Vaillant Air/flue gas system, VKK Series Installation Manual

For the competent person

Installation manual

Installation manual

Air/flue gas system

VKK ../3

GB

Legal information

Document type: Installation manual

Product: Air/flue gas system

– 130 mm diameter system

– 160 mm diameter system

– 200 mm diameter system

Target group: Authorised competent person

Language: EN

Document number_version: 0020058722_04

Created on: 26.09.2012

Publisher/manufacturer

Vaillant GmbH

Berghauser Str. 40 D-42859 Remscheid

Telefon +49 21 91 18‑0 Telefax +49 21 91 18‑28 10

info@vaillant.de www.vaillant.de

© Vaillant GmbH 2012

These instructions, or extracts thereof, may only be printed with the written consent of Vaillant GmbH.

All designations of products in these instructions are brand names/trade marks of the companies in question.

We reserve the right to make technical changes.

Contents

1 Notes on the documentation .............................. 4

1.1 Observing other applicable documents ................. 4

1.2 Storing documents................................................. 4

1.3 Applicability of the instructions .............................. 4

2 Safety .................................................................... 5

2.1 Action-related warnings ......................................... 5

2.2 Required personnel qualifications ......................... 5

2.3 General safety information .................................... 5

2.4 Intended use .......................................................... 7

2.5 Regulations (directives, laws, standards) .............. 8

3 System overview.................................................. 9

3.1 Combination options for systems with VKK........... 9

3.2 130 mm diameter system ...................................... 9

3.3 160 mm diameter, 200 mm diameter system ........ 9

4 Certified air/flue gas systems and

components ....................................................... 11

4.1 Certified air/flue gas systems and components,

130 mm diameter................................................. 11

4.2 Certified air/flue gas systems and components,

160 mm diameter................................................. 11

4.3 Certified air/flue gas systems and components,

200 mm diameter................................................. 11

4.4 Certified flue gas systems.................................... 12

5 System conditions............................................. 12

5.1 Maximum pipe lengths......................................... 12

5.2 General installation instructions........................... 17

6 Installing the 130 mm diameter system........... 18

6.1 Installation instructions ........................................ 18

6.2 Installing the basic set for shaft installation ......... 19

6.3 Flue gas connection and installing the

horizontal flue gas pipe........................................ 20

6.4 Installing the combustion air line ......................... 21

7 Installing the 160 mm diameter and 200 mm

diameter systems .............................................. 22

7.1 Installing the flue gas pipe in the shaft ................ 22

7.2 Installing a flue gas pipe on a support pipe

(optional).............................................................. 25

7.3 Installing the vertical roof duct ............................. 25

7.4 Installing the flue gas pipe on the external

wall....................................................................... 26

7.5 Stabilising the flue gas pipe ................................. 30

7.6 Flue gas connection and installing the

horizontal flue gas pipe........................................ 31

7.7 Installing the combustion air line ......................... 31

8 Customer service............................................... 32

Index ................................................................................... 33

Contents

0020058722_04 Air/flue gas system Installation manual 3

1 Notes on the documentation

1 Notes on the documentation

1.1 Observing other applicable documents

For the competent person:

– Installation instructions for the installed Vaillant product.

1.2 Storing documents

▶ Pass these instructions and all other applicable docu-

ments on to the system operator.

The system operator should retain these instructions for further use.

1.3 Applicability of the instructions

These instructions apply only for the Vaillant heat generator

named in the other applicable documents and referred to as

the "product" in this document.

4 Installation manual Air/flue gas system 0020058722_04

Safety 2

5mm

15°

2 Safety

2.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in accordance

with the severity of the possible danger using the following

warning signs and signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of severe personal

injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental damage

2.2 Required personnel qualifications

These instructions are intended for the competent person.

▶ As part of the annual maintenance, inspect the flue gas

system in terms of:

– external faults such as brittleness and damage

– safe pipe connections and secure fastenings

2.3.3 Risk of death from leaks in the flue gas

route

Flue gas may escape from leaking pipes or damaged seals.

Mineral-oil-based greases can damage the seals.

▶ Transport the pipes to the installation site only in the ori-

ginal packaging.

▶ If the temperature is lower than 0 °C, warm the pipes

before beginning installation.

▶ When installing the flue gas installation, use only flue

pipes of the same material.

▶ Do not install any damaged pipes.

▶ When connecting, always slide the pipes into the sleeve

until they reach a stop.

▶ Shorten the flue pipes to the suitable lengths at right

angles along their smooth side.

2.2.1 Authorised competent person

The installation, assembly and removal, start-up, maintenance, repair and decommissioning of Vaillant products and

accessories must only be carried out by authorised competent persons.

Note

Each competent person is qualified for specific

activities on the basis of their training. They must

only work on units if they have the required qualification.

When working on the units, the competent persons must

observe all applicable directives, standards, laws and other

regulations.

2.3 General safety information

2.3.1 Informing the responsible departments

▶ Before installing the flue pipe, inform the local gas supply

company and the district master chimney sweep.

2.3.2 Risk of poisoning due to escaping flue gas

Improperly installed flue gas pipes may cause flue gas to

escape.

▶ Before starting up the product, check that the whole flue

pipe is securely fastened and sealed.

▶ File off sharp burrs and chamfer the ends of the pipes be-

fore assembling them so that the seals are not damaged,

and dispose of the shavings.

▶ Never use mineral-oil-based grease for the installation.

▶ Only 130 mm diameter systems: if necessary, only use

water to facilitate installation.

▶ Only 160 mm diameter and 200 mm diameter systems:

Use the lubricant supplied to facilitate installation.

The flue gas pipe may become damaged by unforeseeable

external influences.

0020058722_04 Air/flue gas system Installation manual 5

2 Safety

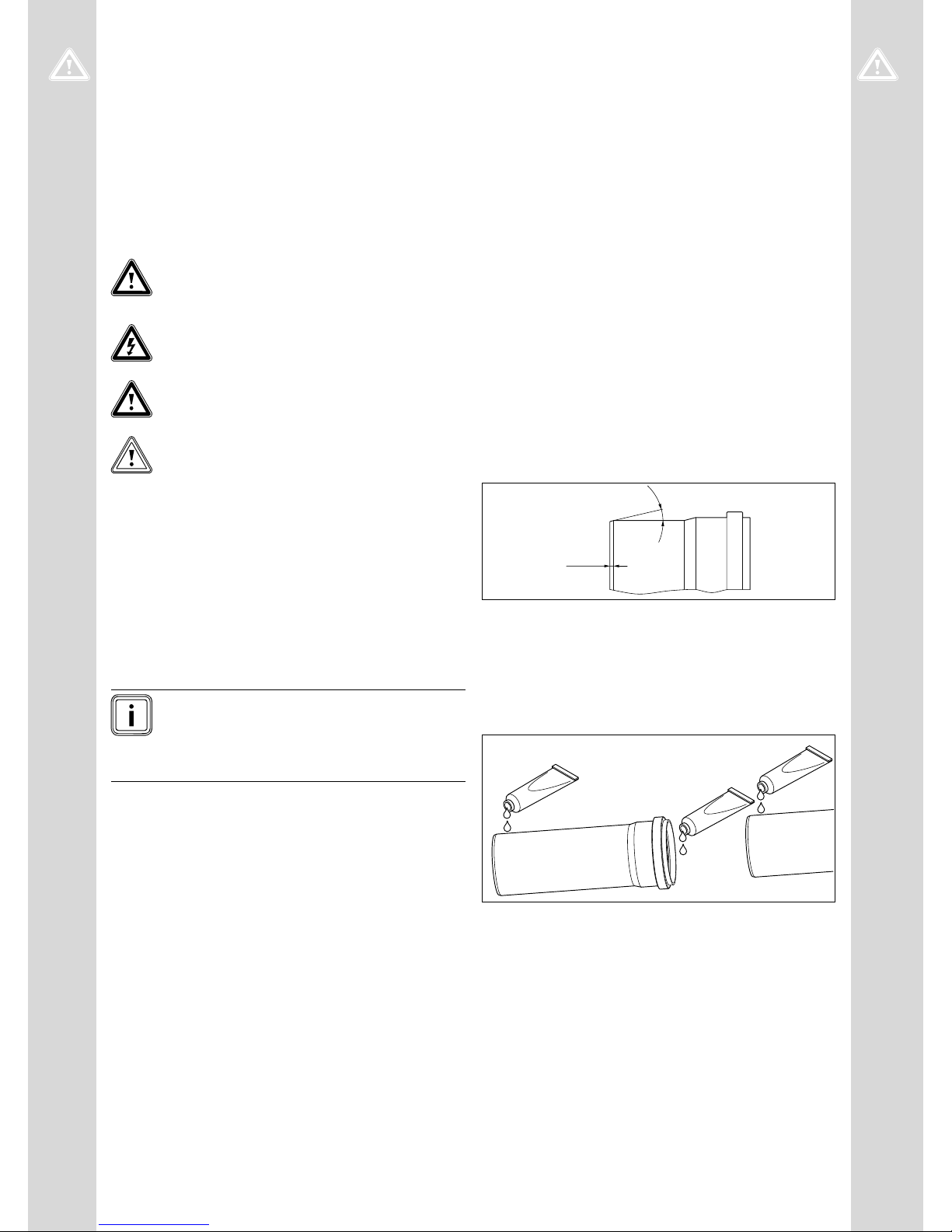

1

2

▶ When fitting the flue pipes, make absolutely sure the

seals are correctly positioned. The lip of the seal must

be facing inwards (1), not outwards (2).

▶ Do not use any damaged seals.

Mortar residues, shavings, etc. in the flue pipe may restrict

the outward flow of the flue gas. Flue gas may escape into

the room.

▶ After installation, remove all mortar residues, shavings,

etc. from the flue pipe.

Extensions that are not secured to the wall or ceiling may

bend and separate due to thermal expansion.

▶ Secure each extension to the wall or ceiling using a pipe

clamp.

▶ Where possible, use the original pipe clamps from the

product range.

– If you are using standard pipe clamps, the tension-

ing range must be between 130 mm, 160 mm and

200 mm, and the bearing capacity must be at least

200 kg.

– The distance between two pipe clamps must not be

greater than the length of the extension.

– The pipe clamps must be isolated from structure-

borne sound.

– Downward gradient to the product: 3°

Note

3° corresponds to a downward gradient of

approx. 50 mm per metre of pipe length.

2.3.4 Risk of death from flue gas escaping from

openings in the flue pipe

All openings in the flue pipe that can be opened for inspection purposes must be closed before start-up and during operation.

▶ The openings of the flue pipe must only be opened by a

competent person.

2.3.5 Risk of fire and electronic damage caused

by missing lightning protection for the flue

gas installation

The product may be damaged by the effects of lightning and

this may lead to fires.

▶ If the building is equipped with a lightning protection sys-

tem, incorporate the air/flue gas pipe into the lightning

protection.

▶ If the vertical flue gas pipe contains materials made from

metal, incorporate it into the potential balancing system.

2.3.6 Risk of injury from snow falling from roofs

Where flue pipes penetrate the roof skin, the water vapour

contained in flue gas may precipitate as ice on the roof or the

roof structures in unfavourable weather conditions.

▶ At the installation site, ensure that this ice build-up does

not slide from the roof.

▶ If necessary, install an ice collection mesh.

The flue gas pipe expands when warm. If the pipes are obstructed when expanding, this may lead to a forced fracture

and flue gases will escape.

▶ Secure each of the pipe clamps to the wall or the ceiling

using a hanger bolt or threaded bolt M8/M10. This allows

for sufficient elasticity of the fastening in the event of

thermal expansion of the pipes.

▶ Secure the pipe clamps using hanger bolts or stud bolts.

Loads on the flue gas guiding may damage the flue gas pipe

and lead to flue gas escaping.

▶ Do not secure any loads to the flue gas guiding.

Mechanical impact loading of the flue gas pipe may damage

the flue gas pipe. Flue gases may escape.

▶ Do not install the flue gas pipe in areas with mechanical

impact loading. The flue gas pipe can also be protected

against impact using protection devices that are created

on-site.

Standing condensate can damage the seals of the flue gas

pipe.

▶ Route the horizontal flue pipe with a downward gradient.

6 Installation manual Air/flue gas system 0020058722_04

2.3.7 Risk of suffocation from lack of rear

ventilation

The flue gas pipe is not ventilated from behind.

If the installation room for the product is not ventilated, there

is a risk of suffocation.

▶ In the installation room, build a ventilation opening that

leads outside.

– Cross-sectional area: 150 cm²

2.3.8 Risk of corrosion in the flue gas installation

Sprays, solvents, cleaning agents, paints and adhesives may

contain substances that could lead to corrosion in the flue

gas installation in some circumstances when the product is

in operation.

▶ Ensure that the combustion air that is guided to the

product is kept free of chemical substances that may

contain fluorine, chlorine, or sulphur, for example.

▶ Only use appropriate Vaillant components for installing

the flue gas guiding.

Safety 2

2.3.9 Inspect/clean chimneys to which former

solid fuel boilers were once connected

We recommend that you have chimneys inspected and

cleaned by a chimney sweep before the flue gas pipe is

installed if these chimneys were previously used to divert

flue gas away from solid-fuel-fired boilers but should now

supply combustion air. If it is not possible to adequately inspect/clean the chimney (e. g. due to construction features),

you can

– use a separate air supply or

– use open-flued operation for the system.

2.3.10 Risk of corrosion in the product caused by

using a chimney to which the former oilfired boiler was once connected

Chimneys that previously diverted the flue gas away from oilfired boilers should not be used to supply combustion air.

The combustion air may be charged with chemical deposits

and this leads to corrosion in the product.

2.3.11 Risk of fire due to insufficient clearance

▶ Ensure that the flue gas pipe outside the shaft has a min-

imum clearance of 5 cm from flammable components.

2.3.12 Moisture damage caused by incorrect

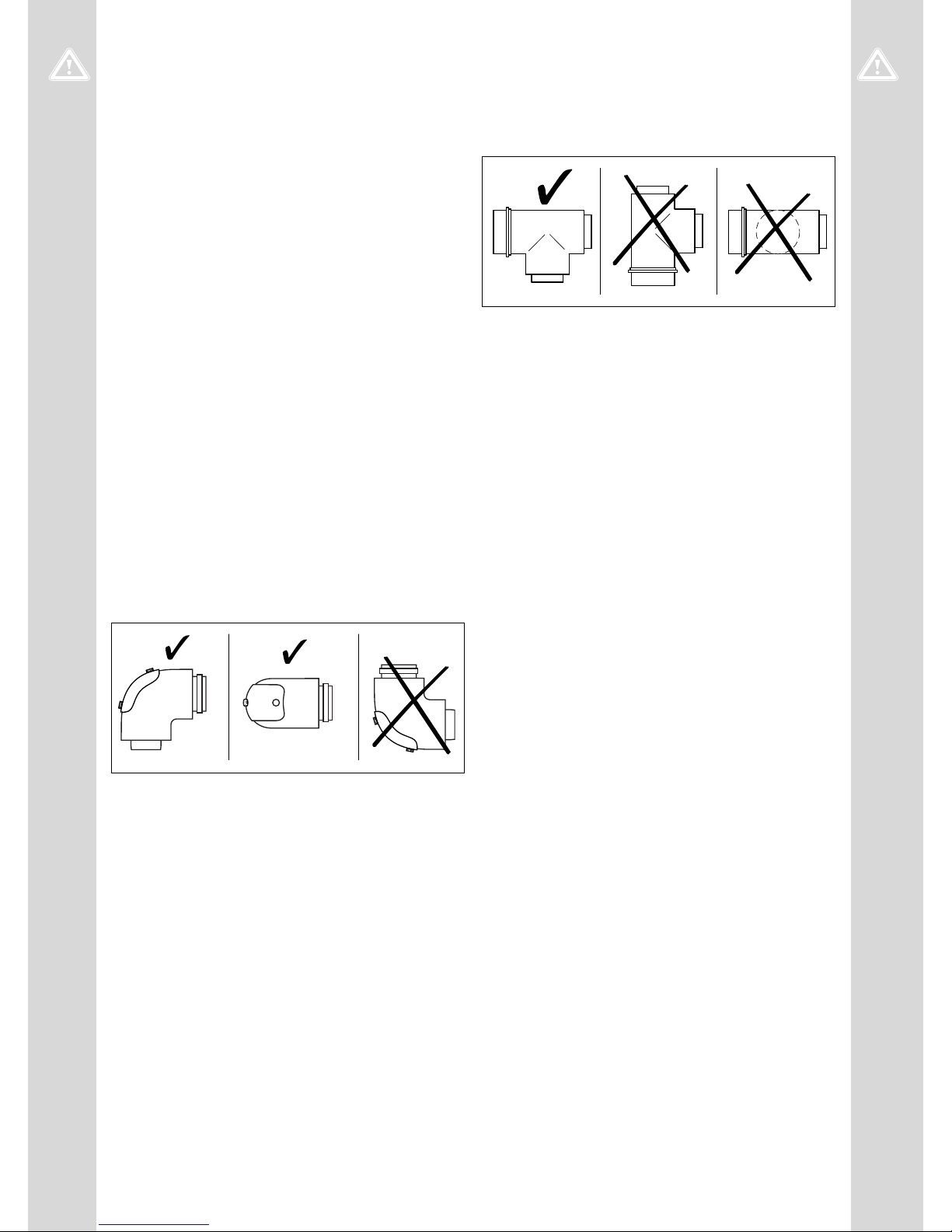

installation location of the inspection elbow

An incorrect installation location leads to condensate leaking

from the lid of the opening for cleaning and may lead to corrosion damage.

▶ Install the inspection elbow in accordance with the illus-

tration.

2.3.13 Moisture damage caused by incorrect

installation location of the inspection Tpiece

An incorrect installation location leads to condensate leaking

from the lid of the opening for cleaning and may lead to corrosion damage.

▶ Install the inspection T-piece in accordance with the illus-

tration.

2.3.14 Material damage due to improper use

and/or unsuitable tools

Improper use and/or the use of unsuitable tools may result in

material damage.

▶ Always use a suitable open-end spanner to tighten or

undo threaded connections.

▶ Do not use pipe wrenches, extensions, etc.

2.4 Intended use

2.4.1 Intended use of the Vaillant air/flue gas

systems

Vaillant air/flue gas systems are constructed using state-ofthe-art technology in accordance with the recognised safety

rules and regulations. Nevertheless, there is still a risk of

injury or death to the system operator or others or of damage

to the products and other property in the event of improper

use or use for which the products are not intended.

The Vaillant air/flue gas systems named in this manual must

only be used in combination with the product types named in

this manual.

Any other use that is not specified in these instructions, or

use beyond that specified in this document, shall be considered improper use.

Intended use includes the following:

– observance of accompanying operating, installation and

servicing instructions for the Vaillant product as well as

for all other components of the system

– installing and fitting the product in accordance with the

product and system approval

– compliance with all inspection and maintenance condi-

tions listed in the instructions.

0020058722_04 Air/flue gas system Installation manual 7

2.4.2 CE certification

The products are certified as boiler systems with attached

flue gas installation according to the EU gas appliances directive 90/396/EEC or 2009/142/EC.

2 Safety

This installation manual is a component of the certification

and is cited in the type testing certificate. In compliance

with the regulatory statutes of this installation manual, the

proof of usability of the products identified by Vaillant article

numbers that are designed for the flue pipe is provided. If

you do not use certified elements for the Vaillant flue pipe

when installing the products, this voids the CE conformity of

the product. We therefore strongly recommend that you fit

Vaillant air/flue gas systems.

2.5 Regulations (directives, laws, standards)

Please observe the existing national rules and regulations,

standards, laws and guidelines.

8 Installation manual Air/flue gas system 0020058722_04

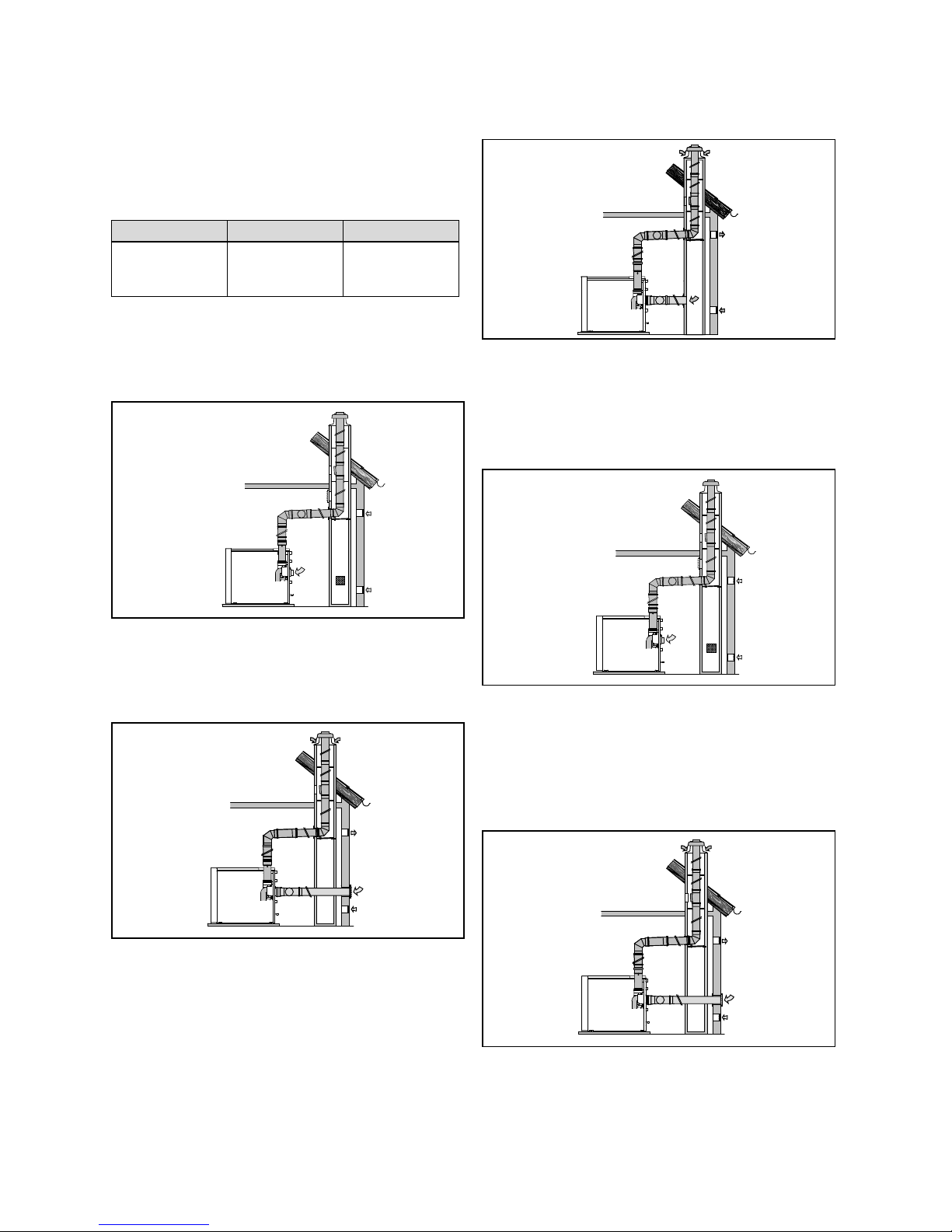

System overview 3

3 System overview

Observe the maximum pipe lengths, see "Maximum pipe

lengths" (→ Page 12).

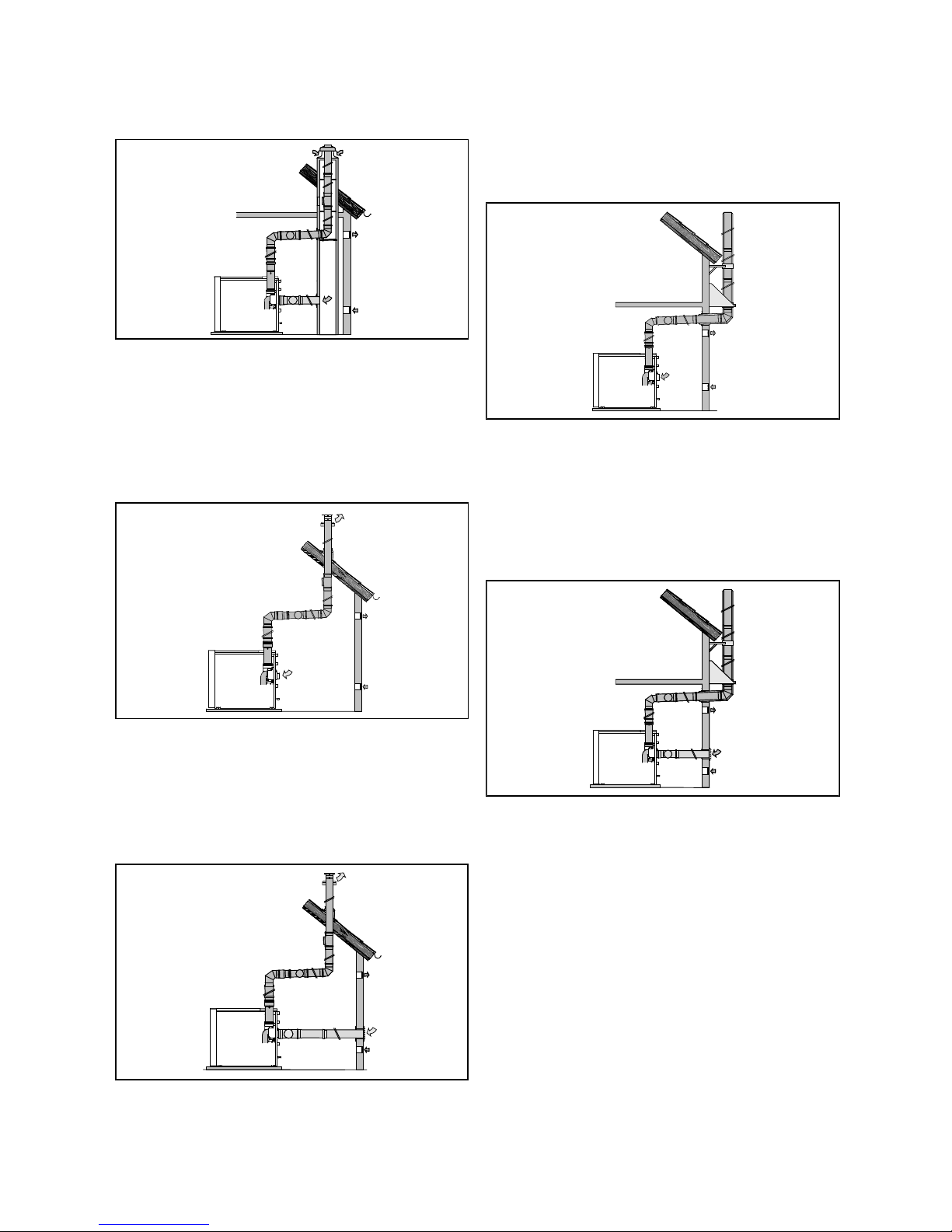

3.1 Combination options for systems with VKK

130 mm diameter 160 mm diameter 200 mm diameter

VKK 806/3-E-HL

VKK 1206/3-E-HL

VKK 1606/3-E-HL

3.2 130 mm diameter system

3.2.1 Flue gas pipe in the shaft, combustion air

from the installation room

VKK 806/3-E-HL

VKK 1206/3-E-HL

VKK 1606/3-E-HL

VKK 2006/3-E-HL

VKK 2406/3-E-HL

VKK 2806/3-E-HL

3.2.3 Flue gas pipe in the shaft, combustion air

from the shaft

▶ Installing the 130 mm diameter system (→ Page 18)

3.3 160 mm diameter, 200 mm diameter system

3.3.1 Flue gas pipe in the shaft, combustion air

from the installation room

▶ Installing the 130 mm diameter system (→ Page 18)

3.2.2 Flue gas pipe in the shaft, combustion air

through the external wall

▶ Installing the 130 mm diameter system (→ Page 18)

▶ Installing the flue gas pipe in the shaft (→ Page 22)

▶ Flue gas connection and installing the horizontal flue gas

pipe (→ Page 31)

3.3.2 Flue gas pipe in the shaft, combustion air

through the external wall

▶ Installing the flue gas pipe in the shaft (→ Page 22)

▶ Installing the combustion air line in the external wall

(→ Page 31)

▶ Flue gas connection and installing the horizontal flue gas

pipe (→ Page 31)

0020058722_04 Air/flue gas system Installation manual 9

3 System overview

3.3.3 Flue gas pipe in the shaft, combustion air

from the shaft

▶ Installing the flue gas pipe in the shaft (→ Page 22)

▶ Installing the combustion air line in the shaft (→ Page 31)

▶ Flue gas connection and installing the horizontal flue gas

pipe (→ Page 31)

3.3.4 Flue gas pipe through the roof, combustion

air from the installation room

▶ Flue gas connection and installing the horizontal flue gas

pipe (→ Page 31)

3.3.6 Flue gas pipe on the external wall,

combustion air from the installation room

1. Installing the flue gas pipe on the external wall

(→ Page 26)

2. Flue gas connection and installing the horizontal flue

gas pipe (→ Page 31)

3.3.7 Flue gas pipe on the external wall,

combustion air through the external wall

▶ Installing the roof duct (→ Page 26)

▶ Flue gas connection and installing the horizontal flue gas

pipe (→ Page 31)

3.3.5 Flue gas pipe through the roof, combustion

air through the external wall

▶ Installing the roof duct (→ Page 26)

▶ Installing the combustion air line in the external wall

(→ Page 31)

▶ Installing the flue gas pipe on the external wall

(→ Page 26)

▶ Installing the combustion air line in the external wall

(→ Page 31)

▶ Flue gas connection and installing the horizontal flue gas

pipe (→ Page 31)

10 Installation manual Air/flue gas system 0020058722_04

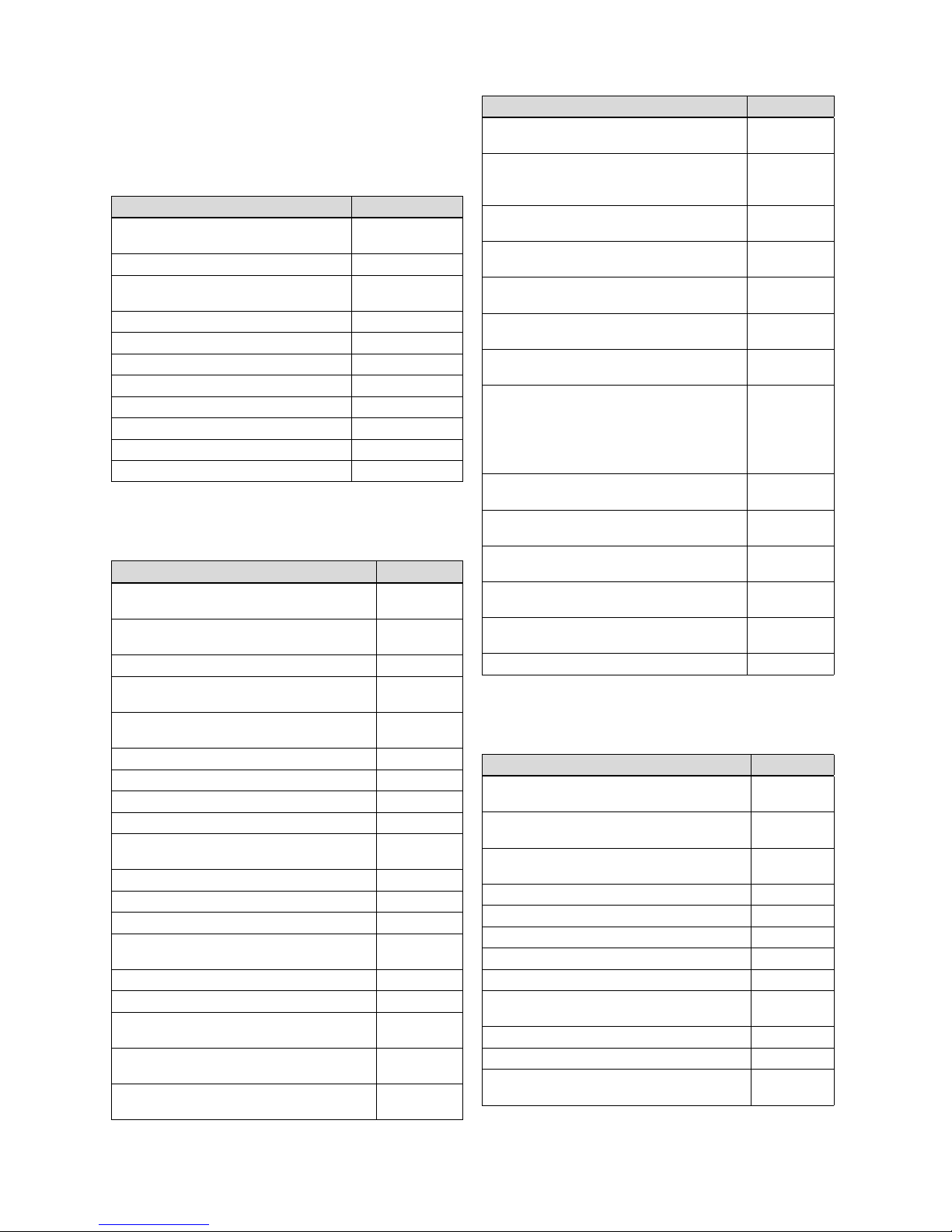

Certified air/flue gas systems and components 4

4 Certified air/flue gas systems and

components

4.1 Certified air/flue gas systems and

components, 130 mm diameter

Components Art. no.

Basic set for shaft installation (PP),

130 mm diameter

Spacer (PP), 7 pcs, 130 mm diameter 0020042763

Inspection opening with cover (PP),

130 mm diameter

87° elbow (PP), 130 mm diameter 0020042765

45° elbow (PP), 130 mm diameter 0020042766

30° elbow (PP), 130 mm diameter 0020042767

15° elbow (PP), 2 pcs, 130 mm diameter 0020042768

Extension (PP), 1.0 m, 130 mm diameter 0020042769

Extension (PP), 2.0 m, 130 mm diameter 0020042770

Extension (PP), 0.5 m, 150 mm diameter 0020095543

Basic set for air intake, 130 mm diameter 0020060591

4.2 Certified air/flue gas systems and

components, 160 mm diameter

Components Art. no.

Unit connection (PP) with measurement opening, 150 – 160 mm diameter

Basic set for shaft installation (PP), 160 mm

diameter

Set for air intake (PP), 160 mm diameter 0020095535

End pipe (stainless steel), 0.5 m, 160 mm diameter

Installation aid with a line loop, 160 mm diameter

Extension (PP), 0.5 m, 160 mm diameter 0020095545

Extension (PP), 1.0 m, 160 mm diameter 0020095546

Extension (PP), 2.0 m, 160 mm diameter 0020095547

87° elbow (PP), 160 mm diameter 0020095552

87° elbow (PP) with inspection opening,

160 mm diameter

45° elbow (PP), 160 mm diameter 0020095556

30° elbow (PP), 160 mm diameter 0020095558

15° elbow (PP), 160 mm diameter 0020095560

Inspection element (PP) 0.21 m, 160 mm diameter

Spacer (1 pc), 160 mm diameter 0020095563

Spacer (4 pcs), 160 mm diameter 0020095565

Vertical roof duct (PP), concentric, 160/186 mm

diameter

Universal pitched roof tile (25° - 45°), black, for

roof duct, 160/186 mm diameter

Universal pitched roof tile (25° - 45°), red, for

roof duct, 160/186 mm diameter

0020042762

0020042764

0020095531

0020095533

0020095537

0020095541

0020095554

0020095561

0020095567

0020095568

0020095569

Components Art. no.

Flat roof penetration collar (aluminium), for the

roof duct, 160/186 mm diameter

External wall connection (stainless steel), elbow,

support console, external collar, 160/225 mm

diameter

External wall pipe bracket (stainless steel),

225 mm diameter

Extension (stainless steel) for external wall

laying, 0.5 m, concentric, 160/225 mm diameter

Extension (stainless steel) for external wall

laying, 1.0 m, concentric 160/225 mm diameter

Vertical roof duct (stainless steel) for external

wall laying, concentric, 160/225 mm diameter

Opening piece (stainless steel), 160/225 mm

diameter

Tile for pitched roof for 160/225 mm diameter

system, dependent on the angle

15° - 25°

25° - 35°

35° - 45°

Flat roof penetration collar (stainless steel) for

160/225 mm diameter system, stainless steel

Inspection element (stainless steel), 0.4 m,

160/225 mm diameter

Support elbow mounting rail, long version, 500mm0020095539

Air clamp (stainless steel) for 160/225 mm

diameter

45° elbow (stainless steel) for external wall

laying, concentric, 160/225 mm diameter

Fastening clamp, 160 mm diameter 0020151162

0020095570

0020095573

0020095575

0020095577

0020095579

0020095581

0020095583

0020095585

0020130600

0020130601

0020095587

0020095589

0020095540

0020095544

4.3 Certified air/flue gas systems and

components, 200 mm diameter

Components Art. no.

Unit connection (PP) with measurement opening,

200 mm diameter

Basic set for shaft installation (PP), 200 mm

diameter

End pipe (stainless steel), 0.5 m, 200 mm diameter

Installation aid with line loop, 200 mm diameter 0020095542

Extension (PP), 0.5 m, 200 mm diameter 0020095549

Extension (PP), 1.0 m, 200 mm diameter 0020095550

Extension (PP), 2.0 m, 200 mm diameter 0020095551

87° elbow (PP), 200 mm diameter 0020095553

87° elbow (PP) with inspection opening, 200 mm

diameter

45° elbow (PP), 200 mm diameter 0020095557

30° elbow (PP), 200 mm diameter 0020095559

Inspection element (PP), 0.5 m, 200 mm diameter

0020095532

0020095534

0020095538

0020095555

0020095562

0020058722_04 Air/flue gas system Installation manual 11

Loading...

Loading...