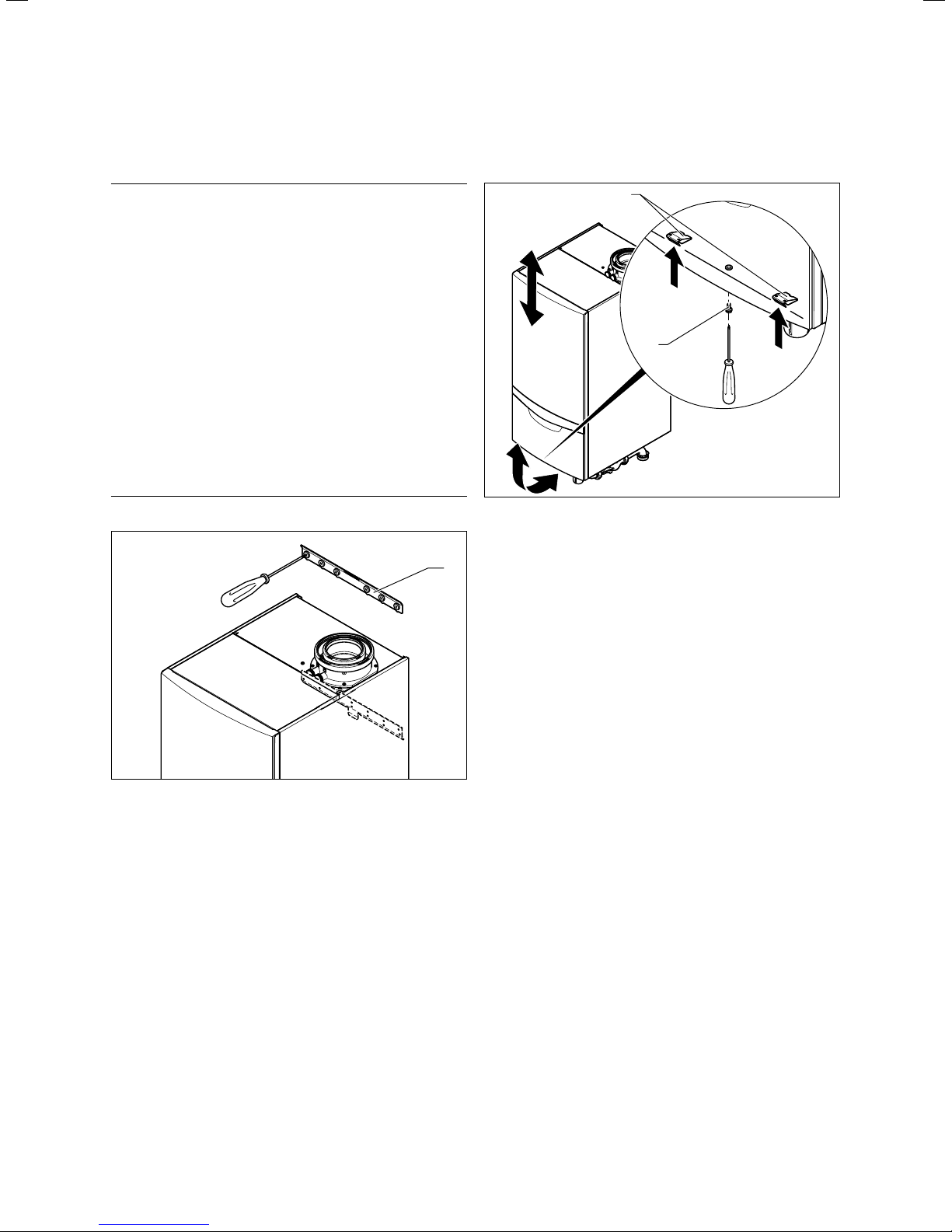

4.6 Removing/fitting the front casing

2

1

4.4 Removing the front casing

Removing the front casing

1

> Undo the screw (1)

> Push in both retaining clips (2) so that the front casing is

released.

> Pull the front casing forwards at the bottom edge.

> Lift the front casing upwards from the bracket.

4.3 Wall-mounting the boiler

> Fit the hanging bracket (1) to the wall using the rawl

plugs and screws provided with the unit.

> Hang the boiler (3) on the hanging bracket from above

using the suspension bracket.

Fitting the front casing

> Place the front casing on the upper brackets.

> Push the front casing onto the boiler until the retaining

clips (2) on the front casing snap into place. For support,

you can also pull the retaining clips (2) downwards at the

same time.

> Secure the front casing by tightening the screw (1).

16 ecoTEC plus installation and maintenance instructions 0020134823_01

Page 17

Gas installation

5

5 Gas installation

The work described in this section must only be carried out

by a competent person.

5.1 Preparing for installation

Danger!

Risk of death caused by improper gas

a

a

b

b

installation!

An incorrect gas installation may result in

leaks and an explosion.

> During installation, the legal directives

and the local regulations for gas supply

companies must be observed.

Danger!

Risk of death caused by improper gas

installation!

Tension in the gas line may result in leaks

or an explosion.

> Make sure there are no stresses in the

gas lines when it is installed.

Caution.

Risk of material damage caused by incorrect gas installation.

Excess test pressure may cause damage to

the gas valve.

> When checking the gas valve for leak-

tightness, use a max. test pressure of

1.1kPa (110mbar).

> During the gas installation, ensure that

the home pressure regulation for the

required gas flow pressure of 5mbar is

maintained in accordance with the technical data (

Caution.

Risk of material damage caused by contaminated lines.

Foreign bodies, such as welding remnants,

sealing residue or dirt in the supply lines

for gas, may cause damage to the boiler.

> Blow the gas line thoroughly clean prior

to installation.

¬section18).

Caution.

Risk of material damage caused by the

b

5.2 Connecting the gas line

5.1 Gas connection

> Fit an approved gas valve to the unit with a screw

connector.

> Fit the gas supply line to the gas valve.

> Purge the gas line before you start up the unit.

> Check the gas connection for leak-tightness.

incorrect gas type.

Using the wrong gas type may cause a fault

shutdown on the boiler. Furthermore, ignition and combustion noise may occur in the

boiler.

> Only use the gas type specified in the

type overview (

¬section1.5).

ecoTEC plus installation and maintenance instructions 0020134823_01 17

Page 18

Hydraulic installation

6

6 Hydraulic installation

The work described in this section must only be carried out

by a competent person.

6.1 Preparing for installation

Danger!

Risk of personal injury caused by incor-

a

Any condensate that occurs must only be fed in under consideration of the local regulations regarding neutralisation.

b

b

rect installation!

Heating water that leaks from the drain line

of the expansion relief valve can cause

severe burns.

> Install the expansion relief valve to

ensure that there is no danger to other

persons.

> Route a discharge pipe with inlet funnel

and siphon on the customer side from

the discharge line of the expansion relief

valve to a suitable drain.

> Make sure that the drain is visible.

Caution.

Risk of material damage caused by contaminated lines.

Foreign bodies such as welding remnants,

sealing residue or dirt in the water pipes

may cause damage to the boiler.

> Flush the heating installation thoroughly

prior to installation.

Caution.

Risk of damage from corrosion.

If non-diffusion-tight plastic pipes are used

in the heating installation, this may cause

air to enter the heating water and corrosion

of the heat generation circuit and the

boiler.

> If using non-diffusion-tight plastic pipes

in the heating installation, separate the

system by installing an external heat

exchanger between the boiler and the

heating installation.

Danger!

Risk of scalding and/or damage due to

a

b

b

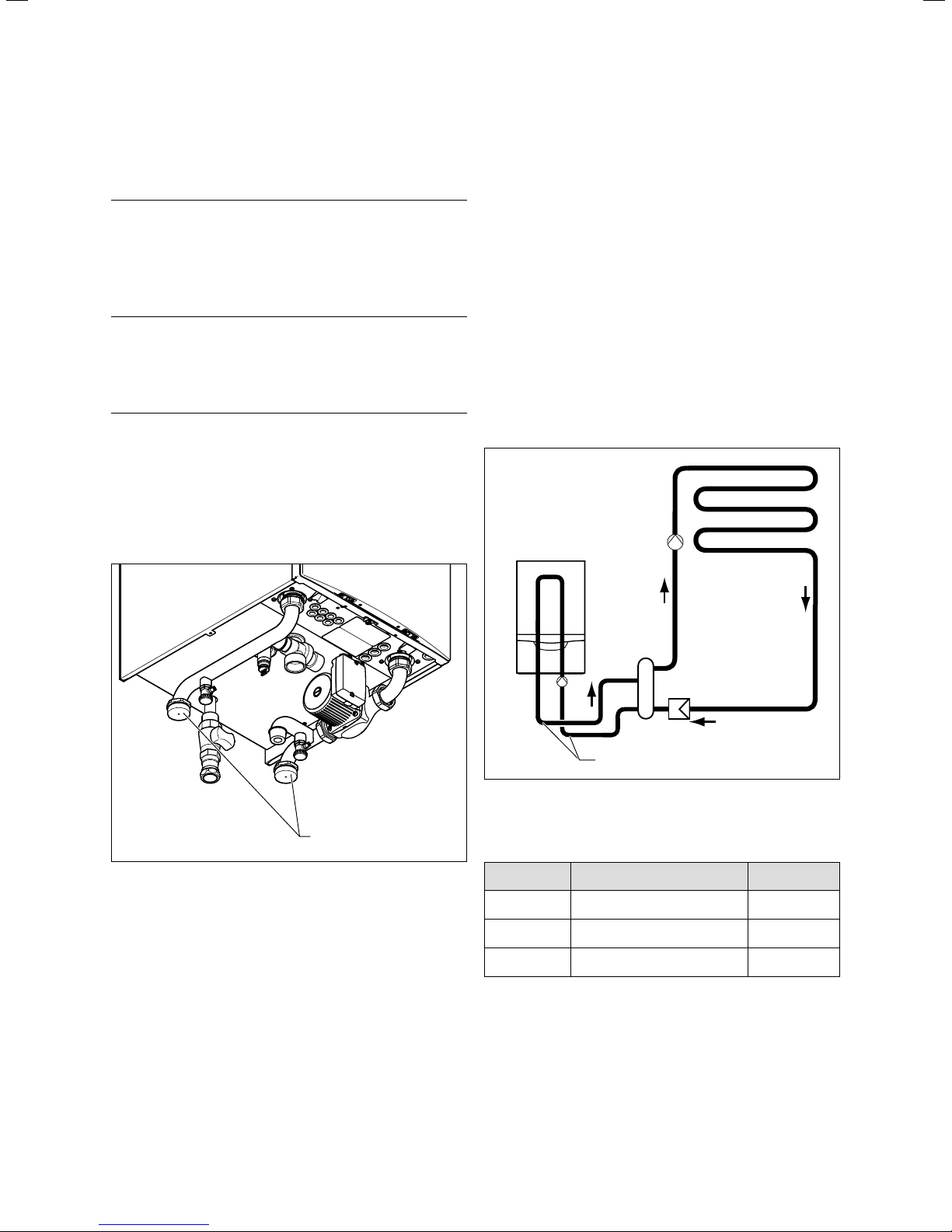

The Vaillant ecoTEC boiler should be connected using a

Vaillant pump group with modulating pumps (available as

an accessory).

This pump group has a connection option for an expansion

vessel (right-hand connection) and an expansion relief valve

(left-hand connection). You can also purchase these as

accessories.

> When installing the pump group, observe the installation

sequence for the insulation and the hydraulic pipes

(¬pump group installation instructions).

> Note that the boiler pump must always be fitted in the

return line. Otherwise, this may lead to a unit fault.

When connecting several units in cascade operation, you

must install a non-return flap from the cascade connection

set for each individual unit in the unit supply.

A non-return flap from a third-party manufacturer must

have no more than 30mbar pressure losses for a volume

flow of 4.5m

leaking water.

Stresses in the supply line may cause leaks.

> Make sure there is no voltage in the sup-

ply lines when they are installed.

Caution.

Risk of damage caused by incorrect

installation.

Stresses in the supply line may cause leaks.

> Make sure there is no voltage in the sup-

ply lines when they are installed.

Caution.

Risk of damage caused by heat transfer

when soldering.

Heat that is transferred during soldering

may cause damage to the seals in the service valves.

> Do not solder the connection pieces if

the connection pieces are screwed to the

service valves.

3

/h.

18 ecoTEC plus installation and maintenance instructions 0020134823_01

Page 19

Hydraulic installation

6

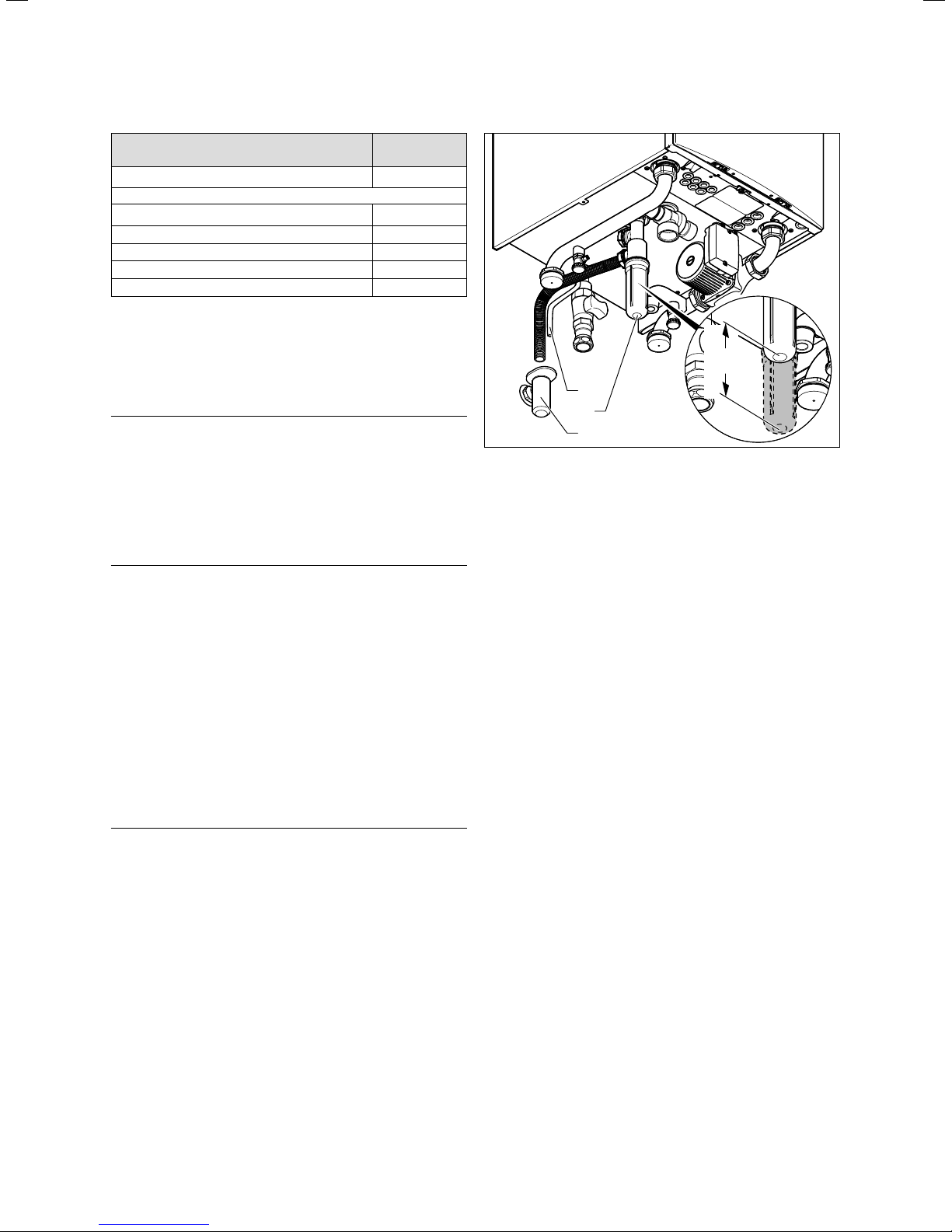

6.2 Connecting the heating flow and heating

return

Caution.

Risk of material damage caused by incor-

b

b

i

rect installation.

Stresses in the supply line may cause leaks.

> Make sure there is no voltage in the sup-

ply lines when they are installed.

Caution.

Risk of damage to the service valves.

> Do not solder the connection pieces if

the connection pieces are screwed to the

service valves.

Seals made of rubber-like materials may be sub-

ject to plastic deformation, which may lead to

pressure losses.

We recommend using seals made of a paste-like

fibre material.

Hydraulic connection

For connection to the system a hydraulic header has to be

used. In difficult cases a plate to plate heat exchanger is

recommended. In all instances the system water should be

adequately treated.

To this end, various plate heat exchangers are available as

accessories, depending on the output of a unit or in cascade connection. The pressure loss is adjusted to the pump

group that is offered as an accessory. The minimum volume

of circulating water is guaranteed in the unit circuit thanks

to the original plate heat exchangers and pump groups, provided the maximum pressure losses are not exceeded in the

piping.

To prevent contamination, it is recommended that you

install a dirt filter when using plate heat exchangers. This

prevents excessive contamination of the heat exchanger.

Back-purging devices for cleaning the plate heat exchanger

are to be placed on-site.

Ø 1 1/4"

6.2 Diameter of the supply lines

1

6.1 Installing the heating flow and heating return

> Insert a flat gasket in each.

> Screw the service valves onto the flow and return con-

nection (1) of the pump group.

> Screw the service valves to the customer's installation.

The diameter of the line is 1 1/2".

ecoTEC plus installation and maintenance instructions 0020134823_01 19

The following remaining feed heads are available at the unit

supply:

Power Description

80 kW Modulating pump

100 kW

120 kW

6.1 Remaining feed head pump group

If you are using a plate heat exchanger to hydraulically separate the system, the following pressure losses must be

maintained:

Modulating pump

Modulating pump

Remaining feed

head

0.042 MPa

(420mbar)

0.026 MPa

(260mbar)

0.024 MPa

(240mbar)

Page 20

Hydraulic installation

min.

180

6

Power

< 120 kW

in conjunction with the hydraulic cascade

< 240 kW

< 360 kW

< 480 kW

< 600 kW

< 720 kW

6.2 System separation pressure loss

Max. pressure

loss (mbar)

86

96

76

82

87

92

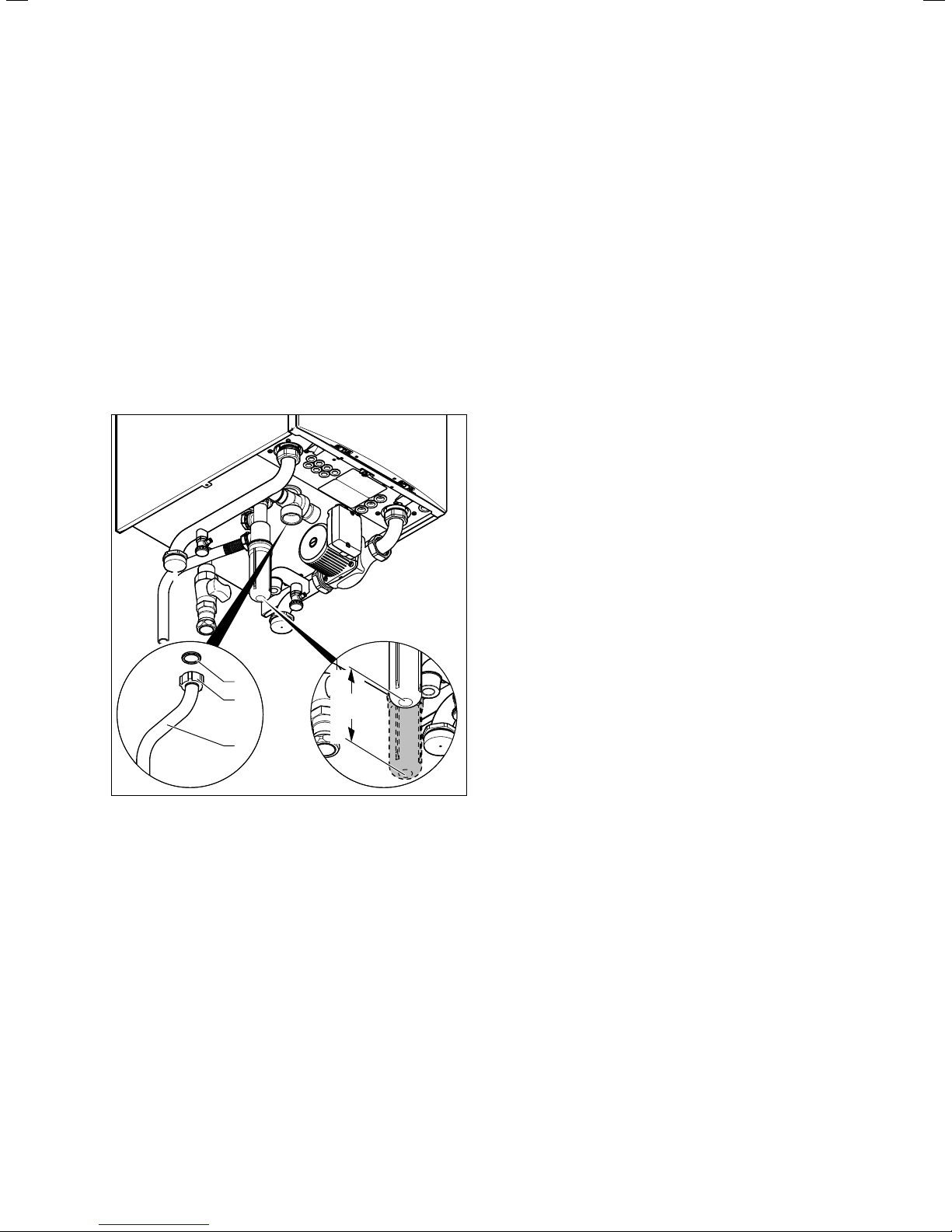

6.3 Connecting the condensate drain pipework

Danger!

Risk of death from escaping flue gases!

a

An empty or insufficiently filled condensate

siphon may allow flue gases to escape into

the room air.

> Make sure that the condensate siphon is

filled with water when switching on the

boiler.

Danger!

Risk of death from escaping flue gases!

a

If the condensate drain pipework is connected tightly to a fixed connection on the

waste-water piping, the internal condensate

siphon can be fully drained until empty.

> Do not connect the condensate drain

pipework tightly to the waste-water

piping.

> It is recommended that the condensate

is drained into a tundish. The condensate

drain is totally sealed. It may be possible

to empty the trap due to syphonic action

causing leackage of combustion

products:

Condensate forms in the boiler during combustion. The condensate drain pipework routes the condensate to the waste

water connection via a tundish.

The boiler is equipped with a condensate siphon. The filling

height is 145mm. The condensate siphon collects any condensate that occurs and feeds it into the condensate drain

pipework.

1

2

3

6.3 Condensate siphon

Install the enclosed condensate siphon as follows:

> Place the condensate siphon on the underside of the

boiler on the condensate drain pipe and secure it using

the retaining clips.

> Leave an installation space of at least 180mm beneath

the condensate siphon so that you can clean the conden-

sate siphon in the case of service work.

> Check the connection for leaks.

> Check if a neutralising unit is required in accordance

with national regulations.

To connect the condensate drain pipework, proceed as

follows:

> Hang the condensate drain pipework of the boiler in the

pre-installed tundish.

> If required, guide the drain hose (1) of the automatic air

vent into the tundish.

The condensate drain pipework connected to the

condensate discharge of the boiler must have a

i

> The connections for the condensate drain pipework must

not be modified or blocked

> The condensate drain pipework must terminate in a suit-

able location.

downward gradient throughout its entire length

(45mm per metre) and should be installed and

connected within the building to prevent possible freezing.

20 ecoTEC plus installation and maintenance instructions 0020134823_01

Further information can be obtained from "BS 6798 Specification for installation of gas-fired boilers of rated input not

exceeding 70 kW net". Before the boiler is started up, the

condensate siphon (1) must be filled with water as

described in the relevant section.

Page 21

6.4 Connecting the discharge pipe to the

min.

180

expansion relief valve on the heating

installation

The expansion relief valve for the heating installation can

be connected to the pump group (left-hand side)

> Install the drain line for the expansion relief valve so that

it is not damaged when removing and fitting the lower

part of the condensate siphon.

We do not recommend shortening the discharge

pipe that is supplied.

i

> Leave an installation space of at least 180mm beneath

the condensate siphon.

Hydraulic installation

6

1

2

3

6.4 Install the discharge pipe on the expansion relief valve

> Insert a seal (1) in the cap nut (2).

> Screw the discharge pipe (3) onto the expansion relief

valve.

> Make the drain line routing as short as possible and in a

downward gradient away from the boiler.

> Allow the line to terminate in such a way that nobody

can be injured and no cable or other electrical components can be damaged if water or steam is ejected.

> Please note that the end of the line must be visible.

ecoTEC plus installation and maintenance instructions 0020134823_01 21

Page 22

Flue gas installation

7

7 Flue gas installation

7.1 Preparing for installation

Danger!

Risk of personal injury and material dam-

a

age due to unapproved flue pipes.

Vaillant boilers are certified only with genuine Vaillant flue pipes. The use of other

accessories may cause personal injury and

material damage as well as operating faults.

> Only use genuine Vaillant flue pipes.

You will find a list of genuine flue pipes in the

Vaillant installation instructions for flue pipes.

i

All ecoTEC plus boilers feature an 110/160mm diameter air/

flue gas connection as standard. Selecting the most suitable system depends on the individual installation and application conditions.

> When installing the flue pipe, observe the provisions of

the applicable national regulations.

> Agree the flue pipe with your chimney sweep.

> Lay the flue pipe with a downward gradient so that any

escaping condensate can easily flow into the drain

(siphon) provided for it without leaving any backwater

residues.

7.2 Installing the flue pipe

> Install the flue pipe using the enclosed installation

instructions.

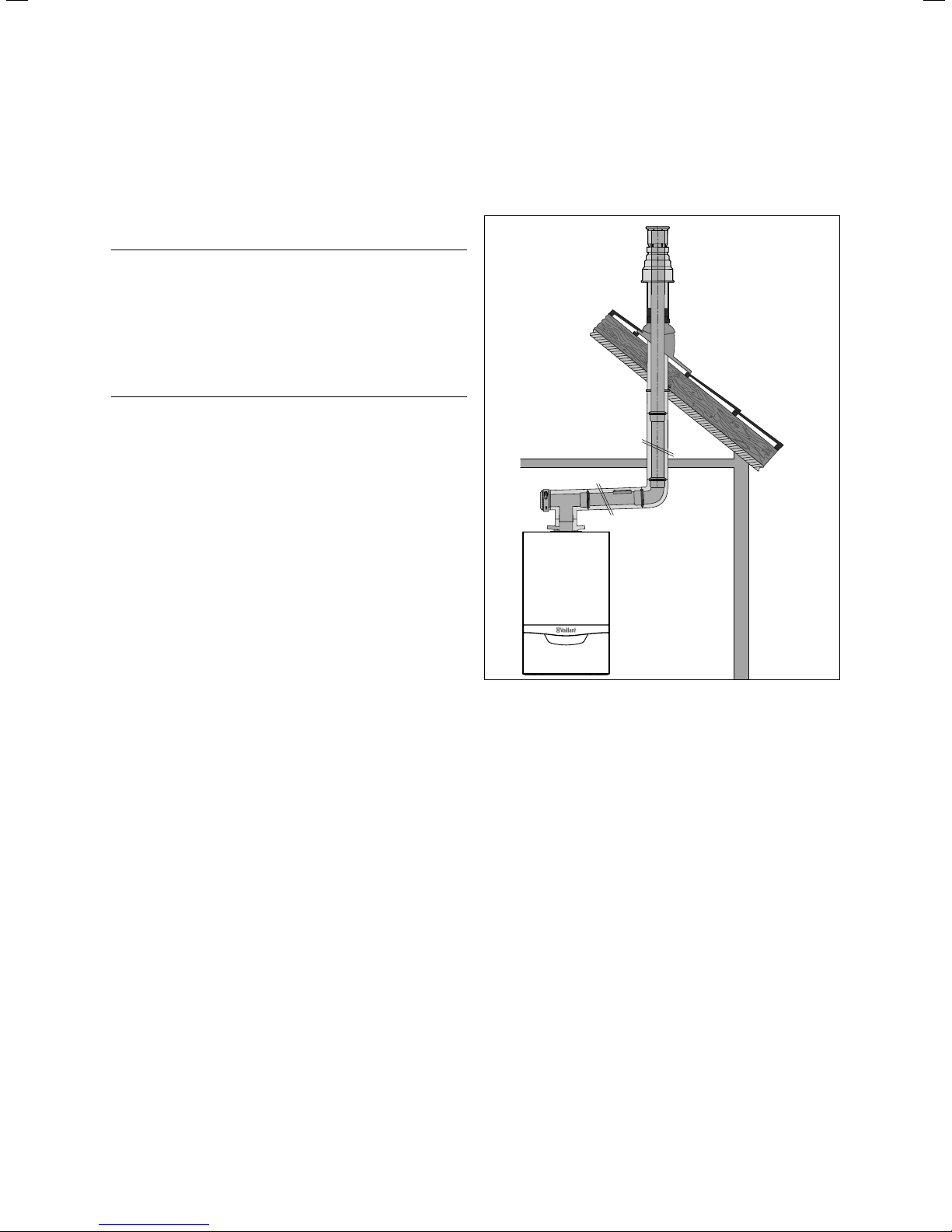

7.1 Installation example: Vertical roof duct

7.3 Flue gas guiding opening

The following information applies to all flue pipe systems.

a. The terminal must be positioned so that the products

of combustion can disperse freely at all times.

b. Water vapour will sometimes be visible from the ter-

minal of the flue gas system. Fitting locations where

this could be a nuisance should be avoided.

c. If the terminal is installed less than 2 m above a bal-

cony, above ground or above a flat roof to which people have access, a suitable terminal guard must then

be provided and fitted (contact Tower Flue Components, Tonbridge, TN9 1TB).

Vertical flues must not terminate within 600mm

of an openable window, air vent or any other

i

The flue gas system must be attached or shielded in such a

way that ignition (causing fire) or damage to any part of the

building is avoided.

22 ecoTEC plus installation and maintenance instructions 0020134823_01

ventilation opening.

Page 23

Flue gas installation

7

B

D,E

2m

H

E

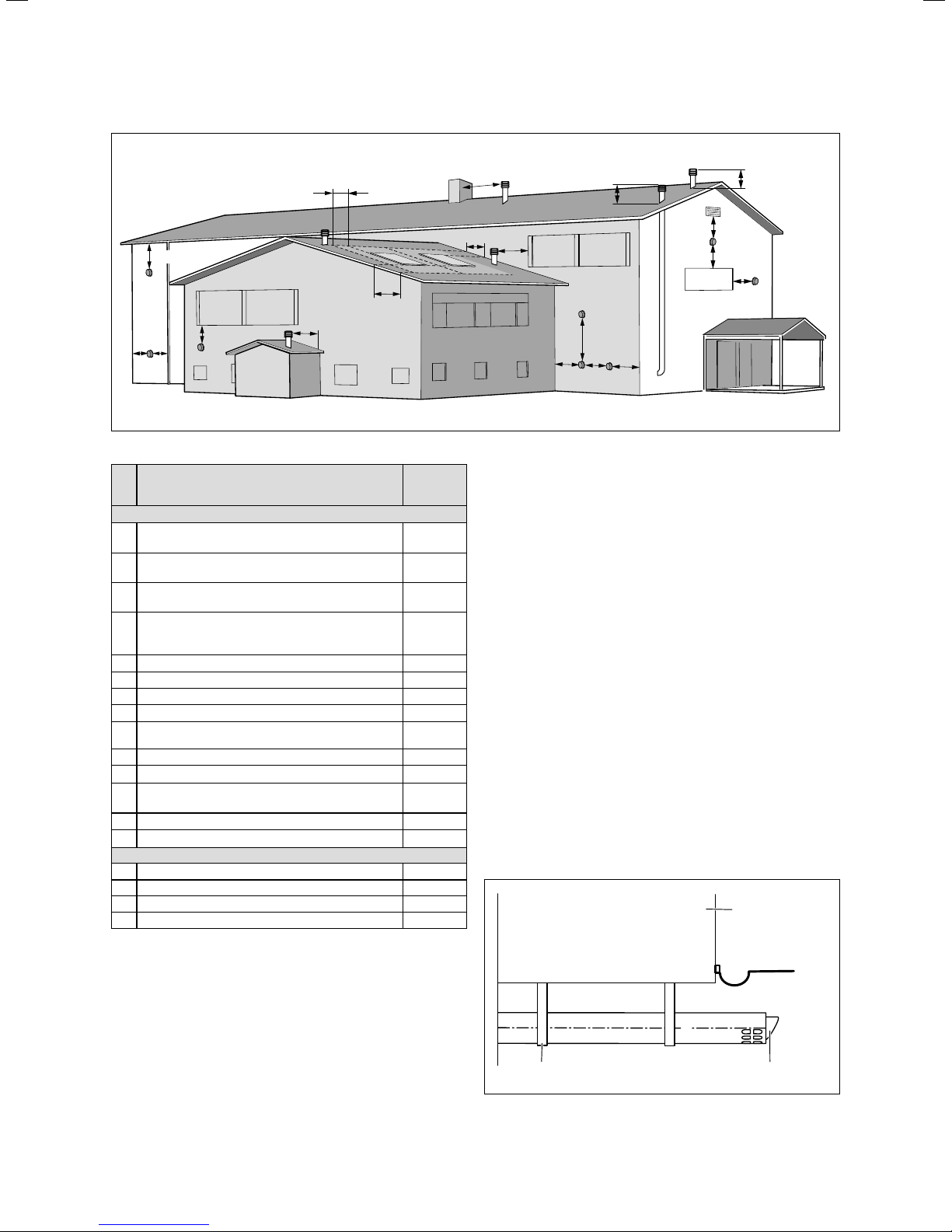

7.2 Opening of the flue pipe

Installation site

Horizontal flue gas pipes

A Directly below an opening, air bricks, opening

windows, etc.

(5)

Above an opening, air bricks, opening windows,

B

etc.

C Horizontally to an opening, air bricks, opening

windows, etc.

D Below temperature-sensitive building compo-

nents e.g. plastic gutters, down pipes or wastewater pipes

(4)

Below eaves, adjacent to wastewater pipes 50 mm

E

F Below balconies or car port roofs 25 mm

(4)

G

From a vertical wastewater pipes or down pipes 50 mm

H From internal or external corners 50 mm

(2)

H

From the edges along to a terminal/outside

corner

J Opposite an edge or a terminal 2000 mm

(2)

J

From a surface facing a terminal 1000 mm

L From an opening in the car port (e.g. door,

window) which leads into the dwelling

M Vertical from a terminal 1500 mm

N Horizontal from a terminal 600 mm

Vertical flue gas pipes

P From another terminal 600 mm

Q Above the roof area 600 mm

(3)

R

From adjacent windows that cannot be opened 1000 mm

(2)

From an adjacent wall to the flue gas pipe 300 mm

S

7.1 Position of the opening of a fan-assisted flue gas guiding

Key:

(1)

There should be no ventilation/opening in the eaves within

600mm distance of the terminal.

(2)

These dimensions comply with the building regulations, but they

may need to be increased to avoid wall staining and nuisance

fron pluming depending on site conditions.

(3)

It is recommended that an elbow termination is fitted to direct

the plume away from windows.

(4)

If the pipe is shielded from the heat this dimension may be

reduced to 25mm.

A

S

Minimum

dimen-

sions

600 mm

600 mm

600 mm

25 mm

300 mm

N/A

P

Q

Q

B

C

A

B

C

M

H

H

N

(5)

The flue through the roof should not be located within the

shaded area.

(6)

Is is recommended that the terminal should not be located

below 2m in any occupied space.

BS 5440–1: It is recommended that the fanned flue terminal

should be positioned as follows:

– at least 2 m from an opening in the building directly

opposite, and

– so that the products of combustion are not discharged

directly across a property boundary.

– Dimensions D, E and F:

(1)

These clearances may be reduced to 25 mm without

affecting the performance of the boiler. In order to

ensure that the condensate vapour plume does not damage adjacent surfaces, the terminal should be extended

as shown in ¬fig.7.3.

– Dimension H:

This clearance may be reduced to 25mm without

adversely affecting the performance of the boiler. However, in order to ensure that the condensate vapour

plume does not damage adjacent surfaces, a clearance

of 300mm is preferred.

For IE, recommendations are given in the current issue

of the IS 813.

Balcony/eaves

Adequately secured

air/flue gas pipe

7.3 Opening of the flue gas system under balconies or eaves

The flue pipe must

protrude beyond any overhang

Gutter

ecoTEC plus installation and maintenance instructions 0020134823_01 23

Page 24

8 Electrical installation

8 Electrical installation

The work described in this section must only be carried out

by a competent person.

8.1 Preparing for installation

Danger!

Risk of death from electric shock!

e

e

Touching live connections may cause serious personal injury.

> Switch off the power supply.

> Secure the power supply against being

switched on again by unauthorised persons while you are working on the boiler.

Danger!

Risk of death from electric shock as a

result of an improper electrical

connection!

An improper electrical connection may

adversely affect the operational safety of

the boiler and result in material damage or

personal injury.

> The electrical installation must be car-

ried out by a suitably qualified competent person who is responsible for complying with the existing standards and

directives.

> Connect the boiler in accordance with

BS7671 (IEE Regulations).

> For IE: Observe the current ETCI regula-

tions (Electro Technical Council for

Ireland).

> Earth the boiler.

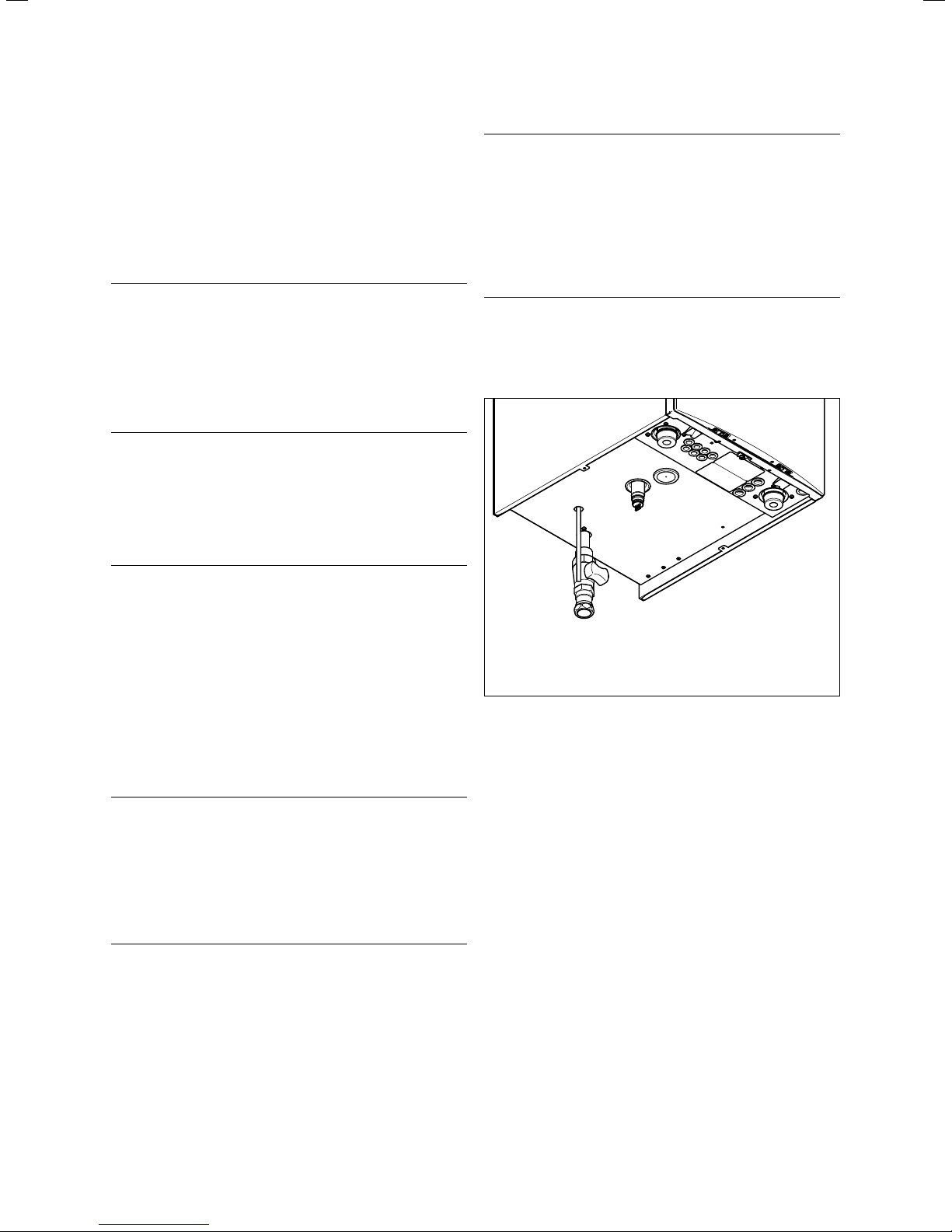

8.2 Opening/closing the electronics box

> Remove the front casing of the boiler (¬ section. 4.6).

2

1

8.1 Opening the back wall of the electronics box

> Tilt the electronics box (1) forwards.

> Loosen the clips (3) from the brackets.

> Tilt the cover (2) upwards.

Closing the electronics box

> Close the cover (2) by pushing downwards on the elec-

tronics box (1).

> Ensure that all clips (3) audibly click into the brackets.

> Tilt the electronics box upwards.

> Push the four right and left clips of the box against the

side panels on the boiler until you hear them click into

place.

> Attach the front casing of the boiler (¬section4.6).

8.3 Establishing the mains connection and

connecting the pump group

3

24 ecoTEC plus installation and maintenance instructions 0020134823_01

e

b

Danger!

Risk of death from electric shock!

Mains connection terminals L and N remain

permanently live even if the boiler on/off

button is switched off!

> Before establishing the mains connec-

tion, switch off the power supply.

Caution.

Risk of material damage caused by the

incorrect supply voltage!

At mains voltages greater than 253 V and

less than 190 V, the functions may be

impaired.

> Make sure that the rated voltage of the

mains is 230 V.

Page 25

Caution.

230V~ 230V~

NL

Risk of damage caused by incorrect

b

b

In IE, reference should be made to the current edition of

the ETCI (Electro-Technical Council for Ireland) rules.

The boiler is supplied for connection to 230 V, ~ 50 Hz supply fused at 3 A. The connection to the supply network is

made using a 3 A fused double-pole isolator with a contact

opening of at least 3 mm at all poles. A prerequisite here is

that only the boiler and controllers are connected). At the

connection point to the mains, it must be possible to completely isolate the boiler and its auxiliary controllers electrically. The connection should be easily accessible and adjacent to the boiler. Use a three-core flexible cable in accordance with BS 6500, tables 6, 8 or 16

(3 x 0.75 to 3 x 1.5mm

The rated voltage of each line in the mains must be 230 V;

with mains voltages over 253 V and below 190 V, the unit

may not function properly.

> Open the electronics box (¬section8.2).

> Use a flexible, commercial mains connection cable that is

compliant with standards.

> Guide the mains connection cable through the cable duct

on the left of the base of the unit.

> Use the grommet supplied to seal the cable duct.

installation.

Mains voltage at the incorrect plug terminals on the ProE system may destroy the

electronics.

> Only connect the mains connection cable

to the terminals marked for the purpose.

> Use a flexible connection cable.

Caution.

Risk of damage caused by incorrect

installation.

Connecting wires that have been stripped

too far may cause short circuits and damage the electronics if a strand accidentally

comes loose.

> Only strip the lines a maximum of 3 cm

to prevent short circuits.

> Lay the lines correctly.

> Use strain reliefs.

2

).

Electrical installation

NL

230V~ 230V~

8.2 Cable routing of the mains connection cable

> Insert the mains connection cable into the electronics

box.

> Uses the strain reliefs provided.

> Shorten the flexible mains connection cable as neces-

sary.

> Strip the flexible mains connection cable by 2-3 cm, but

not more than 3 cm.

> Insulate the conductor of the flexible mains connection

cable.

> Fit conductor end sleeves on the stripped ends of the

conductors.

> Connect the provided green ProE plug for the mains con-

nection to the flexible mains connection cable using a

screwdriver.

> Insert the ProE plug into the corresponding PCB slot

(L, N and earth) (¬fig.8.2).

> Lay the lines correctly.

> Secure the cable in the electronics box using the strain

reliefs.

> Close the electronics box (¬section8.2).

Ensure that the connection cables are securely

fastened to the plug terminals.

i

8

ecoTEC plus installation and maintenance instructions 0020134823_01 25

Page 26

Electrical installation

8

X22

X18

230 V

8.3 Connecting the pump group to the PCB

> Guide the pump cable for the pump group through the

cable duct to the right on the underside of the unit.

> Uses the strain reliefs provided.

> Connect the power supply network plug of the pump

group to the X18 slot on the PCB (¬fig.8.3).

> Connect the control cable of the pump group to the X22

slot on the PCB (¬fig.8.3).

> Lay the lines correctly.

> Secure the lines using the strain reliefs in the electronics

box.

> Close the electronics box (¬section8.2).

Ensure that the connection cables are securely

fastened to the plug terminals.

i

8.4 Connecting the controller

8.4.1 Fitting the controller

> Fit the controller in accordance with the respective

installation instructions.

8.4.2 Connecting controllers to the electronic

system

Caution.

Risk of damage caused by incorrect

b

b

installation.

Connecting wires that have been stripped