Page 1

vacon nx

ac drives

optc6

canopen option board

user manual

Page 2

INDEX

1.

GENERAL ........................................................................................................................... 3

2.

CANOPEN OPTION BOARD TECHNICAL DATA .................................................................... 4

3.

CANOPEN ........................................................................................................................... 5

4.

CANOPEN OPTION BOARD LAYOUT AND CONNECTIONS .................................................. 6

5.

INSTALLATION OF VACON NX CANOPEN BOARD ............................................................. 13

6.

COMMISSIONING .............................................................................................................. 16

7.

CANOPEN-VACON NX INTERFACE ................................................................................... 19

8.

Service Data (SDO) ........................................................................................................... 31

9.

Node Guarding Protocol ................................................................................................... 42

10.

Electronic Data Sheet, EDS-file ....................................................................................... 43

11.

APPENDICES .................................................................................................................... 44

Document code: DPD00896A

Date: 17.01.2012

2.1 General ..................................................................................................................................... 4

2.2 CanOpen cable .......................................................................................................................... 4

4.1 CanOpen option board .............................................................................................................. 6

4.2 Bus terminal resistors ............................................................................................................. 6

4.3 LED indications ......................................................................................................................... 7

4.4 Connection of CanOpen bus cable ............................................................................................ 8

5.1 Board information sticker ...................................................................................................... 15

7.1 CanOpen message frame ....................................................................................................... 19

7.2 Network Management (NMT) ................................................................................................. 21

7.3 Process data (PDO) ................................................................................................................. 22

7.4 Transmission types ................................................................................................................ 23

7.5 Controlling the drive via PDO messages with Drive Profile ................................................... 24

7.6 Using manufacturer specific PDOs with ByPass modes ........................................................ 27

7.7 Drive Monitoring ..................................................................................................................... 29

7.8 Anyparameter service ............................................................................................................ 30

appendix a - device profile for drives ..................................................................................................... 44

appendix b – sdo messages .................................................................................................................... 45

appendix c – process data contents ....................................................................................................... 46

appendix d .............................................................................................................................................. 47

Tel.+358 (0)201 2121 • Fax +358 (0)201 212 205

Page 3

general vacon • 3

1

1. GENERAL

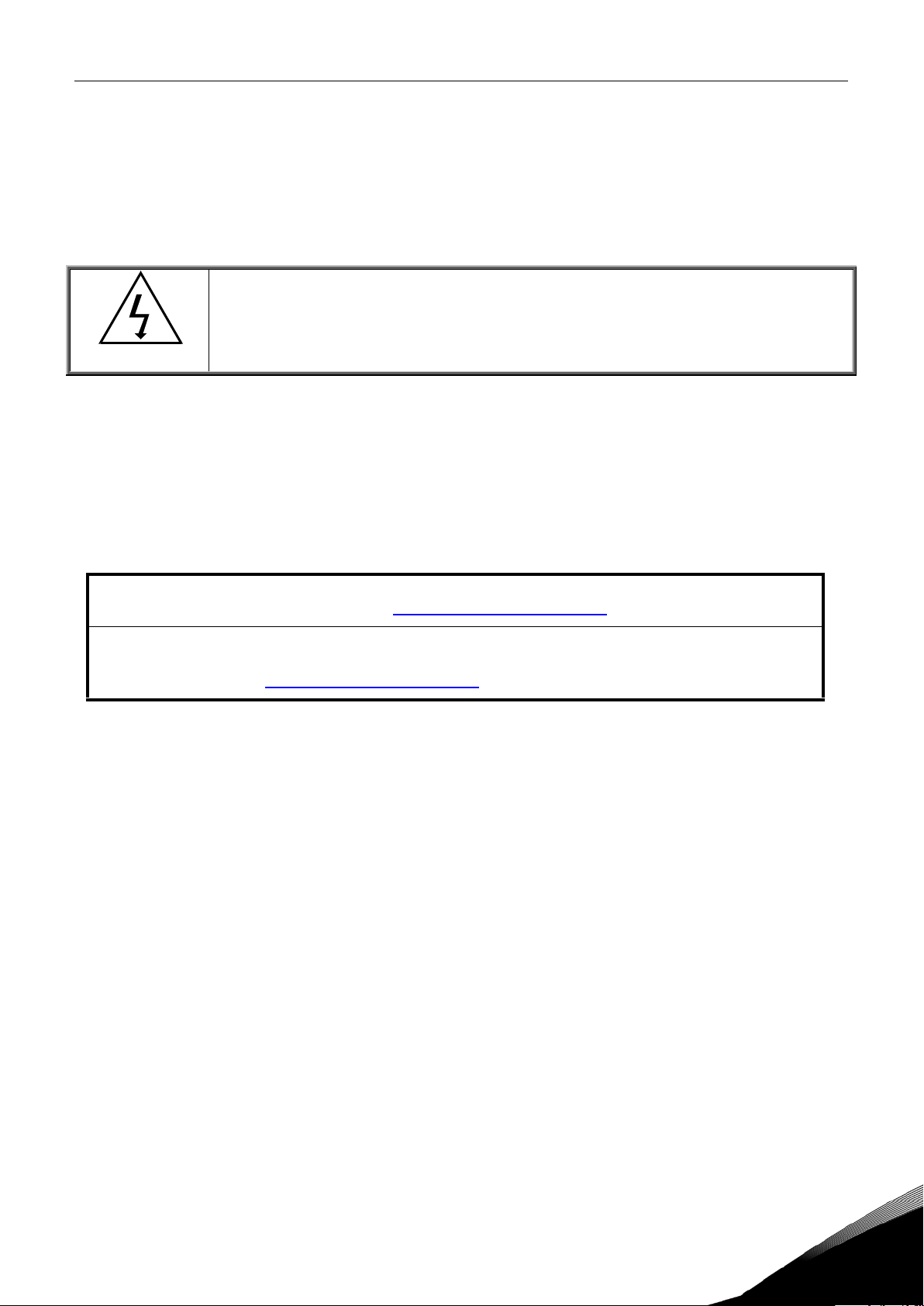

DANGER

NOTE!

Fieldbus@vacon.com.

Vacon NX frequency converters can be connected to the CanOpen system using a fieldbus board. The

converter can then be controlled, monitored and programmed from the Host system.

The CanOpen fieldbus board shall be installed in slot E on the control board of the frequency

converter.

Internal components and circuit boards are at high potential when the frequency

converter is connected to the power source. This voltage is extremely dangerous

and may cause death or severe injury if you come into contact with it.

When experiencing problems with fieldbus functionalities, please contact

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from www.vacon.com/downloads

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site www.vacon.com/downloads

.

.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 4

4 • vacon canopen

2. CANOPEN OPTION BOARD TECHNICAL DATA

2.1 General

2.2 CanOpen cable

Baudrate [Kbit/s]

Max. Bus length [m]

30

CanOpen

connections

Communications CanOpen CiA DS-301

Environment The specifications of the drive are applicable.

Safety Fulfils EN50178 standard

Table 2-1. CanOpen technical data

Interface Open Style Connector (Pluggable connector, 5.08mm)

Data transfer

method

Transfer cable 2 wire twisted shielded cable

Electrical isolation 500 VDC

Baud rate 10 kBaud

Addresses 1 – 127

CAN (ISO 11898)

CiA DSP-402

20 kBaud

50 kBaud

100 kBaud

125 kBaud

250 kBaud

500 kBaud

1000 kBaud

According to the ISO 11898 standard, cables to be chosen for CAN bus lines should have a nominal

impedance of 120Ω, and a specific line delay of nominal 5 ns/m. Line termination has to be provided

through termination resistors of 120Ω located at both ends of the line. The length related resistance

should have 70 mΩ/m. All these mentioned AC and DC parameters are suitable for a 1 Mbit/s

transmission rate.

The table below shows practical bus length for CANopen networks with less than 64 nodes:

1000

800 50

500 100

250 250

125 500

50 1000

20 2500

Tel.+358-(0)201-21 Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

3

Page 5

CanOpen Option Board Vacon • 5

3. CANOPEN

Velocity Mode

CANopen is a networking system based on the serial bus Controller Area Network (CAN). The

CANopen Communication Profile (CiA DS-301) supports both direct access to device parameters and

time-critical process data communication. CANopen device profiles (CiA DS-40x) define standards for

basic device functionality while providing ample scope for additional vendor-specific device features.

CANopen leashes the full power of CAN by allowing direct peer to peer data exchange between nodes

in an organised and, if necessary, deterministic manner. The network management functions

specified in CANopen simplify project design, implementation and diagnosis by providing standard

mechanisms for network start-up and error management.

CANopen supports both-cyclic and event-driven communication. This makes it possible to reduce the

bus load to a minimum but still maintaining extremely short reaction times. High communication

performance can be achieved at relatively low baud rates, thus reducing EMC problems and

minimising cable costs.

CANopen is the ideal networking system for all types of automated machinery. One of the

distinguishing features of CANopen is its support for data exchange at the supervisory control level as

well as accommodating the integration of very small sensors and actuators on the same physical

network. This avoids the unnecessary expense of gateways linking sensor/actuator bus systems with

higher communication networks and makes CANopen particularly attractive to original equipment

manufacturers.

Device Profile Drives and Motion Control (CiA DSP-402)

document represents the standardised

CANopen Device Profile for digital controlled motion products like servo controllers, frequency

converters or stepper motors. All the above-mentioned devices use communication techniques which

conform to those described in the CANopen Application Layer and Communication Profile. The

starting and stopping of the drive and several mode specific commands are executed by the

statemachine. The operation mode defines the behaviour of the drive. The following modes are

defined in this profile:

Homing Mode

Profile Position Mode

Interpolated Position Mode

Profile Velocity Mode

Profile Torque Mode

Velocity Mode

Vacon CanOpen Option Board supports the

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 6

6 • vacon installation

4. CANOPEN OPTION BOARD LAYOUT AND CONNECTIONS

4.1 CanOpen option board

Signal

Connector

Description

CAN_L

2

CAN_L bus line (dominant low)

4.2 Bus terminal resistors

X1

A

M

X6

Jumpers

Interface board

connector

Grounding plate

Bus connector

1

2

3

4

5

Vacon CanOpen Board is connected to the fieldbus through a 5-pin pluggable bus connector (board

NXOPTC6).

The communication with the control board of the frequency converter takes place through the

standard Vacon Interface Board Connector.

Figure 4-1. Vacon CanOpen option board OPT-C6

CAN_GND 1 Ground / 0V / V-

(CAN_SHLD) 3 Optional CAN shield

CAN_H 4 CAN_H bus line (dominant high)

(CAN_V+) 5 -

Table 4-1.OPT-C6 bus connector signals

If Vacon drive is the last device of the CanOpen line the bus termination must be set. Use jumper X6

(ON position see Figure 4-1), or an external resistor (120Ω) connected to terminals 2 and 4.

ON OFF

Tel.+358-(0)201-21 Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

5

Page 7

installation Vacon • 7

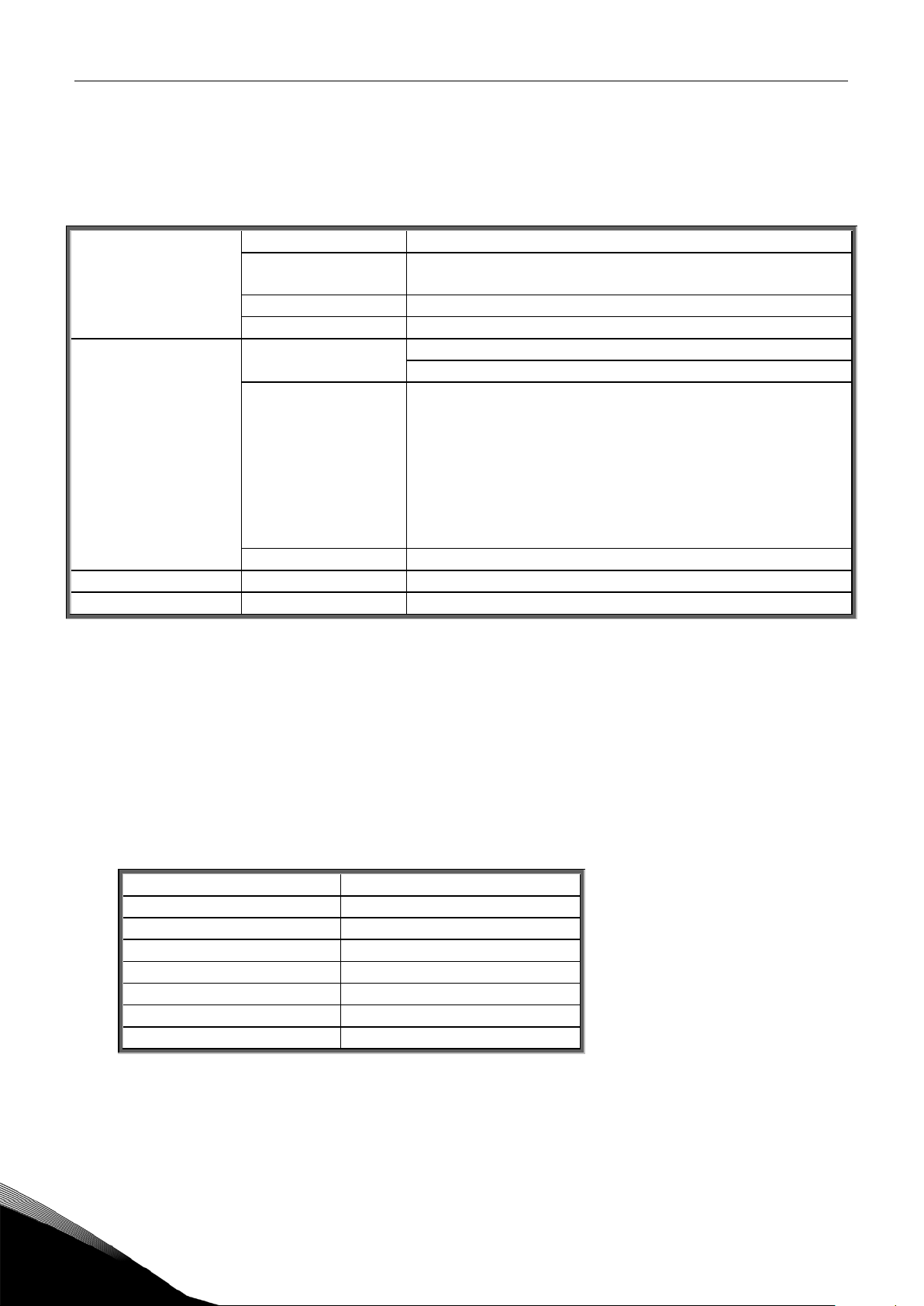

4.3 LED indications

CanOpen board status LED (A) GREEN

OFF

Option board not activated

X1

A

M

X6

N

Green

Green

Not used

1

2

3

4

5

The CanOpen Option Board includes two LED status indicators next to the connector: Fieldbus status

(M), CanOpen(A). Led N is unused.

Figure 4-2. LED indications on the CANopen board

LED is: Meaning:

ON Option board in initialisation state waiting for activation

command from the frequency converter

Blinking fast

(1 blink / s)

Blinking slow

(1 blink/ 5s)

Fieldbus status LED (M) GREEN

LED is: Meaning:

OFF Fieldbus module is waiting for parameters from the

ON Fieldbus module is activated

Blinking fast

(1 blink / s)

Blinking slow

(1 blink / 5s)

Option board is activated and in RUN state

Option board is ready for external communication

Option board is activated and in FAULT state

Internal fault of option board

frequency converter

No external communication

Parameters received and module activated

Module is waiting for messages from the bus

Module is activated and receiving messages from the bus

Module is in FAULT state

No messages from Master within the watchdog time

Bus broken, cable loose or Master off line

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

5

Page 8

8 • vacon installation

4.4 Connection of CanOpen bus cable

Note:

Grounding by clamping the cable to the converter frame

cut off the

grey cable shield

Note:

of both CanOpen cables

Error! Reference source not found.

c a b l e

c a b l e

c a b l e

C a n p e n O C a n p e n

O

O

The bus cable shield can be grounded in three different ways:

a) clamping the cable to the frequency converter frame

b) to the frame of the frequency converter through an RC filter

c) directly to the converter frame

Normally, the option board has already been installed in slot E of the control board. It is not

necessary to detach the whole board for the grounding of the bus cable shield. Just detach the

terminal block.

4.4.1

This manner of grounding is the most effective and especially recommended when the distances

between the devices are relatively short (see 4.4.2.1).

In this manner of grounding, the position of jumper X1 is of no importance

Figure 4-3. Grounding by clamping the cable to the converter frame

C a n p e n

1 Strip about 5 cm of the CanOpen cable in the same way as shown in Figure 4-4 but

.

Remember to do this for both bus cables (except for the last device).

2 Leave no more than 1 cm of the data cable outside the terminal block and strip the data cables at

about 0.5 cm to fit in the terminals. See Figures 4-5 and 4-6.

Do this for both bus cabels

3 Insert the data cables

into terminals #2 and #4. See Figure 4-7.

4 Strip the CanOpen cable at such a distance from the terminal that you can fix it to the frame with

the grounding clamp. See Figure 4-4.

Figure 4-4.

Tel.+358-(0)201-21 Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

5

Page 9

installation Vacon • 9

Grounding the bus cable shield directly to the frequency converter frame using

jumper X1

X1

Note:

Note:

ON

OFF

X1

4.4.2

1 Set jumper

Figure 4-5. Jumper X1 positions

2 Strip about 5 cm of the CanOpen cable as shown in the picture.

grounding shall be done on one cable only cut off the exposed part of the other grounding

cable.

in ON position:

Do the same for both bus cables (except for the last device). However, since the

Figure 4-6.

3 Leave no more than 1 cm of the red and green data cable outside the terminal block and

strip the data cables at about 0.5 cm to fit in the terminals. See pictures below.

Do this for both bus cabels.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

5

Page 10

10 • vacon installation

Figure 4-7.

5

Figure 4-8.

Tel.+358-(0)201-21 Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 11

installation Vacon • 11

of both CanOpen cables

4 We recommend you to use an Abico connector to fit the grounding cable into the grounding

terminal (#3).

Insert the white and brown data cables

and #4 (brown).

into terminals #2 (white)

Figure 4-9.

5 Place the CanOpen board into slot E of the control board (see board installation on page 13)

and fix both the CanOpen cables on the frame with the clamp.

Figure 4-10.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

5

Page 12

12 • vacon installation

X1

C a n O p e n c a b l e

A B C

O C a n p e n O

X1

A

M

ON

OFF

1

2

3

4

5

4.4.2.1 Grounding the bus cable shield directly to the frequency converter frame using an RC-filter

We recommend you to do the grounding in this manner when the distance between the devices

exceeds 50 meters (55 yds.). When the distance between the devices is long disturbances (e.g. voltage

spikes) are more likely to appear. In this grounding method, the disturbances are filtered out. Even if

the ground planes of A, B and C are different (which is very typical e.g. in construction) there is no

current between them because the points do not have a ground connection.

Figure 4-11. Grounding with RC filter

1 Set jumper

in OFF position

C a n p e n

c a b l e

c a b l e

5

Figure 4-12. Jumper X1 positions

2 Carry out the grounding in the same way as advised in Chapter 4.4.1.

Tel.+358-(0)201-21 Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 13

installation Vacon • 13

5. INSTALLATION OF VACON NX CANOPEN BOARD

!

NOTE

IS SWITCHED OFF

A

B

C

MAKE SURE THAT THE FREQUENCY CONVERTER

AN OPTION OR FIELDBUS BOARD IS CHANGED OR ADDED!

Vacon NX frequency converter

Remove the cable cover.

BEFORE

Open the cover of the control unit.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

5

Page 14

14 • vacon installation

D

X6

X1

1

2

3

4

5

E

F

Close the cover of the control unit and

Install CanOpen option board in slot E

on the control board of the frequency

converter. Make sure that the grounding

plate (see below) fits tightly in the

clamp.

Make a sufficiently wide opening for

your cable by cutting the grid as wide as

necessary.

the cable cover.

5

Tel.+358-(0)201-21 Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 15

installation Vacon • 15

5.1 Board information sticker

Drive m odified

:

Option board:

NXOPT................

IP54 upgrade/ Collar

in slot:

Date:...................

A B C D E

EMC level modified: H

Ý

T / T

Ý

H

Date:...................

Date:...................

1

2

3

The CanOpen option board package delivered by the factory includes a sticker (shown below). Please

mark the board type (1), the slot into which the board is mounted (2) and the mounting date (3) on the

sticker. Finally, attach the sticker on your drive.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

5

Page 16

16 • vacon commissioning

6. COMMISSIONING

Note!

M7

Expander board menu (M7)

(G#)

CanOpen parameters

G1

G5

READY

E:NXOPTC6

READY

G1

G2

READY

READY

enter

P1P3

READY

Expander boards

Parameters

Node ID

63

CHANGE VALUE

CONFIRM CHANGE

63

Node ID

READ FIRST CHAPTER 8 'COMMISSIONING' IN VACON NX USER'S MANUAL (Document nr. ud00701,

please visit http://www.vacon.com/support/documents.html).

converter through fieldbus. See Vacon NX User’s Manual, Chapter 7.3.3.1

The Vacon CanOpen board is commissioned with the control keypad by giving values to appropriate

parameters in menu

7).

The

connected to the control board and 2) to reach and edit the parameters associated with the expander

board.

Enter the following menu level

slots A to E with the

line of the display you also see the number of parameter groups associated with the board.

If you still press the

two groups: Editable parameters and Monitored values. A further press on the

takes you to either of these groups.

To commission the CanOpen board, enter the level P7.5.1.# from the

desired values to all CanOpen parameters (see xx and xx).

You must select Fieldbus as the active control place, if you wish to control the frequency

(for locating the expander board menu see Vacon NX User's Manual, Chapter

Expander board menu

makes it possible for the user 1) to see what expander boards are

with the

Browser buttons

Menu button right

to see what expander boards are connected. On the lowermost

once you will reach the parameter group level where there are

Menu button right

. At this level, you can browse through

Menu button right

Parameters

group (G7.5.1). Give

Figure 6-1. Changing the CANopen option board parameters

Tel.+358-(0)201-21 Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

6

Loading...

Loading...