Page 1

user's manual

brake chopper unit (bcu)

application

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

9

Page 2

2 • vacon

Vacon Brake Chopper Unit application

Software: ABFIFF01 V1.01

INDEX Document code: ud01138a

Date: 1.11.2006

1. INTRODUCTION .................................................................................................................................3

1.1 Operation principle of BCU....................................................................................................... 3

1.2 Quick start instructions ............................................................................................................ 5

2. CONTROL I/O ...................................................................................................................................6

3. BRAKE CHOPPER APPLICATION – PARAMETER LISTS ........................................................................... 7

3.1 Monitoring values (Control keypad: menu M1)........................................................................ 7

3.2 Basic parameters (Control keypad: Menu G2 Æ G2.1)............................................................ 8

3.3 Input signals (Control keypad: Menu G2 Æ G2.2).................................................................... 8

3.4 Output signals (Control keypad: Menu G2 Æ G2.3) ................................................................. 9

3.5 BCU In parallel (Control keypad: Menu G2 Æ G2.4)................................................................ 9

3.6 Fieldbus parameters (Control keypad: Menu G2 Æ G2.5)..................................................... 10

3.7 Protections (Menu G2 Æ G2.6) ............................................................................................... 11

3.8 Keypad control (Control keypad: Menu M3)........................................................................... 11

3.9 System menu (Control keypad: Menu M6)............................................................................. 11

3.10 Expander boards (Control keypad: Menu M7) ....................................................................... 11

4. DESCRIPTION OF PARAMETERS.........................................................................................................12

4.1 Basic parameters ................................................................................................................... 12

4.2 Input signals............................................................................................................................ 13

4.3 Output signals......................................................................................................................... 15

4.4 BCU In Parallel ....................................................................................................................... 17

4.5 Fieldbus parameters .............................................................................................................. 17

4.6 Protections.............................................................................................................................. 18

4.7 Keypad control........................................................................................................................ 18

5. FIELDBUS PROFILE FOR VACON BRAKE CHOPPER UNIT ....................................................................... 19

6. FAULT CODES ................................................................................................................................. 21

Tel.+358 (0)201 2121 • Fax +358 (0)201 212 205

Page 3

Introduction vacon • 3

1. INTRODUCTION

1.1 Operation principle of BCU

When you want to slow down a running asynchronous motor fed by a frequency converter it turns

into a generator, feeding energy back into the frequency converter. The energy increases the voltage

in the DC-link. The frequency converter compensates for this increase by increasing the output

frequency, decreasing the instantaneous slip and increasing the motor load. The deceleration is, in

this case, dependent on the power losses in the converter and in the motor. This is usually sufficient

in most cases, for pumps, fans, conveyors etc. where the kinetic energy in the load is small or the

braking time is not critical.

When you have to brake down the motor faster than the losses allow, you have to use BCU module

and an external brake resistor (or resistors) for energy dissipation. The extra energy from the load

is turned into heat in the brake resistor. If the DC link voltage increases too much, the BCU turns on

and discharges the capacitors through the brake resistor. Applications where dynamic braking is

usually needed include centrifuges, cranes, some conveyors and drives requiring very fast

reversing.

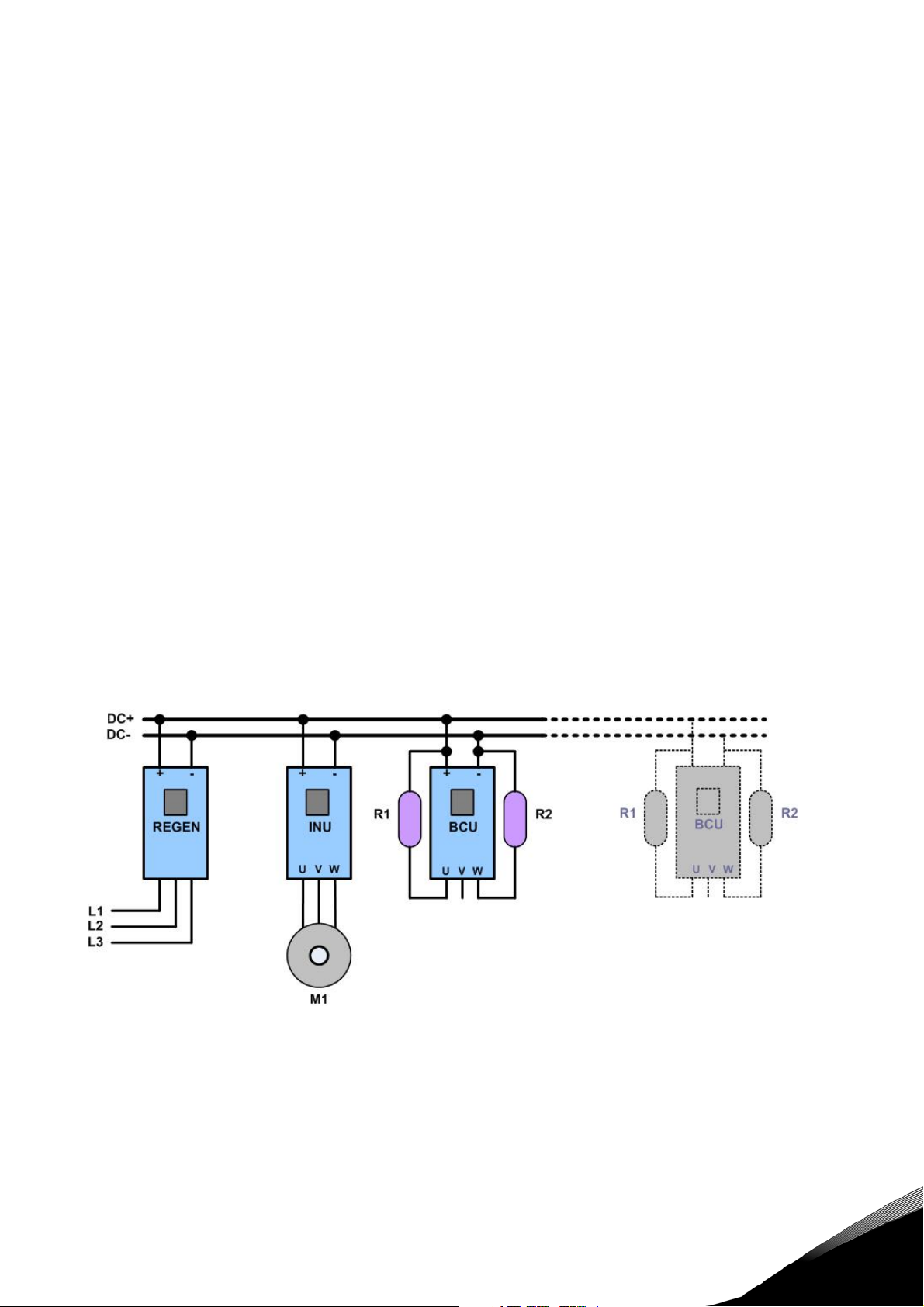

Modules can be connected parallel with other BCU modules in order to increase braking capacity

(Figure 1).

In BCU application you can use either Analogue input or OPT-B8 option board for PT100 sensor

connection.

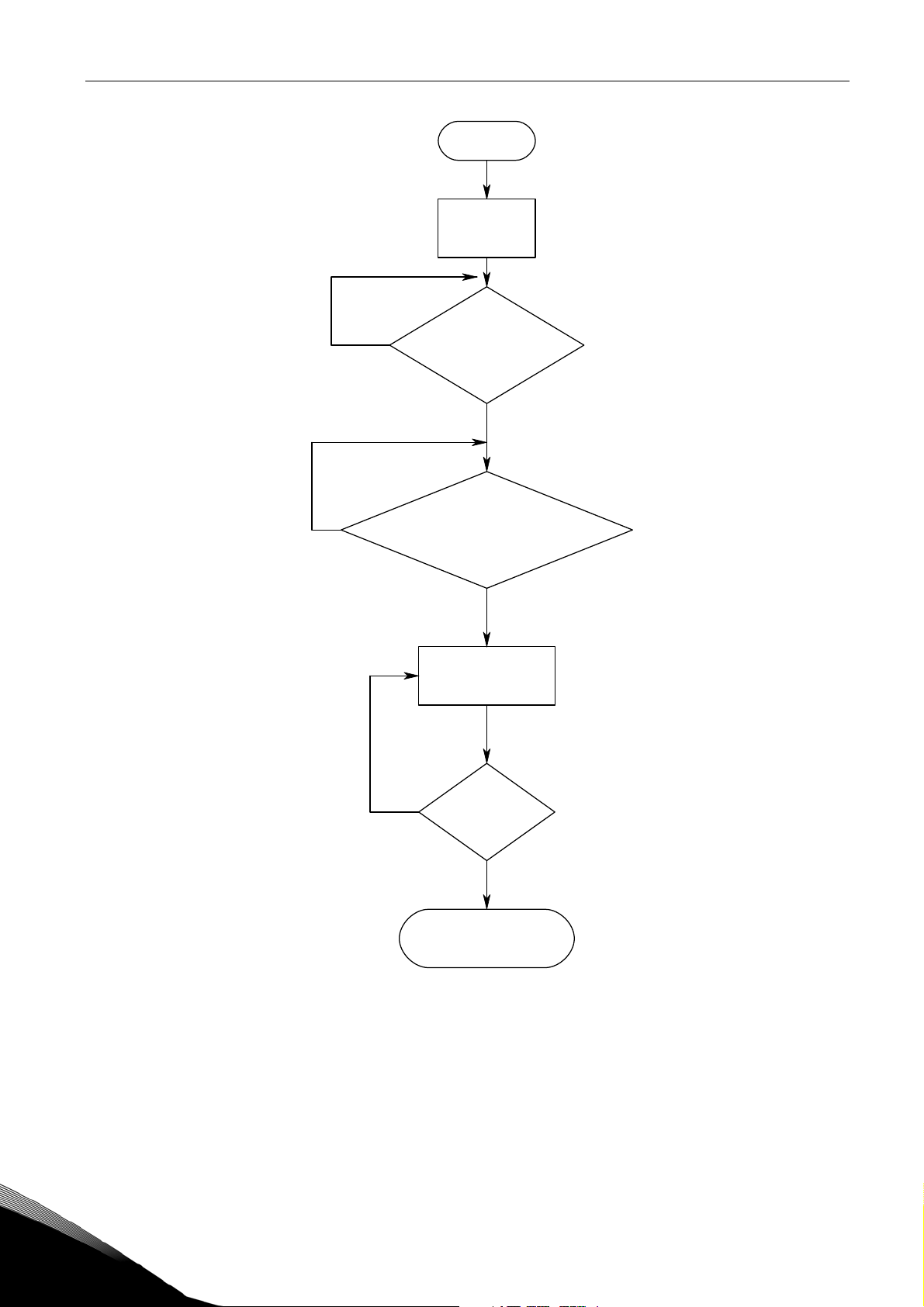

Start-up sequence of BCU application has been illustrated in Figure 2.

Figure 1. BCU in common DC bus system

24-hour support +358 (0)40 8371 150 • Email: vacon@vacon.com

Page 4

4 • vacon Introduction

Init

Softwar e Ini t

complete

Read y to

switch on

DC link voltage

OK?

No

Yes

RunEna ble from I/O (P2.2.1.3)

No

or fieldbus (MCW,bit 1)

Ready to Run

(Ready led is on)

Fault?

Yes

BCU Ru nning

(Run le d is on )

Figure 2. Start-up sequence

Yes

No

Tel.+358 (0)201 2121 • Fax +358 (0)201 212 205

Page 5

Introduction vacon • 5

1.2 Quick start instructions

NOTE! Before taking any commissioning actions read carefully the safety instructions in Vacon NX

User's Manual, chapter 1.

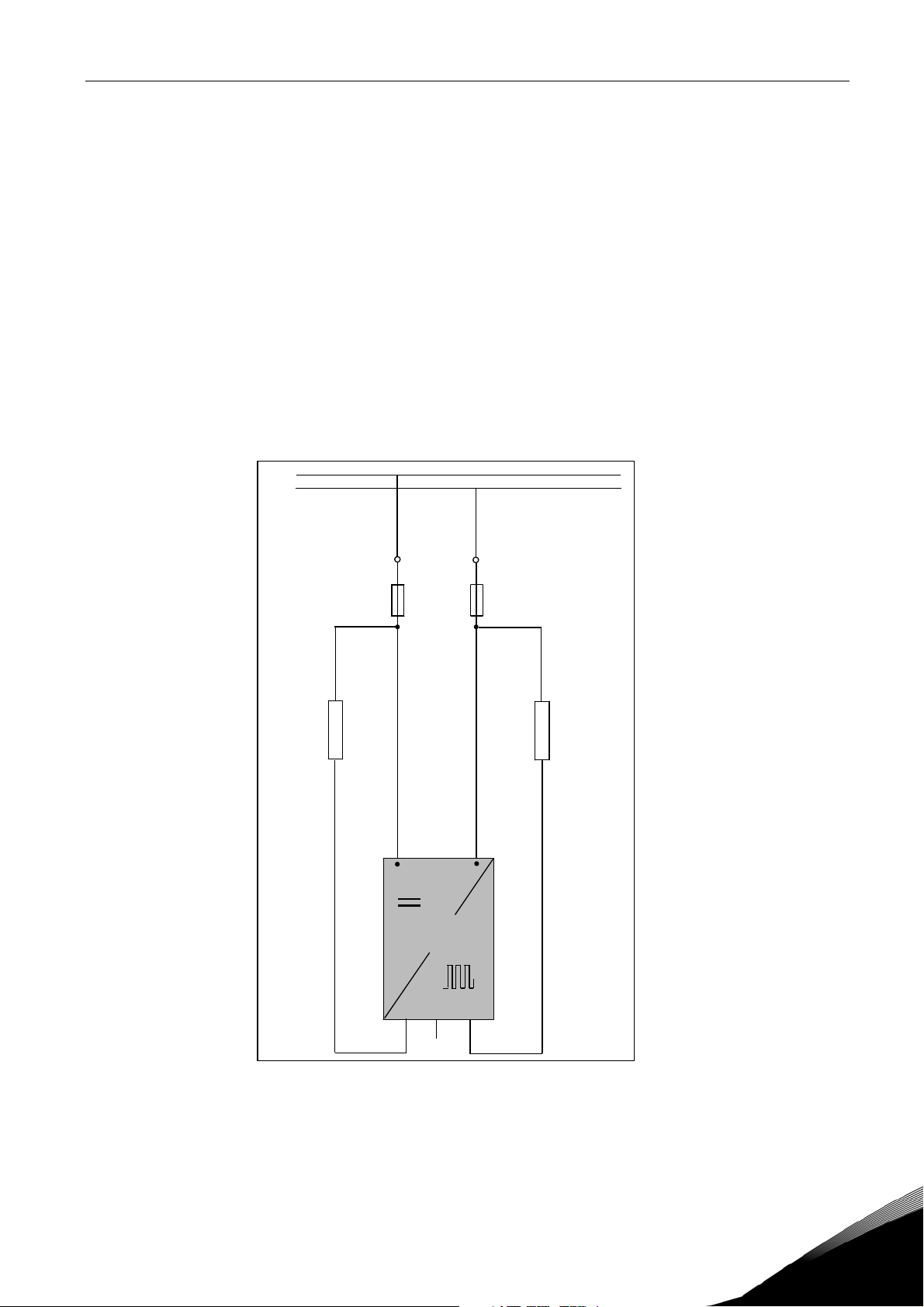

1. Check installations (see Figure 3, Table 2-1 and Table 2-2).

2. Check resistor(s) max. temperature durability.

3. Switch power on.

4. Set PT-100 parameters (P2.2.2.1, P2.2.2.2 and P2.6.1 – P2.6.3) or KLIXON input settings

(P2.2.1.4).

5. Set brake chopper operation level to preferred value (P2.1.2).

6. In case of parallel BCU set Drooping (P2.4.1) = 5%.

7. Set Digital input parameters (P2.2.1.1 – P2.2.1.4) according to connections.

8. Test BCU.

9. If fault occurs see chapter 6.

DC+

DC-

-R1

-U1

DC+

-F1

BCU

UVW

DC-

-R2

Figure 3. Resistor connections

24-hour support +358 (0)40 8371 150 • Email: vacon@vacon.com

Page 6

6 • vacon Control I/O

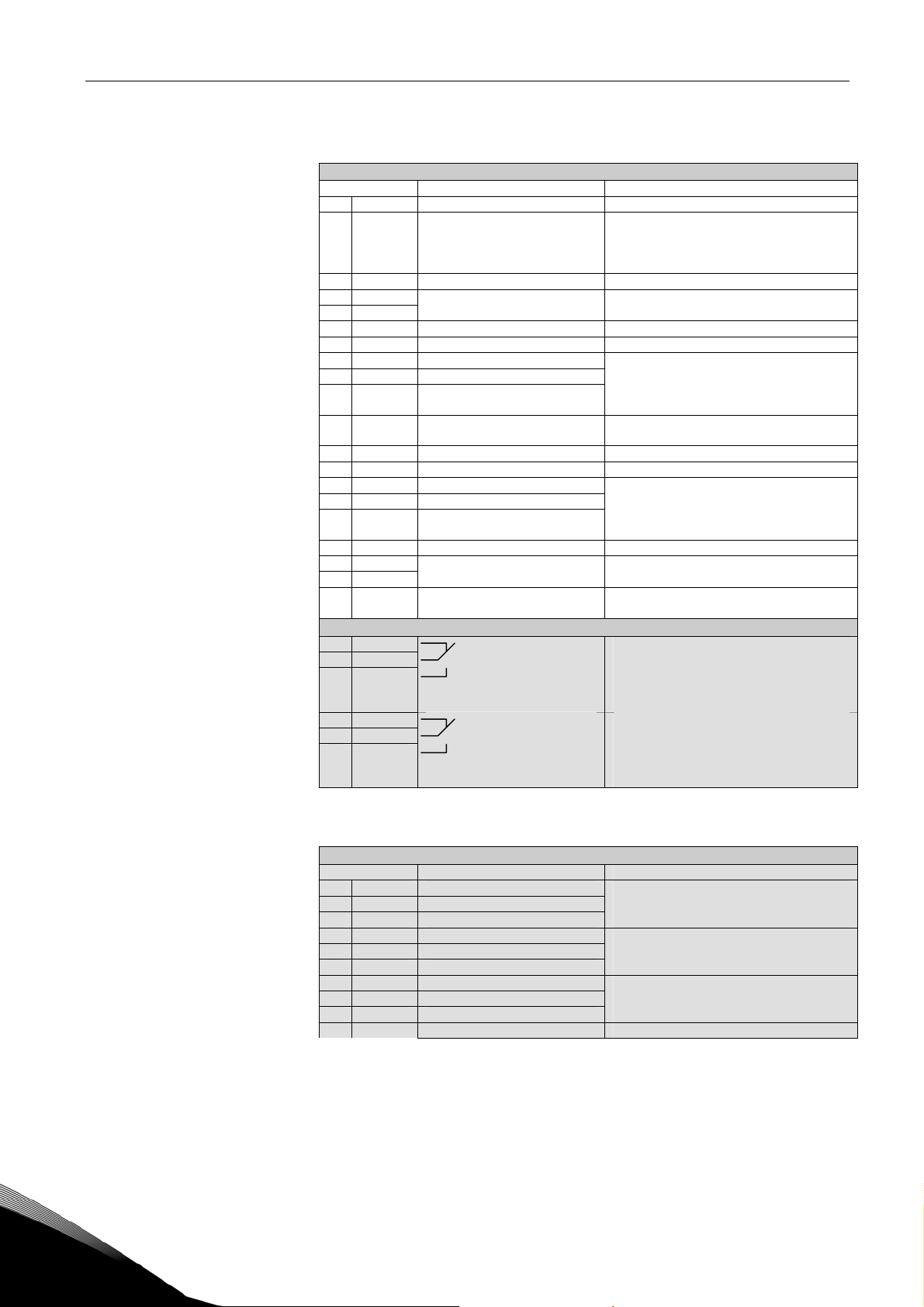

2. CONTROL I/O

OPT-A1

Terminal Signal Description

1 +10V

2 AI1+ Analogue input 1, voltage or

3 AI1- Analogue input common Ground for reference and controls

4 AI2+

5 AI26 +24V Control voltage output Voltage for switches, etc. max 0.1 A

7 GND I/O ground Ground for reference and controls

8 DIN1 Digital input 1

9 DIN2 Digital input 2

10 DIN3 Digital input 3

11 CMA Common for DIN 1—DIN 3 Connect to GND or +24V

12 +24V Control voltage output Voltage for switches (see #6)

13 GND I/O ground Ground for reference and controls

14 DIN4 Digital input 4

15 DIN5 Digital input 5

16 DIN6 Digital input 6

17 CMB Common for DIN4—DIN6 Connect to GND or +24V

18 AO1+

19 AO120 DO1 Digital output

Reference voltage Maximum current 10 mA

ref

current

Analogue input 2 Same as A1 but default is 0-20mA.

Fault Reset (Par. P2.2.1.1)

Run enable (Par. P2.2.1.3)

Analogue output 1 Programmable

READY (Par. P2.2.5)

Default: 0– +10V (Ri = 200 kΩ)

(-10V…..+10V Joy-stick control,

selected with a jumper)

0– 20mA (Ri = 250 Ω)

Ri = min. 5kΩ 18…30V = "1"

Ri = min. 5kΩ 18…30V = "1"

.

Range 0—20 mA/R

Programmable

Open collector, I≤50mA, U≤48 VDC

, max. 500Ω

L

OPT-A2

21 RO1

22 RO1

23 RO1

24 RO2

25 RO2

26 RO2

Relay output 1

Running

Relay output 2

Fault

Switching capacity

24VDC/8A

250VAC/8A

125VDC/0.4A

Min. switching load 5V/10mA

Switching capacity

24VDC/8A

250VAC/8A

125VDC/0.4A

Min. switching load 5V/10mA

Table 2- 1. Default I/O configuration.

OPT-B8

Terminal Signal Technical information

1 R1 + AnIN:X.1

2 Rm1

3 R1 -

4 R2 + AnIN:X.2

5 Rm2

6 R2 -

7 R3 + AnIN:X.3

8 Rm3

9 R3 -

10 NC Not connected

PT100 Input, -30…200°C, one sensor.

Accuracy ≤ 1°C.

Sensor current 10 mA.

PT100 Input, -30…200°C, one sensor.

Accuracy ≤ 1°C.

Sensor current 10 mA.

PT100 Input, -30…200°C, one sensor.

Accuracy ≤ 1°C.

Sensor current 10 mA.

Table 2- 2. I/O terminals on OPT-B8

Tel.+358 (0)201 2121 • Fax +358 (0)201 212 205

Page 7

Brake Chopper Application – Parameter lists vacon • 7

3. BRAKE CHOPPER APPLICATION – PARAMETER LISTS

On the next pages you will find the lists of parameters within the respective parameter groups.

Column explanations:

Code = Location indication on the keypad; Shows the operator the present parameter

number

Parameter = Name of parameter

Default = Value preset by factory

Min = Minimum value of parameter

Max = Maximum value of parameter

Unit = Unit of parameter value; given if available

ID = ID number of the parameter (used with PC tools and fieldbus)

Note = Description of parameter

3.1 Monitoring values (Control keypad: menu M1)

The monitoring values are the actual values of parameters and signals as well as statuses and

measurements. Monitoring values cannot be edited.

See Vacon NX User's Manual, Chapter 7 for more information.

Code Parameter Unit ID Note

V1.1 Total Current A 1104 Filtered braking current in Amperes.

V1.2 Power kW 1106 Braking power in kW.

V1.3 DC-link Voltage V 1108 DC intermediate voltage in Volts

V1.4 Unit Temperature °C 1109 Unit temperature C-degrees.

V1.5 ANALOG OUTPUT 1 % 1112 Analog Output 1 in%

V1.6 DIN1, DIN2, DIN3 15 Digital Inputs A1, A2 and A3 Status (sum)

V1.7 DIN4, DIN5, DIN6 16 Digital Inputs B4, B5 and B6 Status (sum)

V1.8 DO1, RO1, RO2 17 Digital Output and Relay 1&2 Status (sum)

V1.9 Unit Nom Voltage V 111 Nominal voltage rating of the Frequency

V1.10 Unit Nom Current A 1118 Nominal current rating of Frequency Converter.

V1.11 DC Nom Voltage V 1120 Nominal value of Dc-link voltage in Volts.

V1.12 MainControlWord 1160 See the chapter 5

V1.13 MainStatusWord 1162 See the chapter 5

V1.14 Active Fault 37 Active fault code

V1.15 PT100(1) Temperature °C 50 Temperature measured with PT100 sensor 1

V1.16 PT100(2) Temperature °C 51 Temperature measured with PT100 sensor 2

V1.17 PT100(3) Temperature °C 52 Temperature measured with PT100 sensor 3

Table 3-1. Monitoring values

Converter.

(only when OPT-B8 is used)

(only when OPT-B8 is used)

24-hour support +358 (0)40 8371 150 • Email: vacon@vacon.com

Page 8

8 • vacon Brake Chopper Application – Parameter lists

3.2 Basic parameters (Control keypad: Menu G2 Æ G2.1)

Code Parameter Default Min Max Unit ID Note

P2.1.1

P2.1.2 ID Run 0 0 1 631

BrkChopper

Level

648

BrakeChopperLev

elMin

BrakeChopperLev

elMax

V 1267

Brake chopper operation

level in volts

Manual identification for

brake resistor connection.

Table 3-2. Basic parameters G2.1

3.3 Input signals (Control keypad: Menu G2 Æ G2.2)

3.3.1 Digital inputs (G2.2.1)

Code Parameter Default Min Max Unit ID Note

Input Selection for Fault

Resetting.

0 = Not used

1 = DIN1

P2.2.1.1 Fault Reset 3 0 6 1208

P2.2.1.2 External Fault 0 0 6 1214

P2.2.1.3 Run Enable 6 0 6 1212

P2.2.1.4 KLIXON 0 0 6 1209

Table 3-3. Digital input parameters G2.2.1

2 = DIN2

3 = DIN3

4 = DIN4

5 = DIN5

6 = DIN6

Digital input selection for

external fault signal

connection.

As par. P2.2.1.1

Input selection for Run

Enable Ctrl. 0 = Run

Enabled internally

As par. P2.2.1.1

Input Selection for KLIXON

type Temperature Sensor.

As par. P2.2.1.1

3.3.2 Analog inputs (G2.2.2)

Code Parameter Default Min Max Unit ID Note

Select the Analog input for

P2.2.2.1

P2.2.2.2 PT100 In Series 0 0 2 1222

PT100 Analog Input

selection

0 0 2 1221

connecting PT100 Sensor.

0=Not Used,

1=AI1,

2=AI2

Number of PT100 elements in

series.

0=1*PT100,

1=2*PT100,

2=3*PT100.

Table 3-4. Analog input parameters G2.2.2

Tel.+358 (0)201 2121 • Fax +358 (0)201 212 205

Page 9

Brake Chopper Application – Parameter lists vacon • 9

3.4 Output signals (Control keypad: Menu G2 Æ G2.3)

3.4.1 Digital outputs (G2.3.1)

Code Parameter Default Min Max Unit ID Note

P2.3.1.1 DO1 Ctrl 1 0 6 1216 Signal Selection for DO1

P2.3.1.2 DO2 Ctrl 2 0 6 1217 Signal selection for DO2 (RO1)

P2.3.1.3 DO3 Ctrl 3 0 6 1218 Signal selection for DO3 (RO2)

P2.3.1.4 DO4 Ctrl 0 0 6 1385 Signal Selection for DO4

P2.3.1.5 DO5 Ctrl 0 0 6 1386 Signal selection for DO5

P2.3.1.6 DO6 Ctrl 0 0 6 1390 Signal selection for DO6

P2.3.1.7 DO7 Ctrl 0 0 6 1391 Signal Selection for DO7

P2.3.1.8 DO8 Ctrl 0 0 6 1395 Signal selection for DO8

P2.3.1.9 DO9 Ctrl 0 0 6 1396 Signal selection for DO9

P2.3.1.10 DO10 Ctrl 0 0 6 1423 Signal Selection for DO10

P2.3.1.11 DO11 Ctrl 0 0 6 1427 Signal selection for DO11

P2.3.1.12 DO12 Ctrl 0 0 6 1428 Signal selection for DO12

P2.3.1.13 DO13 Ctrl 0 0 6 1429 Signal selection for DO13

Table 3-5. Digital output parameters G2.3.1

3.4.2 Analog output 1 (G2.3.2)

Code Parameter Default Min Max Unit ID Note

P2.3.2.1 AO1 Signal ID 0 0 2000 1233

P2.3.2.2 AO1 Offset 0 0 1 1234

P2.3.2.3 AO1 Filter 10 0,02 10,00 s 1235

P2.3.2.4 AO1 Max. Value 1500 -30000 30000 1236

P2.3.2.5 AO1 Min. Value 0 -30000 30000 1237

Set the ID no. of a signal to be

connected to AO1

Minimum voltage or current

at AO1. 0= 0V/0mA, 1= 4mA

Filter time for the signal

selected for AO1 in Seconds.

Maximum value of a signal

selected for AO1. This will

correspond to +10V/20mA.

Minimum value of a signal

connected to AO1. This will

correspond to 0V/0mA or

2V/4mA depending on the

type of AO1.

Table 3-6. Analog output parameters G2.3.2

3.5 BCU In parallel (Control keypad: Menu G2 Æ G2.4)

Code Parameter Default Min Max Unit ID Note

P2.4.1 Drooping 0 0,00 100,00 % 620

Table 3-7. BCU In Parallel parameters G2.4

Increase in braking current

will increase the DC link

voltage level for operation as

a function of drooping.

24-hour support +358 (0)40 8371 150 • Email: vacon@vacon.com

Page 10

10 • vacon Brake Chopper Application – Parameter lists

3.6 Fieldbus parameters (Control keypad: Menu G2 Æ G2.5)

Code Parameter Default Min Max Unit ID Note

P2.5.1

P2.5.2

P2.5.3

P2.5.4

P2.5.5

P2.5.6

P2.5.7

P2.5.8

P2.5.9

P2.5.10

P2.5.11

P2.5.12

P2.5.13

P2.5.14

P2.5.15

P2.5.16

Fieldbus data out 1

selection

Fieldbus data out 2

selection

Fieldbus data out 3

selection

Fieldbus data out 4

selection

Fieldbus data out 5

selection

Fieldbus data out 6

selection

Fieldbus data out 7

selection

Fieldbus data out 8

selection

Fieldbus data in 1

selection

Fieldbus data in 2

selection

Fieldbus data in 3

selection

Fieldbus data in 4

selection

Fieldbus data in 5

selection

Fieldbus data in 6

selection

Fieldbus data in 7

selection

Fieldbus data in 8

selection

1104 0 65535 1490

1106 0 65535 1491

37 0 65535 1492

0 0 65535 1493

0 0 65535 1494

0 0 65535 1495

0 0 65535 1496

0 0 65535 1497

0 0 10000 876

0 0 10000 877

0 0 10000 878

0 0 10000 879

0 0 10000 880

0 0 10000 881

0 0 10000 882

0 0 10000 883

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID

Choose controlled data with

parameter ID

Choose controlled data with

parameter ID

Choose controlled data with

parameter ID

Choose controlled data with

parameter ID

Choose controlled data with

parameter ID

Choose controlled data with

parameter ID

Choose controlled data with

parameter ID

Choose controlled data with

parameter ID

Table 3-8. Fieldbus parameters G2.5

Tel.+358 (0)201 2121 • Fax +358 (0)201 212 205

Page 11

Brake Chopper Application – Parameter lists vacon • 11

3.7 Protections (Menu G2 Æ G2.6)

Code Parameter Default Min Max Unit ID Note

Number of PT100

inputs in use at OPT-

P2.6.1 PT100 Numbers 0 0 3 739

P2.6.2 PT100 Alarm Lim 110 -30 200 °C 1347

PT100

P2.6.3 PT100 Fault Lim 120

P2.6.4 Thermistor 1 0 2 1351

P2.6.5 External Fault 2 0 2 701

Alarm

limit

(P2.6.2)

300 °C 1348

B8 option board.

Visible only when the

option board has

been installed

Select the

temperature for PT100

sensor above which

PT100 alarm is

generated in the drive.

Select the

temperature for PT100

sensor above which

PT100 fault is

generated in the drive

Response to

thermistor

overtemperature.

0=No Action,

1=Warning,

2=Fault

Response to External

fault.

0=No action,

1=Warning,

2=Fault

Table 3-9. Protections G2.6

3.8 Keypad control (Control keypad: Menu M3)

Code Parameter Default Min Max Unit ID Description

P3.1 Control place 0 0 1 125

0=I/O terminal (default)

1=Fieldbus

Table 3-10. Keypad control parameters M3

3.9 System menu (Control keypad: Menu M6)

For parameters and functions related to the general use of the frequency converter, such as

application and language selection, customised parameter sets or information about the hardware

and software, see Chapter 7.3.6 in the Vacon NX User's Manual.

3.10 Expander boards (Control keypad: Menu M7)

The M7 menu shows the expander and option boards attached to the control board and boardrelated information. For more information, see Chapter 7.3.7 in the Vacon NX User's Manual.

24-hour support +358 (0)40 8371 150 • Email: vacon@vacon.com

Page 12

12 • vacon Description of parameters

4. DESCRIPTION OF PARAMETERS

4.1 Basic parameters

2.1.1 Brake Chopper Level (ID1267)

Brake chopper operation level in volts. This is the DC link voltage level when the BCU

starts to discharge the capacitors through the brake resistor.

2.1.2 ID Run (ID631)

This parameter is used for manual identification for brake resistor connection. Brake

chopper unit makes automatic identification during every power-up. However, if resistor

connection is changed during service, ID Run can be executed manually with this

parameter by setting the value “1=ID Run”.

Tel.+358 (0)201 2121 • Fax +358 (0)201 212 205

Page 13

Description of parameters vacon • 13

4.2 Input signals

4.2.1 Digital Inputs

2.2.1.1 Fault Reset (ID1208)

Input selection for Fault Resetting. The transition from Off to On will reset the fault if the

cause of the fault has been removed.

0 = Not used

1 = DIN1

2 = DIN2

3 = DIN3

4 = DIN4

5 = DIN5

6 = DIN6

2.2.1.2 External fault (ID1214)

This parameter defines if the BCU monitors status of the External fault input. With

External fault it is possible to trig a fault 51. Response to the fault can be defined with

the parameter P2.6.5.

See parameter P2.2.1.1 for the list of values.

2.2.1.3 Run Enable (ID1212)

This parameter is used for choosing the input for external Run Enable signal. If the

option “0 = Not used” have been selected the Run Enable signal is always on.

See parameter P2.2.1.1 for the list of values.

2.2.1.4 KLIXON Input (ID1209)

This parameter is used for choosing the input for KLIXON type temperature sensor. The

function of this input is Normally Closed so the fault “60 = KLIXON” is generated when

the input goes low.

See parameter P2.2.1.1 for the list of values.

24-hour support +358 (0)40 8371 150 • Email: vacon@vacon.com

Page 14

14 • vacon Description of parameters

4.2.2 Analog Inputs

2.2.2.1 PT100 Analog Input selection (ID1221)

Selects the analogue input to be used for temperature measurement using PT100

sensor.

In BCU application you can use either Analogue input or OPT-B8 option board for PT100

connection. Both ways can not be used at the same time. If Analogue input has been

used for PT100 measurement the Analogue Output 1 is forced to 10mA level and it is

used as a power supply for PT100 sensor. Connection has been illustrated in Figure 4.

0 = Not used

1 = AI1

2 = AI2

AO1+

PT100

AO1-

Figure 4. PT100 connection.

2.2.2.2 PT100 In Series (ID1222)

Selects the number of PT100 elements connected in series.

0 = 1 * PT100

1 = 2 * PT100

2 = 3 * PT100

AI+

AI-

Tel.+358 (0)201 2121 • Fax +358 (0)201 212 205

Page 15

Description of parameters vacon • 15

4.3 Output signals

4.3.1 Digital output signals

2.3.1.1 DO1 (ID1216)

Select the signal for controlling the DO1.

0 = Not used

1 = Ready

2 = Running

3 = Fault

4 = No Fault

5 = Warning

6 = Braking active (BCU is braking)

2.3.1.2 DO2 (ID1217)

Select the signal for controlling the relay output 1 (RO1) of OPT-A2 option board.

See parameter P2.3.1.1 for the list of values.

2.3.1.3 DO3 (ID1218)

Select the signal for controlling the relay output 2 (RO2) of OPT-A2 option board.

See parameter P2.3.1.1 for the list of values.

2.3.1.4-

2.3.1.13 DO4 – DO13 (ID1385 – ID1429)

These parameters are only visible when there are additional option boards with digital

outputs installed in the BCU. If for example the option board OPT-B5 has been installed

the parameters for outputs DO4-DO6 become visible.

See parameter P2.3.1.1 for the list of values.

24-hour support +358 (0)40 8371 150 • Email: vacon@vacon.com

Page 16

16 • vacon Description of parameters

4.3.2 Analogue output 1

2.3.2.1 Analogue Output 1 signal ID (ID1233)

Set the ID no. of a signal to be connected to AO1. To connect e.g. DC-link voltage to

Analog output 1, enter 1108 as parameter value.

NOTE! If Analogue input has been chosen to be used for PT100 measurement (P2.2.2.1 >

0) the Analogue Output 1 is forced to 10mA level.

2.3.2.2 Analogue Output 1 Offset (ID1234)

Minimum voltage or current at AO1.

0 = 0V/0mA,

1 = 4mA

2.3.2.3 Analogue Output Filter time (ID1235)

Defines filtering time of the analogue output signal.

%

Unfiltered signal

100%

Filtered signal

63%

ID1235

Figure 5. Analogue output filtering

2.3.2.4 Analogue Output Maximum value (ID1236)

Maximum value of a signal selected for AO1. This will correspond to +10V/20mA.

2.3.2.5 Analogue Output Minimum value (ID1237)

t [s]

NX12K16

Minimum value of a signal selected for AO1. This will correspond to 0V/0mA or 2V/4mA

depending on the type of AO1.

Tel.+358 (0)201 2121 • Fax +358 (0)201 212 205

Page 17

Description of parameters vacon • 17

4.4 BCU In Parallel

2.4.1 Drooping (ID1501)

Increase in braking current will increase the DC link voltage level for operation as a

function of drooping. This parameter is applicable only when there is more than one BCU

connected in parallel.

4.5 Fieldbus parameters

2.5.1 –

2.5.8 Fieldbus data out 1-8 selection (ID1490-ID1497)

Using these parameters, you can monitor any monitoring or parameter value from the

fieldbus. Enter the ID number of the item you wish to monitor for the value of these

parameters.

2.5.9 –

2.5.16 Fieldbus data in 1-8 selection (ID876-ID883)

Using these parameters, you can control any parameter value from the fieldbus. Enter

the ID number of the item you wish to control for the value of these parameters.

24-hour support +358 (0)40 8371 150 • Email: vacon@vacon.com

Page 18

18 • vacon Description of parameters

4.6 Protections

2.6.1 Number of PT100 inputs in use

If you have a PT100 input board (OPTB8) installed in your BCU you can choose here the

number of PT100 inputs in use. See also the Vacon I/O boards manual.

Note: If the selected value is greater than the actual number of used PT100 inputs, the

display will read 200ºC. If the input is short-circuited the displayed value is –30ºC.

This parameter is visible only when there is OPTB8 option board installed in the

BCU.

2.6.2 PT100 Alarm limit (ID1347)

Set here the limit at which the PT100 alarm will be activated.

2.6.3 PT100 Fault limit (ID1348)

Set here the limit at which the PT100 fault will be activated.

2.6.4 Response to thermistor fault (ID1351)

0 = No response

1 = Warning

2 = Fault

Setting the parameter to 0 will deactivate the protection.

2.6.5 Response to External fault (ID1351)

0 = No response

1 = Warning

2 = Fault

This parameter defines a response to an external fault. If the BCU monitors state of the

external fault input (value of P2.2.1.2 > 0) and a fault occurs the drive can be set to

respond to the fault.

4.7 Keypad control

3.1 Control place (ID125)

The active control place can be changed with this parameter.

0 = I/O terminal (default)

1 = Fieldbus

Tel.+358 (0)201 2121 • Fax +358 (0)201 212 205

Page 19

Fieldbus Profile for Vacon brake chopper unit vacon • 19

5. FIELDBUS PROFILE FOR VACON BRAKE CHOPPER UNIT

Following document describes fieldbus profile for Brake Chopper Unit application.

If Profibus, Modbus or CANopen is used then Operate Mode = Bypass is to be used to be able to

read or write the following info.

Signals from Overriding System to Vacon regenerative Drive.

Fieldbus Data Name

Control Word

Reference Value

Process Data IN1

Process Data IN2

Process Data IN3

Process Data IN4

Process Data IN5

Process Data IN6

Process Data IN7

Process Data IN8

Signal

Name Min Max

Main

Control

Word

See bitwise description below

Reserved for future use.

Reserved for future use.

Reserved for future use.

Reserved for future use.

Reserved for future use.

Reserved for future use.

Reserved for future use.

Reserved for future use.

Reserved for future use.

FB

Scale Scaling Description

Table 5-1. Signals from overriding system

Signals from Vacon Drive to Overriding system

FB

Fieldbus Data Name Signal Name

Main Status Word Main Status Word See bitwise description below

Actual Value DC Voltage 1=1V DC Voltage in Volts

ProcessDataOut1 Total current 10=1A Total Current

ProcessDataOut2 Power 10=1% Power

ProcessDataOut3 Active fault Active Fault

ProcessDataOut4 Reserved for future use.

ProcessDataOut5 Reserved for future use.

ProcessDataOut6 Reserved for future use.

ProcessDataOut7 Reserved for future use.

ProcessDataOut8 Reserved for future use.

Scale Scaling Description

Table 5-2. Signals to overriding system

24-hour support +358 (0)40 8371 150 • Email: vacon@vacon.com

Page 20

20 • vacon Fieldbus Profile for Vacon brake chopper unit

Main Control Word

Bit 0 Reserved for future use.

0=Run is disabled, drive will not go to Run state.

Bit 1 Run Enable

Bit 2 Reserved for future use.

Bit 3 Reserved for future use.

Bit 4 Reserved for future use.

Bit 5 Reserved for future use.

Bit 6 Reserved for future use.

Bit 7 Fault reset 0>1 Reset fault.

Bit 8 Reserved for future use.

Bit 9 Reserved for future use.

Bit 10 Fieldbus Control

Bit 11 Reserved for future use.

Bit 12 Reserved for future use.

Bit 13 Reserved for future use.

Bit 14 Reserved for future use.

Bit 15 Reserved for future use.

1=Run is enabled

0= No control from fieldbus

1=Control from fieldbus

Table 5-3. Main Control Word

Main Status Word

0=Drive is not Ready

Bit 0 Rdy On

Bit 1 Running

Bit 2 Braking Active 1=BCU is braking

Bit 3 Fault

Bit 4 Run Enable

Bit 5 Reserved for future use.

Bit 6 Reserved for future use.

Bit 7 Alarm

Bit 8 Reserved for future use.

Bit 9 Fieldbus Control Active

Bit 10 Reserved for future use.

Bit 11 Reserved for future use.

Bit 12 Reserved for future use.

Bit 13 Reserved for future use.

Bit 14 Reserved for future use.

Bit 15 Reserved for future use.

1=Drive is Ready

0=Drive not running

1=Drive running

0=No active fault

1=Fault is active

0=RunEnable from I/O or fieldbus is

disabled.

1=RunEnable is on.

0=No alarm

1=Alarm active

0=Fieldbus control not active

1=Fieldbus control active

Table 5-4. Main Status Word

Tel.+358 (0)201 2121 • Fax +358 (0)201 212 205

Page 21

Fault codes vacon • 21

6. FAULT CODES

The fault codes, their causes and correcting actions are presented in the table below. The shadowed

faults are A faults only. The items written in white on black background present faults for which you

can program different responses in the application. See parameter group Protections.

Note: When contacting distributor or factory because of a fault condition, always write down all texts

and codes on the keypad display.

Fault

code

1 Overcurrent BCU has detected too high current

2 Overvoltage The DC-link voltage has exceeded the

7 Saturation trip Various causes:

8 System fault

9 Undervoltage DC-link voltage is under the BCU fault

13 BCU under-

14 BCU over-

Fault Possible cause Correcting measures

) in the resistor cables:

(>4*I

H

limit:

911V for 500V BCU

1200V for 690V BCU

− defective component

− brake resistor short-circuit or

overload

- component failure

- faulty operation

Note exceptional fault data record

Subcode in T.14:

S1 = Reserved

S2 = Reserved

S3 = Reserved

S4 = Reserved

S5 = Reserved

S6 = Reserved

S7 = Charging switch

S8 = No power to driver card

S9 = Power unit communication (TX)

S10 = Power unit communication (Trip)

S11 = Power unit comm. (Measurement)

voltage limit:

333VDC for 500V BCU

460VDC for 690V BCU

− most probable cause: too low

supply voltage in the system

− BCU internal fault

Heatsink temperature is under –10°C

temperature

Heatsink temperature is over 90°C

temperature

Overtemperature warning is issued

when the heatsink temperature exceeds

85°C.

- Check cables.

- Check resistors

- Cannot be reset from the keypad.

- Switch off power.

- DO NOT RE-CONNECT POWER!

- Contact your local distributor.

Reset the fault and restart.

Should the fault re-occur, contact your

local distributor. Please visit:

http://www.vacon.com/wwcontacts.html

- In case of temporary supply voltage

break, reset the fault and restart the

frequency converter.

- Check the supply voltage.

- If it is adequate, an internal failure has

occurred.

- Contact your local distributor.

Please visit:

http://www.vacon.com/wwcontacts.html

- Check the correct amount and flow of

cooling air.

- Check the heatsink for dust.

- Check the ambient temperature.

24-hour support +358 (0)40 8371 150 • Email: vacon@vacon.com

Page 22

22 • vacon Fault codes

18 Unbalance

(Warning only)

31 IGBT

temperature

(hardware)

35 Application Problem in application software Contact your distributor. If you are

37 Device changed

(same type)

38 Device added

(same type)

39 Device removed Option board removed. Reset. Device no longer available.

40 Device

unknown

41 IGBT temperature IGBT Inverter Bridge overtemperature

44 Device changed

(different type)

45 Device added

(different type)

51 External fault Digital input fault. - Remove fault situation from external

54 Slot fault Defective option board or slot Check board and slot.

58 PT100 fault Temperature limit values set for the

60 KLIXON Status of KLIXON input is LOW.

61 Thermistor

fault

Unbalance between power modules in

paralleled units.

Subcode in T.14:

S1 = Current unbalance

S2 = DC-Voltage unbalance

IGBT Inverter Bridge overtemperature

protection has detected too high short

term overload current

Option board or power unit changed.

New device of same type and rating.

Option board added.

Unknown option board or drive.

Subcode in T.14:

S1 = Unknown device

S2 = Power1 not same type as Power2

protection has detected too high a short

term overload current

Option board or power unit changed.

New device of different type or different

rating than the previous one.

Option board of different type added. Reset

PT100 have been exceeded.

The thermistor input of option board has

detected too high resistor temperature

Should the fault re-occur, contact your

local distributor.

application programmer check the

application program.

Reset. Device is ready for use.

Old parameter settings will be used.

Reset. Device is ready for use.

Old board settings will be used.

Contact the distributor near to you.

Please visit:

http://www.vacon.com/wwcontacts.html

Reset

Set the option board parameters again if

option bard changed. Set converter

parameters again if power unit changed.

Set the option board parameters again.

device.

Contact the nearest Vacon distributor.

Please visit:

http://www.vacon.com/wwcontacts.html

Check resistors.

Check thermistor connection

(If thermistor input of the option board is

not in use it has to be short circuited)

Table 6-1. Fault codes

Tel.+358 (0)201 2121 • Fax +358 (0)201 212 205

Page 23

Vaasa

Vacon Plc (Head office and production)

Runsorintie 7

65380 Vaasa

firstname.lastname@vacon.com

telephone: +358 (0)201 2121

fax: +358 (0)201 212 205

sales companies and representative offices:

Austria

Vacon AT Antriebssysteme GmbH

Aumühlweg 21

2544 Leobersdorf

telephone: +43 2256 651 66

fax: +43 2256 651 66 66

Belgium

Vacon Benelux NV/SA

Interleuvenlaan 62

3001 Heverlee (Leuven)

telephone: +32 (0)16 394 825

fax: +32 (0)16 394 827

France

Vacon France

ZAC du Fresne

1 Rue Jacquard – BP72

91280 Saint Pierre du Perray CDIS

telephone: +33 (0)1 69 89 60 30

fax: +33 (0)1 69 89 60 40

Germany

Vacon GmbH

Gladbecker Strasse 425

45329 Essen

telephone: +49 (0)201 806 700

fax: +49 (0)201 806 7099

Great Britain

Vacon Drives (UK) Ltd.

18, Maizefield

Hinckley Fields Industrial Estate

Hinckley

LE10 1YF Leicestershire

telephone: +44 (0)1455 611 515

fax: +44 (0)1455 611 517

Helsinki

Vacon Plc

Äyritie 12

01510 Vantaa

telephone: +358 (0)201 212 600

fax: +358 (0)201 212 699

Tampere

Vacon Plc

Vehnämyllynkatu 18

33580 Tampere

telephone: +358 (0)201 2121

fax: +358 (0)201 212 750

Italy

Vacon S.p.A.

Via F.lli Guerra, 35

42100 Reggio Emilia

telephone: +39 0522 276811

fax: +39 0522 276890

The Netherlands

Vacon Benelux BV

Weide 40

4206 CJ Gorinchem

telephone: +31 (0)183 642 970

fax: +31 (0)183 642 971

Norway

Vacon AS

Langgata 2

3080 Holmestrand

telephone: +47 330 96120

fax: +47 330 96130

PR China

Vacon Suzhou Drives Co. Ltd.

Building 13CD

428 Xinglong Street

Suchun Industrial Square

Suzhou 215126

telephone: +86 512 6283 6630

fax: +86 512 6283 6618

Vacon Suzhou Drives Co. Ltd.

Beijing Office

A205, Grand Pacific Garden Mansion

8A Guanhua Road

Beijing 100026

telephone: +86 10 6581 3734

fax: +86 10 6581 3754

Vacon Traction Oy

Vehnämyllynkatu 18

33580 Tampere

telephone: +358 (0)201 2121

fax: +358 (0)201 212 710

Russia

ZAO Vacon Drives

Bolshaja Jakimanka 31,

stroenie 18

109180 Moscow

telephone: +7 (095) 974 14 47

fax: +7 (095) 974 15 54

ZAO Vacon Drives

2ya Sovetskaya 7, office 210A

191036 St. Petersburg

telephone: +7 (812) 332 1114

fax: +7 (812) 279 9053

Singapore

Vacon Plc

Singapore Representative Office

102F Pasir Panjang Road

#02-06 Citilink Warehouse Complex

Singapore 118530

telephone: +65 6278 8533

fax: +65 6278 1066

Spain

Vacon Drives Ibérica S.A.

Miquel Servet, 2. P.I. Bufalvent

08243 Manresa

telephone: +34 93 877 45 06

fax: +34 93 877 00 09

Sweden

Vacon AB

Torget 1

172 67 Sundbyberg

telephone: +46 (0)8 293 055

fax: +46 (0)8 290 755

Vacon distributor:

Loading...

Loading...