Page 1

vacon

ac drives

opte9

dual port ethernet option board

installation manual

®

Page 2

Page 3

vacon • 1

TABLE OF CONTENTS

Document: DPD01583D

Release date : 6/10/16

1. Safety...............................................................................................................4

1.1 Danger................................................................................................................................4

1.2 Warnings ............................................................................................................................5

1.3 Earthing and earth fault protection ...................................................................................6

2. OPTE9 Dual Port Ethernet - General................................................................7

2.1 New features ......................................................................................................................8

3. OPTE9 Ethernet board technical data ..............................................................9

3.1 General...............................................................................................................................9

3.2 Cables.................................................................................................................................9

4. Layout and connections..................................................................................10

4.1 Layout and connections ...................................................................................................10

4.2 LED Indications ................................................................................................................11

4.2.1 Profinet IO ........................................................................................................................12

4.3 Ethernet devices ..............................................................................................................13

4.3.1 Human to machine...........................................................................................................13

4.3.2 machine to machine.........................................................................................................14

4.4 Connections and wiring....................................................................................................15

4.4.1 Topology: Star ..................................................................................................................15

4.4.2 Topology: Daisy Chain ......................................................................................................15

4.4.3 Topology: Ring..................................................................................................................16

4.5 ACD (Address Conflict Detection) ....................................................................................20

5. Installation.....................................................................................................21

5.1 Installation in VACON® NX..............................................................................................22

5.2 Installation in VACON® 20...............................................................................................24

5.2.1 Frames MI1, MI2, MI3 ......................................................................................................24

5.2.2 Frames MI4, MI5 ..............................................................................................................27

5.3 Installation in VACON® 20 X and 20 CP ..........................................................................31

5.4 Installation in VACON® 100.............................................................................................33

5.5 installation in VACON® 100 X..........................................................................................36

5.6 PC Tools ...........................................................................................................................39

5.6.1 PC tool support ................................................................................................................39

5.6.2 Updating the OPTE9 option board firmware with VACON® Loader ...............................40

5.6.3 PC Tools for NX / NCIPConfig ..........................................................................................43

5.6.4 PC Tools for NX / NCDrive ...............................................................................................45

5.6.5 PC Tools for VACON® 100 and VACON® 20 / VACON® Live..........................................48

6. Commissioning ..............................................................................................51

6.1 Option board menu...........................................................................................................51

6.1.1 Option board parameters.................................................................................................51

6.1.2 Option board monitoring values ......................................................................................53

6.1.3 Communication protocol .................................................................................................53

6.1.4 IP Mode.............................................................................................................................54

6.1.5 IP Address ........................................................................................................................54

6.1.6 Communication timeout ..................................................................................................54

6.1.7 Profinet IO - Name of Station ..........................................................................................54

6.1.8 EIP Input and Output instance .........................................................................................55

6.1.9 EIP Product code offset ...................................................................................................55

6.1.10 Mode.................................................................................................................................55

6.1.11 MAC Address....................................................................................................................55

6.1.12 Modbus Unit Identifier .....................................................................................................55

6.2 Communication mode......................................................................................................56

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 4

vacon • 2

7. Modbus TCP / Modbus UDP ............................................................................57

7.1 Modbus UDP vs TCP.........................................................................................................58

7.2 Modbus communications.................................................................................................60

7.3 Data addresses in Modbus messages .............................................................................61

7.3.1 Modbus memory map ......................................................................................................61

7.3.2 Modbus data mapping......................................................................................................62

7.4 Modbus communication and connection timeout ...........................................................73

7.5 Quick setup.......................................................................................................................74

7.6 Modbus - example messages ..........................................................................................75

7.6.1 Example 1 - Write process data.......................................................................................75

7.6.2 Example 2 - Read process data .......................................................................................76

7.6.3 Example 3 - Exception response .....................................................................................77

8. PROFINET IO ..................................................................................................78

8.1 PROFIdrive 4.1 profile ......................................................................................................78

8.2 PROFIdrive 4.1 state machine..........................................................................................78

8.3 PROFINET IO process communication ............................................................................79

8.3.1 Telegram types ................................................................................................................79

8.3.2 Telegram building blocks ................................................................................................84

8.3.3 Quick setup.......................................................................................................................89

8.4 PROFIdrive IO parameters...............................................................................................89

8.4.1 Parameters of the PROFIdrive.........................................................................................89

8.4.2 Vendor-specific PROFIdrive parameters.........................................................................91

8.4.3 PROFIdrive signal numbers.............................................................................................92

8.4.4 User specific record data.................................................................................................95

8.4.5 Base Mode Parameter Access Model..............................................................................96

8.4.6 Parameter responses ....................................................................................................100

8.4.7 Drive parameter access using application ID................................................................104

8.4.8 Parameter channel examples .......................................................................................104

8.5 PROFINET IO communications and connection timeout...............................................108

9. EtherNet/IP..................................................................................................109

9.1 General information.......................................................................................................109

9.1.1 Overview .........................................................................................................................109

9.1.2 AC/DC Drive Profile........................................................................................................109

9.1.3 EDS file ...........................................................................................................................109

9.1.4 LED functionality ............................................................................................................110

9.1.5 Explicit Messaging .........................................................................................................111

9.1.6 EtherNet/IP communication and connection timeout...................................................116

9.2 Common Industrial Objects implemented by OPTE9 ....................................................118

9.2.1 CIP Objects .....................................................................................................................118

9.2.2 Vendor Specific Objects .................................................................................................143

9.3 Assembly instances implemented by OPTE9 ................................................................151

9.3.1 CIP I/O Assembly instances for AC/DC Drive ................................................................151

9.3.2 Vendor-specific I/O Assembly Instances.......................................................................155

9.3.3 Mapping of Standard Output Assemblies onto VACON® data......................................165

9.3.4 Mapping of VACON® data onto Standard Input Assemblies ........................................166

9.4 EtherNet/IP connection example ..................................................................................168

10. Fault tracing.................................................................................................169

10.1 Typical fault conditions ..................................................................................................169

10.2 Other fault conditions ....................................................................................................170

11. APPENDIX 1 - PROCESS DATA......................................................................171

12. APPENDIX 2 - CONTROL AND STATUS WORD............................................... 172

12.1 Control Word bit description ...................................................................................172

12.2 Status Word Descriptions ........................................................................................174

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 5

vacon • 3

12.3 Control word bit support in drives...........................................................................175

12.4 Status word bit support in drives.............................................................................176

13. APPENDIX 3 - EXAMPLE WITH SIEMENS PLC .............................................. 177

14. APPENDIX 4 - EXAMPLE WITH SIEMENS SIMATIC PDM ...............................185

15. APPENDIX 5 - FIELDBUS PARAMETRISATION..............................................189

15.1 Fieldbus control and basic reference selection ............................................................189

15.2 Torque control parametrization ....................................................................................190

16. APPENDIX 6 - LWIP LICENCE .......................................................................191

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 6

vacon • 4 Safety

9000.emf

13006.emf

9001.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

1. SAFETY

This manual contains clearly marked cautions and warnings that are intended for your personal

safety and to avoid any unintentional damage to the product or connected appliances.

Read the information included in cautions and warnings carefully.

The cautions and warnings are marked as follows:

Table 1. Warning signs

= DANGER! Dangerous voltage

= WARNING or CAUTION

= Caution! Hot surface

1.1 Danger

The components of the power unit are live when the drive is connected to mains

potential. Coming into contact with this voltage is extremely dangerous and may

cause death or severe injury.

The motor terminals U, V, W and the brake resistor terminals are live when the

AC drive is connected to mains, even if the motor is not running.

After disconnecting the AC drive from the mains, wait until the indicators on the

keypad go out (if no keypad is attached, see the indicators on the cover). Wait 5

more minutes before doing any work on the connections of the drive. Do not open

the cover before this time has expired. After expiration of this time, use a

measuring equipment to absolutely ensure that no

ensure absence of voltage before starting any electrical work!

The control I/O-terminals are isolated from the mains potential. However, the

relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the AC drive is disconnected from mains.

voltage is present.

Always

Before connecting the AC drive to mains make sure that the front and cable

covers of the drive are closed.

During a ramp stop (see the Application Manual), the motor is still generating

voltage to the drive. Therefore, do not touch the components of the AC drive

before the motor has completely stopped. Wait until the indicators on the keypad

go out (if no keypad is attached, see the indicators on the cover). Wait additional 5

minutes before starting any work on the drive.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

Page 7

Safety vacon • 5

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

1.2 Warnings

The AC drive is meant for fixed installations only.

Do not perform any measurements when the AC drive is connected to the mains.

The earth leakage current of the AC drives exceeds 3.5mA AC. According to

standard EN61800-5-1, a reinforced protective ground connection must be

ensured. See Chapter 1.3.

If the AC drive is used as a part of a machine, the machine manufacturer is

responsible for providing the machine with a supply disconnecting device (EN

60204-1).

Only spare parts delivered by VACON® can be used.

At power-up, power break or fault reset the motor will start immediately if the

start signal is active, unless the pulse control for

Furthermore, the I/O functionalities (including start inputs) may change if

parameters, applications or software are changed. Disconnect, therefore, the

motor if an unexpected start can cause danger.

Start/Stop logic has been selected

.

The motor starts automatically after automatic fault reset if the auto restart

function is activated. See the Application Manual for more detailed information.

Prior to measurements on the motor or the motor cable, disconnect the motor

cable from the AC drive.

Do not touch the components on the circuit boards. Static voltage discharge may

damage the components.

Check that the EMC level of the AC drive corresponds to the requirements of your

supply network.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

Page 8

vacon • 6 Safety

13006.emf 13006.emf

1.3 Earthing and earth fault protection

CAUTION!

The AC drive must always be earthed with an earthing conductor connected to the earthing terminal

marked with .

The earth leakage current of the drive exceeds 3.5mA AC. According to EN61800-5-1, one or more

of the following conditions for the associated protective circuit must be satisfied:

a) The protective conductor must have a cross-sectional area of at least 10 mm2 Cu or 16

mm2 Al, through its total run.

b) Where the protective conductor has a cross-sectional area of less than 10 mm2 Cu or 16

mm2 Al, a second protective conductor of at least the same cross-sectional area must be

provided up to a point where the protective conductor has a cross-sectional area not less

than 10 mm2 Cu or 16 mm2 Al.

c) Automatic disconnection of the supply in case of loss of continuity of the protective

conductor.

The cross-sectional area of every protective earthing conductor which does not form part of the

supply cable or cable enclosure must, in any case, be not less than:

-2.5mm

-4mm

2

if mechanical protection is provided or

2

if mechanical protection is not provided.

The earth fault protection inside the AC drive protects only the drive itself against earth faults in the

motor or the motor cable. It is not intended for personal safety.

Due to the high capacitive currents present in the AC drive, fault current protective switches may

not function properly.

Do not perform any voltage withstand tests on any part of the AC drive. There is

a certain procedure according to which the tests must be performed. Ignoring

this procedure can cause damage to the product.

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from

http://drives.danfoss.com/knowledge-center/technical-documentation/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site http://drives.danfoss.com/knowledge-center/technical-documentation/

.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

Page 9

OPTE9 Dual Port Ethernet - General vacon • 7

2. OPTE9 DUAL PORT ETHERNET - GENERAL

The VACON® AC drives can be connected to the Ethernet networks using the VACON® OPTE9 Dual

Port Ethernet fieldbus option board (OPTE9). The drives can be daisy chained by utilizing two

Ethernet ports of OPTE9. The option board supports PROFINET IO, Ethernet/IP, Modbus TCP and

Modbus UDP fieldbus protocols. “EtherNet/IP

topologies are supported. See details in Chapter 4.4 "Connections and wiring".

•Star

•Daisy chain

•Ring

Every appliance connected to an Ethernet network has two identifiers: a MAC address and an IP

address. The MAC address (Address format: xx:xx:xx:xx:xx:xx) is unique for each appliance and

cannot be changed.The Ethernet board’s MAC address can be found on the sticker attached to the

board.

In a local network, IP addresses can be defined by the user as long as all the units connected to the

network are given the same network portion of the address. Overlapping IP addresses cause

conflicts between appliances. For more information about setting IP addresses, see Chapter 6.

TM

is a trademark of ODVA, Inc. The following network

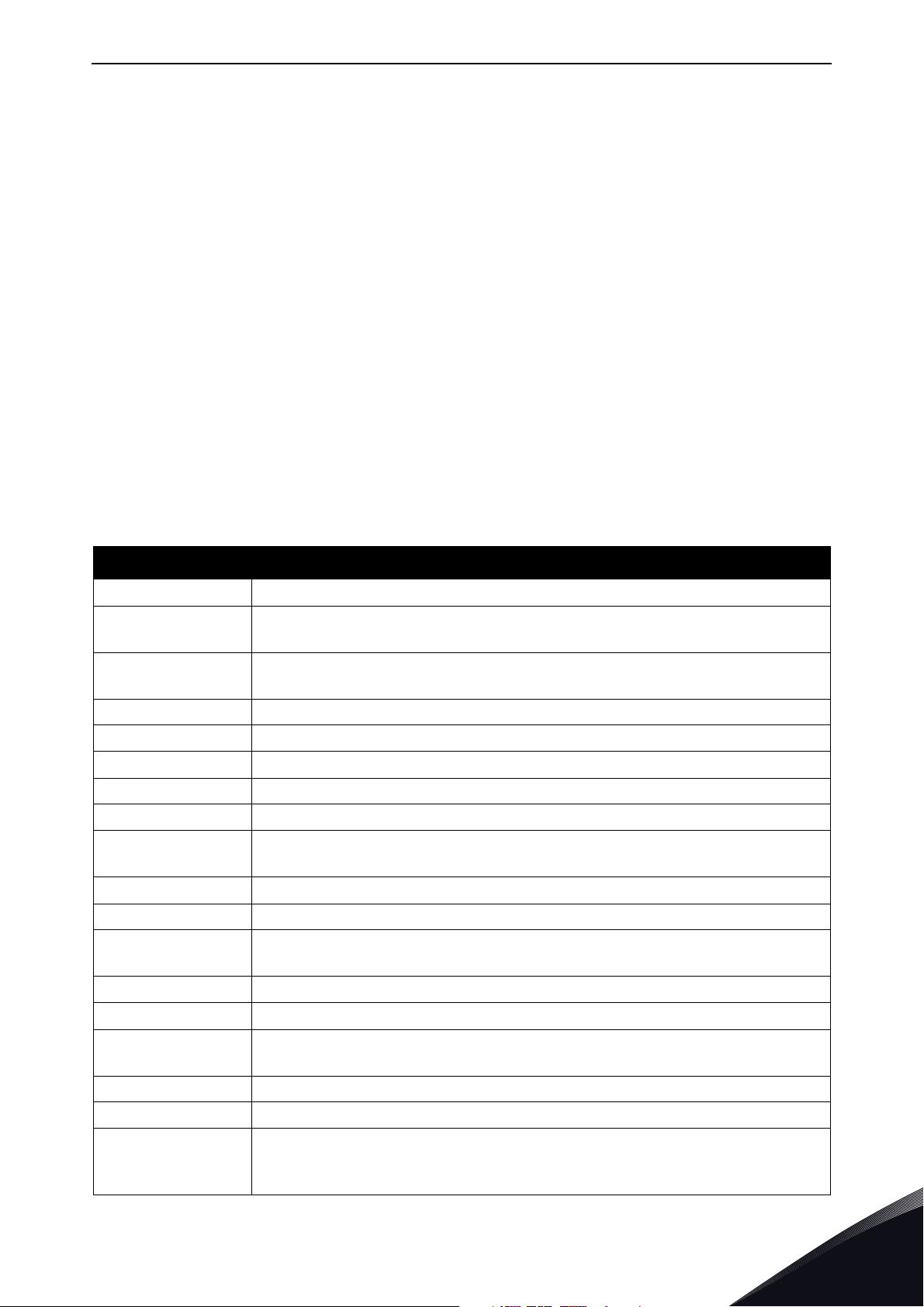

Table 2. List of abbreviations used in this document

Abbreviation Explanation

ACD Address Conflict Detection

CRC

DHCP

FB Fieldbus

GW Gateway

HI Upper 8/16 bits in a 16/32 bit value.

LO Lower 8/16 bits in a 16/32 bit value.

LWIP Light weight TCP/IP protocol stack for embedded systems.

Modbus TCP /

Modbus UDP

PDI Process data in (Profinet IO)

PDO Process data out (Profinet IO)

PHY(X)

PLC Programmable Logic Controller

Cyclic Redundancy Check is an error-detecting code commonly used in

fieldbusses to detect accidental changes to raw data.

Dynamic Host Configuration Protocol is used for dynamical resolving of network configuration parameters like an IP address.

Simple and vendor-neutral communication protocol intended for monitoring

and controlling of field devices.

Ethernet physical interface X, where X represents the number

of interface

PNU Parameter number (Profinet IO)

Profinet IO

RPM Revolutions per minute

RSTP Rapid Spanning Tree Protocol

TCP

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Profinet is a standard for industrial automation in Ethernet network. Profinet IO describes the exchange of data between controllers and field devices.

Transmission Control Layer provides reliable, ordered and error-checked

delivery of data streams between computers that are connected to a local

area network.

2

Page 10

vacon • 8 OPTE9 Dual Port Ethernet - General

Table 3. List of data types used in this document

Type name Bit size Explanation

INT8 8 Signed short integer

UINT8 8 Unsigned short integer

INT16 16 Signed integer

UINT16 16 Unsigned integer

INT32 32 Signed long integer

UINT32 32 Unsigned long integer

FLOAT32 32 32-bit floating point

STRING3 24 Three byte string

STRING5 40 Five byte string

2.1 New features

The following table shows the new features that are added in the OPTE9 Dual Port Ethernet's

firmware versions.

Table 4. New features

New feature Firmware version

EtherNet/IP protocol V004

Ethernet ring support (RSTP) V004

Address Conflict Detection (ACD) V004

Media Redundancy Protocol (MRP) V006

Simple Network Management Protocol (SNMP) V006

LLDP-MIB, LLDP-EXT-DOT3-MIB, LLDP-EXT-PNO-MIB V006

EDD files SIMATIC PDM V006

2

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 11

OPTE9 Ethernet board technical data vacon • 9

3. OPTE9 ETHERNET BOARD TECHNICAL DATA

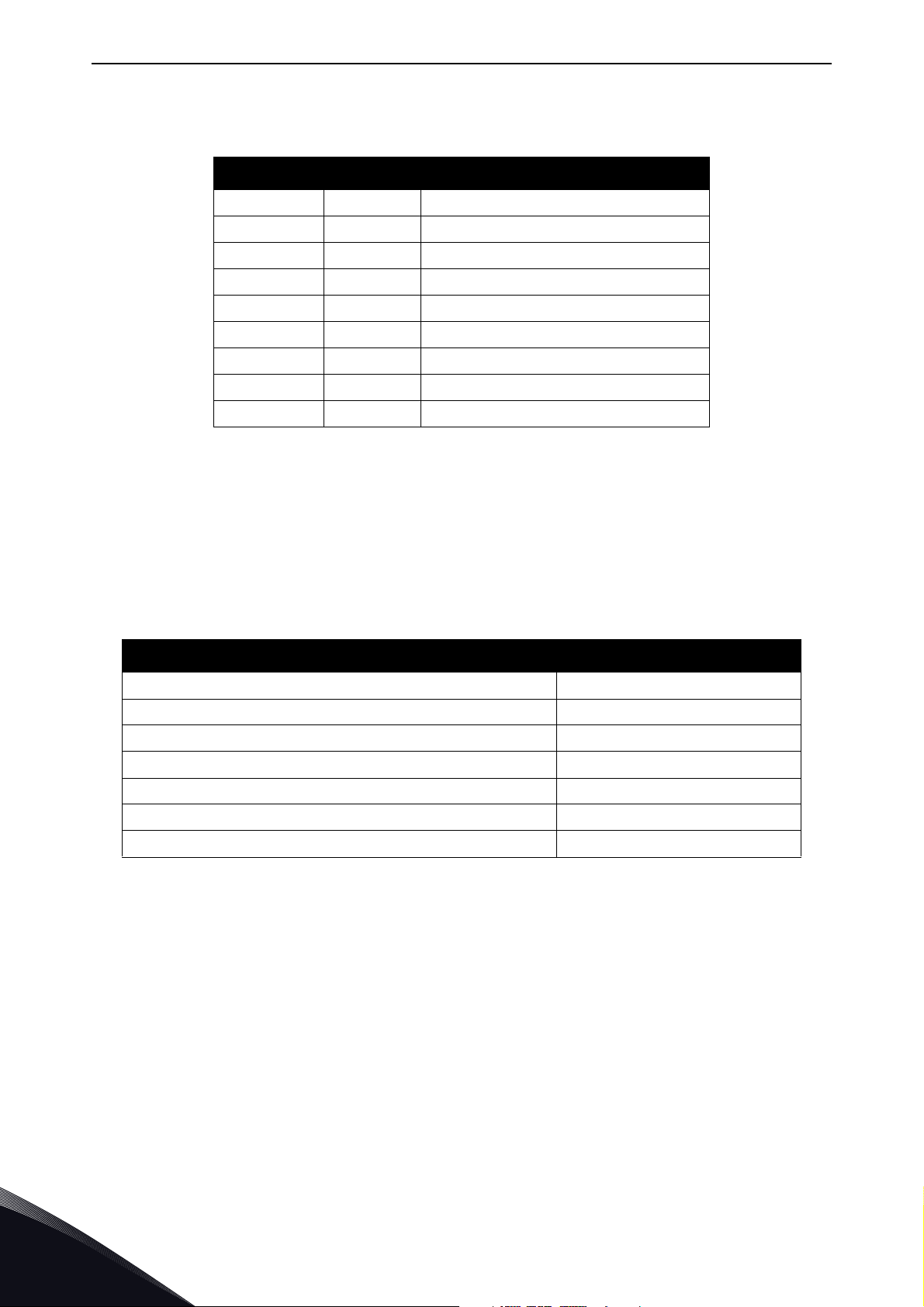

3.1 General

Table 5. Technical da ta

General Board name OPTE9

Ethernet connections

Communications

Protocol Modbus TCP, Modbus UDP, Profinet I/O, EtherNet/IP

Environment

Interface Two RJ-45 connectors

Transfer cable Shielded Twisted Pair (STP) CAT5e

Speed 10 / 100 Mb

Duplex half / full

Default IP-address By default the board is in DHCP mode

Ambient operating temperature

Storing temperature -40°C…70°C

Humidity <95%, no condensation allowed

-10°C…50°C

Altitude Max. 1000 m

Vibration 0.5 G at 9...200 Hz

Safety Fulfills EN50178 standard

3.2 Cables

For connecting the OPTE9 devices, use only Ethernet cables that meet at least the requirements of

category 5 (CAT5) according to EN 50173 or ISO/IEC 11801.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Page 12

vacon • 10 Layout and connections

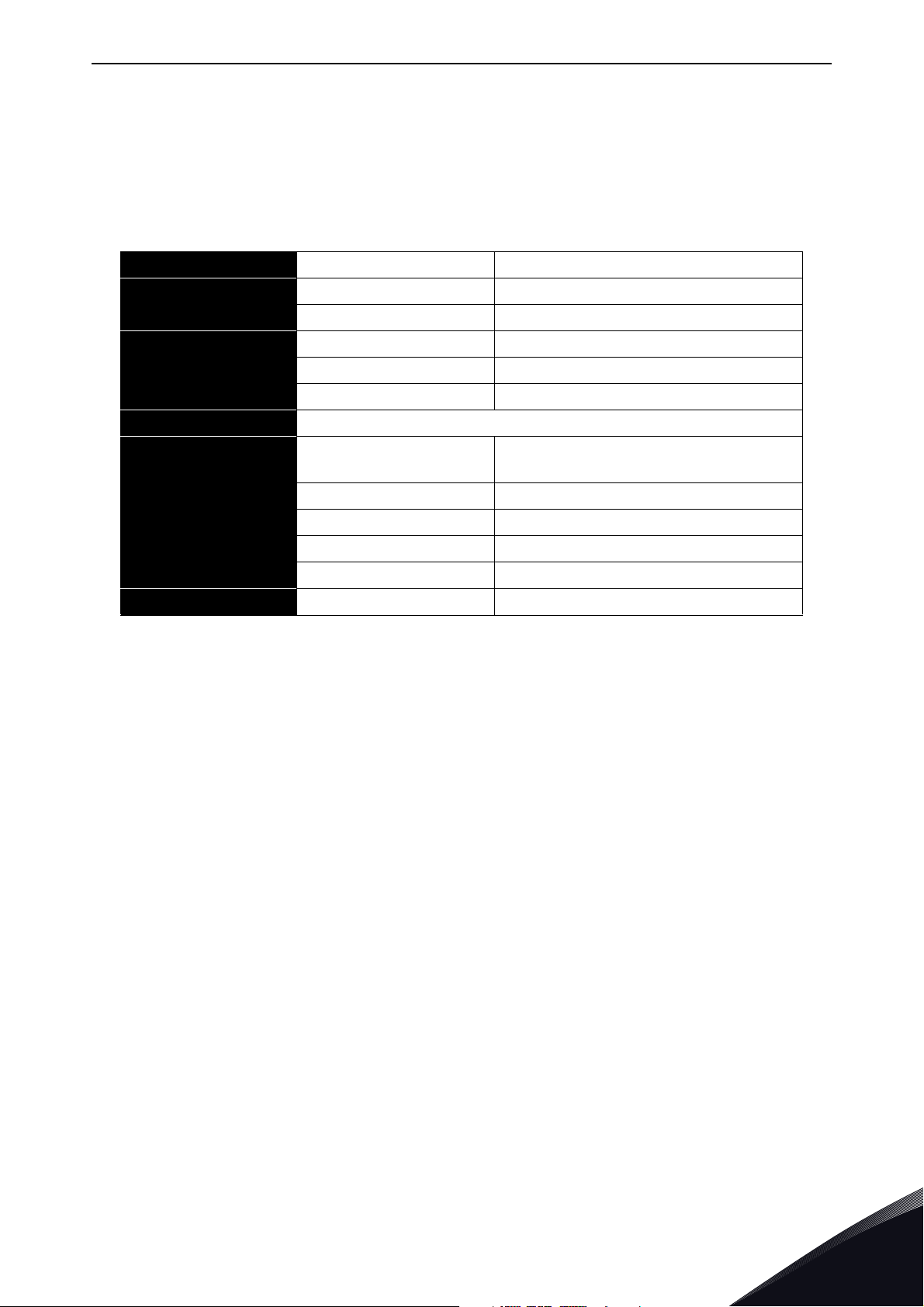

4. LAYOUT AND CONNECTIONS

The VACON® OPTE9 Dual Port Ethernet option board is connected to the Ethernet bus using the

standard RJ45 connectors (1 and 2). The communication between the control board and the AC drive

takes place through a standard VACON® Interface Board Connector.

4.1 Layout and connections

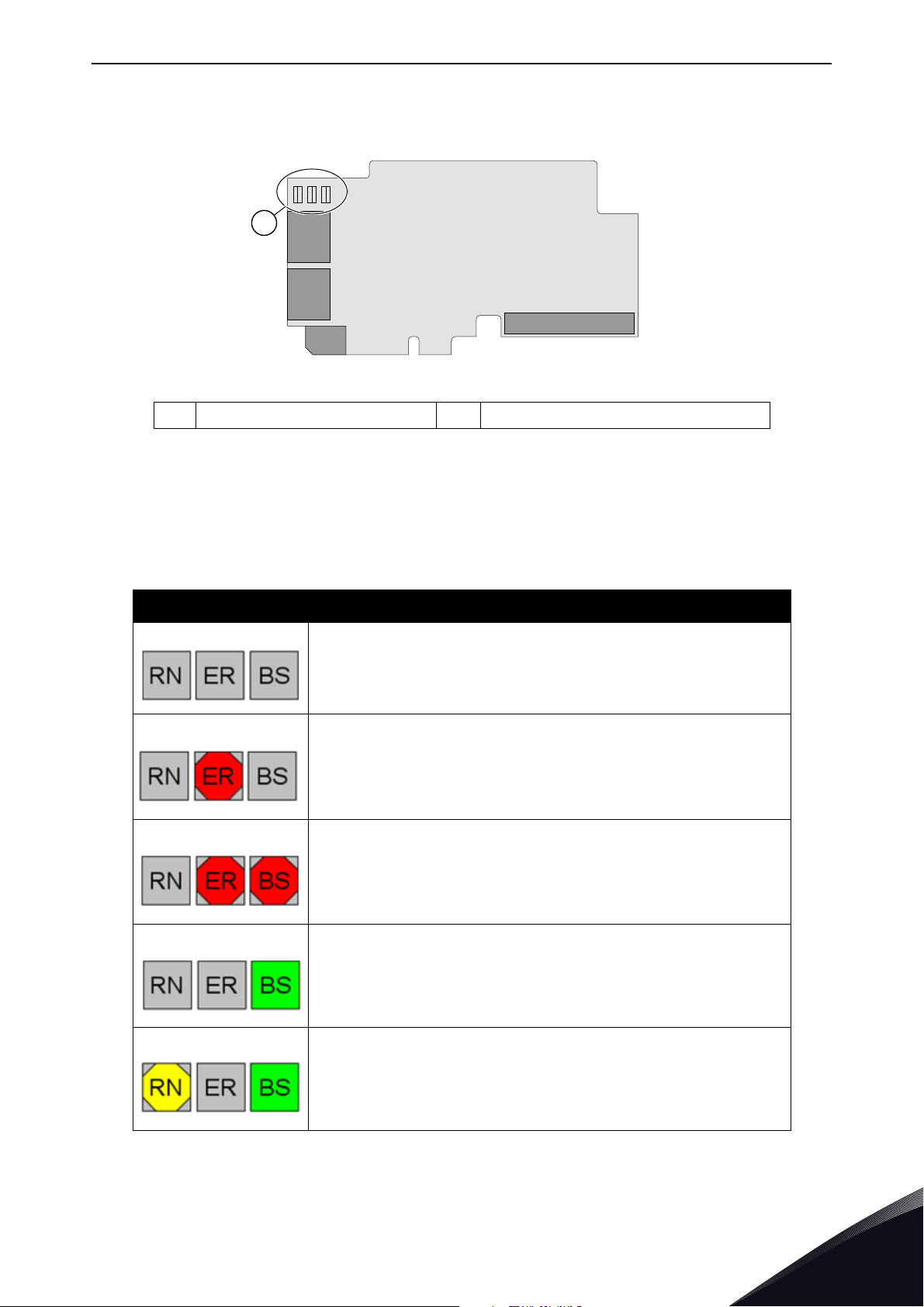

RN ER BS

A

1

B C

2

11592_00

A Ethernet connector C Interface Board connector

B Ethernet connector

Figure 1. The OPTE9 option board

Table 6. OPTE9 Ethernet ports

Ethernet port Description

1 Ethernet port 1 (PHY1)

2 Ethernet port 2 (PHY2)

4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 13

Layout and connections vacon • 11

RN ER BS

A

1

2

11593_00

4.2 LED Indications

ALED indications

Figure 2. The OPTE9 option board LED indicators

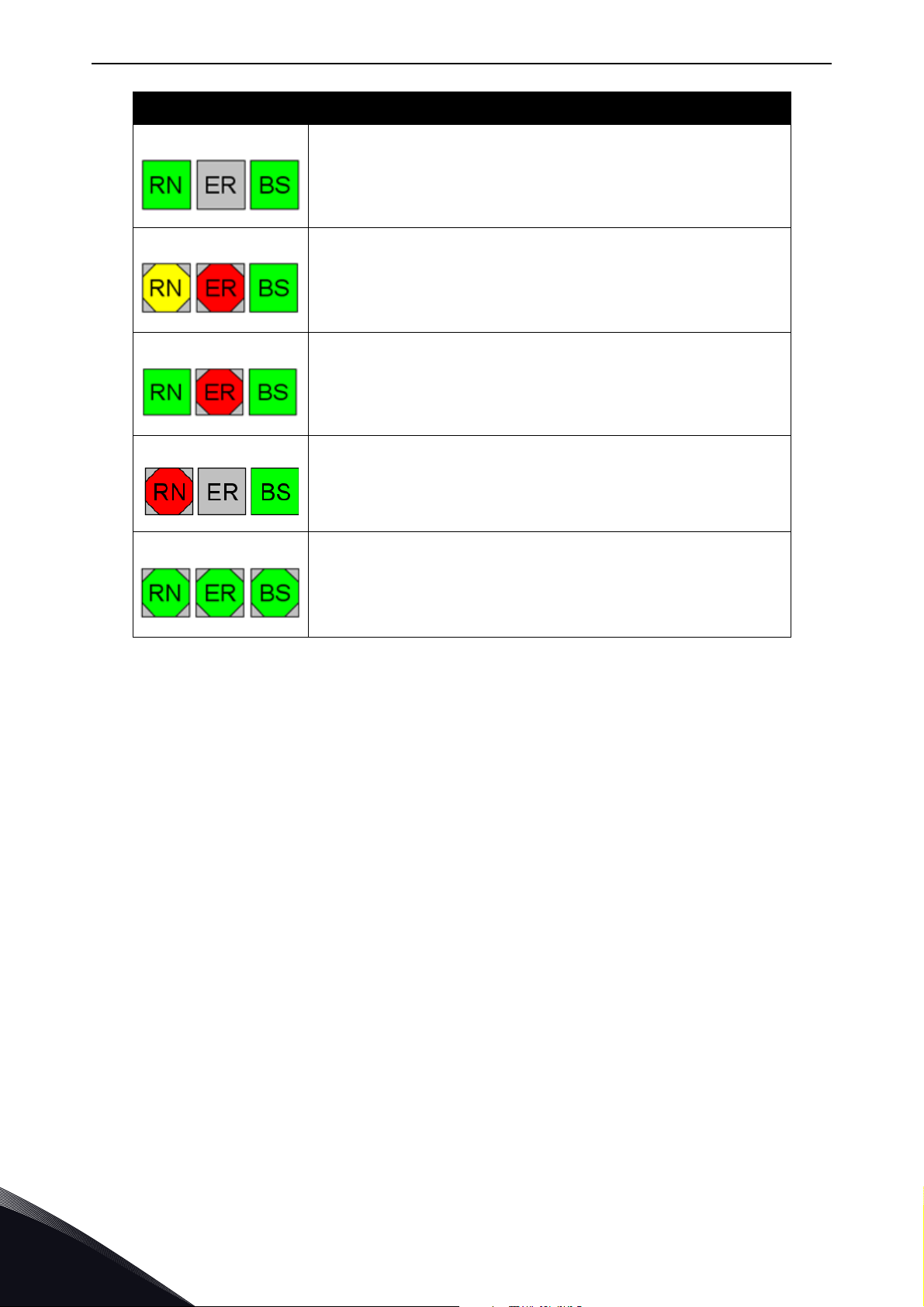

The table below lists possible LED combinations and their meanings. When the EtherNet/IP is

active, the option board follows CIP standard for LED indications. Therefore, the indications

described in Table 7 do not apply. See Chapter 9.1.4 "LED functionality".

Table 7. List of possible LED combinations

LED combinations Description

No power. All LEDs are OFF.

Option board firmware is corrupted or its software is missing.

ER is blinking (0.25s ON / 0.25s OFF)

Option board failure. Option board is not operational. BS and

possibly ER are blinking (2.5s ON / 2.5s OFF)

Option board is operational.

Protocol is ready for communications. RN is blinking (2.5s ON /

2.5s OFF).

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

Page 14

vacon • 12 Layout and connections

LED combinations Description

Protocol is communicating.

Protocol communication fault. ER is blinking to indicate a fault.

RN is blinking to indicate that protocol is again ready for

communications.

Protocol is communicating with an active fault. ER is blinking.

Duplicate IP address detected. RN is blinking.

Profinet IO only! In node flashing test all three LEDs are

blinking.

4.2.1 Profinet IO

When using the "Node Flashing Test" function, you can determine to which device you are directly

connected. For example, in Siemens S7, by using the menu command "PLC > Diagnostics/Setting >

Node Flashing Test..." you can identify the station directly connected to the PG/PC if all three LEDs

are flashing green.

4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 15

Layout and connections vacon • 13

Power

12345678

11594_uk

Vacon PC tools interface

- Parameters

- Slow rate actual

Values:

- Trends

- Fault history

Ethernet switch

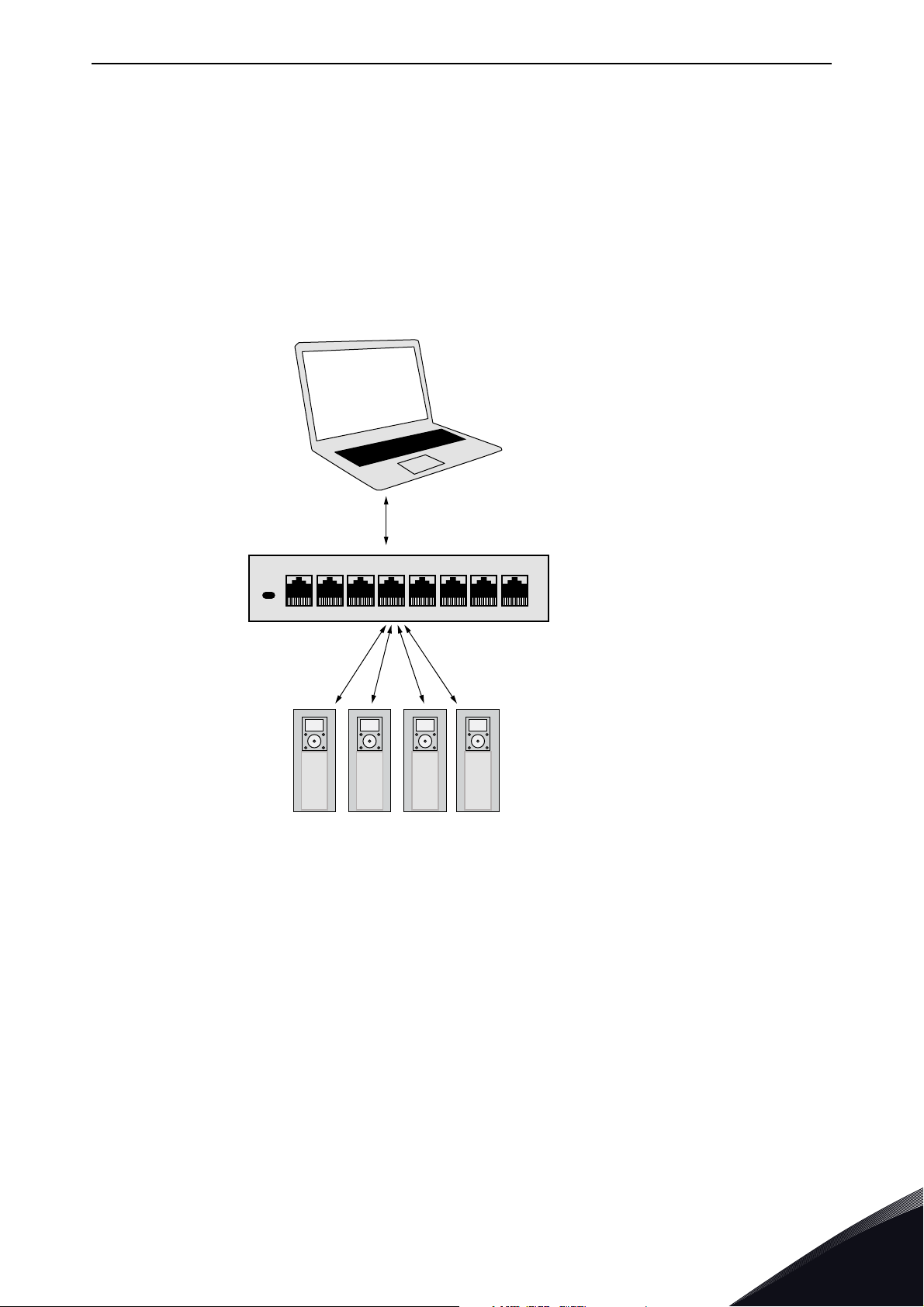

4.3 Ethernet devices

The common-use cases of Ethernet devices are 'human to machine' and 'machine to machine'. The

basic features of these two cases are presented in the pictures below.

4.3.1 Human to machine

Requirements:

- Graphical User Interface

- Relatively slow communication in use

NOTE! NCDrive can be used in NXS and NXP drives via Ethernet. VACON® Live can be used with

VACON® 100.

NOTE! The Ethernet connection to VACON® 20, VACON® 20 X and VACON® 20 CP via the OPTE9

Dual Port Ethernet is not yet supported.

Figure 3. Ethernet , Human to Machine

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

Page 16

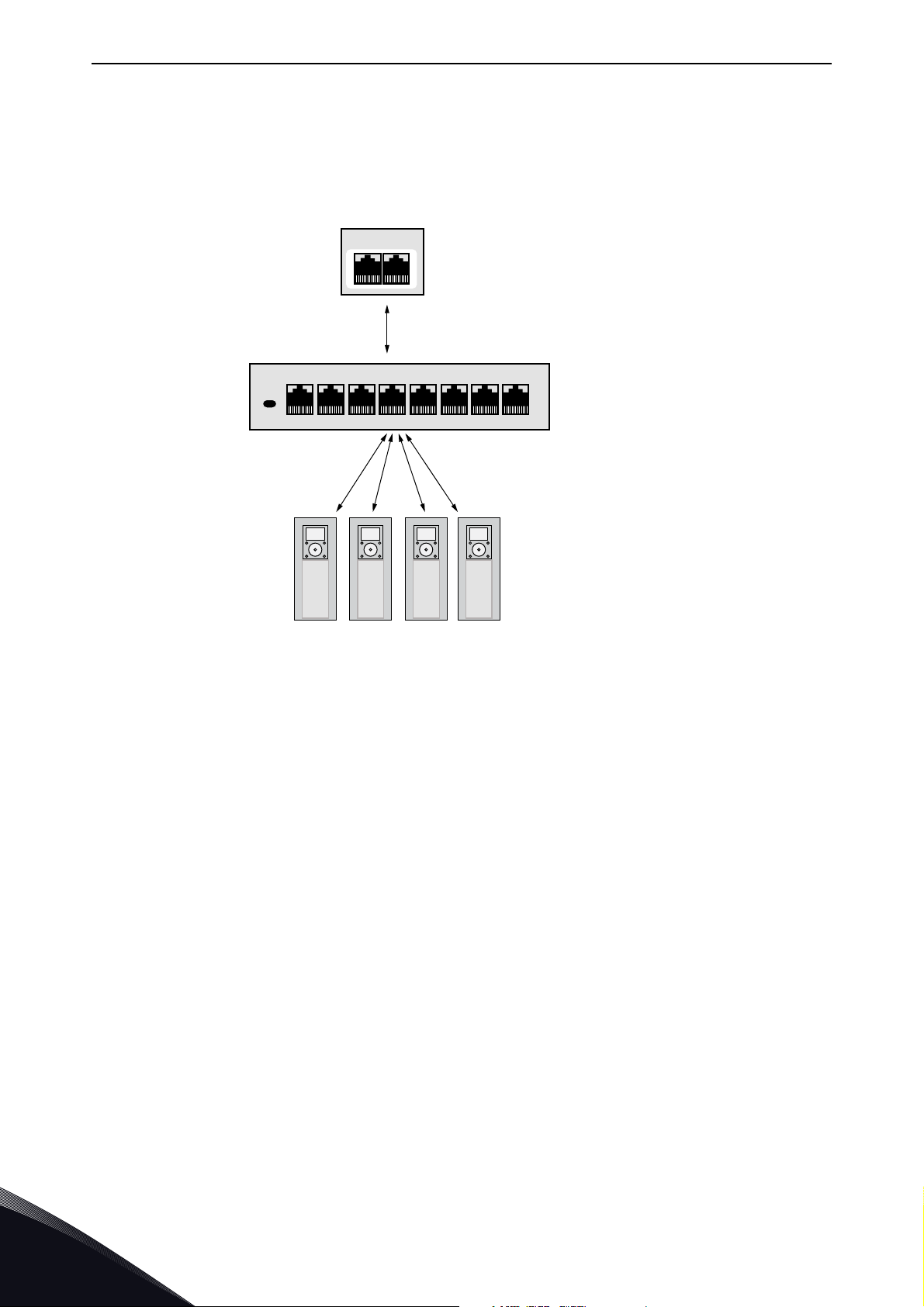

vacon • 14 Layout and connections

Power

12345678

11595_uk

MASTER

Real-Time Control

- Start/Stop, Direction,...

- Reference

- Feedback

Ethernet switch

4.3.2 machine to machine

Requirements:

- Industrial environment

- Fast communication in use

Figure 4. Ethernet, Machine to Machine

4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 17

Layout and connections vacon • 15

k

4.4 Connections and wiring

The OPTE9 has two Ethernet ports and an embedded switch. The option board is seen in network as

a single device as it has only one MAC and IP address. This configuration enables three different

topologies:

• Star (see Chapter 4.4.1)

• Daisy chain (see Chapter 4.4.2)

• Ring (see Chapter 4.4.3)

Each of these topologies has their own advantages and disadvantages. When designing the network

you must carefully consider the risks and benefits against the cost of the selected topology.

The OPTE9 supports 10/100Mb speeds in both Full- and Half-duplex modes. However, real-time

process control requires the Full-duplex mode and the 100-megabit speed. The boards must be

connected to the Ethernet network with a Shielded Twisted Pair (STP) CAT-5e cable (or better).

Use only industrial standard components in the network and avoid complex structures to minimize

the length of response time and the amount of incorrect dispatches. Because of the internal switch

in OPTE9, it does not matter in what port of the option board the Ethernet cables are connected to.

4.4.1 Topology: Star

In star network, all the devices are connected to the same switch(es). This topology reduces the

damage caused by single cable failure. It would affect only to a single drive instead of them all. In

this setup, a drive will receive only broadcast/multicast messages and messages directed to this

drive.

Only one port from the OPTE9 can be connected to a switch in the star topology. Connecting both

ports to switch(es) will cause an involuntary Ethernet ring which, in this setup, will break the

network.

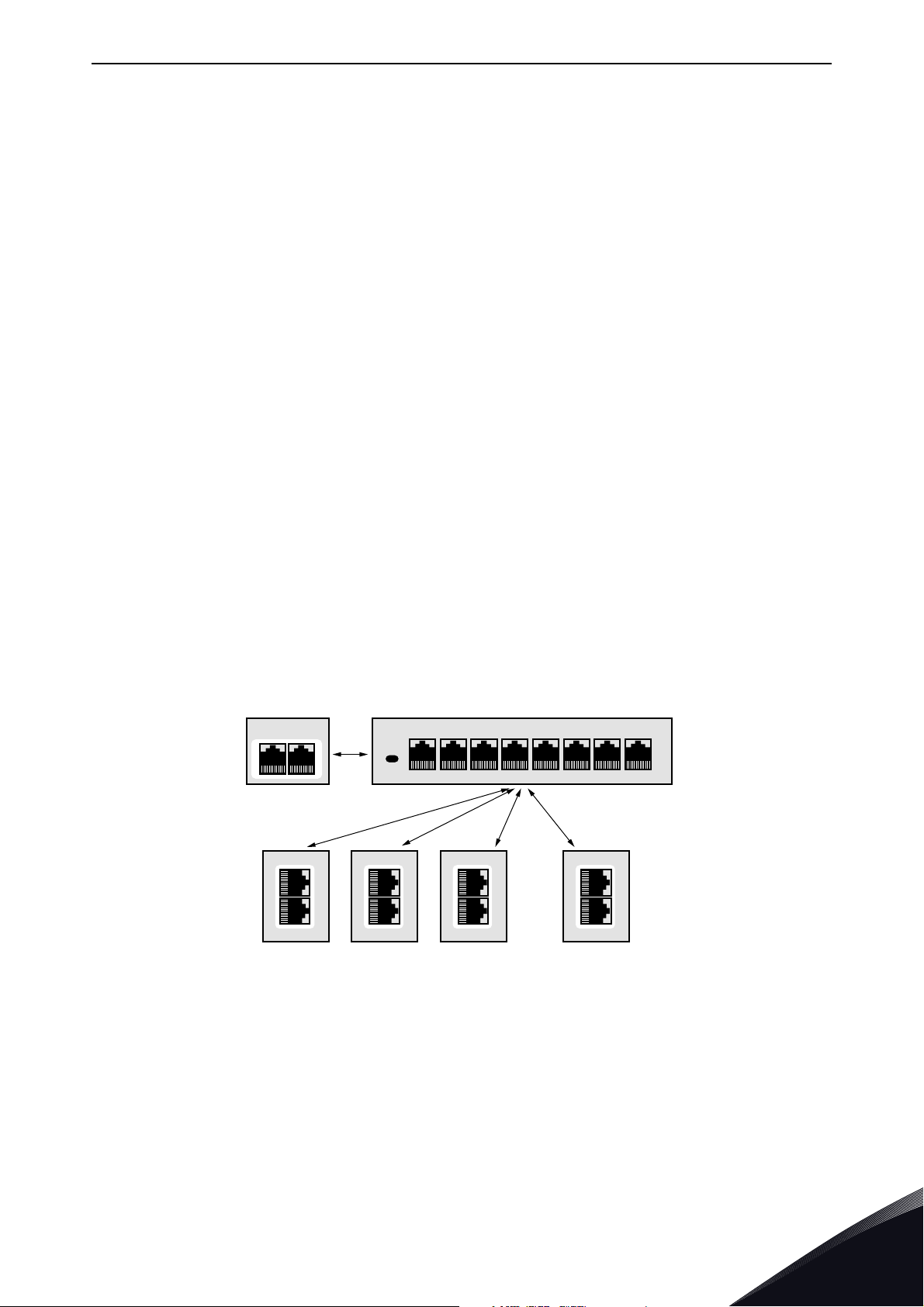

1PLC

2345678

Power

DRIVE

OPTE9-1

DRIVE

OPTE9-2

DRIVE

OPTE9-3

DRIVE

...

OPTE9-8

11660_u

Figure 5. Star Topology

4.4.2 Topology: Daisy Chain

The daisy-chaining allows you to reduce the costs for cabling and networking equipment such as

switches. The maximum number of daisy-chained boards is 32. This restriction comes from the

average latency (20 to 40 microseconds) per Ethernet switch. The drawback in the daisy chain

topology is that it increases traffic in all except the last drive. The first drive in the daisy chain sees

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

Page 18

vacon • 16 Layout and connections

PLC

DRIVE

OPTE9-1

DRIVE

...

OPTE9-2

DRIVE

OPTE9-3

DRIVE

OPTE9-8

11597A_uk

all the traffic in the chain. Also damage to a single cable will drop all drives behind it from the

network.

Both in daisy chain topology and in star topology, the last drive's port must not be connected back

to the same line. This would cause an involuntary Ethernet ring which will break the network.

Figure 6. Daisy chain topology

4.4.3 Topology: Ring

In some cases it is possible to use OPTE9 in a ring topology. These cases are explained in

Chapter 4.4.3.1 and Chapter 4.4.3.2. The ring topology gains the same reduced cabling cost as the

daisy chain topology, but decreases the damage caused by a single cable failure.

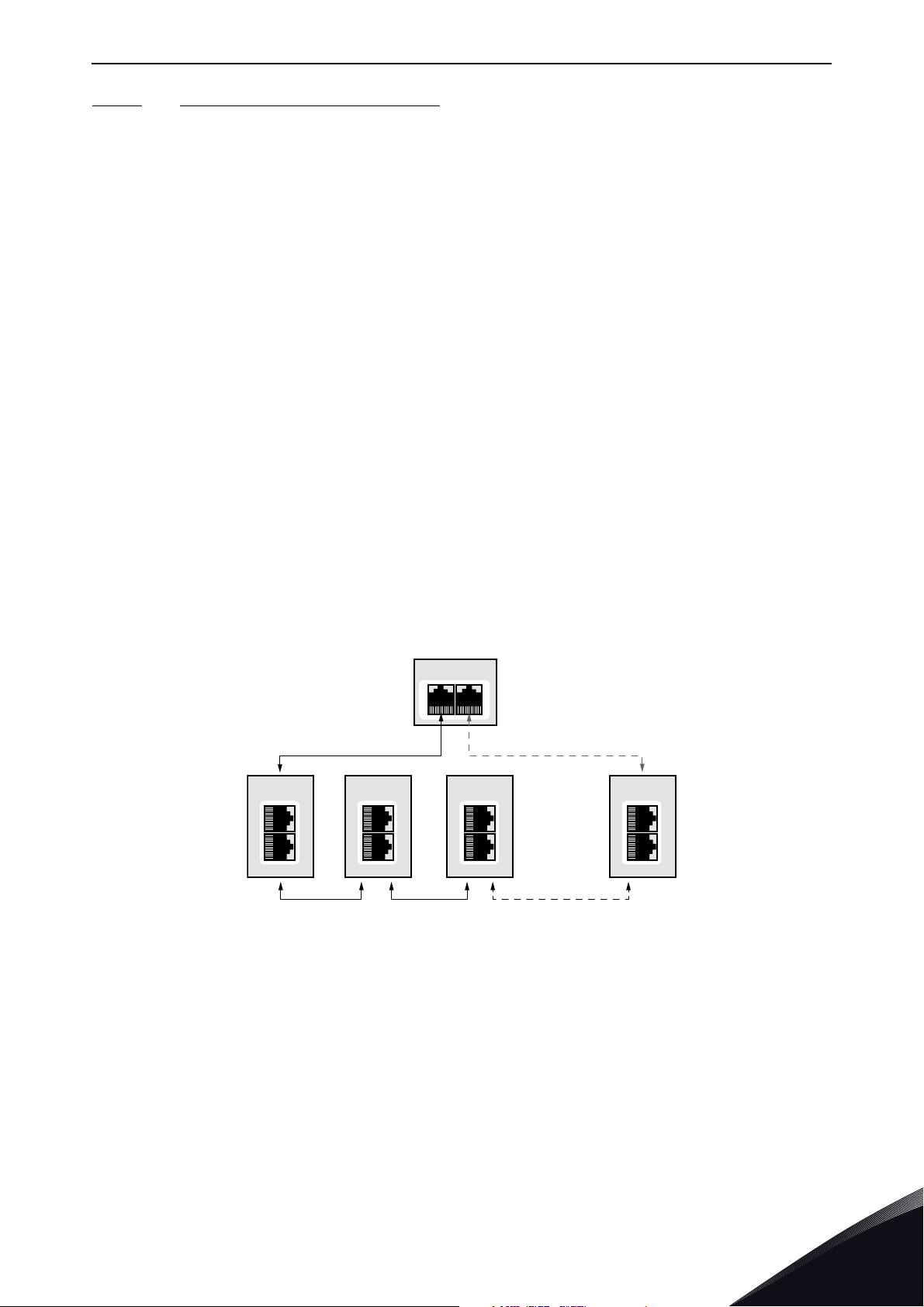

4.4.3.1

Rapid Spanning Tree Protocol (RSTP)

To use the RSTP protocol, add a managed Ethernet switch that supports the RSTP protocol. If a

single link is broken, the RSTP switch will notice this and start sending data from the PLC to both

directions effectively creating two daisy chains. When the link has been repaired, the switch will

notice this too and reverts back to normal operating mode. Compared to the star topology, the ring

topology adds more network traffic to almost all drives. Damage to two cables will always create an

isolated subnetwork.

In the RSTP configuration, one of the ports in the switch is "Designated Port" (DP) and the other

"Alternative Port" (AP). When the network is functioning properly, the traffic flows through the

designated port. Only the BPDU (Bridge Protocol Data Unit) packets are transferred through the AP

port. The BPDU packets are used by the switch to determine if the network is working properly. If it

detects that the BPDU packets do not go through the ring, it will change the alternative port to a

second designated port. Now the switch will send packets to both directions in the broken ring (see

Figure 8).

4

Each designated port has a list of MAC addresses which are behind that port. Only frames directed

to the device in the MAC list are forwarded into that designated port. The broadcast and multicast

frames are sent to all designated ports.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 19

Layout and connections vacon • 17

PLC

Managed switch with RSTP support

DRIVE

OPTE9-1

DRIVE

...

OPTE9-2

DRIVE

OPTE9-3

DRIVE

11661_uk

OPTE9-8

Power

12

DP AP

345678

PLC

Managed switch with RSTP support

DRIVE

OPTE9-1

DRIVE

...

OPTE9-2

DRIVE

OPTE9-3

DRIVE

11662_uk

OPTE9-8

Power

12

DP DP

345678

Figure 7. Ring topology

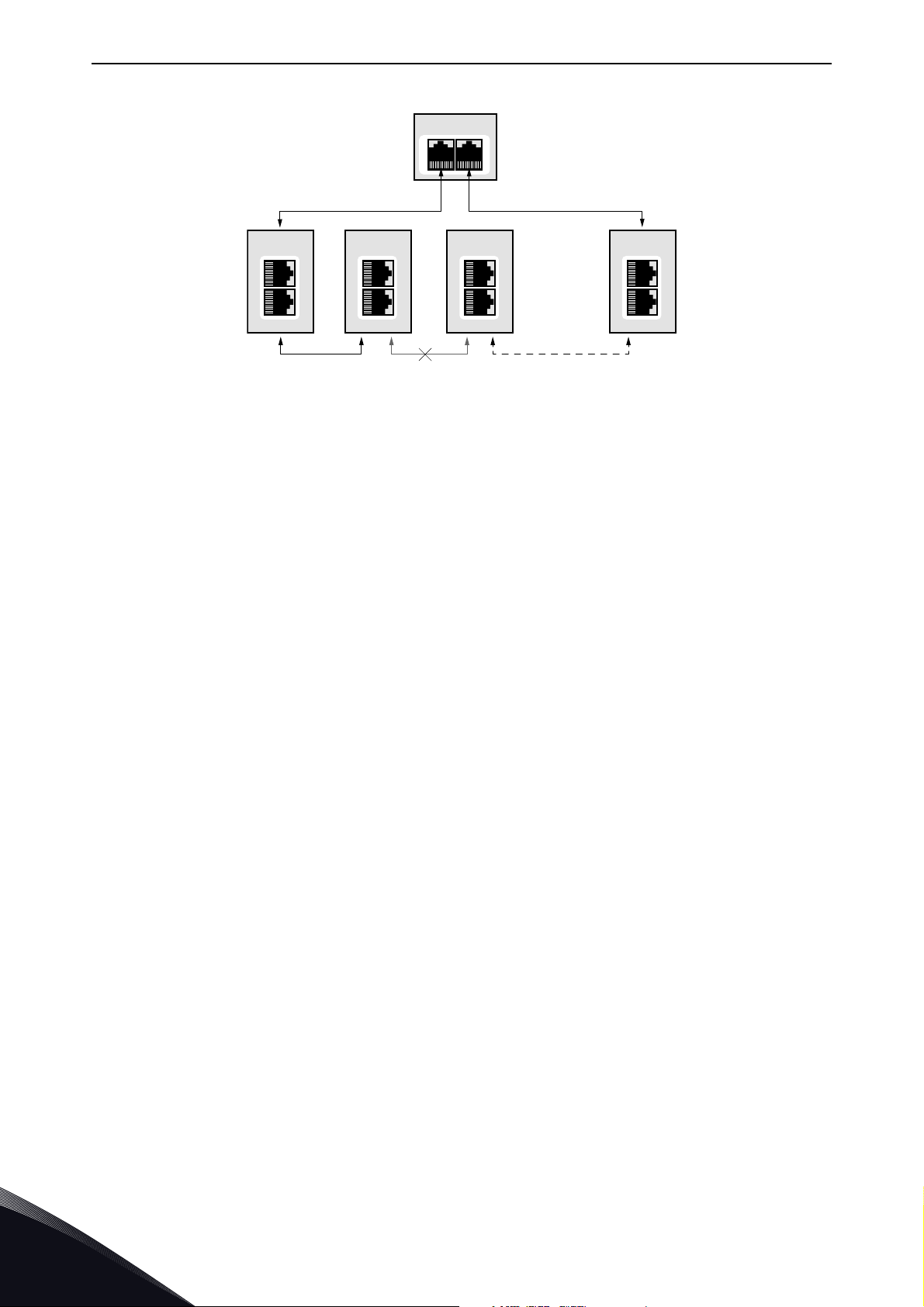

In the example below, the Ethernet communication will be interrupted to device number three and

other devices after that when the link is broken. The Fieldbus communication maybe faulted when

the link is broken, but when the switch enables the second designated port, the connections can be

reopened. In the RSTP protocol, it generally takes few seconds before the second designated port

will be activated. This depends on the BPDU exchange cycle, which is 2 seconds by default.

Figure 8. Ring topology: Error in network

NOTE! The OPTE9 switch itself does not implement the RSTP protocol, so the network will always

need a third party switch to support it.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

Page 20

vacon • 18 Layout and connections

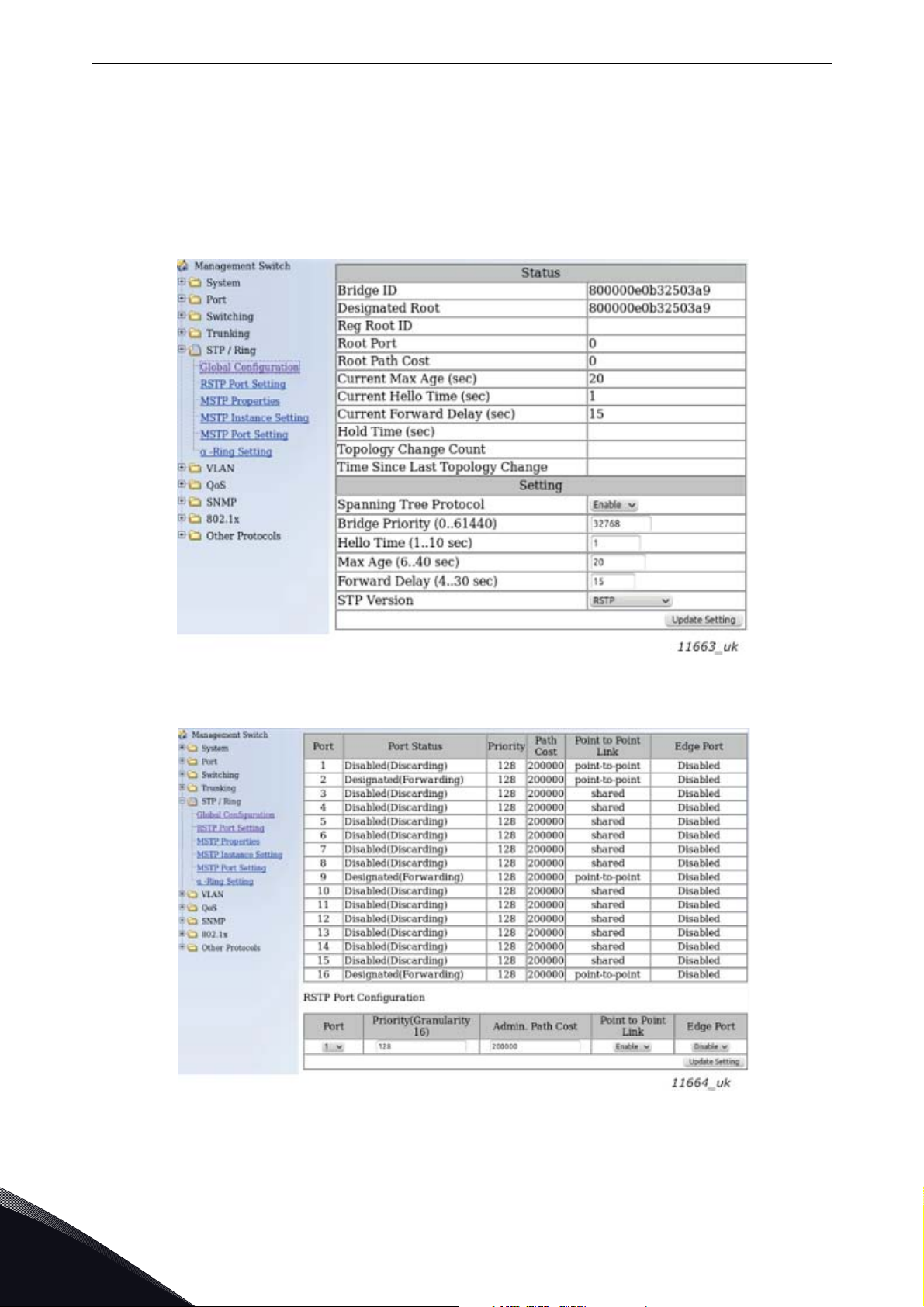

Configuration example

The screenshots below (Figure 9, Figure 10) show one example of configuring the RSTP in the switch

(in this case an EtherWAN switch). Port two is the designated port and port one is the alternative

port. The PLC was connected to port nine (the laptop taking the screenshots was in port 16). When

configuring your switch, refer to the switch manufacturer's manual.

Figure 9. EtherWAN Switch RSTP Configuration example

Figure 10. EtherWAN Switch RSTP Configuration example - Port Settings

4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 21

Layout and connections vacon • 19

4.4.3.2 Media Redundancy Protocol (MRP)

The MRP is designed to react deterministically on a cable failure. This makes it suitable to be used

in process automation. One of the nodes in the network has the role of Media Redundancy Master

(MRM), which observes and controls the ring topology in order to react to network faults. Usually

this device is PLC or network switch.

The other nodes in the network are called Media Redundancy Clients (MRC), and they react on

received configuration frames from the MRM and can detect link changes on its ring ports. OPTE9

supports only MRC functionality.

The MRM and MRC have two ring ports, which take one of the following states:

•DISABLED

- All frames are dropped

•BLOCKING

- All frames are dropped, except the following frames:

a) MRP frames (e.g. MRP_test and MRP_TopologyChange)

b) Frames specified to pass ports in "Discarding" state, e.g. LLDP frames

•FORWARDING

- All frames are forwarded according to normal behaviour

The MRM sends MRP_Test frames in a configured time period to monitor the state of the ring

topology. If the MRM receives its own MRP_Test frames (network is closed), one of the ring ports is

set to FORWARDING state and the other to BLOCKED state (see Figure 11). If the MRP_Test frames

are not received by the MRM (network is open), it sets both of its ring ports to FORWARDING state

(see Figure 12).

The following figure shows an example of a MRP network, where the PLC acts as a MRM.

PLC

MRM

Forwarding Blocked

DRIVE

MRC

OPTE9-1

DRIVE

MRC

OPTE9-2 OPTE9-3

DRIVE

MRC

...

DRIVE

MRC

OPTE9-8

11713_uk

Figure 11. MRP ring: Closed network

In the example below, the Ethernet communication will be interrupted to device number three and

other devices after that when the link is broken. MRP can be configured to send test frames with

different time periods, depending on the maximum allowed recovery time for the network. When

using PROFINET IO, the recovery time is defined as 200 ms. Therefore, if the recovery time if less

than the watchdog time, the fieldbus connection is not interrupted by the cable failure.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

Page 22

vacon • 20 Layout and connections

PLC

MRM

Forwarding Forwarding

DRIVE

MRC

OPTE9-1

DRIVE

MRC

OPTE9-2 OPTE9-3

DRIVE

MRC

...

DRIVE

MRC

OPTE9-8

11714_uk

Figure 12. MRP ring: Error in network

NOTE: The OPTE9 can use MRP (as MRC) only when PROFINET IO is the selected protocol. When

using MRP in a PROFINET IO network, it is suggested to set the watchdog time of each device in the

ring to 200ms, as this is the time that a network of 50 nodes is guaranteed to recover. MRP is

available in OPTE9 version V006 or later.

4.5 ACD (Address Conflict Detection)

The OPTE9 option board implements ACD algorithm (IETF RFC 5227). The implementation includes

requirements from the EtherNet/IP protocol.

The ACD algorithm tries to actively detect if the IP address configured to this device is been used by

another device in the same network. To accomplish this, ACD sends four ARP request packets when

the device's Ethernet interface goes up or when its IP address changes. ACD prevents the use of the

Ethernet interface until the ARP probing finishes. This delays the startup of fieldbus protocols about

one second. During the delay or after it, the ACD passively checks incoming ARP messages for use

of the device's IP address. If another device with the same IP address is detected, the ACD will try

to defend its IP address with a single ARP message. If the other device with the same IP address

also supports ACD, it should stop using the address. If not, the ACD will close the Ethernet

connection and indicate the situation with LEDs. This is done according the "DefendWithPolicyB".

Other policies are not supported. If the fieldbus protocol has been active, a fieldbus fault may be

activated (depends on the fieldbus and drive application configuration).

4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 23

Installation vacon • 21

5. INSTALLATION

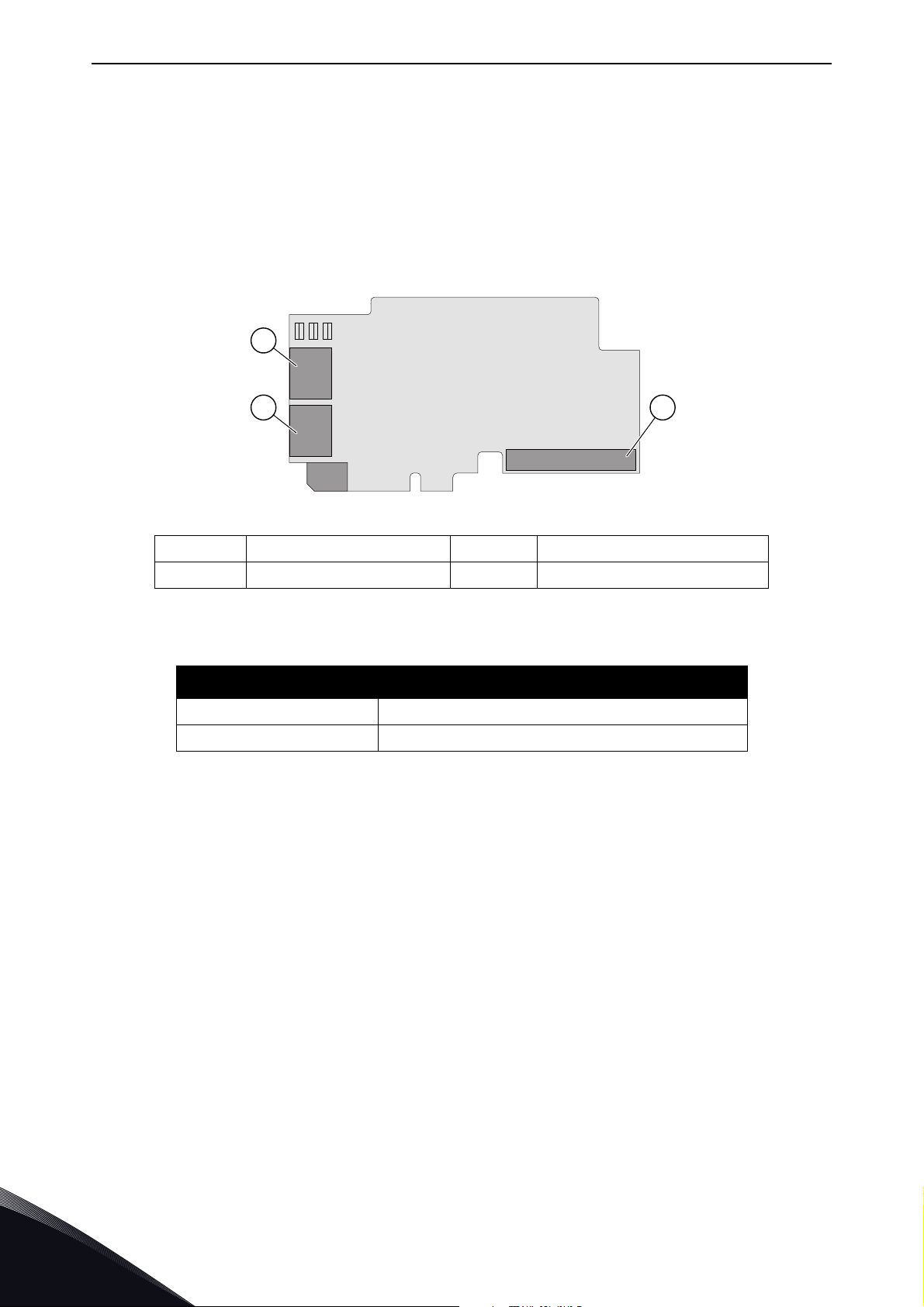

The VACON® OPTE9 Dual Port Ethernet option board can be used with the following VACON® AC

drives.

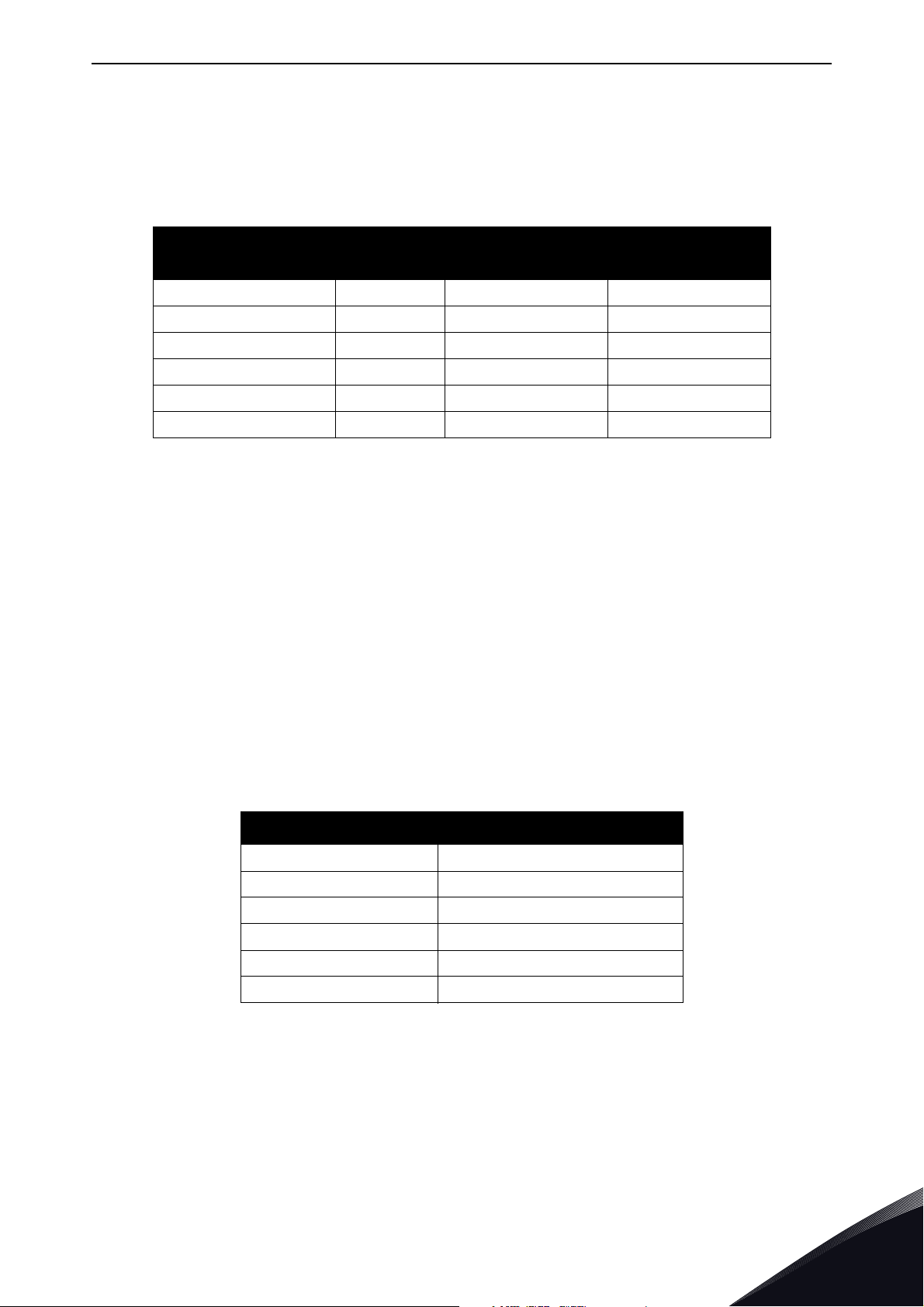

Table 8. Supported drives and slots

Drive Slots

VACON® NXP D, E NXP00002V188 V001

VACON® NXS D, E NXS00002V179 V001

VACON® 100 and 100 X D, E FW0072V018 V003

VACON® 100 FLOW D, E FW0159V012 V003

VACON® 20 - FW0107V011 V002

VACON® 20 X and CP - FW0117V007 V002

VACON® 100 Support

The VACON® 100 drives are supported from the OPTE9 firmware version V003. The process data in

VACON® 100 is 32 bit. The 32-bit process data support is planned for later firmware release. Only

16-bit process data is supported.

EtherNet/IP support

From drive SW

version on

From OPTE9 SW

version on

EtherNet/IP protocol was added to OPTE9 firmware version V004. The table below shows required

minimum drive firmware version .

Table 9. Required minimum drive firmware versions

Drive From drive SW version on

VACON® NXP NXP00002V191

VACON® NXS NXS00002V181

VACON® 100 and 100 X FW0072V018

VACON® 100 FLOW FW0159V012

VACON® 20 FW0107V012

VACON® 20 X and CP FW0117V009

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 24

vacon • 22 Installation

13006.emf

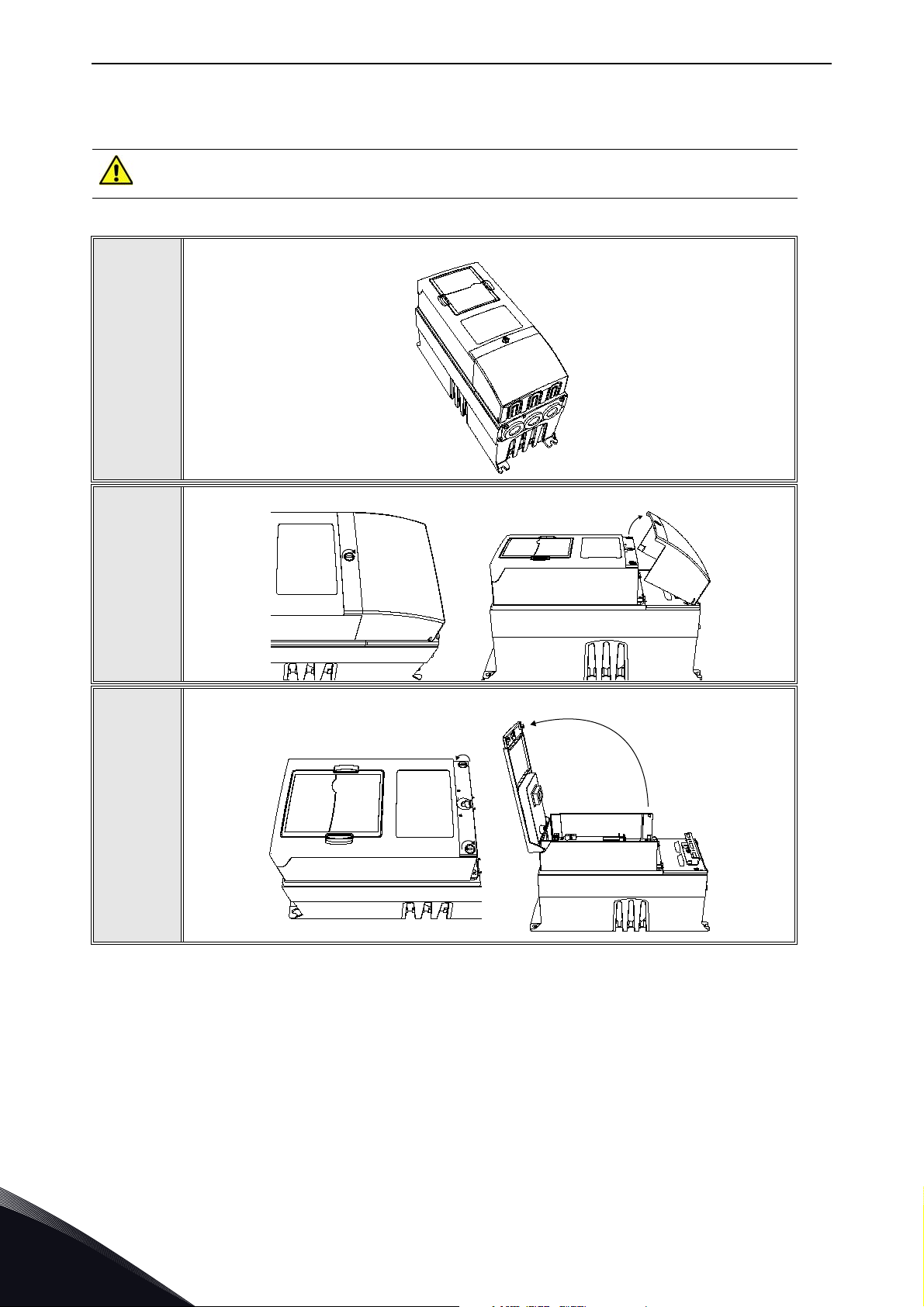

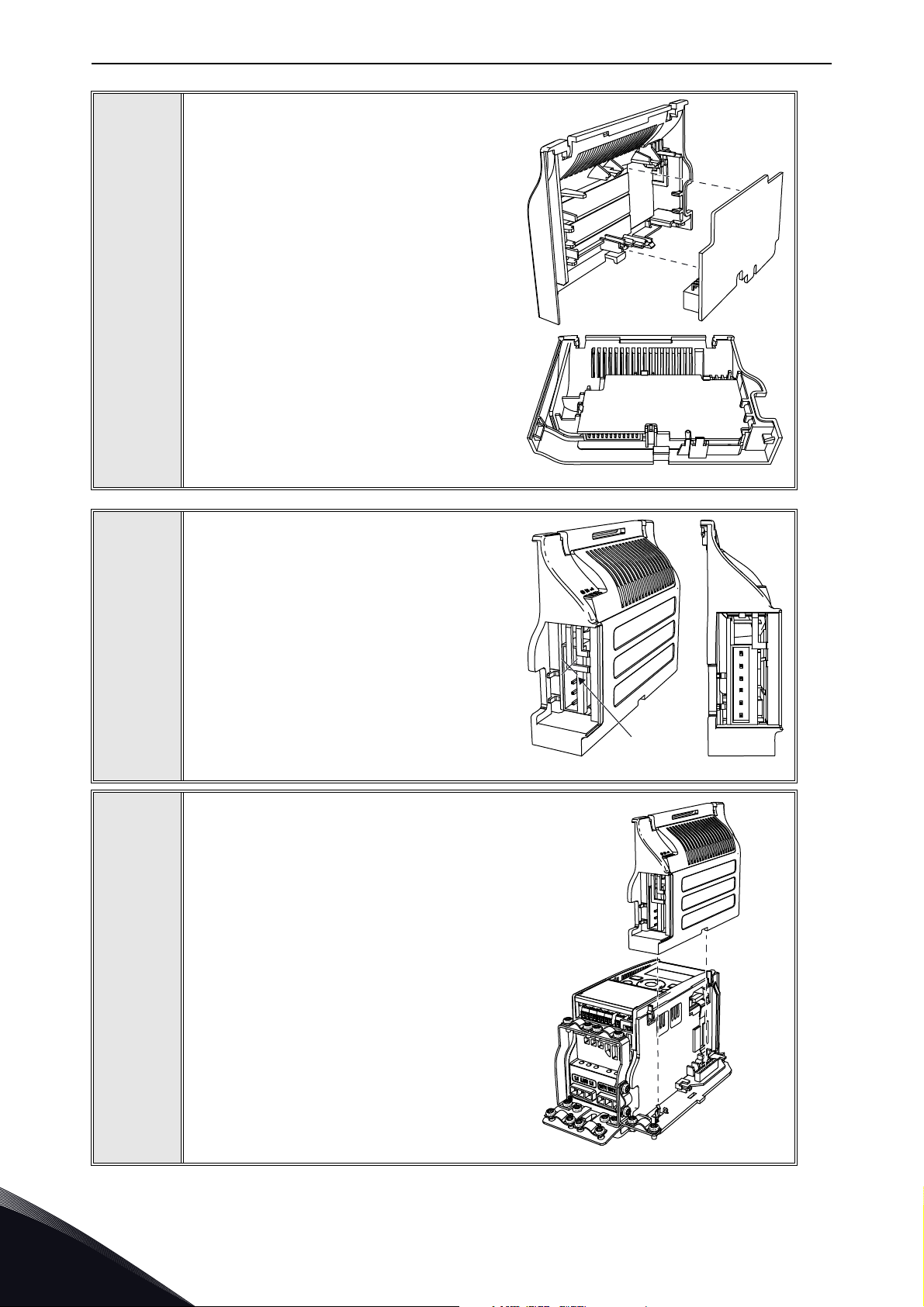

5.1 Installation in VACON® NX

Make sure that the AC drive is switched off before an option or fieldbus board is

changed or added!

VACON® NX AC drive.

1

Remove the cable cover.

2

3

Open the cover of the control unit.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 25

Installation vacon • 23

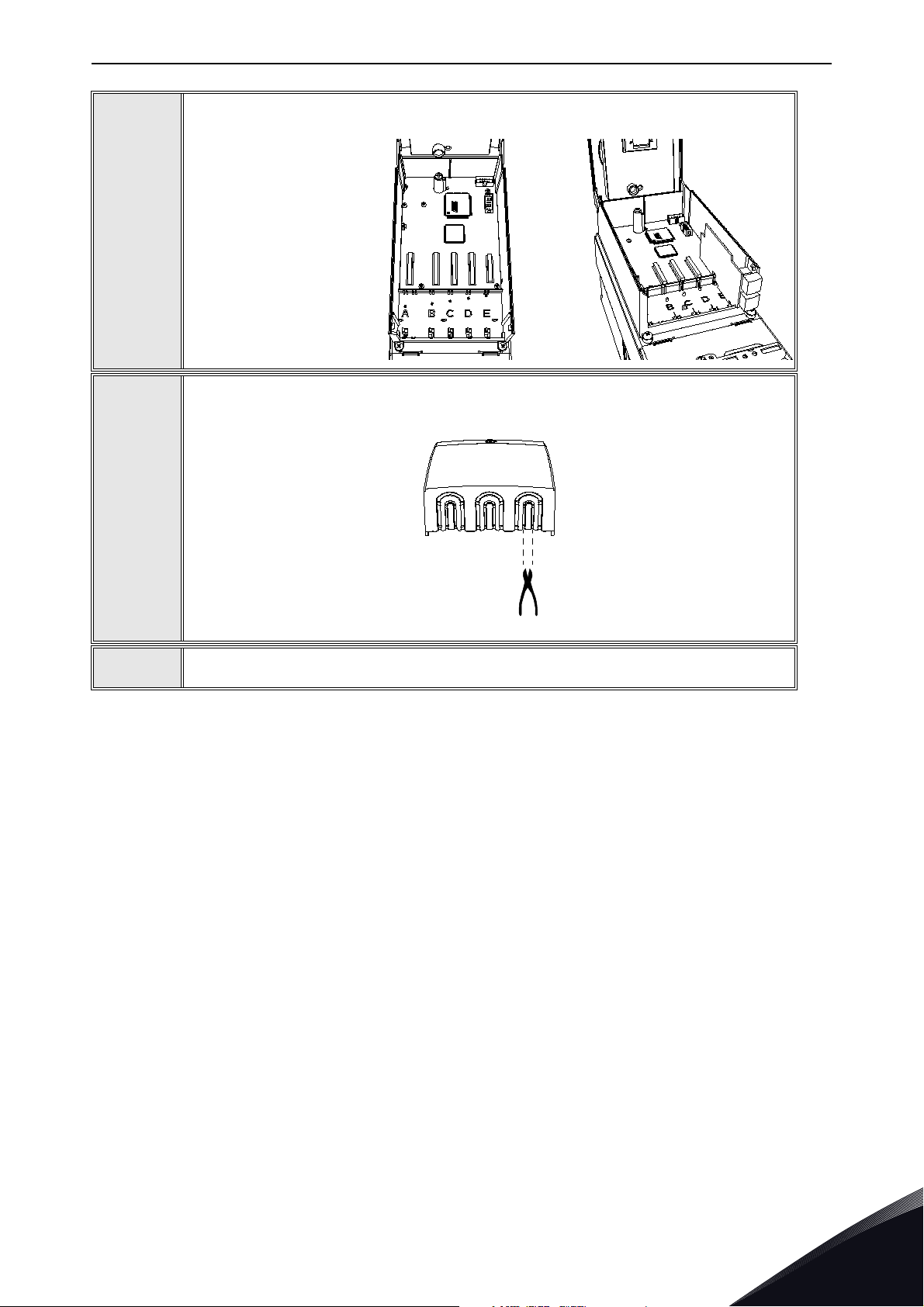

Install the OPTE9 Option Board in slot D or E on the control board of the AC drive.

Make sure that the grounding plate fits tightly in the clamp.

4

Make a sufficiently wide opening for your cable by cutting the grid as wide as

necessary.

5

6

Close the cover of the control unit and the cable cover.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 26

vacon • 24 Installation

11649_00

11556A_00

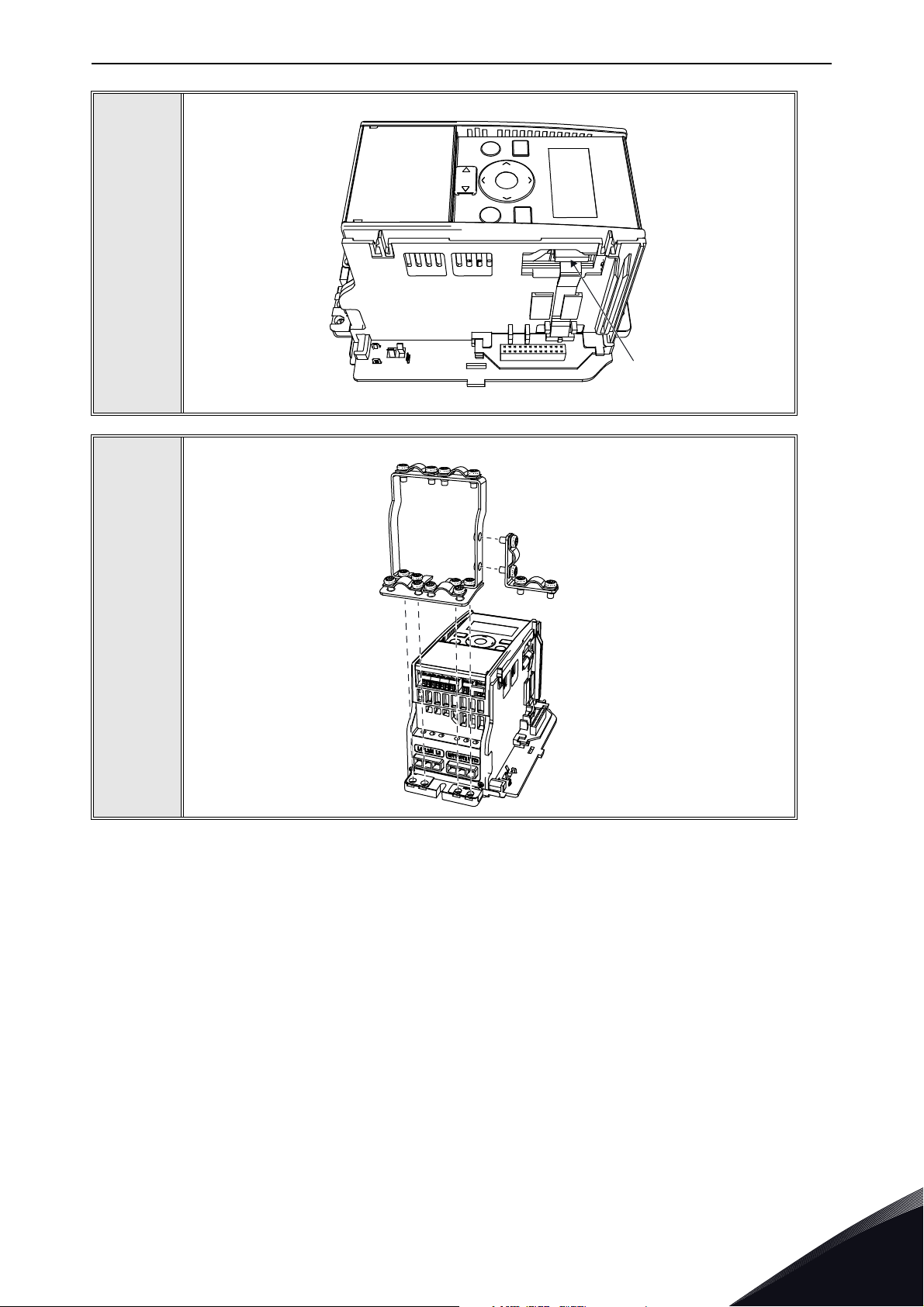

5.2 Installation in VACON® 20

5.2.1 Frames MI1, MI2, MI3

Remove the cable connector lid from the

AC drive.

1

2

11555A_00

Select a correct grounding plate and attach it to the

option board mounting frame. The grounding plate is

marked with the supported enclosure size.

Attach an option board mounting frame to

the AC drive.

5

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 27

Installation vacon • 25

Connect the flat cable from the option board mounting frame to V20.

4

11557A_00

If a cable strain relief is required, attach the parts as shown in the figure.

5

11558A_00

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 28

vacon • 26 Installation

11559A_00

11560A_00

Install the option board to the option board

holder. Make sure that the option board is

securely fastened.

6

7

Cut free a sufficiently wide opening for the

option board connector.

11650_00

Attach the option board cover to V20. Attach

the strain relief cable clamp with screws if

needed.

5

8

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 29

Installation vacon • 27

13006.emf

11562_00

11563_00

5.2.2 Frames MI4, MI5

Make sure power is disconnected before opening the V20 cover.

1a: For MI4: Open the cover.

1

2

11561_00

1b: For MI5: Open the cover and release the fan connector.

Attach the option board support.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 30

vacon • 28 Installation

11564_00

11565_00

Connect the flex cable to option board connector PCB.

3

Connect the option board to connector PCB.

4

5

Attach the option board with connector PCB to V20 and connect the flex cable.

11566_00

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 31

Installation vacon • 29

MI 04

MI 05

11567_00

11568_00

Attach a suitable grounding plate to V20. The grounding plate is marked with

supported enclosure size.

6

Assemble a clamp on top of the grounding plate on both sides of the option board.

7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 32

vacon • 30 Installation

11569_00

11570_00

8a: For MI4: Close the cover.

8

8b: For MI5: Remount the fan connector and close the cover.

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 33

Installation vacon • 31

13006.emf

11643_00

13006.emf

5.3 Installation in VACON® 20 X and 20 CP

Do not add or replace option boards or fieldbus boards on an AC

drive with the power switched on. This may damage the boards.

Open the cover of the drive.

1

MU3 example

The relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the drive is disconnected from mains.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 34

vacon • 32 Installation

7089_00

7090_00

7091_007091_00

Remove the option slot cover.

2

Install the option board into the slot as shown in the figure.

3

4

Mount the option slot cover. Remove the plastic opening for the option board

terminals.

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 35

Installation vacon • 33

M4x55

9174.emf

DANGER

5.4 Installation in VACON® 100

Open the cover of the AC drive.

1

The relay outputs and other I/O-terminals may have a dangerous control voltage

present even when VACON® 100 is disconnected from mains.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 36

vacon • 34 Installation

3023.emf

DE

3024.emf

Open the inner cover to reveal the option board slots (C,D,E).

2

3

Install the fieldbus board into slot D or E.

NOTE: Incompatible boards cannot be installed on VACON® 100. Compatible

boards have a slot coding

that enable the placing of the board.

5

4

Then connect the cable to its appropriate OPTEC EtherCAT option board RJ-45

connector.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 37

Installation vacon • 35

9202.emf

Fieldbus

cables

Unless already done for the other control cables,

cut free the opening on the AC drive cover for the

fieldbus cable (protection class IP21).

NOTE: Cut the opening on the same side you

have installed the board in!

5

Remount the AC drive cover and run the cable as

shown in picture.

NOTE: When planning the cable runs, remember

to keep the distance between the fieldbus cable

and the motor cable at a minimum of 30 cm. It is

recommended to route the option board cables

away from the power cables as shown in the picture.

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 38

vacon • 36 Installation

11638_00

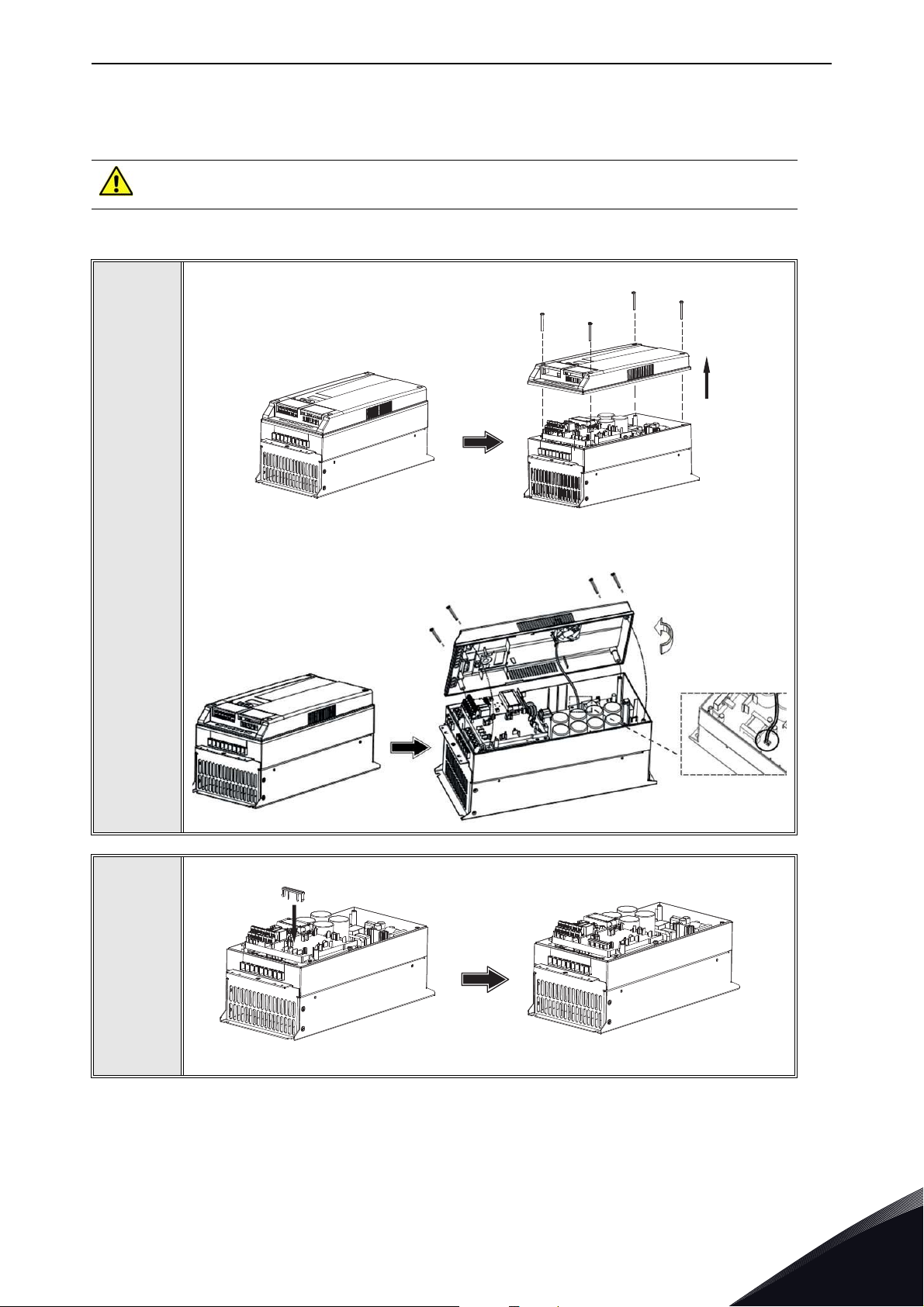

5.5 installation in VACON® 100 X

Open the cover of the AC drive.

1

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 39

Installation vacon • 37

11639_00

To get access to the option board slots, remove the screws and open the cover of

the control unit.

2

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 40

vacon • 38 Installation

11641_00

Install the option board into the correct slot, D or E.

DE

3

4

5

6

11640_00

Close the option board cover.

Remove the cable entry plate. If you

installed the option board in the slot

D, use the cable entry plate on the

right side. If you installed the option

board in the slot E, use the cable

entry plate on the left side.

NOTE! The cable entry plate at the

bottom of the drive is used only for

mains and motor cables.

Open the necessary holes in the cable entry plate. Do not open the other holes.

See the VACON® 100X Installation Manual for the dimensions of the holes.

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 41

Installation vacon • 39

11642_00

Attach a cable gland on the hole in the

cable entry plate. Pull the Ethernet cable

through the hole.

NOTE! The Ethernet cable must go

through the correct cable entry plate to

avoid going near the motor cable.

7

8

9

5.6 PC Tools

Before connecting the OPTE9 option board to the network, its IP addresses must be set according

to the network. By default, the option board uses a DHCP server to get an IP address. If your network

does not have a DHCP server, you need to set an IP address manually. This can be accomplished

with the PC tools described in this chapter or with the drive's keypad (see Chapter 6).

For more information about IP addresses or a DHCP server, contact your network administrator.

5.6.1 PC tool support

This table describes what PC tools are supported in each drive type. The connection type “serial”

means a direct connection to the drive. The connection type “Ethernet” means a connection via the

OPTE9 Ethernet port.

Put the cable entry plate back.

Close the cover of the AC drive.

Table 10. The supported PC tools with different drives

V100 NX V20

Too l Serial Ethernet Serial Ethernet Serial Ethernet

VACON® Loaderxxx

VACON® Live x x x

NCIPConfigxxx

NCDrive x

NCLoad Not supported with OPTE9 Dual Port Ethernet

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 42

vacon • 40 Installation

5.6.2 Updating the OPTE9 option board firmware with VACON® Loader

The VACON® Loader can be downloaded from http://drives.danfoss.com website. It has been

bundled with the VACON® Live software package.

To update the option board firmware, follow the steps below.

NOTE! With VACON® 20, the baud rate 9600 must be used. With VACON® 20 X and VACON® 20 CP,

the following baud rates are supported: 9600, 19200, 38400 or 57600.

Step 1. Connect your PC to the controller by using the USB/RS485 cable.

Then select the firmware file which you want to load to the option board and double click it. This will

start the VACON® Loader software. You can also start the program from the Windows Start menu.

In this case, select the firmware file using the "Browse"-button (see Figure 13).

5

Figure 13. VACON® Loader: File selection

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 43

Installation vacon • 41

Step 2. Press 'next' and wait for the loader to find the network drives.

Then select a drive from the list and press 'Connect to Selected'. See Figure 14.

Figure 14. VACON® Loader: Connecting to drive

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 44

vacon • 42 Installation

Step 3. Select the modules to be updated, press 'next' and wait until the operation is finished. See

Figure 15 and Figure 16.

Figure 15. Option board slot selection

5

Figure 16. VACON® Loader: Firmware loading

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 45

Installation vacon • 43

Figure 17. VACON® Loader: Loading is finished

5.6.3 PC Tools for NX / NCIPConfig

The VACON® OPTE9 Dual Port Ethernet option board can be configured with the NCIPConfig tool.

Before the option board can be used, a valid IP address must be set. By default, the OPTE9 uses a

DHCP server. If your network does not have a DHCP server, you will need to set an IP address

manually and change the "IP Mode" to "static".

For more information about IP addresses or a DHCP server, contact your network administrator.

To install the NCIPConfig tool, start the installation program from the CD or download it from http:/

/drives.danfoss.com website. After starting the installation program, follow the on-screen

instructions.

Once the program is installed successfully, you can launch it by selecting it in the Windows Start

menu. Follow these instructions to set the IP addresses. Select Help --> Manual if you want more

information about the software features.

Step 1. Connect your PC to the Ethernet network with an Ethernet cable.

You can also connect the PC directly to the device using a crossover cable. This option may be

needed if your PC does not support the Automatic crossover function.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 46

vacon • 44 Installation

Step 2. Perform network nodes scanning.

Select Configuration --> Scan (Figure 18) and wait until the devices connected to the bus in the tree

structure are displayed on the left side of the screen.

Figure 18. Network nodes scanning

NOTE! The NCIPConfig uses broadcast messages for scanning devices. Some network switches

might block the broadcast messages. In this case, each network node must be scanned separately.

Step 3. Set the option board settings.

To change the board name, select the cell in the column 'Node' and enter the name of the node. To

change the node IP settings, select the cell in the right column and enter the value according to the

network IP settings. The program will report conflicts with a red color in table cells. To change the

IP Mode, click the cell and select the desired mode from the dropdown list (Figure 19).

To commit the changes, mark the checkbox and select Configuration->Configure- from the menu.

5

Figure 19. Change the option board settings

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 47

Installation vacon • 45

Step 4. Change the protocol settings.

To change the currently active protocol, select the setting from the tree structure. A dialog box

opens. Select the desired protocol from the dropdown list (Figure 20). After clicking "ok" the setting

will be activated.

The rest of the settings can be changed similarly, but values are edited in the tree (Figure 21). See

Chapter 6 for more information about the settings.

Figure 20. Change the currently active protocol value

Figure 21. Change the communication timeout value

5.6.4 PC Tools for NX / NCDrive

You can configure the drive parameters with the NCDrive. Some of the OPTE9 parameters can be

configured with the NCDrive. However, it is recommended to use the NCIPConfig tool for the OPTE9

Dual Port Ethernet configuration in the NX drives.

You need to have a PC with an Ethernet connection and the NCDrive tool installed. To install the

NCDrive, start the installation program from the CD or download it from http://drives.danfoss.com

website. After starting the installation program, follow the on-screen instructions.

Once the program is installed successfully, you can launch it by selecting it in the Windows Start

menu. Select Help --> Contents if you want more information about the software features.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 48

vacon • 46 Installation

Before using the NCDrive, you need to configure the option board IP settings with NCIPConfig. If the

option board does not have valid IP settings you will not be able to connect with the NCDrive.

Step 1. Connect your PC to the Ethernet network with an Ethernet cable.

You can also connect the PC directly to the device using a crossover cable. This option may be

needed if your PC does not support Automatic crossover function.

Step 2. In order to connect to the drive, you need to select the active drive first. Press the "Drive

Select" button (see Figure 22) to scan the network drives.

Figure 22. NC Drive: “Drive Select”

Step 3. In the "Select the active drive" dialog (see Figure 23), select the drive you want to connect to.

Then press the "Set Active Drive" button. Now you can close the dialog.

The IP information presented in the dialog comes from the option board, other information comes

from the drive.

5

Figure 23. NC Drive: Active drive selection

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 49

Installation vacon • 47

Step 4. Press the "ON-LINE" button. The NCDrive will connect to the drive and start loading

parameter information. This will take a few minutes. See Figure 24 and Figure 25.

Figure 24. NC Drive: Going online

Figure 25. Loading information from the drive

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 50

vacon • 48 Installation

Step 5. To change the option board settings, navigate to the "M7Expander boards" menu and select

the slot that the OPTE9 is connected to. You can change the IP address, network mask and default

gate address in the menu item "G 7.x". After you have changed the IP settings, you need to change

"IP Mode" to "Fixed IP" in order to activate the settings.

For more information about these settings, see Chapter 6.1.

Figure 26. NC Drive: OPTE9 parameters

NOTE! The NCDrive software can be used with the Ethernet board in NXS, NXP and NXL drives.

NOTE! The NCDrive software is recommended to be used in LAN (Local Area Network) only.

NOTE! This feature does not work with VACON® 100 drives.

5.6.5 PC Tools for VACON

VACON® Live can be used to configure the IP settings of the OPTE9 option board. VACON® Live can

be downloaded from http://drives.danfoss.com website.

To configure the IP settings of the OPTE9 option board, follow the steps below:

NOTE! VACON

connection over the OPTE9 Ethernet port.

Step 1. Connect your PC to the Ethernet network with an Ethernet cable. You can also connect the

PC directly to the drive using a crossover cable. This option may be needed if your PC does not

support Automatic crossover function.

® 20, VACON® 20 X and VACON® 20 Cold Plate do not support VACON® Live

® 100 and VACON® 20 / VACON® Live

5

You can also connect to the VACON

same for both connections.

NOTE! You cannot use VACON

address. If you change the IP settings of the option board when connected through it, VACON® Live

connection will be lost.

® 100 drive by its serial port. In any case the steps below are the

® Live via the option board if the option board does not have a valid IP

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 51

Installation vacon • 49

Step 2. Start VACON® Live. When the program starts and it asks "Select startup mode", select

"Online". The program will scan your network for compatible drives. When found, they will be added

to the list. Select the drive that the OPTE9 option board is connected to and press "Connect to

select".

Figure 27. VACON® Live: The ”Startup mode” dialogue box

Figure 28. VACON® Live: The “Select devices” dialogue box

NOTE! The first column is the drive's name, but the information about IP and MAC addresses come

from the option board (if the device on the list is an option board).

NOTE! Some switches block broadcast messages. In this case, each network node must be scanned

separately.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 52

vacon • 50 Installation

Step 3. To change the IP settings, navigate to the "5. I/O and Hardware" menu and select the slot

that the OPTE9 is connected to. You can change the IP address, network mask and default gate

address in the menu item "5.x.3 Parameters". After you have changed the IP settings, you need to

change "IP Mode" to "Fixed IP" in order to activate the settings. For more information about these

settings, see Chapter 6.1.

Figure 29. VACON® Live: OPTE9 IP Address Mode

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 53

Commissioning vacon • 51

6. COMMISSIONING

The VACON® OPTE9 Dual Port Ethernet option board is commissioned with the control keypad by

giving values to appropriate parameters in the option board menu (or via PC tools, see Chapter 5.6

"PC Tools").

Keypad commissioning procedures and location of parameters differ a little with different drive

types:

• In the NXP/NXS option board, parameters are located under the menu M5 (Expander board

menu).

• In the VACON® 100 option board, parameters are located under the menu M7 (I/O and Hard-

ware).

6.1 Option board menu

The control keypad makes it possible for the user to see which expander boards are connected to

the control board and to reach and edit the parameters associated with the expander board.

6.1.1 Option board parameters

The OPTE9 board parameters are listed in the table below.

Table 11. Parameters menu structure

# Name Default Range Description

1

2IP Mode* DHCP

3 IP Part 1* 192 1…223 IP Address Part 1

4 IP Part 2* 168 0…255 IP Address Part 2

5 IP Part 3* 0 0…255 IP Address Part 3

6 IP Part 4* 10 0…255 IP Address Part 4

7 Subnet mask P1 255 0…255 Subnet Mask Part 1

8 Subnet mask P2 255 0…255 Subnet Mask Part 2

9 Subnet mask P3 255 0…255 Subnet Mask Part 3

10 Subnet mask P4 255 0…255 Subnet Mask Part 4

Comm.

Protocol*

Modbus

Modbus (1),

Profinet IO (2),

EtherNet/IP (3)

Fixed IP (1),

DHCP (2)

Active protocol

IP mode. When in DHCP

mode, the IP address cannot

be changed manually.

11 Default GW P1 192 0…255 Default Gateway Part 1

12 Default GW P2 168 0…255 Default Gateway Part 2

13 Default GW P3 0 0…255 Default Gateway Part 3

14 Default GW P4 1 0…255 Default Gateway Part 4

15 Comm. Timeout 10 s 0…65535 s

16

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

PNIO Name Of

Station

"" 1...240 char

Communication timeout in

seconds

For Profinet IO only. Only

visible in VACON® 100

drives.

6

Page 54

vacon • 52 Commissioning

# Name Default Range Description

"20" (1),

"21" (2),

17

18

EIP Output

Instance*

EIP Input

Instance*

21

71

"23" (3),

"25" (4),

"101" (5),

"111" (6),

"128" (7),

"131" (8)

"151" (9),

"161" (10)

"70" (1),

"71" (2),

"73" (3),

"75" (4),

"107" (5),

"117" (6),

"127" (7),

"137" (8)

"157" (9),

"167" (10)

EtherNet/IP output assembly instance.

Shows the active output

instance. The instance is

selected during the IO connection open request.

EtherNet/IP input assembly

instance.

Shows the active input

instance. The instance is

selected during the IO connection open request.

19

20 Mode* Normal

21

* These parameters are locked when either PROFINET IO connection, EtherNet/IP implicit connection or a

Modbus connection is established to write process data (i.e. when fieldbus can be used to control the process).

EIP Product

Code Offset

Modbus Unit

Identifier*

00…99

Normal (1),

NX Mode (2),

V100 Mode (3)

255 1…247, 255

Only in VACON® 100. After

this setting is changed,

drive must be restarted.

Modbus Unit Identifier. Used

only with Modbus UDP.

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 55

Commissioning vacon • 53

6.1.2 Option board monitoring values

The monitor menu shows the currently active IP settings. For example, these values will show '0'

when a DHCP server is trying to get an IP address. After the address is received, these values are

updated.

Table 12. Monitor menu structure

# Name Range Description

1IP Part 1

2 IP Part 2 0…255 Current IP Address Part 2

3 IP Part 3 0…255 Current IP Address Part 3

4 IP Part 2 0…255 Current IP Address Part 4

5 Subnet mask P1 0…255 Current Subnet Mask Part 1

6 Subnet mask P2 0…255 Current Subnet Mask Part 2

7 Subnet mask P3 0…255 Current Subnet Mask Part 3

8 Subnet mask P4 0…255 Current Subnet Mask Part 4

9 Default GW P1 0…223 Current Default Gateway Part 1

10 Default GW P2 0…255 Current Default Gateway Part 2

11 Default GW P1 0…255 Current Default Gateway Part 3

12 Default GW P4 0…255 Current Default Gateway Part 4

13 Fieldbus protocol status

14 Communication status 0.0…64.999

1…223

Initializing (1),

Stopped (2),

Operational (3),

Faulted (4)

Current IP Address Part 1

0-64 Number of messages with errors

0-999 Number of messages without

communication errors

15 Drive control word - Control word in drive format (hex)

16 Drive status word - Status word in drive format (hex)

17 Protocol control word - Control word in protocol format (hex)

18 Protocol status word - Status word in protocol format (hex)

19 EIP Product Code -

20 MAC Address -

6.1.3 Communication protocol

The OPTE9 option board comes with several fieldbus protocols. The user can select the one used in

their network from the list. Only one protocol can be active at a time.

Currently used EtherNet/IP Product

Code

Used device MAC address. Available in

NXP, NXS and VACON® 100 drives.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 56

vacon • 54 Commissioning

6.1.4 IP Mode

The IP mode determines how the option board IP settings are set. If a DHCP server is selected, then

the option board will try to retrieve its IP settings from the DHCP server connected to the local

network. If the option board is unable to retrieve its IP settings, it will set a link-local address as the

current IP address after about one minute (for example 169.x.x.x).

If "Fixed IP" is set as IP mode, the settings IP Part 1-4, Subnet Part 1-4 and Default gateway 1-4 are

used.

6.1.5 IP Address

IP is divided into 4 parts. (Part = Octet). Changing these values does not have any effect if the current

IP mode is "DHCP". The value will become active when the mode is changed to "fixed IP". When

these values are changed and the mode is "fixed IP", the changes are taken into use immediately.

6.1.6 Communication timeout

It defines how much time can pass from the last received message from the Master Device before

a fieldbus fault is generated. The functionality of this value is protocol-specific.

A fieldbus fault is also generated if the Ethernet link is down for over 60 seconds after the device

startup. The Ethernet link status is being checked until the fieldbus communication is activated.

After that the active fieldbus protocol controls the activation of the fieldbus fault.

The functionality of this value is protocol-specific.

6.1.6.1

For Modbus, this value defines a time in which a message must be received (from Client in Modbus

TCP/UDP) before a fieldbus fault is generated. If timeout is set to zero, no fault is created.

See Chapter 7.4.

6.1.6.2

For these protocols, this value is considered as an additional timeout which works on top the

timeout mechanism of the protocol. When a connection loss is noticed, a fault activation is started.

If communication timeout value is zero, the fault is activated immediately, otherwise the fault

activates after a specified time. If the connection is reopened before the specified time has elapsed,

no fault is created.

See Chapter 8.5 "PROFINET IO communications and connection timeout" for more details on how a

timeout is created in OPTE9 while using PROFINET IO protocol.

See Chapter 9.1.6 "EtherNet/IP communication and connection timeout" for more details for more

details on how a timeout is created in OPTE9 while using EtherNet/IP protocol.

6.1.7 Profinet IO - Name of Station

Modbus

Profinet IO and EtherNet/IP

6

The Profinet IO "Name of Station" parameter can be set via VACON® Live or NCIPConfig. Other

possibility is to set this name by writing it via Ethernet with the DCP protocol. In case of VACON®

100 drives, the last 18 characters of the Name of Station can be read but not written from the panel.

The name is empty if no name is set, or if name is set as "temporary" by network device.

NOTE! In case of VACON® 20, VACON® 20 X and VACON® 20 CP, the “Name of Station” must be

defined with NCIPConfig tool or by writing the name from the PLC.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 57

Commissioning vacon • 55

6.1.8 EIP Input and Output instance

These parameters will show what instances are being used now. The instances actually used are

taken from the IO connection open request. So, although these values are parameters they act more

like monitoring values.

6.1.9 EIP Product code offset

This value can be used to differentiate drives for the PLC program. For example, if one drive is

running a different application (with different parameters) than other drives, this offset in the

product code will enable the PLC to use a different EDS file to read those parameters from this drive.

Remember that if you change this value, you need also to change the EDS file used or change the

product code value in your EDS file.

6.1.10 Mode

The "Mode"-parameter is available only when the OPTE9 has been installed to the VACON® 100

drive. When the mode is changed, the OPTE9 fieldbus protocols will emulate old C-series option

boards or VACON® 100 internal implementations.

Table 13. Mode values

Mode value Description

Normal Option board will identify itself as OPTE9 (depends on fieldbus protocol)

NX Mode

V100 Mode Option board will identify itself as VACON® 100 drive.

6.1.11 MAC Address

This value shows the OPTE9 device MAC address. The format differs between used VACON® AC

drive. In VACON® 100 the format is 00:11:22:33:44:55 and in VACON® NX 001122334455. This value

is not visible in VACON® 20 drives.

Example for VACON® 100: 00:21:99:1a:00:24

Example for VACON® NX: 0021991a0024

6.1.12 Modbus Unit Identifier

This value is used to select Modbus unit identifier / slave address. When using Modbus TCP the

value 255 must be used, and this field is ignored as the IP address is used to access the correct

device. When using Modbus UDP the values and their significance is explained in table below. Values

from 1 to 247 and 255 can be set to OPTE9.

Option board will identify itself as old C-series counterpart and will emu-

late selected features.

Table 14. Modbus Unit Identifier field description when using Modbus UDP

# Unit identifier Description

0 Broadcast Broadcast address, messages are accepted by all devices

1...247 Slave address Messages with this unit identifier and broadcast (0) are accepted

255 Non-significant Messages with all unit identifiers are accepted (setting is ignored)

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 58

vacon • 56 Commissioning

The value 0 can be used to control several devices with a broadcast message, e.g. to command all

devices to stop at the same time. This feature will also work if all devices have the unit identifier

value 255.

6.2 Communication mode

The OPTE9 option board shall support multiple communication modes to AC drive in future release.

This will, among other features, enable transmitting and receiving 16 process data items at 1 ms

interval.

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 59

Modbus TCP / Modbus UDP vacon • 57

11608_uk

Master´s

message

Slave

response

Start

Address

Function

Data

CRC

End

Start

Address

Function

Data

CRC

End

7. M ODBUS TCP / MODBUS UDP

Modbus is a communication protocol developed by Modicon systems. In simple terms, it is a way of

sending information between electronic devices. The device requesting the information is called the

Modbus Master (or the Client in Modbus TCP/UDP) and the devices supplying information are

Modbus Slaves (in Modbus TCP/UDP servers). In a standard Modbus network, there is one Master

and up to 247 Slaves, each with a unique Slave Address from 1 to 247. The Master can also write

information to the Slaves. Modbus is typically used to transmit signals from instrumentation and

control devices back to the main controller or data gathering system.

The Modbus communication interface is built around messages. The format of these Modbus

messages is independent of the type of physical interface used. The same protocol can be used

regardless of the connection type. Because of this, Modbus gives the possibility to easily upgrade

the hardware structure of an industrial network, without the need for large changes in the software.

A device can also communicate with several Modbus nodes at once, even if they are connected with

different interface types, without the need to use a different protocol for every connection.

Figure 30. Basic structure of Modbus frame

On simple interfaces like RS485, the Modbus messages are sent in plain form over the network. In

this case, the network is dedicated to Modbus. When using more versatile network systems like

TCP/IP over Ethernet, the Modbus messages are embedded in packets with the format necessary

for the physical interface. In that case Modbus and other types of connections can co-exist at the

same physical interface at the same time. Although the main Modbus message structure is peerto-peer, Modbus is able to function on both point-to-point and multidrop networks.

Each Modbus message has the same structure. Four basic elements are present in each message.

The sequence of these elements is the same for all messages, to make it easy to parse the content

of the Modbus message. A conversation is always started by a master in the Modbus network. A

Modbus master sends a message and depending of the contents of the message a slave takes action

and responds to it. There can be more than one master in a Modbus network. Addressing in the

message header is used to define which device should respond to a message. All other nodes on the

Modbus network ignore the message if the address field does not match their own address.

If you need to contact VACON® service in problems related to Modbus TCP/UDP, send a description

of the problem together with the Drive Info File to tech.supportVDF@vacon.com. If possible, also

send a "Wireshark" log from the situation if applicable.