Page 1

For the competent person

Installation and maintenance instructions

aroCOLLECT

VWL 11/4 SA

GB

Installation and maintenance instructions

Publisher/manufacturer

Vaillant GmbH

Berghauser Str. 40 D-42859 Remscheid

Tel. +49 21 91 18‑0 Fax +49 21 91 18‑2810

info@vaillant.de www.vaillant.de

Page 2

Contents

2 Installation and maintenance instructions aroCOLLECT 0020217119_01

Contents

1 Safety .................................................................... 3

1.1 Action-related warnings ......................................... 3

1.2 Intended use.......................................................... 3

1.3 General safety information .................................... 3

1.4 Regulations (directives, laws, standards) .............. 4

2 Notes on the documentation .............................. 6

2.1 Observing other applicable documents ................. 6

2.2 Storing documents................................................. 6

2.3 Applicability of the instructions .............................. 6

3 System overview.................................................. 6

3.1 Heat pump system design ..................................... 6

4 Product description............................................. 6

4.1 Information on the identification plate.................... 6

4.2 CE label ................................................................. 6

4.3 Product design....................................................... 7

5 Installation............................................................ 7

5.1 Checking the scope of delivery.............................. 7

5.2 Removing the transport locks ................................ 7

5.3 Selecting the installation site ................................. 8

5.4 Dimensions............................................................ 9

5.5 Minimum clearances.............................................. 9

5.6 Creating the foundation ....................................... 11

5.7 Hydraulics installation.......................................... 12

5.8 Filling and purging the brine circuit ...................... 14

5.9 Electrical installation ............................................ 17

6 Start-up ............................................................... 20

6.1 Start-up ................................................................ 20

6.2 Handing the product over to the operator............ 20

7 Inspection and maintenance ............................ 20

7.1 Inspection and maintenance interval ................... 20

7.2 Carrying out inspection and maintenance

work ..................................................................... 21

7.3 Procuring spare parts .......................................... 21

7.4 Cleaning the product............................................ 21

7.5 Cleaning the condensate discharge .................... 21

8 Decommissioning.............................................. 21

8.1 Temporary decommissioning .............................. 21

8.2 Permanently decommissioning............................ 21

9 Customer service............................................... 21

10 Recycling and disposal..................................... 21

Appendix ............................................................................ 22

A Product diagram ................................................ 22

A.1 Product diagram .................................................. 22

B Connection diagram .......................................... 23

C Technical data.................................................... 24

C.1 General................................................................ 24

C.2 Air heat source..................................................... 26

Index ................................................................................... 29

Page 3

Safety 1

0020217119_01 aroCOLLECT Installation and maintenance instructions 3

1 Safety

1.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in

accordance with the severity of the possible

danger using the following warning signs and

signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of

severe personal injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental

damage

1.2 Intended use

There is a risk of injury or death to the user or

others, or of damage to the product and other

property in the event of improper use or use

for which it is not intended.

The product is intended exclusively for domestic use as an air/brine collector to be

connected to the VWF xx1/4, VWF xx2/4,

VWF xx7/4, VWF xx7/4 S1 or VWF xx8/4

heat pumps. Operating the heat pump in conjunction with the air/brine collector and outside the application limits results in the heat

pump being switched off by the internal control and safety devices.

Intended use includes the following:

– observance of accompanying operating,

installation and servicing instructions for

the product and any other system components

– installing and fitting the product in accord-

ance with the product and system approval

– compliance with all inspection and main-

tenance conditions listed in the instructions.

Intended use also covers installation in accordance with the IP class.

Any other use that is not specified in these

instructions, or use beyond that specified in

this document shall be considered improper

use. Any direct commercial or industrial use

is also deemed to be improper.

Caution.

Improper use of any kind is prohibited.

1.3 General safety information

1.3.1 Risk caused by inadequate

qualifications

The following work must only be carried out

by competent persons who are sufficiently

qualified to do so:

– Installation

– Disassembly

– Installation

– Start-up

– Maintenance

– Repair

– Decommissioning

▶ Observe all instructions that are included

with the product.

▶ Proceed in accordance with the current

state of technology.

▶ Observe all applicable directives, stand-

ards, laws and other regulations.

1.3.2 Danger caused by improper

operation

Improper operation may present a danger to

you and others, and cause material damage.

▶ Carefully read the enclosed instructions

and all other applicable documents, particularly the "Safety" section and the warnings.

▶ Only carry out the activities for which in-

structions are provided in these operating

instructions.

1.3.3 Risk of death due to lack of safety

devices

The schematic drawings included in this document do not show all safety devices required for correct installation.

▶ Install the necessary safety devices in the

system.

▶ Observe the applicable national and inter-

national laws, standards and guidelines.

Page 4

1 Safety

4 Installation and maintenance instructions aroCOLLECT 0020217119_01

1.3.4 Risk of death from electric shock

There is a risk of death from electric shock if

you touch live components.

Before commencing work on the product:

▶ Disconnect the product from the power

supply by switching off all power supplies

(electrical partition with a contact opening

of at least 3 mm, e.g. fuse or line protection switch).

▶ Secure against being switched back on

again.

▶ Wait for at least 3 minutes until the capa-

citors have discharged.

▶ Check that there is no voltage.

1.3.5 Risk of injury due to chemical burns

caused by brine fluid

The brine fluid ethylene glycol is harmful to

health.

▶ Avoid contact with the skin and eyes.

▶ Always wear gloves and protective

goggles.

▶ Do not inhale or swallow.

▶ Observe the safety data sheet that accom-

panies the brine fluid.

1.3.6 Risk of burns due to hot and cold

components

There is a risk of burns and frostbite from any

uninsulated pipelines and from the auxiliary

electric heating.

▶ Only carry out work on the components

once they have reached ambient temperature.

1.3.7 Risk of death due to changes to the

product or the product environment

▶ Never remove, bridge or block the safety

devices.

▶ Do not alter the safety devices in any way.

▶ Do not damage or remove any seals on

components. Only authorised competent

persons or customer services may modify

sealed components.

▶ Do not make any changes to:

– The product itself

– The product environment

– The brine fluid, air and current supply

lines

– The drain line and expansion relief valve

for the heat source circuit

– to constructional conditions that may

affect the operational reliability of the

product

1.3.8 Material damage due to unsuitable

installation surface

The installation surface must be even and

have sufficient load-bearing capacity to support the operating weight of the product. An

uneven installation surface may cause leaks

in the product.

If the installation surface does not have sufficient load-bearing capacity, the product may

topple.

There is a risk of death if the connections are

subject to leaks.

▶ Make sure that the product is positioned

flush against the installation surface.

▶ Ensure that the installation surface has

sufficient load-bearing capacity to bear the

operating weight of the product.

1.3.9 Risk of injury during transport due

to a high product weight

▶ Make sure that the product is transported

by at least two people.

1.3.10 Risk of material damage caused by

using an unsuitable tool

▶ Use the correct tool to tighten or loosen

screw connections.

1.4 Regulations (directives, laws,

standards)

When setting up, installing and operating the

heat pump and the domestic hot water cylinder, you must observe the following points in

particular:

– Local specifications, regulations, rules and

directives regarding electrical connections

– Local specifications, regulations, rules and

directives for the power company

– Local specifications, regulations, rules and

directives for the water supply company

– Local specifications, regulations, rules and

directives regarding the use of geothermal

energy

Page 5

Safety 1

0020217119_01 aroCOLLECT Installation and maintenance instructions 5

– Local specifications, regulations, rules and

directives regarding the integration of heat

source systems and heating installations

– Local specifications, regulations, rules and

directives regarding saving energy

– Local specifications, regulations, rules and

directives regarding hygiene

Page 6

2 Notes on the documentation

6 Installation and maintenance instructions aroCOLLECT 0020217119_01

2 Notes on the documentation

2.1 Observing other applicable documents

▶ You must observe all the operating and installation in-

structions included with the system components.

2.2 Storing documents

▶ Pass these instructions and all other applicable docu-

ments on to the system operator.

2.3 Applicability of the instructions

These instructions apply only to:

Product

VWL 11/4 SA

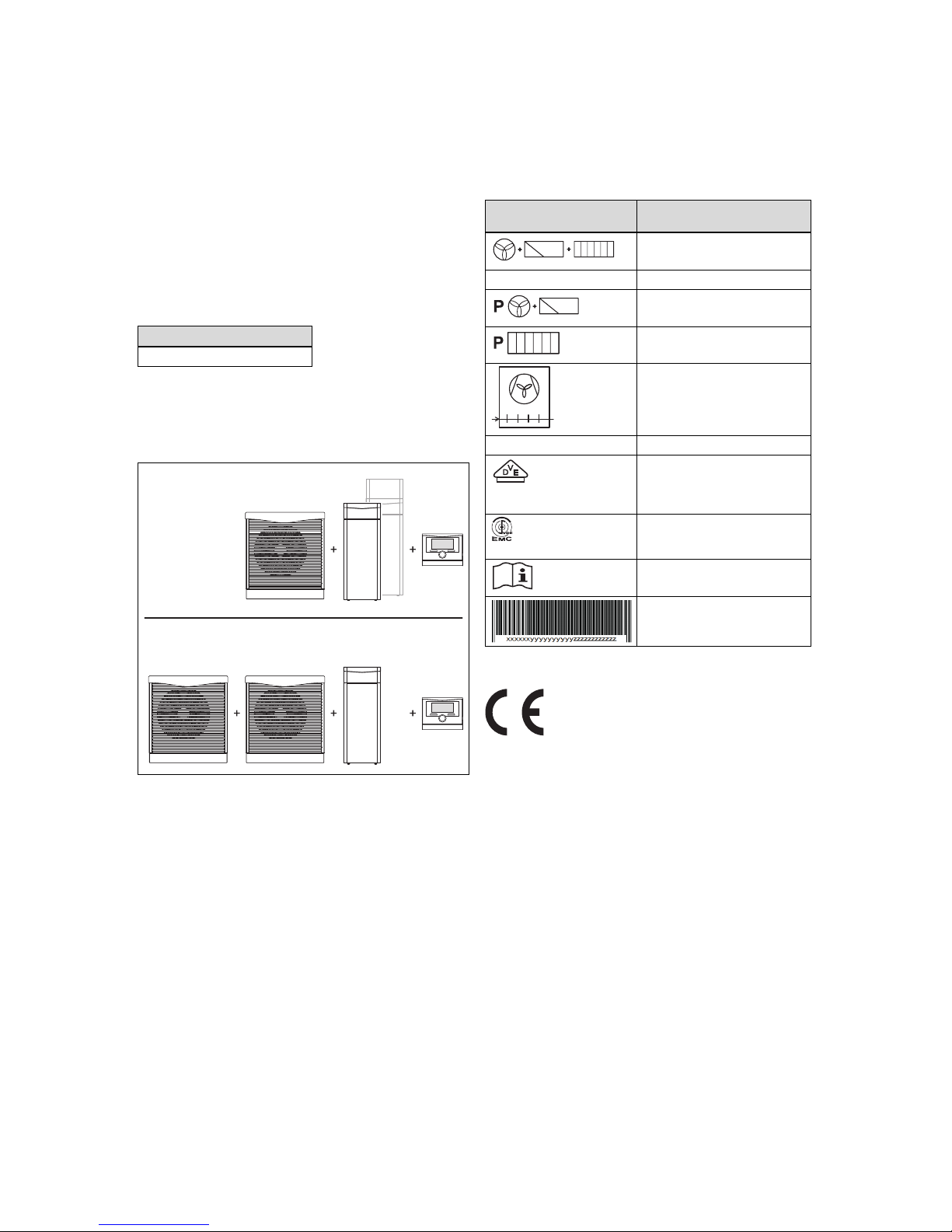

3 System overview

3.1 Heat pump system design

5 - 11 kW

15 - 19 kW

The heat pump system consists of the following components,

as a minimum:

– Air/brine collector(s)

– Heat pump

– System controller

The heat pump system generates heat in heating installations and in hot water generation by extracting the thermal

energy from a heat source circuit and releasing this into

the heating circuit via the internal refrigeration circuit. At the

same time, there is an opportunity for active cooling to take

place via circulation reversal. For this, the heat pump is connected to the air/brine collector(s). The air/brine collector is

used to exchange heat between the brine circuit and the outside air.

4 Product description

4.1 Information on the identification plate

The identification plate is attached at the factory to the underside of the electronics box.

Information on the identification plate

Meaning

Rated voltage and frequency of

the fan, controller and de-icer

P max Maximum rated power

Rated power of the fan and

controller

De-icer rated power

→ A2/W35

Rated power and pressure of

the air/brine collector at an air

inlet temperature of 2 °C and

a heating flow temperature of

35 °C

IP Level of protection

Verband deutscher Elektrotechniker (German Association for

Electrical, Electronic & Information Technologies)

Electromagnetic Compatibility

in accordance with the Verband

deutscher Elektrotechniker

Read the instructions.

Bar code with serial number,

7th to 16th digit = product article

number

4.2 CE label

The CE label shows that the products comply with the basic

requirements of the applicable directives as stated on the

identification plate.

The declaration of conformity can be viewed at the manufacturer's site.

Page 7

Installation 5

0020217119_01 aroCOLLECT Installation and maintenance instructions 7

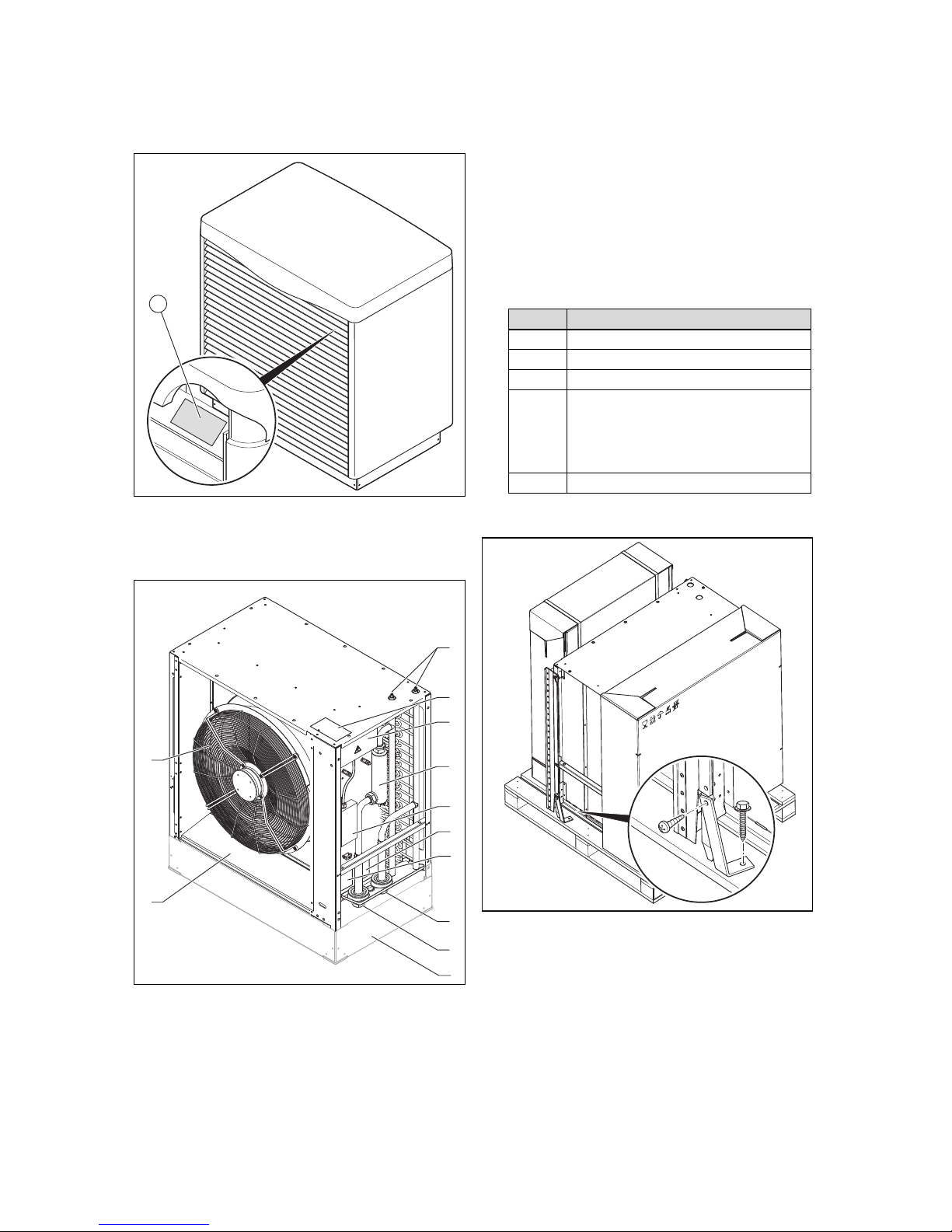

4.3 Product design

4.3.1 Front view, closed

1

1 Type designation with

serial number

4.3.2 Front view, open

12

11

3

6

2

1

8

9

4

5

10

7

1 Purging valves

2 Simple identification

plate

3 Electronics box

4 De-icer

5 Connection box

6 Identification plate with

service sticker

7 Warning sticker

8 Connecting the brine

line to the heat pump

(hot brine)

9 Connecting the brine

line from the heat pump

(cold brine)

10 Base (accessory)

11 Condensate tray

12 Ventilator

5 Installation

5.1 Checking the scope of delivery

1. Carefully remove the packaging and padding without

damaging the parts of the product.

2. Check that the scope of delivery is complete.

Quantity Description

1 Box: Cover and side sections of the casing

2 Louvred grill (pre-installed)

1 Air/brine collector

1 Installation material:

– 2 x O-ring seals

– 10 x M8x20 screws (to secure the cover,

the side casing and the air/brine collector

to the base (accessories))

1 Enclosed documentation

5.2 Removing the transport locks

2 x

▶ Remove the transport locks as shown in the illustration.

Page 8

5 Installation

8 Installation and maintenance instructions aroCOLLECT 0020217119_01

5.3 Selecting the installation site

Caution.

Risk of material damage caused by corro-

sion.

Caustic vapours may cause corrosion damage on the product. The extracted air must be

free from ammonia, methane gas and other

corrosive elements.

▶ Do not install the product close to stables

and manure pits.

▶ Set up the product outdoors away from rooms. Depend-

ing on the weather, condensate may form and appear

under the collector.

– Maximum installation height: 2000 m above normal

sea level

▶ Ensure that there is a sufficiently stable, frost-proof, hori-

zontal foundation that meets local requirements and complies with the rules of structural engineering.

▶ For efficiency reasons, the clearance between the heat

pump and the air/brine collector should be kept as small

as possible.

– Total length of the connection line, cold brine and hot

brine: 2 x 30 m

▶ If the clearance between the product and the building

falls below 3 m, position the product in such a way that

the outlet side does not point towards the building.

▶ Assess the installation site to ensure that no persons can

be at risk at the outlet side. No public roads/pathways

should run through the area of the outlet side.

▶ Install the product with the intake side towards the wall

(recommended installation).

▶ Comply with the local and statutory minimum clearances

with regards to:

– Vegetation

– Walls

– Awnings

– Open fire or embers

– Children's toys

▶ When selecting the installation site, take into consider-

ation the fact that, during full load mode in winter, noise

(depending on the current output requirement, up to approx. 66 dB(A) sound power level) is emitted from the

product, and this noise may be amplified by reverberative

surfaces.

▶ Observe the national regulations regarding noise.

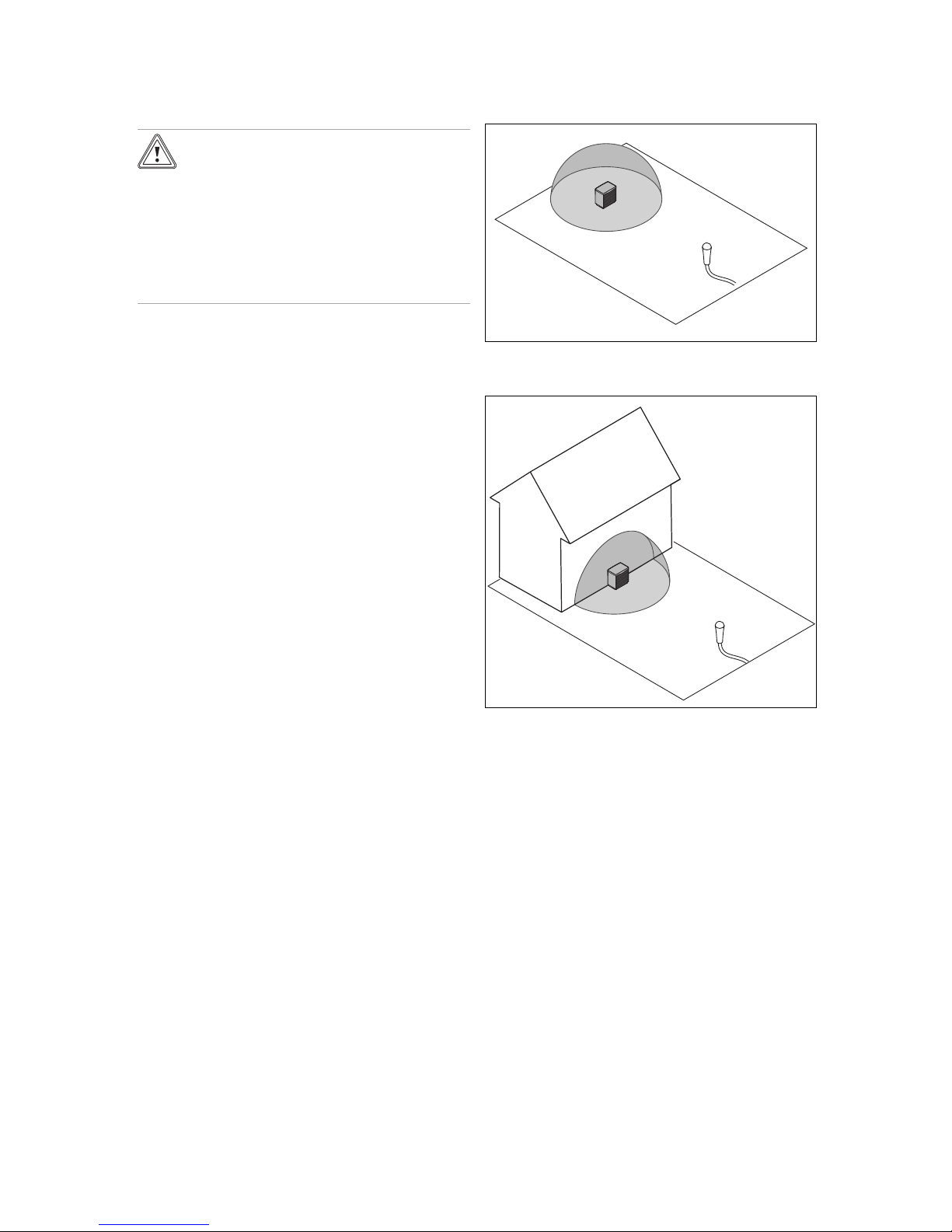

Sound propagation form: Hemisphere

Sound propagation with a free-standing air/brine collector.

Sound propagation form: Quarter-sphere

Sound propagation for the adjacent building: On just one

side.

Page 9

Installation 5

0020217119_01 aroCOLLECT Installation and maintenance instructions 9

Sound propagation form: An eighth of a sphere

Sound propagation for the adjacent building: On two sides

and at a right-angle.

LWA= L

PFA

– 10 lg S

LWA= Sound pressure level (dB(A))

L

PFA

= Sound power level (dB(A))

S = Sound propagation form* (clearance from the product in

m)²

Sound propagation form: Hemisphere = 6.28

Sound propagation form: Quarter-sphere = 3.14

Sound propagation form: Eighth of a sphere = 1.57

Example

L

PFA

= 54 dB(A), max. sound power level without noise re-

duction

Sound propagation form = Hemisphere = 6.28

Distance to the product = 10 m

LWA= 54 dB(A) – 10 lg (6.28 * 100)

LWA= 54 dB(A) – 10 lg (628)

LWA= 54 dB(A) – 28

LWA= 26 dB(A)

▶ Choose the installation site so that the legally required

emissions values for noise outside of buildings can be

complied with, without having to use the heat pump system's noise reduction function, if possible.

▶ In certain weather conditions, take into consideration

the possibility of black ice forming directly in front of the

product's outlet side; if condensate escapes, the black

ice may form all around the product.

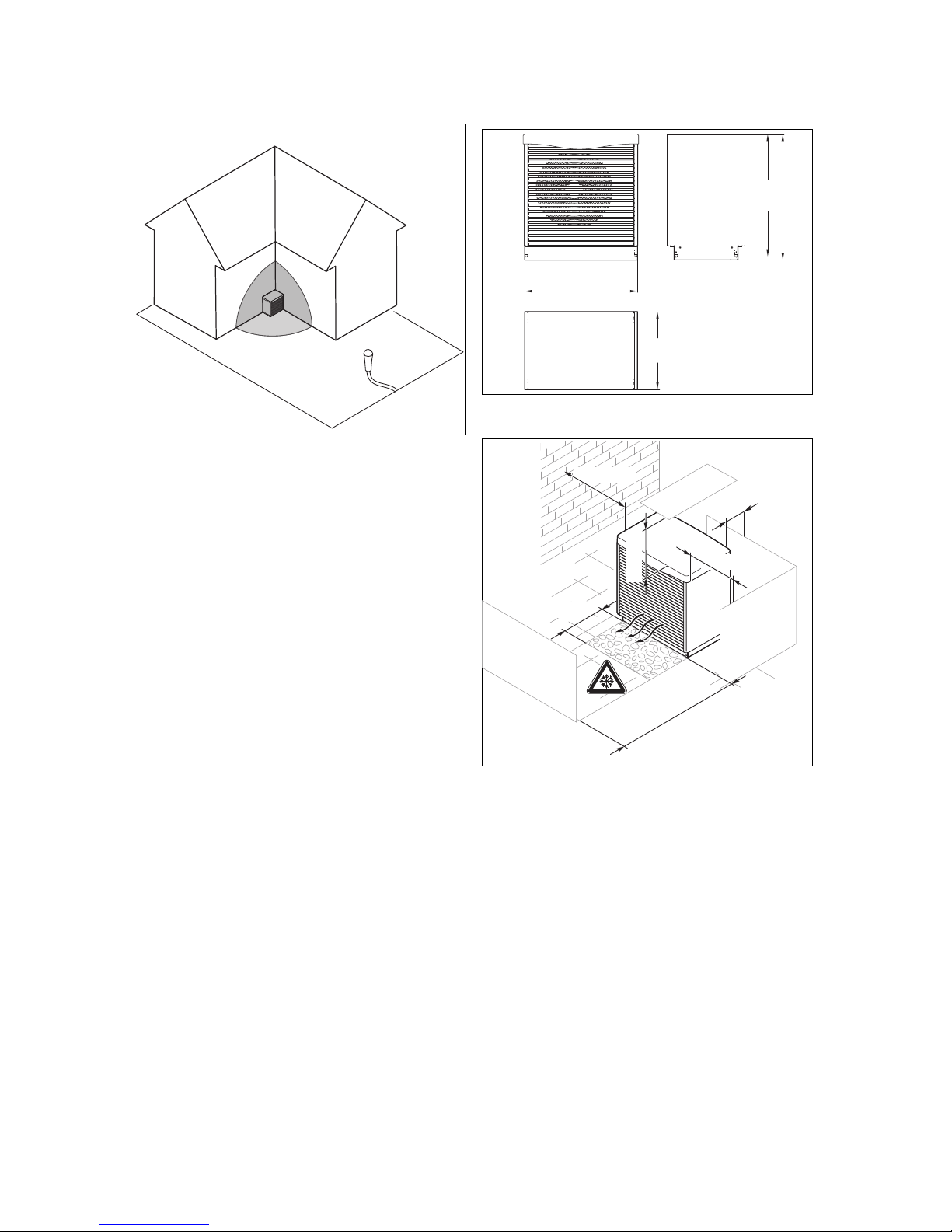

5.4 Dimensions

1192

785

1256

1162

5.5 Minimum clearances

≥ 0,3 m

≥ 0,5 m

≥ 0,5 m

≥ 3 m

ca. 0,5 m

≥ 0,5 m

< +5 °C

Clearances that must be complied with for an air/brine collector

Page 10

5 Installation

10 Installation and maintenance instructions aroCOLLECT 0020217119_01

ca. 0,5 m

≥ 0,3 m

≥ 0,5 m

≥ 0,5 m

≤ 5 m

≥ 3 m

≥ 0,5 m

< +5 °C

< +5 °C

≥ 0,5 m

Clearances that must be complied with for two air/brine collectors

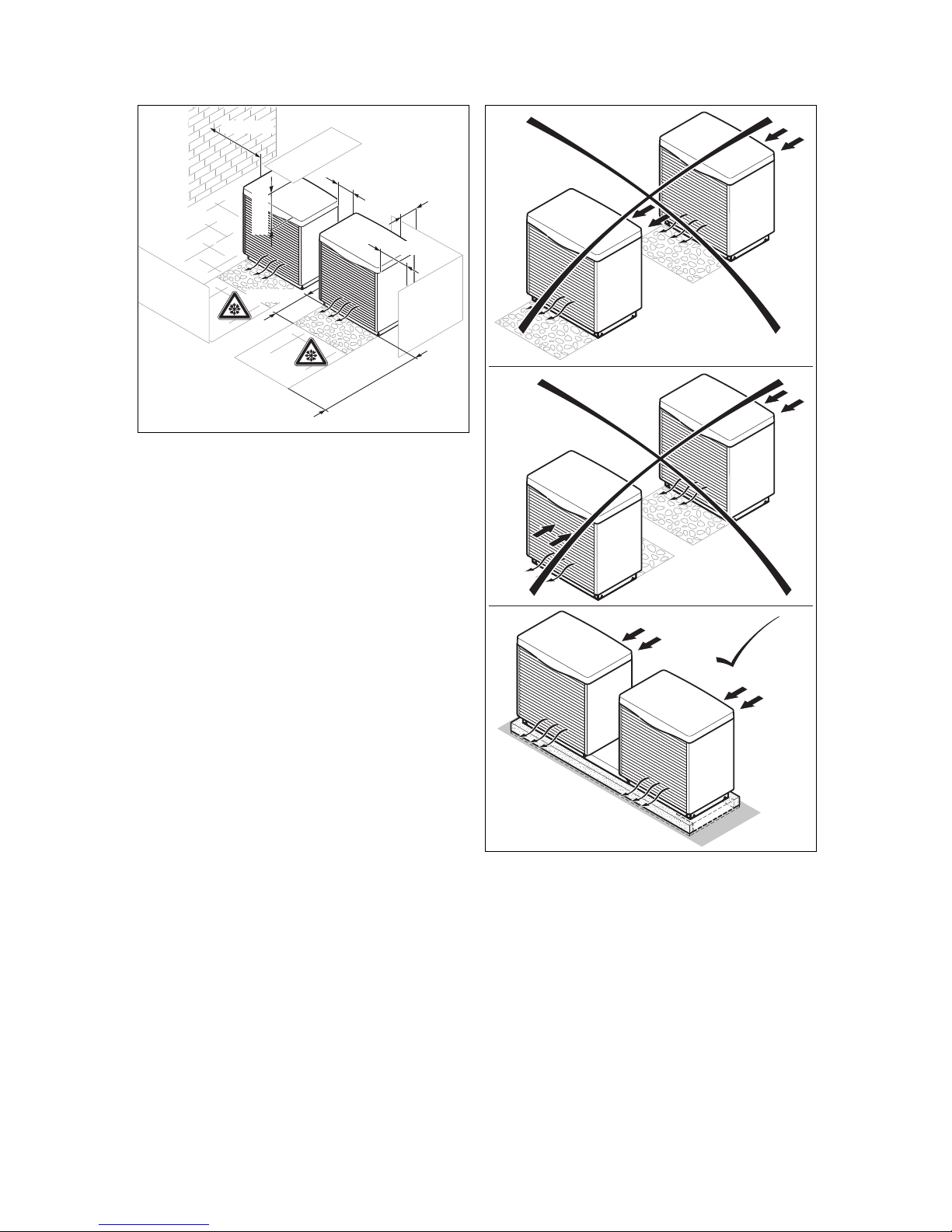

Positioning of the collectors

▶ Use the mounting base, which is available as an access-

ory, for the installation.

▶ To guarantee sufficient air flow and to facilitate mainten-

ance work, observe the minimum clearances that are

specified above.

▶ Ensure that there is sufficient room to install the hydraulic

lines.

▶ If the product is to be installed in areas where heavy

snow falls, ensure that the snow does not accumulate

around the product and that the minimum clearances

specified above are observed. If you cannot ensure this,

install an additional heat generator in the heating circuit.

An elevating base and condensate tray heating are available as accessories.

Page 11

Installation 5

0020217119_01 aroCOLLECT Installation and maintenance instructions 11

▶ If you install two air/brine collectors, you must create a

concrete foundation and use the connection pipe set that

is available as an accessory.

5.6 Creating the foundation

³ 0,8 m

1

3

5

2

4

6

1 Air/brine collector

2 Foundation

3 Compacted gravel

4 Ground

5 Condensate drain pipe

6 Gravel bed in a frost-

free area

1. Prepare the ground for the foundation in accordance

with the illustration.

2. As a condensate drain pipe, route a pipe that drops

vertically and that is ≥ DN 110. Route this pipe as far

as the frost-free ground. To lay the pipe at ground level

and so that it comes out of the mounting base at the

side, use the accessory that is available for this.

A

A

B

B

Ø 12

120 x=cm

34 18

62

52

49

41

Ø 5

14

Ø 7

8

18

110

60

23

15

13

10

26

Ø 7

A Connecting the air/brine

collector to the heat

pump (hot brine)

B Connecting the heat

pump to the air/brine

collector (cold brine)

3. Create a frost-free and stable foundation or set the

product on paving slabs. When doing so, observe the

rules of structural engineering and the instructions that

are enclosed with the recommended VWL S installation

set for PE pipes.

³ 0,8 m

DN 110

4. Establish the connections for a foundation made of paving slabs in accordance with the illustration.

Page 12

5 Installation

12 Installation and maintenance instructions aroCOLLECT 0020217119_01

DN 110

³ 0,8 m

5. Establish the connections for a concrete foundation in

accordance with the illustration.

6. Install the base that is available as an accessory.

5.7 Hydraulics installation

5.7.1 Routing the connection lines

Caution.

Risk of material damage caused by

ground lifting up as a result of frozen

ground.

At operating temperatures close to freezing

level, the ground in the area of the PE pipes

may freeze and therefore damage the structure as a result of the ground lifting up.

▶ Insulate all of the PE lines that are to be

routed under buildings, terraces, pathways, etc. so that they are vapour-diffusion-tight.

▶ If possible, route PE pipes in the ground

with a clearance of 70 cm from each other

and from adjacent supply lines (except for

electrical lines).

The total length (connection lines from the heat pump to the

product and from the product to the heat pump) must be no

greater than 60 m.

▶ Keep the clearance between the product and the heat

pump as short as possible and minimise the use of elbows and angles. This is because each additional pressure loss that is caused by the use of these reduces efficiency.

▶ Route the PE pipes in accordance with the applicable

technical directives.

▶ For a total line length of between ≥ 20 m and 60 m, use

a PE pipe with DN 50 (e.g. PE 80/100, outer diameter

50 mm, wall thickness 4.6 mm). Up to a total line length

of ≤ 20 m, you can also use a PE pipe with DN 40

(e.g. PE 80/100, outer diameter 40 mm, wall thickness

3.7 mm).

▶ When using more than eight PE elbows, use an extra

2 m of pipeline for each elbow.

▶ When using copper pipes, use only copper pipes that

have a cross-section of ≥ 35 mm. If you use a smaller

cross-section (e.g. copper 28 mm), this will result in pressure losses (2 m copper 28 = 8 m copper 35).

Note

If the prescribed line cross-sections are not

complied with, this results in efficiency losses

and reduced annual operating figures.

▶ If required, when routing the PE pipes above-ground,

ensure that they are protected against UV radiation.

Conditions: Installing two air/brine collectors

Page 13

Installation 5

0020217119_01 aroCOLLECT Installation and maintenance instructions 13

≤ 10m DN 40*

> 10m ≤ 30m DN 50*

A

B

A

B

* = one way

▶ Connect the air/brine collector in accordance with the

Tichelmann principle. This means that the air/brine collector with the shorter flow has the longest return.

Caution.

Risk of material damage caused by a leak.

When tightening screwed connections,

ensure that O-rings are inserted correctly

as, otherwise, they may pop out or become

jammed, become damaged, or cause leaks.

▶ Insert the O-rings properly and untwisted

into the cap nuts for the air/brine collector's brine connections.

▶ Screw the cap nuts to the connection adaptors on the

"hot brine" and "cold brine" brine lines in the brine circuit

(cross-reference) on the mounting base.

▶ To purge each individual air/brine collector, install

two shut-off units.

5.7.2 Transporting the product

Caution.

Risk of material damage caused by incor-

rect transport.

▶ Do not transport the product using a hand

truck.

▶ If required, remove the louvred grill to prevent damage.

5.7.3 Installing the product

1. Place the product on the base that is available as an

accessory.

2. Connect the brine lines to the product as shown.

3. Screw the product to the base.

5.7.4 Installing brine lines in the building

71

42a

65

48

64

56

62

61

63

70

72

A

B

A

B

≤ 10m DN 40*

> 10m ≤ 30m DN 50*

42a Expansion relief valve

48 Pressure gauge

56 Heat pumps for brine

filling unit (accessory)

61 Stop valve

62 Stop valve

63 Stop valve

64 Stop valve

65 Brine collecting con-

tainer

70 Stop valve

71 Brine diaphragm expan-

sion tank

72 Stop valve

Page 14

5 Installation

14 Installation and maintenance instructions aroCOLLECT 0020217119_01

A From the heat source

to the heat pump (hot

brine)

B From the heat pump to

the heat source (cold

brine)

* One way

1. Install the brine lines between the product and the heat

pump within the building and using all of the associated

components in accordance with the applicable technical

directives.

Note

Do not install dirt filters in the brine circuit for

a prolonged period of time. The brine fluid is

cleaned during the filling process.

2. Reduce the pre-charge pressure of the brine diaphragm

expansion tank (which is available as an accessory)

from 0.25 MPa (2.5 bar) to 0.10 MPa (1.0 bar).

3. Insulate all of the brine lines and the connections for

the heat pump and product so that they are vapourdiffusion-tight.

Note

Vaillant recommends that you install the

Vaillant heat pump brine filling unit. By doing this, it is then possible to carry out a preparatory partial bleed of the brine circuit, e. g.

the flow and return of the brine circuit to the

product.

5.8 Filling and purging the brine circuit

5.8.1 Calculating the required volume of brine

fluid

▶ Use the information in the following table to calculate the

required volume of brine fluid.

▶ Plan an allowance of 10 l for the calculated volume in

order to facilitate the rinsing process.

▶ Label the vessel for the remaining volume with informa-

tion about the type and concentration of brine fluid and,

after start-up, pass the vessel on to the operator so that

they have brine fluid available for when the tank needs to

be topped up.

Brine fluid volume in the product in litres (± 1

litre)

Total

VWF 5x/4 + VWL 11/4 SA 2.5 + 19 21.5

VWF 57/4 S1 + VWL 11/4 SA 2.5 + 19 21.5

VWF 8x/4 + VWL 11/4 SA 3.1 + 19 22.1

VWF 87/4 S1 + VWL 11/4 SA 3.1 + 19 22.1

VWF 11x/4 + VWL 11/4 SA 3.6 + 19 22.6

VWF 117/4 S1 + VWL 11/4 SA 3.6 + 19 22.6

VWF 157/4 + 2x VWL 11/4 SA 4.5 + 38 42.5

VWF 157/4 S1 + 2x VWL 11/4 SA 4.5 + 38 42.5

VWF 197/4 + 2x VWL 11/4 SA 5.3 + 38 43.3

VWF 197/4 S1 + 2x VWL 11/4 SA 5.3 + 38 43.3

Pipe type Brine fluid volume per running metre

in litres

DN 40 0,8

DN 50 1,26

Example

VWF 197/4 with VWL 11/4 SA and 60 m DN 50 PE pipe

provides the following total content in litres:

5.3 + 2 x 19 + 60 x 1.26 + 10 (reserve) = 129 l.

Page 15

Installation 5

0020217119_01 aroCOLLECT Installation and maintenance instructions 15

5.8.2 Filling the brine circuit (1 air/brine collector)

29

69

66

64

48

56

62

71

42a

63

61

33

67

65

A

B

70

72

A

B

≤ 10m DN 40*

> 10m ≤ 30m DN 50*

29 Brine pump

33 Dirt filter

42a Expansion relief valve

48 Pressure gauge

56 Heat pumps for brine filling unit

61 Stop valve

62 Stop valve

63 Stop valve

64 Stop valve

65 Brine collecting container

66 Brine container

67 Filling pump

69 Purging valves

70 Stop valve

71 Brine diaphragm expansion tank

72 Stop valve

A From the heat source to the heat pump (hot brine)

B From the heat pump to the heat source (cold brine)

* One way

1. Connect the filling pump's pressure line to the stop valve (62).

2. Close stop valves (63), (70) and (72).

3. Open stop valves (62) and (64).

4. Connect a hose, which leads to the brine fluid, to the stop valve (61).

5. Open the stop valve (61).

Caution.

Risk of material damage caused by an incorrect filling direction.

If you fill the brine pump against the direction of flow, this may lead to a turbine effect which can damage

the pump's electronics.

▶ Ensure that the brine pump is filled in the direction of flow.

6. Use the filling pump (67) to pour the brine fluid from the brine container (66) into the brine circuit.

5.8.3 Filling the brine circuit (two air/brine collectors)

29

66

64

48

56

62

71

42a

63

61

33

67

65

A

B

70

72

69 69

A

B

A

B

≤ 10m DN 40*

> 10m ≤ 30m DN 50*

29 Brine pump 33 Dirt filter

Page 16

5 Installation

16 Installation and maintenance instructions aroCOLLECT 0020217119_01

42a Expansion relief valve

48 Pressure gauge

56 Heat pumps for brine filling unit

61 Stop valve

62 Stop valve

63 Stop valve

64 Stop valve

65 Brine collecting container

66 Brine container

67 Filling pump

69 Purging valves

70 Stop valve

71 Brine diaphragm expansion tank

72 Stop valve

A From the heat source to the heat pump (hot brine)

B From the heat pump to the heat source (cold brine)

* One way

1. Connect the filling pump's pressure line to the stop valve (62).

2. Close stop valves (63), (70) and (72).

3. Open stop valves (62) and (64).

4. Connect a hose, which leads to the brine fluid, to the stop valve (61).

5. Open the stop valve (61).

Caution.

Risk of material damage caused by an incorrect filling direction.

If you fill the brine pump against the direction of flow, this may lead to a turbine effect which can damage

the pump's electronics.

▶ Ensure that the brine pump is filled in the direction of flow.

6. Use the filling pump (67) to pour the brine fluid from the brine container (66) into the brine circuit.

Page 17

Installation 5

0020217119_01 aroCOLLECT Installation and maintenance instructions 17

5.8.4 Purge the brine circuit

1. Position a second person at the air/brine collector(s).

Note

The entire purging/filling process should last

at least 30 minutes. During this time, the purging valves for the air/brine collector(s) must

be opened and closed every five minutes.

We recommend the brine purging support set

for the air/brine collector as this makes the

purging process significantly easier if it is to

be carried out by one person.

2. Remove the protective caps, which are attached and

transparent in their as-delivered condition, from the

purging valves on the air/brine collector and dispose

of these. These are no longer required.

3. Open the purging valves (69) on the air/brine

collector(s).

4. Start up the filling pump (67) in order to fill and rinse the

brine circuit.

5. Allow the filling pump (67) to run.

6. Close the purging valves on the air/brine collector(s)

as soon as brine fluid escapes from the purging valves

(69).

7. If required, open all of the other stop valves that are not

shown in the illustrations.

8. Open and close the purging valves (69) on the air/brine

collector(s) every five minutes consistently until air is no

longer escaping.

9. Open the stop valve (63) so that air in the pipeline

between the stop valves (61) and (62) can escape.

10. Close the stop valve (61).

11. Build up pressure in the system, as described in the

installation instructions for the heat pump.

5.9 Electrical installation

Danger!

Risk of death from electric shock caused

by a residual-current circuit breaker.

In certain cases, residual-current circuit

breakers may not work.

▶ If, to ensure that people are protected

properly and fire is prevented, residualcurrent circuit breakers are required, use

type A pulse-current-sensitive residualcurrent circuit breakers or type B universal-current-sensitive residual-current circuit breakers.

▶ Observe the technical connection conditions for connect-

ing to the power supply network operator's low-voltage

network.

▶ Use the values for the maximum rated power that are

specified in the technical data to determine the required

line cross-sections.

▶ In each case, take into consideration the on-site installa-

tion conditions.

▶ Connect the product using a fixed connection and a parti-

tion with a contact opening of at least 3 mm (e.g. fuses or

power switches).

▶ For the electricity supply, connect the product to a three-

phase 400 V AC network with a neutral line and an earth

line.

▶ Fuse this connection using the exact values that are spe-

cified in the technical data.

▶ At lengths of 10 m or more, supply lines must be laid sep-

arately from sensor or bus lines. Minimum clearance for

the extra-low voltage and mains voltage line at a line

length of > 10 m: 25 cm. If this is not possible, use shielded lines. Lay the shielding on one side of the sheet for

the product's electronics box.

80 mm max.

1

2

1 Connecting wires 2 Insulation

▶ Strip the outer sheathing on the line to the connection

box by approximately 80 mm. Shorten all of the conductors, except for PE, to 60 mm.

▶ Secure the conductors in the connection terminals.

– Max. torque of the connection terminals: 0.5 Nm

Page 18

5 Installation

18 Installation and maintenance instructions aroCOLLECT 0020217119_01

5.9.1 Switch box

L1 L 2L 3 N P E

1

2

3

4

6

7

5

1 Switch box

2 Strain relief

3 eBUS line

4 Connection box

5 Strain relief

6 Voltage supply line

7 Cable duct

5.9.2 Air/brine collector controller PCB

L3 L2 L1 N

1 2 3 4 5 6 7 8 9 10

11

12

1 Fan control signal con-

nection

2 eBUS connection

3 eBUS address switch

(default setting 1)

4 TT40 sensor connection

(pink); TT34 sensor

connection (white)

5 Operating LED

6 Controller PCB power

supply

7 F1 T2 230 V fuse for

fan and safety cut-out

8 Fan voltage supply

9 Safety cut-out connec-

tion

10 De-icer connection

11 Optional 200 W connec-

tion accessory

12 F3 T2 230 V fuse for

optional connection

accessory

Display Meaning

Flashing slowly OK

Display Meaning

1 x brief flash Fan fault

2 x brief flash Fault TT40 (air inlet)

3 x brief flash Fault TT34 (hot brine)

4 x brief flash

The safety cut-out has been triggered.

Fuse F1 is defective.

5 x brief flash

No eBUS connection to the heat pump's

controller PCB

6 x brief flash Power supply not OK (1-2 phases are

missing) or safety relay (OMU) is defective

The flashing period lasts for approx. 3-4 seconds.

5.9.3 Establishing the power supply

eBUS

400 V400 V

1

1

1

1 400 V power supply

network (on-site)

Electrical wiring of one air/brine collector

eBUS

400 V

400 V

1

1

2

2

1

2

1 400 V power supply

network (on-site)

2 eBUS distributor (on-

site)

Electrical wiring of two collectors

Page 19

Installation 5

0020217119_01 aroCOLLECT Installation and maintenance instructions 19

▶ Connect each air/brine collector to a three-phase 400 V

AC network with a neutral line and an earth line.

▶ Strip the voltage supply line by approximately 80 mm.

Shorten all of the conductors, except for PE, to 60 mm.

Remove the insulation by a maximum of 8 mm. If these

lengths are exceeded, there is a risk of a short circuit.

▶ If the energy supply company requires that the heat

pump is controlled using a blocking signal, also connect

the air/brine collector to the heat pump via the electricity

meter so that a block by the energy supply company can

be switched off for both products at the same time.

▶ Connect the eBUS connection X3 to the eBUS connec-

tion on the heat pump. Use a ground connection that is

suitable for laying cables underground and that has a

cross-section of at least 2 x 1.5 mm².

Conditions: Installing two air/brine collectors

▶ Place a junction box close to the heat pump and connect

the eBUS lines to this.

▶ Set the eBUS address switch for the first air/brine col-

lector to 1 and the eBUS address switch for the second

air/brine collector to 2.

5.9.4 Circuit breaker for the air/brine collector

A circuit breaker is used to secure the air/brine collector

against short circuits. If the circuit breaker has been

triggered, the air/brine collector remains switched off until the

short circuit has been rectified and the circuit breaker in the

connection box has been manually reset.

The fault message F.708 or F.782 is shown in the heat pump

display.

5.9.5 Resetting the circuit breaker for the

air/brine collector

1. Check the supply line to the mains connection PCB in

the air/brine collector's electronics box.

2. Check that the air/brine collector's mains connection

PCB is working correctly.

3. Check the supply lines for the air/brine collector.

4. Check that the de-icer is working correctly.

5. Rectify the short circuit.

6. Reset the circuit breaker in the connection box.

5.9.6 Installing the side casing and cover

1

4

2

3

1

1. Arrange each of the side casing sections (1) and (4)

tilted downwards on the product's frame (2) and, in doing so, let the nipples clip into place in the cut-outs that

are provided for this.

2. Move the side casing sections to the correct, vertical

position.

3. Screw each of the side casing sections tightly to the

frame using two screws (3).

4. When installing the retaining bracket, you must observe

the installation location as shown in the illustration.

5. Secure each of the retaining brackets to the cover using

two self-cutting screws.

6. Place the cover on the product.

Page 20

6 Start-up

20 Installation and maintenance instructions aroCOLLECT 0020217119_01

7. Anchor the cover to the product by turning each screw

through the slot in the retaining bracket in the frame.

6 Start-up

6.1 Start-up

1. Ensure that the heat pump and system controller are

installed correctly.

2. Switch the fuses on so that the heat pump and air/brine

collector(s) are supplied with power.

◁ As soon as the heat pump is supplied with power

during the initial start-up, the software initialisation

starts in the heat pump and in the system controller.

3. Implement the other settings with the help of the installation instructions for the heat pump and for the system

controller.

6.2 Handing the product over to the operator

▶ When you have finished the installation, affix the en-

closed sticker (which requests that the user reads the

instructions) to the front of the product in the operator's

language.

▶ Explain to the operator how the safety devices work and

where they are located.

▶ Inform the operator how to handle the product.

▶ In particular, draw attention to the safety information

which the operator must follow.

▶ Inform the operator of the necessity to have the product

maintained according to the specified intervals.

▶ Pass all of the instructions and documentation for the

product to the operator for safe-keeping.

7 Inspection and maintenance

7.1 Inspection and maintenance interval

Annual inspection/maintenance of the product by a competent person is a prerequisite for ensuring that the system is

constantly ready for operation, reliable and has a long service life.

The inspection is intended to determine the actual condition

of the product and compare it with the target condition. This

is done by measuring, checking and observing.

Maintenance is required in order to eliminate any deviations

between the actual condition and the target condition. This is

normally done by cleaning, setting and, if necessary, replacing individual components that are subject to wear.

Danger!

Risk of death from electric shock!

The air/brine collector has its own, separate

power supply and is not automatically de-energised when the heat pump is disconnected

from the power source.

▶ Always switch off the power supply for

each air/brine collector before carrying out

any inspection or maintenance work.

▶ Secure the power supply against being

switched on again.

Danger!

Risk of death from electric shock!

Due to electrical discharge processes, contact with components inside the product may

cause an electric shock.

▶ Do not open the cover for the electronics

box in the product until three minutes after

the all-pole disconnection of the supply

voltage.

▶ Do not remove the louvred grill until at

least three minutes after the all-pole disconnection of the power supply. Never

try to take hold of the ventilator before the

three minutes have elapsed.

Page 21

Decommissioning 8

0020217119_01 aroCOLLECT Installation and maintenance instructions 21

7.2 Carrying out inspection and maintenance

work

Note

Due to the fluctuating outside temperature and

air humidity, it is normal for frost to form or for

the heat exchanger to freeze in the product. In

normal mode, the product automatically starts up

a thawing procedure.

▶ Check the product for dirt and, if required, clean it.

▶ Check the condensate discharge for blockages and, if

required, remove any dirt/blockages.

▶ Check the air inlet and outlet to ensure that the supply

and exhaust air is unobstructed and, if required, request

that the operator removes any vegetation or similar (minimum clearances). (→ Page 9)

▶ Request that, in winter, the operator regularly ensures

that the product is free of snow on the intake and outlet

side.

7.3 Procuring spare parts

The original components of the product were also certified

by the manufacturer as part of the declaration of conformity.

If you use other, non-certified or unauthorised parts during

maintenance or repair work, this may void the conformity of

the product and it will therefore no longer comply with the

applicable standards.

We strongly recommend that you use original spare parts

from the manufacturer as this guarantees fault-free and safe

operation of the product. To receive information about the

available original spare parts, contact the contact address

provided on the reverse of these instructions.

▶ If you require spare parts for maintenance or repair

work, use only the spare parts that are permitted for the

product.

7.4 Cleaning the product

▶ When the casing is completely installed, clean the

product using a sponge and hot water (max. 70 °C) along

with commercially available household cleaners that do

not contain any abrasive elements in an aqueous solution

up to max. 2%. Do not use any sanitary cleaners that

contain chlorine or ammonia.

7.5 Cleaning the condensate discharge

3

2

1

1 Screws for the base

panel

2 Base panel

3 Condensate tray

1. Remove the side sections of the casing (→ Page 19)

and the front louvred grill (outlet side).

2. Unscrew the screws (1) in the front base panel (2) and

remove the base panel.

3. Carefully pull the condensate tray (3) forwards and out

from below the fan.

4. Clean the connectors.

5. Check that the outflow is free of obstructions. If

required, clean or replace this.

6. Insert the condensate tray.

7. Install the side casing and the cover. (→ Page 19)

8 Decommissioning

8.1 Temporary decommissioning

▶ Disconnect the product from the power supply.

8.2 Permanently decommissioning

1. Disconnect the product from the power supply.

2. Drain the product. For this, use suitable collecting containers and only dispose of heat transfer media, such as

brine, at appropriate collection points.

3. Dispose of or recycle the product and its components.

9 Customer service

10 Recycling and disposal

Disposing of the packaging

▶ Dispose of the packaging correctly.

▶ Observe all relevant regulations.

Page 22

Appendix

22 Installation and maintenance instructions aroCOLLECT 0020217119_01

Appendix

A Product diagram

A.1 Product diagram

F1

HG2

HE7

8a

7a

TT 40

TZ 33

TT 34

7a Hot brine to the heat pump (A)

8a Cold brine from the heat pump (B)

TT40 Air inlet temperature sensor

TT34 Hot brine temperature sensor

TZ33 De-icer safety cut-out

F1 Ventilator

HG2 De-icer

HE7 Air/brine heat exchanger

Page 23

Appendix

0020217119_01 aroCOLLECT Installation and maintenance instructions 23

B Connection diagram

L1

NL3

L2

X11 X2

X8

X4

X3

BUS

X6

T10

X5

T9

X1

X9

F3 T2

PE PE

NN

PE

N

L2L1

N

L3

F2 T2

230V

24V

K2

K3

K1

K200

1 2

15

3

4

6

7

8

9

14

5

13

12

10

11

1 Air inlet temperature sensor

2 Hot brine temperature sensor

3 Fan control line

4 Fan voltage supply

5 F3 T2 fuse

6 Connection option: Condensate tray heating

7 Connection option: Safety cut-out

8 Safety cut-out with temperature switch and thermal

fuse

9 Heating element de-icer

10 Connection box

11 Line protection switch

12 Mains connection

13 F2 T2 fuse

14 Control unit

15 Address switch: Address 1 (≤10 kW), address 1/2

(>10 kW)

Page 24

Appendix

24 Installation and maintenance instructions aroCOLLECT 0020217119_01

C Technical data

C.1 General

Dimensions

VWL 11/4 SA

Product dimensions, height with base

1,260 mm

Product dimensions, width

1,200 mm

Product dimensions, depth

785 mm

Weight with packaging

160 kg

Weight without packaging and base

95 kg

Weight without packaging

140 kg

Weight when ready for operation

185 kg

Electrics

VWL 11/4 SA

Measuring voltage

3~/N/PE 400 V / 50 Hz

Fuse type, characteristic B, three-pole

switching (disconnection of the three

mains connection lines by a switching

operation)

10 A

Optional on-site residual-current circuit

breaker

RCCB type A (type A

pulse-current-sensitive

residual-current circuit

breakers) or RCCB type B

(type B universal-currentsensitive residual-current

circuit breakers)

Electrical power consumption, max. total

6.5 kW

Electrical power consumption, de-icer

6.0 kW

Electrical power consumption, fan

0 … 0.25 kW

Electrical power consumption, control

system

0.01 kW

Electrical power consumption, optional

accessory

0.2 kW

Level of protection EN 60529

IP 25

Hydraulics

VWL 11/4 SA

Flow/return heat source connections

Rp 1 1/4"

Diameter of the condensate discharge

70 mm

Installation site

VWL 11/4 SA

Installation site

Outside

Permissible ambient temperature at the

installation site

−30 … 70 ℃

Permissible ambient temperature during

operation

−22 … 40 ℃

Brine circuit

VWL 11/4 SA

Brine fluid

Ethylene glycol 44% vol.

/56% water

Max. operating pressure

0.3 MPa

(3.0 bar)

Min. inlet temperature, cold brine

−28 ℃

Max. inlet temperature, hot brine

60 ℃

Page 25

Appendix

0020217119_01 aroCOLLECT Installation and maintenance instructions 25

VWL 11/4 SA

Brine content of the brine circuit in the

air/brine collector

19.8 l

Materials

Cu, CuZn alloy, stainless

steel, EPDM

Total length of the connection line, cold

brine and hot brine

2 x 30 m

Diameter of the connection line's crosssection up to a total length of ≤ 10 m

DN 40 (40 x 3.8 mm)

Diameter of the connection line's crosssection up to a total length of > 10 and

≤ 30 m

DN 50 (50 x 4.6 mm)

Connection line installation depth

0.2 … 1.5 m

Connection line material

PE pipe, PE 100 or PE 80

Sound power level

VWL 11/4 SA

Sound power level A7/W35,

A7/W45, A7/W55 in accordance with

EN 12102/EN 14511 LWAin heating mode

VWF 57/4

≤ 42.7 dB(A)

VWF 58/4

≤ 42.7 dB(A)

VWF 87/4

≤ 50.6 dB(A)

VWF 88/4

≤ 50.6 dB(A)

VWF 117/4

≤ 56.0 dB(A)

VWF 118/4

≤ 56.0 dB(A)

VWF 157/4

≤ 49.5 dB(A)

Note

When two air/brine

collectors (with VWF 157/4

and VWF 197/4) are

running with the same

sound power level at the

same time, the total sound

power level result is 3

dB(A) higher.

VWF 197/4

≤ 53.0 dB(A)

Note

When two air/brine

collectors (with VWF 157/4

and VWF 197/4) are

running with the same

sound power level at the

same time, the total sound

power level result is 3

dB(A) higher.

Sound power level A35/W18 in accordance with EN 12102/EN 14511 LWAin cooling mode

VWF 57/4

≤ 53.5 dB(A)

VWF 58/4

≤ 53.5 dB(A)

VWF 87/4

≤ 60.5 dB(A)

VWF 88/4

≤ 60.5 dB(A)

VWF 117/4

≤ 66.3 dB(A)

VWF 118/4

≤ 66.3 dB(A)

Page 26

Appendix

26 Installation and maintenance instructions aroCOLLECT 0020217119_01

VWL 11/4 SA

Sound power level A35/W18 in accordance with EN 12102/EN 14511 LWAin cooling mode

VWF 157/4

≤ 59.2 dB(A)

Note

When two air/brine

collectors (on VWF 157/4,

VWF 157/4 S1 and VWF

197/4) are running at the

same sound power level at

the same time, the total

sound power level result is

3 dB(A) higher.

VWF 197/4

≤ 63.7 dB(A)

Note

When two air/brine

collectors (on VWF 157/4,

VWF 157/4 S1 and VWF

197/4) are running at the

same sound power level at

the same time, the total

sound power level result is

3 dB(A) higher.

Fan rotational speed

VWL 11/4 SA

Fan rotational speed A7/W35, A7/W45,

A7/W55 EN 14511 in heating mode

VWF 57/4

300 rpm

VWF 58/4

300 rpm

VWF 87/4

400 rpm

VWF 88/4

400 rpm

VWF 117/4

490 rpm

VWF 118/4

490 rpm

VWF 157/4

390 rpm

VWF 197/4

440 rpm

Fan rotational speed A35/W18 EN 14511

in cooling mode

VWF 57/4

450 rpm

VWF 58/4

450 rpm

VWF 87/4

580 rpm

VWF 88/4

580 rpm

VWF 117/4

710 rpm

VWF 118/4

710 rpm

VWF 157/4

550 rpm

VWF 197/4

650 rpm

C.2 Air heat source

Heat source circuit/brine circuit

VWF 58/4 VWF 88/4 VWF 118/4

Heat source module

1 x VWL 11/4 SA 1 x VWL 11/4 SA 1 x VWL 11/4 SA

Brine fluid type

Ethylene glycol 44% vol. Ethylene glycol 44% vol. Ethylene glycol 44% vol.

Heat source circuit/brine circuit

VWF 57/4 VWF 87/4 VWF 117/4 VWF 157/4 VWF 197/4

Heat source module

1 x

VWL 11/4 SA

1 x

VWL 11/4 SA

1 x

VWL 11/4 SA

2 x

VWL 11/4 SA

2 x

VWL 11/4 SA

Brine fluid type

Ethylene glycol

44% vol.

Ethylene glycol

44% vol.

Ethylene glycol

44% vol.

Ethylene glycol

44% vol.

Ethylene glycol

44% vol.

Performance data

The following performance data is applicable to new products with clean heat exchangers.

Page 27

Appendix

0020217119_01 aroCOLLECT Installation and maintenance instructions 27

VWF 58/4 VWF 88/4 VWF 118/4

Heat source module

1 x VWL 11/4 SA 1 x VWL 11/4 SA 1 x VWL 11/4 SA

A2/W35 heating output

5.70 kW 7.80 kW 10.30 kW

A2/W35 power consumption

1.40 kW 2.10 kW 2.70 kW

A2/W35 output figure/EN 14511 coefficient

of performance

4.20 4.00 3.90

Heating output A7/W35 ΔT 5 K

6.20 kW 8.80 kW 11.50 kW

Power consumption A7/W35 ΔT 5 K

1.40 kW 2.00 kW 2.60 kW

Output figure A7/W35 ΔT 5 K/coefficient of

performance EN 14511

4.80 4.60 4.60

Heating output A7/W45 ΔT 5 K

6.10 kW 9.00 kW 12.00 kW

Power consumption A7/W45 ΔT 5 K

1.70 kW 2.50 kW 3.20 kW

Output figure A7/W45 ΔT 5 K/coefficient of

performance EN 14511

3.70 3.70 3.80

Heating output A7/W55 ΔT 8 K

6.10 kW 9.50 kW 12.20 kW

Power consumption A7/W55 ΔT 8 K

2.00 kW 3.00 kW 3.90 kW

Output figure A7/W55 ΔT 8 K/coefficient of

performance EN 14511

3.10 3.20 3.20

Cooling output A35/W18 ΔT 5 K, active

6.60 kW 8.60 kW 12.10 kW

Power consumption A35/W18 Δ T 5 K, active

1.60 kW 2.80 kW 3.70 kW

Energy efficiency ratio A35/W18 EN 14511

4,30 3,20 3,40

Hot water output figure/coefficient of performance A7/Wxx DIN EN 16147 at target

cylinder temperature of 50 °C and 6 K hysteresis

2,80 2,60 2,50

Hot water draw-off profile A7/Wxx DIN EN

16147

XL XL XL

Hot water mixed water volume 40 °C (V40)

A7/Wxx at target cylinder temperature of

50 °C

229 l 233 l 231 l

Sound power level A7/W35

EN 12102/EN 14511 LWIin heating mode

41.3 dB(A) 43.2 dB(A) 42.5 dB(A)

Sound power level A7/W45

EN 12102/EN 14511 LWIin heating mode

41.6 dB(A) 45.7 dB(A) 44.2 dB(A)

Sound power level A7/W55

EN 12102/EN 14511 LWIin heating mode

44.1 dB(A) 47.4 dB(A) 46.6 dB(A)

Sound power level A35/W18

EN 12102/EN 14511 LWIin cooling mode

51.8 dB(A) 52.6 dB(A) 50.0 dB(A)

Performance data

The following performance data is applicable to new products with clean heat exchangers.

VWF 57/4 VWF 87/4 VWF 117/4 VWF 157/4 VWF 197/4

Heat source module

1 x

VWL 11/4 SA

1 x

VWL 11/4 SA

1 x

VWL 11/4 SA

2 x

VWL 11/4 SA

2 x

VWL 11/4 SA

A2/W35 heating output

5.70 kW 7.80 kW 10.30 kW 13.90 kW 17.40 kW

A2/W35 power consumption

1.40 kW 2.10 kW 2.70 kW 3.50 kW 4.80 kW

A2/W35 output figure/EN 14511 coefficient

of performance

4.20 4.00 3.90 4.10 3.70

Heating output A7/W35 ΔT 5 K

6.20 kW 8.80 kW 11.50 kW 15.30 kW 19.80 kW

Power consumption A7/W35 ΔT 5 K

1.40 kW 2.00 kW 2.60 kW 3.30 kW 4.60 kW

Output figure A7/W35 ΔT 5 K/coefficient

of performance EN 14511

4.80 4.60 4.60 4.80 4.40

Heating output A7/W45 ΔT 5 K

6.10 kW 9.00 kW 12.00 kW 15.60 kW 20.60 kW

Power consumption A7/W45 ΔT 5 K

1.70 kW 2.50 kW 3.20 kW 4.20 kW 5.70 kW

Output figure A7/W45 ΔT 5 K/coefficient

of performance EN 14511

3.70 3.70 3.80 3.90 3.70

Heating output A7/W55 ΔT 8 K

6.10 kW 9.50 kW 12.20 kW 16.00 kW 20.90 kW

Page 28

Appendix

28 Installation and maintenance instructions aroCOLLECT 0020217119_01

VWF 57/4 VWF 87/4 VWF 117/4 VWF 157/4 VWF 197/4

Power consumption A7/W55 ΔT 8 K

2.00 kW 3.00 kW 3.90 kW 5.00 kW 6.70 kW

Output figure A7/W55 ΔT 8 K/coefficient

of performance EN 14511

3.10 3.20 3.20 3.30 3.20

Cooling output A35/W18 ΔT 5 K, active

6.60 kW 8.60 kW 12.10 kW 15.80 kW 22.30 kW

Power consumption A35/W18 Δ T 5 K, active

1.60 kW 2.80 kW 3.70 kW 4.40 kW 6.20 kW

Energy efficiency ratio A35/W18 EN 14511

4,30 3,20 3,40 3,90 3,40

Sound power level A7/W35

EN 12102/EN 14511 LWIin heating mode

40.3 dB(A) 45.8 dB(A) 44.4 dB(A) 48.7 dB(A) 48.1 dB(A)

Sound power level A7/W45

EN 12102/EN 14511 LWIin heating mode

41.0 dB(A) 50.1 dB(A) 46.4 dB(A) 49.4 dB(A) 46.1 dB(A)

Sound power level A7/W55

EN 12102/EN 14511 LWIin heating mode

40.9 dB(A) 52.7 dB(A) 46.1 dB(A) 48.0 dB(A) 46.4 dB(A)

Sound power level A35/W18

EN 12102/EN 14511 LWIin cooling mode

48.3 dB(A) 54.7 dB(A) 49.7 dB(A) 46.8 dB(A) 47.2 dB(A)

Application limits for the heat pump: Heating and cooling (heat source = air)

At the same volume flow rates in the heating circuit (ΔT 5K or ΔT 8 K) as for the nominal heat output test under standard

nominal conditions.

Operation of the pump outside the application limits results in the heat pump being switched off by the internal control and

safety devices.

VWF 58/4 VWF 88/4 VWF 118/4

Application limits for the heat pump: Heating (Air heat source)

– A40/W65

– A40/W25

– A−22/W25

– A−22/W50

– A−2/W65

– A15/W65

– A40/W65

– A40/W25

– A−22/W25

– A−22/W50

– A−2/W65

– A15/W65

– A40/W65

– A40/W25

– A−22/W25

– A−22/W50

– A−2/W65

– A15/W65

Application limits for the heat pump: Cooling (Air heat source)

– A20/W20

– A40/W20

– A40/W5

– A20/W5

– A20/W20

– A40/W20

– A40/W5

– A20/W5

– A20/W20

– A40/W20

– A40/W5

– A20/W5

Application limits for the heat pump: Heating (heat source = air)

At the same volume flow rates in the heating circuit (ΔT 5K or ΔT 8 K) as for the nominal heat output test under standard

nominal conditions.

Operation of the pump outside the application limits results in the heat pump being switched off by the internal control and

safety devices.

VWF 57/4 VWF 87/4 VWF 117/4 VWF 157/4 VWF 197/4

– A40/W65

– A40/W25

– A−22/W25

– A−22/W50

– A−2/W65

– A15/W65

– A40/W65

– A40/W25

– A−22/W25

– A−22/W50

– A−2/W65

– A15/W65

– A40/W65

– A40/W25

– A−22/W25

– A−22/W50

– A−2/W65

– A15/W65

– A40/W65

– A40/W25

– A−22/W25

– A−22/W50

– A−2/W65

– A15/W65

– A40/W65

– A40/W25

– A−22/W25

– A−22/W50

– A−2/W65

– A15/W65

Application limits for the heat pump: Cooling (heat source = air)

At the same volume flow rates in the heating circuit (ΔT 5K or ΔT 8 K) as for the nominal heat output test under standard

nominal conditions.

Operation of the pump outside the application limits results in the heat pump being switched off by the internal control and

safety devices.

VWF 57/4 VWF 87/4 VWF 117/4 VWF 157/4 VWF 197/4

– A20/W20

– A40/W20

– A40/W5

– A20/W5

– A20/W20

– A40/W20

– A40/W5

– A20/W5

– A20/W20

– A40/W20

– A40/W5

– A20/W5

– A20/W20

– A40/W20

– A40/W5

– A20/W5

– A20/W20

– A40/W20

– A40/W5

– A20/W5

Page 29

Index

0020217119_01 aroCOLLECT Installation and maintenance instructions 29

Index

B

Brine fluid, volume...............................................................14

Brine lines, installing............................................................ 13

C

CE label.................................................................................6

Clean the condensate discharge......................................... 21

Clean the product ................................................................ 21

Cleaning the product ...........................................................21

Competent person ................................................................. 3

Connection lines, routing..................................................... 12

Controller PCB .................................................................... 18

Cover, installing................................................................... 19

Creating, foundation ............................................................ 11

D

Decommissioning, permanent ............................................. 21

Decommissioning, temporary .............................................. 21

Design, product .....................................................................7

Design, system...................................................................... 6

Dimensions............................................................................9

Disposal, packaging ............................................................21

Disposing of the packaging ................................................. 21

Documents ............................................................................6

E

Electricity ............................................................................... 4

Electronics box .................................................................... 18

Establishing, power supply.................................................. 18

F

Filling the brine circuit (1 air/brine collector)........................ 15

Filling the brine circuit (two air/brine collectors) .................. 15

Foundation, creating............................................................11

H

Handing over to the operator............................................... 20

I

Identification plate ................................................................. 6

Inspection ............................................................................ 21

Inspection intervals..............................................................20

Installation site....................................................................... 8

Installing, brine lines............................................................13

Installing, cover ................................................................... 19

Installing, product ................................................................13

Installing, side cladding .......................................................19

Intended use..........................................................................3

M

Maintenance........................................................................ 21

Maintenance intervals ......................................................... 20

Minimum clearances ............................................................. 9

N

Noise emission ...................................................................... 8

P

Power supply, establishing.................................................. 18

Product design ...................................................................... 7

Product, installing ................................................................ 13

Purging the brine circuit....................................................... 17

Purging, brine circuit............................................................ 17

Q

Qualification...........................................................................3

R

Removing, transport locks ..................................................... 7

Routing, connection lines ....................................................12

S

Safety device.........................................................................3

Schematic drawing ................................................................ 3

Scope of delivery...................................................................7

Side cladding, installing....................................................... 19

Sound propagation ................................................................ 8

Spare parts..........................................................................21

Starting up ........................................................................... 20

System design.......................................................................6

T

Tool ....................................................................................... 4

Transport ......................................................................... 4, 13

Transport locks, removing ..................................................... 7

V

Voltage ..................................................................................4

Page 30

Page 31

Page 32

0020217119_01 10.05.2016

Vaillant Ltd.

Nottingham Road Belper Derbyshire DE56 1JT

Telephone 0330 100 3461

info@vaillant.co.uk www.vaillant.co.uk

© These instructions, or parts thereof, are protected by copyright and may be reproduced or distributed only with

the manufacturer's written consent.

We reserve the right to make technical changes.

Loading...

Loading...