Page 1

vacon

ac drives

®

nx

active front end ii (afe-ii)

arfiff05

application manual

Page 2

Page 3

Arfiff05 Standard AFE-II vacon • 3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Vacon Standard AFE-II application

INDEX

Document code: DPD01979A

Software code: ARFIFF05V051

Date: 23.3.2018

VACON STANDARD AFE-II APPLICATION .......................................................................................3

1. Introduction ...................................................................................................................................................................................... 6

1.1 Compatibili ty issues in parameters between versions.................................................................................................... 7

2. AFE Units ........................................................................................................................................................................................... 8

2.1 500 Vac units Air Cooled, 465 -800 Vdc .............................................................................................................................. 8

2.2 690 Vac units Air Cooled, 640 -1100 Vdc............................................................................................................................ 8

2.3 500 Vac units Liquid-Cool ed, 465-800 Vdc........................................................................................................................ 9

2.4 690 Vac units Liquid-Cool ed, 640-1100 Vdc...................................................................................................................... 9

2.5 690 Vac units Liquid –Cooled, 640-1200 Vdc.................................................................................................................. 10

3. Operation ........................................................................................................................................................................................ 11

3.1 Charging of DC ...................................................................................................................................................................... 11

3.2 Mai n Circuit breaker control (MCB control ) ................................................................................................................... 11

3.3 Quick Start instructions ...................................................................................................................................................... 12

3.4 Start Sequ ence ..................................................................................................................................................................... 13

3.5 Stop Sequence ...................................................................................................................................................................... 14

3.6 Start Stop timing diagram .................................................................................................................................................. 15

4. CONTROL IO .................................................................................................................................................................................... 16

5. AFE Application – Monitoring Values ....................................................................................................................................... 17

5.1 Monitoring values ................................................................................................................................................................ 18

5.1.1 Monitoring 1 .................................................................................................................................................................... 18

5.1.2 FieldBus Moni toring values ........................................................................................................................................... 18

5.1.3 Line Monitor OPT-D7 ...................................................................................................................................................... 18

5.1.4 Master Follower .............................................................................................................................................................. 19

5.1.5 Monitoring values 2 ........................................................................................................................................................ 19

5.2 Monitoring Values description .......................................................................................................................................... 19

5.2.1 Monitoring 1 values ........................................................................................................................................................ 19

5.2.2 Fieldbus moni toring values ........................................................................................................................................... 21

5.2.3 Line monitoring OPT-D7................................................................................................................................................. 26

5.2.4 Master/Follower.............................................................................................................................................................. 26

5.2.5 Monitoring values 2 ........................................................................................................................................................ 27

6. Parameter List................................................................................................................................................................................ 28

6.1 Basi c parameters.................................................................................................................................................................. 28

6.2 Reference Handling ............................................................................................................................................................. 28

6.3 Input signals .......................................................................................................................................................................... 29

6.3.1 Digi tal inputs .................................................................................................................................................................... 29

6.3.2 Analogue Input 1 ............................................................................................................................................................. 29

6.3.3 Analogue Input 2 ............................................................................................................................................................. 29

6.3.4 Cabi n State DI................................................................................................................................................................... 30

6.3.5 Options.............................................................................................................................................................................. 30

6.4 Output signals....................................................................................................................................................................... 31

6.4.1 Digi tal Outputs................................................................................................................................................................. 31

6.4.2 ANALOG OUTPUT 1 ......................................................................................................................................................... 31

Page 4

4 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.4.3 Options.............................................................................................................................................................................. 32

6.5 Limit Settings ........................................................................................................................................................................ 33

6.5.1 Current Limit .................................................................................................................................................................... 33

6.5.2 Power Limit ...................................................................................................................................................................... 33

6.5.3 Frequency Limit ............................................................................................................................................................... 33

6.5.4 AC Voltage Limit .............................................................................................................................................................. 33

6.5.5 DC Voltage Limi t .............................................................................................................................................................. 33

6.6 Dri ve Control parameters ................................................................................................................................................... 34

6.6.1 Control............................................................................................................................................................................... 34

6.7 Protections ............................................................................................................................................................................ 35

6.7.1 Gen eral.............................................................................................................................................................................. 35

6.7.2 Temperature sensor protections.................................................................................................................................. 35

6.7.3 Fieldbus ............................................................................................................................................................................. 36

6.7.4 OPT-D7 protections ........................................................................................................................................................ 36

6.7.5 Options.............................................................................................................................................................................. 36

6.8 Fieldbus parameters ............................................................................................................................................................ 37

6.9 ID Control Functi ons............................................................................................................................................................ 38

6.9.1 Value control.................................................................................................................................................................... 38

6.9.2 DIN ID Control 1............................................................................................................................................................... 38

6.10 Keypad control (Control keypad: Menu M3) .................................................................................................................. 39

6.11 System menu (Control keypad: Menu M6) ..................................................................................................................... 39

6.12 Expander boards (Control keypad: Menu M7) ............................................................................................................... 39

7. Description of parameters .......................................................................................................................................................... 40

7.1 Basi c parameters.................................................................................................................................................................. 40

7.2 Reference Handling ............................................................................................................................................................. 41

7.3 Input signals .......................................................................................................................................................................... 42

7.3.1 Digi tal inputs .................................................................................................................................................................... 42

7.3.2 Analogue Inputs............................................................................................................................................................... 44

7.3.3 Cabi n State DI................................................................................................................................................................... 47

Options .................................................................................................................................................................................. 47

7.3.4.................................................................................................................................................................................................. 47

7.4 Output signals....................................................................................................................................................................... 48

7.4.1 Digi tal outputs ................................................................................................................................................................. 48

7.4.2 Analogue outputs ............................................................................................................................................................ 50

7.4.3 Options outputs............................................................................................................................................................... 52

7.5 Limit Settings ........................................................................................................................................................................ 53

7.5.1 Current limi ts ................................................................................................................................................................... 53

7.5.2 Power Limits ..................................................................................................................................................................... 53

7.5.3 Frequency limits .............................................................................................................................................................. 53

7.5.4 AC Voltage li mits ............................................................................................................................................................. 54

7.5.5 DC Voltage limit parameters ......................................................................................................................................... 55

7.6 Dri ve control ......................................................................................................................................................................... 56

7.6.1 Control............................................................................................................................................................................... 58

7.7 Protections ............................................................................................................................................................................ 60

7.7.1 Gen eral.............................................................................................................................................................................. 60

7.7.2 Temperature sensor protections.................................................................................................................................. 61

7.7.3 Fieldbus ............................................................................................................................................................................. 62

7.7.4 OPT-D7 Protections......................................................................................................................................................... 63

7.8 Fieldbus parameters............................................................................................................................................................ 64

7.9 ID Functions .......................................................................................................................................................................... 65

7.9.1 Value Control ................................................................................................................................................................... 65

7.9.2 DIN ID Control .................................................................................................................................................................. 67

7.10 Keypad control ..................................................................................................................................................................... 68

8. Status and control words in detail ............................................................................................................................................ 69

8.1 Basi c In ByPass (0)................................................................................................................................................................ 69

Page 5

Arfiff05 Standard AFE-II vacon • 5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8.2 FB Control Word................................................................................................................................................................... 70

8.2.1 Standard (1)...................................................................................................................................................................... 70

8.2.2 Vacon AFE 1 profile (2) ................................................................................................................................................... 71

8.2.3 Vacon AFE 2 Profile (3) ................................................................................................................................................... 73

8.3 FB Status Word..................................................................................................................................................................... 75

8.4 Fault Word 1 ......................................................................................................................................................................... 77

8.5 Fault Word 2 ......................................................................................................................................................................... 77

8.6 Warning Word 1................................................................................................................................................................... 78

8.7 Auxiliary Control Word ....................................................................................................................................................... 79

8.8 Status Word (Application) ID 43........................................................................................................................................ 80

9. Problem Solving ............................................................................................................................................................................. 82

10. Fault codes................................................................................................................................................................................. 83

Page 6

6 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1. INTRODUCTION

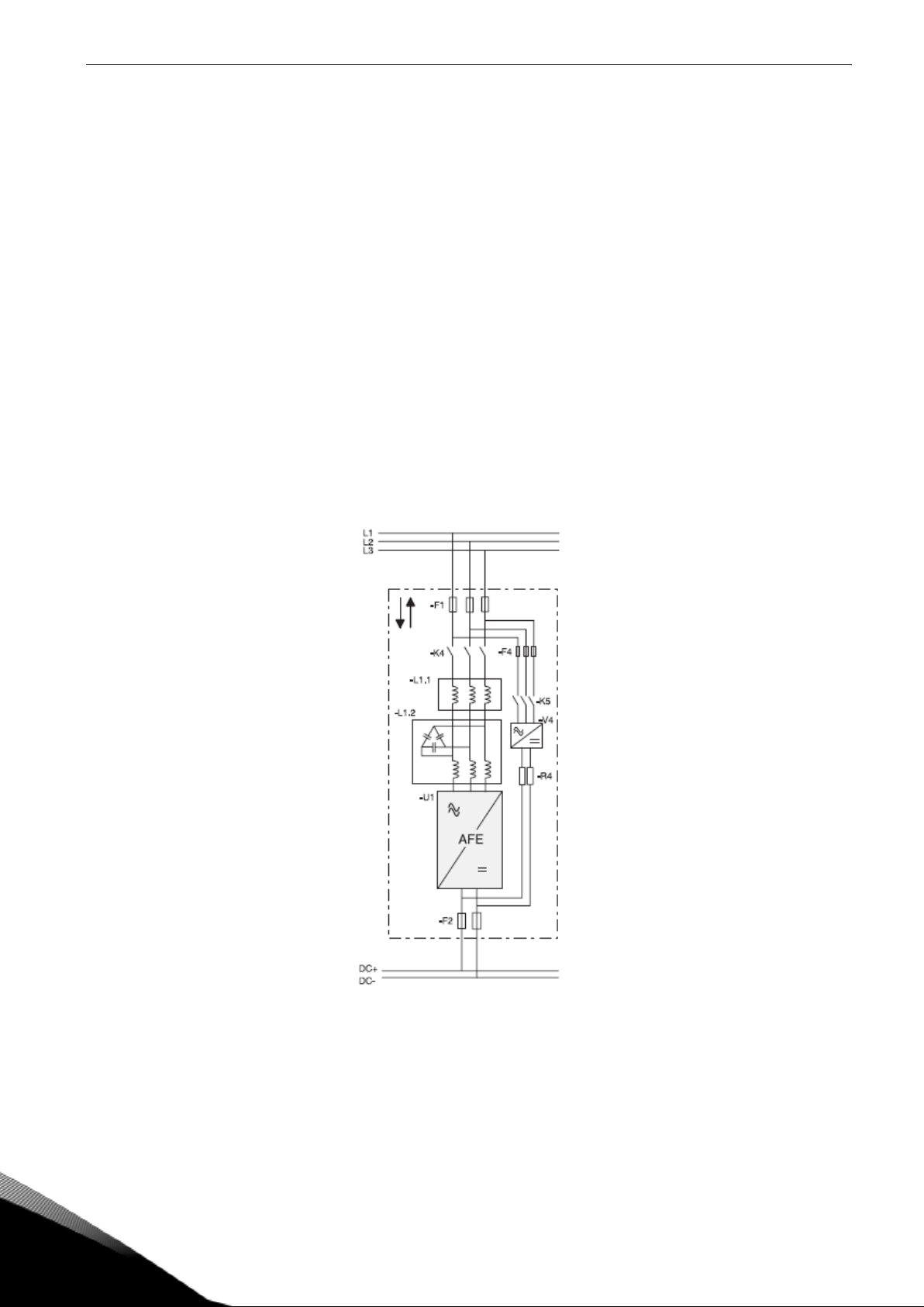

The AFE unit is a regenerative power converter for the front-end of a common DC bus product line.

The AFE unit is utilized by using inverter hardware with special software. An external L(CL)-filter

and charging circuit is needed. This unit is selected when low harmonics are required. The principle

connection of AFE drive has been described in Figure 1.

The Regenerative Application is easy and flexible to use due to its versatile fieldbus features. The

parameters of the Regenerative Application are explained in Chapter 7 of this manual.

The basic I/O-configuration of the AFE drive consists of OPT-A1 and OPT-A2 option cards. The basic

I/O configuration has been described in table 2-1.

As a default the control place (P3.1) of the AFE drive is Keypad.

This application requires NXP3 control board VB00761.

Figure 1, AFE connection

Page 7

Arfiff05 Standard AFE-II vacon • 7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1.1 Compatibility issues in parameters between versions

V025

• Compatibility Issue: MCB Force Open inverted. This to follow NXC cabinet

default signals.

Update Note 1: This application parameters are not kept backwards compatible if new features or

improvements would be difficult to implement by doing so. Read this change note and chapter

Compatibility issues in parameters between versions before updating the application.

Update Note 2:

application, especially in cases when version number change is considerably high.

Application is constantly developed; this includes changing parameter default values, and if

parameters are directly downloaded to drive improved default values may be lost.

Page 8

8 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

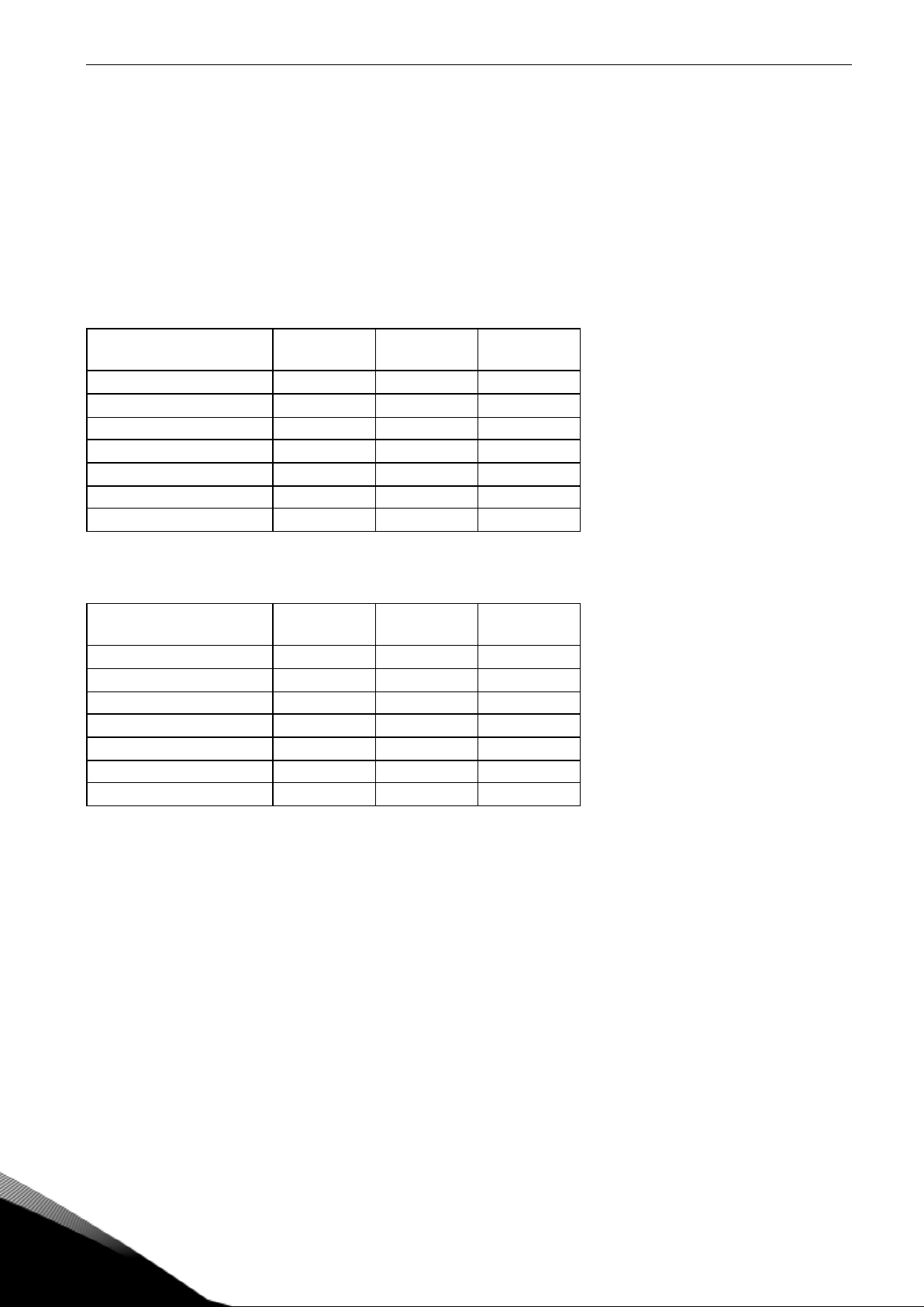

2. AFE UNITS

Air and liquid-cooled products listed in chapter 2 are compatible with AFE application ARFIFF05.

Hardware and software support for AFE use is only available for these products.

Downloading AFE application to products other than those listed in chapter 2 is considered to be a

non-standard product which functionality has not been verified or documented. In such cases User

takes full responsibility for possible hardware and software problems. Application support is not

available for non-standard products.

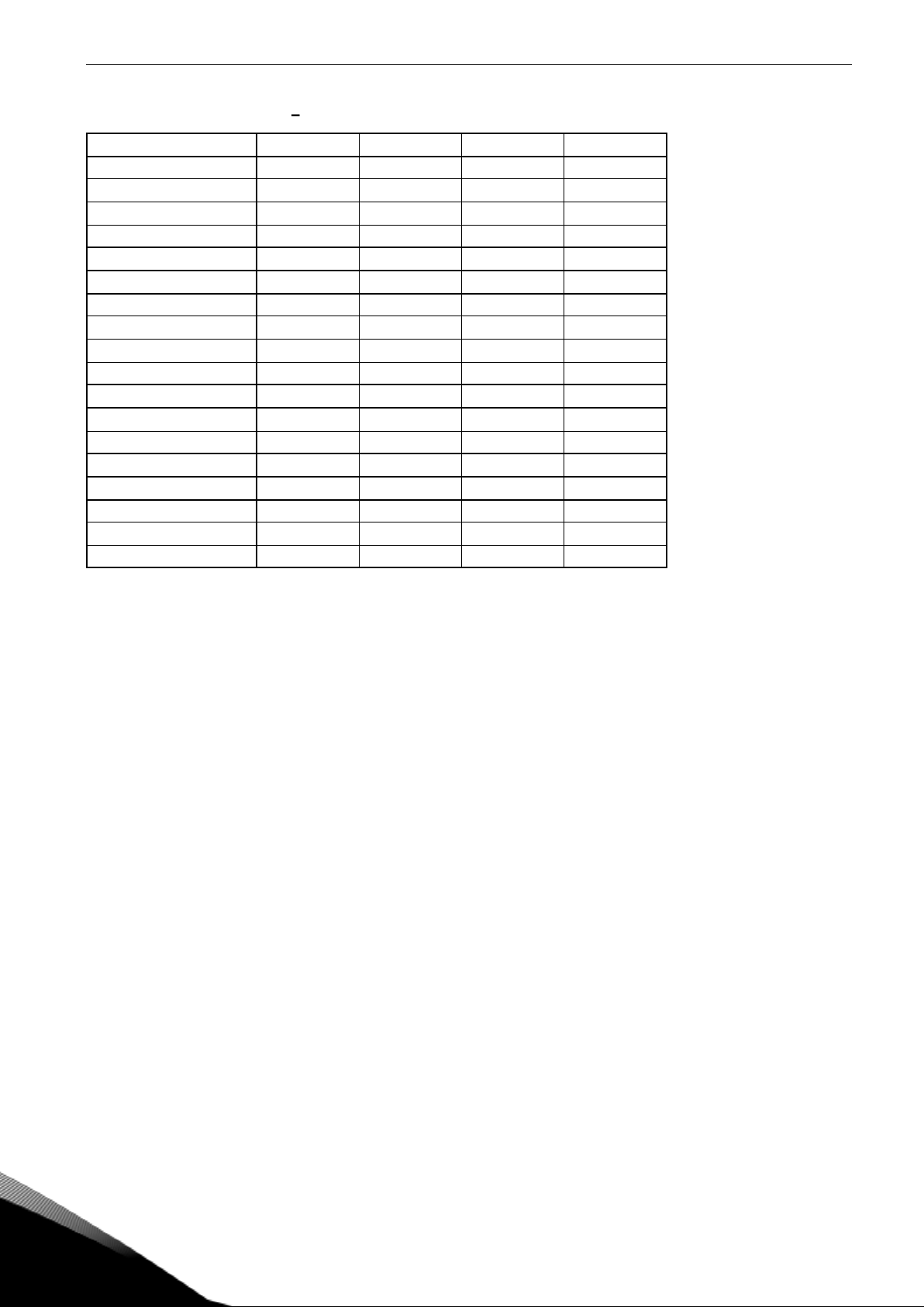

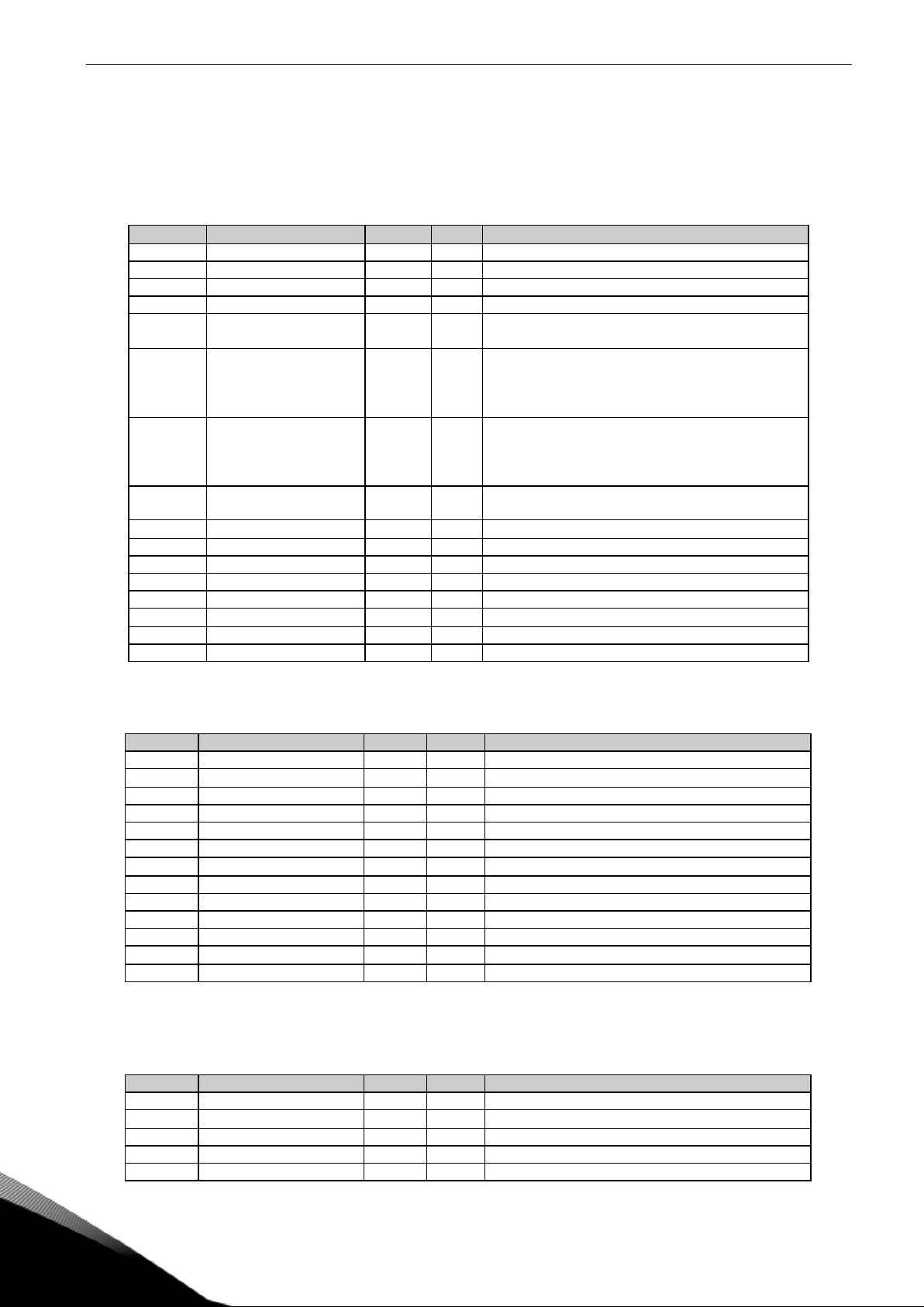

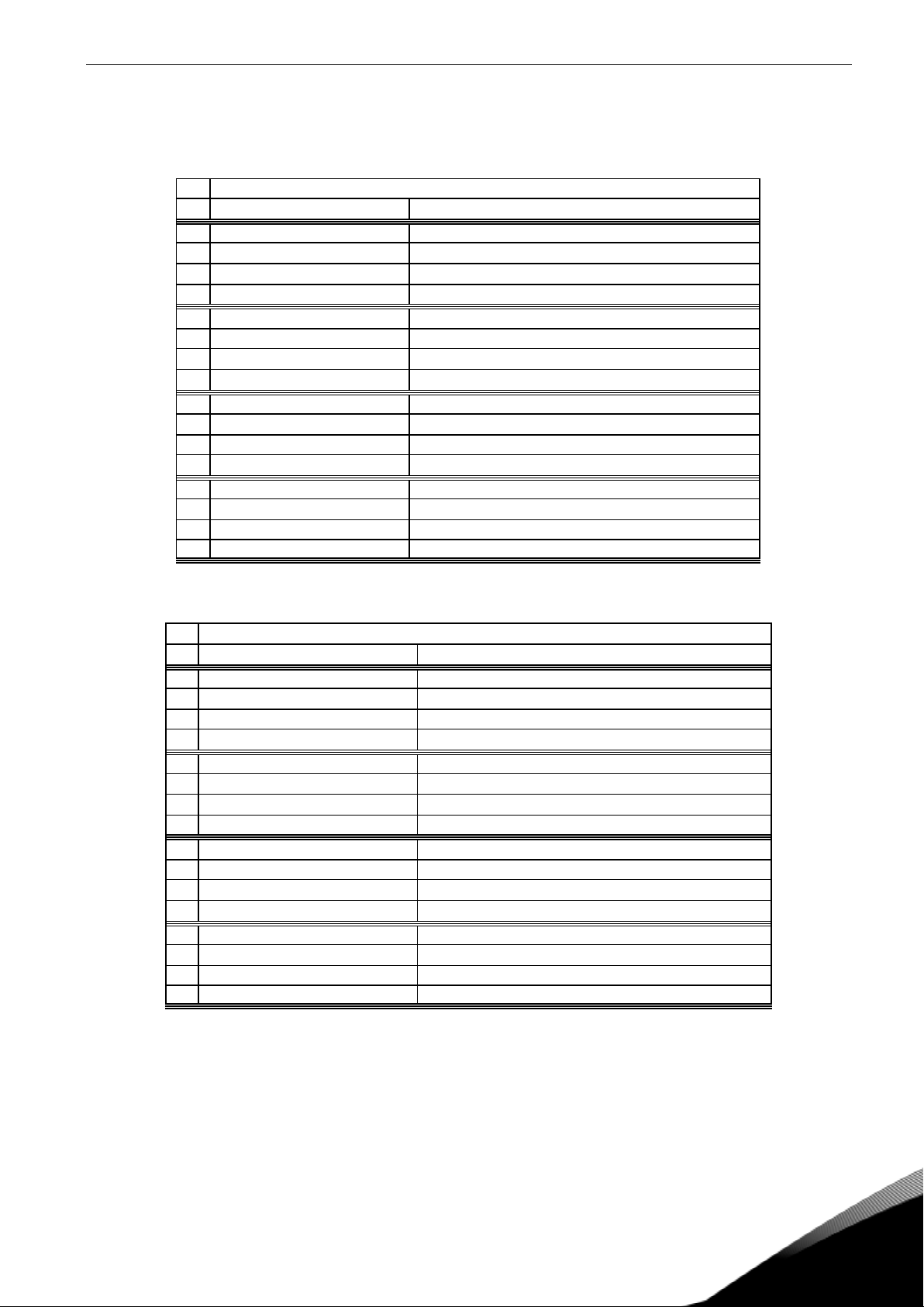

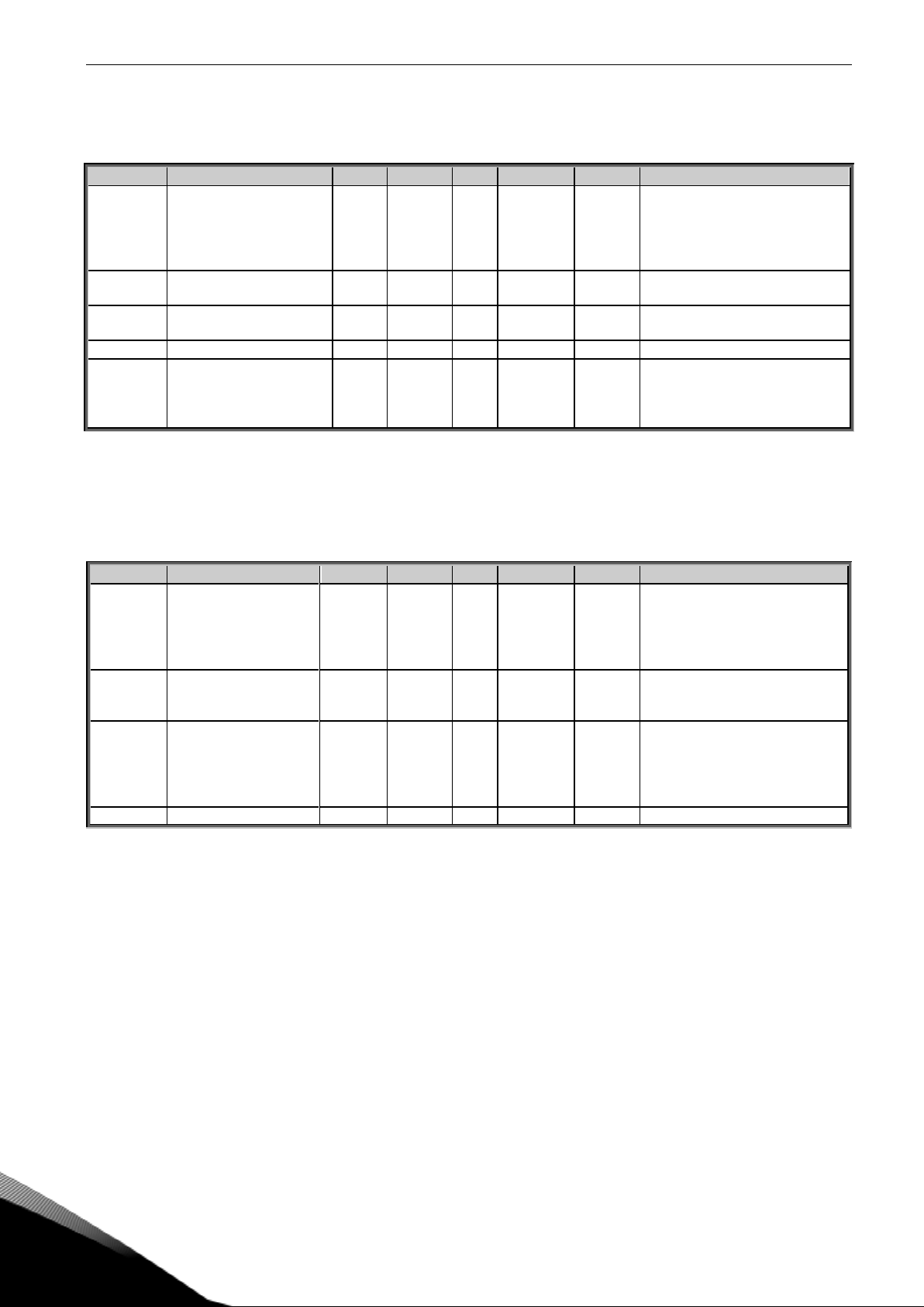

2.1 500 Vac units Air Cooled, 465-800 Vdc

Code

Frame

IL-cont [A]

IH-cont

[A]

NXA_0168 5 A0T02SG

FI9

170

140

NXA_0205 5 A0T02SG

FI9

205

170

NXA_0261 5 A0T02SG

1xFI9

261

205

NXA_0385 5 A0T02SG

1xFI10

385

300

NXA_0460 5 A0T02SG

1xFI10

460

385

NXA_1150 5 A0T02SG

1xFI13

1150

1030

NXA_1300 5 A0T02SG

1xFI13

1300

1150

2.2 690 Vac units Air Cooled, 640-1100 Vdc

Code

Frame

IL-cont [A]

IH-cont

[A]

NXA_0125 6 A0T02SG

1xFI9

125

100

NXA_0144 6 A0T02SG

1xFI9

144

125

NXA_0170 6 A0T02SG

1xFI9

170

144

NXA_0261 6 A0T02SG

1xFI10

261

208

NXA_0325 6 A0T02SG

1xFI10

325

261

NXA_0920 6 A0T02SG

1xFI13

920

820

NXA_1030 6 A0T02SG

1xFI13

1030

920

Page 9

Arfiff05 Standard AFE-II vacon • 9

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

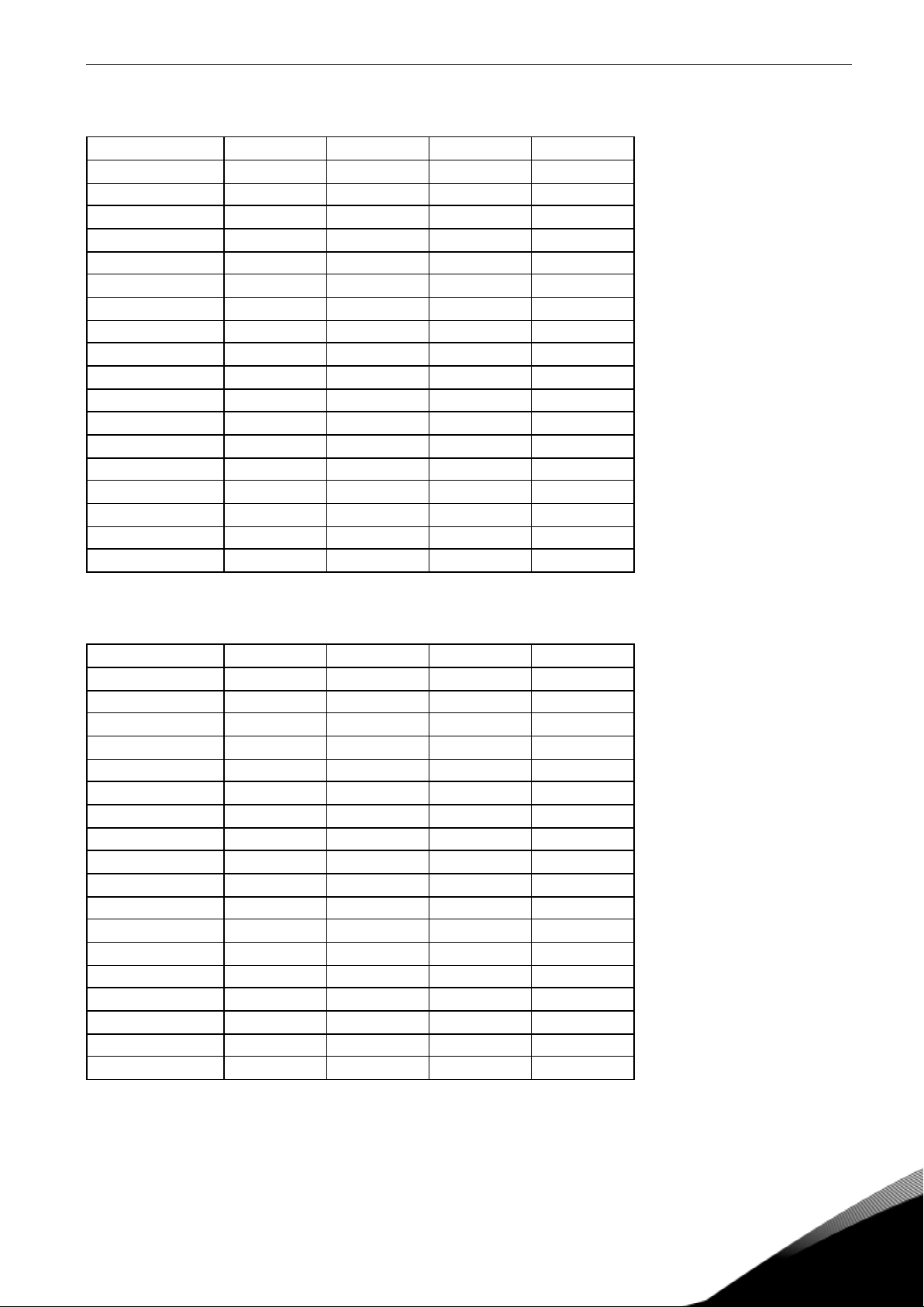

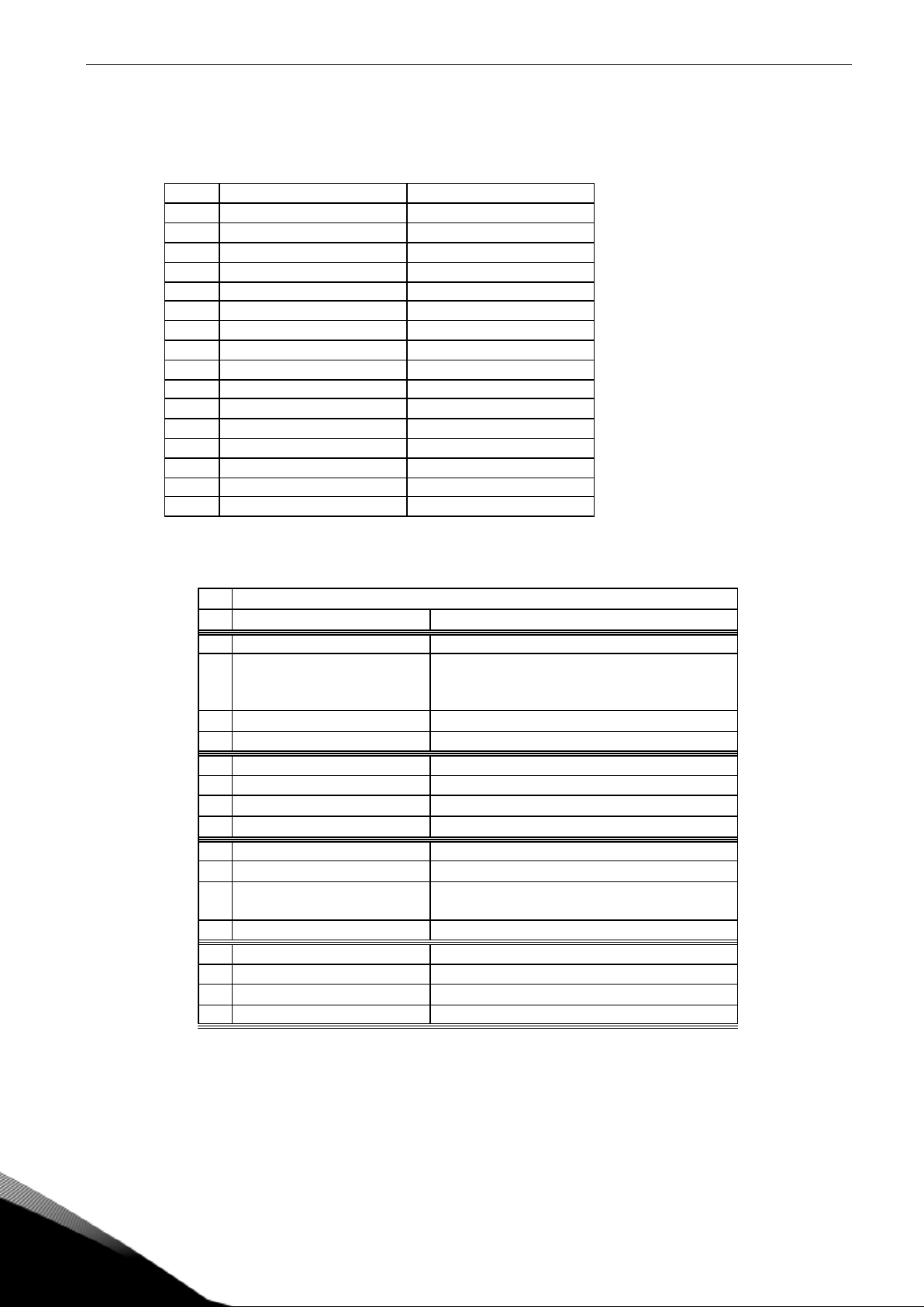

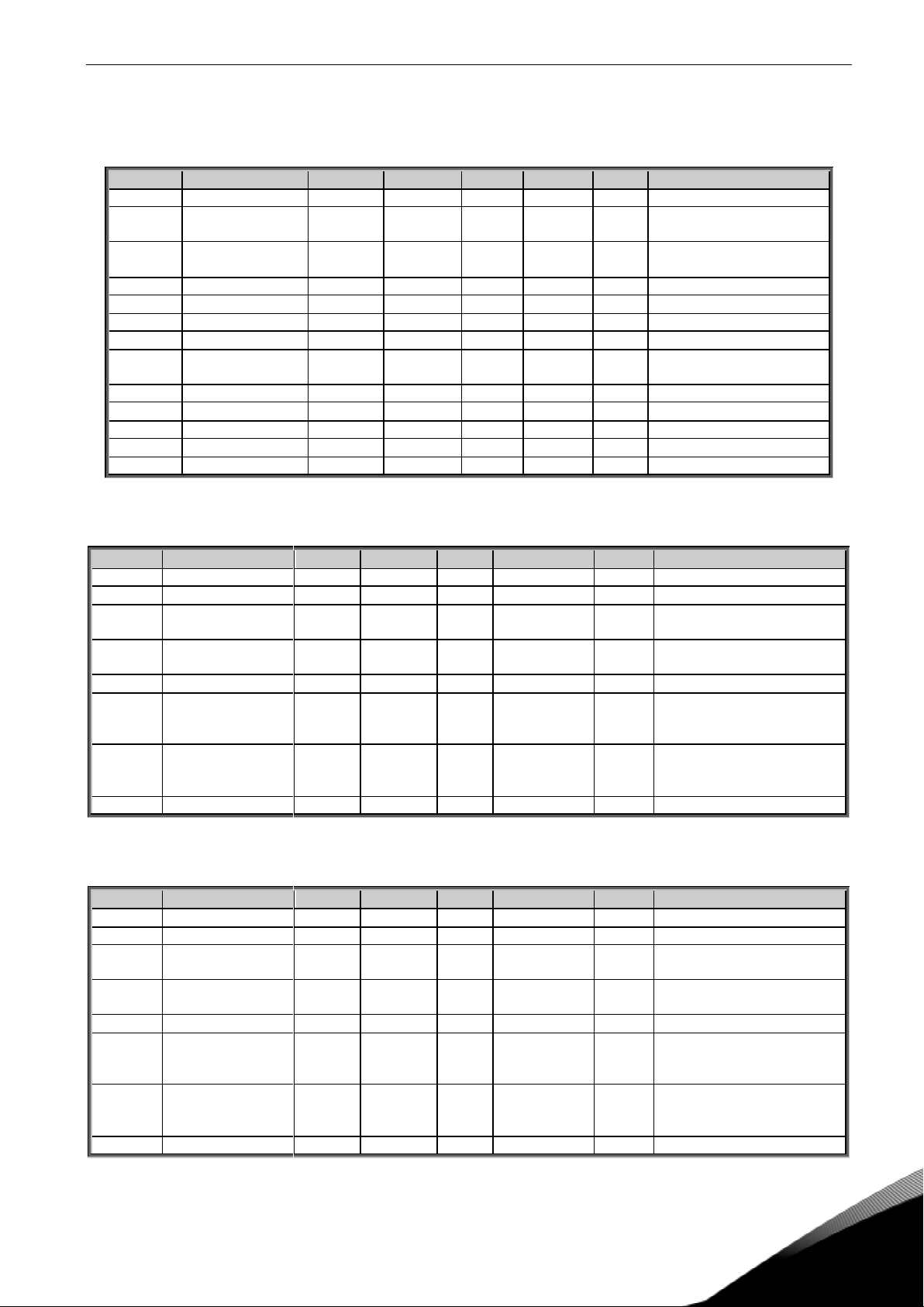

2.3 500 Vac units Liquid-Cooled, 465-800 Vdc

Code

Chassis

Ith [A]

Il [A]

Ih [A]

NXA01685A0T02WS

CH5

168

153

112

NXA02055A0T02WS

CH5

205

186

137

NXA02615A0T02WS

CH5

261

237

174

NXA03005A0T02WF

CH61

300

273

200

NXA03855A0T02WF

CH61

385

350

257

NXA04605A0T02WF

CH62

460

418

307

NXA05205A0T02WF

CH62

520

473

347

NXA05905A0T02WF

CH62

590

536

393

NXA06505A0T02WF

CH62

650

591

433

NXA07305A0T02WF

CH62

730

664

487

NXA08205A0T02WF

CH63

820

745

547

NXA09205A0T02WF

CH63

920

836

613

NXA10305A0T02WF

CH63

1030

936

687

NXA11505A0T02WF

CH63

1150

1045

767

NXA13705A0T02WF

CH64

1370

1245

913

NXA16405A0T02WF

CH64

1640

1491

1093

NXA20605A0T02WF

CH64

2060

1873

1373

NXA23005A0T02WF

CH64

2300

2091

1533

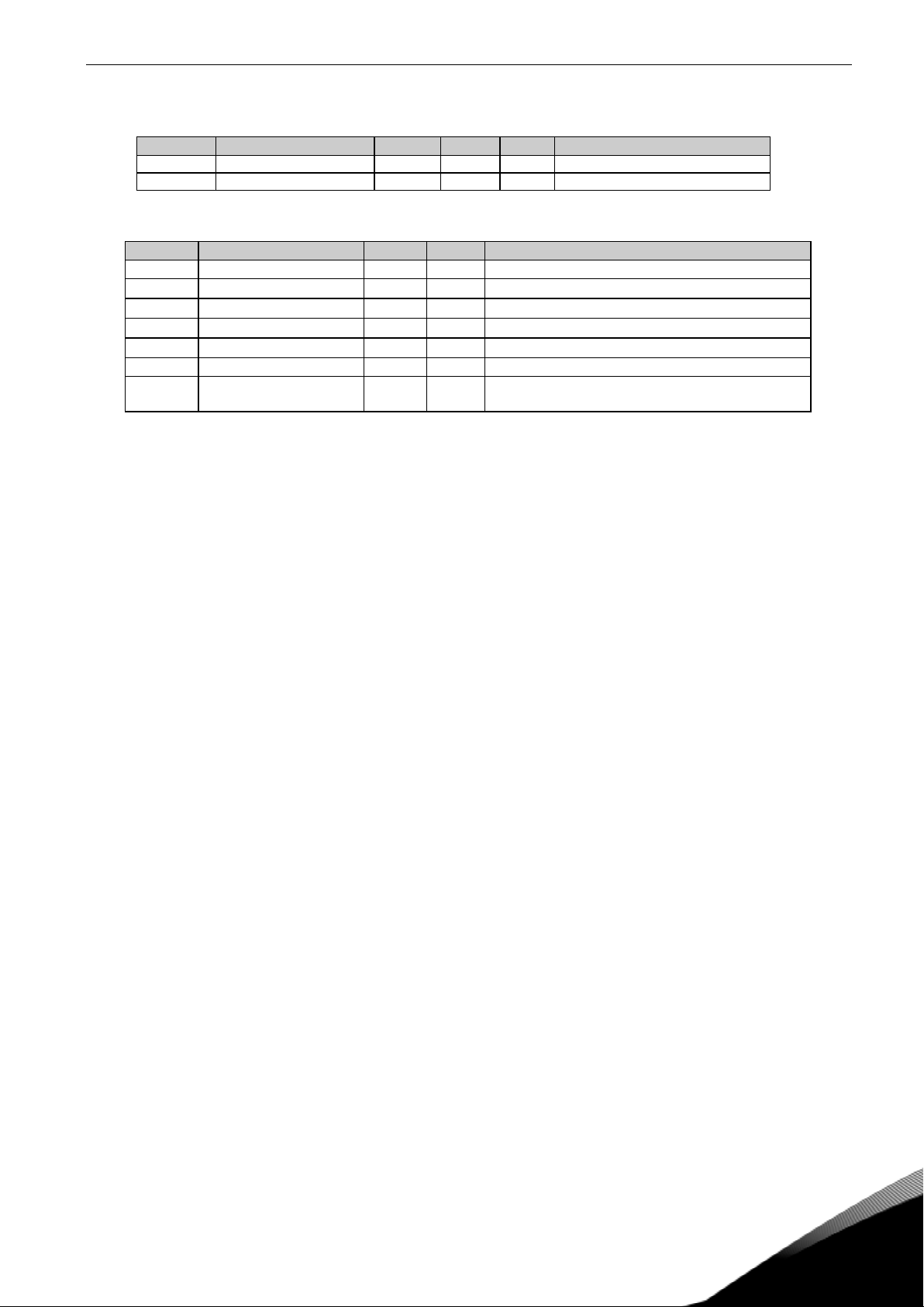

2.4 690 Vac units Liquid-Cooled, 640-1100 Vdc

Code

Chassis

Ith [A]

Il [A]

Ih [A]

NXA01706A0T02WF

CH61

170

155

113

NXA02086A0T02WF

CH61

208

189

139

NXA02616A0T02WF

CH61

261

237

174

NXA03256A0T02WF

CH62

325

295

217

NXA03856A0T02WF

CH62

385

350

257

NXA04166A0T02WF

CH62

416

378

277

NXA04606A0T02WF

CH62

460

418

307

NXA05026A0T02WF

CH62

502

456

335

NXA05906A0T02WF

CH63

590

536

393

NXA06506A0T02WF

CH63

650

591

433

NXA07506A0T02WF

CH63

750

682

500

NXA08206A0T02WF

CH64

820

745

547

NXA09206A0T02WF

CH64

920

836

613

NXA10306A0T02WF

CH64

1030

936

687

NXA11806A0T02WF

CH64

1180

1073

787

NXA13006A0T02WF

CH64

1300

1182

867

NXA15006A0T02WF

CH64

1500

1364

1000

NXA17006A0T02WF

CH64

1700

1545

1133

Page 10

10 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

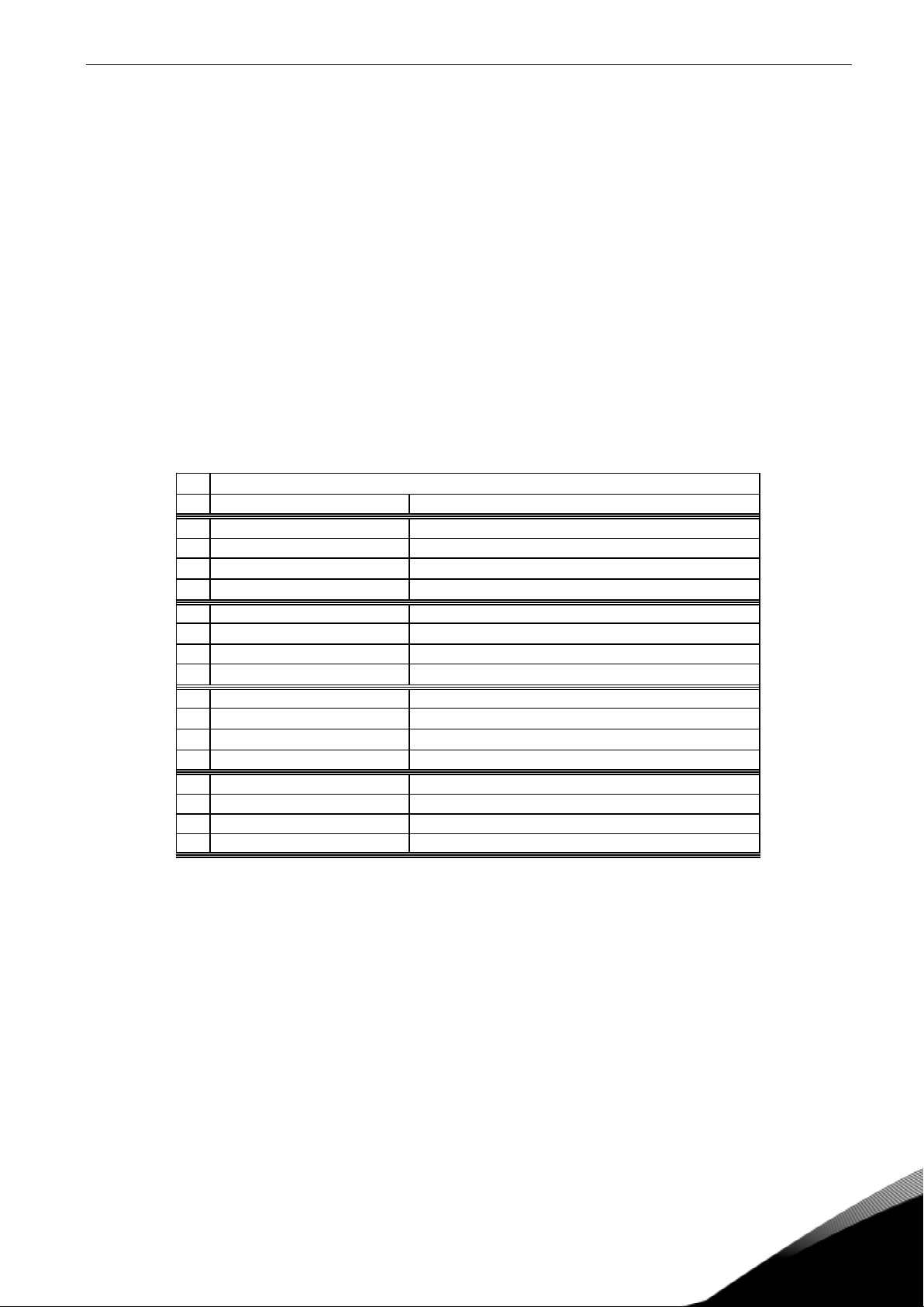

2.5 690 Vac units Liquid Cooled, 640-1200 Vdc

Code

Chassis

Ith [A]

Il [A]

Ih [A]

NXA01708A0T02WFA1A2

CH61

170

155

113,0

NXA02088A0T02WFA1A2

CH61

208

189

139,0

NXA02618A0T02WFA1A2

CH61

261

237

174,0

NXA03258A0T02WFA1A2

CH62

325

295

217,0

NXA03858A0T02WFA1A2

CH62

385

350

257,0

NXA04168A0T02WFA1A2

CH62

416

378

277,0

NXA04608A0T02WFA1A2

CH62

460

418

307,0

NXA05028A0T02WFA1A2

CH62

502

456

335,0

NXA05908A0T02WFA1A2

CH63

590

536

393,0

NXA06508A0T02WFA1A2

CH63

650

591

433,0

NXA07508A0T02WFA1A2

CH63

750

682

500,0

NXA08208A0T02WFA1A2

CH64

820

745

547,0

NXA09208A0T02WFA1A2

CH64

920

836

613,0

NXA10308A0T02WFA1A2

CH64

1030

936

687,0

NXA11808A0T02WFA1A2

CH64

1180

1073

787,0

NXA13008A0T02WFA1A2

CH64

1300

1182

867,0

NXA15008A0T02WFA1A2

CH64

1500

1364

1000,0

NXA17008A0T02WFA1A2

CH64

1700

1545

1133,0

Page 11

Arfiff05 Standard AFE-II vacon • 11

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3. OPERATION

3.1 Charging of DC

This AFE application has own charging control, P2.4.1.9 DC Charge (24 Vdc required for control

board) level

within set time P2.7.1.5 Charge Max Time (provided that DC Voltage reach at least drive under

voltage fault level).

Charging function is activated when P2.4.1.9 DC Charge is A.1 or higher. When control place is IO,

Keypad or NCDrive charging is started from start command.

Charging is not started if:

- Drive is in fault state.

- P2.3.1.2 Enable MCB Close is FALSE

- P2.3.1.6 Run Enable is FALSE

- P2.3.1.7 Quick Stop is FALSE

Charging is also stopped if above conditions happens during charging or start command is removed.

For fieldbus control charging is started with B0 of FB Control Word on supporting FB profiles.

Charging is also stopped if B0 goes low as is MCB opened if already closed.

DC Charge (F80) is given if 85 % of DC Nominal is not reached within P2.7.1.5 Charge Max Time and

charging is stopped.

DC Charging is stopped when drive receives feedback from P2.3.1.5 MCB Status.

Note! Use suitably sized DC Charging resistor by checking Pulse loadability for time duration set in

for Max Charge Time parameter

3.2 Main Circuit breaker control (MCB control)

The AFE application controls the MCB of the system with Relay Output RO2. When charging of the DC

bus is ready the MCB will be closed. The status of the MCB is monitored via digital input P2.3.1.5

MCB Status (Default is DigIn: A.4). MCB feedback is required for correct AFE functionality,

NOTE! MCB feedback is required for correct AFE functionality.

Over Current (F1), Hardware IGBT (F31) and Software IGBT (F41) faults will open MCB immediately.

Some fault can be programmed to open MCB if needed.

NOTE! For correct operation of AFE system, AFE unit needs to be in control of charging circuit and

Main Circuit Breaker (MCB).

Page 12

12 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.3 Quick Start instructions

NOTE! Before taking any commissioning actions read carefully the safety instructions in Vacon NX

User's Manual, chapter 1.

1. Connect the unit according to the Figure 1.

2. Power up the control unit.

3. Set parameters in G2.1 Basic Parameters.

4. Check that digital input parameters (G2.3.1) have been set according to connections. Note

that P2.3.1.5 MCB Status input is needed for correct operation of AFE unit.

5. Check the control place accordingly proves requirements (P3.1 Control Place).

6. Charge DC.

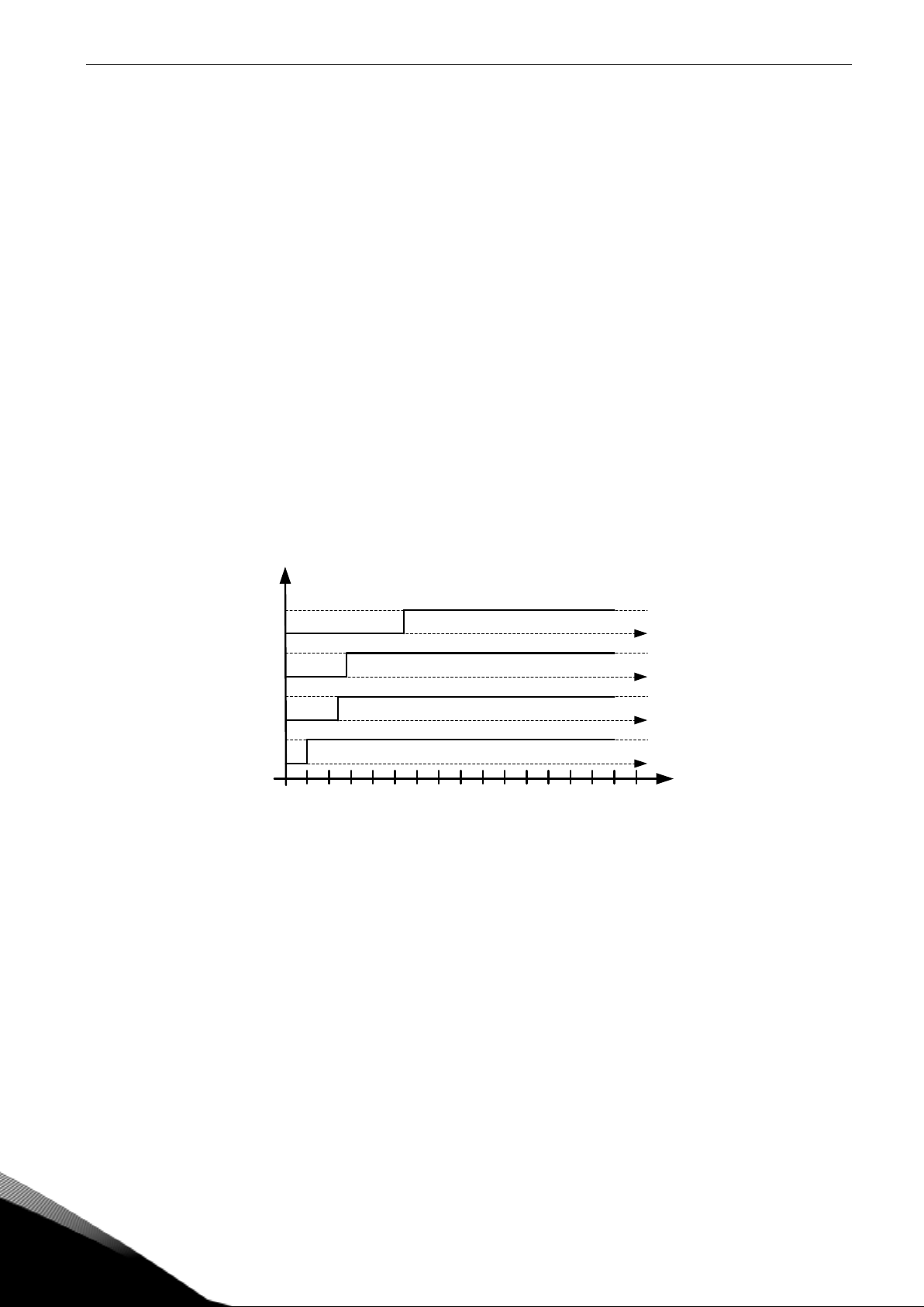

In case of parallel AFE:

1. Set Parallel AFE parameter (P2.1.5) = YES (in every AFE). (This will set also DC Drooping to

4,00 %

2. Set Start Up Delay in AFE units so that starting is in sequence with different intervals.

Time * 100 ms

Stop

AFE 1

Run

Stop

AFE 2

Run

Stop

AFE 3

Run

Stop

AFE 4

Run

Page 13

Arfiff05 Standard AFE-II vacon • 13

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

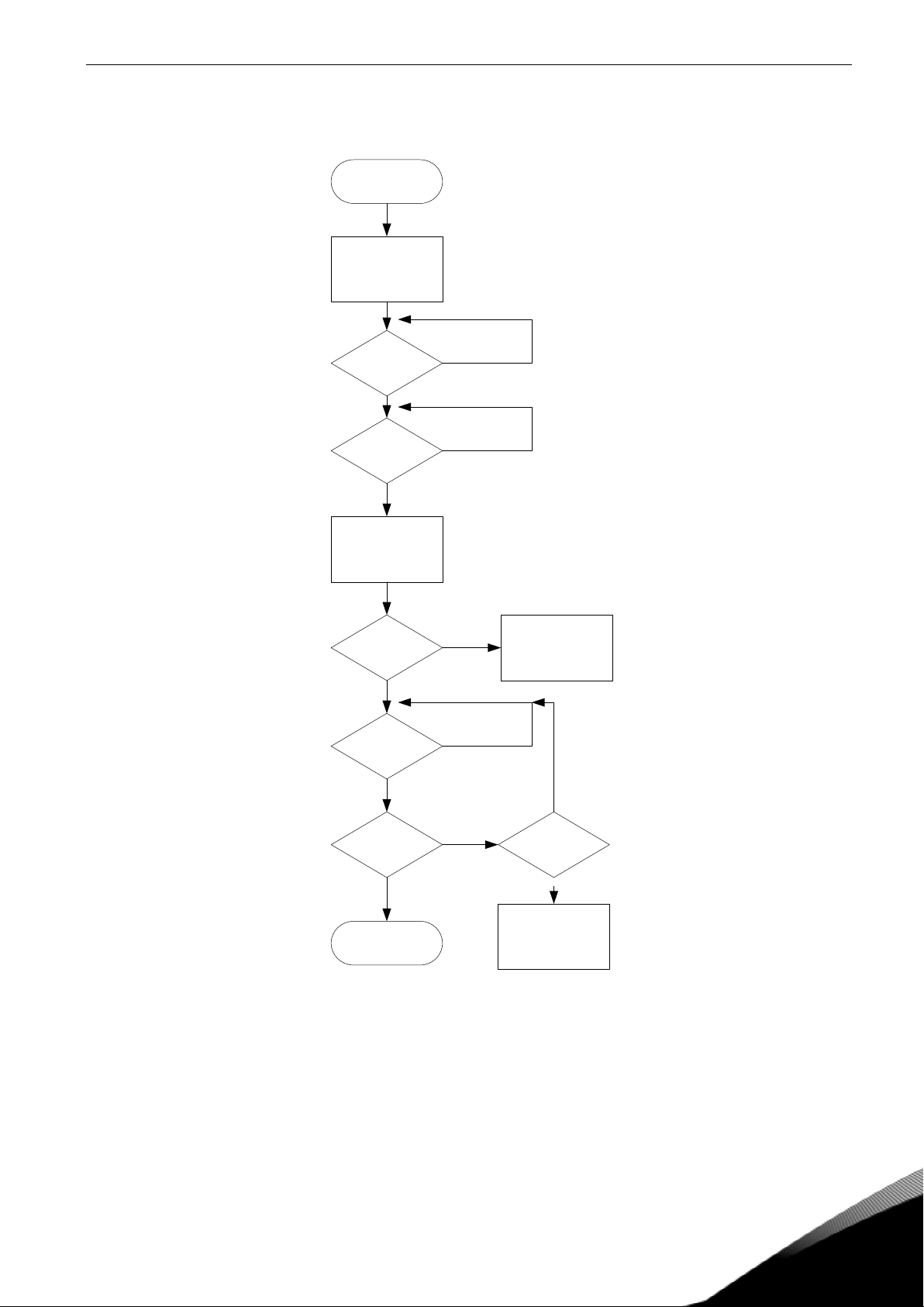

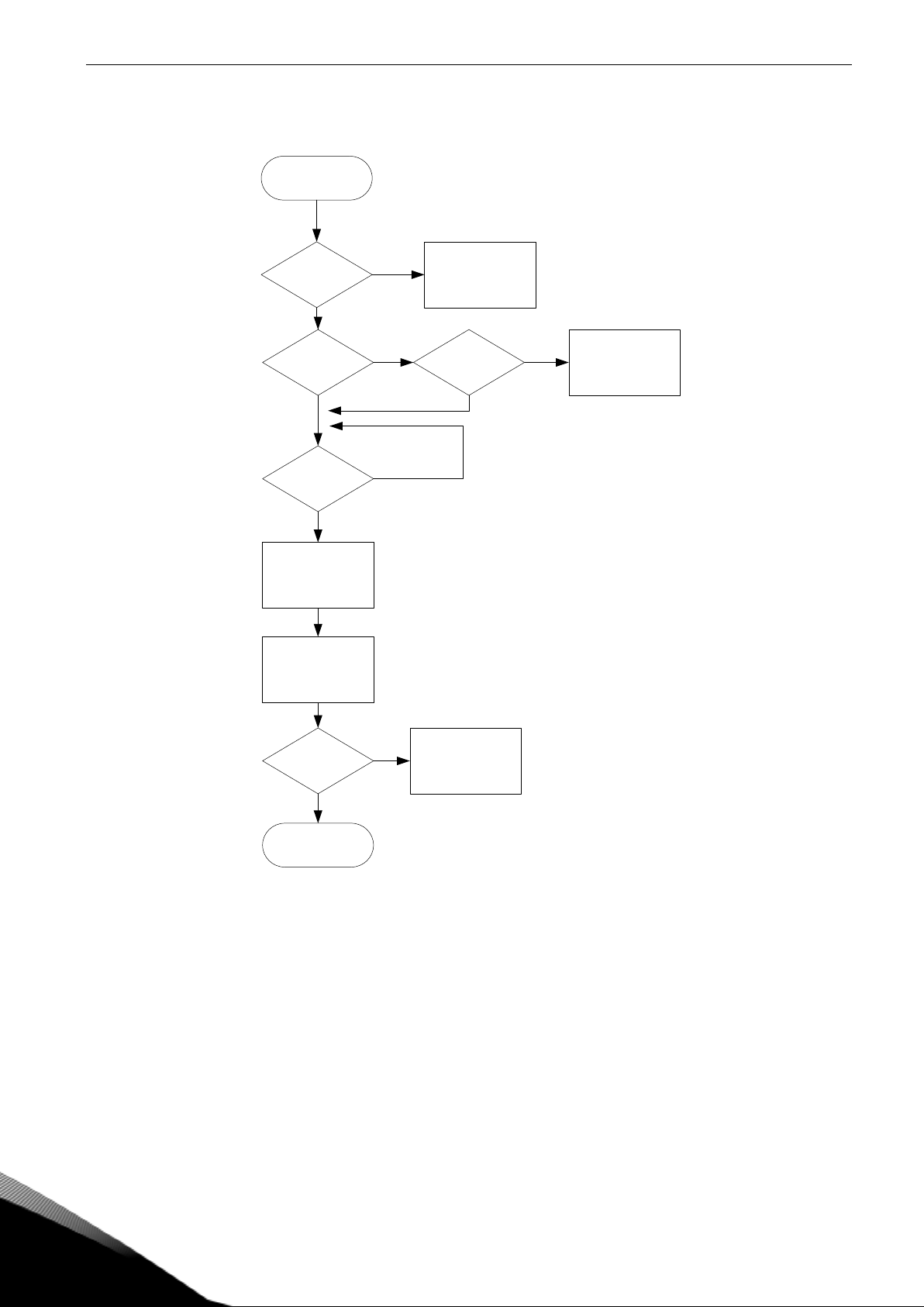

3.4 Start Sequence

Init

Ready to

switch on

DC > 85 %

Close MCB

MCB close

enable

MCB Closed

Start

Command

Synchronized Trials >= 5

Modulating

F10: LineSynch

No

Yes

No

Yes

Yes

Yes

Yes

No

No

No

No

Yes

F64 A2

(Delayed)

Figure 0-2. AFE start sequence

Page 14

14 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.5 Stop Sequence

Modulating

MCB Closed

No

F64 A4

Open MCB

No

Yes

Yes

Stop Modulation

(If Run State)

Open MCB

Stop Request MCB Closed

No

F64 A2

(If DC > 75 %)

(Delayed)

Yes

MCB Closed

No

Yes

F64 A3

(Delayed)

End

Figure 0-3. AFE stop sequence

Page 15

Arfiff05 Standard AFE-II vacon • 15

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

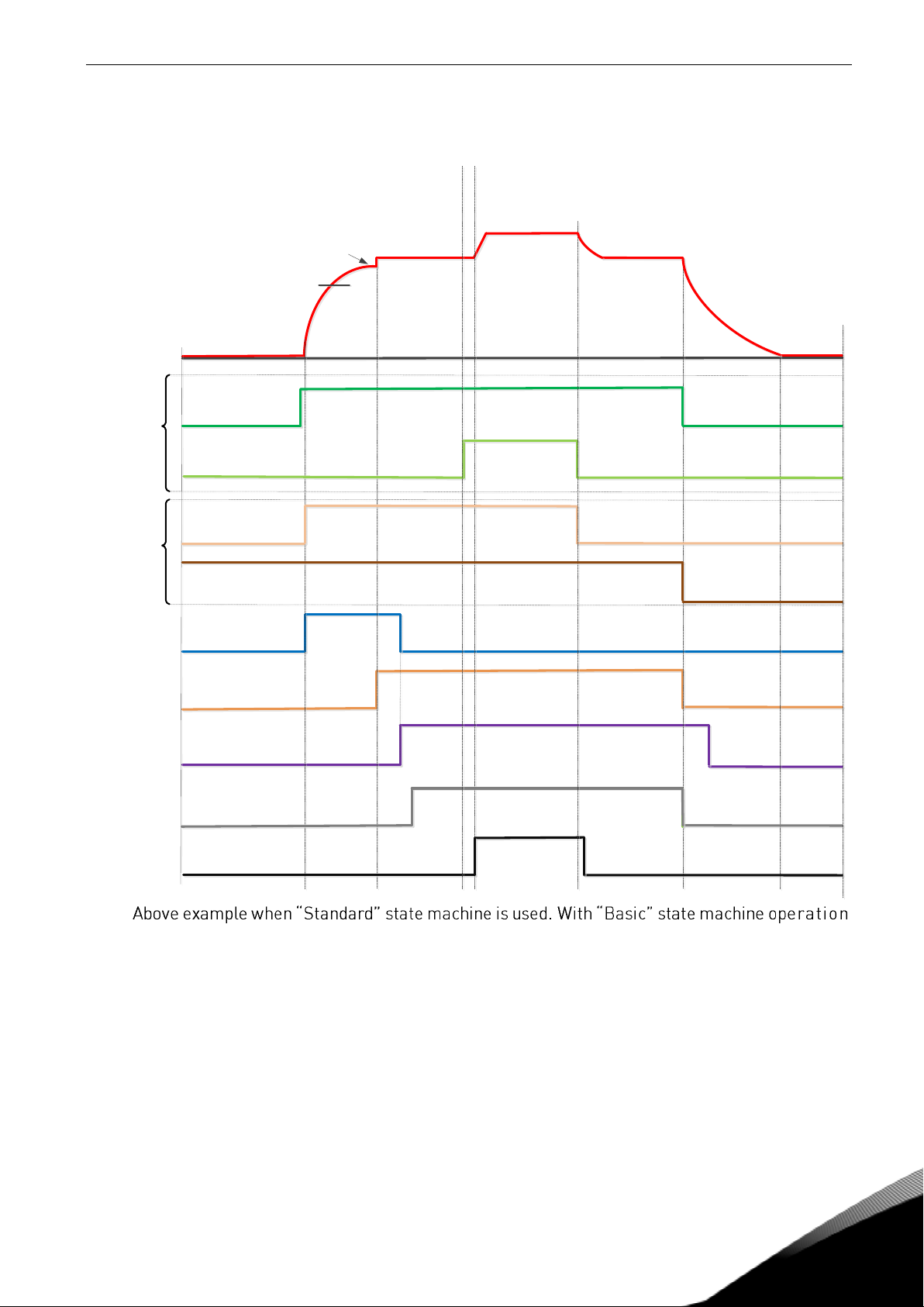

3.6 Start Stop timing diagram

DC Voltage

Charge Control

MCB Feedback

MCB Close Control

MCB Close level

Stable DC

Ready

IO Start

Run

FB CW.B00

Control in

FB Control

FB CW.B03

Contro in

IO Control

P. Start Delay

IO MCB Open

Command

is like in IO Control.

Page 16

16 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

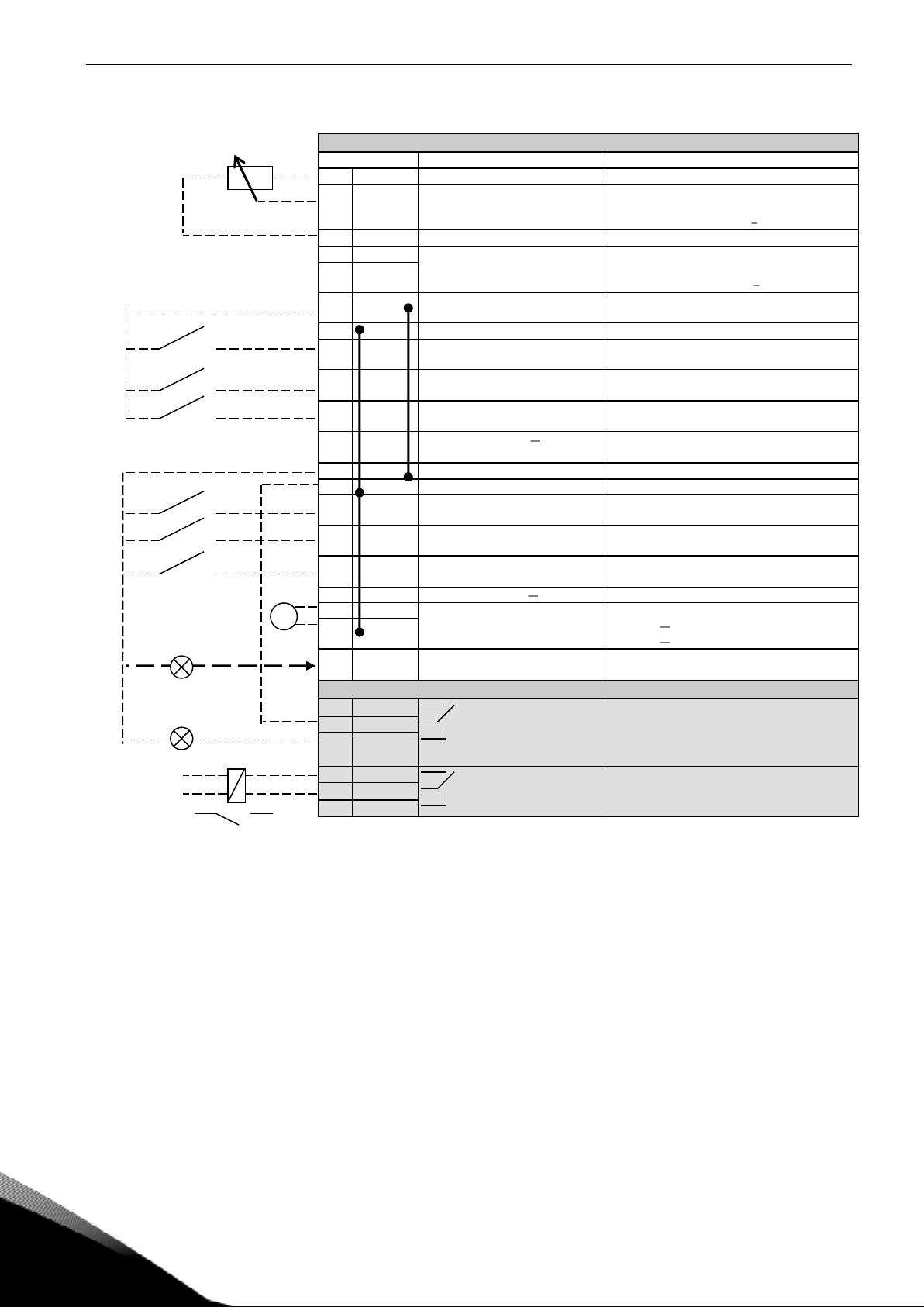

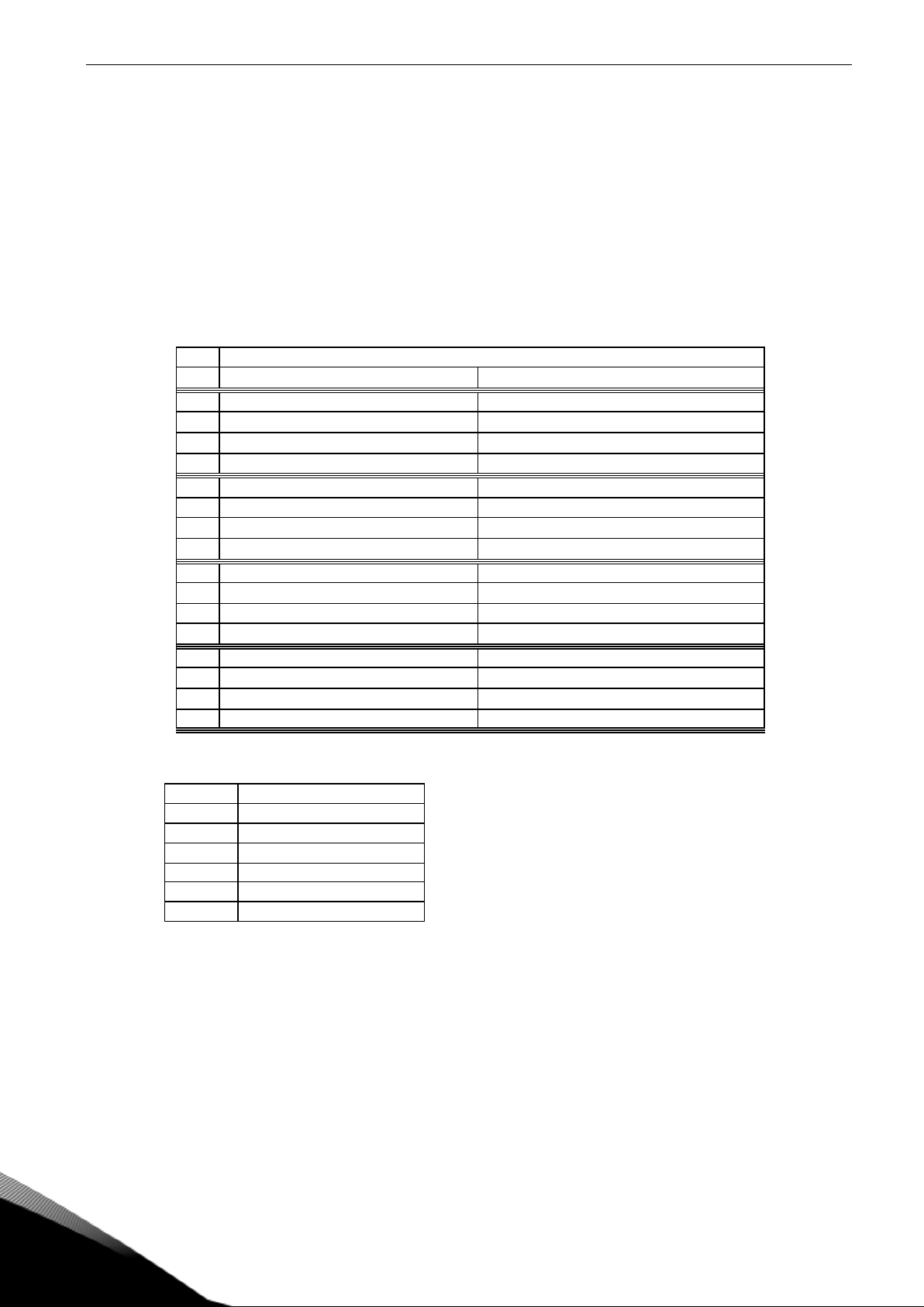

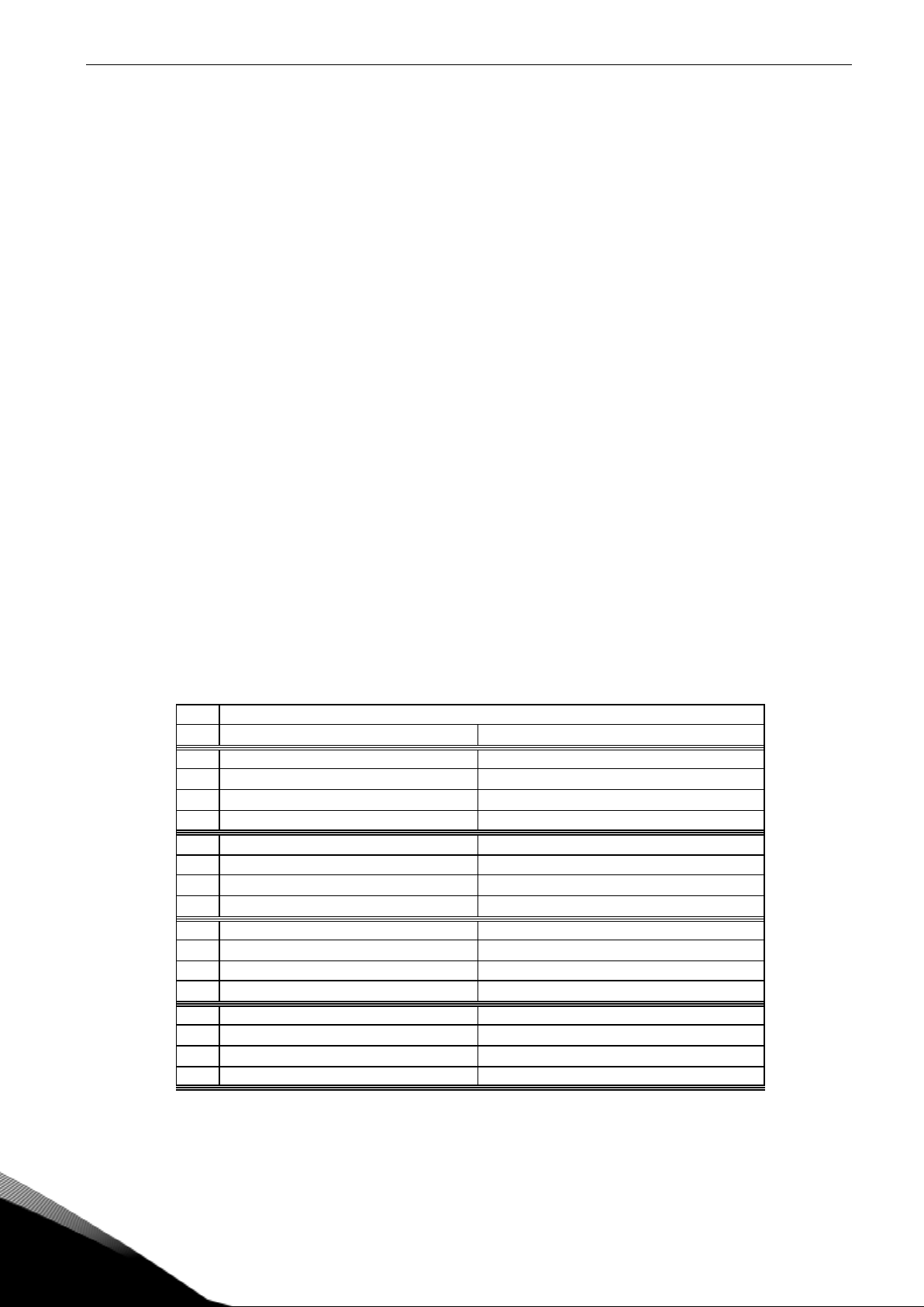

4. CONTROL IO

NXOPTA1

Terminal

Signal

Description

1

+10Vref

Reference voltage output

Voltage for potentiometer, etc.

2

AI1+

Analogue input 1.

Range 0-10V, Ri = 200

Range 0-20 mA Ri = 250

Analogue input 1

Input range selected by jumpers.

Default range: Voltage 0 10 V

3

AI1-

I/O Ground

Ground for reference and controls

4

AI2+

Analogue input 2.

Range 0-10V, Ri = 200

Range 0-20 mA Ri = 250

Analogue input 2

Input range selected by jumpers.

Default range: Current 0 20 mA

5

AI2-

6

+24V

Control voltage output

Voltage for switches, etc. max 0.1 A

7

GND

I/O ground

Ground for reference and controls

8

DIN1

Start Request

Programmable G2.3.1

Contact closed = Start Request

9

DIN2

Programmable G2.3.1

No function defined at default

10

DIN3

Fault Reset

Programmable G2.3.1

Contact closed = Fault Reset

11

CMA

Common for DIN 1 DIN 3

Connect to GND or +24V

12

+24V

Control voltage output

Voltage for switches (see #6)

13

GND

I/O ground

Ground for reference and controls

14

DIN4

MCB feedback

Contact open = MCB open

Contact closed = MCB Closed

15

DIN5

Programmable G2.3.1

No function defined at default

16

DIN6

Programmable G2.2.1

17

CMB

Common for DIN4 DIN6

Connect to GND or +24V

18

AOA1+

Analogue output 1

Programmable P2.3.1.2

Output range selected by jumpers.

Range 0 20 mA. RL, max. 500

Range 0 10 V. RL > 1k

19

AOA1-

20

DOA1

Digital output

Ready / Warning (Blinking)

Programmable

Open collector, I50mA, U48 VDC

NXOPTA2

21

RO1

Relay output 1

Programmable G2.4.1

Switching capacity

24 VCD / 8 A

250 VAC / 8 A

125 VDC / 0.4 A

22

RO1

23

RO1

24

RO2

Relay output 2

MCB Contl

Cannot be reprogrammed

Fixed to MCB control.

Closes when DC at 85 % of nominal DC.

Opens when DC below 75 % of nominal DC

25

RO2

26

RO2

Table 5-2. Default I/O configuration.

220

VAC

mA

K1

Q1

Page 17

Arfiff05 Standard AFE-II vacon • 17

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5. AFE APPLICATION MONITORING VALUES

On the next pages you will find the lists of parameters within the respective parameter groups.

Column explanations:

Code = Location indication on the keypad; Shows the operator the present parameter

number

Parameter = Name of parameter

Min = Minimum value of parameter

Max = Maximum value of parameter

Unit = Unit of parameter value; Given if available

Default = Value preset by factory

Cust =

ID = ID number of the parameter

_____ = On parameter code: Parameter value can only be changed after the Drive has been

stopped.

_____ = Monitoring value is possible to control from fieldbus by ID number

The manual presents signals that are not normally visible for monitoring. i.e. is not a parameter or

standard monitoring signal. These signals are presented with [Letter]. e.g.

[FW]MotorRegulatorStatus

[V] Normal monitoring signal

[P] Normal parameter in application.

[FW] Firmware signal, Can be monitored with NCDrive when signal type is selected Firmware

[A] Application signal, can be monitored with NCDrive when signal type is selected Application.

[R] Reference type parameter on keypad.

[F] Function. Signal is received as a output of function.

[DI] Digital input signal.

CB Circuit Breaker

MCB Main Circuit Breaker = AFE controller Circuit Breaker

Page 18

18 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5.1 Monitoring values

The monitoring values are the actual values of parameters and signals as well as statuses and

measurements. Monitoring values cannot be edited.

5.1.1 Monitoring 1

Code

Signal

Unit

ID

Description

V1.1.1

DC-Link Voltage

Vdc

1108

Measured DC Link voltage in Volts, filtered.

V1.1.2

DC-Link Ref.

Vdc

25

DC Voltage Reference in Vdc

V1.1.3

DC Voltage Ref.

%

1200

Used DC Voltage Reference

V1.1.4

DC Voltage Act.

%

7

Actual DC Voltage

V1.1.5

Total Current

A

3

Total current of the regenerative unit in

Amperes.

V1.1.6

Active Current

%

1125

Avtive current of the regenerative drive in % of

Rated Line Current.

> 0 power from AC side to DC side

< 0 power from DC side to AC side

V1.1.7

Reactive Current

%

1157

Reactive current of the regenerative drive in % of

Rated Line Current.

> 0 Inductive current

< 0 Capacitive current

V1.1.8

Supply Frequency

Hz

1

Supply frequency in ##.## Hz .The sign indicates

the phase order.

V1.1.9

Supply Voltage

V

6

Input AC voltage, RMS line to line Volts.

V1.1.10

Unit Temperature

°C

8

Heat sing temperature

V1.1.11

Status Word

43

V1.1.12

DIN 645. 321

15 V1.1.13

Analogue Input 1

%

13 V1.1.14

Analogue Input 2

%

14 V1.1.15

Analogue Out 1

%

26 V1.1.16

Operation Hours

h

1856

5.1.2 FieldBus Monitoring values

Code

Signal

Unit

ID

Description

V1.2.1

FB Control Word

1160

Control word from fieldbus

V1.2.2

FB Status Word

68

Status word to fieldbus

V1.2.3

Fault Word 1

1172

V1.2.4

Fault Word 2

1173 V1.2.5

DIN Status Word 1

56 V1.2.6

DIN Status Word 2

57 V1.2.7

Warning Word 1

1174

V1.2.8

DC Voltage

44

Unfiltered DC-Link voltage

V1.2.9

Current

1113

Unfiltered total current

V1.2.10

Drive Power

kW

1508

Electrical AFE terminal power

V1.2.11

Fault History

37 V1.2.12

Final DC Ref

%

1131

V1.2.13

Cabin State Word

1884

5.1.3 Line Monitor OPT-D7

Code

Signal

Unit

ID

Description

V1.3.1

Line Voltage

V

1650 V1.3.2

Line Frequency

Hz

1654 V1.3.3

Synch Error D7

1659 V1.3.4

Line Voltage THD

1670 V1.3.5

Line Voltage HF rms

1671

Page 19

Arfiff05 Standard AFE-II vacon • 19

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5.1.4 Master Follower

Code

Parameter

Unit

Form.

ID

Description

V1.4.1

SB SystemStatus

1601 V1.42

Master CW

93

5.1.5 Monitoring values 2

Code

Signal

Unit

ID

Description

V1.5.1

Measured temperature 1

Cº

50

4 s filtering.

V1.5.2

Measured temperature 2

Cº

51

4 s filtering.

V1.5.3

Measured temperature 3

Cº

52

4 s filtering.

V1.5.4

Measured temperature 4

Cº

69

4 s filtering.

V1.5.5

Measured temperature 5

Cº

70

4 s filtering.

V1.5.6

Measured temperature 6

Cº

71

4 s filtering.

V.1.5.7

PT-100 Temperature

Cº

42

Highest temperature of OPTB8/OPTBH board. 4 s

filtering.

5.2

Monitoring Values description

5.2.1 Monitoring 1 values

V1.1.1 DC-Link Voltage Vdc ID44

Measured DC voltage, filtered.

V1.1.2 DC-Link Ref. Vdc ID25

DC-Link voltage reference in Vdc.

V1.1.3 DC Voltage Ref. % ID1200

Used DC Voltage reference in %

V1.1.4 DC Voltage Act. % ID7

Actual DC Voltage in %

V1.1.5 Total Current A ID3

Total current of the regenerative unit in Amperes, filtered

V1.1.6 Active Current % ID1125

Active current in % of System Rated Current.

Negative value means that current is flowing to AC side from DC side i.e. regenerating.

V1.1.7 Reactive Current % ID1157

Reactive current of the regenerative drive in % of System Rated Current.

Positive is Inductive current.

Negative is capacitive current.

V1.1.8 Supply Frequency Hz ID1

Supply frequency in ##.## Hz .The sign indicates the phase order. Updated when drive in

run state. Updated also in stop state when OPT-D7 is used or Regen Options B9 is

activated.

Page 20

20 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

V1.1.9 Supply Voltage V ID6

Input AC voltage, RMS line to line Volts. Updated when drive in run state.

Updates also when OPT-D7 is used.

V1.1.10 Unit Temperature °C ID8

Temperature of the unit in degrees Celsius

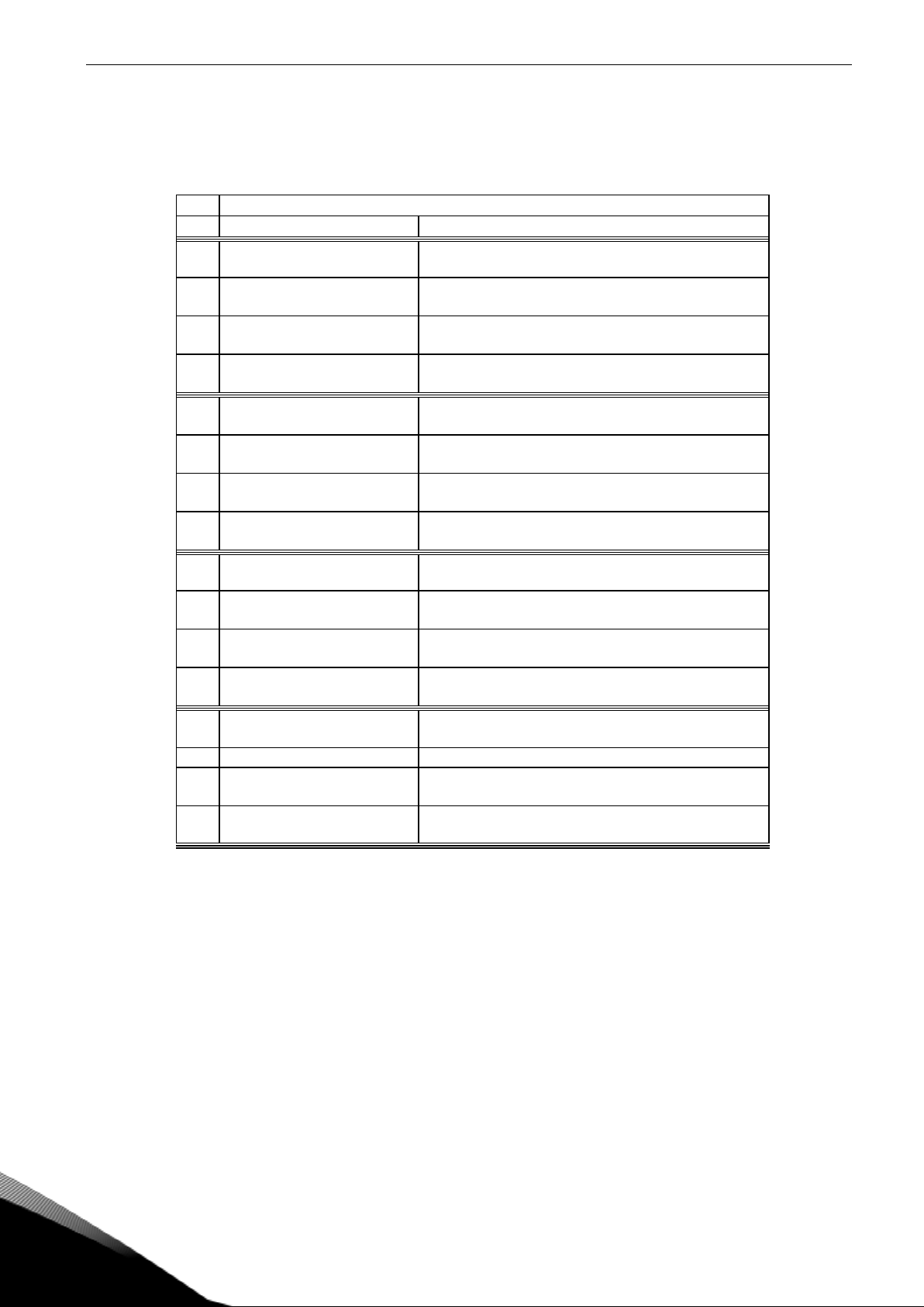

V1.1.11 Status Word ID43

Application Status Word combines different drive statuses to one data word.

Application Status Word ID43

FALSE

TRUE

b0

b1

Not in Ready state

Ready

b2

Not Running

Running

b3

No Fault

Fault

b4

b5

Quick Stop Active

Quick Stop Not Active

b6

Run Disabled

Run Enable

b7

No Warning

Warning

b8 Charging Switch closed (internal)

b9 MCB Control (DO Final)

b10 MCB Feedback

b11 DO Charging Active

b12

No Run Request

Run Request

b13

b14

b15

V1.1.12 DIN 645. 321 ID15

DIN1/DIN2/DIN3 status

B0

DIN1

B1

DIN2

B2

DIN3

B3

DIN4

B4

DIN5

B5

DIN6

V1.1.13 Analogue Input 1 % ID13

V1.1.14 Analogue Input 2 % ID14

Unfiltered analogue input level.

0 % = 0 mA / 0 V, -100 % = -10 V, 100 % = 20 mA / 10 V.

Monitoring scaling is determined by the option board parameter.

V1.1.15 Analogue Out 1 % ID26

Analogue Output value 0 % = 0 mA / 0 V, 100 % = 20 mA / 10 V

Page 21

Arfiff05 Standard AFE-II vacon • 21

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

V1.1.16 Operation Hours ID1856

Run state hours

5.2.2 Fieldbus monitoring values

V1.2.1 FB Control Word ID 1160

Control word from fieldbus. Below table is for bypass operation for such fieldbus board that natively

supports this or can be parameterized to bypass mode.

FB Control Word ID1160

Signal

Comment

SM

B00

DC Charge

0= Open MCB.

1= Close DC charge contactor, MCB closed automatically, see

B01.

1,2,3

B01

MCB Close Enable

0= Disable Closing of MCB (Also opens if Control

Options.B0=TRUE)

1= Enable Closing of MCB (Works also for reclosing)

3

B02

Quick Stop

0= Quick Stop

1= No Quick Stop

3

B03

Run

0= AFE is stopped

1= AFE is started

1,2,3

B04

Output Power Limit to

Zero

0= Output Power Limit to Zero (7%)

1= Output Power Limit = P2.5.2.1

3

B05

Disable Power Increase.

Input or Output

0= Disable increase of power.

1= Power limits defined by G2.5.2

3

B06

Input Power Limit to

Zero

0= Input Power Limit to Zero (7%)

1= Output Power Limit = P2.5.2.2

3

B07

Reset

0>1 Reset fault.

1,2,3

B08

DC Voltage Ref B00

B00 | B01

0 | 0 = FB Reference. P2.2.1, if not FB Control & FB Ref > 50,00 %

0 | 1 = 110 %

1 | 0 = 115 %

1 | 1 = 120 %

2,3

B09

DC Voltage Ref B01

2,3

B10

Fieldbus Control

0= No control from fieldbus

1=Control from fieldbus

2,3

B11

Watchdog

communication between fieldbus master and the drive.

2,3

B12

FB DIN2

Can be used to control RO or directly parameter by ID number.

G2.4.1

1,2,3

B13

FB DIN3

Can be used to control RO or directly parameter by ID number.

G2.4.1

1,2,3

B14

FB DIN4

Can be used to control RO or directly parameter by ID number.

G2.4.1

1,2,3

B15

Reserved for future use.

Page 22

22 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

V1.2.2 FB Status Word ID 68

FB Status word to fieldbus. Below table is for bypass operation for such fieldbus board that natively

supports this or can be parameterized to bypass mode.

FB Status Word ID68

Signal

Comment

b0

Ready On

0=Drive not ready to switch on

1=Drive ready to start charging

b1

Ready Run

0=Drive not ready to run

1=Drive ready and MCB is ON

b2

Running

0=Drive not running

1=Drive in Run state (Modulating)

b3

Fault

0=No active fault

1=Fault is active

b4

Run Enable Status

0= Run Disabled. Drive in stop state

1= Run Enabled. Drive can be started.

b5

Quick Stop Active

0=Quick Stop Active

1=Quick Stop not Active

b6

MCB Control NOT OK

0= MCB Control OK

1= MCB Requested open but DC stays high

b7

Warning

0= No active warnings

1= Warning active

b8

At Reference

0= DC Voltage Ref and Act DC Voltage are not

same.

b9

Fieldbus Control Active

0=Fieldbus control not active

1=Fieldbus control active

b10

Above Limit

0= DC Voltage is below P2.5.5.1 level

1=The DC Voltage is above the P2.5.5.1 level

b11

MCB Control (DO Final)

0= Drive is controlling MCB to be Open.

1= Drive is controlling MCB to be Closed

b12

MCB Feedback

0= Feedback indicates MCB to be Open

1= Feedback indicates MCB to be Closed

b13

Reserved for future use.

b14

DC Charge DO Control

0= DC not charged

1= DC Charging Active

b15

Watchdog

Same as received on bit 11 of the FB Control

Word.

Page 23

Arfiff05 Standard AFE-II vacon • 23

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

V1.2.3 Fault Word 1 ID 1172

Fault Word 1 ID1172

Fault

Fault Codes

b0

Over Current

F1

b1

Overvoltage

F2

b2

Under voltage

F9

b3

Not used

b4

Earth Fault

F3

b5

Not used

b6

Unit Over Temperature

F14

b7

Over Temperature

F59, F56,F71

b8

Input Phase loss

F11

b9

Not used

b10

Device Fault

F37, F38, F39, F40, F44, F45

b11

Not used

b12

Not used

b13

Not used

b14

Not used

b15

Not used

V1.2.4 Fault Word 2 ID 1173

Fault Word 2 ID1173

Fault

Fault Codes

b0

Not used

b1

Charging Switch Fault

F5, F80

b2

Not used

b3

Drive Hardware fault

F4, F7

b4

Under Temperature

F13

b5

EPROM or Checksum fault

F22

b6

External fault

F51

b7

Not used

b8

Internal Communication

F25

b9

IGBT Temperature

F31, F41

b10

Not used

b11

Cooling fan

F32, F70

b12

Application fault

F35

b13

Drive Internal fault

F33, F36, F8, F26

b14

MCB State

F64

b15

Not used

Page 24

24 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

V1.2.5 DIN Status 1 ID 56

V1.2.6 DIN Status 2 ID57

DIN Status Word 1

DIN Status Word 2

b0

DIN: A.1

DIN: C.5

b1

DIN: A.2

DIN: C.6

b2

DIN: A.3

DIN: D.1

b3

DIN: A.4

DIN: D.2

b4

DIN: A.5

DIN: D.3

b5

DIN: A.6

DIN: D.4

b6

DIN: B.1

DIN: D.5

b7

DIN: B.2

DIN: D.6

b8

DIN: B.3

DIN: E.1

b9

DIN: B.4

DIN: E.2

b10

DIN: B.5

DIN: E.3

b11

DIN: B.6

DIN: E.4

b12

DIN: C.1

DIN: E.5

b13

DIN: C.2

DIN: E.6

b14

DIN: C.3

b15

DIN: C.4

V1.2.7 Warning Word 1 ID 1174

Warning Word 1 ID1174

Fault

Fault Codes

b0

Not used

b1

Temperature protection

W29: Thermistor warning,

W56: FPT100 warning or

W71: LCL over temperature warning

b2

b3

Supply Phase Warning

W11

b4

Not used

b5

Not used

b6

Not used

b7

Drive over temperature

W14

b8

Not used

b9

Not used

b10

Fan Warning

W32: Fan Cooling

W70: LCL Fan monitor warning

b11

Not used

b12

Not used

b13

Not used

b14

Not used

b15

Not used

V1.2.8 DC Voltage [Vdc] ID44

Unfiltered DC-Link Voltage

Page 25

Arfiff05 Standard AFE-II vacon • 25

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

V1.2.9 Current [A] ID1113

Total unfiltered current

V1.2.10 Drive Power [kW] ID 1508

Drive input terminal electrical power.

V1.2.11 Fault History ID37

Last active fault. If drive has several fault at the same time see from fault history what

was the first fault.

V1.2.12 Final DC Ref [%] ID1131

Final DC Reference, including offset control.

V1.2.13 Cabin State Word ID1884

Cabin State Word ID1884

Fault

Fault Codes

b0

Main Fuse

W81

b1

Aux voltage

W82

b2

STO Fuse

W83

b3

Insulation Fault

W84

b4

Earthswitch Fault

W85

b5

Arc Relay

W86

b6

high Amb Temp.

W88

b7

Leakage

W89

b8

Not used

b9

Not used

b10

Not used

b11

Not used

b12

Not used

b13

Not used

b14

Not used

b15

Not used

Page 26

26 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5.2.3 Line monitoring OPT-D7

V1.3.1 Line Voltage V ID1650

The measured line voltage rms value when using the OPT-D7 option board in slot C.

V1.3.2 Line Frequency Hz ID1654

The measured line voltage frequency when using the OPT-D7 option board in slot C.

V1.3.3 Synch Error D7 ID1659

An error on voltage angles between the drive and the measurement taken by OPT-D7.

-3072...+3071 = -180...180 degrees.

If the value is not near to zero when running in AFE mode, the phase order may be wrong

even if the OPT-D7 frequency is correct (Error about 2047 = 120 degree). If measurement

is after Dyn11 transformer error is usually about 512 (30,0 Degree).

V1.3.4 Line Voltage THD ID1670

V1.3.5 LineVoltageHFrms ID1671

5.2.4 Master/Follower

Here are gathered relevant signals in Master follower system.

V1.4.1 SB SystemStatus ID 1601

System Bus Status Word ID1601

FALSE

TRUE

b0 Not used

b1 Drive 1 Ready

b2 Drive 1 Running

b3 Drive 1 Fault

b4 Not used

b5 Drive 2 Ready

b6 Drive 2 Running

b7 Drive 2 Fault

b8 Not used

b9 Drive 3 Ready

b10 Drive 3 Running

b11 Drive 3 Fault

b12 Not used

b13 Drive 4 Ready

b14 Drive 4 Running

b15 Drive 4 Fault

V1.4. 2 Master CW ID93

Master Drive Control Word. Master Sending, Follower receiving.

Page 27

Arfiff05 Standard AFE-II vacon • 27

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5.2.5 Monitoring values 2

V1.5.1 Measured temperature 1 Cº ID 50

V1.5.2 Measured temperature 2 Cº ID 51

V1.5.3 Measured temperature 3 Cº ID 52

V1.5.4 Measured temperature 4 Cº ID 69

V1.5.5 Measured temperature 5 Cº ID 70

V1.5.6 Measured temperature 6 Cº ID 71

V1.5.7 PT-100 Temperature Cº ID 42

Highest temperature of OPTB8/OPTBH board. 4 s filtering.

Page 28

28 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6. PARAMETER LIST

6.1 Basic parameters

Code

Parameter

Min

Max

Unit

Default

ID

Note

P2.1.1

Grid Nominal Voltage

500V:

380V

690V:

525V

500V:

500V

690V:

690V

V

400

110

Set here the nominal voltage of

the grid.

P2.1.2

Grid Nominal

Frequency

48

63

Hz

50

1532

Set here the nominal

frequency of the grid.

P2.1.3

System Rated Current

0,0

Ih A Ih

113

Capacity of supply, used if

oversized AFE.

P2.1.4

System Rated Power

0

32000

kW 0 116

P2.1.5

Parallel AFE

0 3 0 1501

0 = Single AFE

1 = Parallel AFE

1 = Master

1 = Follower

Table 5-2. Basic parameters

6.2 Reference Handling

Code

Parameter

Min

Max

Unit

Default

ID

Note

P2.2.1

DC Voltage Ref.

105

Varies

%

110,00

1462

DC Voltage reference as % of

Nominal DC Voltage

Nominal DC voltage = 1,35 *

Supply voltage

P 2.2.2

DC Voltage Drooping

0,00

100,00 0,00

620

AFE drooping DC-voltage. Set

to 3,00 % when parallel AFE

operation is selected

P2.2.3

Reactive Current

Reference

-100,0

100,0 % 0,0

1459

Regenerative reactive current

reference 100,0 = nominal

current.

Positive =Inductive

Negative = Capacitive

P2.2.4

DC Reference Offset

-5,00

5,00 % 0,00

1777

Table 1- 1, Reference Handling

Page 29

Arfiff05 Standard AFE-II vacon • 29

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.3 Input signals

6.3.1 Digital inputs

Code

Parameter

Min

Max

Unit

Default

ID

Description

P2.3.1.1

Start Signal 1

0.1

E.10

DigIn:

A.1

403

P2.3.1.2

Enable MCB Close

0.1

E.10

DigIn:

0.2

1619

With CO.B00; Opens MCB

also

P2.3.1.3

Open MCB Power

Dawn

0.1

E.10

DigIn:

0.2

1600

Power down command

P2.3.1.4

LCL Temp. X51

0.1

E.10

DigIn:

0.2

1179

P2.3.1.5

LCL Temp. X52

0.1

E.10

DigIn:

0.2

1125

P2.3.1.6

MCB Status

0.1

E.10

DigIn:

A.4

1453

P2.3.1.7

Run Enable

0.1

E.10

DigIn:

0.2

407

P2.3.1.8

Quick Stop

0.1

E.10

DigIn:

0.2

1213

Power down with a

warning

P2.3.1.9

Ext. Fault 1

0.1

E.10

DigIn:

0.1

405

P2.3.1.10

Ext. Fault 2

0.1

E.10

DigIn:

0.1

406

P2.3.1.11

Fault Reset

0.1

E.10

DigIn:

0.1

414

P2.3.1.12

LC Cooling

0.1

E.10

DigIn:

0.2

750

P2.3.1.13

MCB Trip State

0.1

E.10

DigIn

0.1

1706

Table 5-3. Digital inputs parameters

6.3.2 Analogue Input 1

Code

Parameter

Min

Max

Unit

Default

ID

Note

P2.4.3.1

AI1 signal selection

0.1

E.10

AnIN:

0.1

377

P2.4.3.2

AI1 filter time

0,000

32,000 s 0,000

324

P2.4.3.3

AI1 custom

minimum setting

-160,00

160,00 % 0,00

321

P2.4.3.4

AI1 custom

maximum setting

-160,00

160,00 % 100,00

322

P2.4.3.5

AI1 signal inversion

0 1 0 387

P2.4.3.6

AI1 reference

scaling, minimum

value

-32000

32000 0

303

P2.4.3.7

AI1 reference

scaling, maximum

value

-32000

32000 0

304

P2.4.3.8

AI1 Controlled ID

0

10000 0

1507

Table 1- 2, ANALOG INPUT1,

6.3.3 Analogue Input 2

Code

Parameter

Min

Max

Unit

Default

ID

Note

P2.4.4.1

AI2 signal selection

0.1

E.10

AnIN:

0.1

388

P2.4.4.2

AI2 filter time

0,000

32,000 s 0,000

329

P2.4.4.3

AI2 custom

minimum setting

-160,00

160,00 % 0,00

326

P2.4.4.4

AI2 custom

maximum setting

-160,00

160,00 % 100,00

327

P2.4.4.5

AI2 signal inversion

0 1 0 398

P2.4.4.6

AI2 reference

scaling, minimum

value

-32000

32000 0

393

P2.4.3.7

AI2 reference

scaling, maximum

value

-32000

32000 0

394

P2.4.4.8

AI2 Controlled ID

0

10000 0

1511

Table 1- 3, ANALOG INPUT2

Page 30

30 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.3.4 Cabin State DI

Code

Parameter

Min

Max

Unit

Default

ID

Description

P2.3.4.1

Main Fuse

0.1

E.10

DigIn:

0.2

1700

P2.3.4.2

Aux Voltage

0.1

E.10

DigIn:

0.2

1703

P2.3.4.3

STO Fuse

0.1

E.10

DigIn:

0.2

1702

P2.3.4.4

Insulation Fault

0.1

E.10

DigIn:

0.2

1704

P2.3.4.5

Earthswitch Fault

0.1

E.10

DigIn:

0.2

1732

P2.3.4.6

Arc Relay

0.1

E.10

DigIn:

0.2

1733

P2.3.4.7

High Amb Temp.

0.1

E.10

DigIn:

0.2

1734

P2.3.4.8

Leakage

0.1

E.10

DigIn:

0.2

1735

6.3.5 Options

Code

Parameter

Min

Max

Unit

Default

ID

Note

P2.3.5.1

Start/Stop Logic

0 2 0 300

0/Static

1/ Rising edge

2/ Pulse

P2.3.5.2

Input Inversion

0

65535 0

1091

Table 1- 4, Digital input options

Page 31

Arfiff05 Standard AFE-II vacon • 31

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.4 Output signals

6.4.1 Digital Outputs

Code

Parameter

Min

Max

Unit

Default

ID

Description

P2.4.1.1

MCB Control (Close)

B.2

B.2

DigOUT:

B.2

1218

Static if ID1219 < DigOUT:A.1

P2.4.1.2

MCB Control Open

0.1

E.10

DigOUT:

0.1

1219

Pulse, if used also ID1218 is

pulse control.

P2.4.1.3

Ready

0.1

E.10

DigOUT:

0.1

432

P2.4.1.4

Run

0.1

E.10

DigOUT:

0.1

433

P2.4.1.5

Fault

0.1

E.10

DigOUT:

0.1

434

P2.4.1.6

Fault,Inverted

0.1

E.10

DigOUT:

0.1

435

P2.4.1.7

Warning

0.1

E.10

DigOUT:

0.1

436

P2.4.1.8

DC Above Limit

0.1

E.10

DigOUT:

0.1

451

P2.4.1.9

DC Charge

0.1

E.10

DigOUT:

0.1

1668

P2.4.1.10

Ready To Start

0.1

E.10

DigOUT:

0.1

1686

P2.4.1.11

FB Dig Input 1

0.1

E.10

DigOUT:

0.1

455

P2.4.1.12

FB Dig 1 Input Par

0

10000

ID 0 891

P2.4.1.13

FB Dig Input 2

0.1

E.10

DigOUT:

0.1

456

P2.4.1.14

FB Dig 2 Input Par

0

10000

ID 0 892

P2.4.1.15

FB Dig Input 3

0.1

E.10

DigOUT:

0.1

457

P2.4.1.16

FB Dig 3 Input Par

0

10000

ID 0 893

P2.4.1.17

FB Dig Input 4

0.1

E.10

DigOUT:

0.1

169

P2.4.1.18

FB Dig 4 Input Par

0

10000

ID 0 894

P2.4.1.19

FB Dig Input 5

0.1

E.10

DigOUT:

0.1

170

P2.4.1.20

FB Dig 5 Input Par

0

10000

ID 0 895

Table 5-4. Digital outputs parameters

6.4.2 ANALOG OUTPUT 1

Code

Parameter

Min

Max

Unit

Default

ID

Note

P2.4.2.1

Iout 1 signal

0.1

E.10

AnOUT

A.1

464

P2.4.2.2

Iout Content

0 4 307

0 = 4 mA

1 = DC-Link Voltage

2 = Current

3 = Power

4 = +- Power

P2.4.2.3

Iout Filter

Time

0

10 s 1

308

0=No filtering

P2.4.2.4

Iout Invert

0 1 0 309

0=Not inverted

1=Inverted

P2.4.2.5

Iout Minimum

0 1 0 310

0=0 mA

1=4 mA

P2.4.2.6

Iout Scale

10

1000 % 100

311

Percentage multiplier.

Defines output when

content is it maximum value

P2.4.2.7

Iout Offset

-100

100 % 0

375

Add -1000 to 1000% to the

analogue output.

Table 1- 5, Output signals, G2.3.4

Page 32

32 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.4.3 Options

Code

Parameter

Min

Max

Unit

Default

ID

Note

P2.4.3.1

Output

Inversion

0 1

0

1806

P2.4.3.2

MCB Close

Mode

0 2

0

1607

0 = DC Voltage

1 = DC or Start command

2 = Start Command.

Page 33

Arfiff05 Standard AFE-II vacon • 33

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.5 Limit Settings

6.5.1 Current Limit

Code

Parameter

Min

Max

Unit

Default

ID

Note

P2.5.1.1

Current Limit

0

Varies A Varies

107

Total current limit

P2.5.1.2

Output Active

Current Limit

0

300,0 % 150,0

1290

Generating Active Current

limit in AFE mode to grid.

P2.5.1.3

Input Active Current

Limit

0

300,0 % 150,0

1289

Motoring active current limit

in AFE mode to DC-link.

6.5.2 Power Limit

Code

Parameter

Min

Max

Unit

Default

ID

Note

P 2.5.2.1

Output Power Lim

0

300,0 % 150,0

1288

Generating power limit

P 2.5.2.2

Input Power Lim

0

300,0 % 150,0

1287

Motoring power limit

6.5.3 Frequency Limit

Code

Parameter

Min

Max

Unit

Default

ID

Note

P 2.5.3.1

Low Frequency Trip

Limit

42

120 % 80

1717

P 2.5.3.2

High Frequency Trip

Limit

42

120 % 120

1716

6.5.4 AC Voltage Limit

Code

Parameter

Min

Max

Unit

Default

ID

Note

P 2.5.4.1

Low AC Voltage Trip

Limit

50

150 % 80

1711

P 2.5.4.2

High AC Voltage Trip

Limit

50

150 % 120

1710

6.5.5 DC Voltage Limit

Code

Parameter

Min

Max

Unit

Default

ID

Note

P2.5.5.1

DC Super Vision

Limit

0

1300

Vdc

600

1454

P2.5.5.2

High MCB Close

Limit

0

1300

Vdc 0 1251

Page 34

34 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.6 Drive Control parameters

Code

Parameter

Min

Max

Unit

Default

ID

Description

P2.6.1

AFE Options 1

0

65535

544

1463 P2.6.2

AFE Options 2

0

65535 0

1464

P2.6.3

Control Options

0

65536 0

1707

Control word for activating

special features.

P2.6.4

Start Delay

0,00

320,00

s

0,50

1500

Starting delay when run

command is given. When

programming different

delay to paralleled units,

the units will start in

sequence.

P2.6.5

Modulator Type

0 4

Single:

2

Parallel

1

1516

0 = Hardware

1 = Software 1

2 = Software 2

3 = Software 3

4 = Software 4

P2.6.6

Operation Time

0

2^32

1855

Table 5-6. Drive control parameters G2.4

6.6.1 Control

Code

Parameter

Min

Max

Unit

Default

ID

Description

P2.6.7.1

Capacitor Size

0

100 % 6,3

1460 P2.6.7.2

Inductor Size

0

100 % 15,5

1461 P2.6.7.3

Dynamic Support Kp

0

32000 0

1797 P2.6.7.4

Synch Kp

0

32000

2000

1457 P2.6.7.5

Synch Ti

0

1000 50

1458 P2.6.7.6

Active Current Kp

0

4000 400

1455 P2.6.7.7

Active Current Ti

0,0

100,0 1,5

1456 P2.6.7.8

Synch. Kp Start

0

10000

4000

1300 P2.6.7.9

Voltage Ctrl Kp

0

32000

200

1451

P2.6.7.10

Voltage Ctrl Ti

0

1000

ms

50

1452

P2.6.7.11

Switching Frequency

3,4

Varies

Hz

3,6

601

Table 5-6. Drive control parameters G2.4

Page 35

Arfiff05 Standard AFE-II vacon • 35

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.7 Protections

6.7.1 General

Code

Parameter

Min

Max

Unit

Default

ID

Description

2.7.1.1

Response to

Thermistor fault

0 3 2 732

0=No response

1=Warning

2=Fault

3=Fault, DC OFF

2.7.1.2

Input Filter Over

Temperature

Response

0 3 2 1505

0=No response

1=Warning

2=Fault

3=Fault, DC OFF

2.7.1.3

External Fault

Response

0 3 2 701

0=No response

1=Warning

2=Fault

3=Fault, DC OFF

2.7.1.4

MCB At Fault

0 1 0 1699

2.7.1.5

Charge Max Time

0,00

60,00

s

10,00

1522

Charging time limit when

drive charging options are

used.

Table 5-9. General Protections parameters G2.7.1

6.7.2 Temperature sensor protections

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

P2.7.2.1

No. of used inputs

on board 1

0 5

0 739

0=Not used (ID Write)

1 = Sensor 1 in use

2 = Sensor 1 & 2 in use

3 = Sensor 1 & 2 & 3 in use

4 = Sensor 2 & 3 in use

5 = Sensor 3 in use

P2.7.2.2

Response to

temperature fault

0 3

2 740

0=No response

1=Warning

2=Fault,stop acc. to 2.3.2

3=Fault,stop by coasting

P2.7.2.3

Board 1 warning

limit

30,0

200,0

Cº

120,0

741

P2.7.2.4

Board 1 fault limit

30,0

200,0

Cº

130,0

742

P2.7.2.5

No. of uses inputs

on board 2

0 5

0 743

0=Not used (ID Write)

1 = Sensor 1 in use

2 = Sensor 1 & 2 in use

3 = Sensor 1 & 2 & 3 in use

4 = Sensor 2 & 3 in use

5 = Sensor 3 in use

P2.7.2.6

Response to

temperature fault

0 3

2 766

0=No response

1=Warning

2=Fault,stop acc. to 2.3.2

3=Fault,stop by coasting

P2.7.2.7

Board 2 warning

limit

30,0

200,0

Cº

120,0

745

P2.7.2.8

Board 2 fault limit

30,0

200,0

Cº

130,0

746 P2.7.2.9.1

Channel 1B Warn

-30,0

200,0

Cº

0,0

764 P2.7.2.9.2

Channel 1B Fault

-30,0

200,0

Cº

0,0

765 P2.7.2.9.3

Channel 1C Warn

-30,0

200,0

Cº

0,0

768 P2.7.2.9.4

Channel 1C Fault

-30,0

200,0

Cº

0,0

769 P2.7.2.9.5

Channel 2B Warn

-30,0

200,0

Cº

0,0

770 P2.7.2.9.6

Channel 2B Fault

-30,0

200,0

Cº

0,0

771

P2.7.2.9.7

Channel 2C Warn

-30,0

200,0

Cº

0,0

772

P2.7.2.9.8

Channel 2C Fault

-30,0

200,0

Cº

0,0

773

Page 36

36 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.7.3 Fieldbus

Code

Parameter

Min

Max

Unit

Default

ID

Description

2.7.3.1

FB Fault Response

0 2 2 733

0=No response

1=Warning

2=Fault

2.7.3.2

FB WD Delay

0,00

30,00 0,00

1354

0,00 = Disabled WD

Table 5-9. Fieldbus Protections parameters G2.7.2

6.7.4 OPT-D7 protections

Code

Parameter

Min

Max

Unit

Default

ID

Description

2.7.4.1

THD Response

0 2 0 1672

2.7.4.2

THD Warn. Limit

0,00

50,00 % 6,00

1673

2.7.4.3

THD Fault Limit

0,00

50,00

%

10,00

1674

2.7.4.4

HF rms Response

0 2 0 1675

2.7.4.5

HF rms Warn Limit

0,0

400,0 V 20,0

1676

2.7.4.6

HF rms Fault Limit

0

400,0 V 60,0

1677

Table 5-9. OPT-D7 Protection parameters G2.7.3

6.7.5 Options

Code

Parameter

Min

Max

Unit

Default

ID

Description

2.7.5

Fault Simulation

0

65535 0

1569

2.7.6

Reset Datalogger

0 1 0 1857

Resets datalogger to

defaults.

Table 5-9. Options parameters G2.7.2

Page 37

Arfiff05 Standard AFE-II vacon • 37

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.8 Fieldbus parameters

Code

Parameter

Min

Max

Unit

Default

ID

Description

P2.8.1

FB Actual Value

Selection

0

65535

ID 7 1853

P2.8.2

Fieldbus data out 1

selection

0

65535

ID 0 852

Choose monitoring data

with parameter ID

P2.8.3

Fieldbus data out 2

selection

0

65535

ID 0 853

P2.8.4

Fieldbus data out 3

selection

0

65535

ID 0 854

P2.8.5

Fieldbus data out 4

selection

0

65535

ID 0 855

P2.8.6

Fieldbus data out 5

selection

0

65535

ID 0 856

P2.8.7

Fieldbus data out 6

selection

0

65535

ID 0 857 P2.8.8

Fieldbus data out 7

selection

0

65535

ID 0 858

P2.8.9

Fieldbus data out 8

selection

0

65535

ID 0 859

P2.8.10

Fieldbus data in 1

selection

0

65535

ID 0 876

Choose controlled data

with parameter ID

P2.8.11

Fieldbus data in 2

selection

0

65535

ID 0 877

P2.8.12

Fieldbus data in 3

selection

0

65535

ID 0 878

P2.8.13

Fieldbus data in 4

selection

0

65535

ID 0 879

P2.8.14

Fieldbus data in 5

selection

0

65535

ID 0 880

P2.8.15

Fieldbus data in 6

selection

0

65535

ID 0 881

P2.8.16

Fieldbus data in 7

selection

0

65535

ID 0 882

P2.8.17

Fieldbus data in 8

selection

0

65535

ID 0 883

P2.8.18

GSW ID

0

65535

ID

68

897

P2.8.19

State Machine

0 3 1 896

Table 5-8. Fieldbus parameters G2.6

Page 38

38 • Vacon arfiff05 Standard AFE-II

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.9 ID Control Functions

6.9.1 Value control

Table 1. Power reference input signal selection, G2.2.8

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Description

P2.9.1.1

Control Input Signal

ID

0

10000

ID

0

1580

P2.9.1.2

Control Input Off

Limit

-32000

32000 0

1581

P2.9.1.3

Control Input On

Limit

-32000

32000 0

1582

P2.9.1.4

Control Output Off

Value

-32000

32000 0

1583

P2.9.1.5

Control Output On

Value

-32000

32000 0

1584

P2.9.1.6

ID

0

10000

ID

0

1585

P2.9.1.7

Control Mode

0 5

0

1586

0 = SR ABS

1 = Scale ABS

2 = Scale INV ABS

3 = SR

4 = Scale

5 = Scale INV

P2.9.1.8

Control Output

Filtering rime

0.000

32.000 s 0.000

1721

6.9.2 DIN ID Control 1

Table 2. DIN ID control parameters, G2.2.8

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Description

P2.9.2.1

ID Control DIN

0.1

E.10

0.1

1570

Slot Board input No.

If 0.1 ID61 can be

controlled from FB

P2.9.2.2

Controlled ID

0

10000

ID

0 1571

Select ID that is

controlled by digital input

P2.9.2.3

False value

-32000

32000 0 1572

Value when DI is low

P2.9.2.4

True value

-32000

32000 0 1573

Value when DI is high

Page 39

Arfiff05 Standard AFE-II vacon • 39