Page 1

vacon nx

ac drives

basic i/o boards

expander i/o boards

adapter i/o boards

user manual

®

Page 2

Page 3

vacon • 1

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

TABLE OF CONTENTS

Document: DPD00884B

Release date : 1/9/16

1. General information.........................................................................................2

1.1 Board slots on the control board of VACON® NXS and NXP............................................2

1.2 Board Slots on the control board of VACON® NXL...........................................................3

1.3 Option board types .............................................................................................................4

1.4 Technical data ....................................................................................................................5

1.4.1 Isolation..............................................................................................................................6

1.4.2 Analogue inputs (mA/V) .....................................................................................................6

1.4.3 Analogue outputs (mA/V) ...................................................................................................6

1.4.4 Control voltage (+24V/EXT +24V)........................................................................................6

1.4.5 Digital input signal conversion ..........................................................................................7

1.5 Hardware protections ........................................................................................................9

1.5.1 Terminal block coding .......................................................................................................9

1.5.2 Board slot guides and allowed slots..................................................................................9

1.6 Type identification number ..............................................................................................10

1.7 Defining functions to inputs and outputs.........................................................................10

1.8 Defining a terminal for a certain function with NCDrive programming tool ..................11

1.9 Option board related parameters ....................................................................................12

2. Installation of VACON® Option Boards .......................................................... 13

2.1 Control cables ..................................................................................................................15

2.1.1 Cable grounding...............................................................................................................15

2.2 Board information sticker................................................................................................16

3. Descriptions of VACON® option boards .........................................................17

3.1 Basic boards OPTA_.........................................................................................................17

3.1.1 OPTA1 ...............................................................................................................................18

3.1.2 OPTA2 ...............................................................................................................................21

3.1.3 OPTA3 ...............................................................................................................................22

3.1.4 OPTA4 ...............................................................................................................................23

3.1.5 OPTA5 ...............................................................................................................................29

3.1.6 OPTA7 ...............................................................................................................................33

3.1.7 OPTA8 ...............................................................................................................................39

3.1.8 OPTA9 ...............................................................................................................................42

3.1.9 OPTAL...............................................................................................................................43

3.1.10 OPTAE...............................................................................................................................45

3.1.11 OPTAN ..............................................................................................................................49

3.2 I/O Expander Boards OPTB_............................................................................................53

3.2.1 OPTB1...............................................................................................................................54

3.2.2 OPTB2...............................................................................................................................56

3.2.3 OPTB4...............................................................................................................................57

3.2.4 OPTB5...............................................................................................................................58

3.2.5 OPTB8...............................................................................................................................60

3.2.6 OPTB9...............................................................................................................................63

3.2.7 OPTBB ..............................................................................................................................64

3.2.8 OPTBH ..............................................................................................................................69

3.3 Adapter Boards OPTD_ ....................................................................................................71

3.3.1 OPTD1...............................................................................................................................71

3.3.2 OPTD2...............................................................................................................................73

3.3.3 OPTD3...............................................................................................................................77

3.3.4 OPTD6...............................................................................................................................79

4. VACON® Option Boards – operational details................................................81

Page 4

1

vacon • 2 General information

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1. GENERAL INFORMATION

VACON® NX range embodies a wide selection of expander and adapter boards with which the

available I/O of VACON

®

NX AC drive can be increased and its versatility improved.

The input and output configuration (I/O) of VACON

®

NX is designed with modularity in mind. The

total I/O is comprised of option boards, each having its own input and output configuration. The

boards contain not only normal analogue and digital inputs and outputs, but also fieldbuses and

additional application-specific hardware.

The basic, expander and adapter boards are placed in the board slots on the control board of the AC

drive. The I/O boards are usually interchangeable between different VACON

®

types, i.e. NXS and

NXP. However, the control boards of these types differ from each other to some extent which means

that the use of some I/O boards in different VACON

®

AC drive types may be restricted.

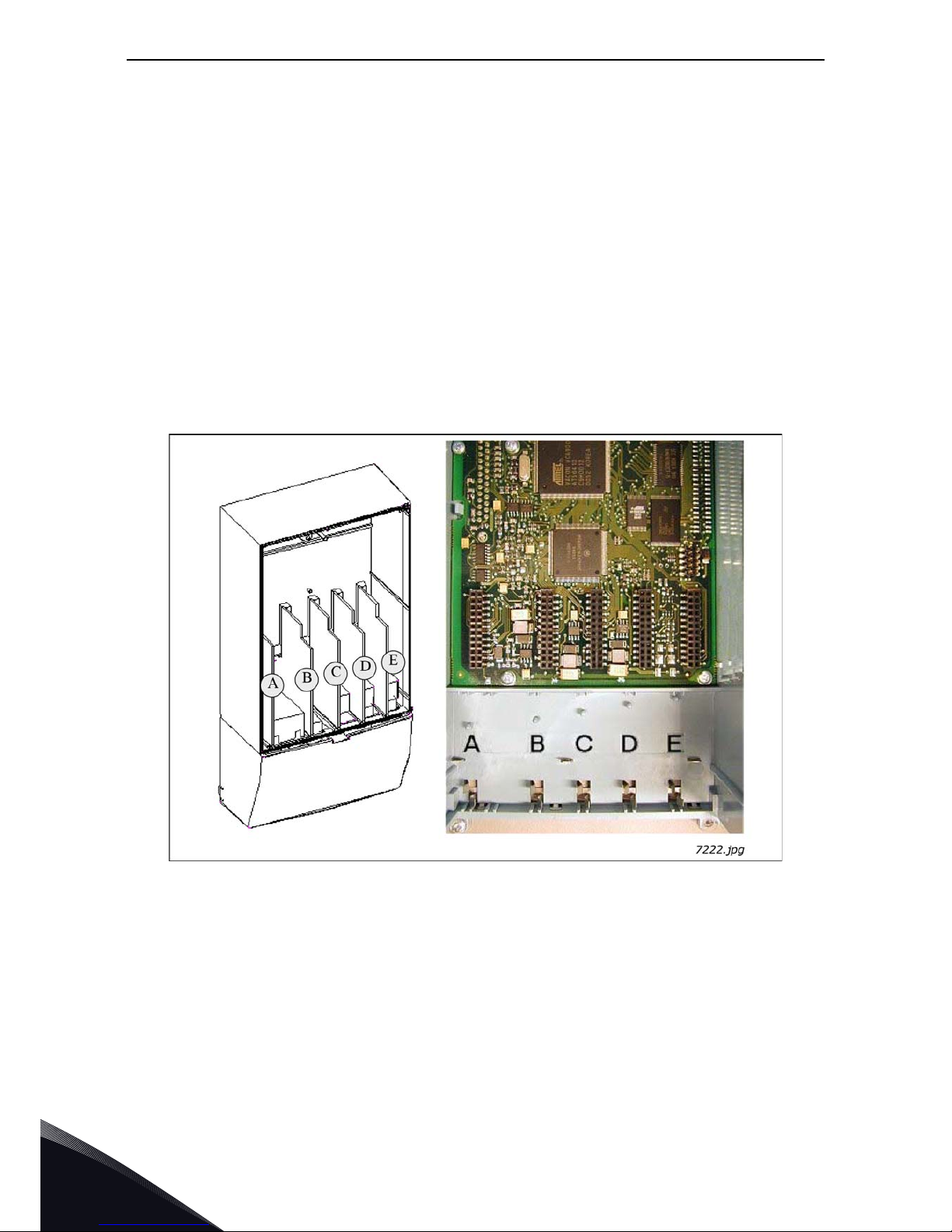

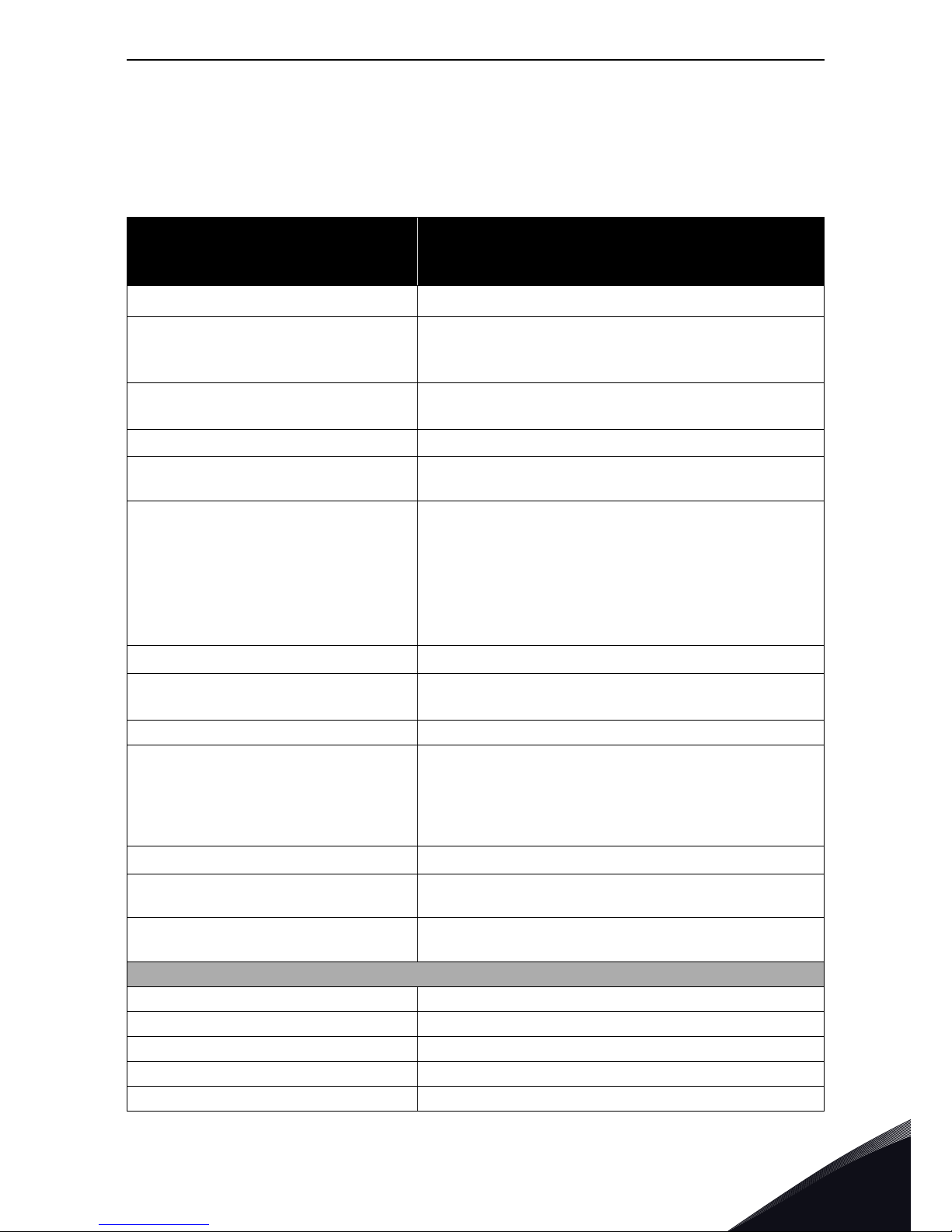

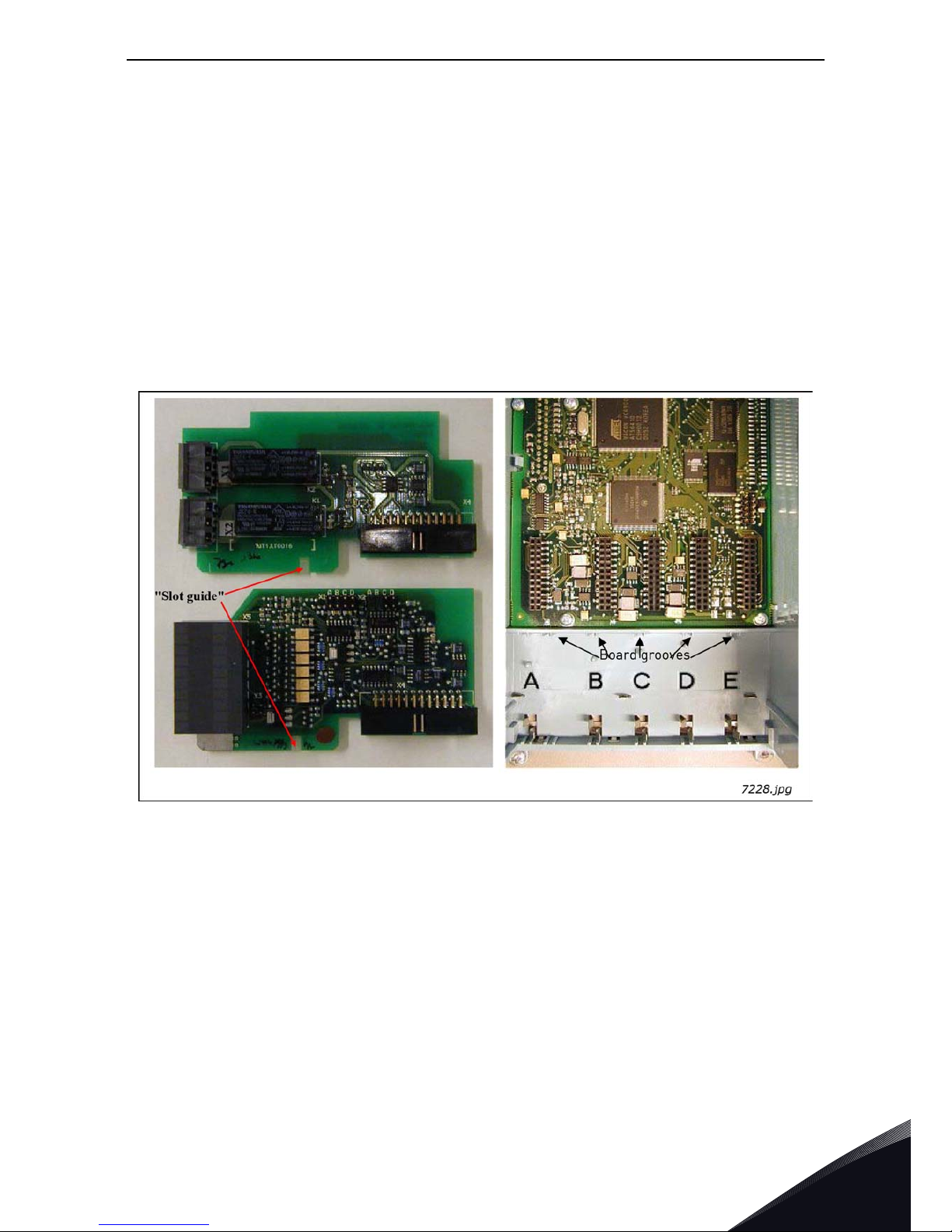

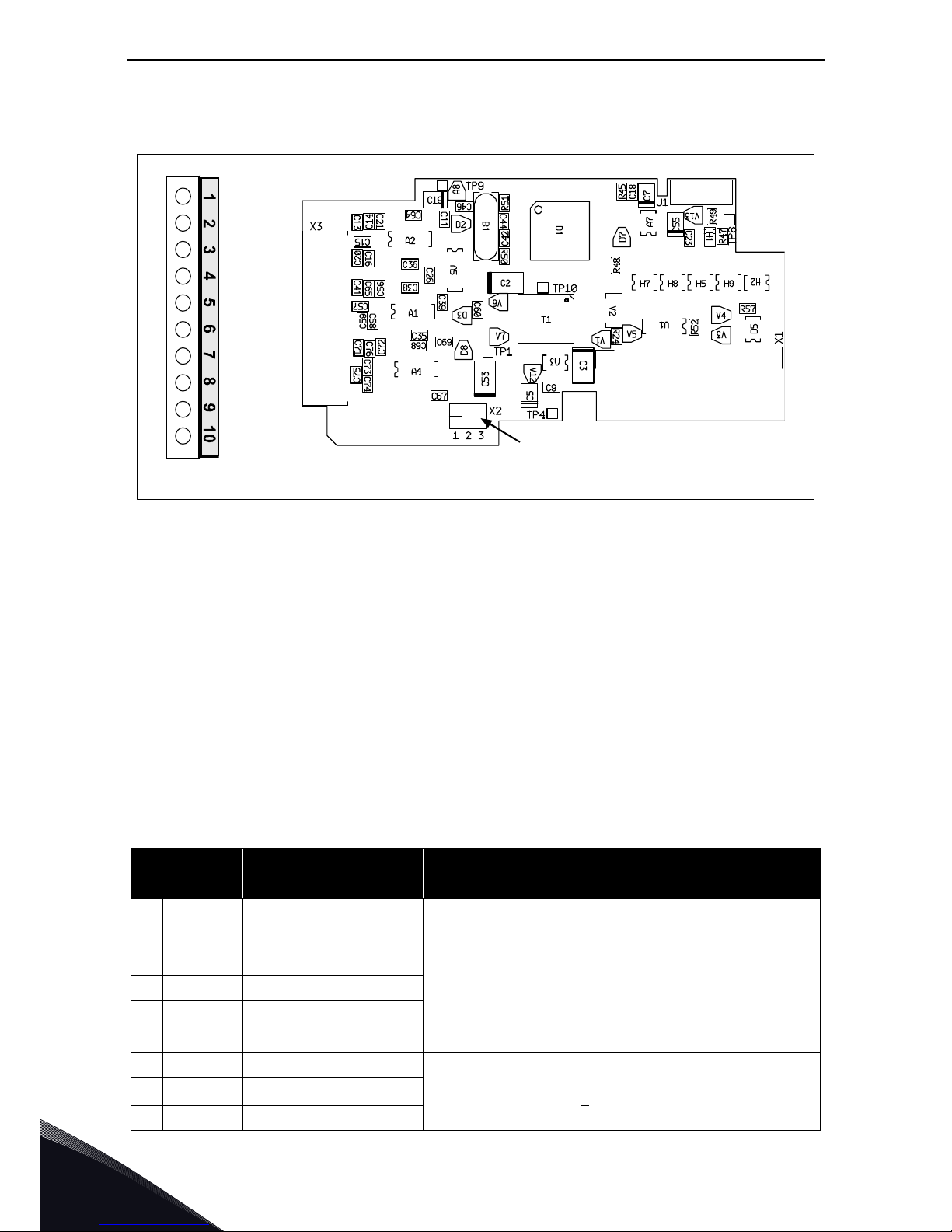

1.1 Board slots on the control board of VACON® NXS and NXP

Figure 1. Board slots on control board of the VACON® NXS and NXP

The control board is situated inside the control unit of the VACON

®

NX AC drive. There are five board

slots (labelled A to E) on the control board of NXS and NXP (See NXS/P User Manual): The

connectability of different option boards to different slots depends greatly on the type of the board.

For more information on this, see Chapter 1.2. See also the descriptions of the options boards on

pages 18 to 79.

Usually, when the AC drive is delivered from the factory, the control unit includes at least the

standard compilation of two basic boards (I/O board and relay board) which are normally installed

in slots A and B. The I/O boards mounted at the factory are indicated in the type code of the AC drive.

The three expander slots C, D and E are available for different option boards i.e. I/O expander

boards, fieldbus boards and adapter boards.

Page 5

General information vacon • 3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

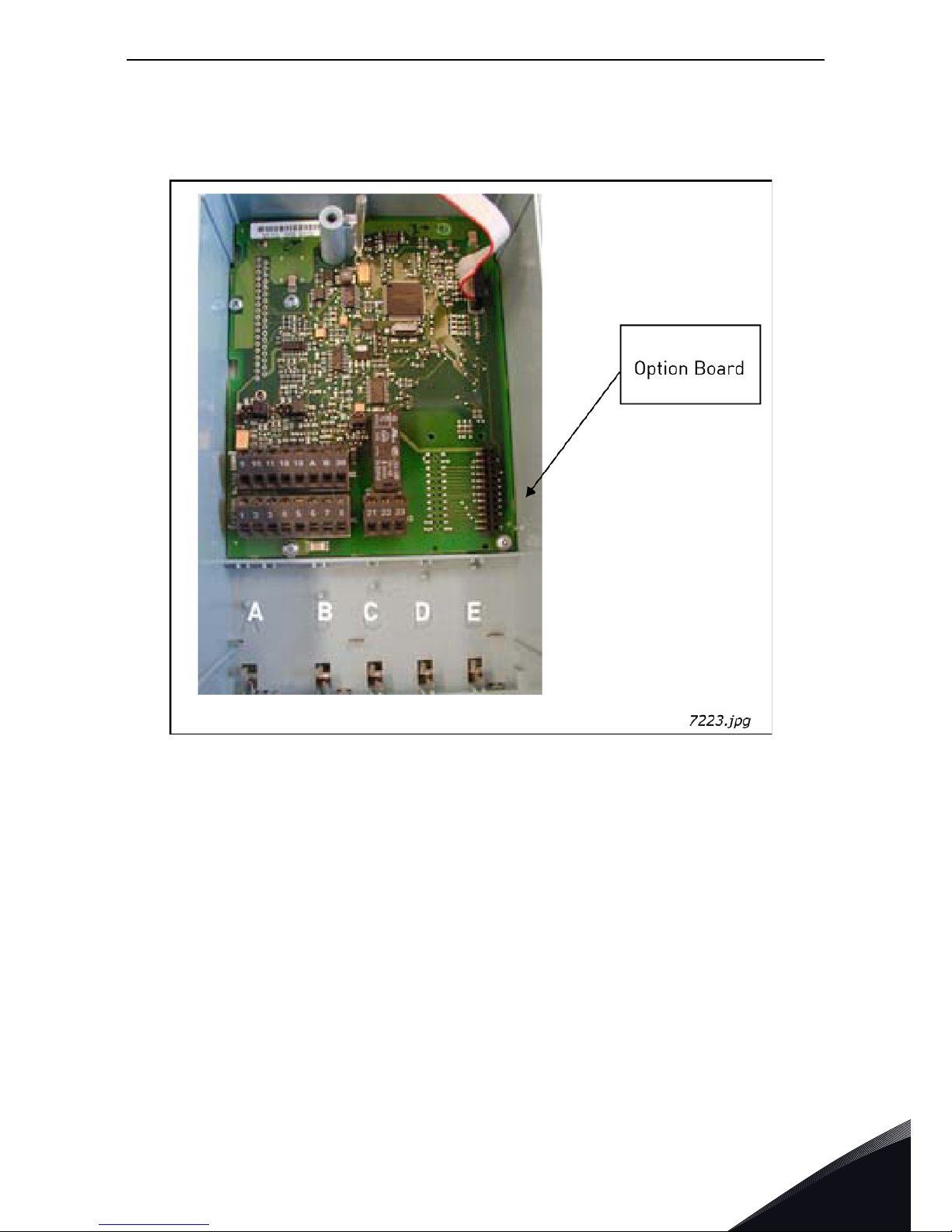

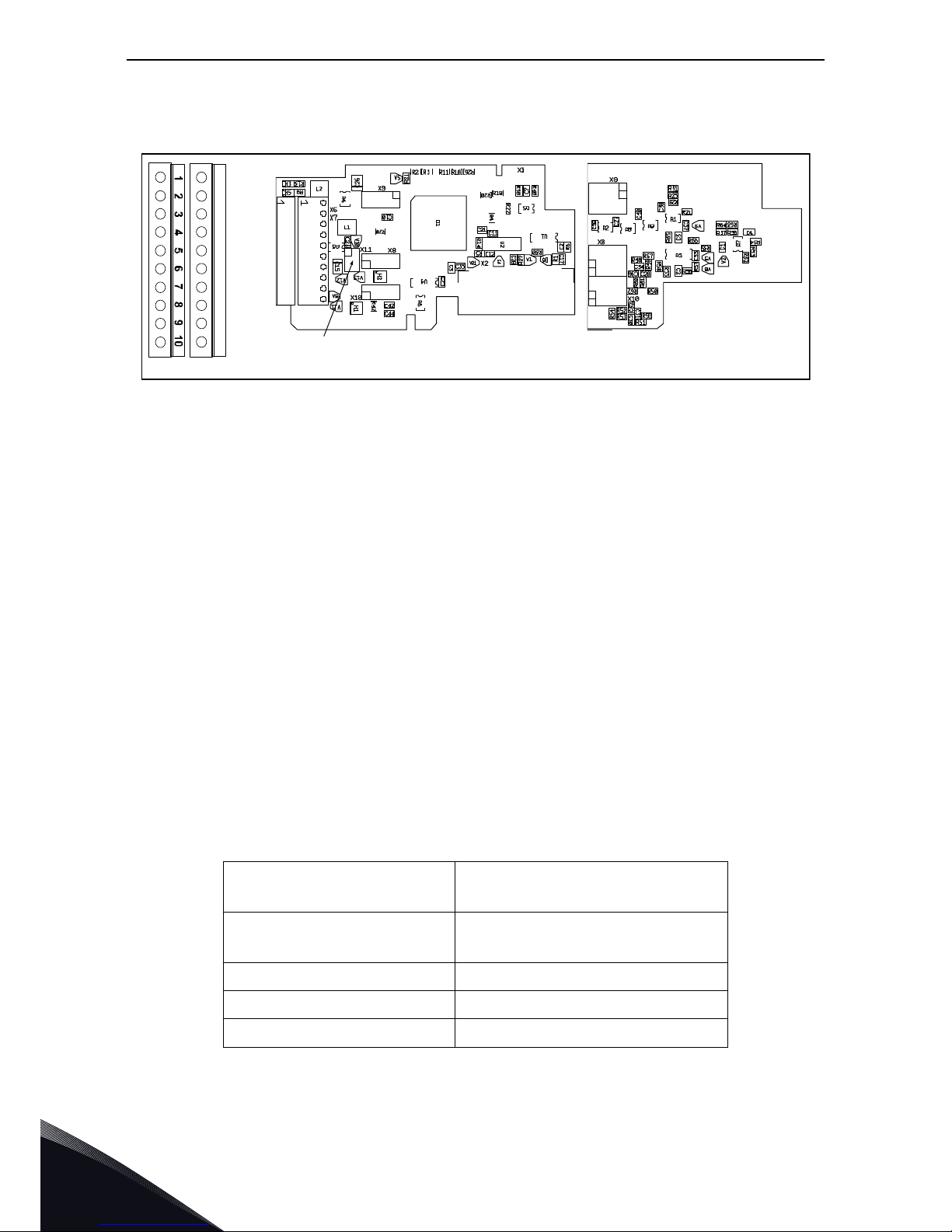

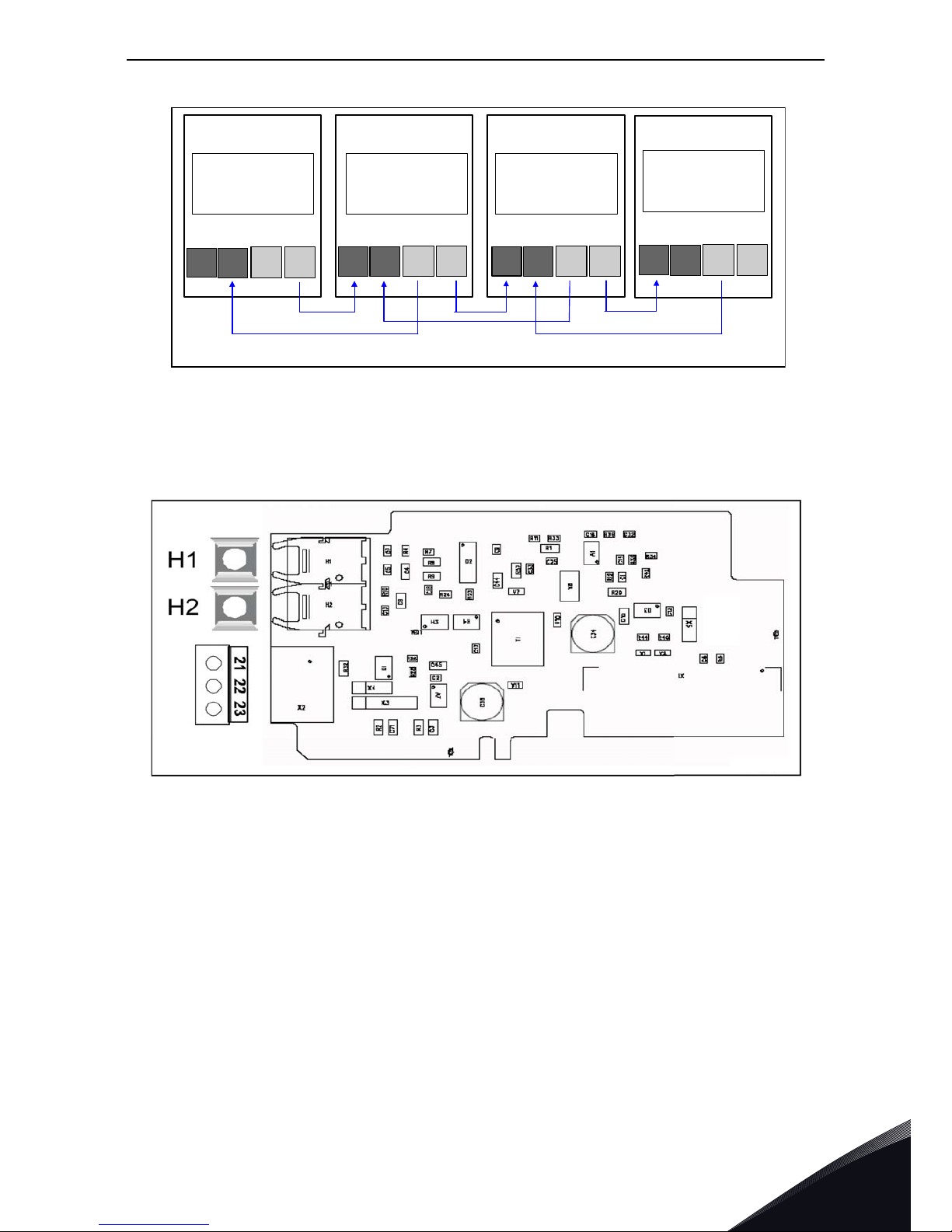

1.2 Board Slots on the control board of VACON® NXL

Figure 2. Board slots on control board of VACON® NXL.

The control board of NXL includes fixed standard I/O and one place for option boards (see NXL User

Manual of NXL). The most typical option board for NXL, OPT-AA, is specified in the NXL

User Manual.

Page 6

1

vacon • 4 General information

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1.3 Option board types

The VACON® option boards are divided in four groups according to their characteristics: types A, B,

C and D. Short descriptions of the types below:

OPTA_

• Basic boards used for basic I/O (NXS, NXP); normally pre-installed at the factory.

• This board type uses slots A, B or C.

See pages 17 to 49 for a detailed presentation of the boards of this type. See also the principle

diagram on the options boards and their equipment on page 81.

OPTB_

• Option boards used for I/O expansion.

• Normally pluggable into slots B, C, D and E.

See pages 53 to 64 for a detailed presentation of the boards of this type. See also the principle

diagram on the options boards and their equipment on page 81.

OPTC_

• Fieldbus boards (e.g. Profibus or Modbus).

• These boards are connected to slots D and E.

See a separate manual on each individual Fieldbus Board. Ask factory or your nearest distributor

for more information.

OPTD_

• Adapter boards

• Boards with fiber optic adapters, e.g. System Bus Fiber Optic Adapter Board.

• Connect the adapter boards to slots D and E (see however page 77).

See pages 69 to 79 for a detailed presentation of the boards of this type. See also the principle

diagram on the option boards and their equipment on page 81.

Page 7

General information vacon • 5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

1.4 Technical data

The data in the table below applies to the inputs and outputs on all basic and expander boards.

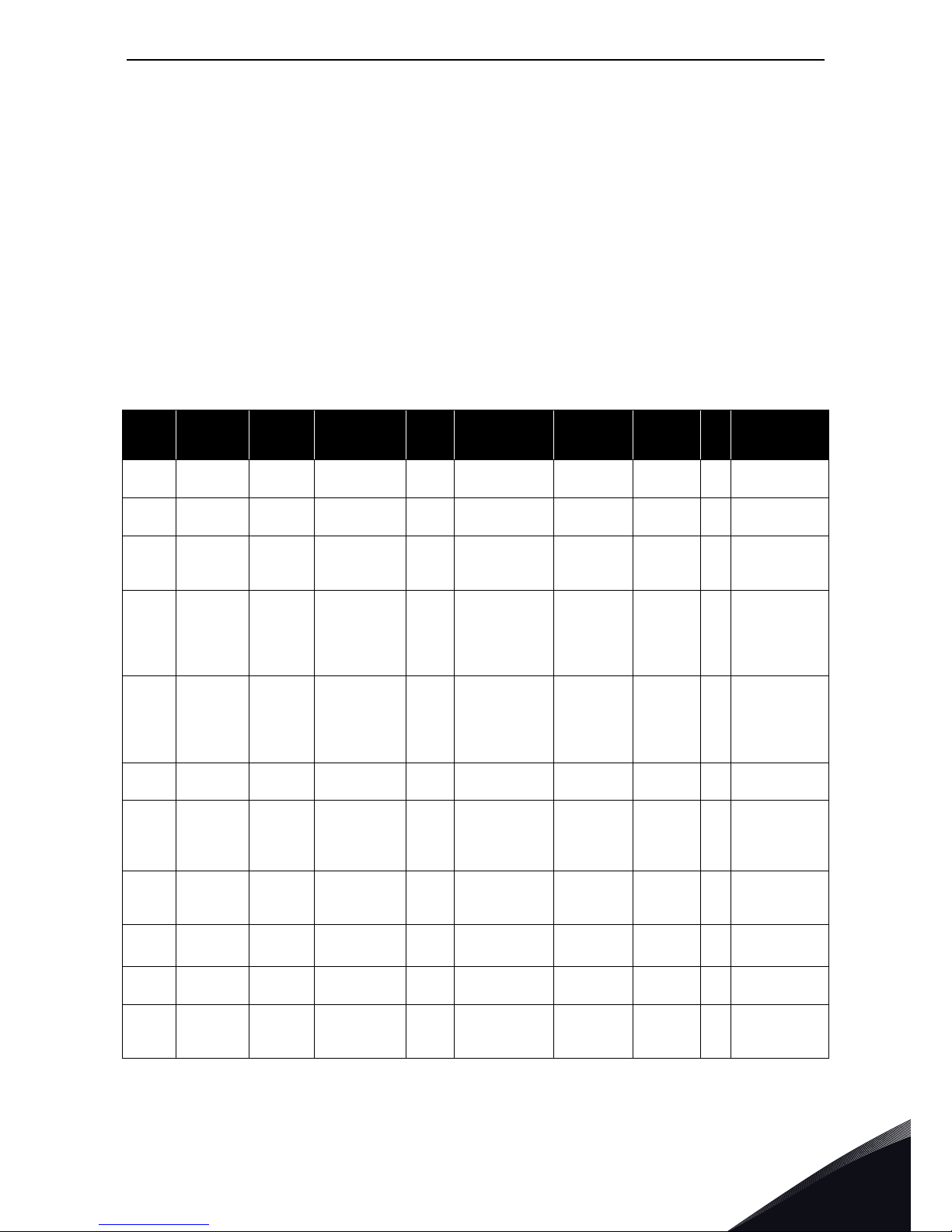

Table 1. Tec hn ica l d at a

Safety (all boards)

Comply with EN50178, C-UL and EN60204-1

Inputs/outputs galvanically isolated; Isolation voltage

rate 500V

Input/output type Specification

Analogue inputs (AI), voltage

0…±10V, R

i

≥ 200 kΩ, single-ended;

Resolution 10 bits/0.1%, accuracy ±1% of the full display

(–10…+10V joystick control)

Analogue inputs (AI), current

0(4)…20mA, R

i

= 250Ω, differential

Resolution 10 bits/0.1%, accuracy ±1% of the full display

Digital inputs (DI), DC voltage controlled

24V: "0"≤10V, "1"≥18V, R

i

> 5kΩ

Digital inputs (DI), AC voltage controlled

Control voltage 42…240 VAC

"0"<33V, "1">35V

Auxiliary voltage (output) (+24V)

24V (±15%), max 250mA (total summarized load from

ext. +24V outputs, max. 150 mA from one board.

Auxiliary voltage (input) (ext. +24V)

24VDC (±10%, max. ripple voltage 100mV RMS), max. 1A.

In special applications where PLC type functions are

included in the control unit the input can be used as

external auxiliary power supply for control boards as

well as I/O boards.

Reference voltage (output) (+10V

ref

)

10V – 0% – +2%, max. 10mA

Analogue output (AO), current (mA)

0(4)…20mA, R

L

<500Ω, resolution 10 bits/0.1%, accuracy

≤ ±2%

Analogue output (AO), voltage (V) 0(2)…10V, RL ≥ 1kΩ, resolution 10 bits, accuracy ≤ ±2%

Relay outputs (RO)

Switching capacity

Max. continuous load

Min.switching load:

24VDC/8A

250VAC/8A

125VDC/0.4A

2A rms

5V/10mA

Thermistor input (TI)

R

trip

= 4 kΩ (PTC type)

Encoder control voltage (+5V/+12V/

+15V/+24V)

See OPTA4, OPTA5, OPTA7, OPTAE and OPTBB technical

data

Encoder connections (inputs, outputs)

See OPTA4, OPTA5, OPTA7, OPTAE and OPTBB technical

data

Environment (all boards)

Ambient operating temperature –10…55°C

Storing temperature –40…60°C

Humidity <95%, no condensation allowed

Altitude Ma 1000m

Vibration 0.5 G at 9…200 Hz

Page 8

1

vacon • 6 General information

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1.4.1 Isolation

The control connections are isolated from the mains potential and the I/O ground is connected

directly to the frame of the AC drive. Digital inputs and relay outputs are isolated from the I/O

ground. For digital input arrangements, see Chapter Digital input signal conversions on page 7.

1.4.2 Analogue inputs (mA/V)

Analogue inputs of I/O boards can be used as either current inputs or voltage inputs (see detailed

description of each board). The signal type is selected with a jumper block on the board. In case the

voltage type input is used you still have to define the voltage range with another jumper block. The

factory default value for the analogue signal type is given in the description of the board. For detailed

information, see the description of the board in question.

1.4.3 Analogue outputs (mA/V)

In the same way as in the analogue inputs, the output signal type (current/voltage) can be selected

with jumper except for some expander boards with analogue outputs used only with current signals.

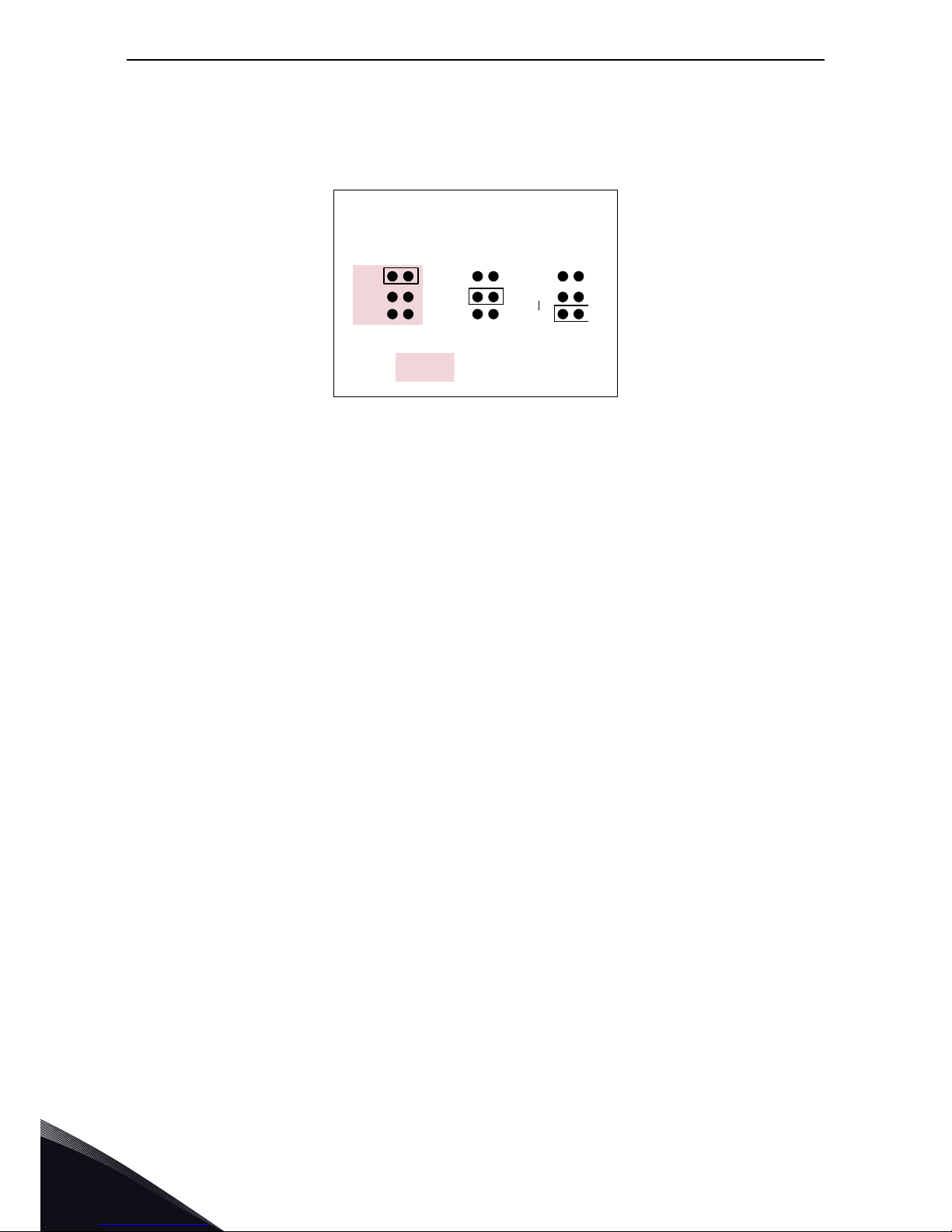

1.4.4 Control voltage (+24V/EXT +24V)

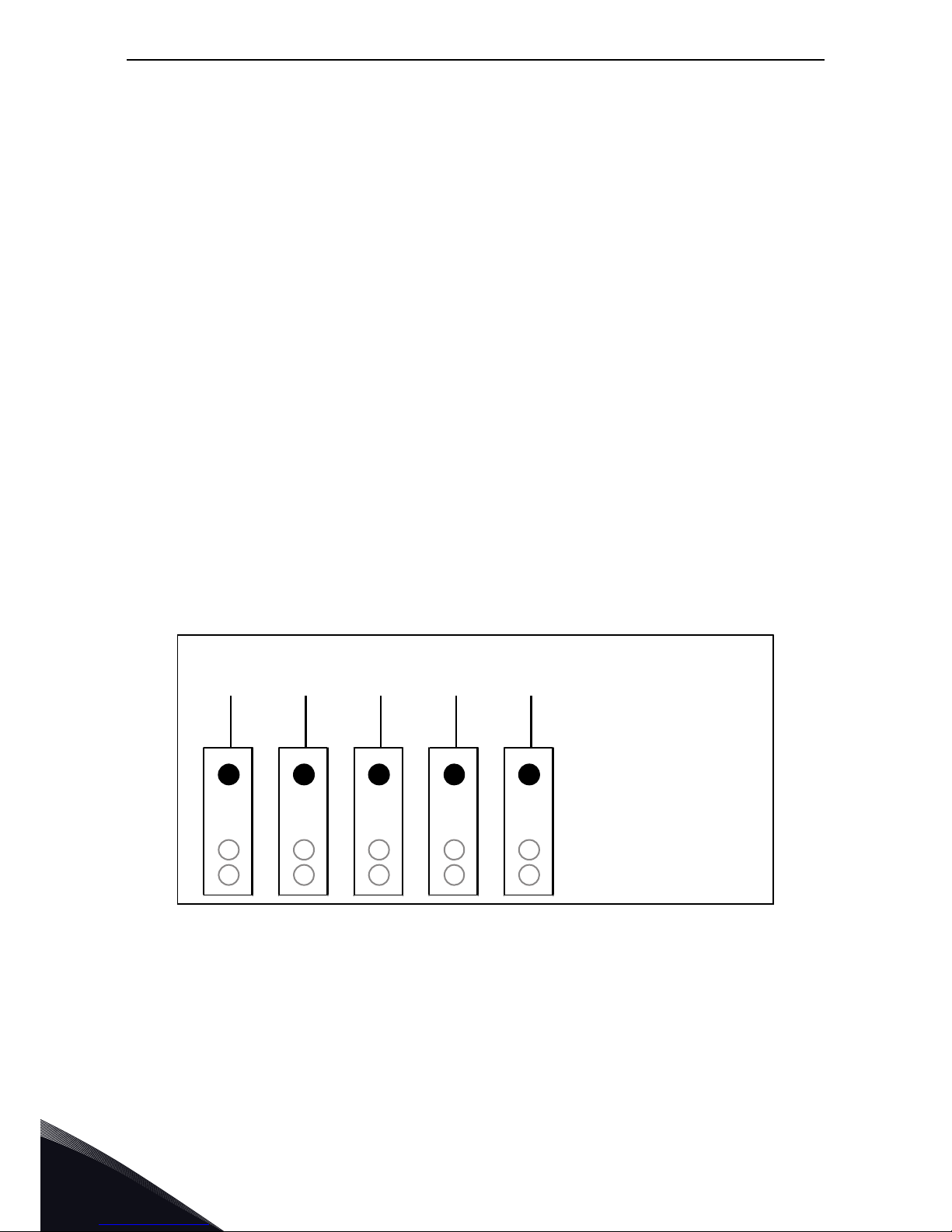

The control voltage output +24V/EXT+24V can be used in two ways. Typically, the +24V control voltage

is wired to digital inputs through an external switch. The control voltage can also be used to powerup external equipment, such as encoders and auxiliary relays.

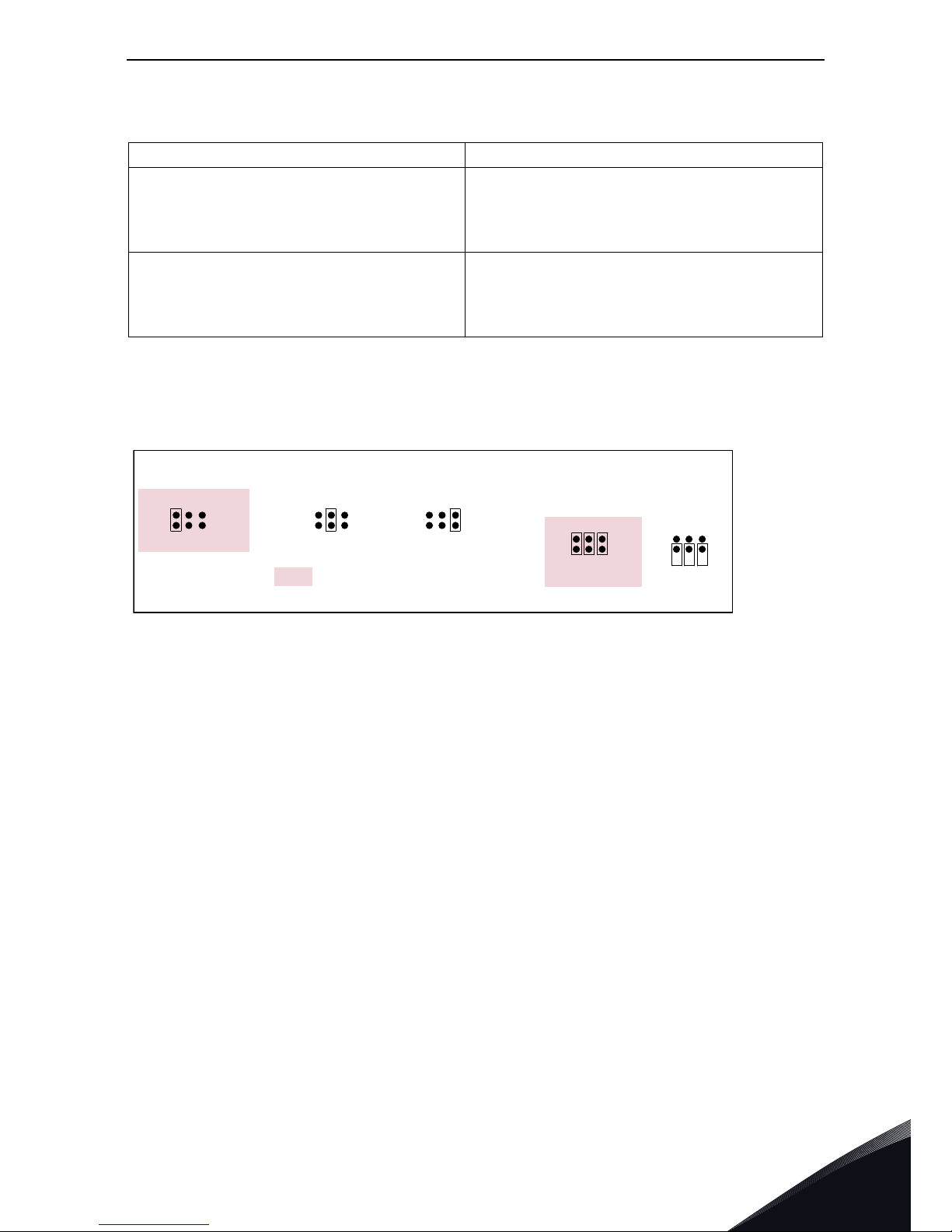

Observe that the specified total load on all available +24V/EXT+24V output terminals must not

exceed 250mA. The maximum load on the +24V/EXT+24V output per board is 150mA. See Figure 3.

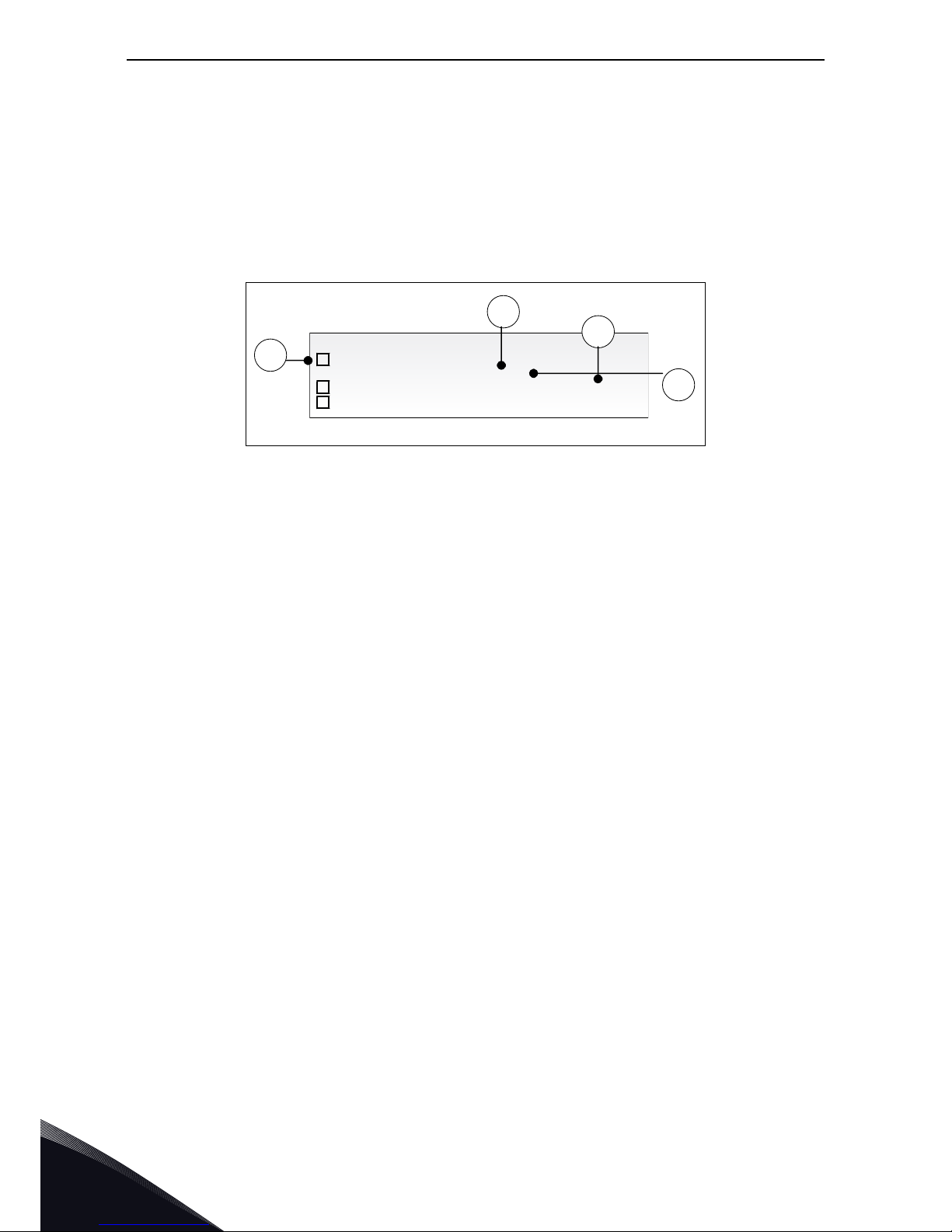

Figure 3. Maximum loads on +24V/EXT+24V output

The +24V/EXT+24V outputs can further be used to externally power-up the control board as well as

the basic and expander boards. If an external power supply is connected to EXT+24V output, the

control board, basic boards and expander boards remain live even if mains is lost on the AC drive.

This ensures sufficient functioning of the control logic (not the motor control, however) and some

alarms in exceptional power-loss situations. Furthermore, fieldbus links remain powered which

enables e.g. the Profibus Master to read valuable data on the AC drive.

NOTE: The power unit is not powered through the EXT+24V and therefore the motor control does not

work if the mains is lost.

+24V

out

+24V

out

+24V

out

+24V

out

+24V

out

++++

= max. 250mA

max.

150mA

max.

150mA

max.

150mA

max.

150mA

max.

150mA

7224.emf

Page 9

General information vacon • 7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

Requirements for an external power back-up:

- output voltage +24DC±10%, max. ripple voltage 100mV RMS

-max. current 1A

- 1A external fuse (no internal short-circuit protection on the control board

NOTE: Analogue outputs and inputs do not work with only +24V supplied to the control unit.

If there is a +24V/EXT+24V output on the board it is short-circuit protected locally. If one of the +24V/

EXT+24V outputs short-circuits, the others remain powered because of the local protection.

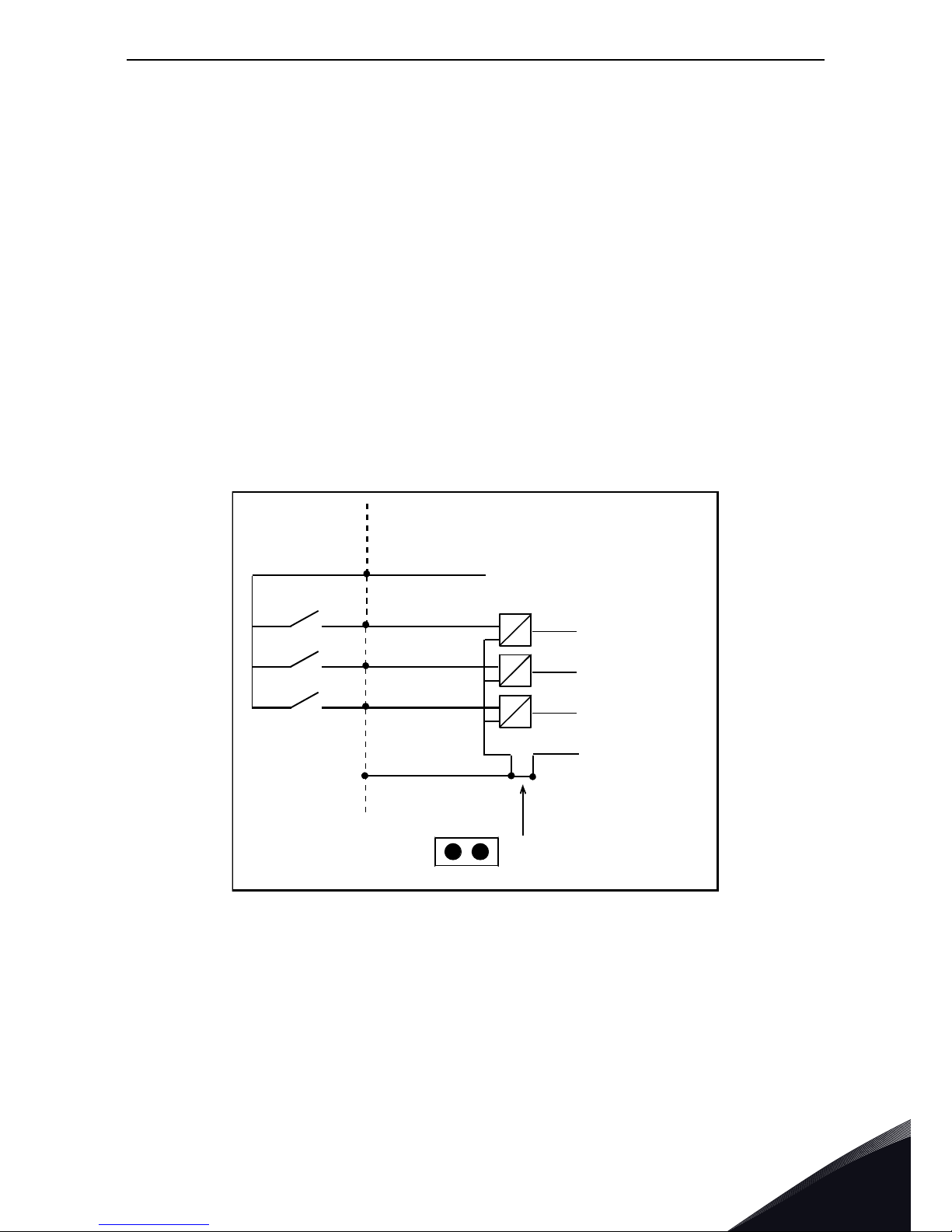

1.4.5 Digital input signal conversion

The active signal level depends on which potential the common input CMA (and CMB if available) is

connected to. The alternatives are +24V or Ground (0V). See Figure 4, Figure 5 and Figure 6.

The 24-volt control voltage and the ground for the digital inputs and the common input (CMA) can

be either internal or external.

Some typical input signal conversion examples are shown below. If you use the internal +24V from

the AC drive, the following arrangements are possible:

Figure 4. If CMA is connected to GND with inboard jumper the internal +24V is used and the CMA terminal

ed not be wired

+24V/EXT+24V

DI1

DI2

DI3

GND

Jumper setting: = CMA connected to GND

7225.emf

Page 10

1

vacon • 8 General information

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

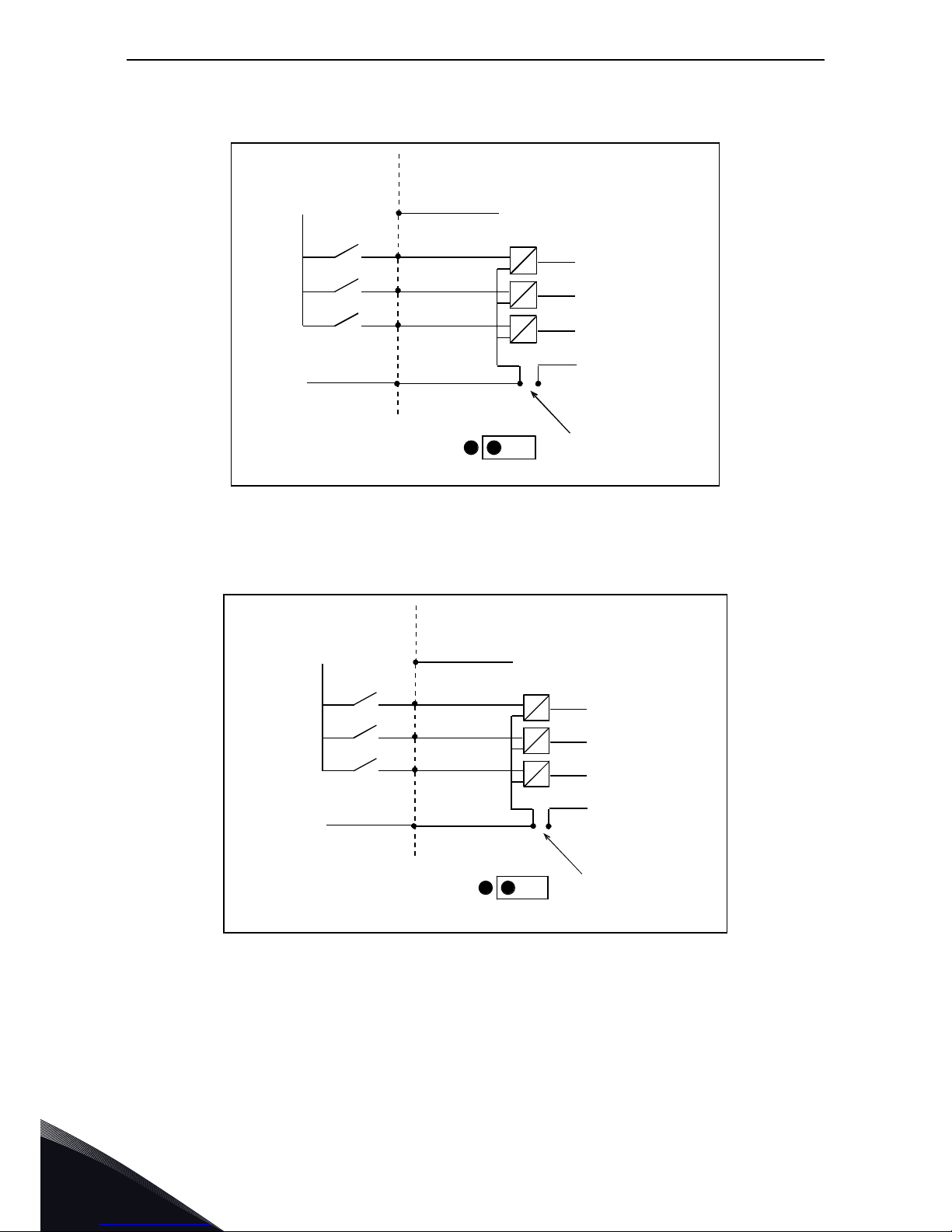

If you use an external +24V the following arrangements are possible:

Figure 5. Positive logic with external +24V when CMA is isolated from GND using onboard jumper. The

input is active when the switch is closed

Figure 6. Negative logic with external +24V when CMA is isolated with onboard jumper. The input is active

when the switch is closed (0V is the active signal)

You can make the positive and negative logic arrangements also with the internal +24V. Place the

jumper block in the 'CMA isolated from GND' position (as above) and wire the CMA terminal to the

GND terminal of the AC drive.

+24V/EXT+24V

DI1

DI2

DI3

GND

Jumper setting:

= CMA isolated from GND

Ground

External +24V

7226.emf

+24V/EXT+24V

DI1

DI2

DI3

GND

Jumper setting:

= CMA isolated from GND

External +24V

Ground

7227.emf

Page 11

General information vacon • 9

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

1.5 Hardware protections

1.5.1 Terminal block coding

In order to avoid incorrect connections of terminal blocks to boards, some terminal blocks as well

as related terminal connectors on the board are uniquely coded. For more information, see the

description of the individual board.

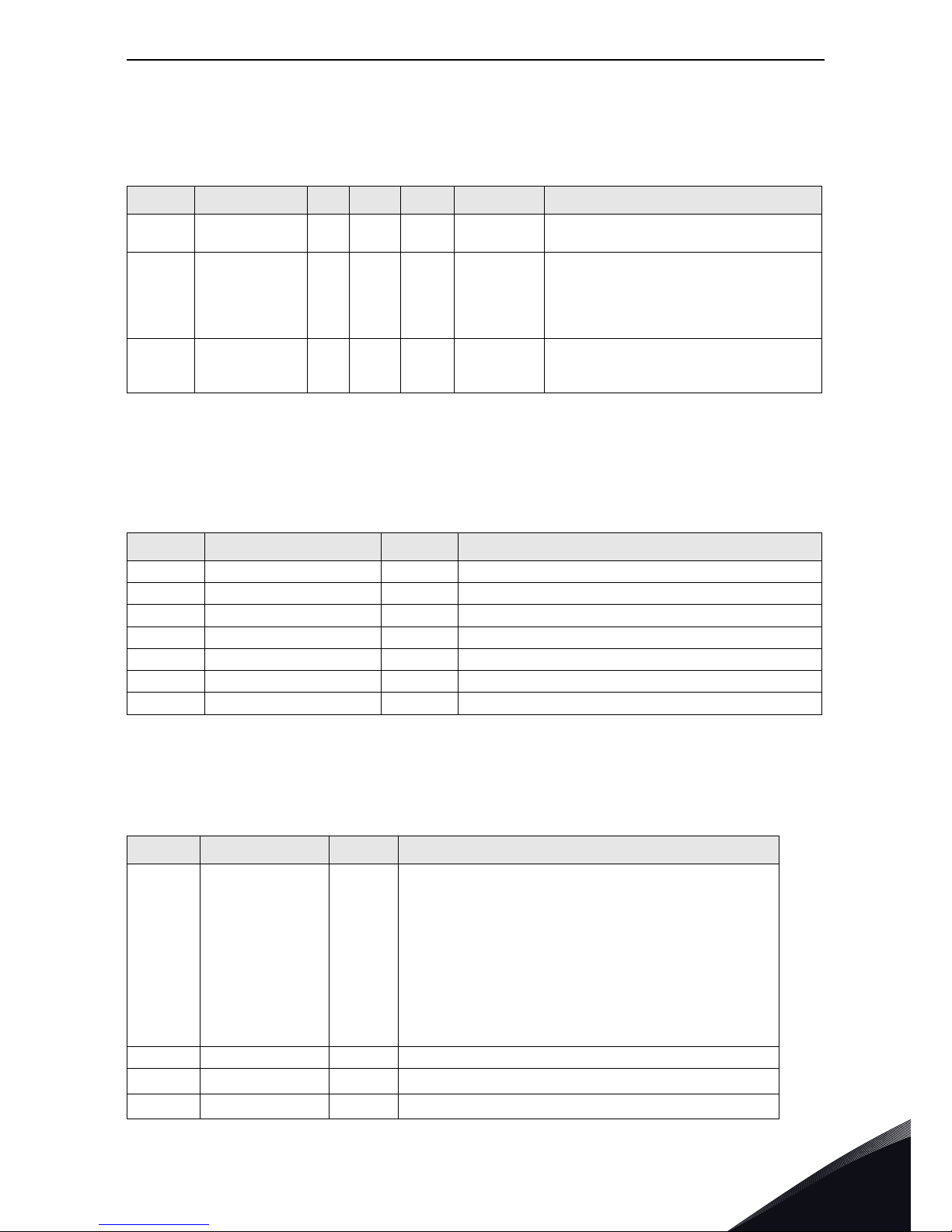

1.5.2 Board slot guides and allowed slots

You cannot mount an option board into any slot.Table 46 and Table 47 show which slots are allowed

for which option boards. For reasons of safety, slots A and B are protected in hardware against

mounting of unallowed boards. As regards mounting of unallowed boards into slots C, D and E, the

boards just will not work, there is no danger of health or equipment damage.

Figure 7. Board guide to prevent incorrect mountings

Page 12

1

vacon • 10 General information

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1.6 Type identification number

NOTE: This information is relevant only for special applications designers using the VACON®

NC1131-3 engineering tool.

Each VACON

®

OPTxx board has a unique type designation code. Besides the type designation code,

each board has a unique Type identification number which is used by the system program to identify

which board is plugged into which board slot. The system program and the application use the Type

ID also to establish the needed connections in order to achieve the desired functionality of the

available I/O boards in the control unit. The ID code is loaded in the memory of the board.

1.7 Defining functions to inputs and outputs

How to connect functions and the available I/O depends on the application you use. The VACON® All

in One Application Package includes seven applications: Basic Application, Standard Application,

PID Control Application, Multi-Step Speed Control Application, Local/Remote Control Application,

Pump and Fan Control Application with Autochange and Multipurpose Control Application (see Allin-One Application Manual). All but two applications of these use the conventional VACON

®

method

to connect functions and the I/O. In the Function to Terminal Programming Method (FTT), you have

a fixed input or output that you define a certain function for. The mentioned two applications, Pump

and Fan Control and Multipurpose Control Application, however, use the Terminal to Function

Programming Method (TTF) in which the programming process is carried out the other way round:

Functions appear as parameters which the operator defines a certain input/output for.

Connecting a certain input or output to a certain function (parameter) is done by giving the

parameter an appropriate value, the address code. The code is formed of the Board slot on the

VACON

®

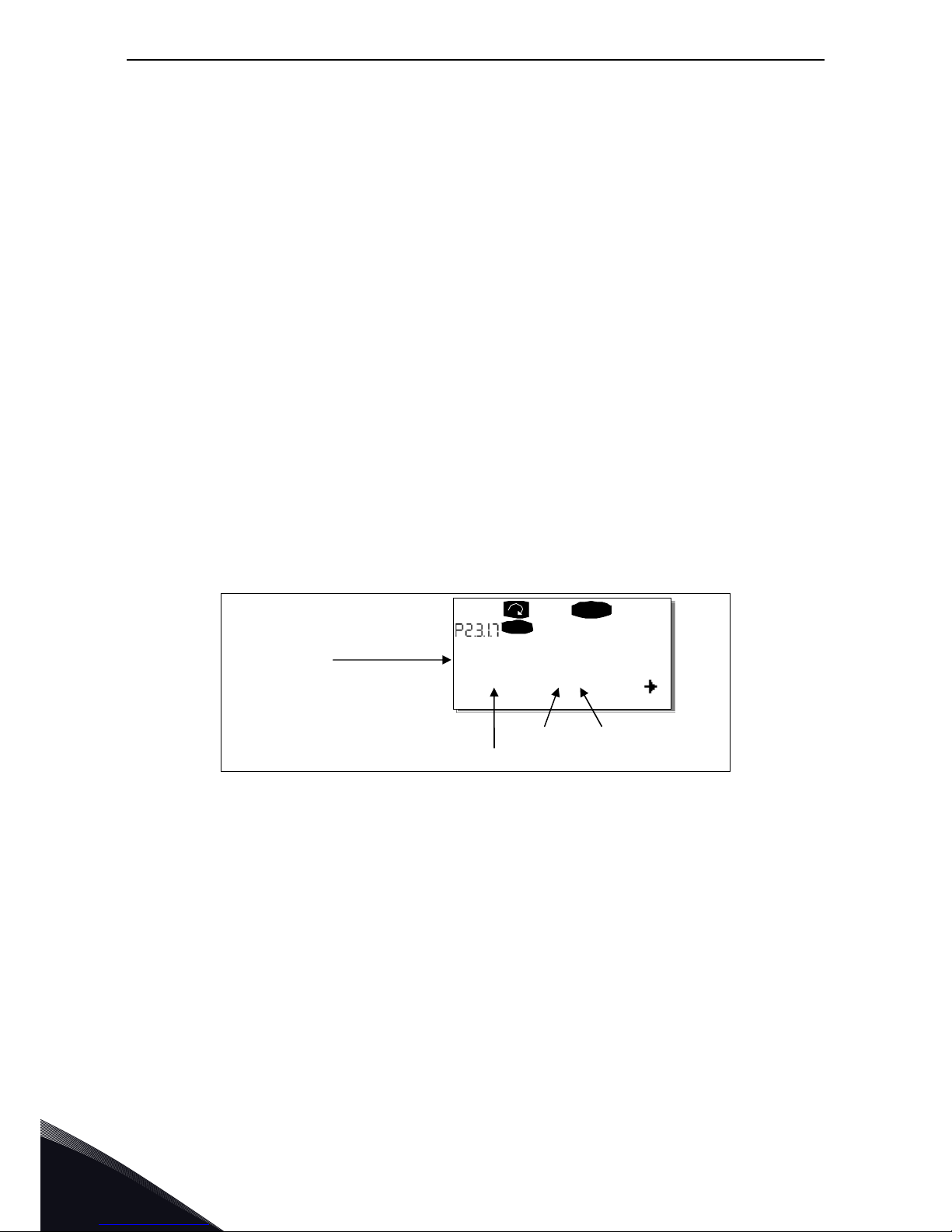

NX control board (see page 2 and 3) and the respective input/output number. See below.

Example: You use the Pump and Fan Control Application. You want to connect the digital output

function Reference fault/warning (parameter 2.3.1.7) to the digital output DO1 on the basic board

OPTA1.

First find the parameter 2.3.1.7 on the keypad. Press the Menu button right once to enter the edit

mode. On the value line, you will see the terminal type on the left (DigIN, DigOUT, An.IN, An.OUT)

and on the right, the present input/output the function is connected to (B.3, A.2 etc.), or if not

connected, a code 0.#.

When the value is blinking, hold down the Browser button up or down to find the desired board slot

and input/output number. The program will scroll the board slots starting from 0 and proceeding

from A to E and the I/O numbers from 1 to 10.

READY

I/O term

DigOUT:B.1

AI

R

ef Faul/Warn

Function name

rebmunlanimreTtolS

epytlanimreT

7229.emf

Page 13

General information vacon • 11

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

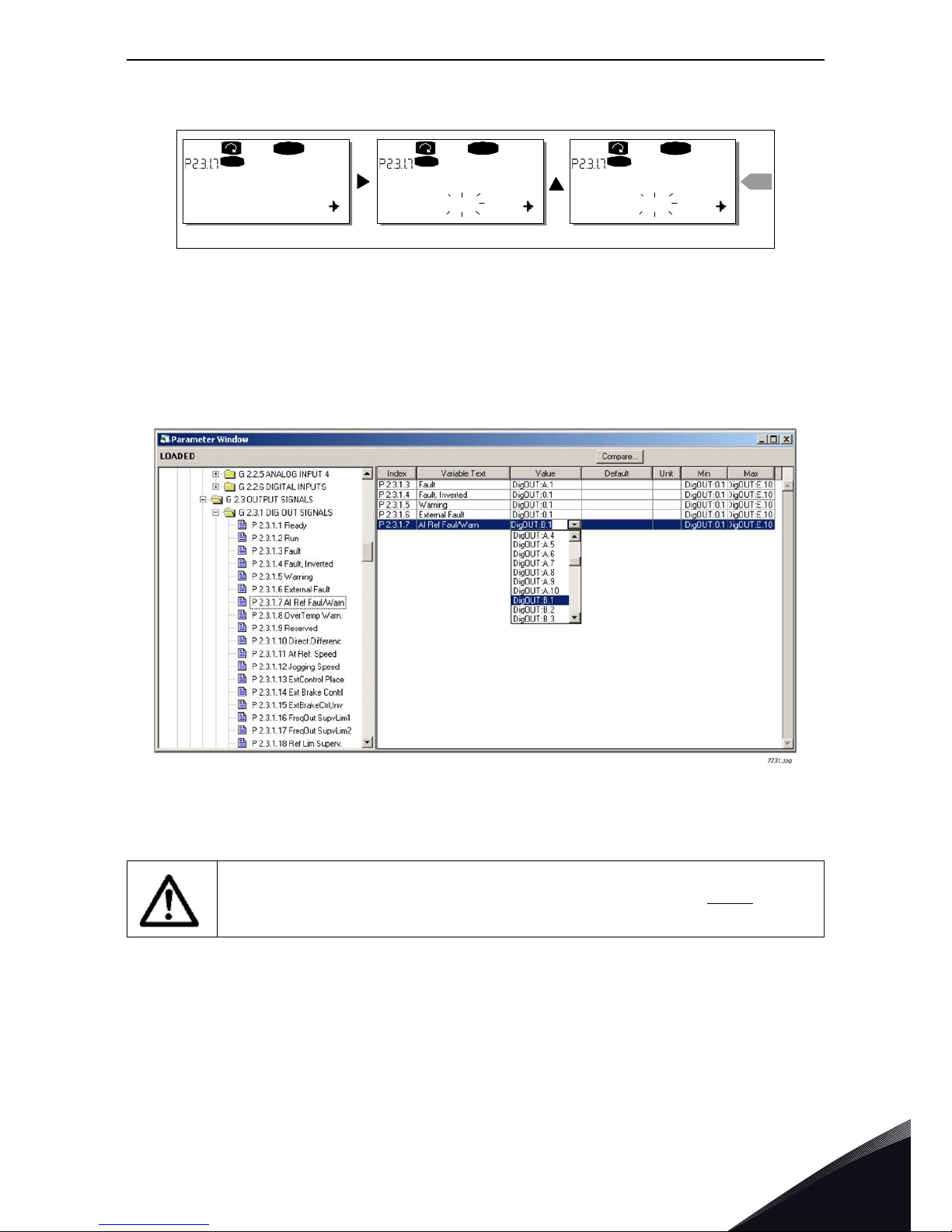

Once you have set the desired code, press the Enter button once to confirm the change.

1.8 Defining a terminal for a certain function with NCDrive

programming tool

If you use the NCDrive Programming Tool for parametrizing you will have to establish the

connection between the function and input/output in the same way as with the control panel. Just

pick the address code from the drop-down menu in the Value column (see Figure 8 below).

Figure 8. Screenshot of NCDrive programming tool; Entering the address code

NOTE: The inputs, unlike the outputs, cannot be changed in RUN state.

Be ABSOLUTELY sure not to connect two functions to one and same output

in order

to avoid function overruns and to ensure flawless operation.

READ Y

I/Oterm

DigOUT:0.0

READ Y

I/Oterm

DigOUT:0.0

READ Y

I/Oter m

DigOUT:A.1

ent er

AIRefFaul/Warn AIRefFaul/Warn AIRefFaul/Warn

7230.emf

Page 14

1

vacon • 12 General information

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

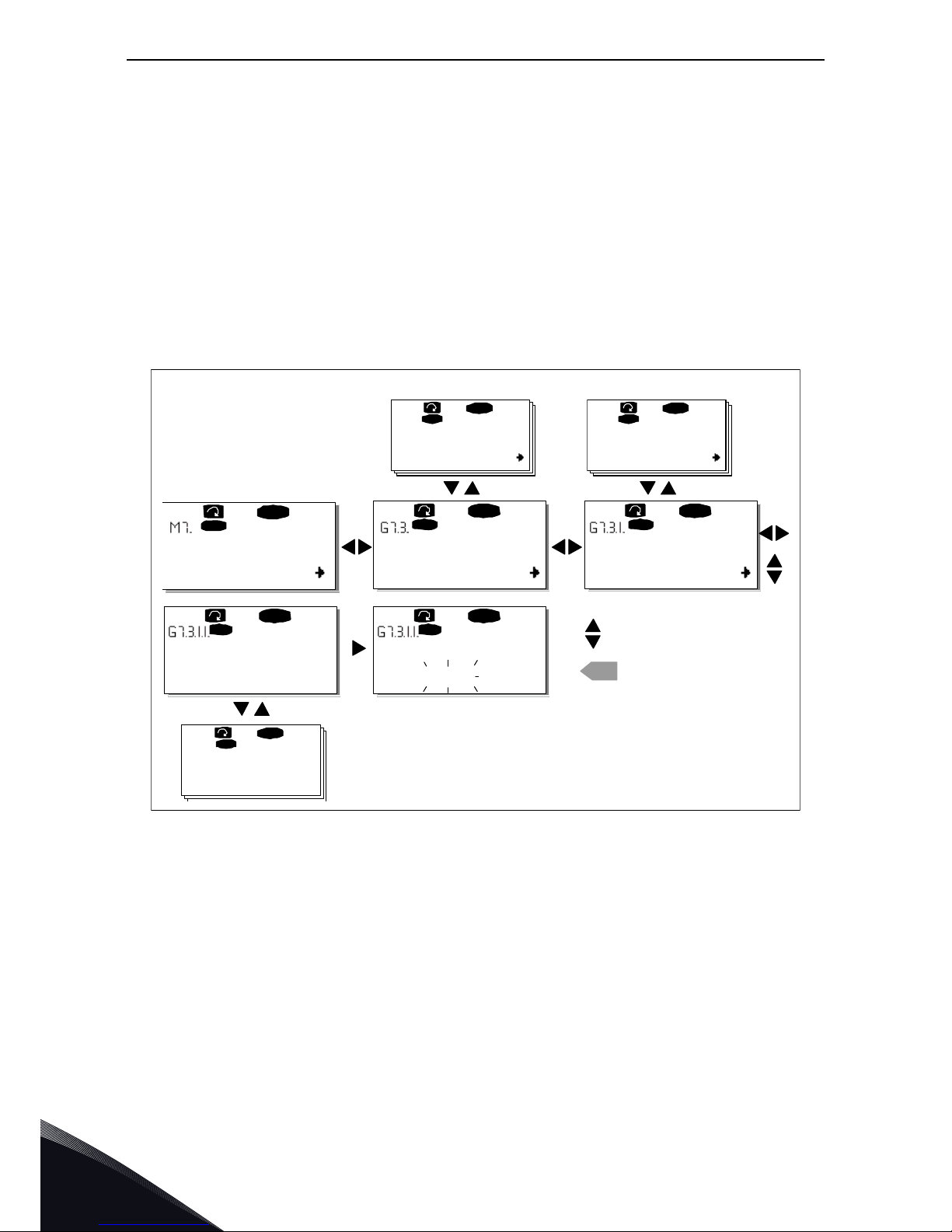

1.9 Option board related parameters

Some of the input and output functions of certain option boards are controlled with associated

parameters. The parameters are used to set the signal ranges for analogue inputs and outputs as

well as values for different encoder functions.

The board-related parameters can be edited in the Expander Board Menu (M7) of the control

keypad.

Enter the following menu level (G#) with the Menu button right. At this level, you can browse through

slots A to E with the Browser buttons to see what expander boards are connected. On the lowermost

line of the display you also see the number of parameters associated with the board. Edit the

parameter value as shown below. For more information on the keypad operation, see VACON

®

NXS/

P User Manual. See Figure 9.

Figure 9. Board parameter value editing

NOTE: Fieldbus boards (OPTC_) also have fieldbus-related parameters. These boards are, however,

described in the separate fieldbus board manuals (see http://drives.danfoss.com/knowledgecenter/technical-documentation/).

G1

G5

READY

I/Oter m

C:NXOPTC1

READY

I/Oter m

G1G2

READY

I/Oter m

READY

I/Oterm

enter

P1P4

D:NXOPTC2

READY

I/ Ot e r m

G1G2

READY

I/O te rm

V1V2

READY

I/Oter m

READY

I/Oterm

Exp ander boards

Parameters

Slave address

126

CHANGE VALUE

CONFIRM CHANGE

Slave address

126

Baud rate

Auto

Monitor

7232.emf

Page 15

Installation of VACON® Option Boards vacon • 13

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2

2. INSTALLATION OF VACON® OPTION BOARDS

Do not add or replace option boards or fieldbus boards on an AC drive with the power

switched on. This may damage the boards.

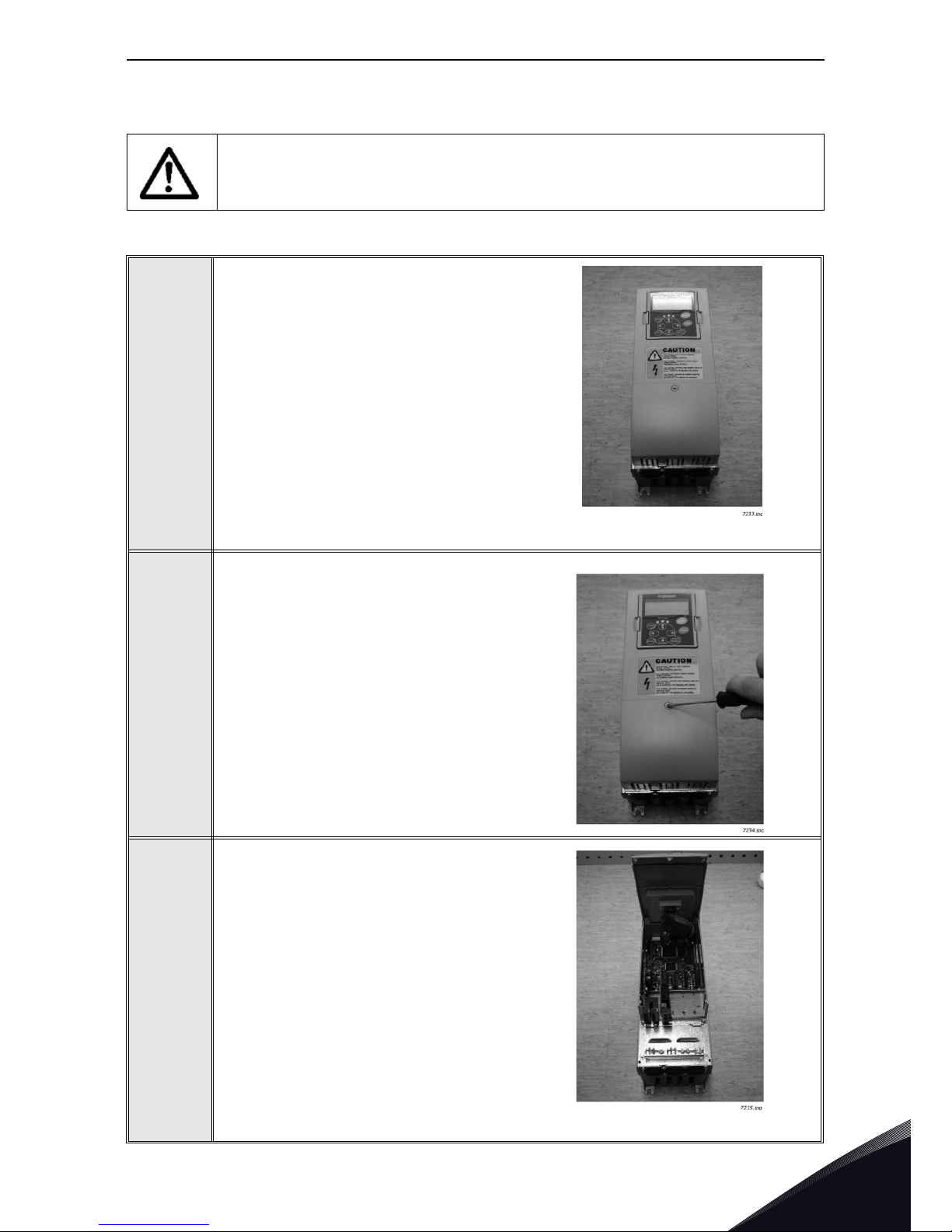

A

VACON® NX AC drive.

B

Remove the cable cover.

C

Open the cover of the control unit.

Page 16

2

vacon • 14 Installation of VACON® Option Boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

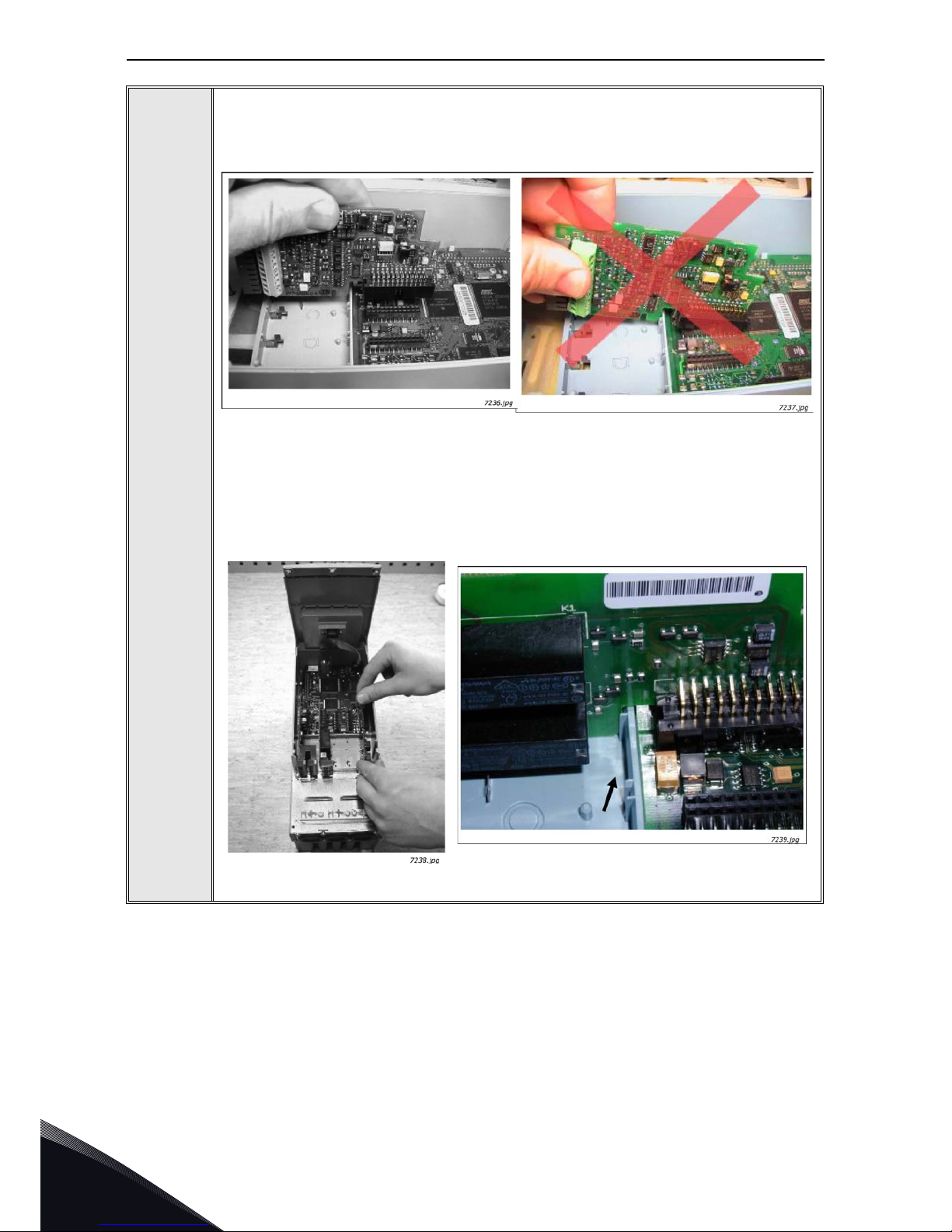

D

Install the option board in a correct slot on the control board of the AC drive. On

attaching (also removing) the board, hold it in horizontally straight position to avoid

twisting the connector pins. See the photos below.

Make sure that the board (see below) fits tightly in the metal clamp and the plastic

groove. If the board seems to be difficult to fit in the slot you may have to check the

allowed slots for your option board.

NOTE: Check that the jumper settings on the board correspond to you needs.

Finally, close the cover of the AC drive and the cable cover.

Page 17

Installation of VACON® Option Boards vacon • 15

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2

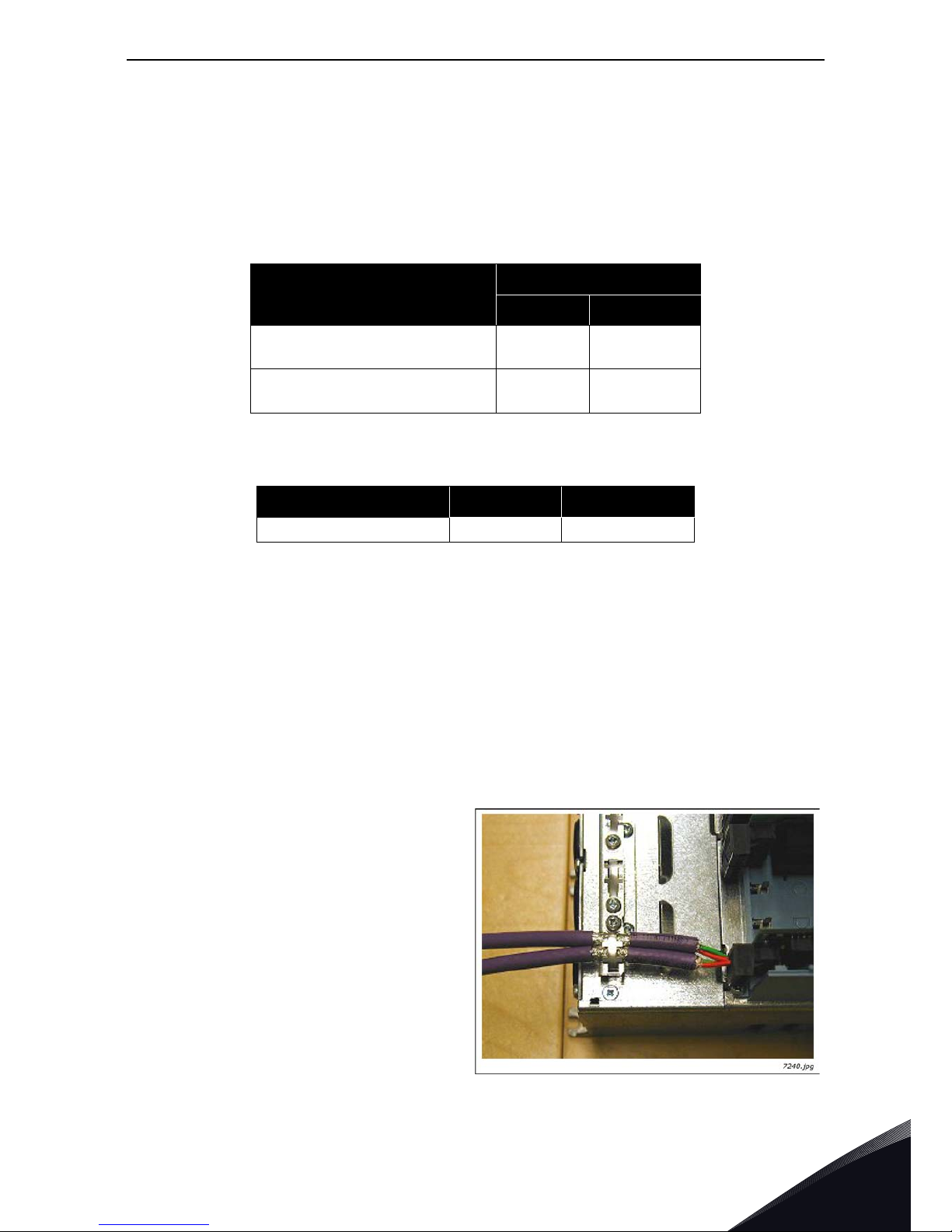

2.1 Control cables

The control cables used must be at least 0.5mm2 screened multicore cables. The maximum

terminal wire size is 2.5mm

2

for the relay terminals and 1.5 mm2 for other terminals.

Find the tightening torques of the option board terminals in the table below.

2.1.1 Cable grounding

We recommend to ground the control cables in the manner presented above.

Strip the cable at such distance from the

terminal that you can fix it to the frame with the

grounding clamp.

Figure 10. Grounding of control cable

Table 2. Tightening torques of terminals

Termin al sc rew Tightening torque

Nm lb-in.

Relay and thermistor terminals

(screw M3)

0.5 4.5

Other terminals

(screw M2.6)

0.2 1.8

Table 3. Cable types required to meet standards

Cable type Level H, C Level L

Control cable 4 4

Level H =

EN 61800-3+A11, 1

st

environment, restricted distribution

EN 61000-6-4

Level L =

EN61800-3, 2

nd

environment

4 =

Screened cable equipped with compact low-impedance shield

(NNCABLES /Jamak, SAB/ÖZCuY-O or similar).

Page 18

2

vacon • 16 Installation of VACON® Option Boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2.2 Board information sticker

Each I/O option board package delivered by the factory includes a sticker (shown below) where

possible modifications made in the AC drive are noted. Please check Option board (1), mark the

board type (2), the slot into which the board is mounted (3) and the mounting date (4) on the sticker.

Finally, attach the sticker on your drive.

Drive mod if ied :

Option board:

NXOPT................

IP54 upgrade/ Collar

in slot:

Date:...................

ABCDE

EMC level modifi ed: H to T / T to H

Date:...................

Date:...................

3

2

4

1

7241.emf

Page 19

Descriptions of VACON® option boards vacon • 17

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

3. DESCRIPTIONS OF VACON® OPTION BOARDS

3.1 Basic boards OPTA_

• Basic boards used for basic I/O; normally pre-installed at the factory.

• This board type uses slots A, B and C.

The standard VACON

®

NXS and NXP AC drives contain two boards placed in slots A and B. The board

in slot A (OPTA1, OPTA8 or OPTA9) has digital inputs, digital outputs, analogue inputs and an

analogue output. The board in slot B (OPTA2) has two change-over relay outputs. As an alternative

to OPTA2, a board of type OPTA3 can also be placed in slot B. In addition to the two relay outputs,

this board has one thermistor input.

The boards you wish to have installed in your AC drive have to be defined in the type designation code

of the AC drive when ordering it from the factory.

Table 4. VACON

®

NX Basic boards and their equipment

FC

type

I/O

board

Allowed

slots

DI DO AI AO RO TI Other

NXS

NXP

OPTA1 A 6 1

2 (mA/V), incl.

-10…+10V

1

(mA/V)

+10Vref

+24V/ EXT+24V

NXS

NXP

OPTA2 B

2

(NO/NC)

NXS

NXP

OPTA3 B

1

(NO/NC)

+ 1 NO

1

NXS

1)

NXP

OPTA4 C

3 DI encoder

(RS-422) +

2 DI

(qualifier &

fast input)

+5V/+15V/+24V

(progr.)

NXS

1)

NXP

OPTA5 C

3 DI encoder

(wide range) +

2 DI

(qualifier &

fast input)

+15V/+24V

(progr.)

NXP OPTA7 C 6 (enc.) 2 (enc)

+15V/+24V

(progr.)

NXS

NXP

OPTA8 A 6 1

2 (mA/V), incl.

-10…+10V (decoupled from

GND)

1 (mA/V)

(decoupled

from GND)

+10Vref (decoupled from GND)

+24V/ EXT+24V

NXS

NXP

OPTA9 A 6 1

2 (mA/V),

incl. -10…+10V

1 (mA/V)

+10ref (2.5 mm

terminals)

+24V/ EXT+24V

NXS

1)

NXP

OPTAE C

3 DI encoder

(wide range)2 (Enc.)

+15V/+24V

(progr.)

NXS

NXP

OPTAL A

6

42…240 VAC

1

2 (AI1 0-10V)

(AI2 +-10V)

2 (AO1 mA)

(AO2 V)

+15V/+24V

NXP OPTAN A 6

2 (mA/V),

incl.

-10…+10V

2 (mA/V),

incl.

-10…+10V

+10Vref

-10Vref

+24V/ EXT+24V

1)

Encoder board can be used in VACON® NXS with special applications only.

DI = Digital input DO = Digital output TI = Thermistor input

AI = Analogue input AO = Analogue output RO = Relay output

Page 20

3

vacon • 18 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

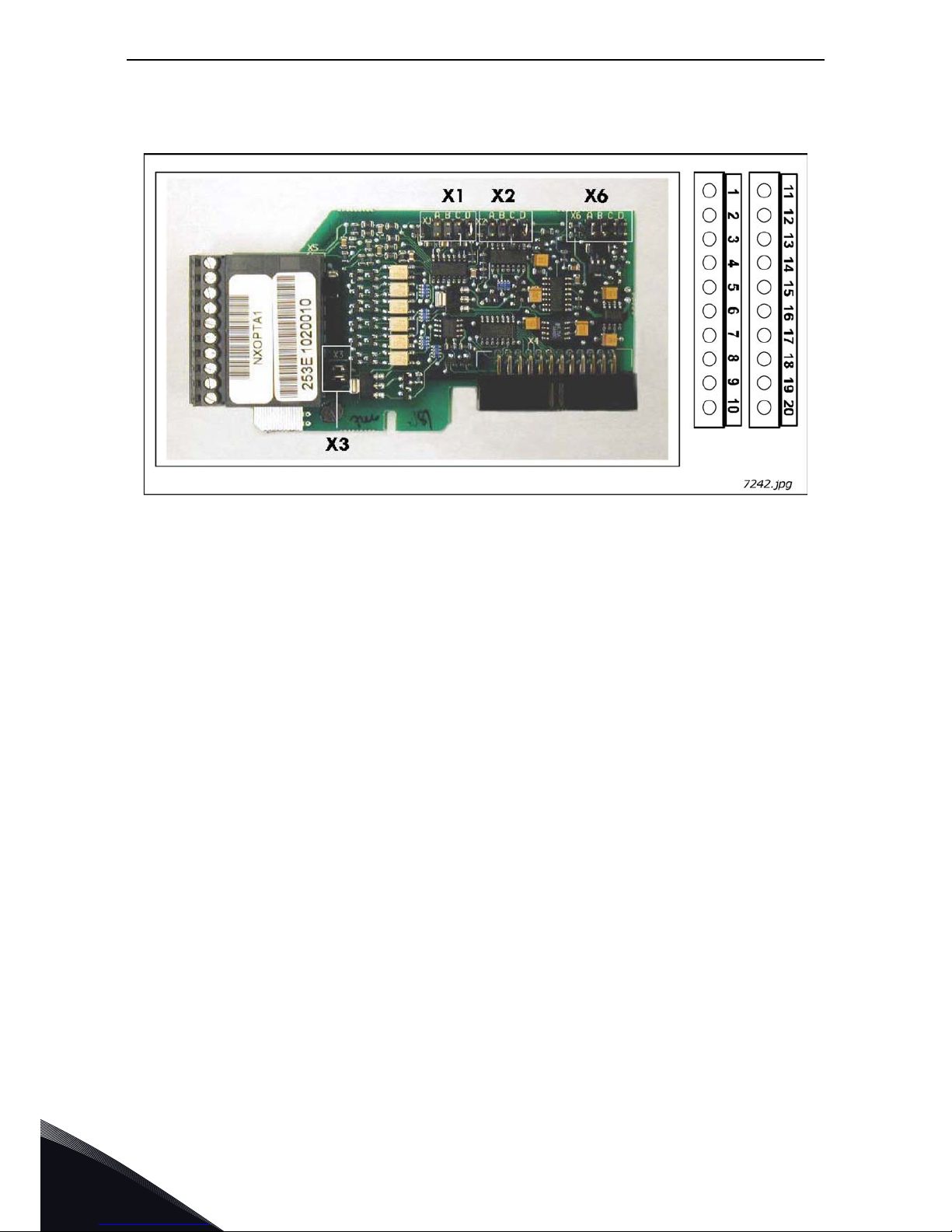

3.1.1 OPTA1

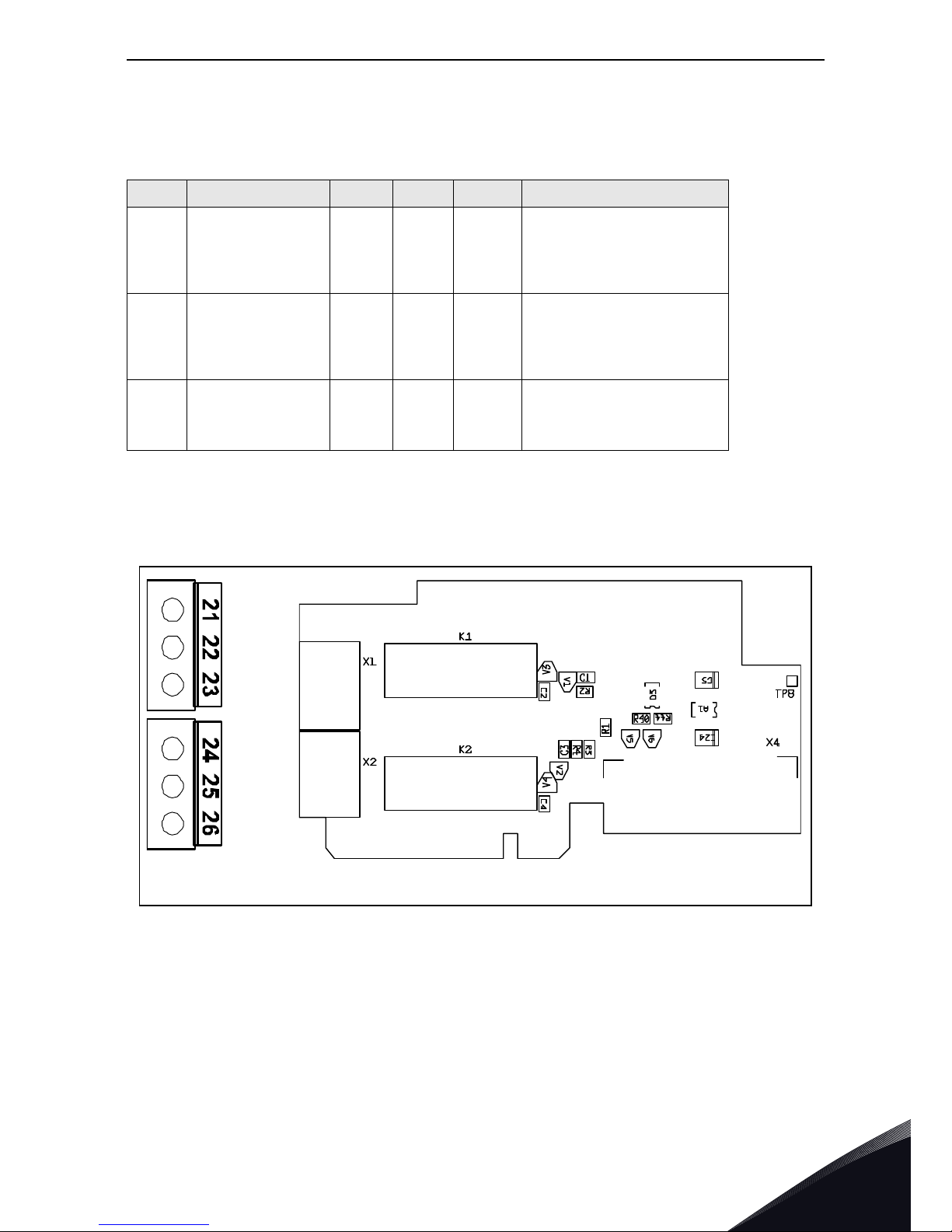

Figure 11. VACON

®

OPTA1 option board

Description: Standard I/O board with digital inputs/outputs and analogue inputs/outputs

Allowed slots: A

Type ID: 16689

Termi nal s: Two terminal blocks (coded = mounting of blocks in wrong order prevented,

terminals #1 and #12);

Screw terminals (M2.6)

Jumpers: 4; X1, X2, X3 and X6 (See Figure 12)

Board parameters: Board parameters:Yes (See page 21)

Page 21

Descriptions of VACON® option boards vacon • 19

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

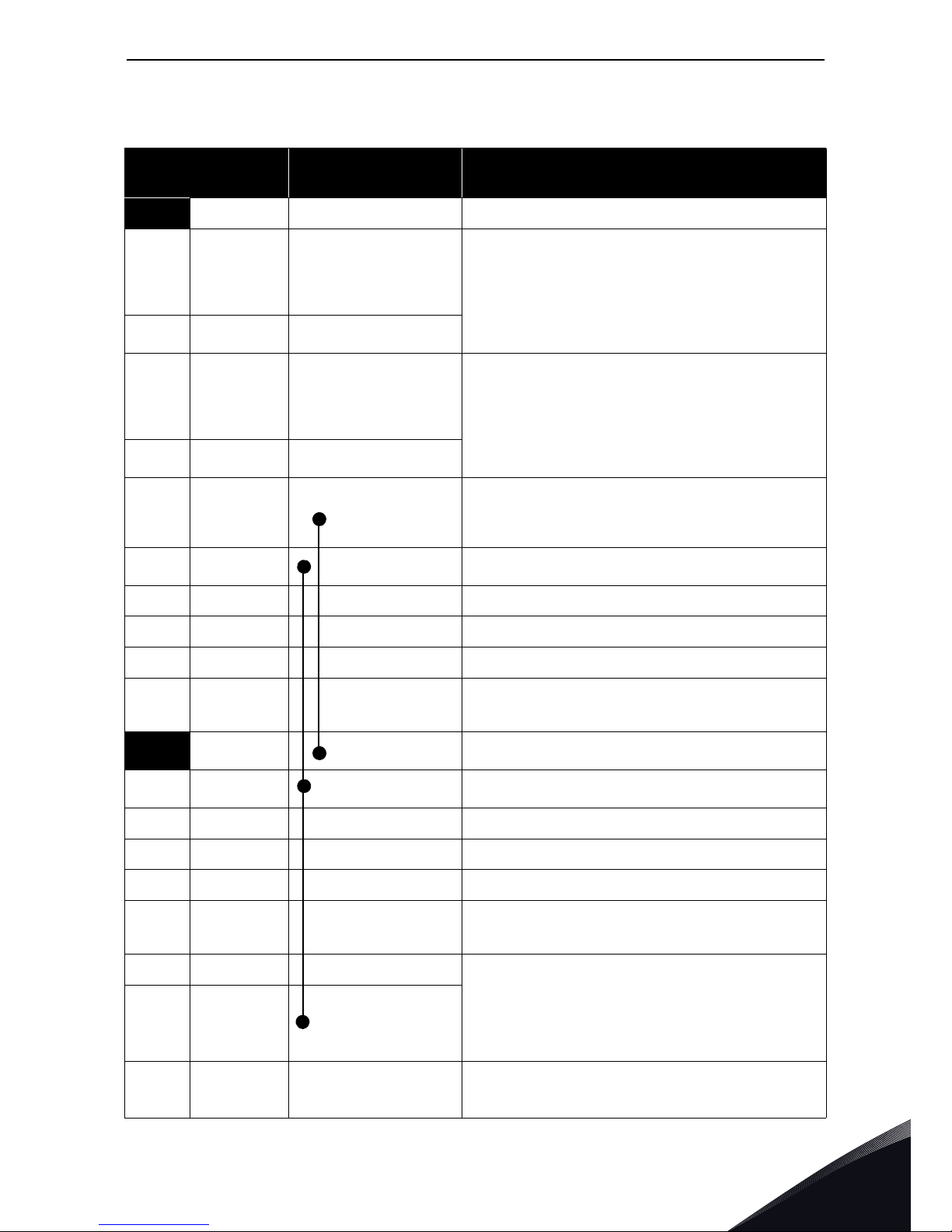

I/O terminals on OPTA1 (coded terminals painted black)

Table 5. OPTA1 I/O terminals

Ter mi na l

Parameter reference

on keypad and NCDrive

Technical information

1

+10 Vref Reference output +10V; Maximum current 10 mA

2

AI1+ An.IN:A.1

Selection V or mA with jumper block X1 (see page 20):

Default: 0– +10V (Ri = 200 kΩ)

(-10V..+10V Joy-stick control, selected with ajumper)

0– 20mA (Ri = 250 Ω)

Resolution 0.1%; Accuracy ±1%

3

AI1–

Differential input if not connected to ground;

Allows ±20V differential mode voltage to GND

4

AI2+ An.IN:A.2

Selection V or mA with jumper block X2 (see page 20):

Default: 0– 20mA (Ri = 250 Ω)

0– +10V (Ri = 200 kΩ)

(-10V..+10V Joy-stick control, selected with a jumper)

Resolution: 0.1%; Accuracy ±1%

5

AI2–

Differential input if not connected to ground;

Allows ±20V differential mode voltage to GND

6

24 Vout (bidirectional)

24V auxiliary voltage output. Short-circuit protected.

±15%, maximum current 150 mA, see 1.4.4.

+24Vdc external supply may be connected.

Galvanically connected to terminal #12.

7

GND

Ground for reference and controls

Galvanically connected to terminals #13,19.

8

DIN1 DigIN:A.1

Digital input 1 (Common CMA); R

i

= min. 5kΩ

9

DIN2 DigIN:A.2

Digital input 2 (Common CMA); R

i

= min. 5kΩ

10

DIN3 DigIN:A.3

Digital input 3 (Common CMA); R

i

= min. 5kΩ

11

CMA

Digital input common A for DIN1, DIN2 and DIN3.

Connection by default to GND.

Selection with jumper block X3 (see page 20):

12

24 Vout (bidirectional)

Same as terminal #6

Galvanically connected to terminal #6.

13

GND

Same as terminal #7

Galvanically connected to terminals #7 and 19

14

DIN4 DigIN:A.4

Digital input 4 (Common CMB); R

i

= min. 5kΩ

15

DIN5 DigIN:A.5

Digital input 5 (Common CMB); R

i

= min. 5kΩ

16

DIN6 DigIN:A.6

Digital input 6 (Common CMB); R

i

= min. 5kΩ

17

CMB

Digital input common B for DIN4, DIN5 and DIN6.

Connection by default to GND.

Selection with jumper block X3 (see page 20):

18

AO1+ AnOUT:A.1

Analogue output

Output signal range:

Current 0(4)–20mA, R

L

max 500Ω or

Voltage 0—10V, R

L

>1kΩ

Selection with jumper block X6 (see page 20):

Resolution: 0.1% (10 bits); Accuracy ±2%

19

AO1–

20

DO1 DigOUT:A.1

Open collector output

Maximum U

in

= 48VDC

Maximum current = 50 mA

Page 22

3

vacon • 20 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

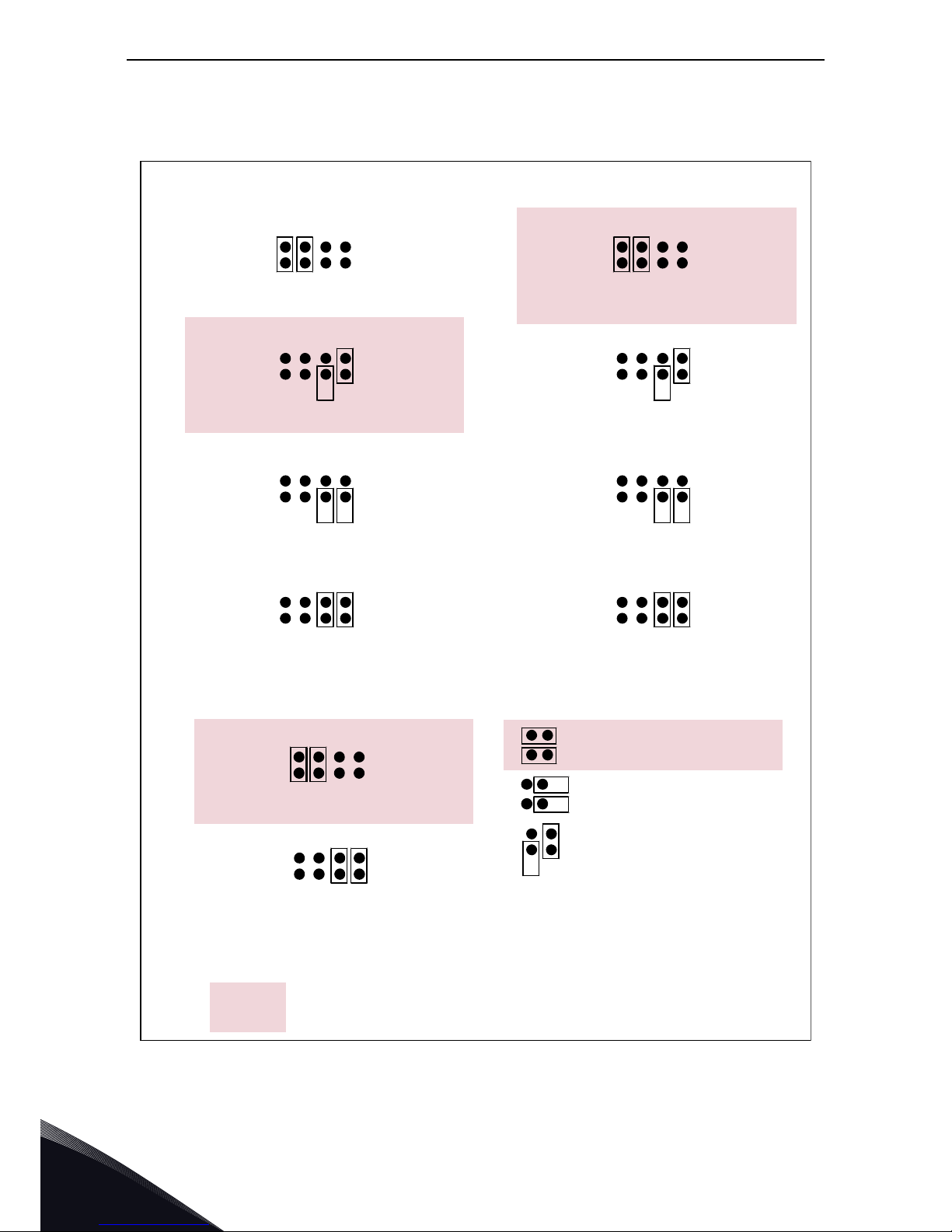

Jumper selections

There are four jumper blocks on the OPTA1 board. The factory defaults and other available jumper

selections are presented below.

Figure 12. Jumper block selection on OPTA1

ABCD

ABCD

ABCD

ABCD

ABCD

ABCD

ABCD

ABCD

ABCD

ABCD

Jum per block X 1 :

AI1 mode

AI1 mode: Voltage input; 0...10V

AI1 mode: Voltage input; 0...10V (differential)

AI1 mode: Voltage input; -10...10V

Jum per blockX2:

AI2 mode

AI2 mode: 0...2 0 mA; Current input

AI2 mode: Voltage i np ut; 0 . ..10 V

AI2 mode: Voltage input; 0...1 0V (differential)

AI2 mode: Voltage input; -10 ...10V

Jumper block X 3:

CMA a nd CMB grounding

CMB connected to GN D

CMA connected to GND

CMB isolated from GN D

CMA isolated from GN D

CMB and CM A

interna lly connected to g ether,

isolated from GND

=Factorydefault

Jumper block X 6:

AO1 m ode

AO 1 mode: 0... 2 0 mA; Current output

AO1 mode: Voltage output; 0...10V

AI1 mode: 0...20mA; Current input

7243.emf

Page 23

Descriptions of VACON® option boards vacon • 21

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

OPTA1 parameters

3.1.2 OPTA2

Table 6. OPTA1 board-related parameters

Number Parameter Min Max Default Note

1 AI1 mode 1 5 3

1 = 0...20mA

2 = 4...20mA

3 = 0...10V

4 = 2...10V

5 = -10...+10V

2 AI2 mode 1 5 1

1 = 0...20mA

2 = 4...20mA

3 = 0...10V

4 = 2...10V

5 = -10...+10V

3AO1 mode 141

1 = 0...20mA

2 = 4...20mA

3 = 0...10V

4 = 2...10V

Description:

Standard VACON

®

NX AC drive relay board with two relay outputs

Allowed slots: B

Type ID: 16690

Termi nal s: Two terminal blocks; Screw terminals (M3); No coding

Jumpers: None

Board parameters: None

7244.emf

Page 24

3

vacon • 22 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

I/O terminals on OPTA2

3.1.3 OPTA3

Table 7. OPTA2 I/O terminals

Ter mi na l

Parameter reference

on keypad and NCDrive

Technical information

21

22

23

RO1/normal closed

RO1/common

RO1/normal open

DigOUT:B.1

Relay output 1 (NO/NC)

Switching capacity

Min. switching load

24VDC/8A

250VAC/8A

125VDC/0.4A

5V/10mA

24

25

26

RO2/normal closed

RO2/common

RO2/normal open

DigOUT:B.2

Relay output 2 (NO/NC)

Switching capacity

Min. switching load

24VDC/8A

250VAC/8A

125VDC/0.4A

5V/10mA

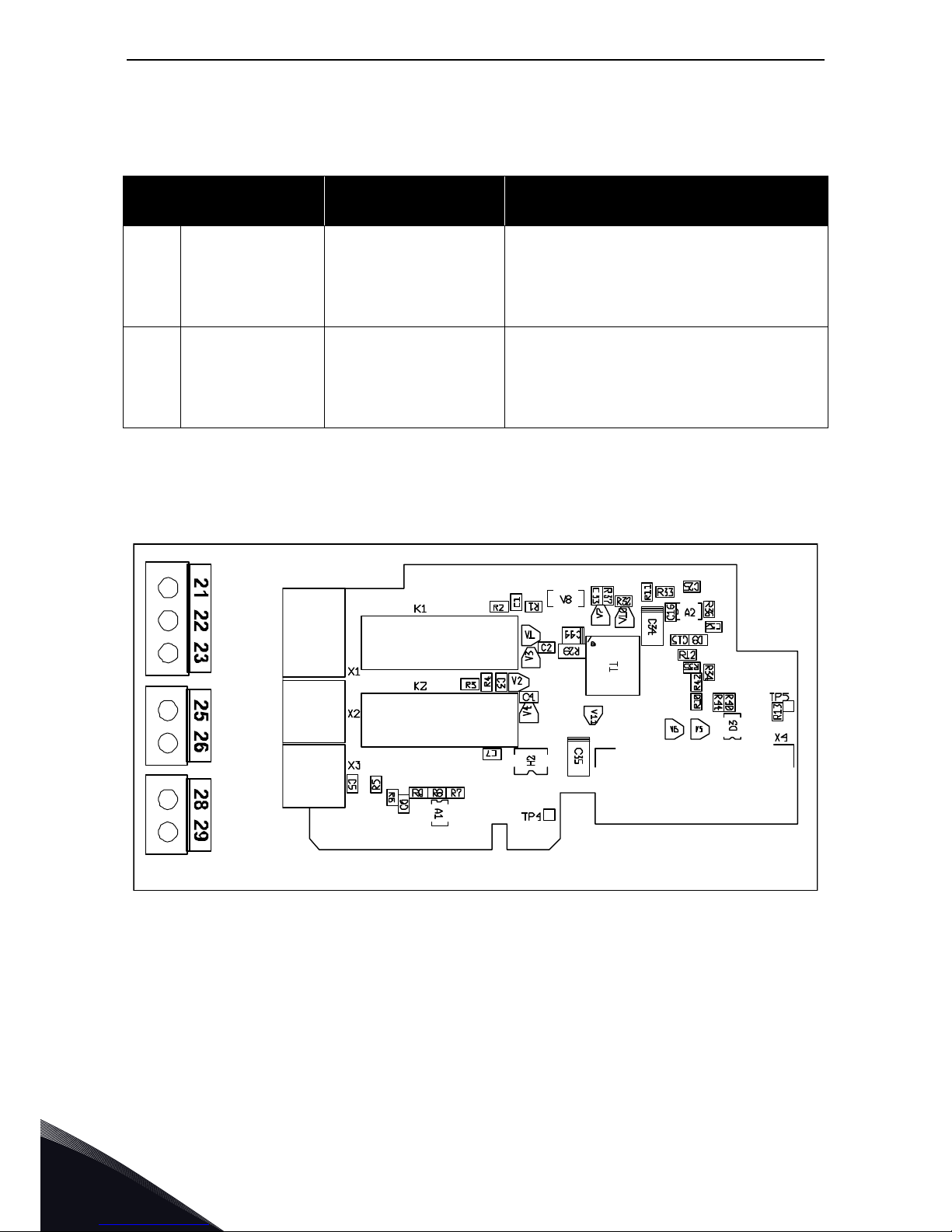

Description:

Relay board with two relay outputs and one thermistor input for VACON

®

NX

AC drive

Allowed slots: B

Type ID: 16691

Termi nal s: Three terminal blocks; Screw terminals (M3); No coding.

Jumpers: None

Board parameters: None

7245.emf

Page 25

Descriptions of VACON® option boards vacon • 23

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

I/O terminals on OPTA3

3.1.4 OPTA4

Table 8. OPTA3 I/O terminals

Ter mi na l

Parameter reference

on keypad and NCDrive

Technical information

21

22

23

RO1/normal closed

RO1/common

RO1/normal open

DigOUT:B.1

Relay output 1 (NO/NC)

Switching capacity

Min. switching load

24VDC/8A

250VAC/8A

125VDC/0.4A

5V/10mA

2526RO2/common

RO2/normal open

DigOUT:B.2

Relay output 2 (NO)

Switching capacity

Min. switching load

24VDC/8A

250VAC/8A

125VDC/0.4A

5V/10mA

2829TI1+

TI1–

DigIN:B.1

Thermistor input; R

trip

= 4 kΩ (PTC)

JumperX4

Jumper X2

7246.emf

Page 26

3

vacon • 24 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

I/O terminals on OPTA4 (coded terminal painted black)

Description:

Encoder board for VACON

®

NXP. Encoder input board with programmable

control voltage for an encoder.

The encoder board OPTA4 is for TTL type encoders (TTL, TTL(R)) providing

input signal levels that meet the RS_422 interface standard. Encoder inputs

A, B and Z are not galvanically isolated. The OPTA4 board includes, too, the

qualifier input ENC1Q (meant to trace the Z-pulse in certain situations) and a

special/fast digital input DIC4 (used to trace very short pulses). These two

inputs are used in special applications.

The TTL type encoders do not have an internal regulator and use therefore a

supply voltage of +5V±5% whereas the TTL(R) type encoders have an internal

regulator and the supply voltage can be e.g. +15V±10% (depending on the

encoder manufacturer).

Allowed slots: C

Type ID: 16692

Termi nal s: One terminal block; Screw terminals (M2.6); Coding in terminal #3.

Jumpers: 2; X4 and X2 (see page 25)

Board parameters: Yes (see page 27)

Table 9. OPTA4 I/O terminals

Ter mi na l

Parameter reference

Keypad/NCDrive

Technical information

1DIC1A+ Pulse input A

2DIC1A–

3 DIC2B+

Pulse input B; phase shift of 90 degrees compared

to Pulse input A

4 DIC2B–

5 DIC3Z+ Pulse input Z; one pulse per revolution

6DIC3Z–

7 ENC1Q Reserved for future use

8 DIC4 Reserved for future use

9 GND Ground for control and inputs ENC1Q and DIC4

10 +5V/+15V/+24V

Control voltage (auxiliary voltage) output to

encoder;

Output voltage selectable with jumper X4. See

chapter 1.4.4.

Page 27

Descriptions of VACON® option boards vacon • 25

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Technical data:

Jumper selections

On the OPTA4 board, there are two jumper blocks. The jumper X2 is used to define the status of the

termination resistor (R=135Ω). The jumper X4 is used to program the control voltage (auxiliary

voltage). The factory default and other available jumper selections are presented below.

Encoder control voltage, +5V/+15V/+24V Control voltage selectable with jumper X4.

Encoder input connections,

inputs A+, A–, B+, B–, Z+, Z–

Max. input frequency ≤150kHz

Inputs A, B and Z are differential

Encoder inputs are RS-422 interface compatible

Max. load per encoder input I

low

= I

high

≈ 25mA

Qualifier input ENC1Q

Fast digital input DIC4

Max. input frequency ≤10kHz

Min. pulse length 50μs

Digital input 24V; R

i

>5kΩ

Digital input is single-ended; connected to GND

ABC ABC

Jump er blockX2:

Ter m i na t io n r esi st or

Termination resistor

used

Termination resistor

not used

5V

15V

24V

=

Fa ct o r y d ef a ul t

5V

15V

24V

5V

15V

24V

Jump er block X 4:

Auxiliary voltage level

Auxiliary voltage +15 V Auxiliary voltage +24VAuxiliary voltage +5V

7247.emf

NOTE: If one encoder is connected to one

drive only, the termination resistor on the

board must be used. If the encoder is connected to several drives, the termination

resistor of the last drive must be used.

Page 28

3

vacon • 26 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Encoder connection – Differential

Figure 13. RS-422 type encoder connection using differential inputs

NOTE:

The encoder pulses are handled by VACON

®

software as presented below:

GND

A-

B-

+5V**

5V/15V/24V fro m the OPT-A4board or from external supply*

OPT-A4

board

.

.

10 +5V/+15V/+24V

9GND

1DIC1A+

2DIC1A3DIC2B+

4DIC2B5DIC3Z+

6DIC3Z7ENC1Q

8DIC1

.

.

*If external supply is used remember

to connectthe ground of external

supply to terminal #9 of theOPT-A4

and t o the en code r grou nd

**+5V/15V/+24V

Encoder

Tw i st e d p a ir s

with ow n shield

A+

B+

7248.emf

A

OUTPUT SIGNALS

Clockwise, seen from shaft

B

360º el.

1period

90º el. (channel separation)

7249.emf

Page 29

Descriptions of VACON® option boards vacon • 27

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

OPTA4 parameters

Par 7.3.1.4 Encoder Type (can be selected with boards A4, A5 and A7 (encoder 2 mode))

Table 10. OPTA4 board-related parameters

Number Parameter Min Max Default Note

7.3.1.1 Pulse/revolution 1 65535 1024

7.3.1.2 Invert direction 0 1 0

0 = No

1 = Yes

7.3.1.3 Reading rate 0 4 1

Time used to calculate speed actual value.

NOTE: Use value 1 in Closed Loop mode.

0 = No

1 = 1 ms

2 = 5 ms

3 = 10 ms

4 = 50 ms

7.3.1.4 Encoder type 1 3 1

1 = A,B = speed

2 = A = REF, B = DIR

3 = A= FORW, B = REV

1 = A, B = Speed

Only with this input type it is possible to use Closed Loop speed control in an NXP

drive. NXS drives do not have Closed Loop possibility, but encoder signal can be

used e.g. for reference or positioning.

This input mode requires that both channels A and B are receiving pulses, differential connection is recommended.

Direction of speed is determined from 90° difference in signals.

2 = A = Ref, B = Dir

This type cannot be used for Closed Loop control!

In this mode only channel A is receiving pulses. Channel B will determine if direction is negative or positive. Input in channel B must be static signal.

A

B

90°

7250.emf

Page 30

3

vacon • 28 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

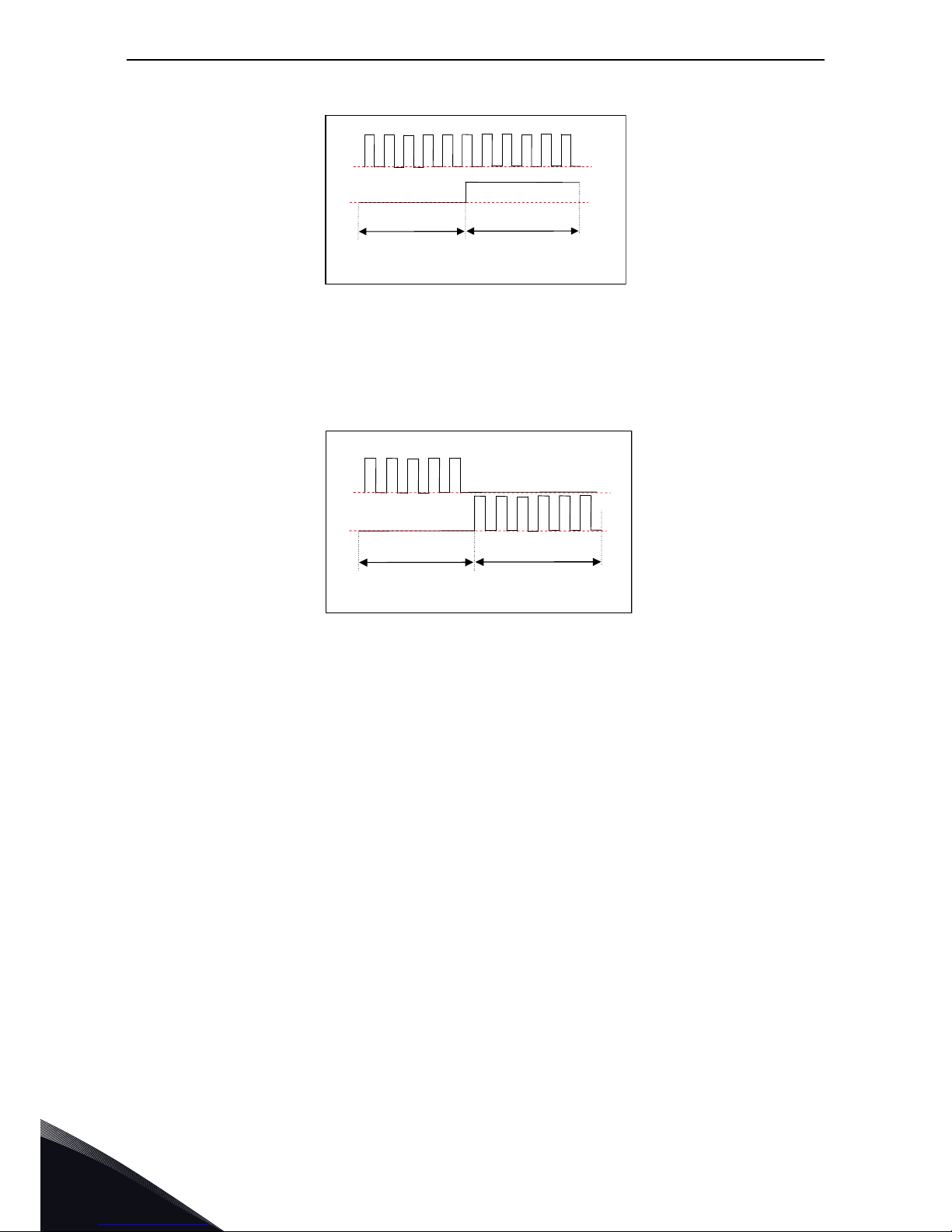

3 = A = Forw, B = Rev

This type cannot be used for Closed Loop control!

In this mode both channels are receiving signal but not at the same time.

Pulses on channel A means positive direction.

Pulses on channel B means negative direction.

A

B

-25 Hz

+25 Hz

7251.emf

A

B

+25 Hz

-25 Hz

7252.emf

Page 31

Descriptions of VACON® option boards vacon • 29

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

3.1.5 OPTA5

Description:

Encoder board for VACON

®

NXP. Encoder input board with programmable

control voltage for an encoder.

The OPTA5 board is designed for HTL (High voltage Transistor Logic) type

encoders (voltage output type push-pull HTL, open collector output type HTL)

which provide input signal levels dependent on the supply voltage of the

encoder. The encoder inputs A, B and Z are galvanically isolated. The OPTA5

board includes, too, the qualifier input ENC1Q (meant to trace the Z-pulse in

certain situations) and a fast digital input DIC4 (used to trace very short

pulses). These two inputs are used in special applications.

The OPTA5 is similar to the OPTA4 in connections but the encoder inputs A, B

and Z have different signal levels (voltage level). The input levels for A, B and

Z of the OPTA4 are compatible with RS-422 while those of the OPTA5 are

more general wide range inputs. Inputs ENC1Q and DIC4 are identical in both

boards.

Allowed slots: C

Type ID: 16693

Termi nal s: One terminal block; Screw terminals (M2.6); Coding in terminal #3.

Jumpers: 4; X2, X4, X5, X6 (see page 31)

Board parameters: Yes (see page 27)

X4

X2

X5

X6

Jumpers

7253.emf

Page 32

3

vacon • 30 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

I/O terminals on OPTA5 (coded terminal painted black)

NOTE: Encoder inputs are wide range inputs that can be used with encoders using +15V or +24V.

Technical data:

NOTE: A high pulse frequency combined with a great cable capacitance places a considerable load

on the encoder. Apply therefore as low a voltage as possible for the encoder supply, rather lower

than 24V. The manufacturer also recommends to place jumper X4 to position +15V, if allowed in the

voltage range specification of the encoder.

Table 11. OPTA5 I/O terminals

Ter mi na l

Parameter reference

Keypad/NCDrive

Technical information

1 DIC1A+ Pulse input A (differential); Voltage range 10…24V

2 DIC1A–

3 DIC2B+

Pulse input B; phase shift of 90 degrees compared to

Pulse input A (differential); Voltage range 10…24V

4 DIC2B–

5

DIC3Z+

Pulse input Z; one pulse per revolution (differential);

Voltage range 10…24V

6 DIC3Z–

7 ENC1Q Reserved for future use

8 DIC4 Reserved for future use

9 GND Ground for control and inputs ENC1Q and DIC4

10

+15V/+24V

Control voltage (auxiliary voltage) output to encoder;

Output voltage selectable with jumper X4. See chapter

1.4.4.

Encoder control voltage, +15V/+24V Control voltage selectable with jumper X4.

Encoder input connections,

inputs A+, A–, B+, B–, Z+, Z–

Max. input frequency ≤150kHz

Inputs A, B and Z are differential

Qualifier input ENC1Q

Fast digital input DIC4

Max. input frequency ≤10kHz

Min. pulse length 50μs

Digital input 24V; R

i

>5kΩ

Digital input is single-ended; connected to GND

Page 33

Descriptions of VACON® option boards vacon • 31

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Jumper selections

On the OPTA5 board, there are four jumper blocks; X4 is used to program the control voltage

(auxiliary voltage), X2, X5 and X6 are set according the voltage of the encoder. The factory default

and other available jumper selections are presented below.

Jumper blocks X2, X5 and X6:

When these jumpers are set to High (default and typically good for 24V encoders), it means that

when the voltage at the channel goes above 8V, it will acknowledge a new pulse.

When they are set to Low = 2.3 V, it means that when the voltage at the channel goes above 2.3V, it

will acknowledge a new pulse.

Usage: Closed Loop Vector Control. The OPTA5 board is mainly used in conventional industrial

applications where encoder cable lengths are relatively long.

Encoder connection – Differential

Figure 14. HTL type encoder connection using differential inputs

24V

15V

24V

15V

High

Low

High

Low

Jumper block X4:

Auxiliary voltage level

Auxiliary voltage +24V Auxiliary voltage +15V

=

Factory default

Jumper blocks X2, X5 and X6:

encoder voltage level

7254.emf

GND

A-

B-

15V**

15V/24V from the OPT-A5board or from external supply*

OPT-A5

board

.

.

10 + 15V/ +24 V

9GND

1DIC1A+

2DIC1A3DIC2B+

4DIC2B5DIC3Z+

6DIC3Z7ENC1Q

8DIC1

.

.

*If external supply is usedremember

to connect the ground of external

supply to termi nal #9 of the OPT-A5

and t o the enco der gr ou nd

**+ 15V/+24 V

Encoder

Tw i s te d p a i rs

with own shield

A+

B+

DIC4

7255.emf

Page 34

3

vacon • 32 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Encoder connection – Single-ended

Figure 15. HTL type encoder connection (open source) using single-ended inputs

NOTE! Grounding is to be connected only at the AC drive to avoid circulating current in the shield.

Isolate shield at the encoder.

It is recommended to use double shielded cable for encoder connection.

Figure 16. HTL type encoder connection (open collector) using single-ended inputs

NOTE! Grounding is to be connected only at the AC drive to avoid circulating current in the shield.

Isolate shield at the encoder.

It is recommended to use double shielded cable for encoder connection.

OPTA5 parameters

See page 27 and 27.

GND

GND

GND

15V/24V from the OPT-A5board or from external supply*

OPT-A5

board

.

.

10 +15V/+24V

9GND

1DIC1A+

2DIC1A3DIC2B+

4DIC2B5DIC3Z+

6DIC3Z7ENC1Q

8DIC1

.

.

*If external supply is used remember

to connect the ground ofexternal

supply to terminal #9 of the OPT-A5

and t o the en co der gr ound

**+1 5V/ +24V

Encoder

Tw i st e d pa i r s

with o wn s hield

+

A+

B+

DIC4

7256.emf

GND

A-

B-

15V /24V f ro m t he O PT-A 5board or from external supply*

OPT-A5

board

.

.

10 +1 5V/+ 24V

9GND

1DIC1A+

2DIC1A3DIC2B+

4DIC2B5DIC3Z+

6DIC3Z7ENC1Q

8DIC1

.

.

*If external supply is usedremember

to connectthe groundof external

supply to terminal #9 of the OPT- A5

andtotheencoderground

**+ 15V /+ 24V

Encoder

Tw i st e d p a ir s

with ow n shield

+

+

+

DIC4

7257.emf

Page 35

Descriptions of VACON® option boards vacon • 33

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

3.1.6 OPTA7

Description:

Duplicate encoder board for VACON

®

NXP. Encoder input board with

programmable control voltage for the encoder.

The OPTA7 board is designed for HTL (High voltage Transistor Logic) type

encoders (voltage output type push-pull HTL, open collector output type HTL)

which provide input signal levels dependent on the supply voltage of the

encoder. The encoder inputs A, B and Z are galvanically isolated. The OPTA7

board includes, too, the qualifier inputs ENC1Q and ENC2Q meant to trace

positions in positioning applications.

The board can be used as both Master and Slave device. The encoder input

signal is repeated on the board and carried to the next device through the

digital output.

Allowed slots: C

Type ID: 16695

Termi nal s: Two terminal blocks; Screw terminals (M2.6); Coding in terminals #3 and

#14.

Jumpers: 4; X4, X5, X15 and X16 (see page 35)

Board parameters: Yes, see page 38.

Jumper X4

Jumper X5 Jumpers X15 and X16

7258.emf

Page 36

3

vacon • 34 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

I/O terminals on OPTA7

NOTE: Encoder inputs are wide range inputs that can be used with encoders using +15V or +24V.

Table 12. OPTA7 I/O terminals

Ter mi na l

Parameter reference

Keypad/NCDrive

Technical information

1 DIC1A+ Pulse input A (differential); Voltage range 10…24V

2 DIC1A–

3 DIC2B+

Pulse input B; phase shift of 90 degrees compared to

Pulse input A (differential); Voltage range 10…24V

4 DIC2B–

5

DIC3Z+

Pulse input Z; one pulse per revolution (differential);

Voltage range 10…24V

6 DIC3Z–

7 ENC1Q Qualifier input. Single-ended input with GND

8 ENC2Q Qualifier input. Single-ended input with GND

9 GND Ground for control and inputs ENC1Q and ENC2Q

10

+15V/+24V

Control voltage (auxiliary voltage) output to encoder;

Output voltage selectable with jumper X4.

11

DID1A+

Pulse input A (differential input), voltage range

10…24V

12 DID1A–

13

DID2B+

Pulse input B; 90 degrees phase shift compared to the

pulse input A (differential input), voltage range 10…24V

14 DID2B–

15

DID3Z+

Pulse input Z; one pulse per revolution (differential

input), voltage range 10…24V

16 DID3Z–

17

DOD1A+

Pulse output A (differential), output voltage +24V.

Pulse input DIC1A or DID1A is internally repeated in

the card and connected to the DOD1A output.

18

DOD1A–

19

DOD2B+

Pulse output B (differential), output voltage +24V.

Pulse input DIC2A or DID2A is internally repeated in

the card and connected to the DOD2A output.

20

DOD2B–

Page 37

Descriptions of VACON® option boards vacon • 35

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Technical data:

NOTE: A high pulse frequency combined with a great cable capacitance places a considerable load

on the encoder. Apply therefore as low a voltage as possible for the encoder supply, rather lower

than 24V. The manufacturer also recommends to place jumper X4 to position +15V, if allowed in the

voltage range specification of the encoder.

Jumper selections

On the OPTA7 board, there are four jumper blocks.

Jumper X4 is used to program the control voltage (auxiliary voltage).

The setting of jumper X5 defines the encoder channel (DIC/DID) used to carry the signal to the

repeater.

The setting of jumpers X15 and X16 is changed according to whether the board is used as a Master

or Slave device.

In Slave function input, signals DID1A are directly connected to outputs DOD1A and signals DID2B

are directly connected to outputs DOD2B.

In Master Function input signals DIC_ or DID_, as selected with Jumper Block X5 "Encoder

Channel", DIC1A or DID1A are actively connected to outputs DOD1A and DIC2A or DID2A are actively

connected to outputs DOD2B.

The factory default and other available jumper selections are presented below.

Encoder control voltage, +15V/+24V Control voltage selectable with jumper X4.

Encoder input connections,

inputs A+, A–, B+, B–, Z+, Z–

Max. input frequency ≤150kHz

Inputs A, B and Z are differential

Qualifier input ENC1Q

Fast digital input DIC1

Max. input frequency ≤10kHz

Min. pulse length 50μs

Digital input 24V; R

i

>5kΩ

Digital input is single-ended; connected to GND

Page 38

3

vacon • 36 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Usage: Closed Loop Vector Control, positioning applications. The OPTA7 encoder board is mainly

used in demanding system applications, e.g. when measuring the motor speed with two encoders.

24V

15V

24V

15V

Jumper block X4:

Auxiliary voltage level

Auxiliary voltage +24V Auxiliary voltage +15V

= Factory default

Jumper block X5:

Encoder channel

Channel DIC

selected

Channel DID

selected

Master function

selected

Slave function

selected

Jumper blocks

X15 and X16:

Master/Slave

function

7259A_uk

X5

X5

X16X15

X16X15

Page 39

Descriptions of VACON® option boards vacon • 37

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

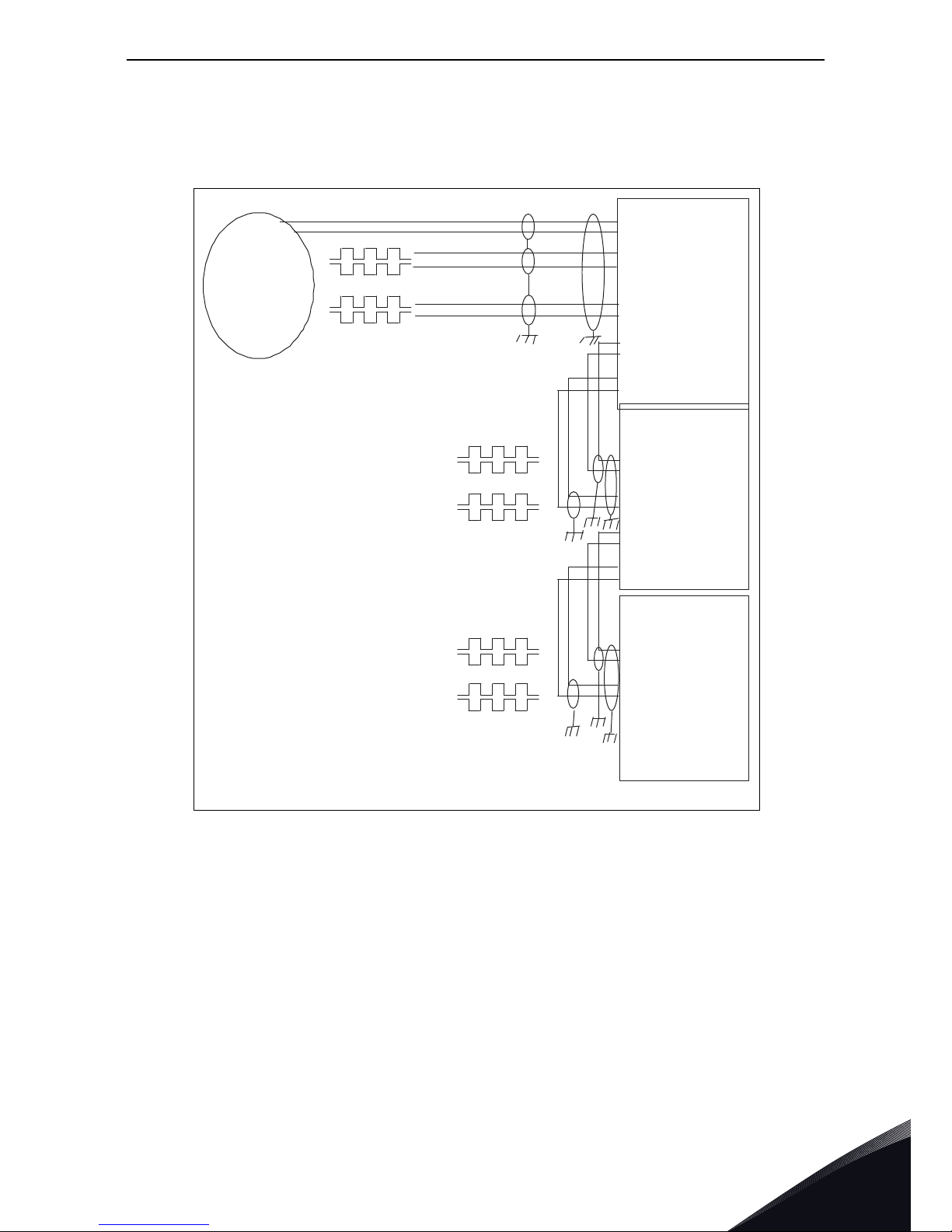

Encoder connection

The figures below present examples of a chain connection of several OPTA7 boards (Figure 17) and

a connection of two encoders to the OPTA7 option board (Figure 18).

Figure 17. Connection of encoder and three OPTA7 boards

B+

B-

A+

A-

B+

B-

A+

A-

B+

B-

A+

A-

O

PT-A7

10 +15V/+24V

9 GND

1/11 DIC1A+/DID1A+

2/12 DIC1A-/DID1A-

3/13 DIC2B+/DID2B+

4/14 DIC2B-/DID2B-

17 DOD1A +

18 DOD1A -

19 DOD2B +

20 DOD2B -

OPT-A7

1/11 DIC1A+/DID1A+

2/12 DIC1A-/DID1A-

3/13 DIC2B+/DID2B+

4/14 DIC2B-/DID2B-

17 DOD1A+

18 DOD1A-

19 DOD2B+

20 DOD2B-

OPT-A7

1/11 DIC1A+/DID1A+

2/12 DIC1A-/DID1A-

3/13 DIC2B+/DID2B+

4/14 DIC2B-/DID2B-

17 DOD1A+

18 DOD1A-

19 DOD2B+

20 DOD2B-

Encoder

7260A_uk

Page 40

3

vacon • 38 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Figure 18. Connection of two encoders to OPTA7 board

OPTA7 parameters

Table 13. OPTA7 parameters

Number Parameter Min Max Default Note

7.3.1.1 Encoder 1 Pulse/revolution 0 65535 1024

7.3.1.2 Invert encoder 1 direction 0 1 0

0 = No

1 = Yes

7.3.1.3 Reading rate 0 4 1

Time used to calculate speed actual value.

NOTE: Use value 1 in Closed Loop mode.

0 = No

1 = 1 ms

2 = 5 ms

3 = 10 ms

4 = 50 ms

7.3.1.4 Encoder 2 Pulse/revolution 0 65535 1024

7.3.1.5 Encoder 2 type 1 3 1

1 = A,B = speed

2 = A = REF, B = DIR

3 = A= FORW, B = REV

See page 27 for explanations!

B+

B-

B+

B-

A+

A-

B+

B-

A+

A-

A+

A-

15V/24V from OPT-A7

OPTA-7

10 +15V/+24V

9GND

1DIC1A+

2DIC1A-

3DIC2B+

4DIC2B.

.

.

11 D ID1A+

12 DID1A-

13 DID2B+

14 DID2B-

17 DOD1A+

18 DOD1A-

19 DOD2B+

20 DOD2B-

Encoder 1

Encode r 2

GND

7261.emf

Page 41

Descriptions of VACON® option boards vacon • 39

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

OPTA7 monitoring values

3.1.7 OPTA8

Table 14. OPTA7 monitoring values

Number Monitored value Unit Description

Mon 7.3.2.1 Encoder 1 frequency Hz Motor speed in Hz calculated from encoder 1 pulses

Mon 7.3.2.2 Encoder 1 speed rpm

Motor speed in rpm calculated from encoder 1

pulses

Mon 7.3.2.3 Encoder 2 frequency Hz Motor speed in Hz calculated from encoder 2 pulses

Mon 7.3.2.4 Encoder 2 speed rpm

Motor speed in rpm calculated from encoder 2

pulses

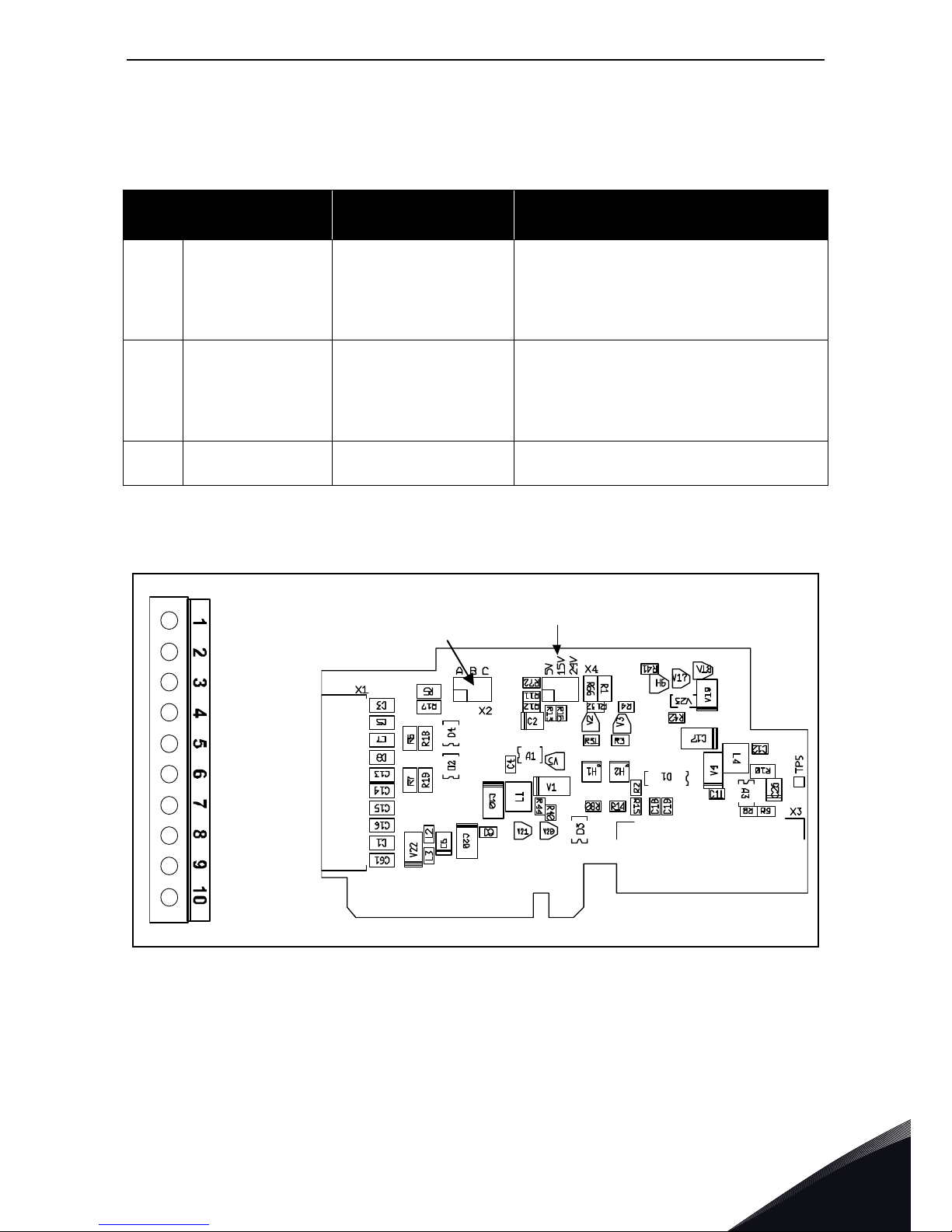

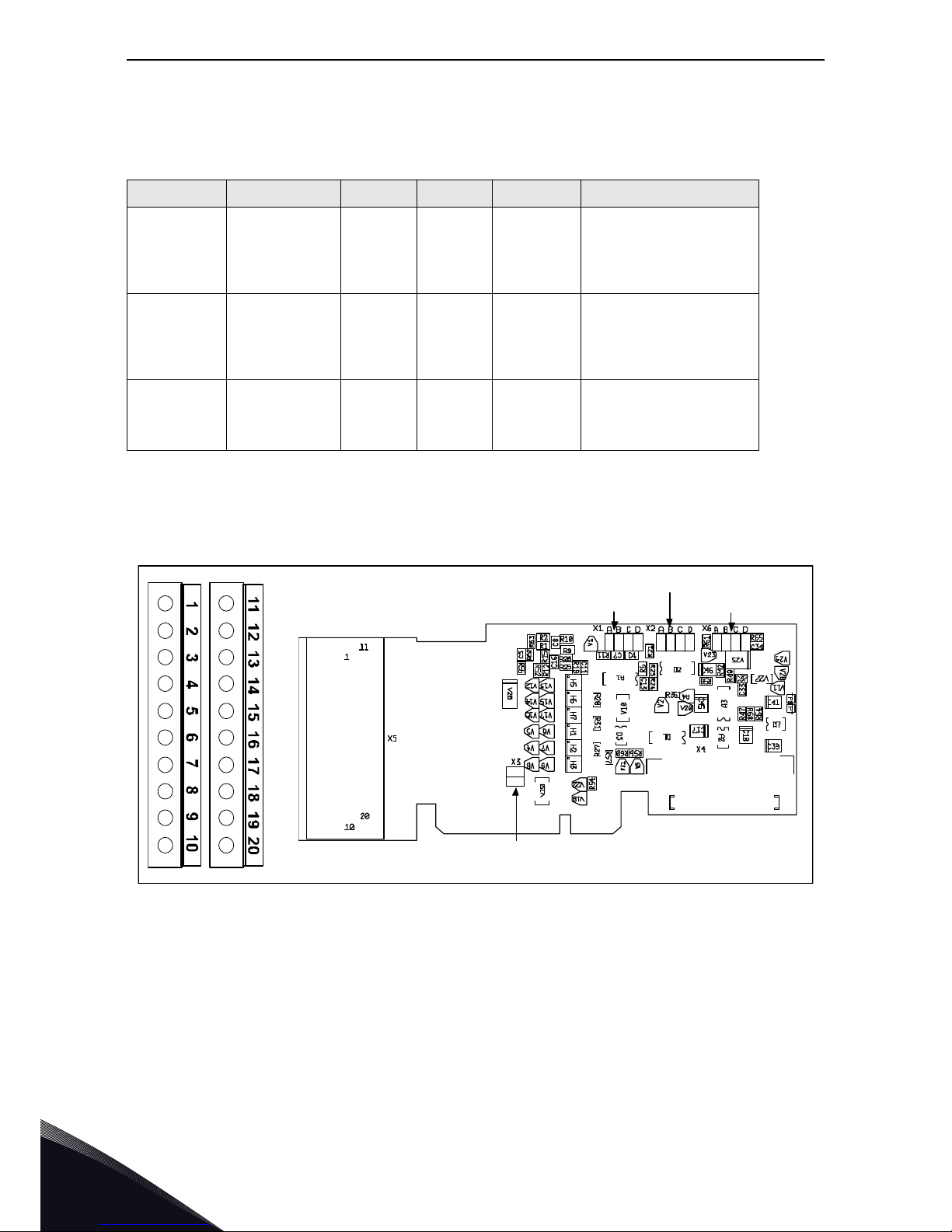

Description:

VACON

®

NX basic I/O board similar to OPTA1 except that the analogue inputs

and output are galvanically isolated.

Allowed slots: A

Type ID: 16696

Termi nal s: Two terminal blocks; Screw terminals (M2.6); Coding in terminals #1 and

#12.

Jumpers: 4; X1, X2, X3 and X6 (see page 41)

Board parameters: Yes (see page 42)

Jumper X1

Jumper X2

Jumper X6

Jumper X3

7262.emf

Page 42

3

vacon • 40 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

I/O terminals on OPTA8 (coded terminals painted black)

Table 15. OPTA8 I/O terminals

Ter mi na l

Parameter reference

Keypad/NCDrive

Technical information

1

+10 Vref Refer.output +10V; Max.current 10mA; Decoupled from FC GND

2

AI1+ An.IN:A.1

Selection V or mA with jumper block X1 (see page 41):

Default: 0– +10V (Ri = 200 kΩ)

(-10V…..+10V Joy-stick control, selected with a jumper)

0– 20mA (Ri = 250 Ω)

Resolution 0.1%; Accuracy ±1%

3

AI1–

(GND ISOL)

GND ISOL/Voltage input;

Connected to GND ISOL (selected with jumper)

4

AI2+ An.IN:A.2

Selection V or mA with jumper block X2 (see page 41):

Default: 0– 20mA (Ri = 250 Ω)

0– +10V (Ri = 200 kΩ)

(-10V…..+10V Joy-stick control, selected with a jumper)

5

AI2–

(GND ISOL)

Resolution: 0.1%; Accuracy ±1%

GND ISOL/Voltage input;

Connected to GND ISOL (selected with jumper)

6

24 Vout

(bidirectional

24V auxiliary voltage output. Short-circuit protected.

±15%, maximum current 150 mA, see 1.4.4.

+24Vdc external supply may be connected.

Galvanically connected to terminal #12.

7

GND

Ground for reference and controls

Galvanically connected to terminal #13.

8

DIN1 DigIN:A.1

Digital input 1 (Common CMA); R

i

= min. 5kΩ

9

DIN2 DigIN:A.2

Digital input 2 (Common CMA); R

i

= min. 5kΩ

10

DIN3 DigIN:A.3

Digital input 3 (Common CMA); R

i

= min. 5kΩ

11

CMA

Digital input common A for DIN1, DIN2 and DIN3.

Connection by default to GND.

Selection with jumper block X3 (see page 41):

12

24 Vout (bidi-

rectional

Same as terminal #6

Galvanically connected to terminal #6.

13

GND

Same as terminal #7

Galvanically connected to terminals #7

14

DIN4 DigIN:A.4

Digital input 4 (Common CMB); R

i

= min. 5kΩ

15

DIN5 DigIN:A.5

Digital input 5 (Common CMB); R

i

= min. 5kΩ

16

DIN6 DigIN:A.6

Digital input 6 (Common CMB); R

i

= min. 5kΩ

17

CMB

Digital input common A for DIN4, DIN5 and DIN6.

Connection by default to GND.

Selection with jumper block X3 (see page 41):

18

AO1+ AnOUT:A.1

Analogue output

Output signal range:

Current 0(4)–20mA, R

L

max 500Ω or

Voltage 0—10V, R

L

>1kΩ

Selection with jumper block X6 (see page 41):

Resolution: 0.1% (10 bits); Accuracy ±2%;

19

AO1–

20

DO1 DigOUT:A.1

Open collector output; Max. U

in

= 48VDC; Max. current = 50 mA

Page 43

Descriptions of VACON® option boards vacon • 41

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Jumper selections

There are four jumper blocks on the OPTA8 board. The factory defaults and other available jumper

selections are presented below.

Figure 19. Jumper positions for OPTA8

ABCD

ABCD

ABCD

ABCD

ABCD

ABCD

ABCD

ABCD

ABCD

ABCD

Jum per block X 1 :

AI1 mode

AI1 mode: Voltage input; 0...10V

AI1 mode: Voltage input; 0...10V (differential)

AI1 mode: Voltage input; -10...10V

Jum per blockX2:

AI2 m ode

AI2 mode: 0...2 0mA; Current input

AI2 mode: Voltage i np ut; 0 . ..10 V

AI2 mode: Voltage input; 0...1 0V (differential)

AI2 mode: Voltage input; -10 ...10V

Jumper block X 3:

CMA a nd CMB grounding

CMB connected to GN D

CMA connected to GND

CMB isolated from GN D

CMA isolated from GN D

CMB and CM A

interna lly connected to g ether,

isolated from GND

=Factorydefault

Jumper block X 6:

AO1 m ode

AO 1 mod e: 0... 2 0 mA; Current output

AO1 mode: Voltage output; 0...10V

AI1 mode: 0...20mA; Current input

7263.emf

Page 44

3

vacon • 42 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

OPTA8 parameters

3.1.8 OPTA9

Table 16. OPTA8 board-related parameters

Number Parameter Min Max Default Note

1AI1 mode153

1 = 0...20mA

2 = 4...20mA

3 = 0...10V

4 = 2...10V

5 = -10...+10V

2AI2 mode151

1 = 0...20mA

2 = 4...20mA

3 = 0...10V

4 = 2...10V

5 = -10...+10V

3AO1 mode14 1

1 = 0...20mA

2 = 4...20mA

3 = 0...10V

4 = 2...10V

Description:

VACON

®

NX basic I/O board similar to the OPTA1 except that the I/O termi-

nals are bigger (for 2.5mm

2

wires; M3 screws).

Allowed slots: A

Type ID: 16697

Termi nal s: Two terminal blocks; Screw terminals (M3); Coding in terminals #1 and #12.

Jumpers: 4; X1, X2, X3 and X6 (see page 20)

Board parameters: Yes (see page 21)

Jumper X1

Jumper X2

Jumper X6

Jumper X3

7264.emf

Page 45

Descriptions of VACON® option boards vacon • 43

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

I/O terminals on OPTA9

See page 19.

Jumper selections

See page 20.

OPTA9 parameters

See page 21.

3.1.9 OPTAL

Description: Dual I/O expander board with six 42…240 VAC digital inputs, 2 analog inputs,

two analog outputs, one digital output and 15 and 24 V out.

Allowed slots: A

Type ID: 16716

Termi nal s:

Two terminal blocks; Screw terminals (M2.6, 1.5 mm

2

wire terminals 1 – 10;

M3, 2.5 mm

2

wire terminals 11-18); No coding

Jumpers: None

Board parameters: None

Page 46

3

vacon • 44 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

I/O terminals on OPTAL

Table 17. OPTAL I/O terminals

Ter mi na l

Parameter reference

Keypad/NCDrive

Technical information

1 +15 V 15 V out – together with terminal 2 max 200 mA

2 +15 V 15 V out

3 AI1 An.IN:A.1 Analog input 0 – 10 V

4 AI2 An.IN:A.2 Analog input ± 10 V

5 GND Ground for analog signals

6 AO1+ AnOUT:A.1 Analog output 0 (4) – 20 mA

7 AO2+ AnOUT:A.2 Analog output 0 – 10 V

8 DO1 Open collector digital output , 48 V, 50 mA allowed

9 GND Ground for analog signals

10 + 24 V 24 V out – max 200 mA

11

ACIN1 DigIN:X.1

Digital input, 42…240 VAC (threshold 35V)

Control voltage: "0"<33V, "1">35V

12

ACIN2 DigIN:X.2

Digital input, 42…240 VAC (threshold 35V)

Control voltage: "0"<33V, "1">35V

13

ACIN3 DigIN:X.3

Digital input, 42…240 VAC (threshold 35V)

Control voltage: "0"<33V, "1">35V

14

ACIN4 DigIN:X.4

Digital input, 42…240 VAC (threshold 35V)

Control voltage: "0"<33V, "1">35V

15

ACIN5 DigIN:X.5

Digital input, 42…240 VAC (threshold 35V)

Control voltage: "0"<33V, "1">35V

16

ACIN6 DigIN:X.6

Digital input, 42…240 VAC (threshold 35V)

Control voltage: "0"<33V, "1">35V

17

18

COMMON Common input for DI1 - 6

Page 47

Descriptions of VACON® option boards vacon • 45

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

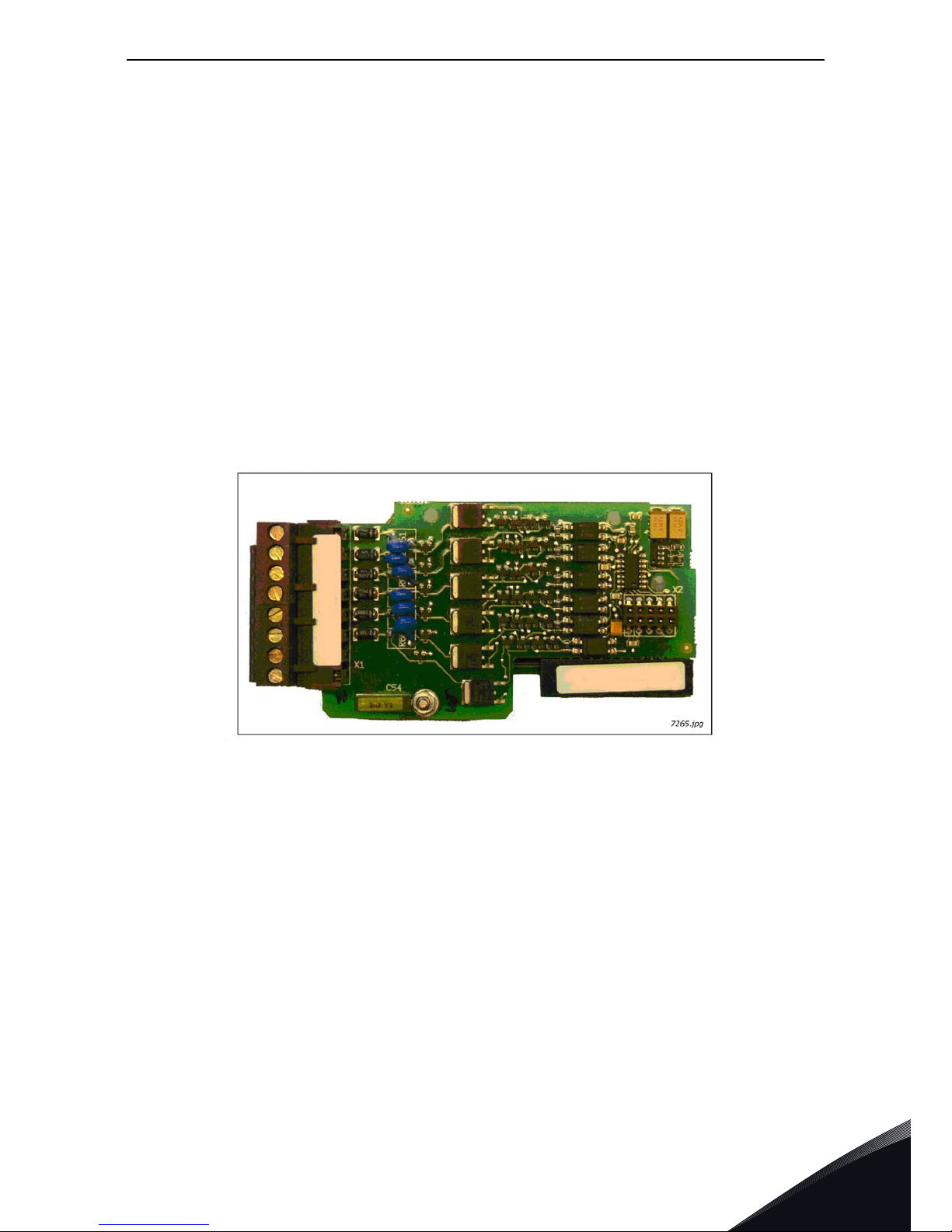

3.1.10 OPTAE

Description:

Encoder board for VACON

®

NXP. Encoder input board with programmable

control voltage for an encoder.

The OPTAE board is designed for HTL (High voltage Transistor Logic) type

encoders (voltage output type push-pull HTL, open collector output type HTL)

which provide input signal levels dependent on the supply voltage of the

encoder. The encoder inputs A, B and Z are galvanically isolated.

In addition, the board includes an Encoder Direction Signal and an Encoder

Pulse Output Signal. The Encoder Direction Signal value ‘1’ indicates a backward motor direction and ‘0’ a forward motor direction. The Encoder Pulse

Output signal is produced from The Encoder input signals (channel A) divided

by the divider parameter (see page 48).

Allowed slots: C

Type ID: 16709

Termi nal s: One terminal block; Screw terminals (M2.6); Coding in terminal #3.

Jumpers: 1; X4 (see page 46 )

Board parameters: Yes

Jumper X4

7266.emf

Page 48

3

vacon • 46 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

I/O terminals on OPTAE (coded terminal painted black)

NOTE: Encoder inputs are wide range inputs that can be used with encoders using +15V or +24V.

Technical data:

Jumper selections

On the OPTAE board, there is one jumper block used to program the control voltage (auxiliary

voltage). The factory default and other available jumper selections are presented below.

Table 18. OPTAE I/O terminals

Ter mi na l

Parameter reference

Keypad/NCDrive

Technical information

1 DIC1A+ Pulse input A (differential); Voltage range 10…24V

2 DIC1A–

3 DIC2B+

Pulse input B; phase shift of 90 degrees compared to

Pulse input A (differential); Voltage range 10…24V

4 DIC2B–

5

DIC3Z+

Pulse input Z; one pulse per revolution (differential);

Voltage range 10…24V

6 DIC3Z–

7

DO1

Encoder divider output. Encoder input signals are

divided by divider paramater (see parameter list on

page 48)

8

DO2

Encoder direction output. The signal value ‘1’ means

that the motor direction is backward and ‘0’ is forward.

9 GND Ground for control

10

+15V/+24V

Control voltage (auxiliary voltage) output to encoder;

Output voltage selectable with jumper X4.

Encoder control voltage, +15V/+24V Control voltage selectable with jumper X4.

Encoder input connections,

inputs A+, A–, B+, B–, Z+, Z–

Max. input frequency ≤150kHz

Inputs A, B and Z are differential

Encoder divider output DO1,

Encoder direction output DO2

Max.load voltage 60Vdc

Max. load current 50mA

Max. output frequency ≤300kHz

=

Fa c to r y d e f a u lt

24V

15V

24V

15V

Auxiliary voltage +24V Auxiliary voltage +15V

7267.emf

Jumper block X4:

Auxilia ry voltage level

Page 49

Descriptions of VACON® option boards vacon • 47

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Usage: Closed Loop Vector Control. The OPTAE board is mainly used in conventional industrial

applications where encoder cable lengths are relatively long.

Encoder connection - single-ended

Figure 20. HTL type encoder connection (open source) using single-ended inputs

NOTE! Grounding is to be connected only at the AC drive to avoid circulating current in the shield.

Isolate shield at the encoder.

It is recommended to use double shielded cable for encoder connection.

Figure 21. HTL type encoder connection (open collector) using single-ended inputs

NOTE! Grounding is to be connected only at the AC drive to avoid circulating current in the shield.

Isolate shield at the encoder.

It is recommended to use double shielded cable for encoder connection.

GND

GND

GND

15V /24V f ro m t he O PT-A E

board or from external supply*

OPT-AE

board

.

.

10 +15V/+24V

9GND

1DIC1A+

2DIC1A3DIC2B+

4DIC2B5DIC3Z+

6DIC3Z7ENC1Q

8DIC1

.

.

*If external supply is usedr emember

to connectthe ground of external

supply to terminal #9 of theOPT-AE

and t o the en code r grou nd

**+ 15V/ +24 V

Encoder

Tw i st e d p ai r s

with ow n shie ld

+

A+

B+

7268.emf

GND

A-

B-

15V/24V from the OPT-AEboard or from external supply*

OPT-AE

board

.

.

10 +1 5V/ +24V

9GND

1DIC1A+

2DIC1A3DIC2B+

4DIC2B5DIC3Z+

6DIC3Z7ENC1Q

8DIC1

.

.

*If external supply is usedremember

to connectthe groundof external

supply to terminal #9 of the OPT- AE

andtotheencoderground

**+ 15V /+ 24V

Encoder

Tw i st e d p a ir s

with ow n shield

+

+

+

DO2

DO1

7269.emf

Page 50

3

vacon • 48 Descriptions of VACON® option boards

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Encoder connection – differential

Figure 22. HTL type encoder connection using differential inputs

OPTAE parameters

Table 19. OPTAE board-related parameters

Number Parameter Min Max Default Note

7.3.1.1 Pulse/revolution 1 65535 1024

7.3.1.2 Invert direction 0 1 0

0 = No

1 = Yes

7.3.1.3 Reading rate 0 4 1

Time used to calculate speed actual value.

NOTE: Use value 1 in Closed Loop mode.

0 = No calculation

1 = 1 ms

2 = 5 ms

3 = 10 ms

4 = 50 ms

7.3.1.4 Divider Value 1 2048 64 Input pulses / Divider = Divider Output

7.3.1.5

Hysteresis for

Direction Out

0511 8

Number of pulses before direction signal

change state

DO2

DO1

GND

15V /24V f ro m t he O PT-A E

board or from external supply*

OPT-AE

board

.

.

10 + 15V/+2 4V

9GND

1DIC1A+

2DIC1A3DIC2B+

4DIC2B5DIC3Z+

6DIC3Z7ENC1Q

8DIC1

.

.

**+ 15V /+ 24V

Encoder

+15V**

DO2

DO1

7270.emf

Page 51

Descriptions of VACON® option boards vacon • 49

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

3.1.11 OPTAN

Description:

Standard I/O board for VACON

®

NXP with 6 galvanically isolated digital inputs

and two analogue inputs/outputs. The Analogue channels are programmable:

1 = 0...20mA

2 = 4...20mA

3 = 0...10V

4 = 2...10V

5 = -10...+10V