Page 1

Instructions for installation and servicing

ecoTEC plus

Wall hung open vent condensing boiler

GB, IE

For the installer

Page 2

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Notes on the documentation. . . . . . . . . . . . . . . . 3

1.1.1 Other instructions supplied with this appliance. . . 3

1.1.3 Safety instructions and symbols . . . . . . . . . . . . . 3

1.2 Validity of the manual . . . . . . . . . . . . . . . . . . . . . . 4

1.3 ecoTEC plus boilers . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 General information . . . . . . . . . . . . . . . . . . . . . . . 4

1.5.1 Gas category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5.2 Gas safety (installation and use) regulations . . 4

1.5.3 Gas testing and certification . . . . . . . . . . . . . . . . 4

1.5.4 Control of substances hazardous to health . . . 5

1.5.5 Insulation pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5.6 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5.7 Manual handling guidance . . . . . . . . . . . . . . . . . . 5

1.5.8 Gas leak or fault . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5.9 Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5.10 Sheet metal parts . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5.11 Sealed components . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5.12 Electrical supply failure . . . . . . . . . . . . . . . . . . . . 5

1.5.13 Protection against freezing . . . . . . . . . . . . . . . . . 5

1.5.14 Boilers installed in a compartment or

cupboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5.15 Boiler casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5.16 Condensate drain . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5.17 Pluming from flue terminal . . . . . . . . . . . . . . . . . 6

1.5.18 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5.19 Maintenance and servicing . . . . . . . . . . . . . . . . . 6

1.5.20 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 Statutory requirements . . . . . . . . . . . . . . . . . . . . 6

1.7 Regulations, rules and guidelines. . . . . . . . . . . . 6

1.8 CE label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.9 Benchmark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.10 Gas council numbers . . . . . . . . . . . . . . . . . . . . . . . 7

2 Boiler specifications . . . . . . . . . . . . . . . . . . . . 8

2.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 General requirements. . . . . . . . . . . . . . . . . . . . . 10

3.1 Preliminary remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Related documents . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Gas supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5 Flue options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5.1 Flue termination . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.5.2 Internal flue installation . . . . . . . . . . . . . . . . . . . . 13

3.6 Air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.7 Cupboard or compartment ventilation . . . . . . . 13

3.8 Domestic hot water cylinder . . . . . . . . . . . . . . . . 13

3.8.1 Unvented hot water cylinder . . . . . . . . . . . . . . . . 13

3.9 Condensate drain . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.10 Heating system controls . . . . . . . . . . . . . . . . . . . . 13

3.11 Draining tap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.12 Safety valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.13 Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.14 Pump specification . . . . . . . . . . . . . . . . . . . . . . . . 13

3.15 Cleanser and inhibitor . . . . . . . . . . . . . . . . . . . . . . 14

3.16 Water pressure loss . . . . . . . . . . . . . . . . . . . . . . . . 15

3.17 Open vented heating system . . . . . . . . . . . . . . . . 16

3.18 Sealed water systems . . . . . . . . . . . . . . . . . . . . . . 16

3.18.1 Safety valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.18.2 Expansion vessel . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.18.3 Pressure gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.18.4 Water make up . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.18.5 Filling a sealed water system . . . . . . . . . . . . . . . 17

4 Boiler installation sequence . . . . . . . . . . . . . . 18

4.1 Boiler location . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.1 Sheet metal parts . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.2 Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.3 Timber frame buildings . . . . . . . . . . . . . . . . . . . . . 18

4.1.4 Contents included with delivery . . . . . . . . . . . . . 18

4.2 Flue exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.1 Other flue options . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Fitting the boiler hanging bracket . . . . . . . . . . . 19

4.3.1 Boiler fixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3.2 Removing the front casing . . . . . . . . . . . . . . . . . . 19

4.3.3 Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3.4 Water connections . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3.5 Condensate trap and siphonic drain

connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3.6 Installing the flue system . . . . . . . . . . . . . . . . . . . 21

4.4 Electrical connections . . . . . . . . . . . . . . . . . . . . . . 21

4.4.1 Connection to the main supply . . . . . . . . . . . . . . 21

4.4.2 Wiring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.3 Electrical board layout . . . . . . . . . . . . . . . . . . . . . 23

4.4.4 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4.5 External electrical controls . . . . . . . . . . . . . . . . . 25

4.4.6 Connection details for external switches

and boiler terminal strip. . . . . . . . . . . . . . . . . . . . 26

4.4.7 Vaillant optional plug in timer

accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.8 Connection details using the VR 65

and VR 61 control centre . . . . . . . . . . . . . . . . . . . 26

5 Commissioning (Part I) . . . . . . . . . . . . . . . . . . 27

5.1 Preliminaries - all systems . . . . . . . . . . . . . . . . . . 27

5.1.1 Gas supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.1.2 Gas pressure statement - Natural gas . . . . . . . . 28

5.1.3 Initial Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1.4 Ignition problems . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1.5 Flue problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1.6 Testing - gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6 Natural gas to LPG conversion . . . . . . . . . . . 30

7 Functional checks commissioning (part II). . 31

7.1 Functional checks . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2 Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.3 Domestic hot water (If optional VR65,

uniSTOR cylinder and Vaillant control

are installed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.4 Pump exercise programme . . . . . . . . . . . . . . . . . 31

7.5 Final flush of the heating system (hot) . . . . . . . 31

7.6 Handing over to the user . . . . . . . . . . . . . . . . . . . 32

Instructions for installation and servicing ecoTEC plus 0020020828_072

Page 3

Contents

Introduction 1

8 Inspection and maintenance . . . . . . . . . . . . . 32

8.1 Inspection and maintenance intervals . . . . . . . . 32

8.1.1 General inspection and maintenance

instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.1.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.1.3 Checking the CO/CO

8.1.4 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.1.5 Spark electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.1.6 Removing the burner . . . . . . . . . . . . . . . . . . . . . . 36

8.1.7 Combustion chamber and heat exchanger . . . . 37

8.1.8 Condensate drain . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.1.9 Inner casing panel seal check . . . . . . . . . . . . . . . 37

8.1.10 Checking the expansion vessel (If fitted). . . . . . 37

8.1.11 Re commissioning the boiler . . . . . . . . . . . . . . . . 38

8.1.12 Test operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9 Combustion analysis . . . . . . . . . . . . . . . . . . . . 38

9.1 Check CO

10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 40

10.1 Logical fault finding procedure . . . . . . . . . . . . . . 40

10.1.1 Status codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

10.1.2 Diagnostic codes . . . . . . . . . . . . . . . . . . . . . . . . . . 40

10.1.3 Fault codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

10.1.4 Fault memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

10.2 Test programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10.3 Resetting parameter to factory settings . . . . . . 44

11 Parts replacement . . . . . . . . . . . . . . . . . . . . . 45

11.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . 45

11.2 Replacing the burner. . . . . . . . . . . . . . . . . . . . . . . 45

11.3 Replacing the gas valve . . . . . . . . . . . . . . . . . . . . 45

11.4 Replacing the fan . . . . . . . . . . . . . . . . . . . . . . . . . . 45

11.5 Replacing the heat exchanger . . . . . . . . . . . . . . . 45

11.6 Replacing the condense trap and

siphonic drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

11.7 Replacing electronics and display . . . . . . . . . . . 46

12 Recycling and disposal . . . . . . . . . . . . . . . . . . 47

12.1 Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12.2 Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

content . . . . . . . . . . . . . . . . . . . . . . . . . 38

2

ratio . . . . . . . . . . . . . . . . . 33

2

1 Introduction

1.1 Notes on the documentation.

To ensure clarity of information in instructions a new

European standard of advice and symbols is being

introduced. To ensure compliance with this new standard

the following details are included.The following information is intended to help you through-out the boilers

entire instruction pack. We assume no liability for any

damage caused by non-observance of these instructions.

1.1.1 Other instructions supplied with this appliance.

For the owner:

Instructions for use no. 0020020829

Short operating instructions no. 838404

Warranty card with return envelope no. 802922

For the installer/service engineer:

Flue installation instructions no. 834449

The instructions for any accessories and controllers

used also apply.

The Benchmark gas boiler commissioning checklist

(in this manual) should be completed by the installer

and/or the commissioning engineer.

If, after reading these instructions, you have any

questions on the operation of the boiler, please contact

either your installer or Vaillant Technical Department.

1.1.2 Retention of documents

Please retain this literature and all related documents

so that they are available whenever they are required.

If you move please pass on the documents to the buyer.

1.1.3 Safety instructions and symbols

Please observe the safety instructions in this literature

for the operation of the appliance.

Danger!

d

Immediate risk of serious injury or death.

13 Factory guarantee and Vaillant service . . . . 47

13.1 Factory guarantee . . . . . . . . . . . . . . . . . . . . . . . . . 47

13.2 Vaillant service . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

14 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Danger!

e

Risk of death from electric shock!

Danger!

H

Risk of burns or scalding!

Caution!

a

Potentially dangerous situations for the

product and environment.

Note!

h

Useful information and instructions.

• Symbol for a necessary task

3Instructions for installation and servicing ecoTEC plus 0020020828_07

Page 4

1 Introduction

Note!

h

Installation and adjustment of the boiler as well as

service, maintenance and repair may only be carried out by a competent person approved at the

time by the Health and Safety executive and in accordance with the gas safety (installation and use)

regulations 1998.

1.2 Validity of the manual

This installation manual applies exclusively to units with

the following part numbers:

– 0010002460

– 0010002461

– 0010002724

– 0010002725

The part number of the unit can be obtained from the

identification plate.

1.3 ecoTEC plus boilers

The ecoTEC plus boilers are designed to provide central

heating from a fully pumped open-vented or sealed

water system. The central heating water temperature

can be adjusted on the boiler. The domestic hot water

can only be adjusted on the boiler if it is installed with a

Vaillant uniSTOR unvented cylinder and relevant controls. Once the controls are set the boiler operates automatically.

A frost protection programme is also included.

Please read these instructions and follow them carefully

for the correct and economical use of your boiler. These

instructions are applicable to the following ecoTEC plus

boilers, available in Natural Gas. All ecoTEC plus boilers

can be converted to LPG.

Appliance Maximum output

ecoTEC plus 415 15 kW

ecoTEC plus 418 18 kW

ecoTEC plus 428 28 kW

ecoTEC plus 438 38 kW

1.4 Intended use

The boiler has been designed for use with a open-vented

central heating system, and comes fully tested and

assembled. The boiler is easily mounted on any internal

wall and can be installed with either a horizontal or vertical RSF (room sealed fan assisted) flue. The boiler uses

a standard flue system (100 mm or 125 mm outside diameter). Flue extensions and additional bends and elbows are available for the flue system to increase the

flexibility. If desired, an inhibitor may be used in the system. Guidance on the use of inhibitors is contained in

these instructions. The boiler has a built in diagnostic

system which indicates the operational status of the

boiler. This feature provides key information to aid commissioning and fault finding. The data badge is fitted to

the combustion chamber cover of the boiler. See text of

General Requirements for installation requirements or

notes.

The Vaillant ecoTEC plus boiler is a state-of-the-art appliance which has been constructed in accordance with

recognised safety regulations. Nevertheless, danger to

the life and limb of the user or third parties can still

occur or the appliance or other material assets be impaired in the event of improper use.

The unit is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities, or lack of experience and/or knowledge, unless

they have been given supervision or instruction concerning use of the unit by a person responsible for their

safety.

Children must be watched to ensure that they do not

play with the unit.

The appliances are designed for central heating systems. Any other use or extended use is considered to be

use other than intended. The user alone bears the risk.

The manufacturer/ supplier is not liable for any resulting damage. Intended use includes the observance of

the operating and installation manual and the adherence to the inspection and maintenance conditions.

Caution!

a

Any incorrect use is forbidden. The appliances

must be installed by a competent person approved at the time by the Health and Safety

Executive, who is responsible for adhering to

the existing regulations, rules and guidelines.

1.5 General information

Thank you for choosing a Vaillant boiler. The information

given in this booklet will enable you to obtain the best

performance from this boiler.

1.5.1 Gas category

The boiler is supplied factory set for use on Natural Gas

(G20). The ecoTEC plus boilers can be field adjusted for

use on LPG (propane G31), see section 6 for instructions

or contact Vaillant Service, 0870 6060 777.

1.5.2 Gas safety (installation and use) regulations

In your own interests and that of safety, it is the Law

that ALL gas appliances are installed by a competent

person approved at the time by the Health and Safety

Executive in accordance with the current issue of the

above regulations.

1.5.3 Gas testing and certification

The boiler is tested and certificated for safety and performance. It is, therefore, important that no alteration is

made to the boiler.

Instructions for installation and servicing ecoTEC plus 0020020828_074

Page 5

Introduction 1

1.5.4 Control of substances hazardous to health

Under Section 6 of The Health and Safety at Work Act 1974,

we are required to provide information on substances hazardous to health. The adhesives and sealants used in this

appliance are cured and give no known hazard in this state.

1.5.5 Insulation pads

These can cause irritation to skin, eyes and the respiratory tract. If you have a history of skin complaint you may

be susceptible to irritation. High dust levels are usual

only if the material is broken. Normal handling should not

cause discomfort, but follow normal good hygiene and

wash your hands before eating, drinking or going to the

lavatory. If you do suffer irritation to the eyes or severe

irritation to the skin seek medical attention.

1.5.6 Spare parts

Only original Vaillant spare parts may be used.

1.5.7 Manual handling guidance

During the appliance installation (and any subsequent replacement of the heat exchanger) it will be necessary to employ caution. All installers and operatives involved from unloading the appliance until it is fully mounted on the wall in

its final installed location must exercise full duty of care for

themselves and others with regard to safe lifting and handling of this appliance. Operatives should employ assistance

whilst lifting the appliance or components. In certain situations it may be required to use a mechanical handling aid.

Take care to avoid trip hazards, slippery or wet surfaces.

Caution!

a

With regards to the Manual Handling Operations, 1992 Regulations, the following lift operation exceeds the recommended weight for a

one man lift.

Employers and installers should refer to the

HSE web site for full advice and manual Handling assessment charts (MAC) tool.

Danger!

d

Smell of gas. Risk of poisoning and explosion

due to a malfunction.

1.5.8 Gas leak or fault

If you smell gas or suspect a gas leak:

• Do not switch lights on or off.

• Do not use any other electrical switches.

• Do not use a telephone in the hazardous area.

• Do not use naked flames, such as matches or cigarette

lighters.

• Do not smoke.

• Turn off the gas supply at the gas meter.

• Open the windows and doors.

• Warn other residents.

• Get out of the house.

• Consult your gas supplier, service agent or other

competent person approved at the time by the Health

and Safety Executive.

Telephone the National emergency number 0800 111 99

1.5.9 Clearances

If fixtures are positioned close to the boiler, space must

be left as shown in fig 4.1. Enough space must also be

left in front of the boiler to allow for servicing.

1.5.10 Sheet metal parts

This boiler contains metal parts (components) and care

should be taken when handling and cleaning, with particular regard to edges.

1.5.11 Sealed components

Under no circumstances must the User interfere with any

sealed component as this could result in a potentially

dangerous situation arising.

Danger!

e

This boiler must be earthed.

1.5.12 Electrical supply failure

The boiler will not work without an electrical supply. Normal

operation of the boiler should resume when the electrical

supply is restored. Reset any external controls to resume

normal operation of the central heating. If the boiler does

not resume normal operation. (The burner fails to ignite

after five attempts). The overheat thermostat may have

operated. Automatic ignition can only take place after you

manually reset the fault, refer to section 5.1.3. to reset.

1.5.13 Protection against freezing

The boiler has a built in frost protection programme as long

as the electricity and gas are left switched on. This device

operates the burner and system pump when the temperature inside the boiler falls to 3°C. Any other exposed areas

of the system should be protected by a separate frost thermostat. If the mains electricity and gas are to be turned off

for any long periods during severe weather, it is recommended that the whole system, including the boiler, should

be drained to avoid the risk of freezing. Make sure that, if

fitted, the immersion heater in the cylinder is switched off.

If you have a sealed water system contact your installation/

servicing company as draining, refilling and pressurising

MUST be carried out by a competent person approved at

the time by the Health and Safety Executive.

As a safety feature the boiler will stop working if the

condensate drain becomes blocked. During freezing

conditions this may be due to the forming of ice in the

condense drain external to the house. Release an ice

blockage by the use of warm cloths on the pipe. The

boiler should then restart. Contact your installation/

servicing company if the fault persists.

5Instructions for installation and servicing ecoTEC plus 0020020828_07

Page 6

1 Introduction

1.5.14 Boilers installed in a compartment or cupboard

If the boiler is fitted into a compartment or cupboard it

does not require ventilation openings.

Do not use the compartment or cupboard for storage.

1.5.15 Boiler casing

Do not remove or adjust the casing in any way, as incorrect-fitting may result in incorrect operation or failure

to operate at all.

1.5.16 Condensate drain

The condensate drain must not be modified or blocked.

1.5.17 Pluming from flue terminal

All condensing boilers produce a plume of water vapour

from the flue terminal. This is due to the high efficiency

and hence low flue gas temperature. This may increase

in wet, damp weather but this is completely normal and

indicates that the boiler is operating correctly.

1.5.18 Cleaning

This appliance contains metal parts and care should be

taken when handling and cleaning with particular regard

to edges. The boiler casing can be cleaned using a mild

liquid detergent with a damp cloth, then a dry cloth to

polish. Do not use any form of abrasive or solvent cleaner as you may damage the paint work.

1.5.19 Maintenance and servicing

For the continued efficient and safe operation of the

boiler it is recommended that it is checked and serviced

at regular intervals. The frequency of servicing will depend upon the installation conditions and usage, but in

general, once a year should be enough.

If this appliance is installed in a rented property there is

a duty of care imposed on the owner of the property by

the current issue of the Gas Safety (Installation and

Use) Regulations, Section 35. Servicing/maintenance

should be carried out by a competent person approved

at the time by the Health and Safety Executive in accordance with the rules in force in the countries of destination.

Please be advised that on completion of commissioning

and servicing you should complete the Benchmark gas

boiler commissioning checklist.

All competent persons approved at the time by the

Health and Safety Executive carry a ID card, and have a

registration number. Both should be recorded there.

1.5.20 Technical data

All dimensions are given in millimetres (except as

noted). The data label is positioned on the combustion

chamber cover. The Seasonal Efficiency Domestic Boilers UK (SEDBUK) is: All ecoTEC plus boilers : Class ‘A’.

The value is used in the UK Government’s Standard Assessment Procedure (SAP) for energy rating of dwellings. The test data from which it has been calculated

has been certified by B.S.I.

1.6 Statutory requirements

The appliance is suitable only for installation in GB and

IE and should be installed in accordance with the rules

in force. In GB the installation of the boiler must be carried out by a competent person as described in the following regulations:

- The manufacturer’s instructions supplied

- The Gas Safety (Installation and Use) Regulations

- The appropriate Buildings Regulations either

- The Building Regulations

- The Building Regulations (Scotland)

- The Building Regulations (Northern Ireland)

- The Water Fittings Regulations or Water bye laws in

Scotland

- The Health and Safety at Work Act, Control of Substances Hazardous to Health (COSHH)

- The Current I.E.E. Wiring Regulations

Where no specific instructions are given, reference

should be made to the relevant British Standard Code of

Practice. In IE, the installation must be carried out by a

competent person and installed in accordance with the

current edition of I.S.813 “Domestic Gas Installations”,

the current Building Regulations and reference should

be made to the current ETCI rules for Electrical Installation.

In GB the following Codes of Practice apply:

BS 4814, BS 6891

BS 6798 BS 6700

BS 5440 Part 1 and 2 BS 7074 Part 1 and 2

BS 5546 Part 1 BS 7593

BS 5449 BS 7671

In IE:

I.S.813 BS 5546

BS 7074 BS 5449

BS 7593

Manufacturer’s instructions must not be taken as overriding statutory requirements.

Note!

h

For further information, see the current issue

of the Building Regulations, approved document

L1 (in the UK) and the current issue of the following:

• Central heating system specification (CheSS)

• Controls for domestic central heating system

and hot water (BRECSU).

Certification

This boiler certificated to the current issue of EN 483

for performance and safety. It is important that no alteration is made to the boiler, without permission, in

writing, from Vaillant. Any alteration that is not approved by Vaillant, could invalidate the warranty and

could also infringe the current issue of the Statutory

Requirements.

Instructions for installation and servicing ecoTEC plus 0020020828_076

Page 7

1.7 Regulations, rules and guidelines.

This boiler meets the requirements of Statutory Instrument,

No. 3083 The Boiler (Efficiency) Regulations, and therefore is deemed to meet the requirements of Directive

92/42/EEC on the efficiency requirements for new hot

water boilers fired with liquid or gaseous fuels. Type

test for purposes of Regulation 5 certified by: Notified

body 0087. Product/production certified by: Notified

body 0086.

1.8 CE label

The CE label on this appliance shows compliance with:

- Directive 90/396/EEC on the approximation of the laws

of the Member States relating to appliances burning

gaseous fuels.

- Directive 73/23/EEC on the harmonisation of the Laws

of the Member States relating to electrical equipment

designed for use within certain voltage limits.

- Directive 89/336/EEC on the approximation of the Laws

of the Member States relating to electromagnetic

compatibility.

- Directive 92/42/EEC on the efficiency requirements.

Introduction 1

1.9 Benchmark

Note!

h

Vaillant Ltd. support the Benchmark initiative

At the rear of the installation manual, you will

find a Benchmark gas boiler commissioning

checklist. It is very important that this is completed correctly at the time of installation,

commissioning and hand over to the user.

1.10 Gas council numbers

Appliance Gas council numbers

ecoTEC plus 415 41 - 044 - 53

ecoTEC plus 418 41 - 044 - 54

ecoTEC plus 428 41 - 044 - 55

ecoTEC plus 438 41 - 044 - 57

7Instructions for installation and servicing ecoTEC plus 0020020828_07

Page 8

2 Boiler specifi cations

2 Boiler specifications

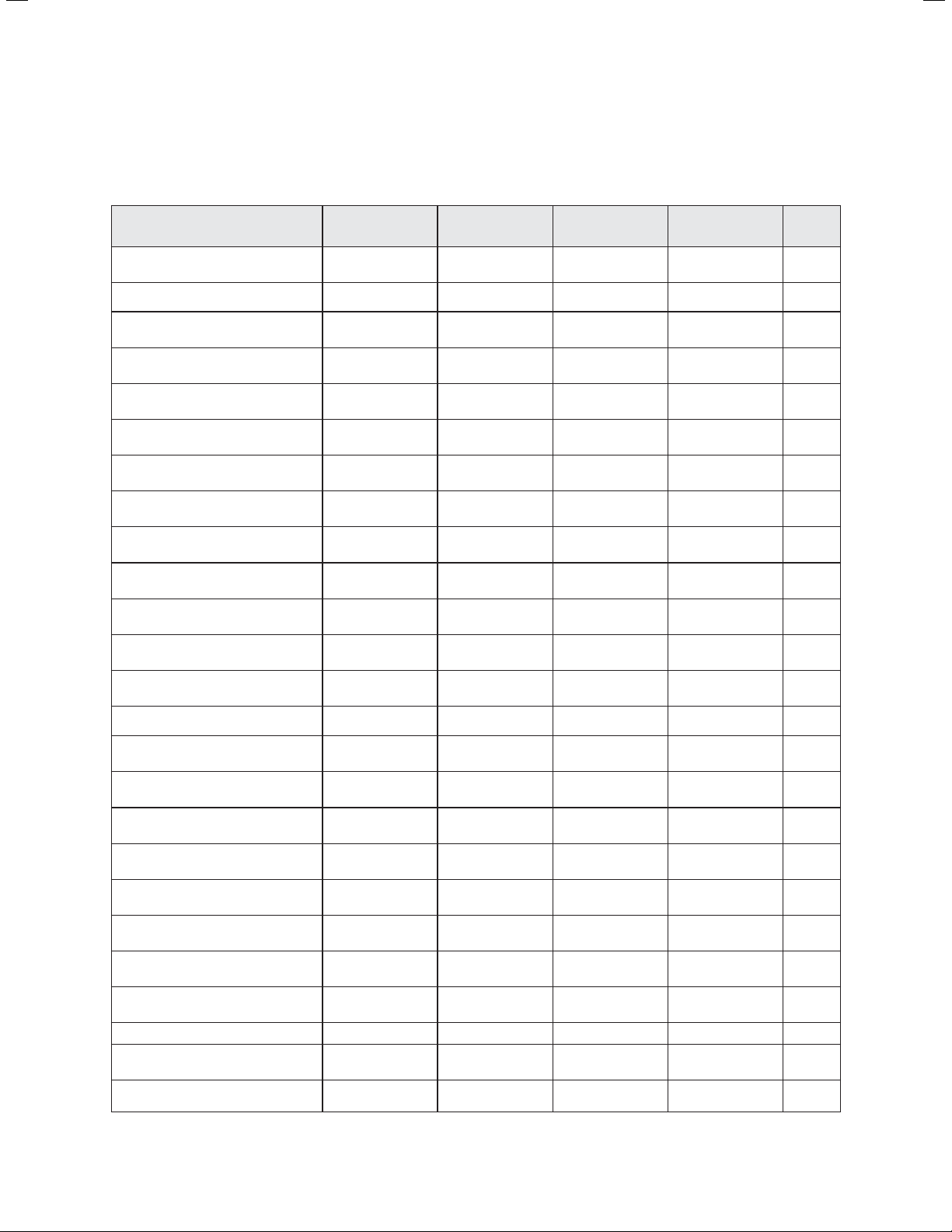

2.1 Technical data

Description ecoTEC plus 415 ecoTEC plus 418 ecoTEC plus 428 ecoTEC plus 438 Unit

Maximum CH heat input (net) 15.3 18.9 28.6 38.4 kW

CH heat output (80/60 °C) 5.0 - 15.0 5.0 - 18.6 5.3 - 28.2 6.3 - 38.0 kW

CH heat output (50/30 °C) 5.3 - 16.2 5.3 - 20.0 5.7 - 30.6 6.8 - 41.0 kW

SEDBUK Band A A A A

SAP Seasonal Efficiency 90.5 90.4 90.6 90.8 %

NOx Class 5 5 5 5

lP rating IPX4D IPX4D IPX4D IPX4D

Inlet gas working pressure required

(natural gas)

Gas supply (G20) Gross CV (s.t.) 37.8 37.8 37.8 37.8 MJ/m

Maximum gas rate 1.61 2.0 3.02 4.06 M3/h

Minimum gas rate 0.53 0.53 0.56 0.71 M3/h

Burner % CO2 (Case on) 9.3 + 0.2 - 0.5 9.3 + 0.2 - 0.5 9.3 + 0.2 - 0.5 9.0 + 0.2 - 0.5 %

Gas connection (compression) 15 15 15 15 mm

Water connections (compression) 22 22 22 22 mm

Condensate drain (internal diameter) 19 min. 19 min. 19 min. 19 min. mm

Main PCB 2 2 2 2 A

Minimum flow rate of water

through the boiler

Weight 31 31 33 33 kg

Electrical supply 230/~50 230/~50 230/~50 230/~50 V~/HZ

External fuse 3 3 3 3 A

20 20 20 20 mbar

10.8 12.9 20.3 27.2 L/min.

3

Power input 60 60 60 60 W

Flue categories C13, C33, C43, C53 C13, C33, C43, C53 C13, C33, C43, C53 C13, C33, C43, C53

Case height 600 600 600 600 mm

Case width 375 375 375 375 mm

Case depth 340 340 340 340 mm

Instructions for installation and servicing ecoTEC plus 0020020828_078

Page 9

Boiler specifi cations 2

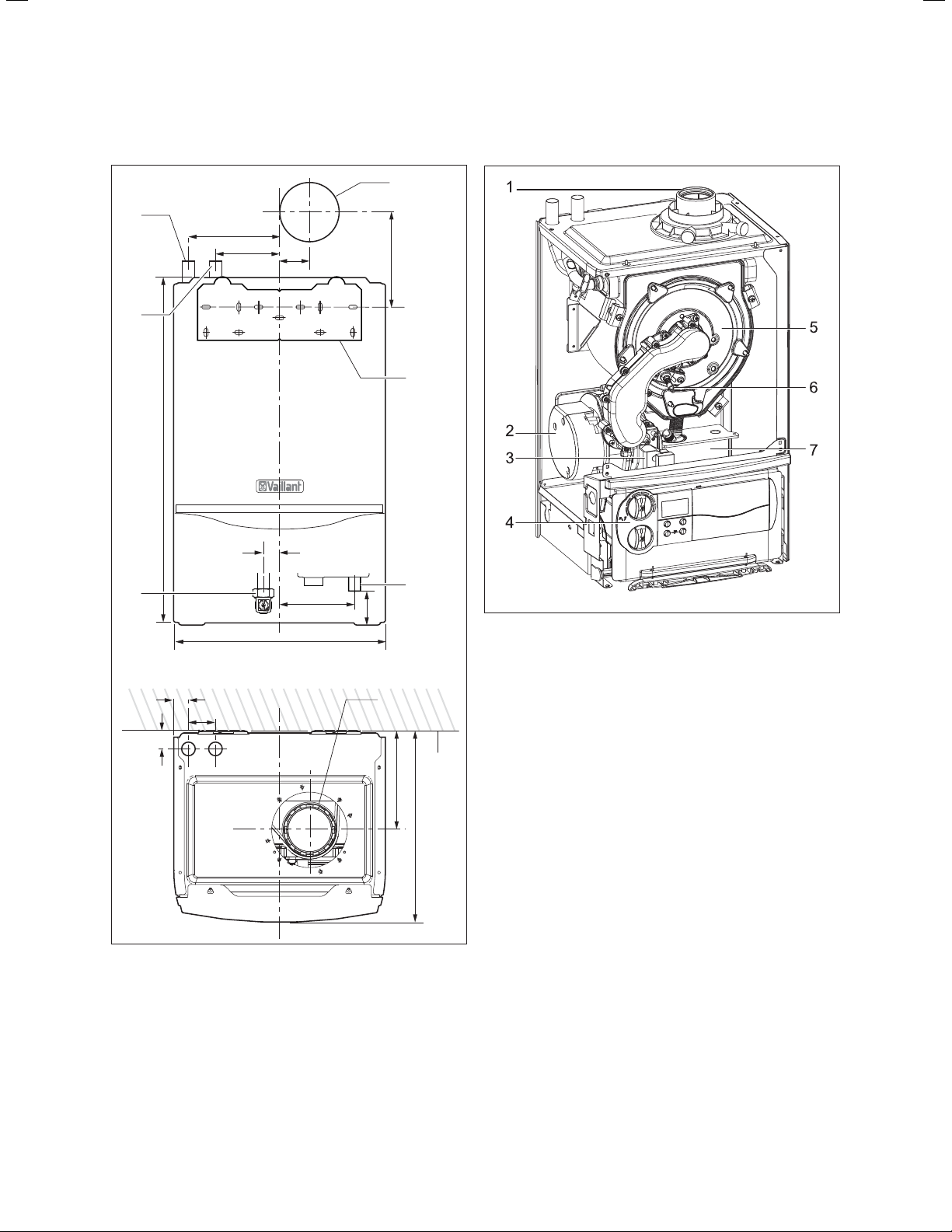

2.1.2 Dimensions

1

161

2

610

3

26

48

33

113

375

53

30

133

56

6

2.1.3 Installation

5

160

4

7

Fig. 2.2 Function elements of boiler

1 Flue pipe connection

2 Fan

3 Gas valve

4 Electronics box

5 Burner module

6 Ignition electrode

7 Condense trap

8

176

Fig. 2.1 Dimensions in mm

1 Heating return pipe Ø 22

2 Heating flow pipe Ø 22

3 Gas connection Ø 15

4 Hanging bracket

5 Flue hole - flue system 303 933

6 Flue pipe connection

7 Condensate drain outlet connection (Ø 21)

8 Outside wall face

340

9Instructions for installation and servicing ecoTEC plus 0020020828_07

Page 10

3 General requirements

3 General requirements

3.1 Preliminary remarks

This appliance must only be installed and commissioned

by a suitably competent person. Please check with your

installer that he is able to carryout all the necessary

works including official notification of the works to the

relevant body upon completion.

3.2 Related documents

The installation of the appliance and any associated hot

water system must be in accordance with (but not limited to) the following; COSHH regulations, Gas Safety (Installation and Use) Regulations 1998, Health and Safety

Document No. 635 (The Electricity at Work Regulations

1989), BS7671 (IEE Wiring Regulations) and the Water

Supply (Water Fitting) Regulations 1999, or The Water

Bylaws 2000 (Scotland). It should also be in accordance

with the relevant requirements of the Local Authority,

Building Regulations, The Building Regulations (Scotland), The Building Regulations (Northern Ireland) and

the relevant recommendations of the following British

Standards:

BS 6700: Services supplying water for domestic use

within buildings and their curtilages.

BS 6798: Specification for installation of gas fired boilers not exceeding 60 kW input.

BS 6891: Specification for installation of low pressure

gas pipework up to 35 mm (R1) in domestic premises

(2nd family gas).

BS 7593: Treatment of water in domestic hot water

central heating systems.

Institute of Gas Engineers Publication IGE/UP/7/1998:

”Guide for gas installations in timber framed housing”

BS. 5482 Pt. 1: Domestic butane and propane gas

burning installations.

IGE/UP1: Soundness testing and purging of industrial

and commercial gas installation.

IGE/UP1B (Edition 2): Tightness testing and direct

purging of small natural gas installations. For larger installation sites consider also IGE/UP1A.

IGE/UP2: Gas installation pipework, boosters and compressors on industrial and commercial premises.

IGE/UP10: Installation of gas appliances in industrial

and commercial p

BS. 6644: Installation of gas fired hot water boilers of

rated inputs between 60 kW and 2 MW (2nd and 3rd

family gases).

BS. 5449: Forced circulation hot water central heating

systems for domestic premises. Note: only up to 45 kW.

BS. 6880: Low temperature hot water heating systems

of output greater than 45 kW.

Part 1 Fundamental and design considerations.

Part 2 Selection of equipment.

Part 3 Installation, commissioning and maintenance.

BS. 4814: Specification for: Expansion vessels using an

internal diaphragm, for sealed hot water heating systems.

remises.

BS. 5440: Installation and maintenance of flues and

ventilation for gas appliances of rated input not exceeding 70 kW net (1st, 2nd and 3rd family gases).

Part 1 Specification for installation of flues.

Part 2 Specification for installation and maintenance

of ventilation for gas appliances.

Caution!

a

The appliance must be installed and serviced by

a competent person approved at the time by

the Health and Safety Executive as stated in

the Gas Safety (Installation and Use) Regulations 1998. In IE, the installation must be in

accordance with the current edition of I.S.813

‘Domestic Gas Installations’, the current Building Regulations and reference should be made

to the current ETCI rules for electrical installation.

Caution!

a

When tightening or slackening screwed connections always use suitable open-ended spanners

(not pipe wrench, or extensions, etc.). Incorrect

use and/or unsuitable tools can lead to damage

being caused (e.g. gas or water leakage)!

3.3 Installation site

The location chosen for the boiler must permit the provision

of a satisfactory flue termination. The location must also provide adequate space for servicing and air circulation around

the boiler. The boiler may be installed in any room, although

particular attention is drawn to the requirements of BS 7671

(IEE Regulations), the electrical provisions of the Building

Standards (Scotland) Regulations, and in IE the current edition of IS 813 and the current ETCI rules, in respect of the installation of a boiler in a room containing a bath or shower.

Note!

h

If a room sealed boiler is installed in a room

with a bath or shower, electrical switches or

boiler controls using the mains power supply

must be placed at locations that cannot be

reached by the person in the bath or shower.

If the boiler is installed in an unusual location, special procedures may be necessary and BS 5546 and BS 6798 give

detailed guidance on this aspect. The boiler must be mounted on a flat, vertical wall, which must be sufficiently robust

to take the weight of the boiler. The boiler may be installed

on a combustible wall, subject to the requirements of the

Local Authorities and Building Regulations. A compartment

used to enclose the boiler must be designed and constructed

specifically for this purpose. (An existing cupboard or compartment may be used provided that it is modified for the

purpose). Details of essential features of cupboard/compartment design including airing cupboard installations are given

in BS 6798. If the boiler is to be fitted in a timber framed

building, it should be fitted in accordance with Institute of

Gas Engineers Publication IG/UP/7 Edition 2 “Gas installa-

Instructions for installation and servicing ecoTEC plus 0020020828_0710

Page 11

General requirements 3

tions in timber framed and light steel framed buildings“.

Please note the safety instructions below before deciding

where to install the boiler:

Caution!

a

Do not install the appliance in rooms prone to

frost. In rooms with aggressive steam or dust,

the appliance must be operated independent of

the ambient air.

When choosing the place of installation and while operating the

appliance, make sure that the air supply is free of chemical

substances containing fluorine, chlorine, sulphur etc. Sprays,

solvents and cleaning agents, paints, adhesives etc. contain the

kind of substances that can lead to corrosion even in the exhaust system when the appliance is operated depending on the

ambient air in the worst case scenario. Particularly in hair-cutting salons, lacquering and finishing, cleaning facilities, the appliance must be operated independent of the ambient air! Otherwise, a separate installation room is required to guarantee

that the air supply is free of the above mentioned substances.

3.4 Gas supply

The gas supplier should ensure the availability of an adequate supply of gas. A gas meter may only be connected

to the service pipe by the supplier of gas or their contractor. An existing meter should be checked to ensure that it

is capable of passing the rate of gas supply required. Installation pipes should be fitted in accordance with BS

6891. In IE the current edition of IS 813. Pipe work from

the meter to the boiler must be of an adequate size. Do

not use pipes of a smaller size than the boiler gas connection (15 mm). The complete installation must be

checked for leaks and purged as described in BS 6891.

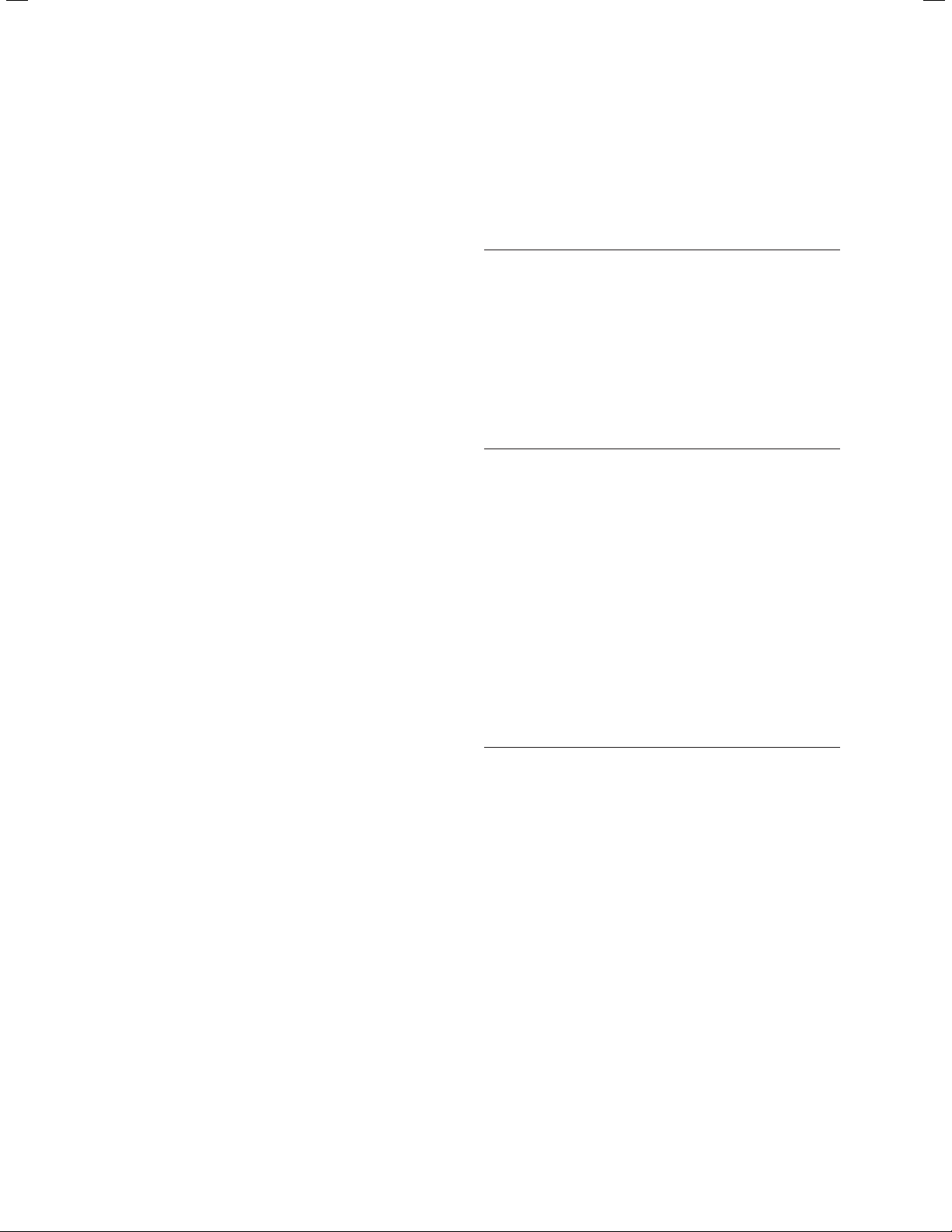

667

Fig. 3.1 Art. No. 30 39 33

Fig. 3.2 Art. No. 30 39 36

Danger!

d

Vaillant appliances are certified only for use

with genuine Vaillant flue pipes. Only use genuine Vaillant flue pipes. Malfunctions can occur if

you use other accessories. These may result in

damage and injury. You will find a list of genuine flue pipes in the Vaillant installation manual

for flue pipes. The CE mark is valid only if the

appliance is operated with Vaillant flue pipes.

3.5 Flue options

There are various flue systems to choose from, as follows:

60/100 standard horizontal air/flue duct, see fig 3.1.

60/100 telescopic horizontal air/flue duct, see fig 3.2.

60/100 Vertical air/flue duct and terminal, see fig 3.3.

80/125 horizontal air/flue duct, see fig 3.4.

80/125 Vertical air/flue duct and terminal, see fig 3.5.

Flue extensions are available to extend the length, both

90° bends and 45° elbows are also available. Refer to

flue system installation instructions for full details.

When extension pipes are used the flue system must be

designed to have a continuous fall to the boiler of at

least 3° to allow condensate to run out via the drain.

Fig. 3.3 Art. No. 30 39 00

Fig. 3.4 Art. No. 30 32 09

11Instructions for installation and servicing ecoTEC plus 0020020828_07

Page 12

3 General requirements

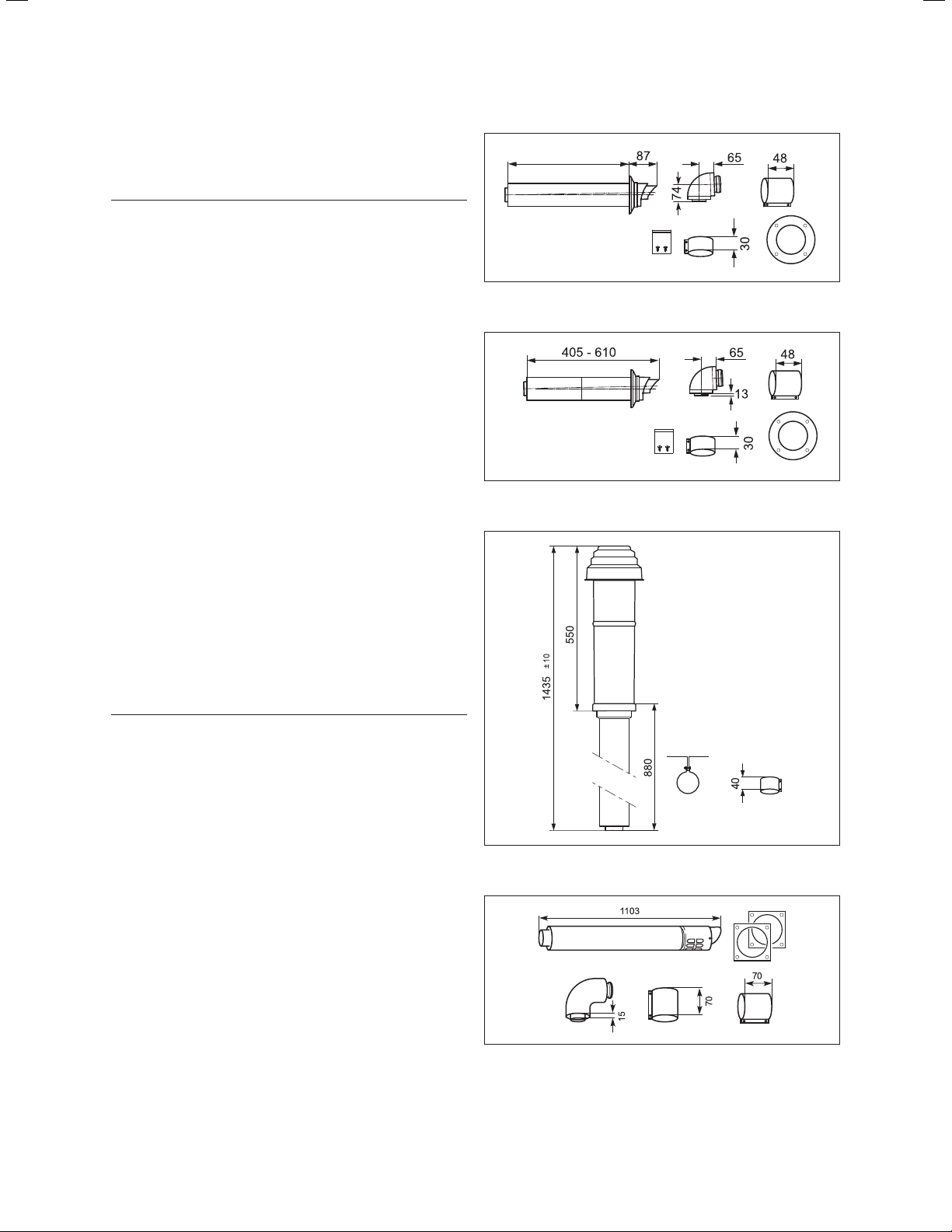

Fig. 3.5 Vertical Flue System Art. No. 30 32 00

3.5.1 Flue termination

The following details refer to both flue systems.

a. The terminal must be located where the combustible

substances can escape freely at all times.

b. A plume of water vapour will sometimes be visible

from the flue terminal. Positions where this could be a

nuisance should be avoided.

c. If the terminal is fitted less than 2 m above a balcony,

above ground or above a flat roof to which people

have access then a suitable terminal guard must be

provided and fitted (made by Tower Flue Components,

Tonbridge, TN9 1TB, Model K3, plastic coated).

Note!

h

Vertical flues must not terminate within

600mm of an openable window, air vent or any

other ventilation opening.

The flue assembly shall be so placed or shielded as to

prevent ignition or damage to any part of the building.

Fig. 3.6 Terminal locations

Note!

h

Vertical flues must not terminate within

600mm of an openable window, air vent or any

other ventilation opening.

Terminal position mm

Directly below an opening, above an opening or hori-

A

zontal to an opening, air brick, opening window, etc.

B Below gutters, soil pipes or drain pipes 75

C Below eaves 200

D Below balconies 200

E From vertical drain pipes and soil pipes 25

F From internal or external corners 300

G Above ground, roof or balcony 300

H From a surface facing a terminal 600

I From a terminal facing a terminal 1200

From an opening in the car port (e.g. door, window)

J

into the dwelling

K Vertically from a terminal on the same wall 1500

L Horizontally from a terminal on the same wall 300

M Distance from adjacent wall for vertical Flue 500

Table 3.1 Flue terminal position for a fan assisted concentric flue

The flue assembly shall be so placed or shielded as to

prevent ignition or damage to any part of the building.

Note!

h

In addition, the terminal should not be located

closer than 150 mm from a wallopening provided

for e.g. a window. Boundary flue terminations

must as a minimum comply with Building regulation part „J“ 600 mm and should also be in

accordance with the Guide to Condensing Boiler

Installation which recommends 2.5 m from wall,

fence or boundary.

Where a plume diverter terminal is used this is

measured in the direction of the flow of products.

BS 5440–1: It is recommended that the fanned flue terminal should be positioned as follows:

a. at least 2 m from an opening in the building directly

opposite, and

b. so that the products of combustion are not directed

to discharge across a boundary.

1. Dimensions B, C and D: These clearances may be reduced to 25 mm without affecting the performance of

the boiler. In order to ensure that the condensate

plume does not affect adjacent surfaces the terminal

should be extended as shown in Fig. 3.7.

2. Dimension F: This clearance may be reduced to 25

mm without effecting the performance of the boiler.

However, in order to ensure that the condensate

plume does not affect adjacent surfaces a clearance

of 300 mm is preferred. For IE, recommendations are

given in the current edition of IS 813.

300

1200

Instructions for installation and servicing ecoTEC plus 0020020828_0712

Page 13

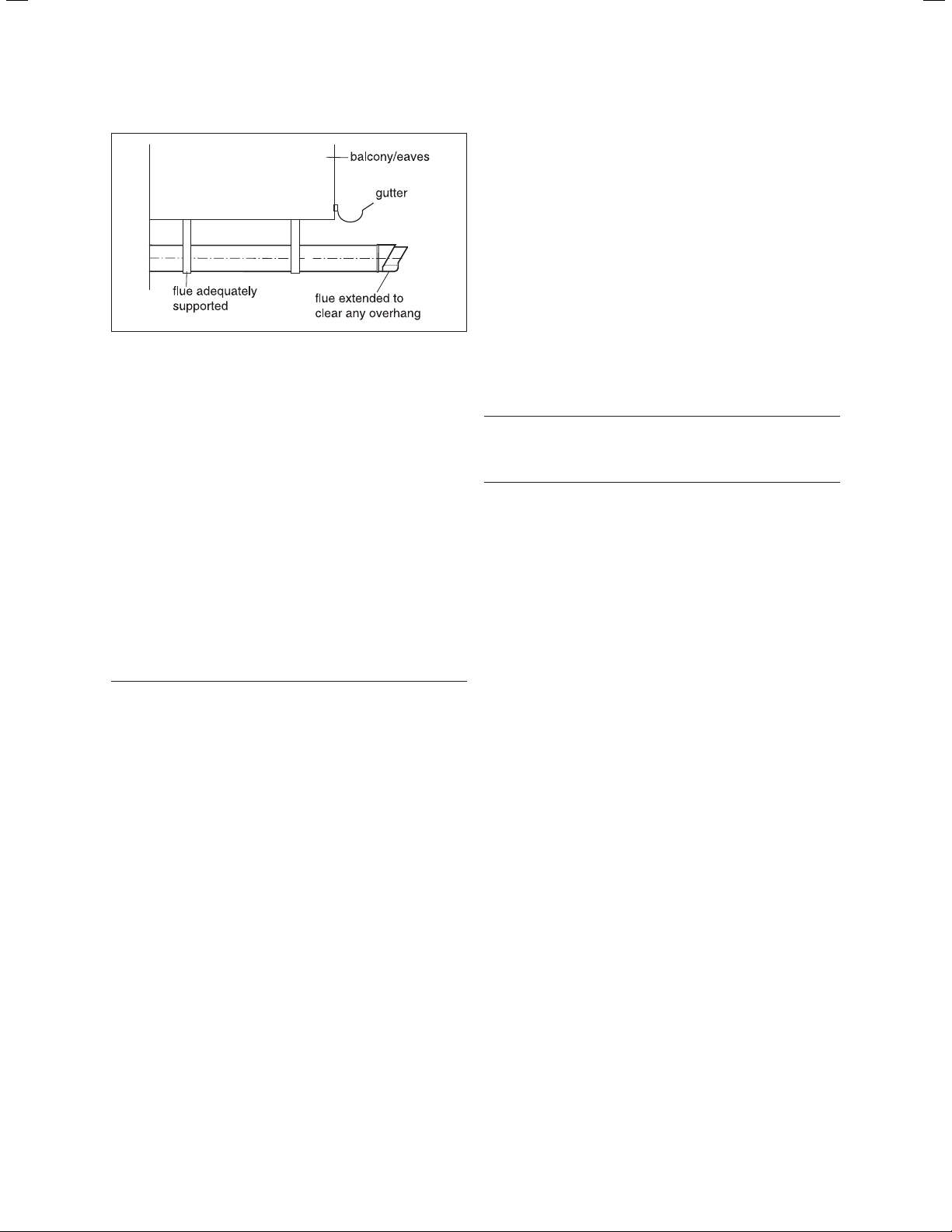

Fig. 3.7 Flue termination under balcony/eves

3.5.2 Internal flue installation

The flue can be installed from inside the building when

access to the outside wall face is not practicable.

3.6 Air supply

Detailed recommendations for air supply are given in

BS 5440: Part 2. It is not necessary to have an air vent in

the room or internal space in which the boiler is installed.

3.7 Cupboard or compartment ventilation

The boilers are very high efficiency appliances.

As a consequence the heat loss from the appliance

casing during operation is very low. For cupboard or

compartment installations it is therefore not necessary

to provide any high or low level permanent air vents

for cooling purposes.

3.8 Domestic hot water cylinder

Caution!

a

Single feed indirect cylinders are not suitable.

The domestic hot water cylinder must be of the

double feed fully indirect coil type. It must be

suitable for working at a gauge pressure of

0.35 bar above the safety valve setting.

3.8.1 Unvented hot water cylinder

The ecoTEC plus can be connected to an unvented hot

water cylinder. Vaillant offer a range of cylinders called

uniSTOR with capacities from 125 litres to 310 litres. All

unvented domestic hot water cylinders must be installed

by a competent person approved at the time by the

Health and Safety Executive to the current building regulations and water regulations at the time of installation.

For building regulations refer to G3 and for water regulations guidance G17 to G24 and recommendation R17

to R24. For Ireland: The current issue of BS5546 and

BS6700. If fitting to an existing system the local authority should be informed.

General requirements 3

3.9 Condensate drain

A plastic drain pipe must be fitted to allow discharge of

condensate to a drain.

Condensate should, if possible, be discharged into the

internal household draining system. If this is not

practical, discharge can be made externally into the

household drainage system or a purpose designed soak

away, see Section 4.3.5 for more details.

3.10 Heating system controls

It is recommended that a programmer and room thermostat control the boiler. Vaillant have a range of optional easy fit controls available.

Thermostatic radiator valves must be installed, however

they must not be fitted in a room where the room thermostat is located.

Note!

h

All systems must have at least one radiator

not fitted with a thermostatic valve.

Note!

h

For further information, see the current issue

of the Building Regulations, approved document

L1, and the following current issues of:

1. Central heating system specification (CheSS)

2. Controls for domestic central heating system

and hot water (BRECSU).

3.11 Draining tap

A draining tap must be provided at all the lowest points

of the system, which will allow the entire system and

hot water system to be drained. Draining taps shall be

to the current issue of BS 2879.

3.12 Safety valve

A safety valve need not be fitted to an open-vented system.

3.13 Bypass

A system bypass will be required fitted at least 1.5 metres

away from the boiler, refer to the current issue of central

heating system specifications (CHeSS).

3.14 Pump specification

The pump should be fitted on the flow pipe from the

boiler and have isolating valves each side.

13Instructions for installation and servicing ecoTEC plus 0020020828_07

Page 14

3 General requirements

3.15 Cleanser and inhibitor

In the case of an existing installation, it is essential that

prior to installing the new boiler the system is thoroughly flushed. For optimum performance after installation

of a new system, the boiler and its associated central

heating system should also be flushed. Flushing should

be carried out in accordance with BS7593: 1992 using

a cleanser. For long-term corrosion protection, after

flushing, an inhibitor suitable for stainless steel heat

exchangers should be used, refer to the current issue of

BS 5449 and BS 7593 on the use of inhibitors in central

heating systems.

Caution!

a

It is essential that the cleanser is fully

removed from the system after flushing and

before adding inhibitor. Take care to ensure

that all low points in the system are fully drained.

Mixing additives with the heating water can result in material damage. However, up to now, no incompatibility

with Vaillant appliances has been detected with proper

use of the following products.

• When using additives, follow the additive manufacturer‘s instructions without exception.

Vaillant accepts no liability for the compatibility of any

additive or its effectiveness in the entire heating system.

Additives for cleaning purposes

(subsequent flushing required)

- Fernox F3

- Jenaqua 400

- Sentinel X 300

- Sentinel X 400

Additives intended to remain permanently in the system

- Fernox F1

- Fernox F2

- Sentinel X 100

- Sentinel X 200

Additives for frost protection intended to remain permanently in the system

Fernox Antifreeze Alphi 11

-

- Sentinel X 500

• Inform the operator of the necessary measures in

case you have used any of these additives.

• Inform the operator of the required procedures for

frost protection.

• Observe the applicable national regulations and technical standards for the treatment of filling and top-up

water.

Provided the national regulations and technical standards do not specify any higher requirements, the following applies:

• You must treat the heating water

- if the total volume of filling and top-up water ex-

ceeds thrice the nominal volume of the heating system over the service life of the system

or

- if the limits given in the following tables are not ad-

hered to.

Total heating

output

kW mol/m

< 50 No requirement or < 3

> 50 to ≤ 200

> 200 to ≤ 600

> 600

1) with systems equipped with wall-hung boiler and systems with electric heating elements

2) of the specific system volume (nominal capacity in litres/heating output; in case of multiple boiler systems the lowest individual

heating output should be used)

These data only apply up to 3x the system volume for filling and top-up water. Once this triple system volume is exceeded, the

water will have to be treated exactly the same as in case of exceeding the limit values given in table 3.3 (softening, desalination,

hardness stabilisation and desludging).

Table 3.2 Guidelines for the heating water: Water hardness

Total hardness at 20 l/kW

for the smallest boiler heating

2)

surface

3

1)

2 1,5 0,02

1,5 0,02 0,02

0,02 0,02 0,02

Total hardness at > 20 l/kW

< 50 l/kW for the smallest boiler

heating surface

mol/m3 mol/m

2 0,02

2)

Instructions for installation and servicing ecoTEC plus 0020020828_0714

Total hardness at > 50 l/kW

for the smallest boiler heating

surface

2)

3

Page 15

General requirements 3

Heating water

qualities

Electric conductivity

at 25 °C

Appearance Free of sedimentary substances

pH-value at 25 °C 8,2-10,0

Oxygen mg/L

1) With aluminium and aluminium alloys, the ph value range is

restricted from 6.5 to 8.5.

Table 3.3 Guidelines for heating water: Salinity

Unit Low-salt saline

μS/cm < 100

1)

< 0,1 < 0,02

100-1500

8,2-10,0

1)

Caution!

b

Aluminium corrosion resulting in leakages

caused by unsuitable heating water!

Unlike materials such as steel, cast iron or copper, aluminium is reactive to alkalised heating

water (pH-value > 8,5) which results in significant corrosion.

With aluminium, ensure that the pH value of

the heating water ranges between 6.5 up to a

maximum of 8.5.

Caution!

b

Risk of material damage if the heating water is

treated with unsuitable frost or corrosion protection agents!

Frost and corrosion protection agents may

cause changes in the seals, noises during heating and possibly subsequent damage.

Do not use any unsuitable frost or corrosion

protection agents.

3.16 Water pressure loss

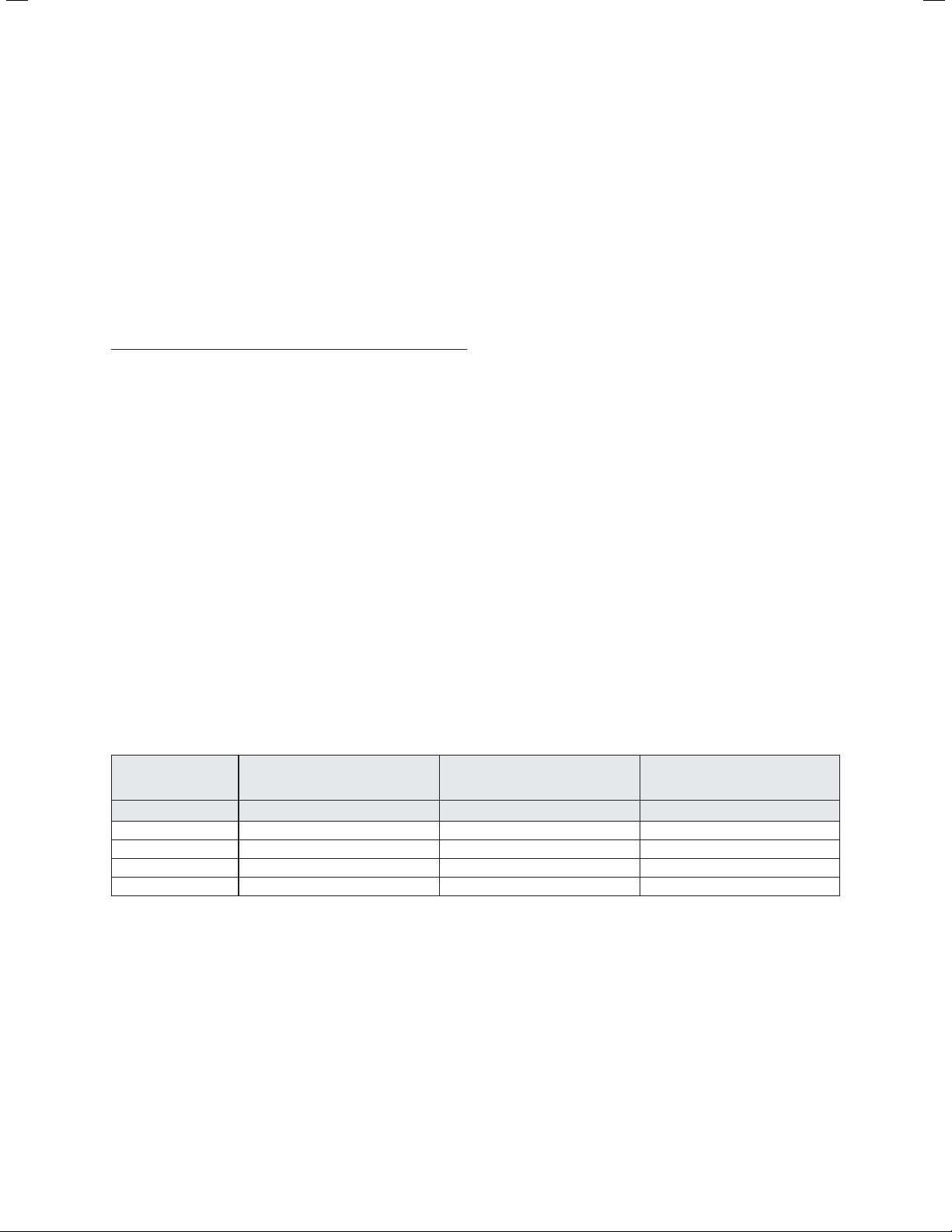

ecoTEC plus 415 pressure loss graph

ecoTEC plus 418 pressure loss graph

Water pressure loss (metres head of water)

Flow Rate (litres/hour)

773.86 l/hr = 20 diff @ 18 kW

Fig. 3.8.2 Pressure loss ecoTEC plus 418

ecoTEC plus 428 pressure loss graph

Water pressure loss (metres head of water)

Flow Rate (litres/hour)

1220 l/hr = 20 diff @ 30 kW

Fig. 3.8.3 Pressure loss ecoTEC plus 428

Water pressure loss (metres head of water)

Flow Rate (litres/hour)

646 l/hr = 20 diff @ 12 kW

Fig. 3.8.1 Pressure loss ecoTEC plus 415

15Instructions for installation and servicing ecoTEC plus 0020020828_07

Page 16

3 General requirements

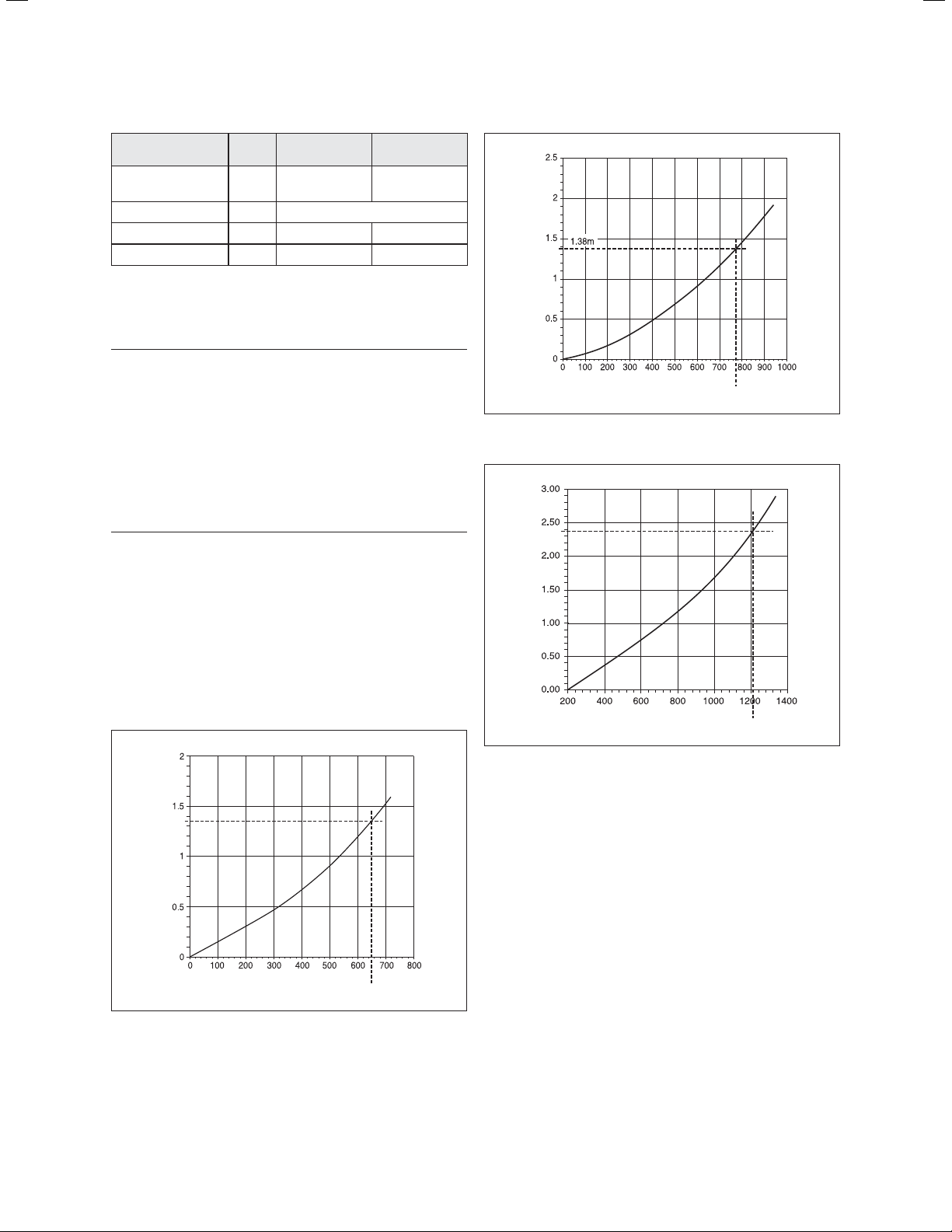

ecoTEC plus 438 pressure loss graph

Water pressure loss (metres head of water)

Flow Rate (litres/hour)

1633 l/hr = 20 diff @ 38 kW

Fig. 3.8.4 Pressure loss ecoTEC plus 438

3.17 Open vented heating system

The boiler must be supplied from an unrestricted water

supply taken from a feed and expansion cistern situated

at a maximum height of 27 metres (90ft) above the boiler.

The cold feed must be 15mm minimum size. The vent

must rise continuously and be unrestricted. It is important that the relative positions of the pump, cold feed

and open vent are as shown in fig 3.9.

Open (vented) system.

450 mm

(min.)

height

1000 mm

(min.)

Recommended

relationship between

pump, cold feed and vent.

22 mm (min.)

vent feed and

expansion cistern

15 mm (min.) cold feed

15 mm (min.)

automatic by-pass

return

flow

3.18 Sealed water systems

The installation must comply with the appropriate requirements of the current issue of BS4814, BS5449,

BS6759, BS6798 and BS7074 Part 1 and 2. For IE your

attention is drawn to the current edition of IS 813. It is

highly recommend to use the Vaillant Sealed System Kit

Article; 020053207 This includes all necessary components and is included in your Vaillant warranty. See also

fig 3.10.

3.18.1 Safety valve

A safety valve must be fitted to a sealed system. It shall

be preset, non-adjustable with a lift pressure of 3-bar,

incorporating seating of a resilient material, a test device

and a connection for drain. The safety valve discharge

pipe must be routed to outside the building, must not

discharge above an entrance or window or any type of

public access area, be clear of any electrical fittings and

positioned so that any discharge can be seen.

3.18.2 Expansion vessel

A diaphragm type expansion vessel, conforming to the

current issue of BS4814 (see also BS7074 Part 1 and 2).

For IE the current edition of IS 813, must be connected

at a point close to the inlet side of the circulating pump,

see the Typical installation, Fig. 3.10. unless laid down

differently by the manufacturer. The expansion vessel

volume depends on the total water system volume and

the initial system design pressure. For any system an

accurate calculation of vessel size is given in the current

issue of BS5449 and BS7074 Part 1. Example: For an

initial design pressure of 0.7 bar, the minimum total

vessel volume required is 0.063 x Total System Volume.

Note!

h

A higher initial design pressure requires a larger

volume expansion vessel.

The charge pressure must not be less than the static

head of the system, that is, the height of the highest

point of the system above the expansion vessel.

3.18.3 Pressure gauge

A pressure gauge with a set pointer and covering at least

0 to 4 bar (0 to 60 lb/in2) shall be fitted permanently to

the system in a position where it can be seen when filling

the system.

boiler

Fig. 3.9 Open vented system

150 mm (max.)

pump

cylinder

3.18.4 Water make up

Provision should be made for replacing water loss from

the system using a make up bottle mounted in a position

higher than the top point of the system, connected

heating

through a non-return valve to the return side of either

the heating circuit or the hot water cylinder. Alternatively,

provision for make up water should be made using a

proprietary filling loop.

Instructions for installation and servicing ecoTEC plus 0020020828_0716

Page 17

3.18.5 Filling a sealed water system

Provision for filling the system at low level must be

made. This can be achieved by the use of a proprietary

filling loop.

3 litres (o.66 gals) make-up bottle (if required)

General requirements 3

non-return

valve

make-up alternatives

Fig. 3.10 Typical installation

heating

circuit

auto air vent

flow

flow control valve 'A'

return

flow control valve 'A' air release point

filling point

automatic

bypass

valve 'B'

safety valve

circulating pump

pressure

gauge

expansion vesselboiler drain cock

17Instructions for installation and servicing ecoTEC plus 0020020828_07

Page 18

4 Boiler installation sequence

4 Boiler installation sequence

4.1 Boiler location

Note!

h

This boiler is not suitable for outdoor installation.

This boiler may be installed in any room, although

particular attention is drawn to the installation

of a boiler in a room containing a bath or shower

where reference must be made to the relevant

requirements. This boiler is suitable for installation in bathroom zone 2.

4.1.1 Sheet metal parts

Caution!

a

When installing the appliance, care should be

taken to avoid any possibility of personal injury

when handling sheet metal parts.

In GB this is the current I.E.E. WIRING REGULATIONS

and BUILDING REGULATIONS. In IE reference should

be made to the current edition of I.S.813 “Domestic Gas

Installations” and the current ETCI rules. The boiler must

be mounted on a flat wall, which is sufficiently robust to

take its total weight, see boiler specifications 2.1.

4.1.2 Clearances

The boiler should be positioned so that at least the minimum operational and servicing clearances are provided,

see fig 4.1. Additional clearances may be beneficial

around the boiler for installation and servicing. For flue

installations where external access is not practicable,

consideration should be given for the space required to

insert the flue internally, which may necessitate clearance larger than those specified in fig 4.1.

4.1.3 Timber frame buildings

If the boiler is to be installed in a timber frame building

it should be fitted in accordance with the Institute of

Gas Engineers document IG/UP/7 Edition 2 “Gas installations in timber framed and light steel framed buildings“. If in doubt seek advice from the local gas undertaking or Vaillant.

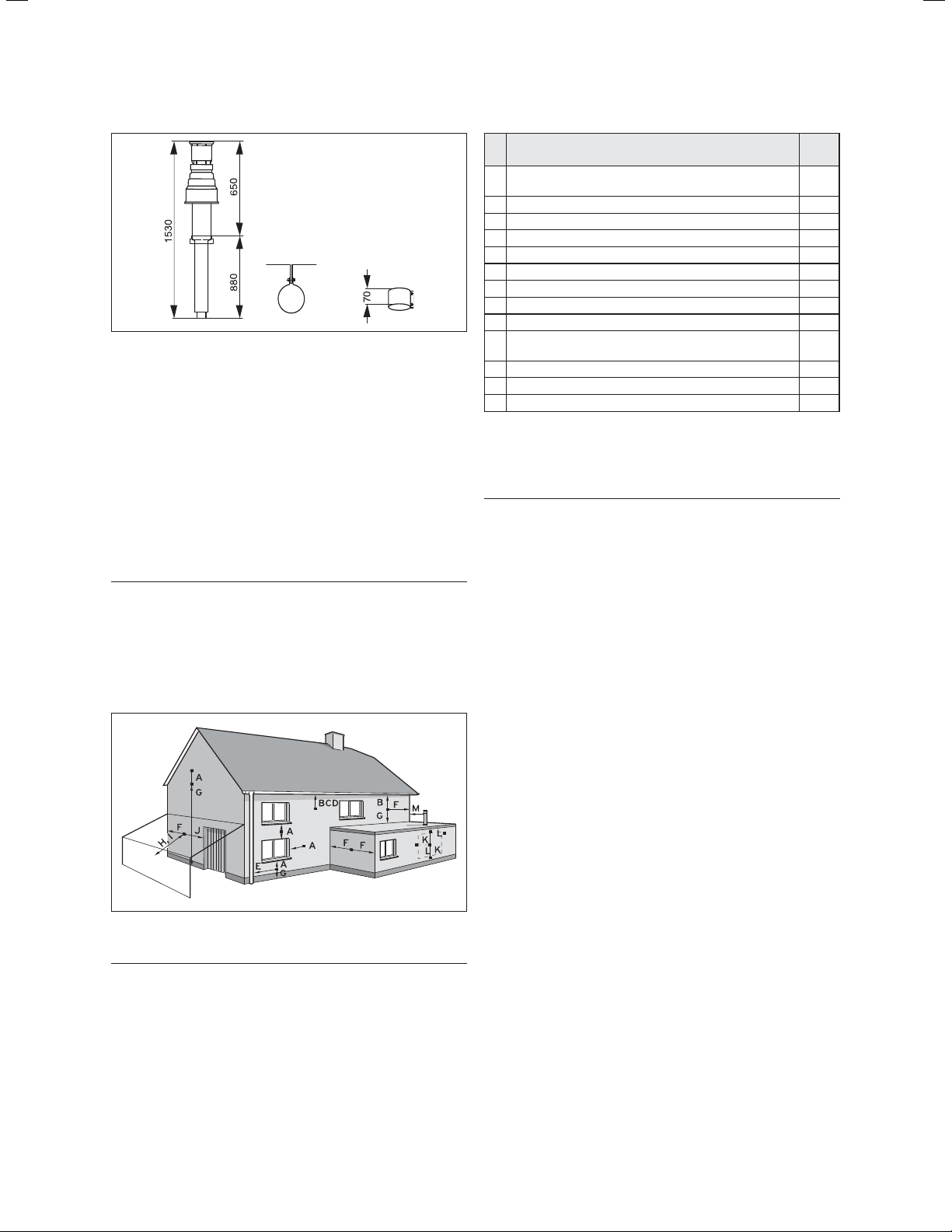

4.1.4 Contents included with delivery

The Vaillant ecoTEC plus is delivered pre-mounted in a

package unit. Check that all the parts have been delivered intact (see fig. 4.2 and table 4.1. Do not remove the

boiler from the polystyrene base at this stage. Place

aside the flue adaptor and connections pack until required.

Fig. 4.1 Distance during installation

* A removable compartment door can be placed at least 5 mm

in front of the appliance

Fig. 4.2 Contents included with delivery

Item Quantity Description

1 1 Boiler

2 1 Hanging bracket

3 1 Flue connection adaptor

4 1 Instruction booklets

5 2 Guarantee card and envelope

6 1 Template

7 1 Screws/wallplugs

81

Table 4.1 Contents included with delivery

Instructions for installation and servicing ecoTEC plus 0020020828_0718

Gas service valve, compression couplers

and condense drain pipe coupler

Page 19

Boiler installation sequence 4

Note!

h

Care should be taken not to scratch the white

surface of the boiler casing.

4.2 Flue exit

Refer to flue system installation instructions for full details.

Danger!

d

Vaillant appliances are certified only for use

with ge-nuine Vaillant flue pipes. Only use genuine Vaillant flue pipes. Malfunctions can occur

if you use other accessories. These may result

in damage and injury. You will find a list of genuine flue pipes in the Vaillant installation manual for flue pipes. The CE mark is valid only if

the appliance is operated with Vaillant flue

pipes.

4.2.1 Other flue options

Flue instructions for other flue systems such as vertical

RSF flues, flues run to the side of the boiler and the use

of additional bends etc. are detailed in the flue installation instructions.

4.3 Fitting the boiler hanging bracket

Reposition the wall template over the flue hole ensuring

the template is vertical and mark the position of the fixing holes for the hanging bracket, see fig 4.3. Mark and

drill the fixing holes and secure the hanging bracket. Fix

the hanging bracket to the wall using the screws supplied. Ensure the uppermost set of screw positions are

used (it may be necessary to use additional or alternative fixings to ensure adequate support).

slowly move downwards until engaged in the hanging

bracket.

4.3.2 Removing the front casing

Remove the front casing securing screws then lift the

case upwards off the two top retaining dowels, see fig

4.4.

Note!

h

Take care not to damage the front casing.

4.3.3 Gas connection

retaining dowel (2 off)

front casing

screw (2 off)

Fig. 4.4 Removing front casing

160

wall template

hanging bracket

screw n° 12 x 50 mm (4 off)

wall plug (4 off)

Fig. 4.3 Boiler hanging bracket

Note!

h

If the boiler is to be fitted in a timber framed

building ensure that the bracket is secured to

a substantial part of the timber frame capable

of taking the weight of the boiler.

4.3.1 Boiler fixing

Lift the boiler into position in the following manner:

Lean the top of the boiler slightly to the wall and position just above the hanging bracket. Allow the boiler to

Danger!

d

The gas connection may only be made by a

competent person approved at the time by the

Health and Safety Executive. The legal directives and the local regulations for gas supply

companies must be observed.

Caution!

a

Ensure a stress-relief assembly of the gas

pipes to avoid leakages!

Caution!

a

The gas regulating block may be tested for

leakage only with a maximum pressure of 150

mbar! Higher testing pressures can damage the

gas fitting.

Caution!

a

When making final connection to the boiler, if

using soldered fittings, extra care should be

taken to avoid damage to isolation valves

through heat transfer. Before connection check

the supply of local gas.

19Instructions for installation and servicing ecoTEC plus 0020020828_07

Page 20

4 Boiler installation sequence

Note!

h

Ensure the gas supply pipe work is adequately

sized so that a 20 mbar gas pressure is available at the boiler inlet at full flow rate.

• Tighten all connections.

• Check the gas connection with leak indicator

spray for leakage.

The gas supply can be connected from below, or

through the wall at the rear of the boiler. See fig 4.5.

and refer to section 3.4. The whole of the gas installation, including the meter, should be inspected, tested for

soundness and purged in accordance with the current

issue of BS6891 and in IE the current edition of I.S.813

“Domestic Gas Installations”.

condensate

3

trap

spigot

coupling

condensate

drain pipe

internal

discharge

system

soakawaygulley

union

cennector

gas supply in

1

2

a

internal

stack pipe

Fig. 4.5 Gas and condense connections

3

4

6

5

b

c

d

4.3.4 Water connections

Caution!

a

When making final connection to the boiler use

the compression fittings supplied to avoid damage through heat transfer.

22 mm compression

is the recommended

fixing for servicing.

Provision is made for the water connections to be made

from above the boiler, see fig 4.6 (using the two 22 mm

compression couplers supplied). The position is shown

on the wall template. Flush out the domestic hot water

and the heating systems before connecting to the boiler.

4.3.5 Condensate trap and siphonic drain connection

The condensate drain pipework must have a continuousfall (45 mm per metre) and should whenever possible

terminate at a suitable drain point within the heated envelope of the building that will remain frost free under

long periods of low external temperatures.

•

During installation remove all burs from inside of cut

pipe work and avoid excessive adhesive which may

trap small pockets of water close to the pipe wall

which can freeze and build into a larger ice plug.

• As with other pipe work insulate the condensate discharge pipe to minimise any risk of freezing and beware when crossing cavities that the fall is maintained

and the pipe sleeved.

Refer to fig 4.5. The condensate drain connection is at

the underside rear of the boiler. The condense drain is

suitable for use with standard overflow pipe and couplings do not use adhesive when connecting to the spigot (1) The condense drain pipe (2) should be plastic. The

condensate is discharged periodically in ‘slugs’ by siphonic action. It is not necessary to provide air breaks

or extra traps in the discharge pipe as there is already a

75 mm high trap inside the boiler. Fitting an extra trap

may cause the boiler siphon to work incorrectly. Refer

to BS5546 or BS6798 for advice on disposal of boiler

condensate.

(a) Preferably the drain pipe should run and terminate

internally to the house soil and vent stack at least

450mm above the invert of the stack.

(b) Connecting into the internal discharge branch

(e.g. sink waste or washing machine) with an external termination, the condensate drain pipe should

have a minimum diameter of 22 mm with no length

restriction and preferably made down stream of the

sink waste trap, if the connection is only possible up

stream, then an air break is needed between the two

traps. This is normally provided by the sink waste.

(c) Termination in a gully (5) below grid level (6) and

above the water level. The external pipe length

should be kept as short as possible to minimise the

risk of freezing and should not be more than 3 metres.

(d) At a condensate absorption point (soak away) (7).

The external pipe length should not be more than 3

metres.

Return

Fig. 4.6 Water connections

Flow

Refer to the latest issue of BS 6798 Specification for

installation of gas fired boilers of rate input not exceeding 70kW net for further information. Before operating

the boiler the condensate trap must be filled with water.

Instructions for installation and servicing ecoTEC plus 0020020828_0720

Page 21

Boiler installation sequence 4

4.3.6 Installing the flue system

• Install the flue system (refer to the separate air/flue

duct installation instructions).

4.4 Electrical connections

Danger!

e

This appliance must be earthed. Electrocution

caused by touching live parts can be fatal.

Before working on the appliance, turn off the

power supply and secure against restart.

• The boiler must be earthed.

• All system components shall be of an approved type

and all wiring to current I.E.E. wiring regulations.

• External wiring must be correctly earthed, polarised

and in accordance with the relevant standards.

- In GB this is BS 7671.

- In IE this is the current edition of I.S.813 “Domestic

Gas Installations”.

• The boiler must be connected to a permanent 230V

ac, 50Hz supply.

• Connection of the whole electrical system of the boiler, inclu-ding any heating controls, to the electrical

supply must be through one common isolator and

must be fused 3 Amp maximum.

• Isolation should be by a double pole switched fused

spur box, with a minimum gap of 3 mm for both poles.

The fused spur box should be readily accessible and

preferably adjacent to the appliance. It should be

identified as to its use.

• Alternatively connection can be made through an unswitched shuttered socket and 3A fused 3-pin plug

both to the current issue of BS 1363 may be used, provided they are not used in a room containing a bath or

shower.

• A 3 core flexible cord according to BS6500 tables 6,

8 or 16 (3 x 0.75 to 3 x 1.5mm2) should be used.

Note!

h

Ensure that all cables pass through grommets

in the outer casing and are securely fixed by

the cable clamps in the rear of the electronics

box. Ensure that the power supply is connected

such that the current carrying conductors

become taut before the earth conductor should

the supply cable slip from the cable clamp.

4.4.1 Connection to the main supply

• Lower the electronics box, see fig. 4.7.

unclip

electronics box

Fig. 4.7 Mains Supply Connection

Opening the electronics box

• Unclip the bottom of the electronics box cover and

hinge back to reveal the connection plugs.

• Feed the power supply flex into the appliance and the

electronics box through the cable clamps provided.

Caution!

a

This appliance must be wired in accordance

with these instructions. Any fault arising from

incorrect wiring cannot be put right under the

terms of the Vaillant guarantee.

Danger!

e

Mains connection terminals L and N remain live

“unless isolated at the fused spur or electrical

outlet supplying the boiler”.

Caution!

a

Do not connect any mains 230V power to the

connections 7-8-9 or BUS (+,-).

21Instructions for installation and servicing ecoTEC plus 0020020828_07

Page 22

4 Boiler installation sequence

4.4.2 Wiring system

• Connect the mains supply to the terminal block, see

fig 4 .8.1 the pump can be connected directly to the

terminal block or alternatively as shown in diagram

4.8.2 .

Fig 4.8.1 Mains Supply Connection

red link *

mains supply

connection

pump

connecticon

Note!

h

• Ensure that the wires are securely fixed in

the terminal block.

• Refit the electronics box cover by pushing

into place until it clips back into position.

• Raise the electronics box.

• Check the electrical installation by carrying out short

circuit, earth continuity and resistance to earth tests

and a check for correct polarity.

230 Vac system controls

• zone valve

• programmer

• room thermostat

• cylinder thermostat

CH pump

Note: All cables connected

to the appliance should be

permanently fixed to the wall

* Remove red link if

external 230V controls

are to be fitted

Fig. 4.8.2 Mains supply and alternative pump switch live connection

junction box

3 amp fuse

double pole isolator

230 Vac 50 Hz

permanent

supply

Green/yellow (earth) wire – boiler terminal Earth sign

Blue (neutral) wire – boiler terminal N

Brown (live) wire – boiler terminal L

Caution!

a

Do not connect any mains 230V power to the

connections 7-8-9 or BUS (+,-).

Instructions for installation and servicing ecoTEC plus 0020020828_0722

Page 23

4.4.3 Electrical board layout

pp

Boiler installation sequence 4

eBUS accessory connection

X31

BUS 24V 230V

-+

789 LN 345

X20 X2

X40 X41

Burner cable harness

Accessory module connection

Diagnosis via eBUS

vrnet DIALOG

ext. flow or return probe

outer probe

ext. flow or return probe

Hydraulic cable harness

Connection for external

eBUS controller

Room thermostat 24V:

Connection 7, 8 and 9

No bi-directional

interface (analogue only)

Caution:

Do not connect

supply voltage!

Risk of damage

to electronics!

Fig. 4.9 Connection wiring

X12

Mains supply: 230V / 50Hz

Room thermostat 230V / 50Hz

(remove bridge on connection)

Heating pump

2A fuse, slow

Igniter

Connection: 230V

ly for accessory module

Su

23Instructions for installation and servicing ecoTEC plus 0020020828_07

Page 24

4 Boiler installation sequence

NTC return

X 20/5 red

X 20/7 black

X 20/8 blue

Gas valve assembly

NTC flow

black link

X 20/18 red (24 Vdc)

X 20/9 blue (earth)

Ignition electrode

Fan unit

X 20/16 blue (earth)

X 20/4 grey (PWM)

X 20/3 black (hall signal)

X 20/17 red (24 Vdc)

green/ yellow

X20

black

Electronic control box

Fig. 4.10 Mains Supply Connection

red

X2

bus 24 V

Chassis earth

pump connection

red

230 V

green/yellow

green/ yellow

fuse T2E

250 Volts

Instructions for installation and servicing ecoTEC plus 0020020828_0724

Page 25

Boiler installation sequence 4

4.4.4 Controls

Controls Article no. Installation

VRT 392 Programmable Room Control 0020028509 Wall mounted

VRT 392f RF Programmable Room Control 0020028514 Wall mounted

VRC 470 Weather Compensator 0020108130 Wall mounted or plug in

VRC 470f Weather Compensator (From Q3 2011) 0020108137 Wall mounted

Accessories Article no. Installation

VR 65 control centre 307215 Allows ebus connection of 1 x hot water and 1 x heating zone

VR 61/2 Mixer Module 002019330

VR 81/2 Remote Control Unit 0020129323

VR 68/2 Solar Module 0020129873 Allows Weather compensator to add solar control functionality

Table 4.2 Vaillant controls

(used in conjunction with the VR 65 accessory)

4.4.5 External electrical controls

The boiler terminals 3, 4 and 5 are for connecting

external electrical controls. Terminals 3 and 4 are linked

together when the boiler is supplied. If external controls

are used, this link must be removed, and the controls

connected to terminal 4. Terminal 5 is an additional

neutral connection for external neutrals such as from

the anticipator of a room thermostat.

Allows two zone heating systems to wire to ebus system