Vaillant ecoTEC plus 806 VU GB 806/5-5, ecoTEC plus 1006 VU GB 1006/5-5, ecoTEC plus 1206 VU GB 1206/5-5 Installation And Maintenance Instructions Manual

Page 1

For the competent person

Installation and maintenance instructions

ecoTEC plus

VU GB .../5‑5

GB, IE

Installation and maintenance instructions

Publisher/manufacturer

Vaillant GmbH

Berghauser Str. 40 D-42859 Remscheid

Tel. +49 21 91 18‑0 Fax +49 21 91 18‑2810

info@vaillant.de www.vaillant.de

Page 2

Contents

2 Installation and maintenance instructions ecoTEC plus 0020134823_04

Contents

1 Safety .................................................................... 4

1.1 Action-related warnings ......................................... 4

1.2 Intended use.......................................................... 4

1.3 General safety information .................................... 4

1.4 Regulations (directives, laws, standards).............. 6

2 Notes on the documentation .............................. 7

2.1 Observing other applicable documents ................. 7

2.2 Storing documents................................................. 7

2.3 Applicability of the instructions .............................. 7

2.4 Benchmark............................................................. 7

3 Product description............................................. 7

3.1 Design of the product............................................. 7

3.2 Information on the identification plate.................... 8

3.3 CE label ................................................................. 8

4 Installation............................................................ 8

4.1 Unpacking the product........................................... 8

4.2 Checking the scope of delivery.............................. 8

4.3 Product dimensions and connection

dimensions............................................................. 9

4.4 Minimum clearances and installation

clearances ............................................................. 9

4.5 Clearance from combustible components ............. 9

4.6 Using the installation template............................... 9

4.7 Wall-mounting the product................................... 10

4.8 Removing/installing the front casing.................... 10

4.9 Removing/fitting the upper casing ....................... 10

4.10 Removing/installing the side section (as

required) .............................................................. 11

5 Installation.......................................................... 11

5.1 Gas installation .................................................... 11

5.2 Hydraulics installation.......................................... 12

5.3 Flue gas installation ............................................. 14

5.4 Electrical installation ............................................ 15

6 Operation............................................................ 17

6.1 Operating concept of the product ........................ 17

6.2 Live Monitor (status codes) ................................. 17

6.3 Test programmes................................................. 17

7 Start-up ............................................................... 18

7.1 Auxiliary service equipment:................................ 18

7.2 Carrying out the initial start-up............................. 18

7.3 Checking and treating the heating water/filling

and supplementary water .................................... 18

7.4 Switching on the product ..................................... 19

7.5 Running the installation assistants ...................... 19

7.6 Restarting the installation assistants ................... 19

7.7 Calling up appliance config. and diagnostics

menu.................................................................... 19

7.8 Using check programmes.................................... 19

7.9 Reading off the filling pressure ............................ 20

7.10 Preventing low water pressure ............................ 20

7.11 Filling and purging the heating installation .......... 20

7.12 Flushing the heating installation for the first

time ("cold") ......................................................... 21

7.13 Filling the condensate trap .................................. 21

7.14 Checking and adjusting the gas ratio setting ....... 21

7.15 Checking leak-tightness ...................................... 24

7.16 Thoroughly flushing the heating installation

("hot")................................................................... 24

8 Adapting the unit to the heating

installation.......................................................... 25

8.1 Calling up diagnostics codes ............................... 25

8.2 Setting the heating partial load ............................ 25

8.3 Setting the pump overrun and pump operating

mode.................................................................... 25

8.4 Setting the maximum flow temperature ............... 25

8.5 Setting the return flow temperature control ......... 25

8.6 Burner anti-cycling time ....................................... 26

8.7 Setting the maintenance interval ......................... 26

8.8 Setting the pump output....................................... 26

8.9 Handing the product over to the operator............ 26

9 Inspection and maintenance ............................ 26

9.1 Observing inspection and maintenance

intervals ............................................................... 27

9.2 Procuring spare parts .......................................... 27

9.3 Using the function menu...................................... 27

9.4 Carrying out electronics self-tests ....................... 28

9.5 Removing the gas-air mixture unit....................... 28

9.6 Cleaning the heat exchanger............................... 29

9.7 Checking the burner ............................................ 30

9.8 Replacing the ignition and ionisation

electrodes ............................................................ 30

9.9 Cleaning the condensate trap.............................. 30

9.10 Installing the gas-air mixture unit ......................... 30

9.11 Draining the product ............................................ 31

9.12 Completing inspection and maintenance work .... 31

10 Troubleshooting ................................................ 31

10.1 Contacting your service partner........................... 32

10.2 Calling up service messages ............................... 32

10.3 Reading off the fault codes .................................. 32

10.4 Querying the fault memory .................................. 32

10.5 Resetting the fault memory.................................. 32

10.6 Performing diagnostics ........................................ 32

10.7 Using check programmes .................................... 32

10.8 Resetting parameters to factory settings ............. 32

10.9 Preparing the repair work .................................... 32

10.10 Replacing defective components......................... 33

10.11 Completing repair work........................................ 35

11 Decommissioning.............................................. 35

11.1 Decommissioning the product ............................. 35

12 Recycling and disposal..................................... 35

13 Customer service............................................... 35

Appendix ............................................................................ 36

A Installer level menu structure – Overview....... 36

B Overview of diagnostics codes........................ 38

C Inspection and maintenance work –

Overview............................................................. 40

Page 3

Contents

0020134823_04 ecoTEC plus Installation and maintenance instructions 3

D Status codes – Overview .................................. 41

E Overview of fault codes .................................... 42

F Connection diagram .......................................... 44

G Initial start-up checklist..................................... 45

G.1 Initial start-up checklist ........................................ 45

H Commissioning Checklist ................................. 48

I Opening of the flue pipe.................................... 51

I.1 Positioning of the opening of a fan-supported

flue gas guiding.................................................... 51

I.2 Text from BS 5440-1 on fan-supported flue

gas guiding .......................................................... 52

I.3 Opening of the flue pipe below eaves and

balconies.............................................................. 52

J Treating the heating water................................ 52

K Technical data.................................................... 53

Index ................................................................................... 55

Page 4

1 Safety

4 Installation and maintenance instructions ecoTEC plus 0020134823_04

1 Safety

1.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in

accordance with the severity of the possible

danger using the following warning signs and

signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of

severe personal injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental

damage

1.2 Intended use

There is a risk of injury or death to the user or

others, or of damage to the product and other

property in the event of improper use or use

for which it is not intended.

The product is intended as a heat generator

for closed heating installations and for hot

water generation.

Depending on the gas-fired boiler type, the

products referred to in these instructions

must only be installed and operated in conjunction with the air/flue pipe accessories listed in the other applicable documents.

Intended use includes the following:

– observance of accompanying operating,

installation and servicing instructions for

the product and any other system components

– installing and fitting the product in accord-

ance with the product and system approval

– compliance with all inspection and main-

tenance conditions listed in the instructions.

Intended use also covers installation in accordance with the IP class.

Any other use that is not specified in these

instructions, or use beyond that specified in

this document shall be considered improper

use. Any direct commercial or industrial use

is also deemed to be improper.

Caution.

Improper use of any kind is prohibited.

1.3 General safety information

1.3.1 Risk caused by inadequate

qualifications

The following work must only be carried out

by competent persons who are sufficiently

qualified to do so:

– Installation

– Disassembly

– Installation

– Start-up

– Maintenance

– Repair

– Decommissioning

1.3.2 Risk of death due to blocked or

leaking flue gas routes

Installation errors, damage, tampering, unauthorised installation sites or similar can cause

flue gas to escape and result in a risk of poisoning.

What to do if you smell flue gas in the property:

▶ Open all accessible doors and windows

fully to provide ventilation.

▶ Switch off the product.

▶ Check the flue gas routes in the product

and the flue gas diversions.

1.3.3 Risk of poisoning and burns caused

by escaping hot flue gases

▶ Only operate the product if the air/flue pipe

has been completely installed.

▶ With the exception of short periods for

testing purposes, only operate the product

when the front casing is installed and

closed.

1.3.4 Risk of death due to explosive and

flammable materials

▶ Do not use or store explosive or flammable

materials (e.g. petrol, paper, paint) in the

installation room of the product.

Page 5

Safety 1

0020134823_04 ecoTEC plus Installation and maintenance instructions 5

1.3.5 Danger caused by improper

operation

Improper operation may present a danger to

you and others, and cause material damage.

▶ Carefully read the enclosed instructions

and all other applicable documents, particularly the "Safety" section and the warnings.

▶ Only carry out the activities for which in-

structions are provided in these operating

instructions.

1.3.6 Risk of death from escaping gas

What to do if you smell gas in the building:

▶ Avoid rooms that smell of gas.

▶ If possible, open doors and windows fully

and ensure adequate ventilation.

▶ Do not use naked flames (e.g. lighters,

matches).

▶ Do not smoke.

▶ Do not use any electrical switches, mains

plugs, doorbells, telephones or other communication systems in the building.

▶ If it is safe to do so, close the emergency

control valve or the main isolator.

▶ If possible, close the gas isolator cock on

the product.

▶ Warn other occupants in the building by

yelling or banging on doors or walls.

▶ Leave the building immediately and ensure

that others do not enter the building.

▶ Notify the gas supply company or the Na-

tional Grid +44 (0) 800 111999 by telephone once you are outside of the building.

1.3.7 Risk of death due to lack of safety

devices

The schematic drawings included in this document do not show all safety devices required for correct installation.

▶ Install the necessary safety devices in the

system.

▶ Observe the applicable national and inter-

national laws, standards and guidelines.

1.3.8 Risk of injury during transport due

to a high product weight.

▶ Make sure that the product is transported

by at least two people.

1.3.9 Risk of death from electric shock

There is a risk of death from electric shock if

you touch live components.

Before commencing work on the product:

▶ Disconnect the product from the power

supply by switching off all power supplies

(electrical partition with a contact opening

of at least 3 mm, e.g. fuse or line protection switch).

▶ Secure against being switched back on

again.

▶ Wait for at least 3 minutes until the capa-

citors have discharged.

▶ Check that there is no voltage.

1.3.10 Risk of being burned or scalded by

hot components

▶ Only carry out work on these components

once they have cooled down.

1.3.11 Risk of death from escaping flue

gas

If you operate the product with an empty condensate siphon, flue gas may escape into the

room air.

▶ In order to operate the product, ensure that

the condensate siphon is always full.

1.3.12 Risk of scalding from hot water

There is a risk of scalding at the hot water

draw-off points if the hot water temperatures

are greater than 60 °C. Young children and

elderly persons are particularly at risk, even

at lower temperatures.

▶ Select a moderate set target temperature.

1.3.13 Risk of material damage caused by

using an unsuitable tool

▶ Use the correct tool to tighten or loosen

screw connections.

Page 6

1 Safety

6 Installation and maintenance instructions ecoTEC plus 0020134823_04

1.3.14 Risk of material damage caused by

frost

▶ Do not install the product in rooms prone

to frost.

1.3.15 Risk of corrosion damage due to

unsuitable combustion and room

air

Sprays, solvents, chlorinated cleaning

agents, paint, adhesives, ammonia compounds, dust or similar substances may lead

to corrosion on the product and in the air/flue

pipe.

▶ Ensure that the supply of combustion air is

always free of fluorine, chlorine, sulphur,

dust, etc.

▶ Ensure that no chemical substances are

stored at the installation site.

▶ If you are installing the product in

hairdressing salons, painter's or joiner's

workshops, cleaning businesses or similar

locations, choose a separate installation

room in which the room air is technically

free of chemical substances.

1.4 Regulations (directives, laws,

standards)

▶ Observe the national regulations, stand-

ards, guidelines and laws.

Page 7

Notes on the documentation 2

0020134823_04 ecoTEC plus Installation and maintenance instructions 7

2 Notes on the documentation

2.1 Observing other applicable documents

▶ You must observe all the operating and installation in-

structions included with the system components.

2.2 Storing documents

▶ Pass these instructions and all other applicable docu-

ments on to the system operator.

2.3 Applicability of the instructions

These instructions apply only to:

Product article number

Article number

Gas Council

Number

806 (VU GB 806/5‑5)

0010010767 41-044-68

1006 (VU GB 1006/5‑5)

0010010780 41-044-69

1206 (VU GB 1206/5‑5)

0010010791 41-044-70

2.4 Benchmark

Vaillant is a licensed member of the Benchmark Scheme.

Benchmark places responsibilities on both manufacturers

and installers. The purpose is to ensure that customers are

provided with the correct equipment for their needs, that it is

installed, commissioned and serviced in accordance with the

manufacturer’s instructions by a competent person approved

at the time by the Health and Safety Executive and that it

meets the requirements of the appropriate Building Regulations. The Benchmark Checklist can be used to demonstrate compliance with Building Regulations and should be

provided to the customer for future reference.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark

Code of Practice which is available from the Heating and

Hotwater Industry Council who manage and promote the

Scheme.

Benchmark is managed and promoted by the Heating and

Hotwater Industry Council.

For more information visit www.centralheating.co.uk

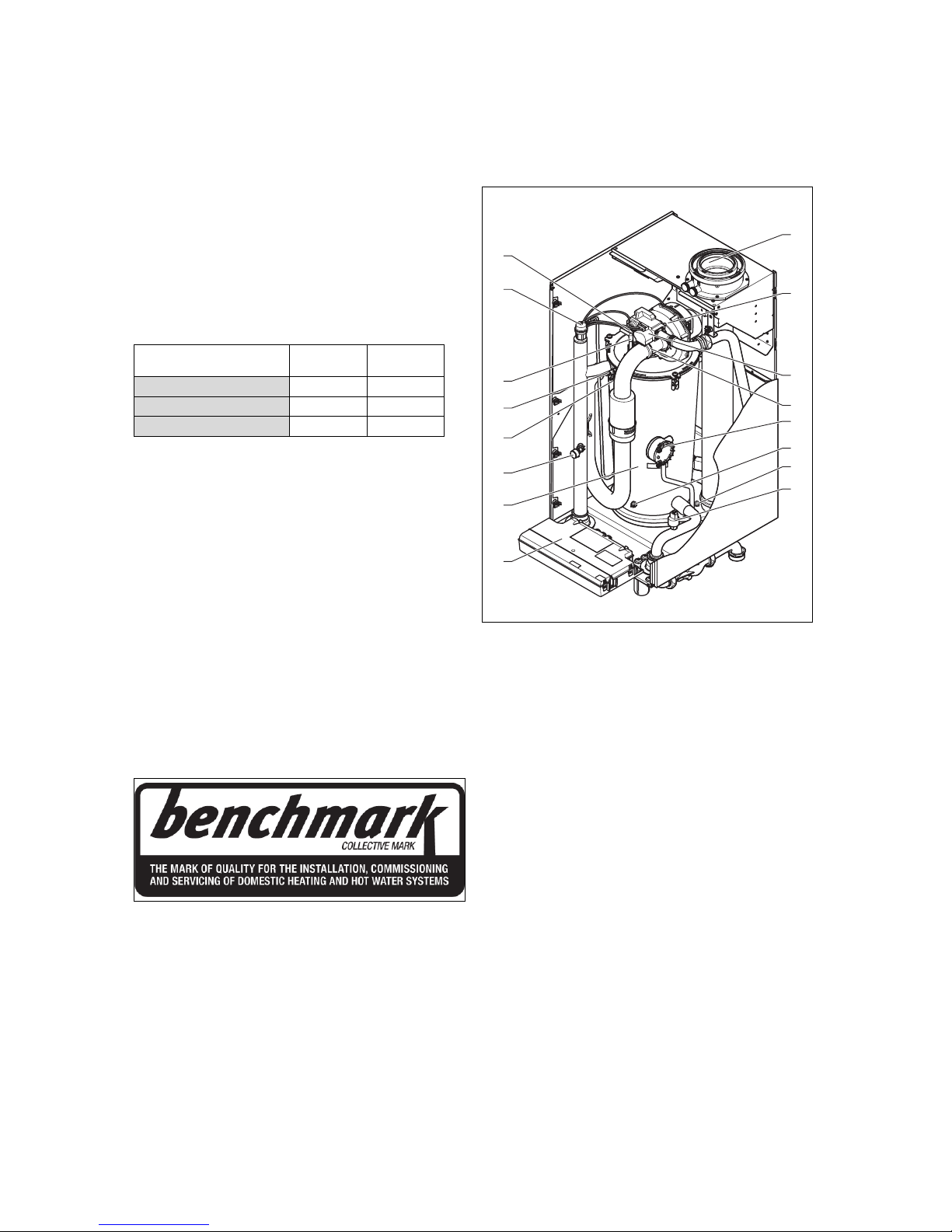

3 Product description

3.1 Design of the product

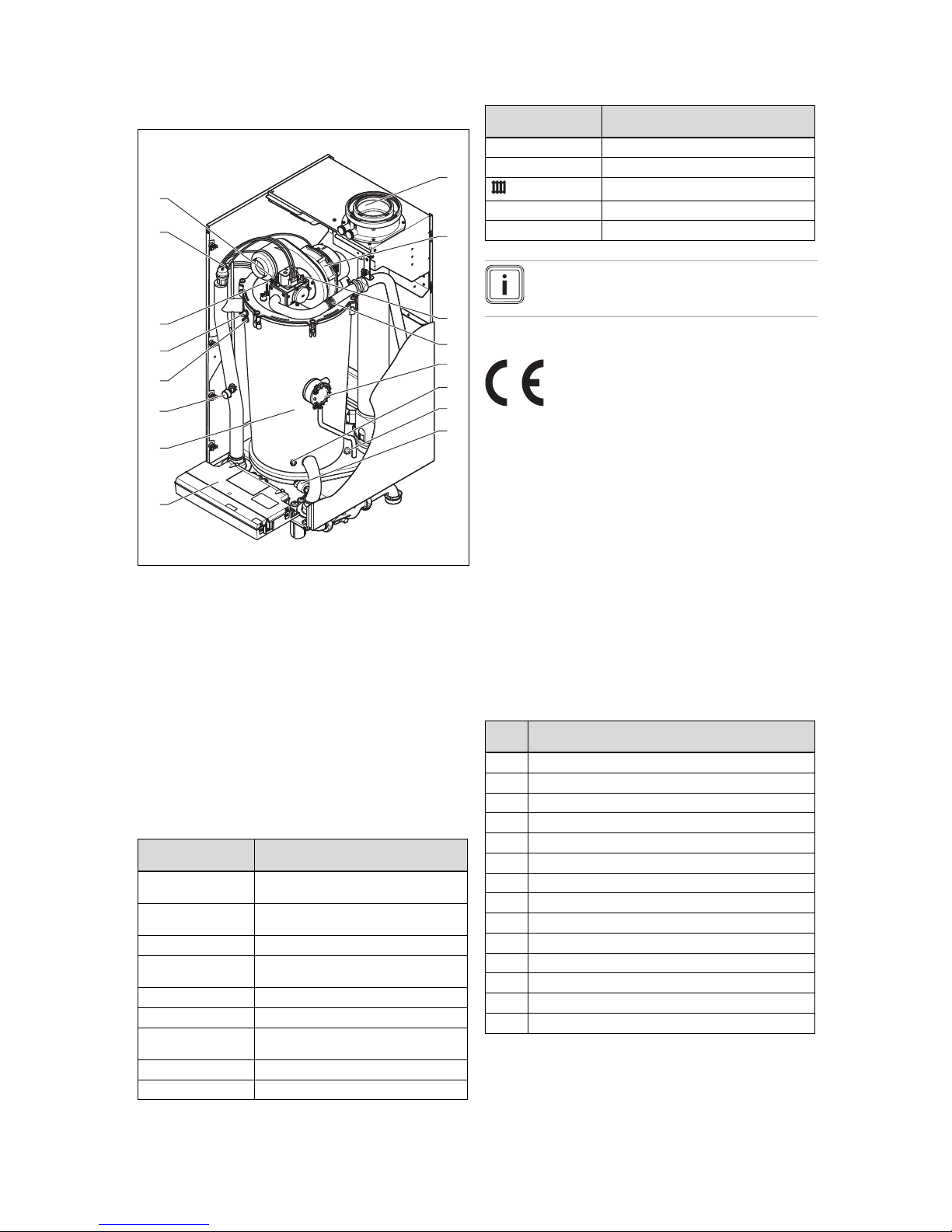

3.1.1 Functional elements (806/5‑5)

1

2

3

4

6

5

7

8

10

9

12

13

14

15

16

11

1 Connection for the flue

pipe

2 Fan

3 Gas valve

4 Connection for air in-

take pipe

5 Flue gas pressure

cartridge

6 Return temperature

sensor

7 Water pressure sensor

8 Electronics box

9 Integrated condensation

heat exchanger

10 Pressure gauge

11 Flow temperature

sensor

12 Safety overheat cut-off

device

13 Ignition electrode

14 Automatic air vent

15 Monitoring electrode

Page 8

4 Installation

8 Installation and maintenance instructions ecoTEC plus 0020134823_04

3.1.2 Functional element (1006/5‑5 and 1206/5‑5)

1

2

3

6

7

5

4

8

10

9

12

13

14

15

16

11

1 Connection for the flue

pipe

2 Fan

3 Gas valve

4 Supply air connector

5 Flue gas pressure

cartridge

6 Return temperature

sensor

7 Water pressure sensor

8 Electronics box

9 Integrated condensation

heat exchanger

10 Pressure gauge

11 Flow temperature

sensor

12 Safety overheat cut-off

device

13 Ignition electrode

14 Automatic air vent

15 Monitoring electrode

3.2 Information on the identification plate

The identification plate is mounted on the underside of the

product in the factory.

Information on the

identification plate

Meaning

Serial number for identification; 7th to 16th digits =

product article number

VU… Vaillant gas-fired wall-hung boiler for

heating

ecoTEC plus Product description

H, G20 – 20 mbar

(2.0 kPa)

Gas group and gas connection pressure

as set at the factory

Cat. (e.g. II

2H3P

) Unit category

Types (e.g. C33) Gas-fired boiler types

PMS (e.g. 6 bar

(0.6 MPa))

Permissible total overpressure

T

max.

(e.g. 85 °C) Max. flow temperature

230 V 50 Hz Electric connection

Information on the

identification plate

Meaning

(e.g. 260) W Max. electrical power consumption

IP (e.g. X4D) Level of protection

Heating mode

P Nominal heat output range

Q Heat input range

Note

Make absolutely sure that the product is compatible with the gas group at the installation site.

3.3 CE label

The CE label shows that the products comply with the basic

requirements of the applicable directives as stated on the

identification plate.

The declaration of conformity can be viewed at the manufacturer's site.

4 Installation

4.1 Unpacking the product

1. Remove the product from its box.

2. Remove the protective film from all parts of the product.

4.2 Checking the scope of delivery

▶ Check that the scope of delivery is complete and intact.

4.2.1 Scope of delivery

Number

Description

1

Hanging bracket

1

Heat generator

1

Condensate trap

1 Condensate drain hose

1

Installation template

1

Enclosed documentation

1

Enclosed unit fastening

1

Bag with small parts

1

Gas connection piece

1

Service valve (1 1/2 inches), red handle

1

Service valve (1 1/2 inches), blue handle

1

Bag with seals for service valves

1

Expansion relief valve, 6 bar

1

R 1 straight-through gas valve

Page 9

Installation 4

0020134823_04 ecoTEC plus Installation and maintenance instructions 9

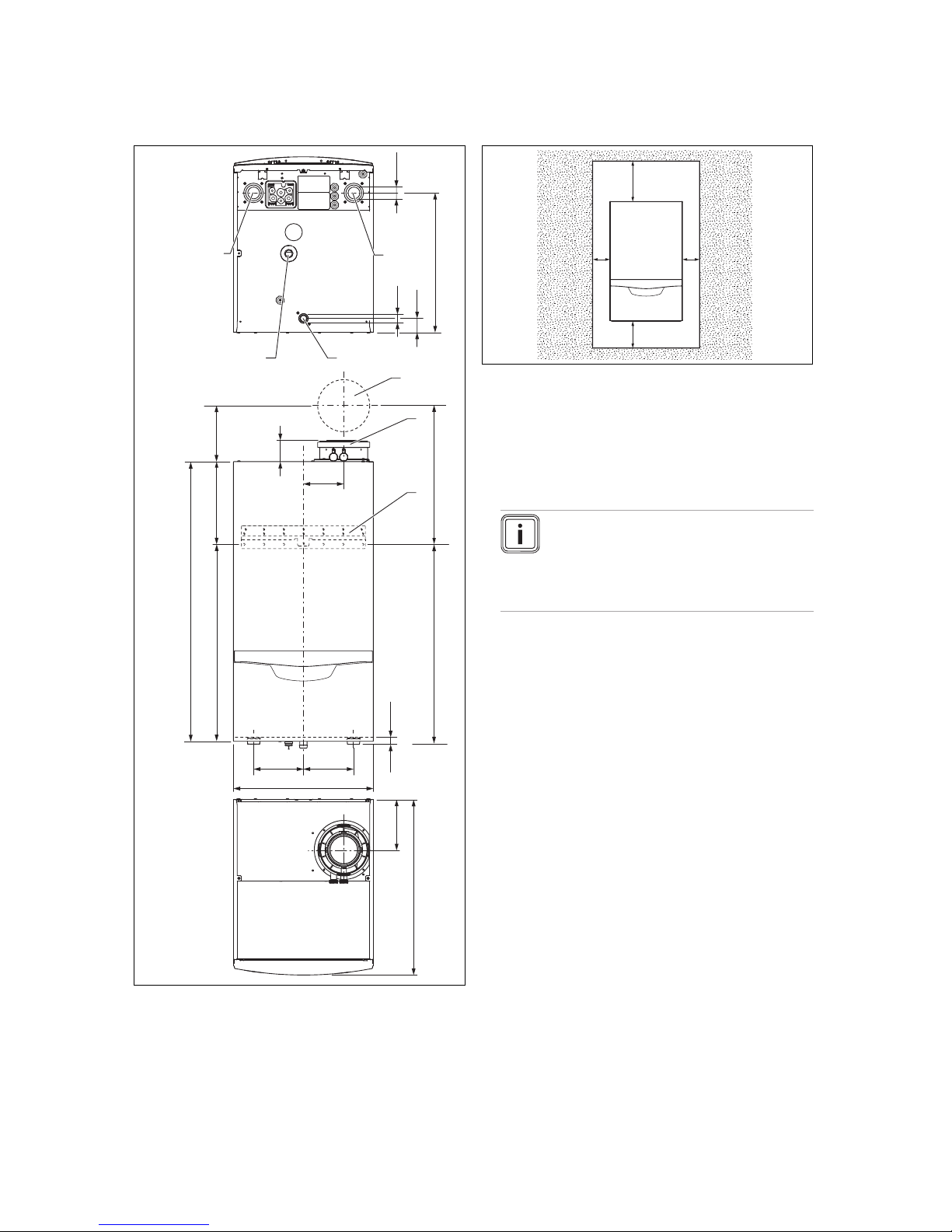

4.3 Product dimensions and connection

dimensions

287

190

673

603

480

175

138

172 172

70

22

482

Ø25

49

G 1 1/4

960

477

680,5

1

2

3

4

5

6

7

1 Wall duct for flue pipe

2 Flue pipe connection

3 Hanging bracket

4 Heating flow

5 Condensate trap con-

nection

6 Gas connection

7 Heating return

4.4 Minimum clearances and installation

clearances

CC

AB

A 350 mm (110/160 mm

diameter flue pipe)

At least 450 mm for

cascade design

B 400 mm

C Optional approx. 200

mm

D Clearance of 600 mm

in front of the product

for easy access during

maintenance work

▶ When using the accessories, observe the minimum clear-

ances/installation clearances.

Note

A lateral clearance is not required, however

you can also remove the side sections if there

is sufficient space at the side (approx. 200

mm) in order to facilitate maintenance or repair work.

▶ Where units are installed in cascade, observe the gradi-

ent of the flue pipe (approx. 50 mm/m).

4.5 Clearance from combustible components

It is not necessary to ensure that there is a clearance

between the product and combustible components, as the

temperature of the product will never exceed the maximum

permissible temperature of 85 °C at its nominal heat output.

The same applies to the external air guiding of the concentric

flue pipe.

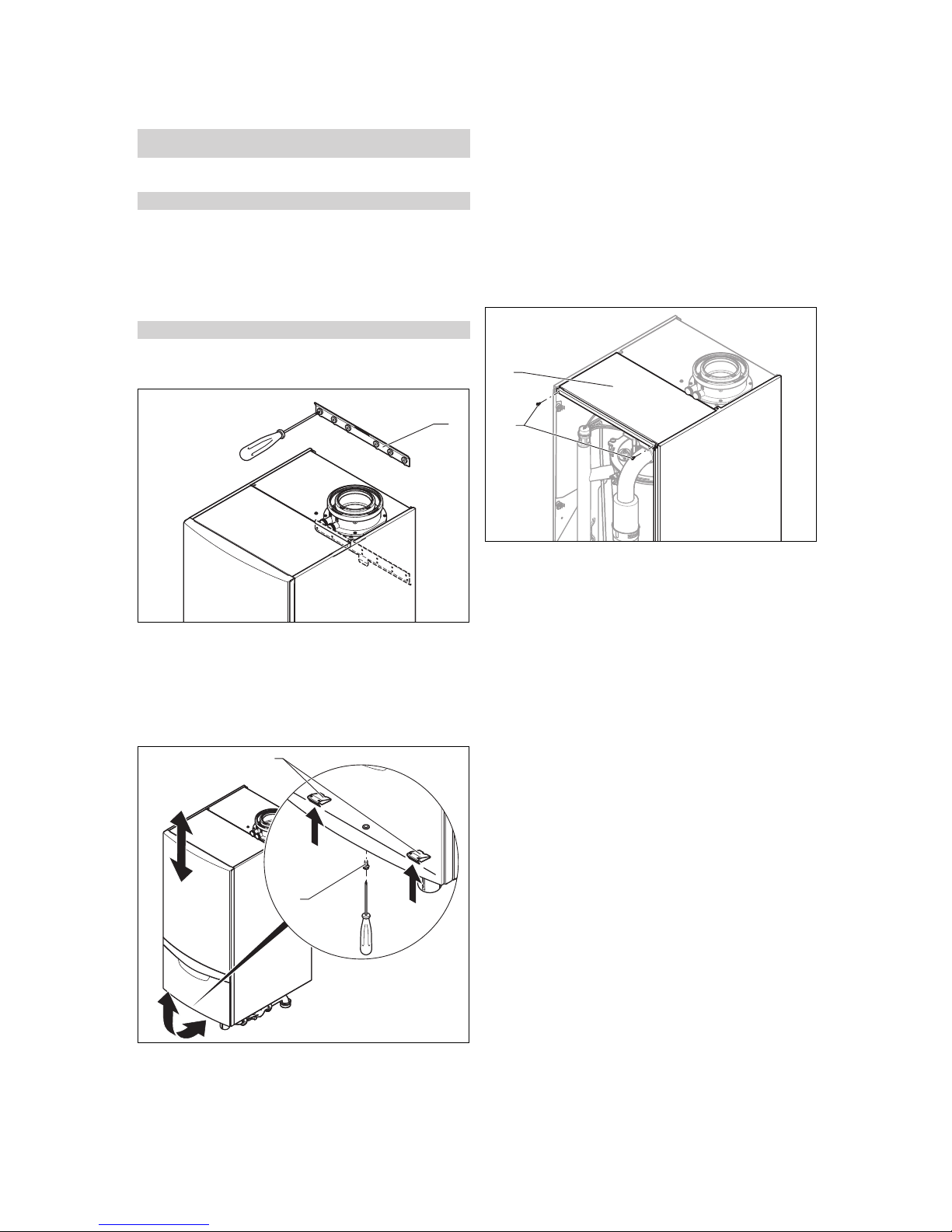

4.6 Using the installation template

1. Position the installation template vertically over the in-

stallation site.

2. Secure the template to the wall.

3. Mark on the wall all the points required for your installa-

tion.

4. Remove the installation template from the wall.

5. Drill all the holes required.

6. Make any perforations necessary.

Page 10

4 Installation

10 Installation and maintenance instructions ecoTEC plus 0020134823_04

4.7 Wall-mounting the product

Conditions: The load-bearing capacity of the wall is sufficient, The fixing

material may be used for the wall

▶ Wall-mount the product as described.

Conditions: The load-bearing capacity of the wall is not sufficient

▶ Ensure that wall-mounting apparatus on-site has a suf-

ficient load-bearing capacity. Use individual stands or

primary walling, for example.

▶ Do not wall-mount the product if you cannot provide

wall-mounting apparatus with a sufficient load-bearing

capacity.

Conditions: The fixing material may not be used for the wall

▶ Wall-mount the product as described using the permitted

fixing material provided on-site.

1

1. Install the hanging bracket (1) on the wall.

2. Suspend the product on the hanging bracket from

above using the suspension bracket.

4.8 Removing/installing the front casing

4.8.1 Removing the front casing

2

1

1. Undo the bolt (1).

2. Push in both retaining clips (2) so that the front casing

is released.

3. Pull the front casing forwards at the bottom edge.

4. Lift the front casing upwards from the bracket.

4.8.2 Installing the front casing

1. Place the front casing on the upper brackets.

2. Push the front casing onto the product until both retaining clips (2) snap into place at the front casing.

3. Secure the front casing by tightening the bolt (1).

4.9 Removing/fitting the upper casing

4.9.1 Removing the upper casing

2

1

1. Unscrew the screws (2).

2. Pull out the upper casing (1) towards the front.

4.9.2 Installing the upper casing

1. From above, place the upper casing (1) on the product.

2. Use the screws (2) to secure the upper casing (1).

Page 11

Installation 5

0020134823_04 ecoTEC plus Installation and maintenance instructions 11

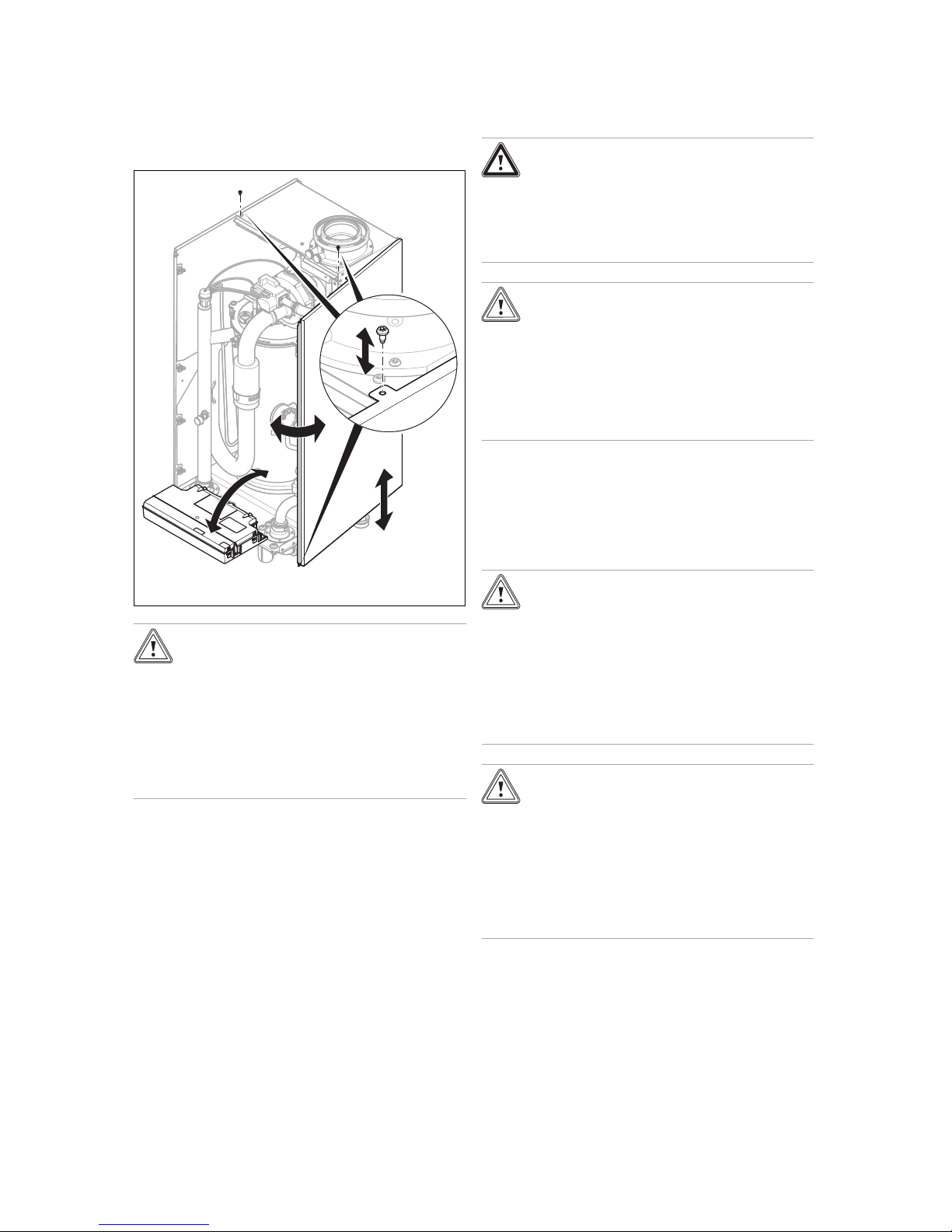

4.10 Removing/installing the side section (as

required)

4.10.1 Removing the side section

Caution.

Risk of material damage caused by mech-

anical deformation.

Removing both side sections may cause

mechanical distortion in the product, which

may cause damage to the piping, for example, and potentially result in leaks.

▶ Always remove only one side section –

never both side sections at the same time.

1. Tilt the electronics box forward.

2. Remove the upper casing. (→ Page 10)

3. Hold on to the side section so that it cannot fall, and

unscrew the lower front and upper central screws from

the side section.

4. Tilt the side section slightly to the side and pull it out

towards the front.

4.10.2 Installing the side section

1. Push the side section into the bracket. When doing so,

and to prevent leaks, ensure that all straps on the side

section engage with the back wall.

2. Slide the side section to the rear.

3. Secure the side section using two screws in the front

lower area and in the upper central area.

4. Install the upper casing. (→ Page 10)

5. Fold up the electronics box.

5 Installation

Danger!

Risk of explosion or scalding caused by

incorrect installation.

Stresses in the supply line can cause leaks.

▶ Make sure there is no voltage in the sup-

ply lines when they are installed.

Caution.

Risk of damage caused by contaminated

lines.

Foreign bodies, such as welding remnants,

sealing residue or dirt in the water pipes, may

cause damage to the boiler.

▶ Flush the heating installation thoroughly

prior to installation.

Seals made of rubber-like materials may be subject to plastic

deformation, which can lead to pressure losses. We recommend using seals made of a paste-like fibre material.

5.1 Gas installation

5.1.1 Performing the gas installation

Caution.

Risk of material damage caused by incor-

rect gas installation.

Excessive test pressure may cause damage

to the gas valve.

▶ When checking the entire gas installation

for leak-tightness, the maximum permissible pressure at the gas valve is 7.5 kPa

(75 mbar).

Caution.

Risk of material damage caused by the

incorrect gas type.

Using the wrong gas type may cause a fault

shutdown of the product. Furthermore, ignition and combustion noise may occur in the

product.

▶ Only use the gas types in accordance with

the identification plate.

Page 12

5 Installation

12 Installation and maintenance instructions ecoTEC plus 0020134823_04

▶ Remove the residues from the gas line by blowing

through the gas line beforehand.

▶ Make sure that the existing gas meter is capable of

passing the rate of gas supply required.

▶ Install an approved gas isolator cock on the product us-

ing the gas connection piece.

▶ Install the gas line on the gas isolator cock without ten-

sion.

▶ Purge the gas line before start-up.

▶ Check that the gas connection is leak-tight (→ Page 24).

5.2 Hydraulics installation

Caution.

Risk of material damage due to high tem-

peratures.

Plastic pipes in the heating installation may

become damaged by overheating if a fault

occurs.

▶ When using plastic pipes, install a max-

imum thermostat on the heating flow.

Caution.

Risk of material damage due to corrosion.

If non-diffusion-tight plastic pipes are used in

the heating installation, this may cause air to

enter the heating water and lead to corrosion

of the heat generation circuit and the product.

▶ If using non-diffusion-tight plastic pipes

in the heating installation, separate the

system by installing an external heat exchanger between the product and the

heating installation.

Caution.

Risk of material damage due to heat trans-

fer during soldering.

▶ Only solder connection pieces if the con-

nection pieces are not yet screwed to the

service valves.

The product should be connected using a Vaillant pump

group (accessories).

– Modulating pump

This pump group has a connection option for an expansion

vessel (right-hand connection) and an expansion relief valve

(left-hand connection). You can find information about available accessories from the Vaillant price list or from the contact address provided on the reverse of this document.

▶ When installing the pump group, observe the installa-

tion sequence for the insulation and the hydraulic pipes (

Pump group installation instructions).

▶ Note that the boiler pump must always be fitted in the

return line. Otherwise, this may lead to a malfunction in

the product.

When connecting several products in cascade operation, you

must install a non-return flap from the cascade connection

set in the flow line of each individual product.

A non-return flap from a third-party manufacturer must have

no more than 30 mbar pressure loss for a volume flow of

4.5 m³/h.

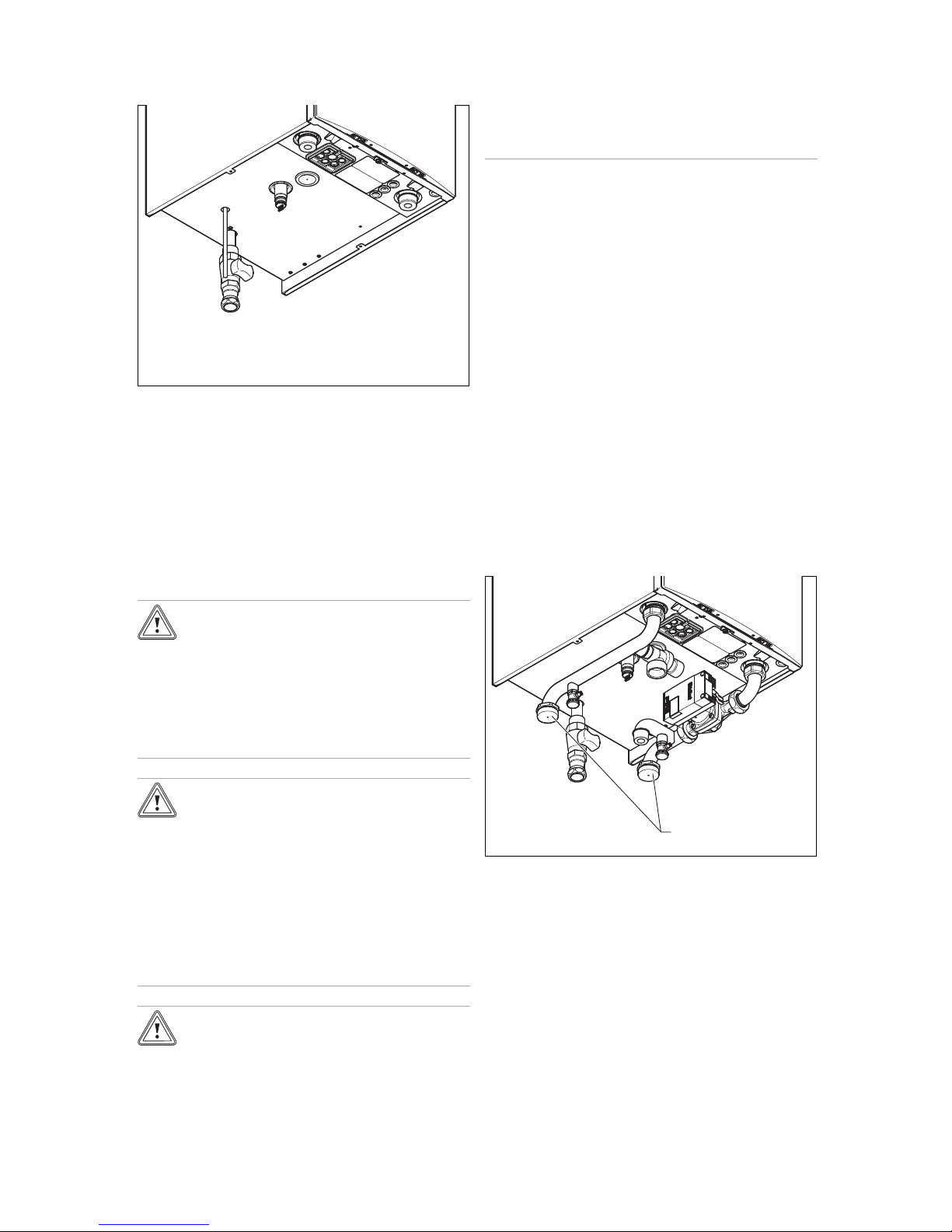

5.2.1 Connecting the heating flow and heating

return

1

1. In each case, insert a flat seal into the service valve

(Vaillant accessories).

2. Screw the service valves onto the flow and return con-

nection (1) of the pump group.

3. Screw the service valves to the customer's installation.

– Diameter of the heating line: 1 1/4″

Page 13

Installation 5

0020134823_04 ecoTEC plus Installation and maintenance instructions 13

5.2.2 Installing an expansion vessel

1

▶ Install an expansion vessel on the connection (1) in the

return.

– Connection to the pump group: 1/2″

Conditions: Using a system separation

– Large expansion vessel: ≥ 10 l

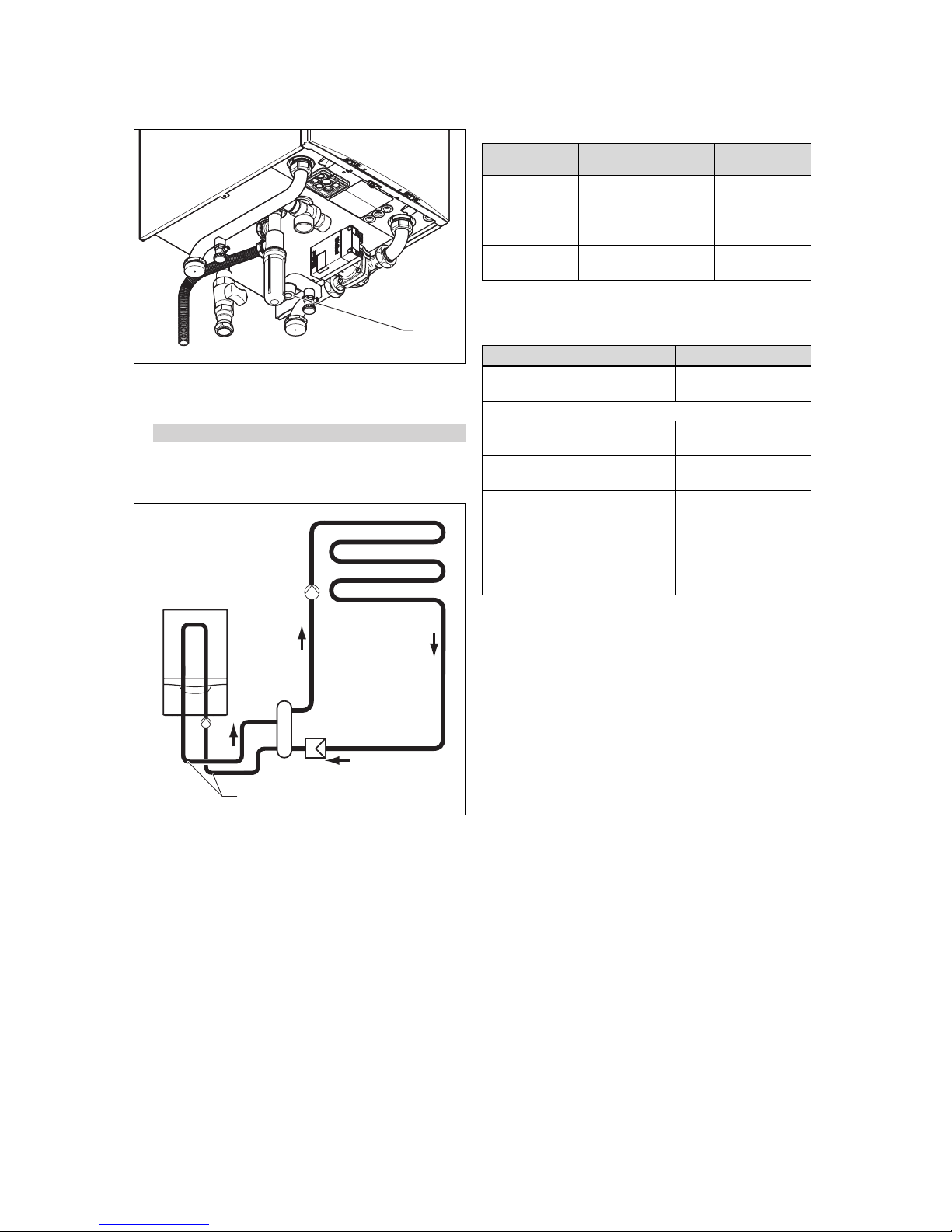

5.2.3 Hydraulic connection

Ø 1 1/4"

For the hydraulic connection to the heating installation, we

strongly recommend that you use a low loss header or a

plate heat exchanger for the hydraulic system partition. In

addition, we recommend that you install a dirt filter in the

system before the low loss header or the plate heat exchanger. For the maintenance of the plate heat exchanger,

we recommend that you install cleaning connections on

the heating side so that the plate heat exchanger can be

backwashed during maintenance work.

To this end, various plate heat exchangers and low loss

headers are available as accessories, depending on the output of a product or the cascade system. The pressure loss is

adjusted to the pump groups that are offered as an accessory. The minimum volume of circulating water is guaranteed

in the unit circuit thanks to the original accessories, provided

the maximum pressure losses are not exceeded in the piping.

Select the plate heat exchanger according to output.

Depending on your choice of pump group, the following remaining feed heads are available in the unit supply:

Power Description Remaining feed

head

80 kW Modulating pump 0.042 MPa

(0.420 bar)

100 kW Modulating pump 0.026 MPa

(0.260 bar)

120 kW Modulating pump 0.024 MPa

(0.240 bar)

If you are using a plate heat exchanger to hydraulically partition the system, the following pressure losses must be maintained (rated water volume when ΔT=20 K):

Power Pressure loss

< 120 kW 86 mbar

(0.086 bar)

In conjunction with the hydraulic cascade

< 240 kW 96 mbar

(0.096 bar)

< 360 kW 76 mbar

(0.076 bar)

< 480 kW 82 mbar

(0.082 bar)

< 600 kW 87 mbar

(0.087 bar)

< 720 kW 92 mbar

(0.092 bar)

5.2.4 Connecting the condensate trap

Condensate forms in the product during combustion. The

condensate drain pipework routes the condensate to the

waste water connection.

The product is equipped with a condensate trap. The filling

height is 145 mm. The condensate trap collects any condensate that forms and feeds it into the condensate drain

pipework.

▶ Place the condensate trap on the underside of the

product on the condensate drain pipe and secure it using

the retaining clips.

▶ Leave installation space of at least 180 mm below the

condensate trap so that you can clean the condensate

trap in the event of maintenance work.

▶ Check the connection for leak-tightness.

Page 14

5 Installation

14 Installation and maintenance instructions ecoTEC plus 0020134823_04

5.2.5 Connecting the condensate drain pipework

min.

180

2

1

3

▶ When making the condensate pipe connections ensure

that there is adequate branch ventilation and that there

can be no backflow of water into the boiler via the condensate pipe work.

▶ Check if a neutralising unit is required in accordance with

national regulations.

▶ Observe the local regulations on neutralising the con-

densate.

Note

You can obtain neutralisation with or without a

condensate pump as an accessory.

▶ If required, guide the drain hose (1) from the automatic

air vent into the tundish.

Note

The condensate drain pipework must have a

continuous fall (45 mm per metre) and should

whenever possible terminate at a suitable

drain point within the heated envelope of the

building that will remain frost free under long

periods of low external temperatures.

You can find further information in BS 656: "Specification for

installing and maintaining gas-fired boilers with a nominal

heat loading greater than 70 kW but less than or equal to

300 kW". Before the boiler is started up, the condensate

trap (1) must be filled with water as described in the relevant

section.

5.2.6 Connecting the expansion relief valve

Note

The product is delivered with a 6 bar expansion

relief valve, which must be installed on the

product and must be guided to a secure, but visible, point. The discharge pipe on the expansion

relief valve must have a minimum diameter of 18

mm and must only be used for this purpose.

1. Ensure that all components that are installed in the

heating installation are suitable for a max. operating

pressure of 6 bar.

1

Danger!

Risk of scalding!

Heating water that leaks from the exit point of

the expansion relief valve may cause severe

burns.

▶ Install the expansion relief valve drain to a

professional standard.

2. Connect the expansion relief valve (1).

Note

When selecting the expansion relief valve,

note the max. operating pressure of the heating installation.

5.3 Flue gas installation

5.3.1 Air/flue pipes that can be connected

▶ When installing the air/flue pipe, observe the provisions

of the applicable national regulations.

Note

All products feature an 110/160 mm diameter

air/flue gas connection as standard.

You can find out which air/flue pipes may be used by consulting the enclosed "Air/flue pipe installation manual".

5.3.2 Installing the air/flue pipe

Caution.

Risk of poisoning due to escaping flue

gas.

Mineral-oil-based greases can damage the

seals.

▶ Instead of grease, use only water or com-

mercially available soft soap to aid installation.

Page 15

Installation 5

0020134823_04 ecoTEC plus Installation and maintenance instructions 15

Danger!

Risk of personal injury and material dam-

age due to unapproved air/flue pipes.

Vaillant boilers are certified only with Vaillant

original air/flue pipes. The use of other accessories may cause personal injury and material damage, as well as operating faults. For

installation type B23P, third-party accessories are also permitted (see the technical data

in the appendix).

▶ Only use Vaillant original air/flue pipes.

▶ If third-party accessories are permitted

for B23P, ensure that the flue pipe connections are properly routed, sealed and

secured against slipping out.

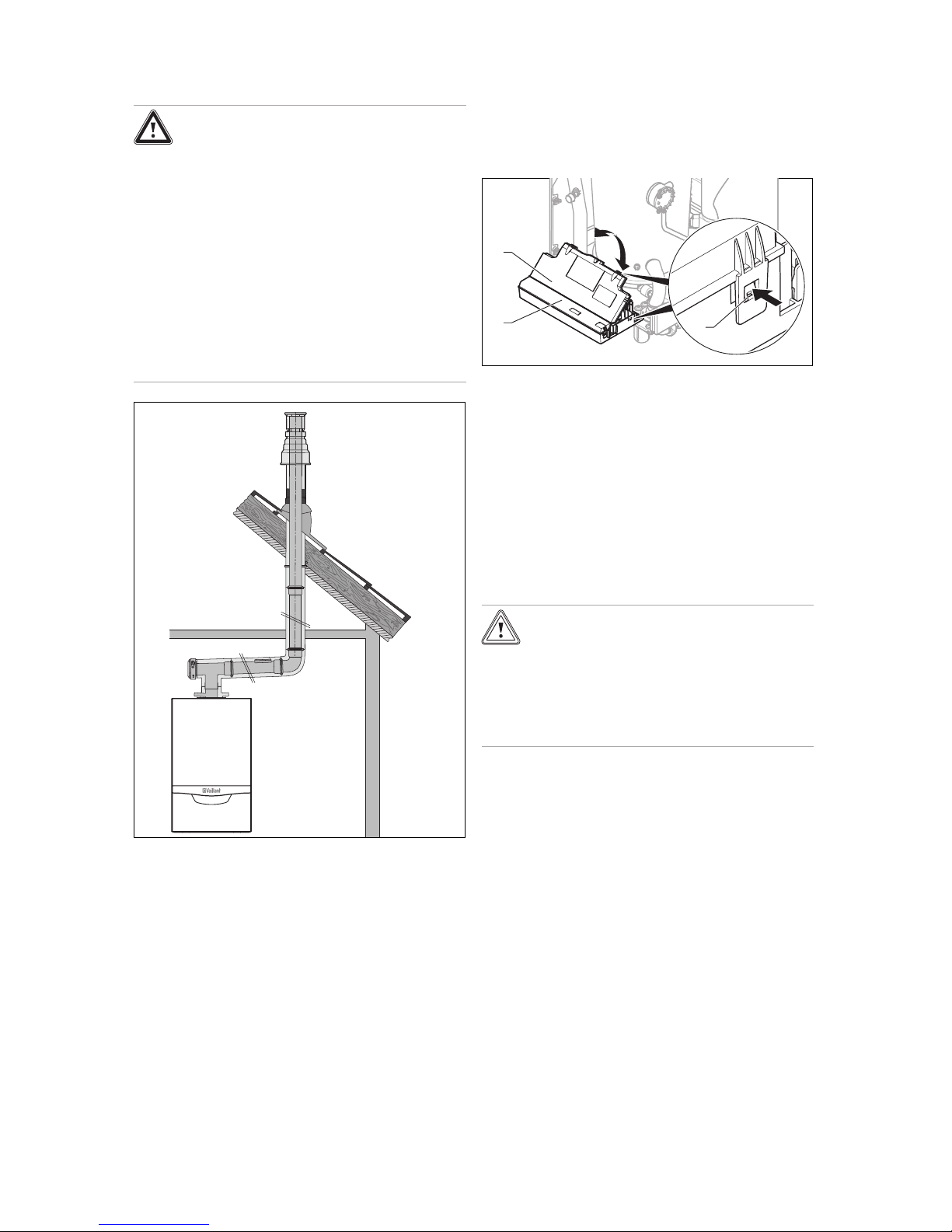

1. Install the flue pipe using the installation manual.

2. When installing the air/flue pipe, observe the provisions

of the applicable national regulations.

3. Route the flue pipe with a downward gradient so that

the condensate that accumulates can easily flow into

the condensate trap provided for it.

5.4 Electrical installation

5.4.1 Opening/closing the electronics box

5.4.1.1 Opening the electronics box

2

1

3

1. Remove the front casing. (→ Page 10)

2. Tilt the electronics box (1) forward.

3. Undo the clips (3) from the brackets.

4. Fold up the cover (2).

5.4.1.2 Closing the electronics box

1. Close the cover (2) by pushing downwards on the electronics box (1).

2. Ensure that all the clips (3) audibly click into the brackets.

3. Tilt the electronics box upwards.

5.4.2 Establishing the power supply

Caution.

Risk of material damage due to high con-

nected voltage.

At mains voltages greater than 253 V, electronic components may be damaged.

▶ Ensure that the rated voltage of the mains

is 230 V (+10%/-15%) ~ 50 Hz.

1. Observe all valid regulations.

2. Open the electronics box. (→ Page 15)

3. Provide one common electricity supply for the boiler

and for the corresponding controller:

– Power supply: Single-phase, 230 V, 50 Hz

– Fuse protection: ≤ 3 A

4. Connect the product using a fixed connection and a

partition with a contact opening of at least 3 mm (e.g.

fuses or power switches).

5. Use a flexible line for the mains feed line, which is

routed through the cable duct into the product.

6. Carry out the wiring. (→ Page 16)

7. Observe the connection diagram (→ Page 44).

8. Screw the supplied ProE plug to a suitable, flexible

three-core mains connection cable which complies with

the relevant standards.

9. Close the electronics box. (→ Page 15)

10. Make sure that access to the mains connection is al-

ways available and is not covered or blocked.

Page 16

5 Installation

16 Installation and maintenance instructions ecoTEC plus 0020134823_04

5.4.3 Carrying out the wiring

Caution.

Risk of material damage caused by incor-

rect installation.

Mains voltage at the incorrect plug terminals

on the ProE system may destroy the electronics.

▶ Do not connect any mains voltage to the

eBUS terminals (+/-).

▶ Only connect the mains connection cable

to the terminals marked for the purpose.

1. Route the supply lines of the components to be connected through the cable duct provided on the underside of

the product.

2. Use the strain reliefs provided.

3. Shorten the supply lines as necessary.

4. To prevent short circuits if a strand accidentally comes

loose, only strip the outer sheathing of flexible lines to a

maximum of 30 mm.

5. Ensure the inner conductor insulation is not damaged

when stripping the outer sheathing.

6. Only strip inner conductors just enough to establish

good, sound connections.

7. To avoid short circuits resulting from loose individual

wires, fit conductor end sleeves on the stripped ends of

the conductors.

8. Screw the respective ProE plug to the supply line.

9. Check whether all conductors are sitting mechanically

securely in the terminals of the ProE plug. Remedy this

if necessary.

10. Plug the ProE plug into the associated PCB slot.

11. Secure the cable in the electronics box using the strain

reliefs.

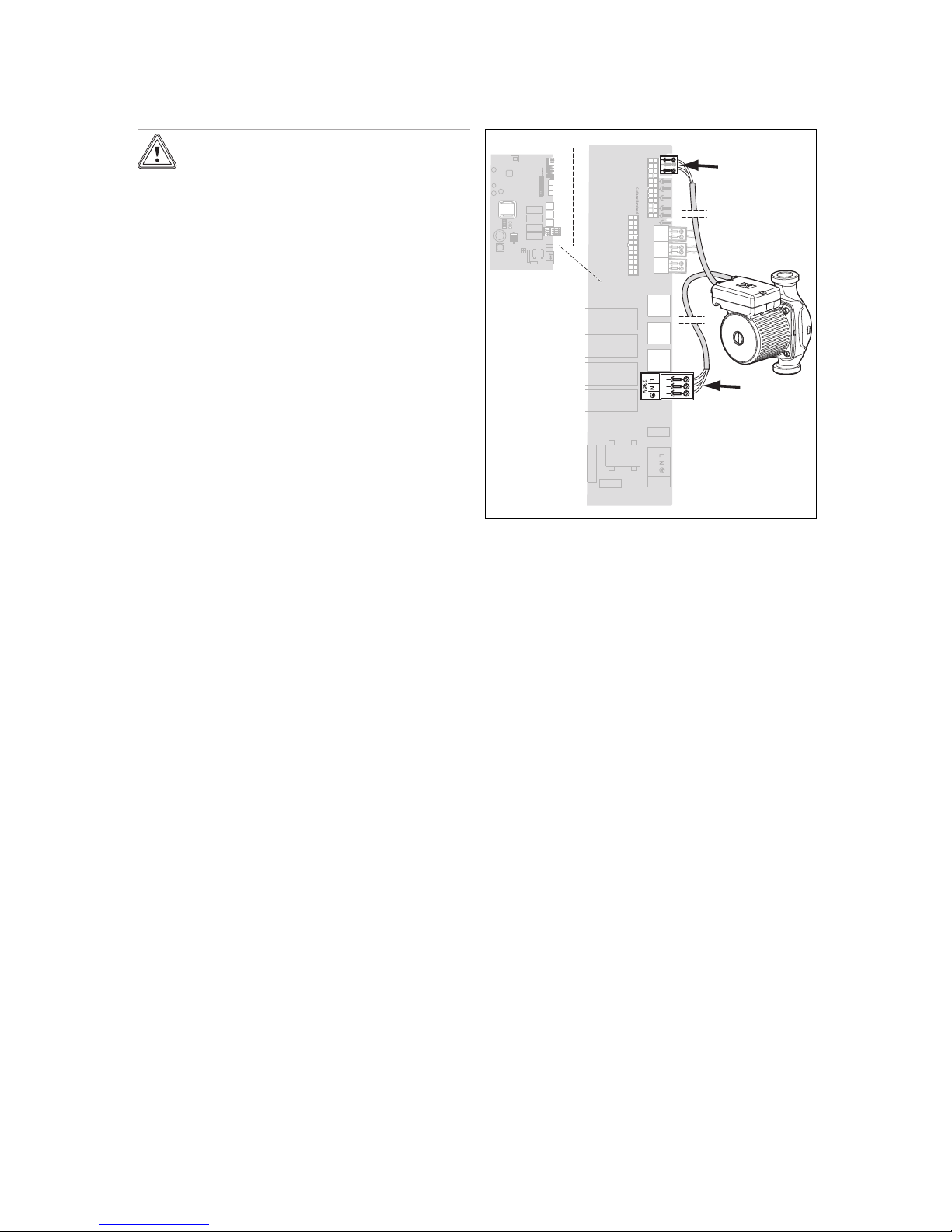

5.4.4 Connecting the pump group

X18

230 V

X22

1. Open the electronics box. (→ Page 15)

2. Carry out the wiring. (→ Page 16)

3. Use the strain reliefs provided.

4. Plug the ProE plug for the mains power cable into slot

X18.

5. Plug the ProE plug for the control cable into slot X22.

6. Close the electronics box. (→ Page 15)

5.4.5 Installing the controller

▶ Install the controller if necessary.

5.4.6 Connecting controllers to the electronic

system

1. Open the electronics box. (→ Page 15)

2. Carry out the wiring. (→ Page 16)

3. If you connect a weather compensator or room thermostat to the product via eBUS, bridge the input 24 V = RT

(X100 or X106) if no bridge exists.

4. If you use a low-voltage controller (24 V), connect this

instead of the bridge 24 V = RT (X100 or X106).

5. When connecting a maximum thermostat (contact thermostat) for underfloor heating, connect this instead of

the bridge (Burner off) at the ProE plug.

6. Close the electronics box. (→ Page 15)

7. In order to achieve the Comfort pump operating mode

(continuously running pump) for multi-circuit controllers,

change D.018 Pump operating mode (→ Page 25) from

Eco (intermittent pump) to Comfort.

8. If a system separation is installed, set the pump to

Comfort D.018 and set the pump output to at least

4 (85%, D.014). This also applies for installing in

cascade.

Page 17

Operation 6

0020134823_04 ecoTEC plus Installation and maintenance instructions 17

5.4.7 Connecting additional components

You can use the multi-functional module to actuate two additional components.

The following components can be actuated:

– Circulation pump

– External pump

– Cylinder charge pump

– Extractor hood

– External solenoid valve

– External fault signal

– Solar pump (not active)

– eBUS remote control (not active)

– Legionella protection pump (not active)

– Solar valve (not active).

5.4.7.1 Using the VR 40 ("2 in 7" multi-functional

module)

1. Install the components in accordance with the respect-

ive instructions.

2. Select D.027 (→ Page 25) to actuate relay 1 on the

multi-functional module.

3. Select D.028 (→ Page 25) to actuate relay 2 on the

multi-functional module.

5.4.7.2 Using the flue non-return flap

For cascade operation, you must provide a flue non-return

flap for each product. Either use only electrical flue non-return flaps or use only mechanical flue non-return flaps for all

products in a cascade.

The electrical flue non-return flap is actuated by the VR 40

multi-functional module. The installation instructions for the

VR 40 describe how the flue non-return flap is activated. The

mechanical flue non-return flap has an integrated siphon,

which must be filled with water before starting up the unit.

You can omit the flue non-return flap if you can ensure that

the flue gas installation is operated completely under negative pressure.

Conditions: Operating with natural gas

▶ For smooth operation with natural gas and a flue non-

return flap, use diagnostics code D.050 (→ Page 25) to

increase the fan speed in partial load operation to 1500

rpm.

Conditions: Operating with liquid gas

▶ You must never raise the speed under D.050

(→ Page 25) any higher because a higher speed is

already being used when operating with liquid gas.

5.4.8 Actuating the circulation pump according

to requirements

1. Connect the wiring in the same way as described

in "Connecting controllers to the electronic system

(→ Page 16)".

2. Connect the supply line for the external button using

terminals 1 (0) and 6 (functional drawing) on the X41

edge connector, which is supplied with the controller.

3. Plug the edge connector into the PCB slot X41.

6 Operation

6.1 Operating concept of the product

The operating concept and the read-off and setting facilities

of the operator level are described in the operating instructions.

An overview of the read-off and setting facilities of the installer level can be found in the section "Overview of the

menu structure – Installer level" (→ Page 36).

6.1.1 Calling up the installer level

Caution.

Risk of material damage caused by incor-

rect handling.

Incorrect settings at installer level may cause

damage and operating faults to the heating

installation.

▶ You must only access the installer level if

you are an approved competent person.

Note

The installer level is protected against unauthorised access using a password.

1.

Press and ("i") simultaneously.

◁ The following menu appears in the display.

2.

Scroll using the or button, until the menu point

Installer level appears.

3. Press (OK) to confirm your selection.

◁ In the display, the text Enter code appears along

with the value 00.

4.

Use or to set the value 17 (code).

5. Press (OK) to confirm your selection.

◁ The installer level appears with a selection of menu

points.

6.2 Live Monitor (status codes)

Menu → Live Monitor

Status codes in the display provide information on the product's current operating status.

Status codes – Overview (→ Page 41)

6.3 Test programmes

As well as the installation assistants, you can also call up the

test programmes for start-up, service and troubleshooting.

Menu → Installer level Test programs

There you will find the Check programs (→ Page 19), in

addition to the Function menu, an Electronics self-test

and the Gas family check.

Page 18

7 Start-up

18 Installation and maintenance instructions ecoTEC plus 0020134823_04

7 Start-up

7.1 Auxiliary service equipment:

The following test and measuring equipment is required for

start-up:

– CO2measuring instrument

– Digital or U tube manometer

– Flat blade screwdriver, small

– 2.5 mm Allen key

7.2 Carrying out the initial start-up

Initial start-up must be carried out by a customer service

technician or an authorised competent person using the

first-commissioning-checklist and the start-up checklist.

The first-commissioning-checklist and the start-up checklist

(→ Page 48) in the appendix for the installation instructions

must be filled out and stored carefully along with the product

documentation.

Initial start-up checklist (→ Page 45)

▶ Carry out the initial start-up using the checklist and the

start-up checklist in the appendix.

▶ Fill out and sign the checklists.

7.3 Checking and treating the heating

water/filling and supplementary water

Caution.

Risk of material damage due to poor-qual-

ity heating water

▶ Ensure that the heating water is of suffi-

cient quality.

▶ Before filling or topping up the system, check the quality

of the heating water.

Checking the quality of the heating water

▶ Remove a little water from the heating circuit.

▶ Check the appearance of the heating water.

▶ If you ascertain that it contains sedimentary materials,

you must desludge the system.

▶ Use a magnetic rod to check whether it contains mag-

netite (iron oxide).

▶ If you ascertain that it contains magnetite, clean the sys-

tem and apply suitable corrosion-protection measures, or

fit a magnet filter.

▶ Check the pH value of the removed water at 25 °C.

▶ If the value is below 8.2 or above 10.0, clean the system

and treat the heating water.

▶ Ensure that oxygen cannot get into the heating water.

Checking the filling and supplementary water

▶ Before filling the system, measure the hardness of the

filling and supplementary water.

Treating the filling and supplementary water

▶ Observe all applicable national regulations and technical

standards when treating the filling and supplementary

water.

Provided the national regulations and technical standards

do not stipulate more stringent requirements, the following

applies:

You must treat the heating water in the following cases:

– If the entire filling and supplementary water quantity dur-

ing the operating life of the system exceeds three times

the nominal volume of the heating installation, or

– If the guideline values listed in the following table are not

met, or

– If the pH value of the heating water is less than 8.2 or

more than 10.0.

Total

heating

output

Water hardness at specific system volume

1)

≤ 20 l/kW

> 20 l/kW

≤ 50 l/kW

> 50 l/kW

kW

ppm

CaCO₃

mol/m³ppm

CaCO₃

mol/m³ppm

CaCO₃

mol/

m³

< 50 < 300 < 3 200 2 2 0.02

> 50

to ≤ 200

200 2 150 1.5 2 0.02

> 200

to ≤ 600

150 1.5 2 0.02 2 0.02

> 600 2 0.02 2 0.02 2 0.02

1) Nominal capacity in litres/heating output; in the case of multiboiler systems, the smallest single heating output is to be used.

Caution.

Risk of material damage if the heating

water is treated with unsuitable additives.

Unsuitable additives may cause changes in

the components, noises in heating mode and

possibly subsequent damage.

▶ Do not use any unsuitable frost and cor-

rosion protection agents, biocides or sealants.

No incompatibility with our products has been detected to

date with proper use of the following additives.

▶ When using additives, follow the manufacturer's instruc-

tions without exception.

We accept no liability for the compatibility of any additive or

its effectiveness in the rest of the heating system.

Additives for cleaning measures (subsequent

flushing required)

– Fernox F3

– Sentinel X 300

– Sentinel X 400

Additives intended to remain permanently in the

system

– Fernox F1

– Fernox F2

– Sentinel X 100

– Sentinel X 200

Additives for frost protection intended to remain

permanently in the system

– Fernox Antifreeze Alphi 11

– Sentinel X 500

▶ If you have used the above-mentioned additives, inform

the operator about the measures that are required.

Page 19

Start-up 7

0020134823_04 ecoTEC plus Installation and maintenance instructions 19

▶ Inform the operator about the measures required for frost

protection.

7.4 Switching on the product

▶ Press the on/off button on the product.

◁ The basic display appears on the display.

7.5 Running the installation assistants

The installation assistant is displayed whenever the product

is switched on until it has been successfully completed.

It provides direct access to the most important check

programmes and configuration settings for starting up the

product.

Confirm the launch of the installation assistant. All heating

and hot water requests are blocked whilst the installation

assistant is active.

Confirm that you want to navigate to the next point by pressing Next.

If you do not confirm the launch of the installation assistant,

it is closed 10 seconds after you switch on the unit and the

basic display then appears.

7.5.1 Language

▶ Set the required language.

▶ Press (OK) twice to confirm the set language and to

avoid unintentionally changing it.

If you have unintentionally set a language that you do not

understand, proceed as follows to change it:

▶

Simultaneously press and hold and .

▶ Also press the fault clearance key for a short time.

▶

Press and hold and until the display shows the

language setting option.

▶ Select the required language.

▶ Confirm this change by pressing (OK) twice.

7.5.2 Filling mode

Filling mode (check programme P.06) is activated automatically in the installation assistant for as long as the filling mode

appears on the display.

7.5.3 Purging

1. Unlike in the check programmes menu, to purge the

system, start up the check programme P.00 by pressing

or .

2. If you need to change the circuit that is being purged,

press .

7.5.4 Target feed temperature, hot water

temperature, Comfort mode

1. To set the target feed temperature, hot water temperature and Comfort mode, use the and buttons.

2. Confirm the setting by pressing (OK).

7.5.5 Heating partial load

The heating partial load of the product is set to Auto at

the factory. This means that the product independently

determines the optimum heating output depending on the

current heat demand of the system. The setting can also be

changed at a later point using D.000.

7.5.6 Auxiliary relay and multi-functional module

Additional components that are connected to the product can

be adjusted here. This setting can be changed using D.027

and D.028.

7.5.7 Telephone number for the competent

person

You can store your telephone number in the unit menu. The

operator can view the telephone number. The telephone

number can be up to 16 digits long and must not contain any

spaces.

7.5.8 Ending the installation assistant

Once the installation assistant has been completed and confirmed, it will not start up automatically next time the unit is

switched on.

7.6 Restarting the installation assistants

You can restart the installation assistant at any time by calling it up in the menu.

Menu → Installer level → Start inst. assistant

7.7 Calling up appliance config. and

diagnostics menu

To recheck and reset the most important system parameters,

call up the Appliance config..

Menu → Installer level Appliance config.

The settings options for more complex systems can be found

in the Diagnostics menu.

Menu → Installer level Diagnostics menu

7.8 Using check programmes

Menu → Installer level → Test programs → Check programs

By activating various check programmes, you can trigger

special functions on the product.

Display Meaning

P.00 Purging check programme:

The boiler circulation pump is cyclically actuated.

The heating circuit is purged via the automatic air

vent.

1 x : Start heating circuit purging

3 x ( ): Restart heating circuit purging

1 x (Cancel): End purge programme

Note

The purge programme runs for 7.5 min per circuit

and then terminates.

Purging the heating circuit:

Actuating the external pump for 15 cycles: 15 s on,

10 s off. Display: Active heating circuit.

P.01 Maximum load check programme:

After successful ignition, the product is operated at

maximum heat input.

Page 20

7 Start-up

20 Installation and maintenance instructions ecoTEC plus 0020134823_04

Display Meaning

P.02 Minimum load check programme:

After successful ignition, the product is operated at

minimum heat input.

P.06 Filling mode check programme:

The burner and pump are switched off (to fill or drain

the product).

P.00 Purging

Cancel

Heating circuit

1,2 bar

Note

If the product is in error condition, you cannot start

any check programmes. You can detect an error

condition by the fault symbol shown in the left

bottom corner of the display. You must first reset.

To terminate the check programmes, you can press (Can-

cel) at any time.

7.9 Reading off the filling pressure

The product's supply pipe is equipped with an analogue

pressure gauge, a symbolic bar graph display and a digital

pressure gauge.

▶

To read off the digital filling pressure value, press the

button twice.

If the heating installation is full, in order to ensure that it operates smoothly, the indicator on the pressure gauge must

point to the upper half of the grey area or to the middle of the

bar graph display on the display (marked by the dashed limit

values) when the heating installation is cold. This corresponds to a filling pressure of between 0.1 MPa and 0.2 MPa

(1.0 bar and 2.0 bar).

If the heating installation extends over several storeys,

higher filling pressures may be required to avoid air entering

the heating installation.

7.10 Preventing low water pressure

To prevent damage to the heating installation that is caused

by low filling pressure, the product is fitted with a water

pressure sensor. If the filling pressure falls below 0.1 MPa

(1.0 bar), the product indicates low pressure by displaying a

flashing pressure value. If the filling pressure falls below 0.05

MPa (0.5 bar), the product switches off. The display shows

F.22.

▶ Top up the heating water to start the product up again.

The pressure value flashes in the display until a pressure of

0.11 MPa (1.1 bar) or higher has been reached.

▶ If you notice frequent drops in pressure, determine and

eliminate the cause.

7.11 Filling and purging the heating installation

1. Flush the heating installation thoroughly before filling it.

2. Select the check programme P.06.

◁ The pumps do not run and the product does not

enter heating mode.

3. Observe the information on the topic of treating

(→ Page 18) heating water.

4. Connect the filling and drainage tap in the heating installation to a heating water supply, if possible with the

cold water valve, in accordance with the relevant standards.

5. Open the heating water supply.

6. Open all thermostatic radiator valves.

7. If necessary, check that both service valves on the

product are open.

8. Slowly open the filling and drainage tap so that the water flows into the heating system.

Note

The product is equipped with an automatic

air vent. Other measures need to be taken

to allow the heating system to be purged

during filling and during commissioning either

manually or using an automatic air vent.

9. Open any available purging valves in the heating system.

10. Purge the lowest radiator until water flows out of the

purging valve without bubbles.

11. Purge all other radiators until the entire heating system

has been filled with water.

12. Close all purging valves.

13. Monitor the rising filling pressure in the heating installa-

tion.

14. Fill with water until the required filling pressure is

reached.

15. Close the filling and drainage tap and the cold water

valve.

16. To purge the heating installation, select the check pro-

gramme P.00.

◁ The product does not start up, the external pump

operates intermittently and purges either the heating

circuit or the hot water circuit. The display shows

the filling pressure of the heating installation.

17. To be able to carry out the purging process properly,

the heating installation filling pressure must not fall below the minimum filling pressure.

– Minimum heating installation filling pressure:

0.1 MPa (1.0 bar)

Note

The check programme P.00 runs for

7.5 minutes per circuit.

At the end of the filling procedure, the

filling pressure of the heating installation

should be at least 0.02 MPa (0.2 bar) above

the counter-pressure of the expansion

vessel ("Exp") (P

Installation

≥ P

Exp

+ 0.02 MPa

(0.2 bar)).

Page 21

Start-up 7

0020134823_04 ecoTEC plus Installation and maintenance instructions 21

18. If there is still too much air in the heating installation at

the end of the check programme P.00, restart the check

programme.

19. Check all connections and the entire system for leaktightness.

7.12 Flushing the heating installation for the first

time ("cold")

Note

The complete heating system must be flushed

at least twice: Once with cold water and once

with hot water in accordance with the following

instructions.

1. Check whether all thermostatic radiator valves and both

service valves on the product are open.

2. Connect a hose to the drain valve that is located at the

lowest position in the heating system.

3. Open the radiator valves and the drain valves so that

the water can drain quickly. Start at the next point in the

system and open the purging valves on the radiators so

that the contaminated water can completely drain.

4. Close the drain cocks.

5. Refill the heating system with water.

6. Check that the expansion relief valve of the heating

system is functioning correctly by turning the handle

on the valve.

7. Check the pressure in the heating system and top up

with water if necessary.

8. Close the filling valve and the cold water valve.

7.13 Filling the condensate trap

Danger!

Risk of poisoning due to escaping flue

gas.

An empty or insufficiently filled condensate

trap may allow flue gas to escape into the

room air.

▶ Fill the condensate trap with water before

starting up the product.

2

1

1. Remove the lower section of the condensate trap(2) by

unscrewing it from the condensate trap (1).

2. Fill the lower section of the condensate trap with water

up to about 10 mm below the upper edge.

3. Secure the lower section of the condensate trap correctly to the condensate trap again.

7.14 Checking and adjusting the gas ratio

setting

7.14.1 Checking the factory setting

Caution.

An incorrect gas group setting may cause

operating faults or a reduction in the

working life of the product.

If the product design does not match the local

gas group, malfunctions will occur or you will

have to replace product components prematurely.

▶ Before you start up the product, compare

the gas group information on the identification plate with the gas group available at

the installation site.

The product's combustion has been factory tested and is

preset for operation with the gas group indicated on the identification plate.

Conditions: The product design is not compatible with the local gas

group

If you want to operate the product with liquid gas, do not start

up the product.

A gas conversion must only be carried out by Vaillant Customer Service or the manufacturer of the product.

▶ Notify Vaillant Customer Service or the manufacturer of

the product that you want a gas conversion carried out.

Page 22

7 Start-up

22 Installation and maintenance instructions ecoTEC plus 0020134823_04

Conditions: The product design is compatible with the local gas group

▶ Proceed as described below.

7.14.2 Checking the leak-tightness of the flue gas

system and for flue gas recirculation

1. Check that the flue gas system is intact, in accordance

with British Gas TB 200.

2. If the flue gas system is longer than 2 m, we urgently

recommend that you test the system for flue gas recirculation as described below.

1

3. Use the air analysis point (1) to check for flue gas recir-

culation.

4. Use the flue gas measuring instrument.

5. If you discover CO or CO2 in the fresh air, search for a

leak in the flue gas system or for the flue gas recirculation.

6. Eliminate the damage.

7. Repeat the above-mentioned test to determine if the

fresh air contains CO or CO2.

8. If you cannot eliminate the damage, you must not start

up the boiler.

7.14.3 Checking the gas flow rate

The boiler is fitted with a multifunctional automatic gas valve

which ensures that the precise air/gas ratio is provided under all operating conditions. The gas flow rate has been set

during production and does not require adjustment. With the

front casing fitted check the gas flow rate of the boiler as follows:

▶ Start up the product with the check programme P.01.

▶ In addition, ensure that maximum heat can be dissipated

into the heating system by turning up the room thermostat.

▶ Wait at least 5 minutes until the boiler has reached its

operating temperature.

▶ Ensure that all other gas appliances in the property are

turned off.

▶ Measure the gas flow rate at the gas meter.

▶ Compare the measured values with the corresponding

values in the table.

Nominal value for the

net heat supply in kW

in accordance with

BS EN 483

H gas in m³/h

Nominal +5% −10%

76.2 8.10 8.51 7.29

95.2 10.10 10.61 9.09

114.3 12.10 12.71 10.89

Conditions: Gas flow rate not in the permissible range

▶ Check all of the piping and ensure that the gas flow rates

are correct.

▶ Only put the product into operation once the gas flow

rates have been corrected.

Conditions: Gas flow rate in the permissible range

▶ End the check programme P.01.

▶ Allow the boiler to cool down by allowing pump overrun to

operate for a minimum of two minutes.

▶ Record the boiler maximum gas flow rate onto the

Benchmark gas boiler commissioning checklist.

7.14.4 Checking the gas flow pressure

1

1

806/5-5

1206/5-5

1006/5-5

1. Ensure that the gas inlet working pressure can be

obtained with all other gas appliances in the property

working.

2. Close the gas isolator cock.

3. Use a screwdriver to undo the sealing screw of the

measuring nipple (1) at the gas valve.

4. Connect a pressure gauge to the measuring nipple (1).

5. Open the gas isolator cock.

6. Start up the product with the check programme P.01.

7. In addition, ensure that maximum heat can be dissipated into the heating system by turning up the room

thermostat.

8. With the boiler operating at full load check that the gas

inlet working pressure at the reference test point (1)

complies with the requirements.

Page 23

Start-up 7

0020134823_04 ecoTEC plus Installation and maintenance instructions 23

– Permissible gas flow pressure for operation with

G20 natural gas: 1.6 … 2.3 kPa (16.0 … 23.0 mbar)

9. Should the pressure recorded at the reference test point

in the boiler be lower than indicated check if there is

any blockage in the pipework or if the pipework is undersized.

Conditions: Gas flow pressure not in the permissible range

Caution.

Risk of material damage and operating

faults caused by incorrect gas flow pressure.

If the gas flow pressure lies outside the permissible range, this can cause operating

faults in and damage to the product.

▶ Do not make any adjustments to the

product.

▶ Check the gas installation.

▶ Do not start up the product.

▶ If you cannot correct the failure, notify the gas supply

company and proceed as follows:

▶ End the check programme P.01.

▶ Allow the boiler to cool down by allowing pump overrun

to operate for a minimum of two minutes.

▶ Close the gas isolator cock.

▶ Remove the pressure gauge and retighten the sealing

screw (1) for the measuring nipple.

▶ Open the gas isolator cock.

▶ Check the measuring nipple for gas tightness.

▶ Close the gas isolator cock.

▶ Install the front casing. (→ Page 10)

▶ Disconnect the product from the power mains.

▶ You must not start up the boiler.

Conditions: Gas flow pressure in the permissible range

▶ End the check programme P.01.

▶ Allow the boiler to cool down allowing pump overrun to

operate for a minimum of two minutes.

▶ Close the gas isolator cock.

▶ Remove the pressure gauge and retighten the sealing

screw (1) for the measuring nipple.

▶ Open the gas isolator cock.

▶ Check the measuring nipple for gas tightness.

▶ Install the front casing. (→ Page 10)

▶ Reset boiler controls for normal operation.

▶ Record the appliance gas inlet working pressure (kPa

resp. mbar) in the Benchmark gas boiler commissioning

checklist.

7.14.5 Checking the CO₂ content and, if

necessary, adjusting it (air index setting)

1. Start up the product with the check programme P.01.

2. Wait at least five minutes until the product reaches its

operating temperature.

1

3. Measure the CO₂ and CO/CO₂ content at the flue gas

analysis point (1).

4. Compare the measured values with the corresponding

values in the table.

Settings Unit G 20

natural

gas

CO₂ after 5 minutes

in full load mode

with front casing

closed

Vol.–% 9.0 ±1.0

CO₂ after 5 minutes

in full load mode

with front casing

removed

Vol.–% 8.8 ±1.0

Set for Wobbe index

W

s

kWh/m³ 15.0

O₂ after 5 minutes

in full load mode

with front casing

closed

Vol.–% 4.89 ±1.80

CO content ppm ≤ 250

CO/CO2content

0.0028

Page 24

7 Start-up

24 Installation and maintenance instructions ecoTEC plus 0020134823_04

Conditions: The CO₂ content must be adjusted

1

1

806/5-5

1006/5-5

1206/5-5

Caution.

Risk of poisoning due to an incorrectly

installed gas valve.

If the gas flow pressure is outside the permissible ranges in the table, this may lead to

personal injury and material damage.

▶ Check the integrity of all gas lines.

▶ Check the flue gas guiding for leaks.

▶ Check the gas flow pressure.

▶ Check the connection value.

▶ Break through the sealing sticker.

▶ Set the CO₂ content (value with front casing removed)

by turning the screw (1).

Note

Turn to the left: Higher CO₂ content

Turn to the right: Lower CO₂ content

▶ Only carry out the adjustment in increments of 1/8 turn

and wait approximately 1 minute after each adjustment

until the value stabilises.

Note

On the VU GB 1006/5-5 and the VU GB

1206/5-5, after changing the direction of

rotation, the CO₂ content only changes

after approx. 1 turn of the adjusting screw

(overcoming the adjustment hysteresis).

The adjusting screw must protrude only

slightly from the casing.

▶ Select (Cancel) once the adjustments have been made.

▶ If an adjustment is not possible in the specified adjust-

ment range, you must not start up the product.

▶ If this is the case, inform Vaillant Customer Service.

▶ Install the front casing. (→ Page 10)

7.15 Checking leak-tightness

▶ Check the gas line, the heating circuit and the hot water

circuit for leak-tightness.

▶ Check the flue gas pipe for correct installation.

7.15.1 Checking the heating mode

1. Make sure that there is a heat requirement.

2. Call up the Live Monitor.

– Menu → Live Monitor

◁ If the product is working correctly, the display shows

S.04.

7.15.2 Checking the hot water generation

Conditions: Cylinder connected

▶ Make sure that the cylinder thermostat is requesting

heat.

1. Call up the Live Monitor.

– Menu → Live Monitor

◁ If the cylinder is charged correctly, the display

shows S.24.

2. If you have connected a controller which can be used to

set the hot water temperature, set the hot water temperature on the boiler to the maximum possible temperature.

3. Adjust the target temperature for the connected domestic hot water cylinder to the controller.

◁ The boiler adopts the set target temperature which

is set on the controller (automatic calibration in

newer controllers).

7.16 Thoroughly flushing the heating installation

("hot")

1. Operate the appliance until the boiler and the heating

system are up to temperature.

2. Check the heating system for leaks.

3. Connect a hose to the drain valve located at the lowest

position of the heating system.

4. Shut off the boiler, open the drain valve and all purge

valves on the radiators and allow the water to flow out

of the heating system and the boiler quickly and fully.

5. Close the drain valve.

Page 25

Adapting the unit to the heating installation 8

0020134823_04 ecoTEC plus Installation and maintenance instructions 25

6. Fill the heating system again with water as described in "Filling and purging the heating installation"

(→ Page 20).

7. Re-fill the system until the system design pressure of

0,1 MPa (1,0 bar) is attained.

Note

The actual reading on the digital pressure

gauge should ideally be 0,05 MPa (0,5 bar)

plus an additional pressure corresponding

to the highest point of the system above the

base of the boiler – 10 m head equals an additional 1 bar reading on the pressure gauge.

The minimum pressure should not be less

than 0,1 MPa (1 bar) in any installation. If

the system is to be treated with an inhibitor it

should be applied at this stage in accordance

with the manufacturer’s instructions. Further

information can be obtained from Sentinel,

Betz Dearborn Ltd., Tel: 0151 420 9595, or

Fernox, Alpha– Fry technologies. Tel: 0870

8700362.

8. Install the side section. (→ Page 11)

9. Install the front casing. (→ Page 10)

8 Adapting the unit to the heating

installation

To reset the most important system parameters, use the

Appliance config. menu point.

Menu → Installer level Appliance config.

Or manually relaunch the installation assistant.

Menu → Installer level → Start inst. assistant

8.1 Calling up diagnostics codes

The settings options for more complex systems can be found

in the Diagnostics menu.

Menu → Installer level Diagnostics menu

Overview of diagnostics codes (→ Page 38)

Using the parameters that are marked as adjustable in the